Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "Large crushing ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

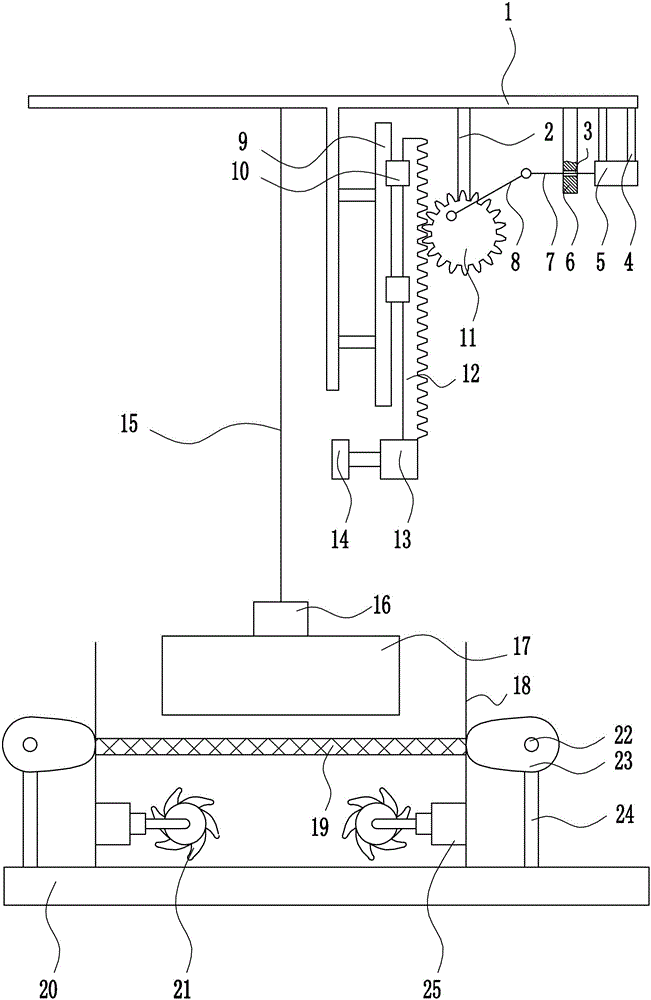

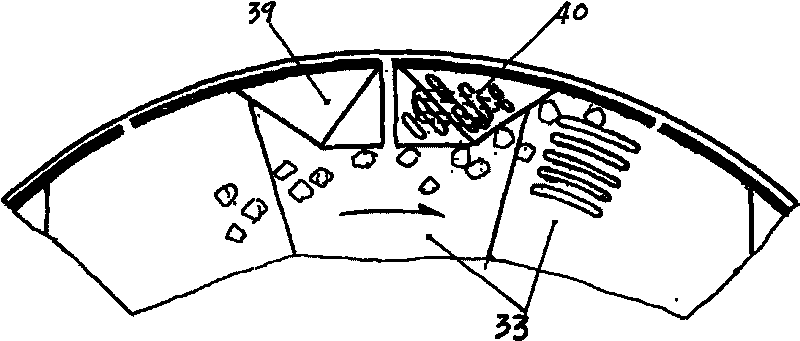

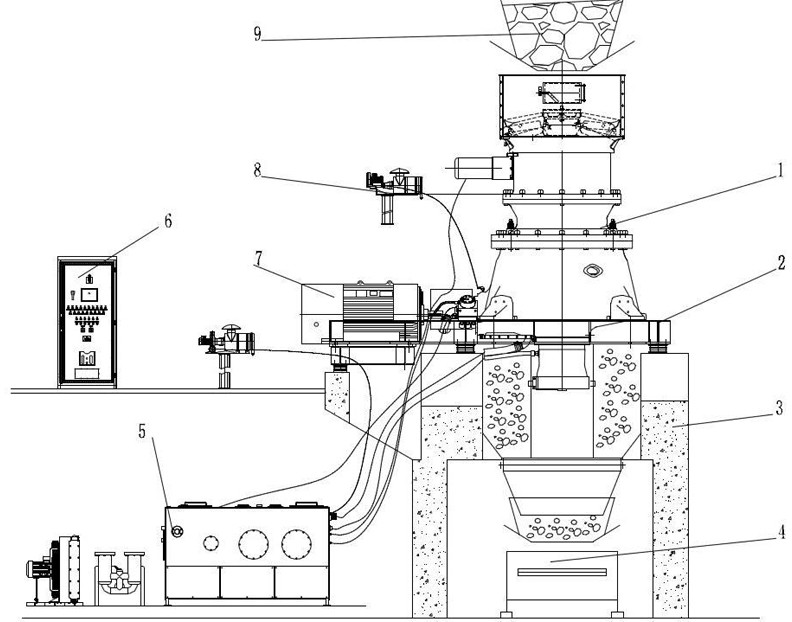

Five-double full-dry method crushing production line and processing method for high-quality sandstone aggregates

PendingCN109731661AGuaranteed cleanlinessGuaranteed growthGrain treatmentsSolid waste managementProduction linePre treatment

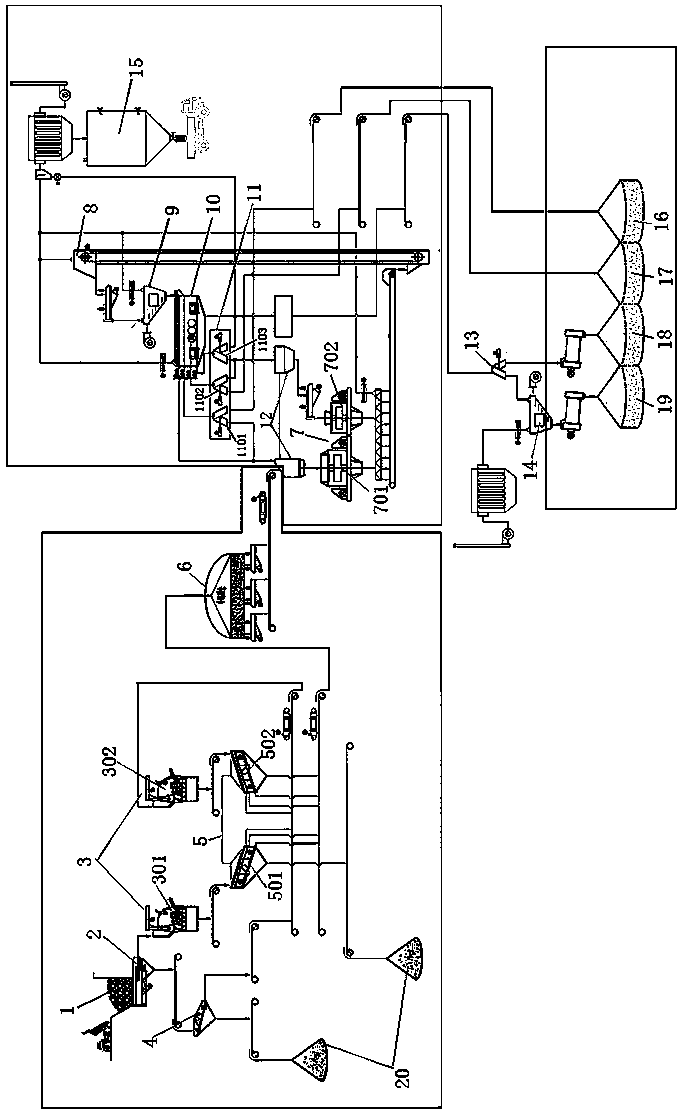

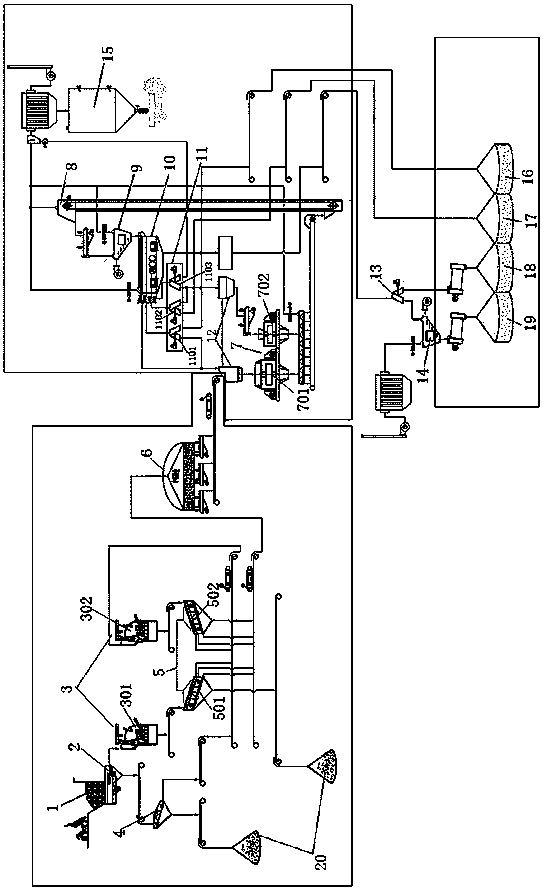

The invention discloses a five-double full-dry method crushing production line and processing method for high-quality sand aggregates. The production line comprises a material pretreatment system. A discharge port of the material pretreatment system is connected with a feed port of double-impact crushing equipment of a fine coarse aggregate processing system, a discharge port of the material pretreatment system is connected with a primary classifier, and a discharge port of the primary classifier is connected with a finished product screening and proportion adjusting circulation system. A super-particle-size material outlet of the finished product screening and proportion adjusting circulation system is circularly connected to a feed inlet of double-speed double-frequency crushing sand making equipment. The fine sand aggregates are connected to corresponding finished product bins or are circularly connected to the feed inlet of the double-speed double-frequency crushing sand making equipment, and multi-stage powder selecting equipment is arranged below a fine sand outlet. According to the production line, the production line with multi-stage desliming, double-countering-impact crushing, double-vertical-shaft impact crushing shaping sand making, multi-stage powder selecting and multi-stage circulation is adopted, so that the system productivity and the quality of the finished sand aggregates are improved effectively, the efficient and energy-saving effects are realized, and the practicability is high.

Owner:GUIZHOU CHENGZHI HEAVY IND SCI TECH

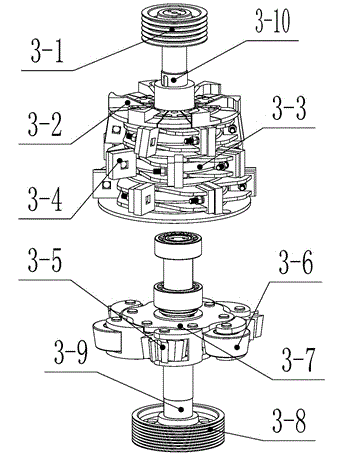

Vertical combined crushing and grinding machine

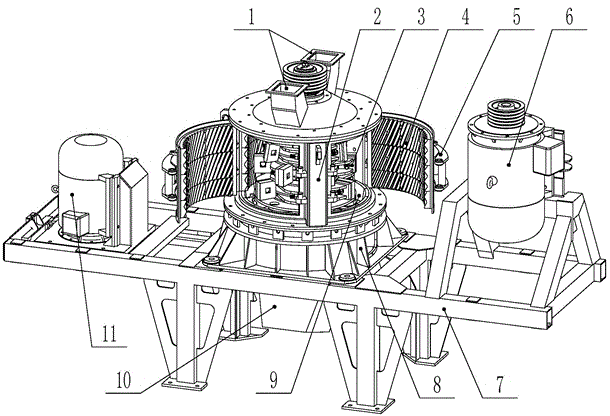

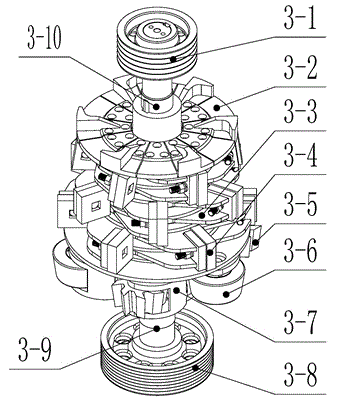

The invention provides a vertical combined crushing and grinding machine. The vertical combined crushing and grinding machine comprises an integral support, a grinding cavity seat, a cylinder body, a vertical rotor body, a spiral impact plate, a discharge hopper, charge hoppers, a turnover door, a grinding cavity wall lining plate, an electromotor, a crushing mechanism and a grinding mechanism. The vertical combined crushing and grinding machine enables the material crushing and grinding processes to be realized by one machine, is compact in structure and small in occupied area, saves the process, and improves the efficiency. Materials are impacted and crushed at high speed by a hammer head on a tower-shaped hammer seat in a spiral through crushing cavity, are thrown to the turnover door, are rebounded to the hammer head on the tower-shaped hammer seat, and are crushed repeatedly in the way, so as to guarantee relatively sufficient crushing. A centrifugal rotation roller acts on a grinding cavity wall lining plate, the materials are ground and crushed to 1mm below, and the qualified materials discharged from the discharge hopper finally are uniform in granularity and high in crushing ratio. In addition, the crushing and grinding cavity of the through combined crushing and grinding machine of the design is difficult to block, is smooth in material discharge and is long in service life, and the industrial cost is reduced.

Owner:四川皇龙智能破碎技术股份有限公司

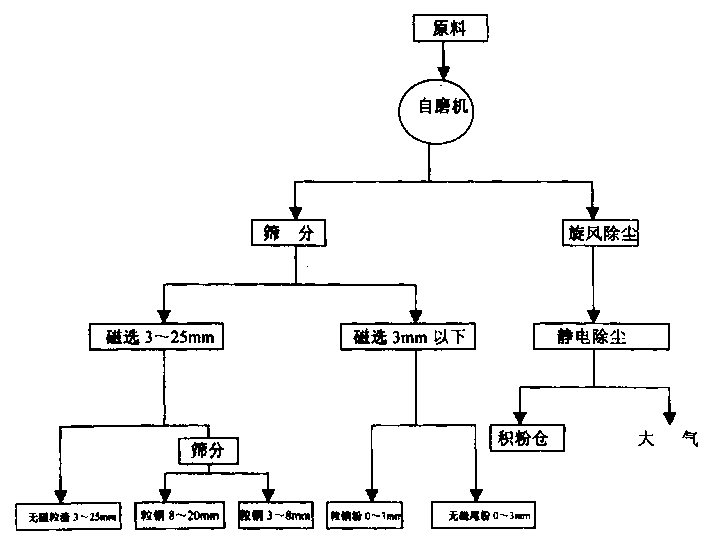

Process for treating steel slag by using self grinding technology

InactiveCN1492058AEfficient use ofImprove developmentBlast furnace detailsRecycling and recovery technologiesGranularitySlag

The grinding treatment process of the present invention is suitable for various kinds steel slag, such as electric furnace steel slag, converter steel slag, etc. It includes the following continuous technological steps: providing steel stag material of granularity up to 800 mm; pulverizing in dry pulverizing machine with pneumatic mechanism to discharge and electrostatic dust collection; sieving into different granularity components; and magnetic dressing to separate magnetic steel powder, granular steel and non-magnetic tail powder and granular slag. The present invention has continuous process, high production efficiency and other advantages.

Owner:庞慧鑫

Method for superfine grinding of walnut dregs by wet process by employing ball mill

The invention discloses superfine grinding technology of walnut dregs by a wet process, belonging to the technical field of agricultural products and food processing. The method comprises the process flows of coarse grinding of walnut dregs, mixture of coarsely ground powder of walnut dregs and water and superfine grinding by the wet process by a ball mill, etc. The temperature is not raised in the process of grinding; therefore, the nutrient components of the walnut dregs can not be damaged. In terms of kg / L, the ratio of coarse powder of walnut dregs to water is 1:(8-14). The parameters of the superfine grinding technology by the wet process by the ball mill are as follows: the ball-to-powder weight ratio is (1-6):10, the media are phi10mm zirconia balls, the milk grinding time is 30-120min and d50 of the walnut milk granule is 6-17mu m. The superfine grinding technology lays the foundation for subsequent preparation of walnut powder through spray drying and the application range of the superfine grinding technology in the food industry is broadened.

Owner:XINJIANG UNIVERSITY

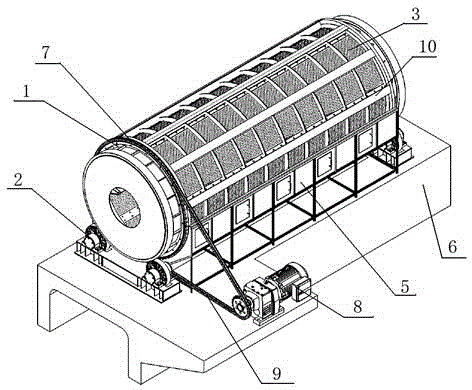

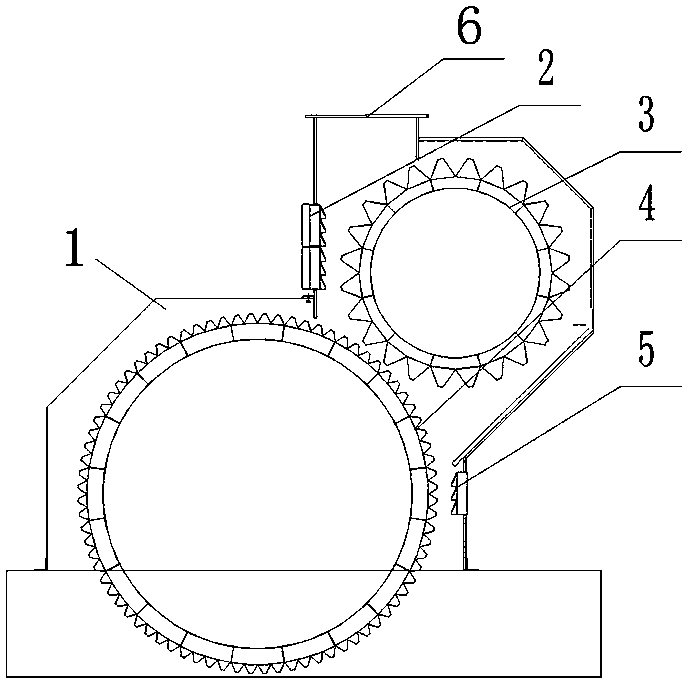

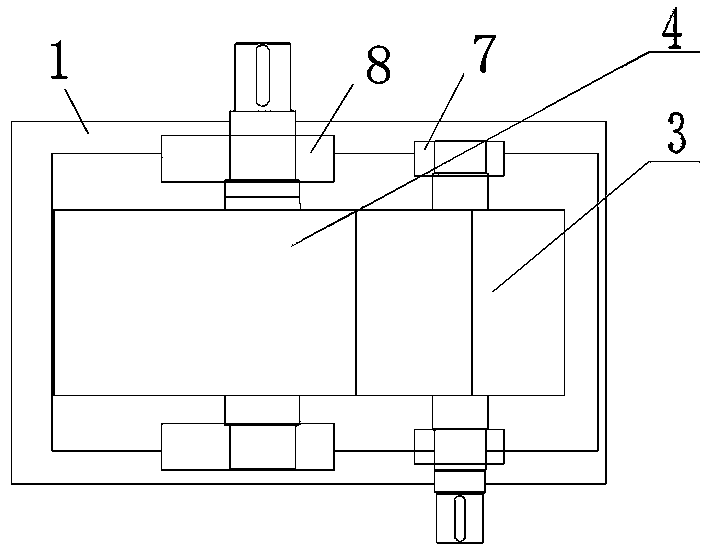

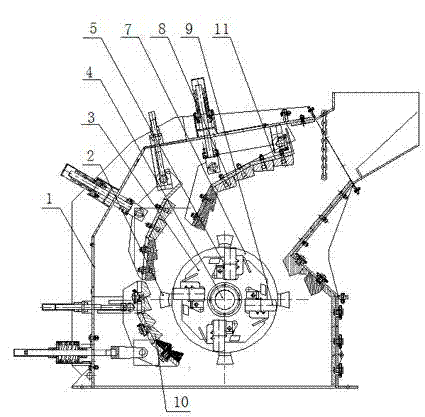

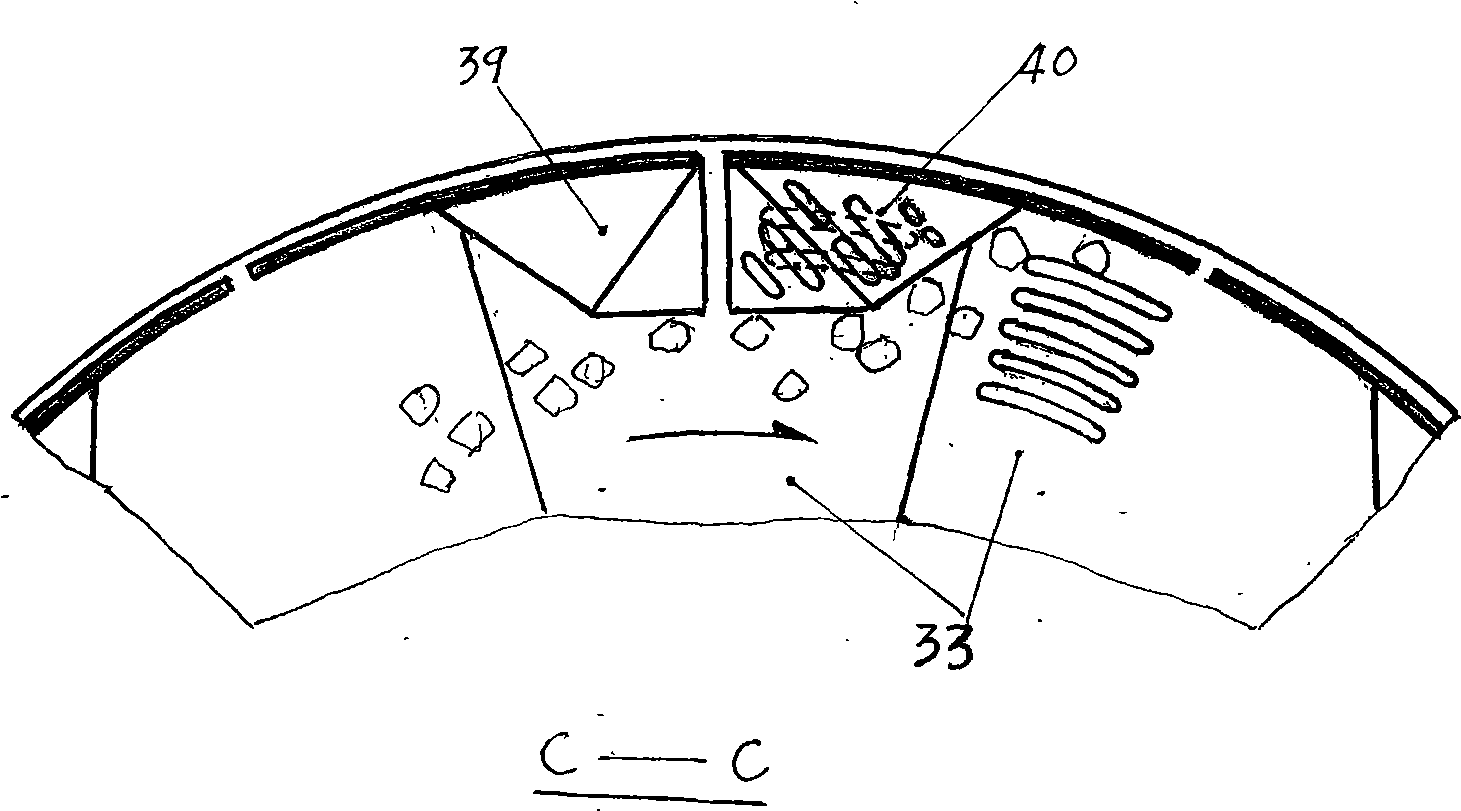

Roller type screening crusher and design method thereof

PendingCN106140400ASmall environment adaptabilityAvoid secondary crushingGrain treatmentsGear wheelProcess engineering

The invention discloses a roller type screening crusher and a design method thereof. The crusher elevates crushed materials to a certain height, and crushing is achieved through mutual impacting and grinding actions of material falling; and after crushing, the materials smaller than screen plate holes fall into a material collecting hopper at the lower portion of the roller type screening crusher through the screen plate holes and are continuously discharged through a conveying device, and therefore the functions of synchronous crushing and screening of the crushed material are achieved. The roller type screening crusher is large in crushing ratio, high in productivity, low in energy consumption and simple in structure, and the product granularity guaranteeing degree is high. The riding wheel supporting design is adopted and is high in environment adaptability, capable of saving investment and low in maintaining difficulty in comparison with a hybrid bearing supporting manner. A chain drive manner is adopted in a roller body and similarly has the beneficial effects of being high in environment adaptability, capable of saving investment and low in maintaining difficulty in comparison with a gear engagement transmission manner. Metal and sundries contained in the materials can be discharged from the tail end of the crusher in a regular material emptying manner, and downstream production and equipment cannot be influenced, wherein the sundries are not prone to breakage.

Owner:贵州莱利斯机械设计制造有限责任公司

Dissociation and recleaning process for coking middlings

ActiveCN105728155ALarge crushing ratioSmall amount of crushingSolid separationGrain treatmentsRefractoryEngineering

The invention discloses a dissociation and recleaning process for coking middlings which are high in ash content and refractory, and belongs to coal washing methods. The coking middlings are divided into lump middlings (+13 mm) and slack middlings (with the granularity of -13 mm, and including coarse granules in floatation tailings) according to the granularity. The dissociation and recleaning process for the lump middlings involves a crushing system, a spiral tailing discarding system and a floatation system according to the characteristics of the lump middlings. The dissociation and recleaning process for the slack middlings involves a crushing system, a coarse slime dissociation and recleaning system, a grading system and a floatation system. Full coverage is realized for recycling of the coking middling resources at different granularity grades, clean coal in the middlings is recycled to the maximum extent, and the process is simple, reliable, small in investment and remarkable in economical benefit.

Owner:CHINA UNIV OF MINING & TECH

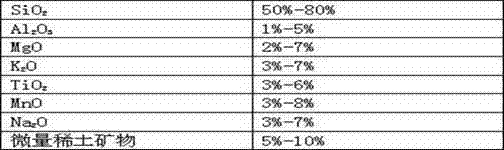

Automobile fuel saving and emission reducing mineral catalyst

InactiveCN103566927AHigh activityBig pollutionLiquid carbonaceous fuelsFuel additivesPtru catalystAir filter

The invention relates to an automobile catalyst and particularly relates to an automobile fuel saving and emission reducing mineral catalyst comprising the following components: SiO2, Al2O3, MgO, K2O, TiO2, MnO, Na2O and trace rare-earth minerals, wherein rear-earth metals contained in the trace rare-earth minerals in the whole catalyst account for 0.01-0.1% of the total weight of a catalytic system. The automobile fuel saving and emission reducing mineral catalyst is an inorganic mineral composition and mainly comprises silicon oxide. The automobile fuel saving and emission reducing mineral catalyst has thermoelectricity and piezoelectricity, can generate charges, release a great number of negative ions and radiation far infrared rays under a convection current condition or when heated, pressurized or excited by other energy, and has a special electromagnetic wave function. The automobile fuel saving and emission reducing mineral catalyst can be placed into an air inlet valve and an air filter, and can be used for improving the activity of an oxygen molecule so that the combustion efficiency is increased.

Owner:黄铂焜 +1

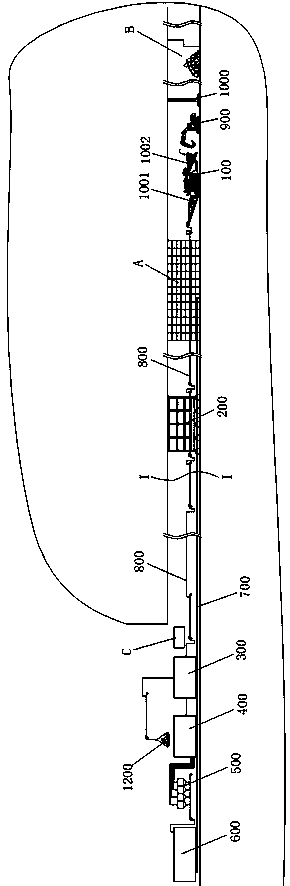

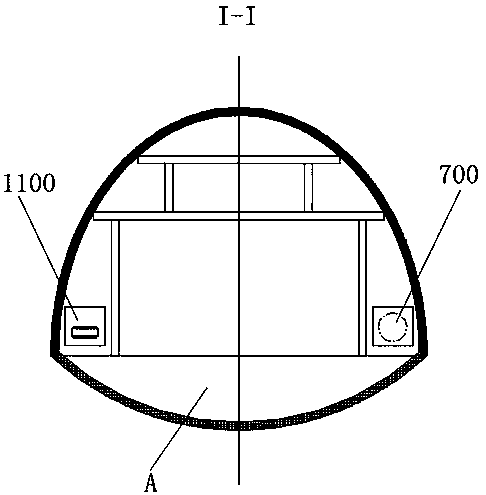

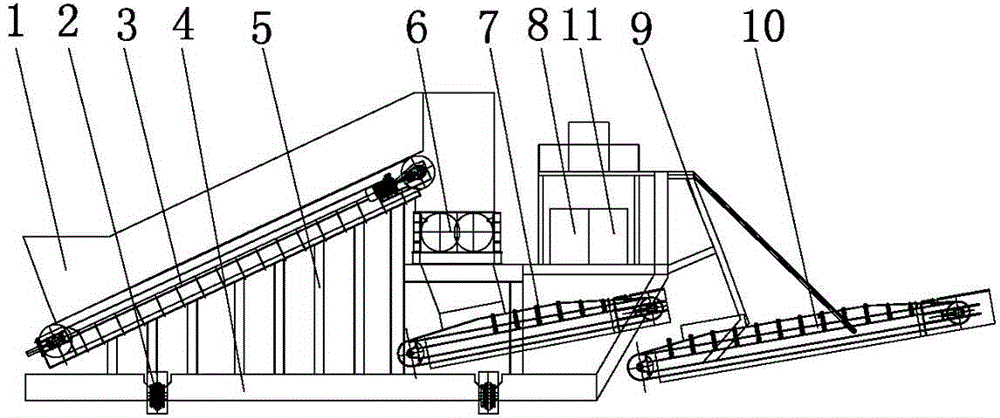

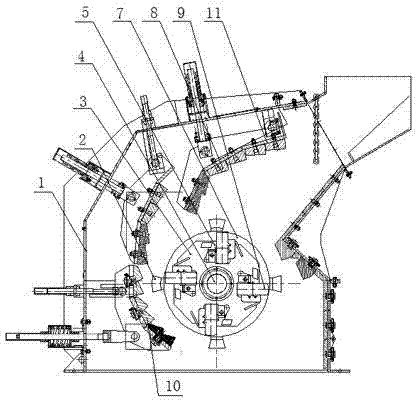

Tunnel slag tapping, sand and gravel processing and concrete processing and conveying integrated equipment and process

PendingCN110130920ASolve the transportation problemReduce in quantityTunnelsMixing operation plantSlagMaterial resources

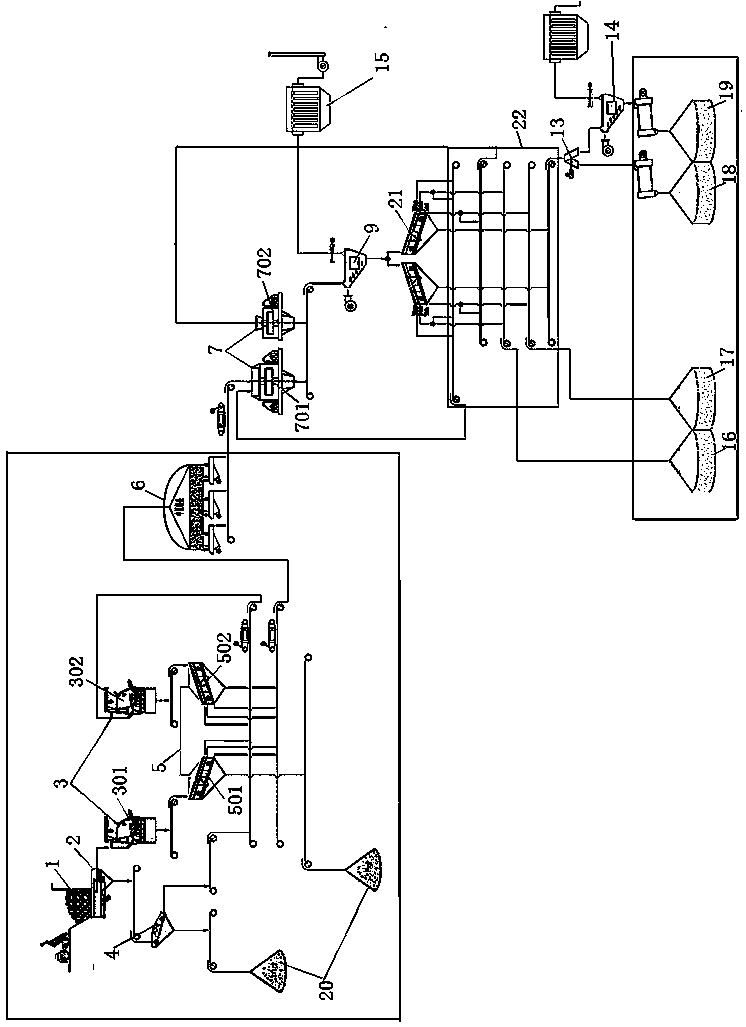

The invention discloses a tunnel slag tapping, sand and gravel processing and concrete processing and conveying integrated equipment and process. The tunnel slag tapping, sand and gravel processing and concrete processing and conveying integrated equipment comprises mobile crushing equipment, wherein a discharging port of the mobile crushing equipment is sequentially connected with a material pre-sorting system, an aggregate processing system and a concrete processing system through a telescopic conveying belt group, and a discharging port of the concrete processing system is connected with aconcrete belt conveying system; after materials in a tunnel blasting area B are preliminarily crushed by the moving crushing equipment, the materials are transported into the pre-sorting system and the aggregate processing system to prepare fine aggregates and fine sand with different gradations, finally transported into the concrete processing system to prepare concrete, and transported to a tunnel construction area through the concrete belt conveying system for concrete construction after penetrating through a lining trolley. The manpower and material resources are reasonably utilized and distributed, the automatic construction of a tunnel is achieved, high flexibility and good safety performance are achieved, and the construction efficiency and quality of the tunnel are greatly improved.

Owner:GUIZHOU CHENGZHI HEAVY IND SCI TECH

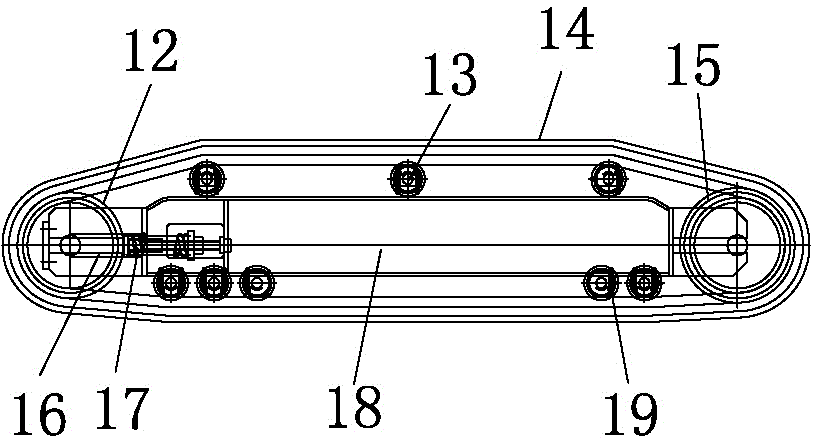

Integrated crawler full-mobility crushing station

InactiveCN104475219ASimple structureFlexible moving processGrain treatmentsHydraulic cylinderElectrical control

The invention relates to an integrated crawler full-mobility crushing station, which effectively solves the problems that the construction cost is high, the period is long, the working efficiency is low and labor and time waste is caused. A hydraulic station, an electrical control cabinet, a crusher, a heavy type plate feeding machine and a belt conveyor II are arranged on a base which is fixedly arranged on a crawler traveling device, a stock bin is arranged on the heavy type plate feeding machine, the crusher is arranged below a nose, the belt conveyor II is arranged on the lower part of the crusher, a belt conveyor I is arranged on the lower part of the belt conveyor II, the hydraulic station is connected with a hydraulic cylinder through an oil pipe, the bottom end of the hydraulic cylinder is fixedly arranged on the base, the push rod end of the hydraulic cylinder and the belt conveyor I are connected, and the hydraulic station, the crawler traveling device, the belt conveyor I, the belt conveyor II, the crusher and the heavy type plate feeding machine are respectively connected with the electrical control cabinet. The integrated crawler full-mobility crushing station is simple in structure, flexible to move, short in mobility assistance time, and not limited by places, the production capacity is large, the crushing ratio is high, the integrated crawler full-mobility crushing station is applicable to various environments and the use effect is good.

Owner:XINXIANG WEIDA MACHINERY

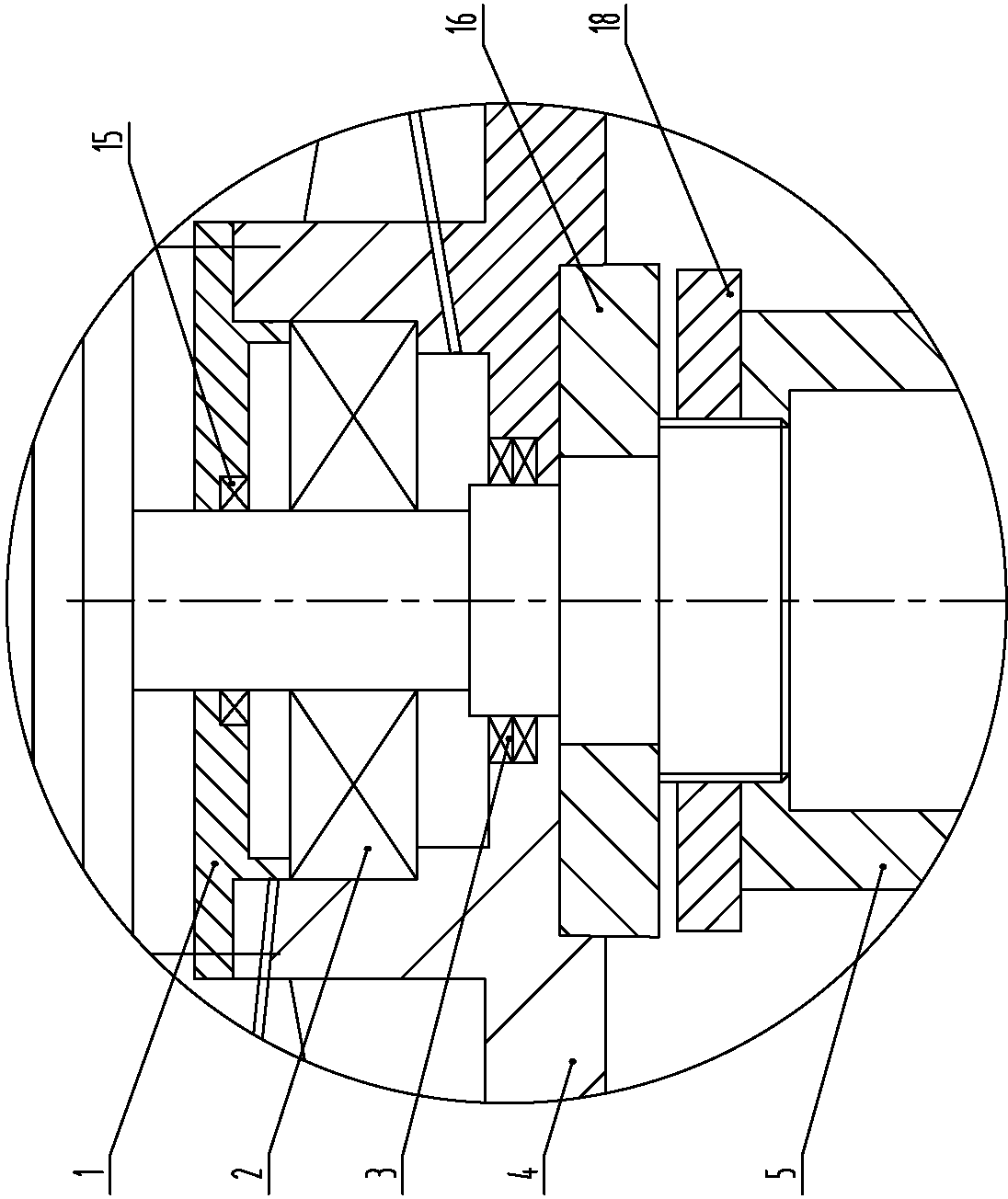

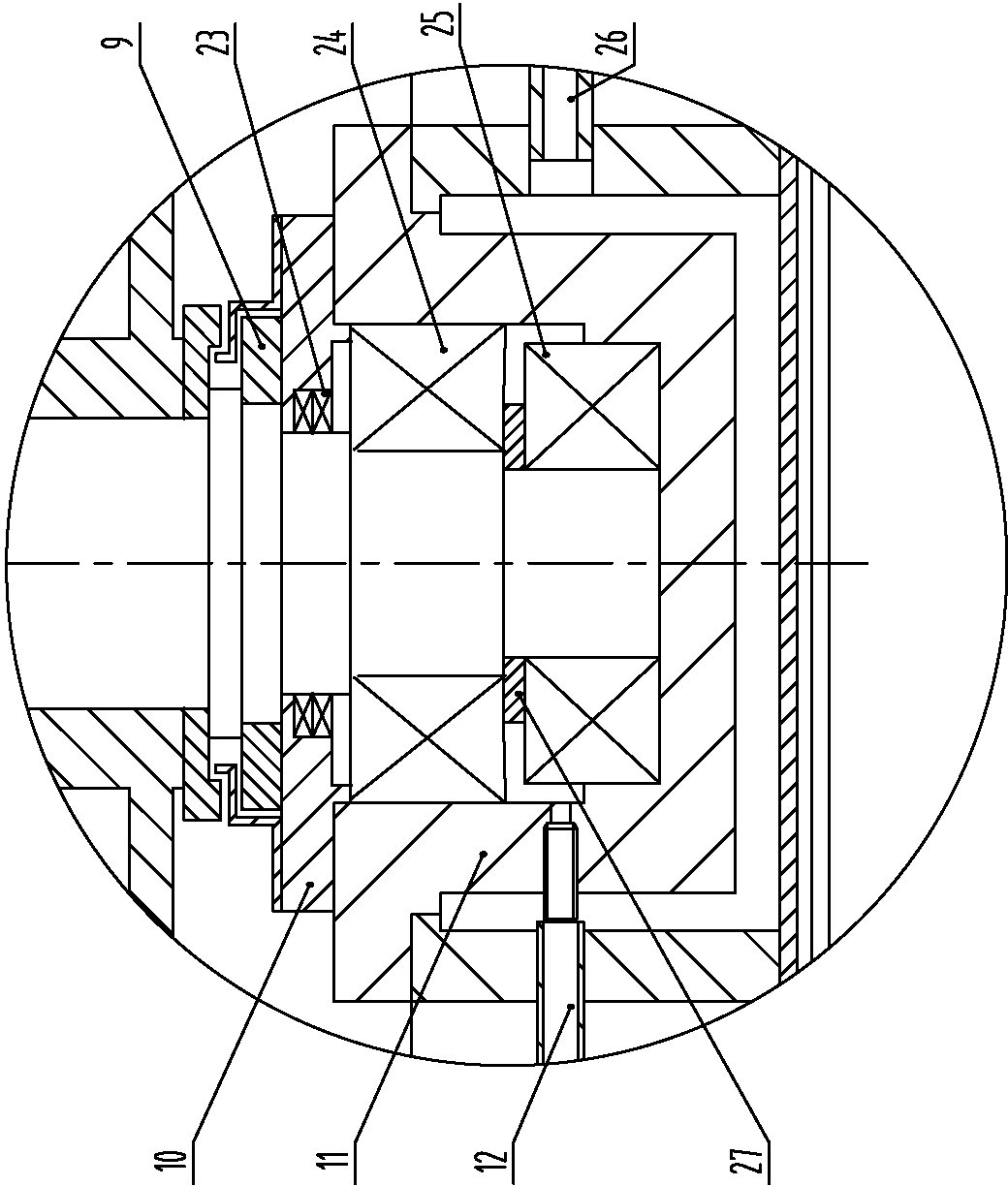

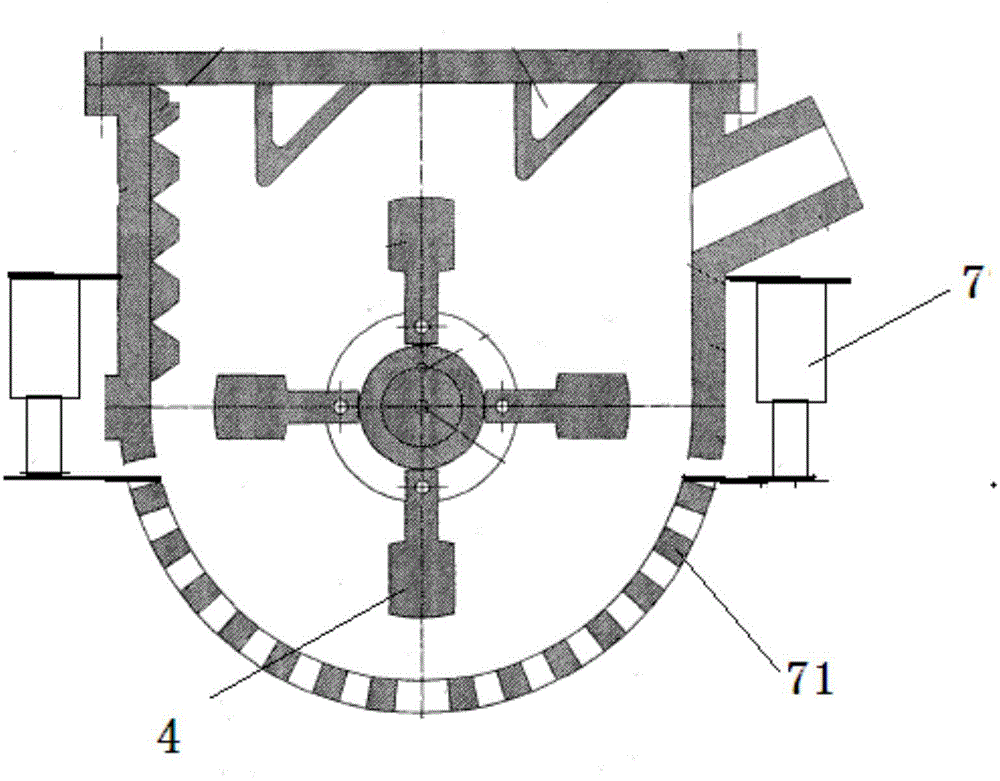

Industrial sand-making crusher

InactiveCN104383984ASmall granularityImprove the efficiency of industrial sand makingGrain treatmentsWear resistantAgricultural engineering

The invention discloses an industrial sand-making crusher and belongs to the field of crushing equipment. The industrial sand-making crusher comprises an upper cover, a cylindrical shell and a pedestal which are in successive connection from top to bottom, and is characterized in that the crusher also comprises a main shaft, the pedestal is provided with a lower bearing seat, and the upper cover is provided with an upper bearing seat; the lower end of the main shaft is installed in the lower bearing seat via a lower bearing, and the upper end of the main shaft is installed in the upper bearing seat via an upper aligning bearing; an upper bearing cover is installed on the upper bearing seat, and a lower bearing cover is installed on the lower bearing seat; the main shaft is provided with a belt pulley disposed above the upper bearing cover; the main shaft in the cylindrical shell is fixedly provided with two or more counterattack rotors along the shaft direction; each counterattack rotor is provided with two or more connection racks along the circumferential direction; and each connection rack is provided with a striking plate. The crusher is capable of enabling a stone material and the stone material, the stone material and the striking plates, and the stone material and a wear-resistant liner plate to generate repeated bump, enabling the granularity of the stone material to be obviously reduced and finally preparing multi-corner-angle circle granular machine-made sand, and helps to improve the industrial sand making efficiency.

Owner:SHANDONG LIJIAN IND SAND TECH

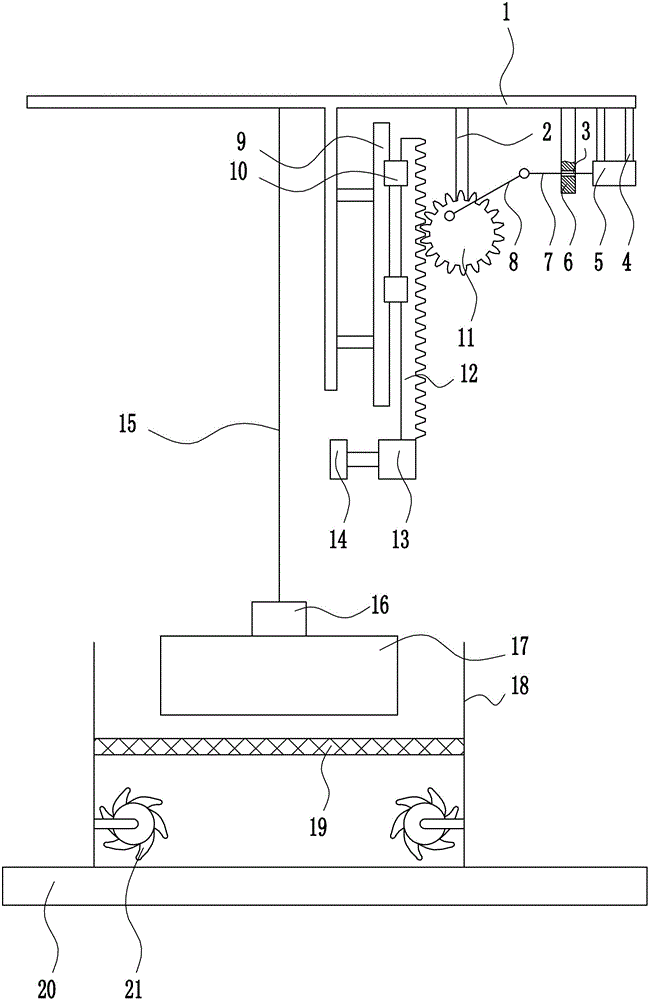

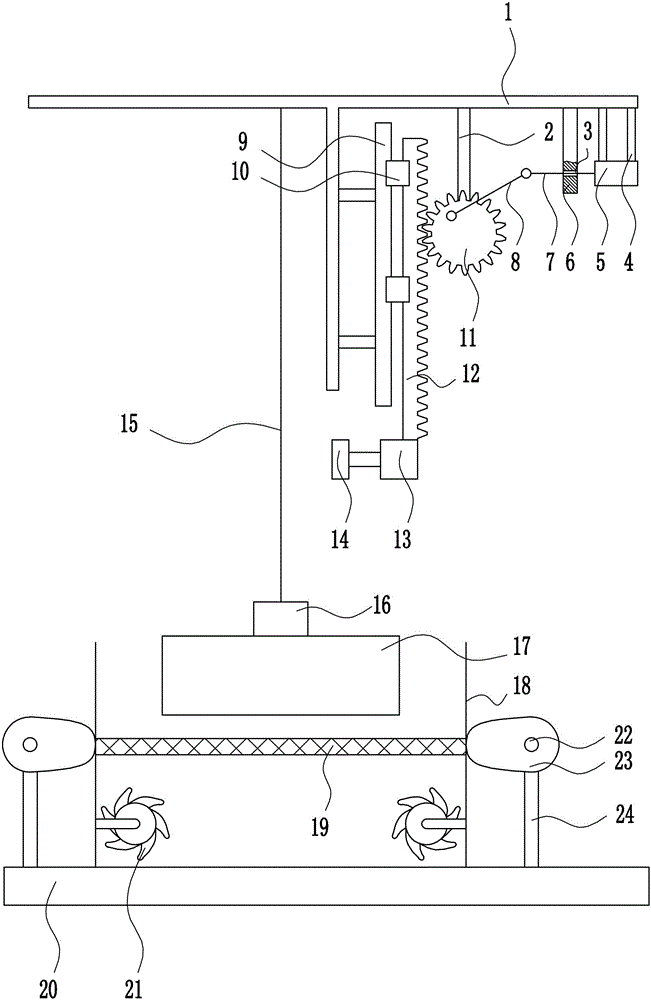

Geological survey ore crushing device

InactiveCN106216007AIncrease productivityShort working hoursGrain treatmentsGeological surveyEngineering

The invention relates to a crushing device, in particular to a geological survey ore crushing device. The technical problem to be solved by the invention is to provide the geological survey ore crushing device with high production efficiency, high crushing ratio and uniform product particle size. In order to solve the technical problems, the invention provides the geological survey ore crushing device. The geological survey ore crushing device comprises a bracket, a first support rod, a second support rod, a first electric push rod, a guide block, a first connecting rod, a second connecting rod, a slide rail, a slide block, a gear, a rack, a second electric push rod, an electromagnet, a stay rope, an iron block, a weight, a crushing groove, an iron wire net, a base and electric crushing wheels; the crushing groove is mounted on the base; the electric crushing wheels are respectively arranged on the left and right two sides in the crushing groove; and the iron wire net is arranged in the crushing groove. The geological survey ore crushing device achieves the effects of high production efficiency, short working time, high crushing ratio and uniform product particle size in the ore crushing operation.

Owner:陈小方

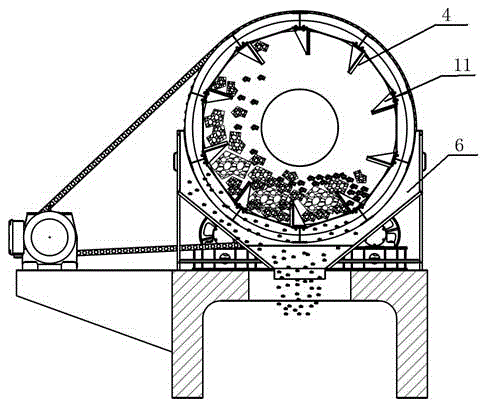

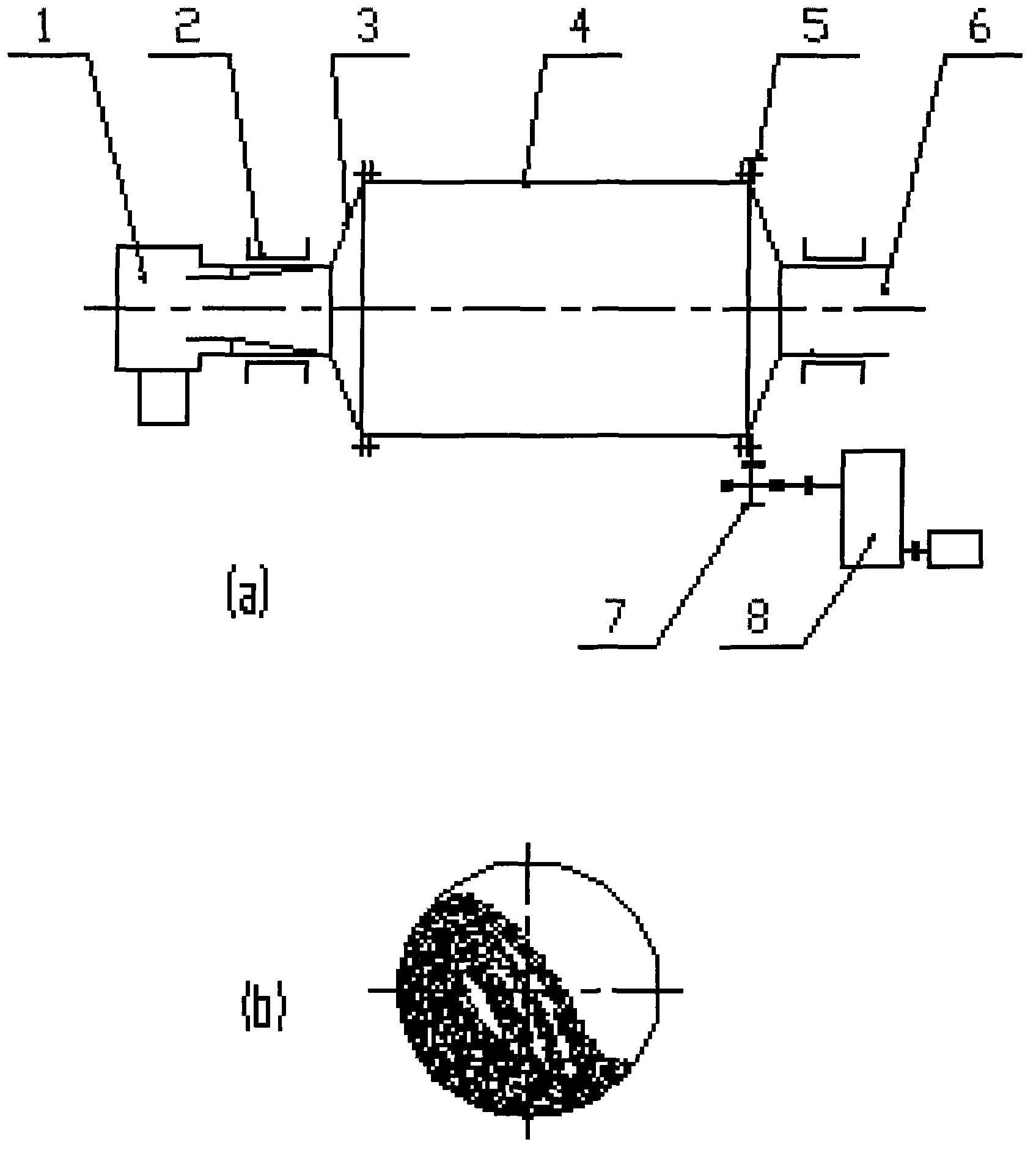

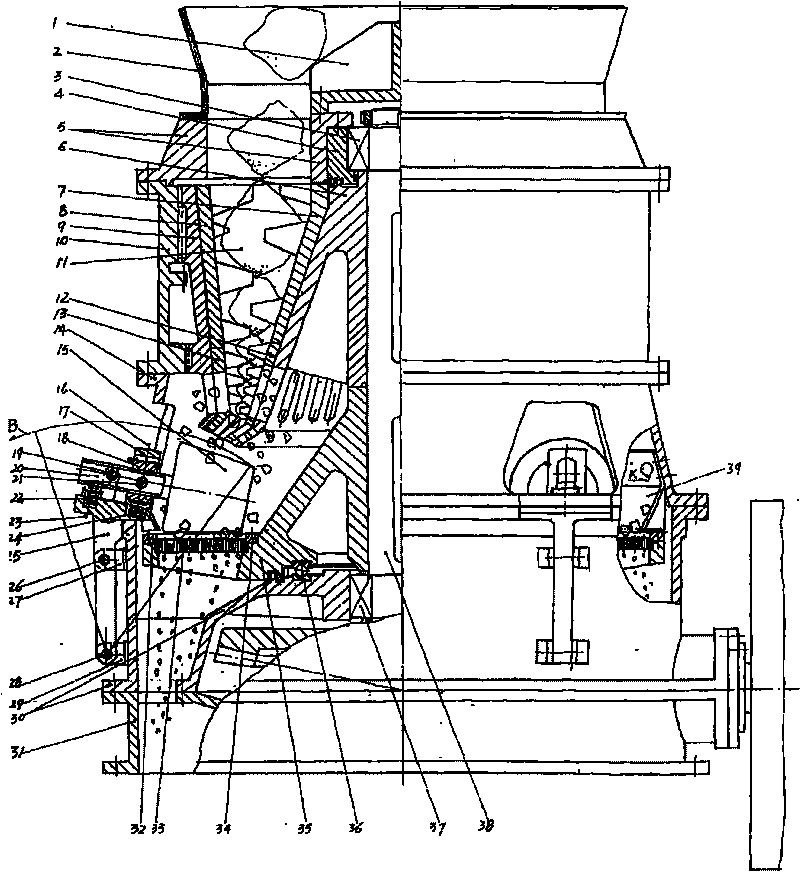

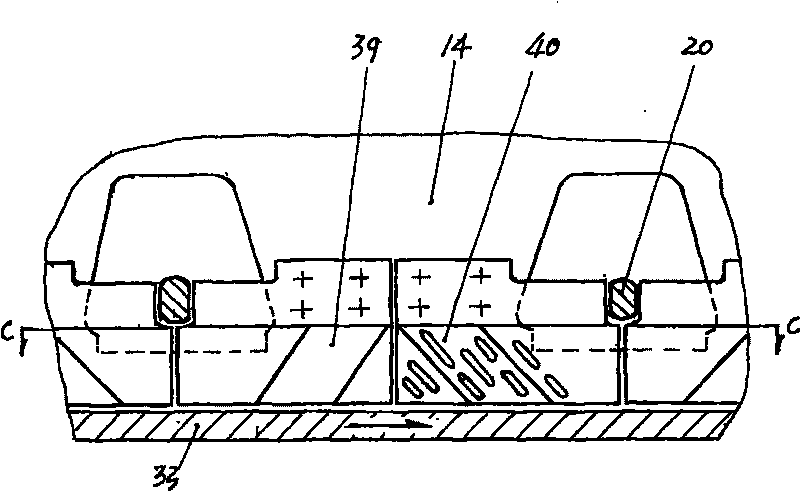

Inertial ball mill

The invention provides an inertial ball mill which is mainly applicable to operations of crushing and grinding massive or granular minerals. The inertial ball mill provided by the invention mainly comprises a moving system, wherein the moving system consists of a cylinder body, a lattice sieve plate, a classifying device, a plurality of vibrating bodies, middling rings and flexible shafts; the vibrating bodies, the middling rings and the flexible shafts are arranged in the cylinder body; the system is driven by a transmission device to perform high-speed rotational swinging movement to crush and grind materials. Through the inertial ball mill, the mill efficiency is greatly improved, and the energy consumption is reduced; the inertial ball mill is small in equipment size, light in weight, simple in structure and easy to maintain.

Owner:张学骞

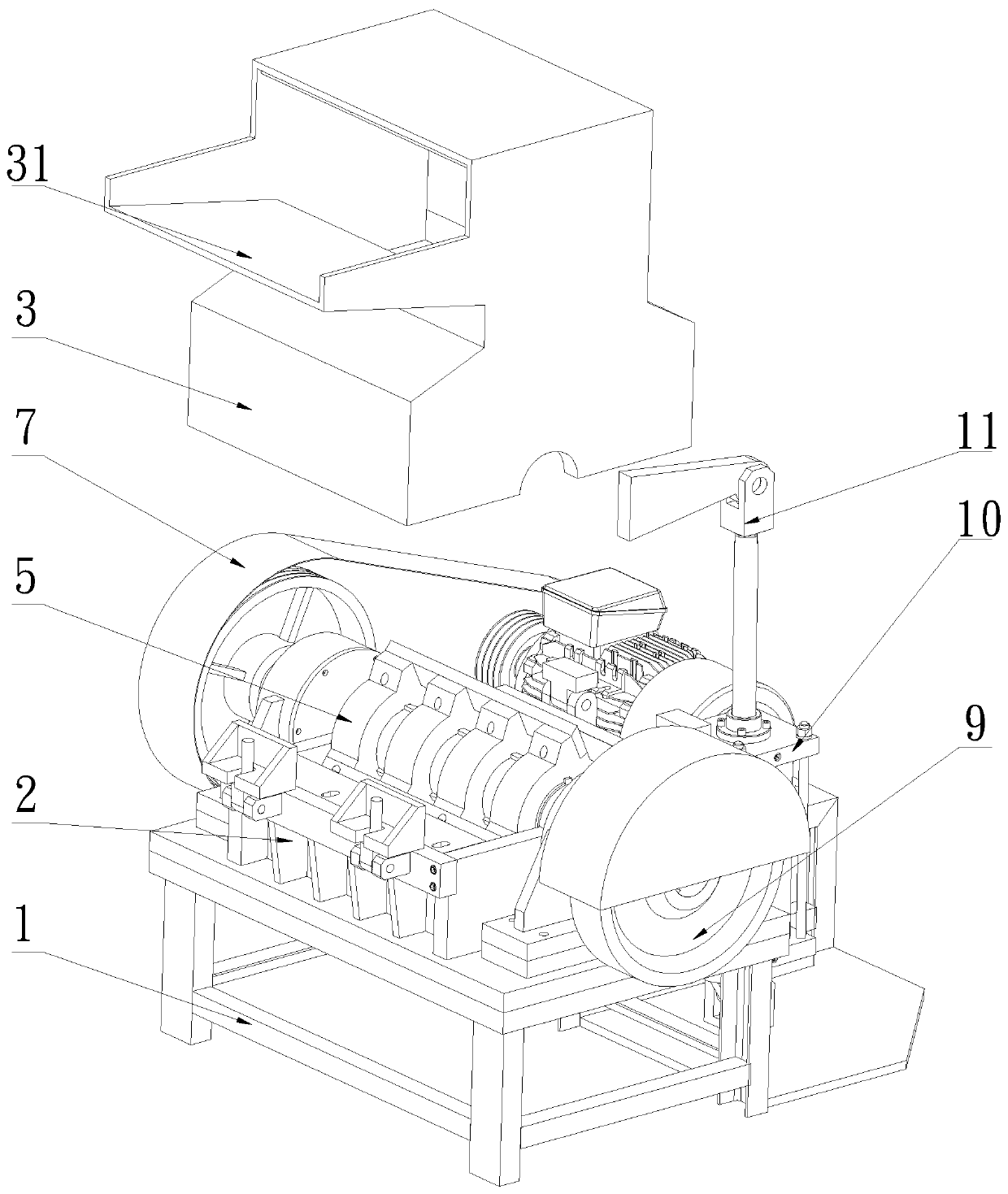

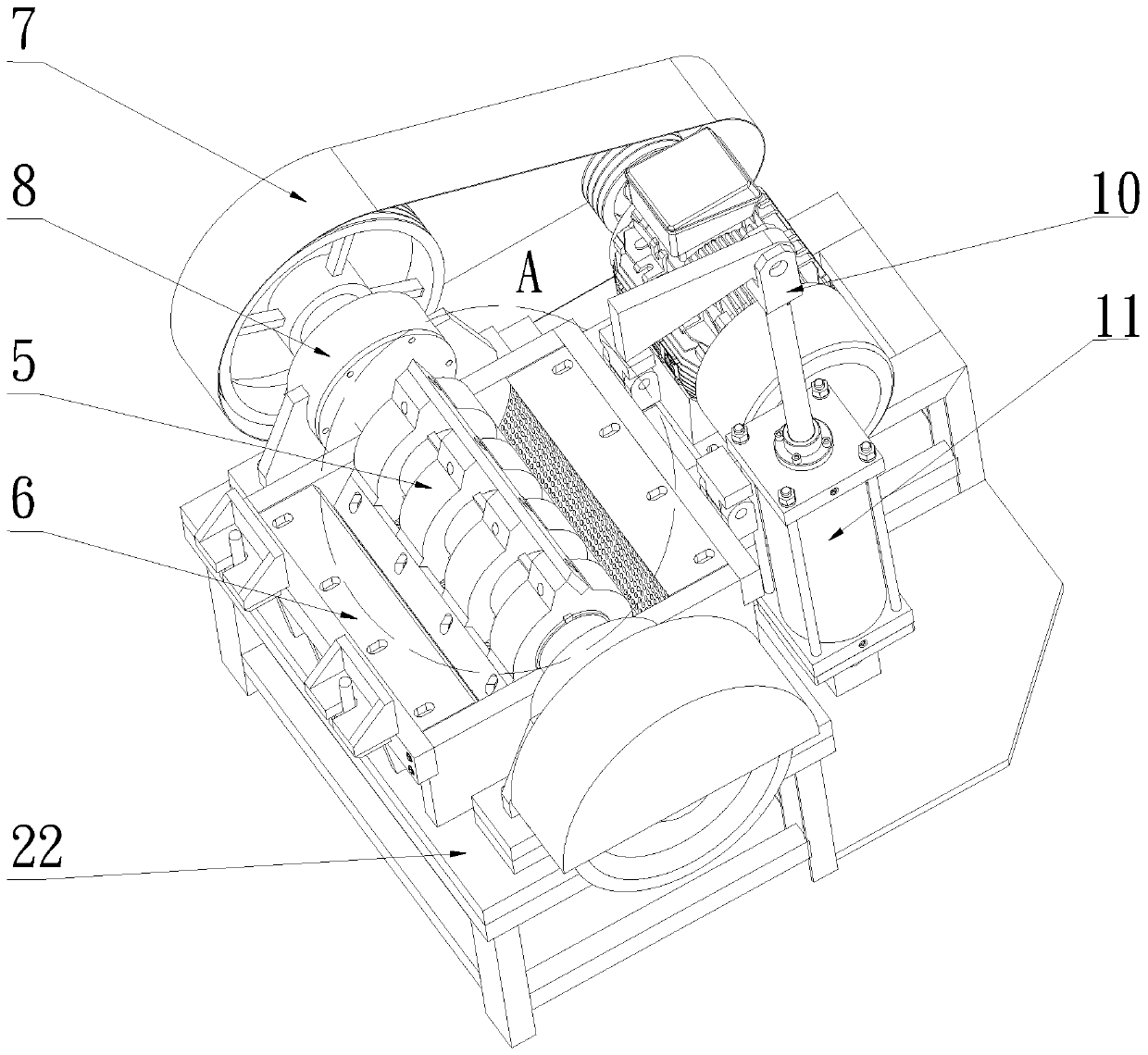

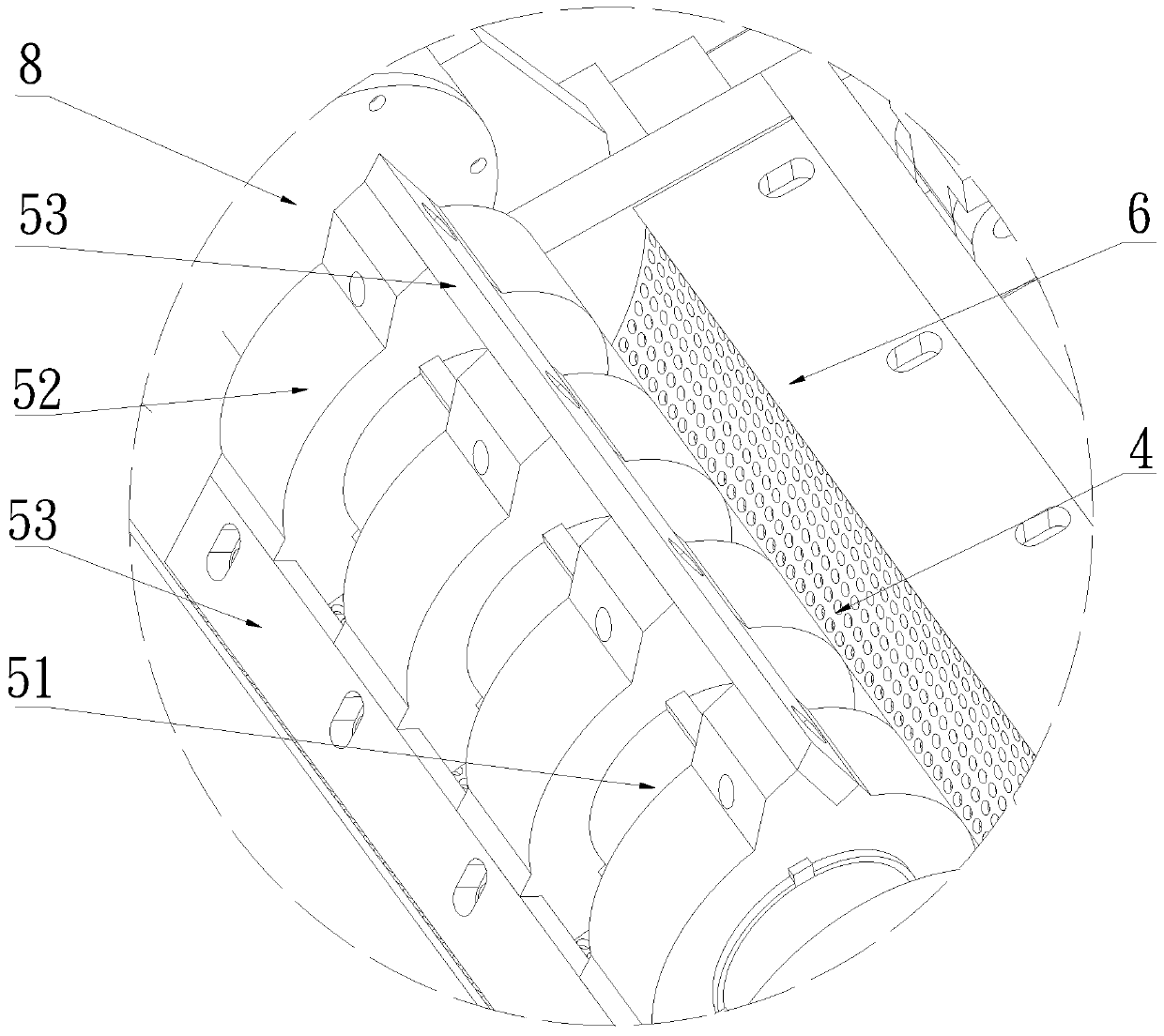

Multi-stage composite crusher

PendingCN111229378AImprove efficiencyMeet production needsGrain treatmentsStructural engineeringCrusher

The invention belongs to the technical field of crushing devices, and particularly relates to a multi-stage composite crusher. The multi-stage composite crusher comprises a rack, an upper fixed toothed plate, an upper movable toothed roller, a lower movable toothed roller and a lower fixed toothed plate, wherein the upper fixed toothed plate is arranged close to the horizontal plane of the axis ofthe upper movable toothed roller, and the rack side of the upper fixed toothed plate is arranged towards the upper movable toothed roller; the lower movable toothed roller is arranged below the uppermovable toothed roller, the lower fixed toothed plate is arranged close to the horizontal plane of the axis of the lower movable toothed roller, and the rack side of the lower fixed toothed plate isarranged towards the lower movable toothed roller; a feeding port is formed in the rack above a gap between the upper fixed toothed plate and the upper movable toothed roller; and the number of teethof the lower movable toothed roller is larger than that of teeth of the upper movable toothed roller, and the tooth pitch of the lower movable toothed roller is smaller than that of the upper movabletoothed roller. The multi-stage composite crusher realizes multi-stage composite crushing operation and can greatly improve the crushing operation efficiency.

Owner:徐州市诚信破碎机械厂

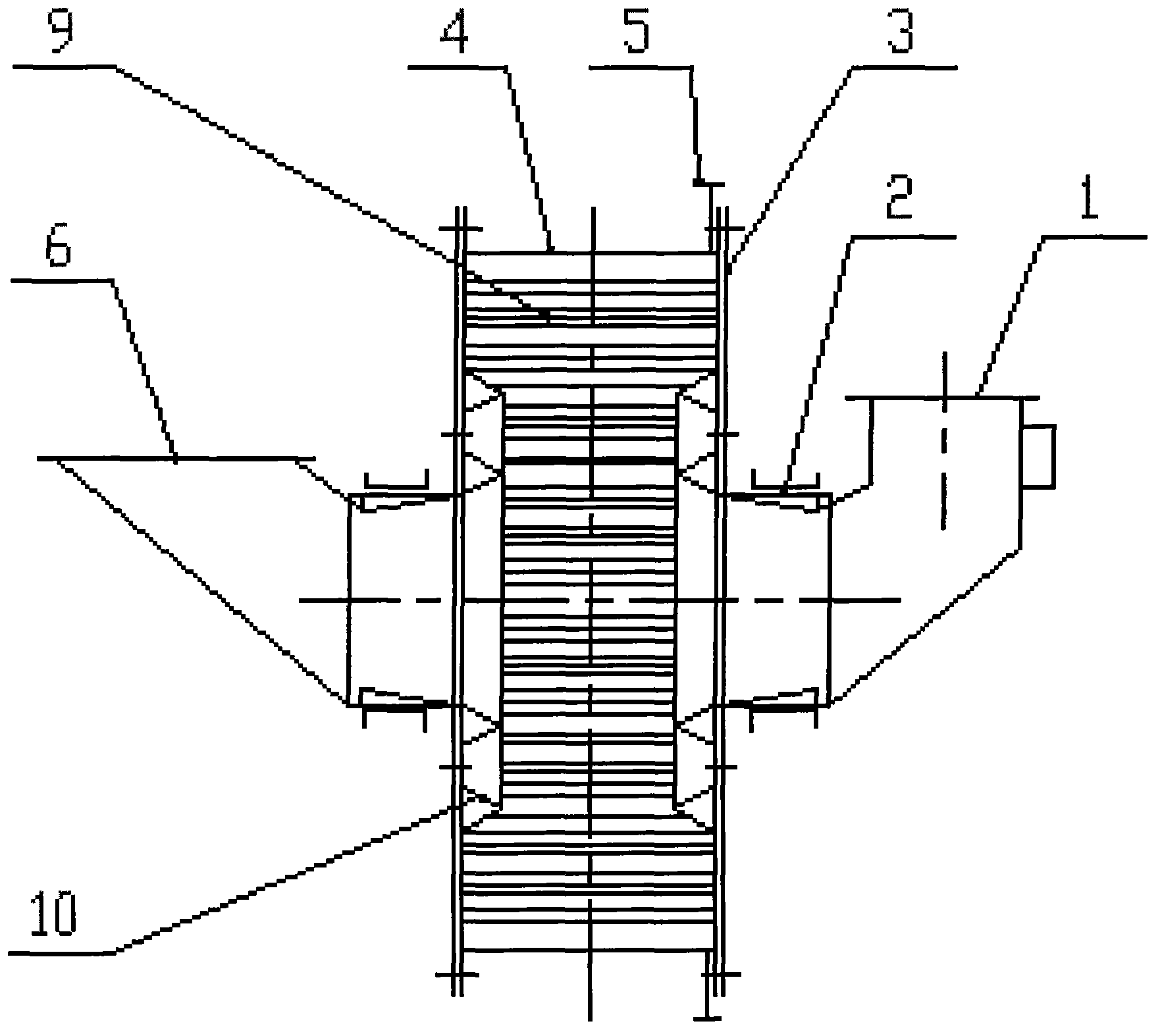

Combined super-fine crusher

InactiveCN101733182AEasy to assemble and disassembleEasy to adjustGrain treatmentsLow noiseLow speed

The invention discloses a combined super-fine crusher. The combined super-fine crusher comprises a speed reducer, a vertically arranged main shaft, an upper jacket, an outer taper sleeve, a movable taper sleeve and a grinding base support sleeve, wherein a power output end of the speed reducer is in transmission connection with the main shaft; the movable taper sleeve and the grinding base support sleeve are in key connection with the main shaft from top to bottom respectively; the upper jacket is arranged outside the outer taper sleeve; the outer side of the movable taper sleeve is provided with a movable conical tooth plate; the inner side of the outer taper sleeve is provided with an outer conical tooth plate; an annular crushing cavity with a wide top and a narrow bottom is formed between the movable conical tooth plate and the outer conical tooth plate; the outer side of the grinding base support sleeve is provided with a grinding base provided with sieve pores; and a grinding device is arranged above the grinding base. The combined super-fine crusher finishes crushing in a plurality of stages according to a brand new design concept, applies forces according to different types, selects materials according to the forces, realizes controllable low speed and completes thick, medium, fine and super-fine crushing in one machine. The combined super-fine crusher has the characteristics of high energy efficiency, low abrasion wear, vibration-free property, low noise and remarkable social and economic benefits.

Owner:黄琳

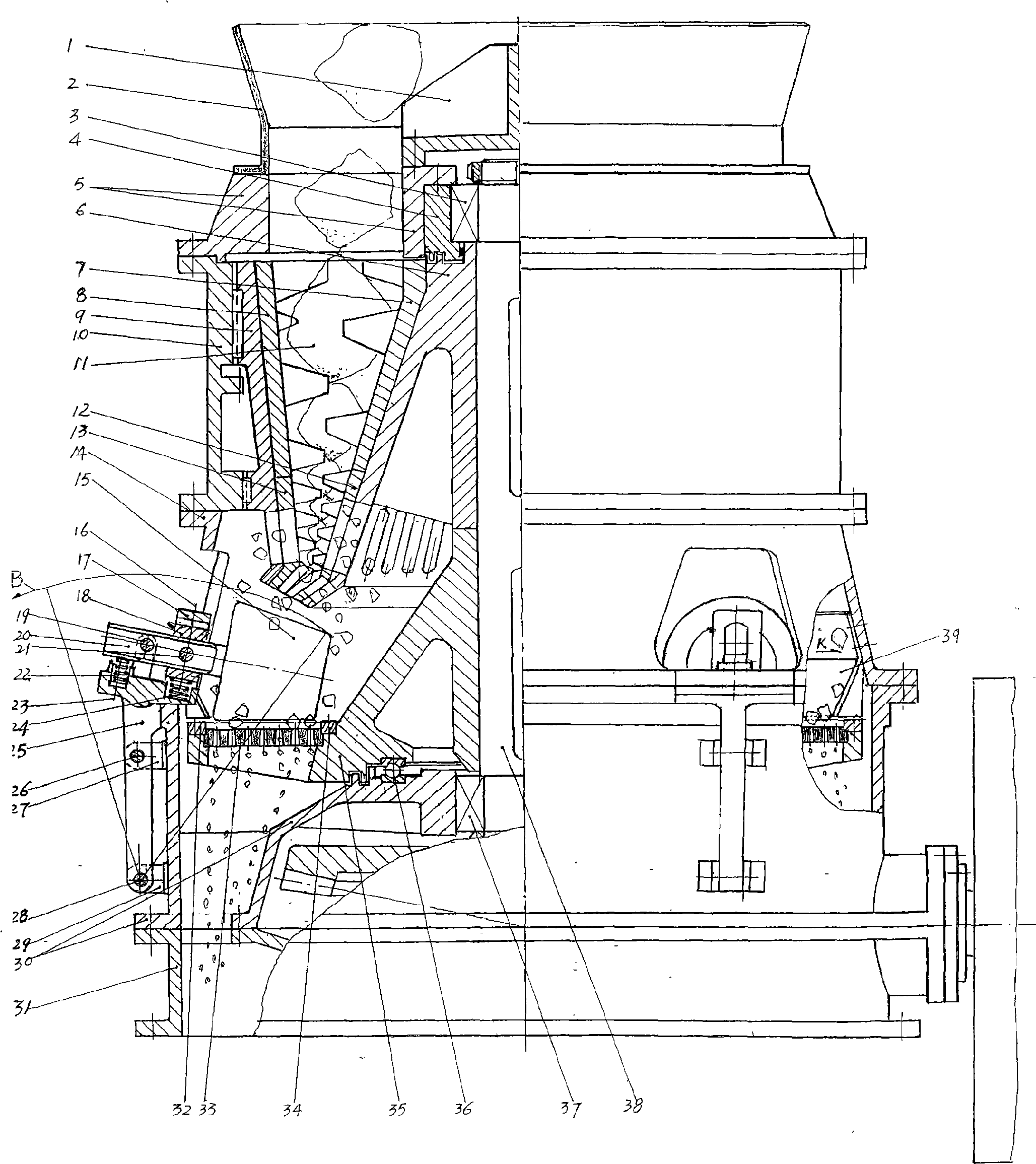

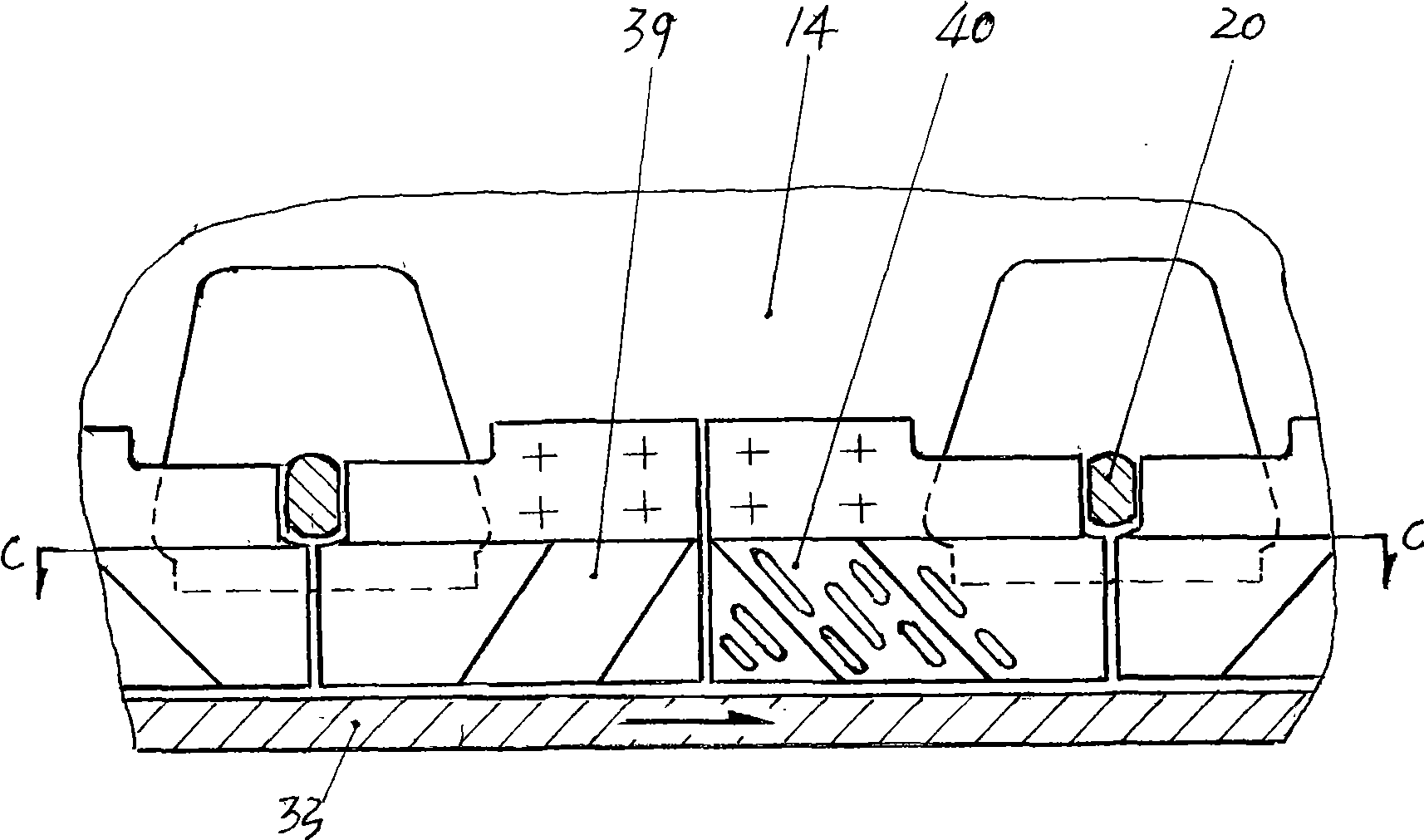

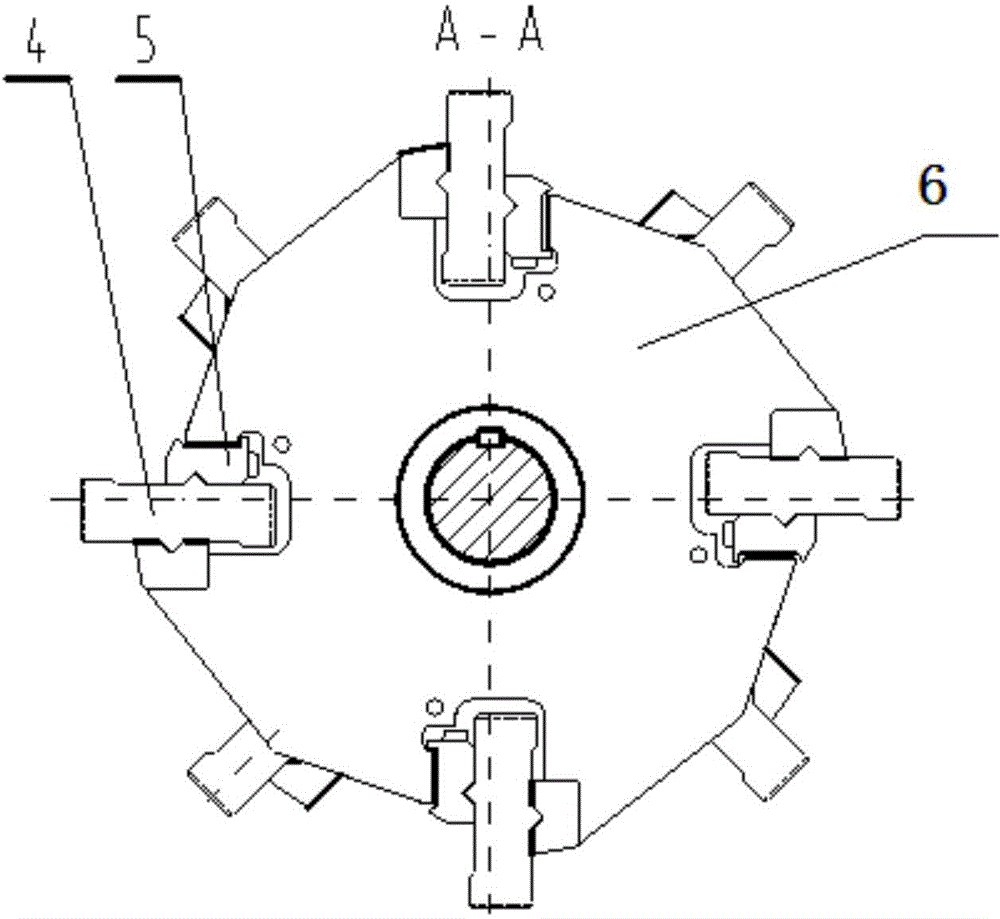

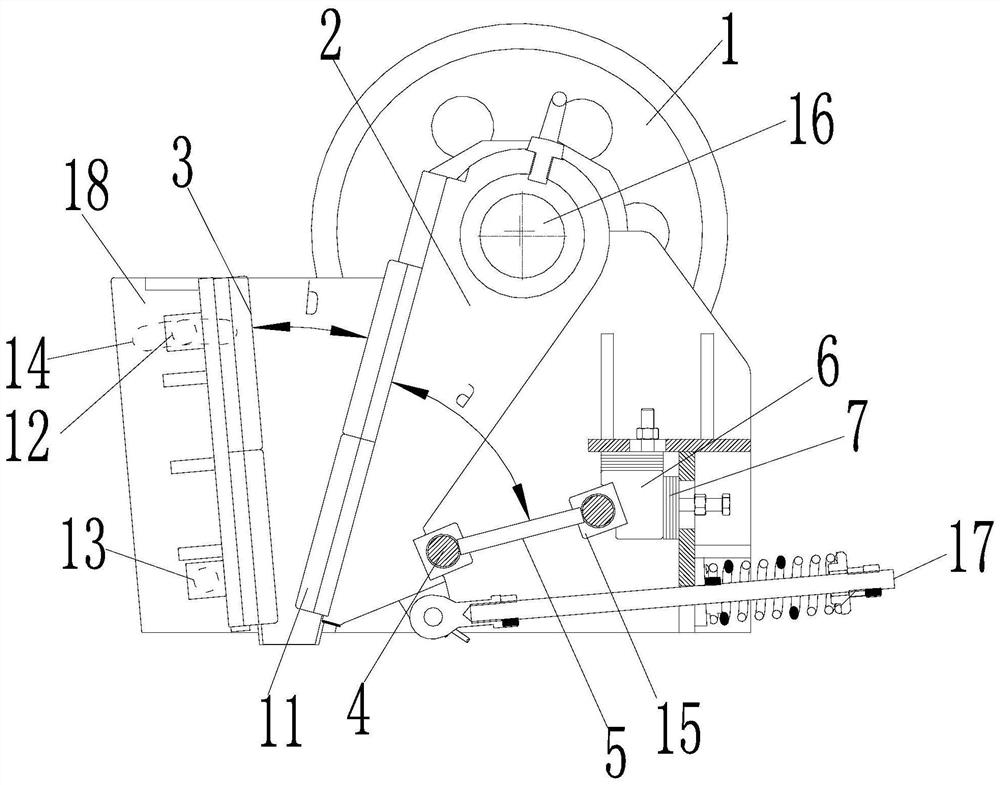

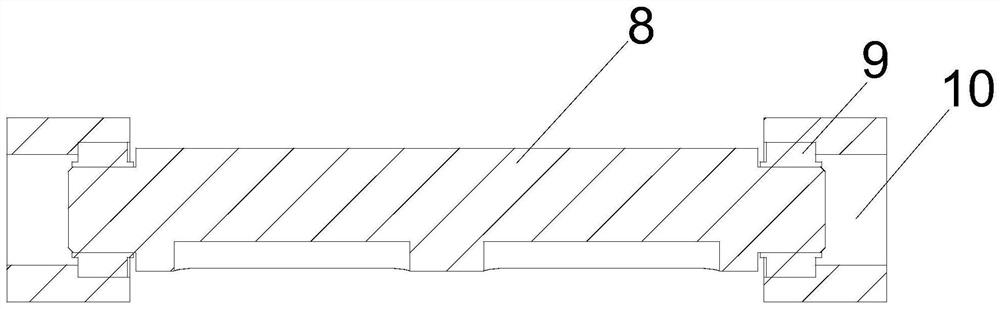

Shaping type crusher

The invention discloses a shaping type crusher. A crushing mechanism and an impact mechanism are arranged in a body (1), the crushing mechanism comprises a hammer type rotor and an impact rotor which are arranged on a main shaft (4), the hammer type rotor comprises a circular faceplate (7) and hammer heads (2), the circular faceplate (7) is arranged at a center of the main shaft (4), and a set of hammer heads (2) are axisymmetrically arranged on the circular faceplate (7). The impact rotor comprises an octagonal faceplate (3) and impact bars (9), and the octagonal faceplate (3) is arranged on the main shaft (4), is positioned at two sides of the circular faceplate (7) and is provided with the impact bars (9). The impact mechanism comprises impact racks (8) arranged on a back wall of the body (1) and impact lining plates (10) arranged on the impact racks (8). The crusher has a simple structure and is convenient to be operated, and the hammer heads and the impact bars coexist and have duty division, so stones are fully crushed, particle shapes of discharging are good, the productive efficiency is high, and energy is saved.

Owner:JIANGSU PENGSHENG HEAVY IND

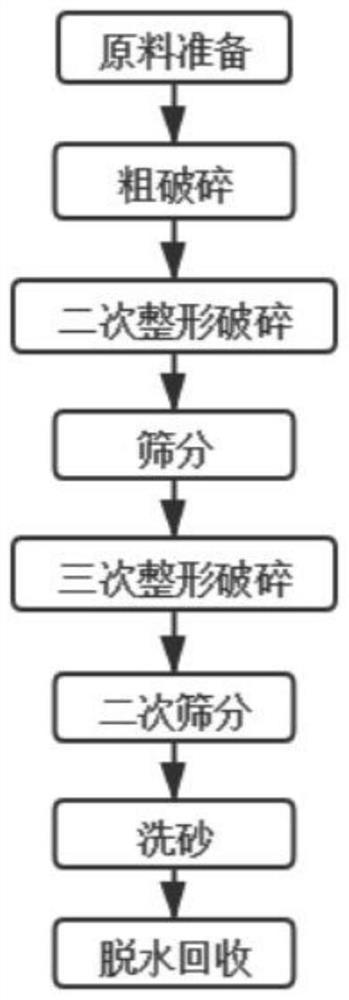

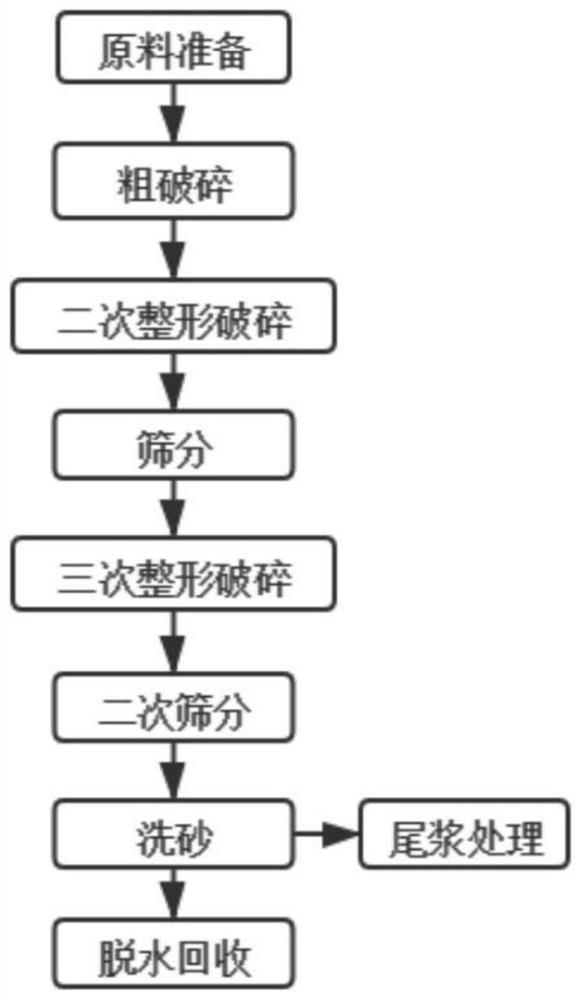

Processing method of high-quality machine-made sand

InactiveCN113019657AParticle size up to standardLarge particle sizeGrain treatmentsEmission standardBelt filter

The invention provides a processing method of high-quality machine-made sand, and belongs to the technical field of sand making processes. The processing method specifically comprises the following steps: 1, preparing raw materials; 2, conducting coarse crushing; 3, conducting secondary shaping and crushing; 4, screening; 5, shaping and crushing for the third time; 6, conducting secondary screening; 7, conducting sand washing; 8, dehydrating and recycling; and 9, performing tail slurry treatment. According to the processing method, through three times of crushing, two times of screening, at least two times of water washing and two times of shaping, it is ensured that the grain size of a sand-gravel material reaches the standard, the grain size and shape are good, discharging is uniform, high yield and low consumption are achieved, and economy and practicability are achieved; through a tail slurry environment-friendly treatment system, mud and water are rapidly separated, clear water reaches the national emission standard and is recycled, and the environment-friendly effect is achieved; and sediment is dehydrated through a belt filter press and extruded into a mud cake which is used for slope greening of a project, so that the method is green and environment-friendly.

Owner:CHINA RAILWAY FIRST GRP CO LTD

Assembled crusher

InactiveCN101518751ALarge crushing ratioReduce energy consumptionCocoaGrain treatmentsReducerEngineering

The invention relates to an assembled crusher. A main shaft is in keyed joint with a movable conical sleeve and a grinding-base support sleeve, wherein the grinding-base support sleeve is connected by a pressure bearing and an upper case of a reducer. A bearing sleeve and a shaft sleeve ray lid are arranged outside the bearing of a main shaft and connected with an upper external ring, a transition ring and an external ring of the upper case of the reducer from top to bottom. The external conical round surface of the movable conical sleeve is provided with a split-type movable conical-tooth plate, and the grinding-base support sleeve is provided with a split-type grinding base with sieve holes. The external conical sleeve is connected into the upper external ring, and the split-type external conical-tooth plate is arranged in the external conical sleeve. The external circle of the upper case of the reducer is provided with more than three turnover roller assemblies comprising roller supports, roller shafts and rollers and arranged on the grinding base on the opening part of the transition ring. The shaft sleeve ray lid is provided with a feeding hopper and a guiding cap. Kick-out plates are arranged in the transition ring. In the whole crushing process, the force applying modes for rock-mine breaking dynamic properties, i.e. impacting, point pressing, breaking, cutting, laminating, and the like are simultaneously used, the ratio of crushing is high, and the effect of ultrafine crushing is obtained at one time.

Owner:黄琳

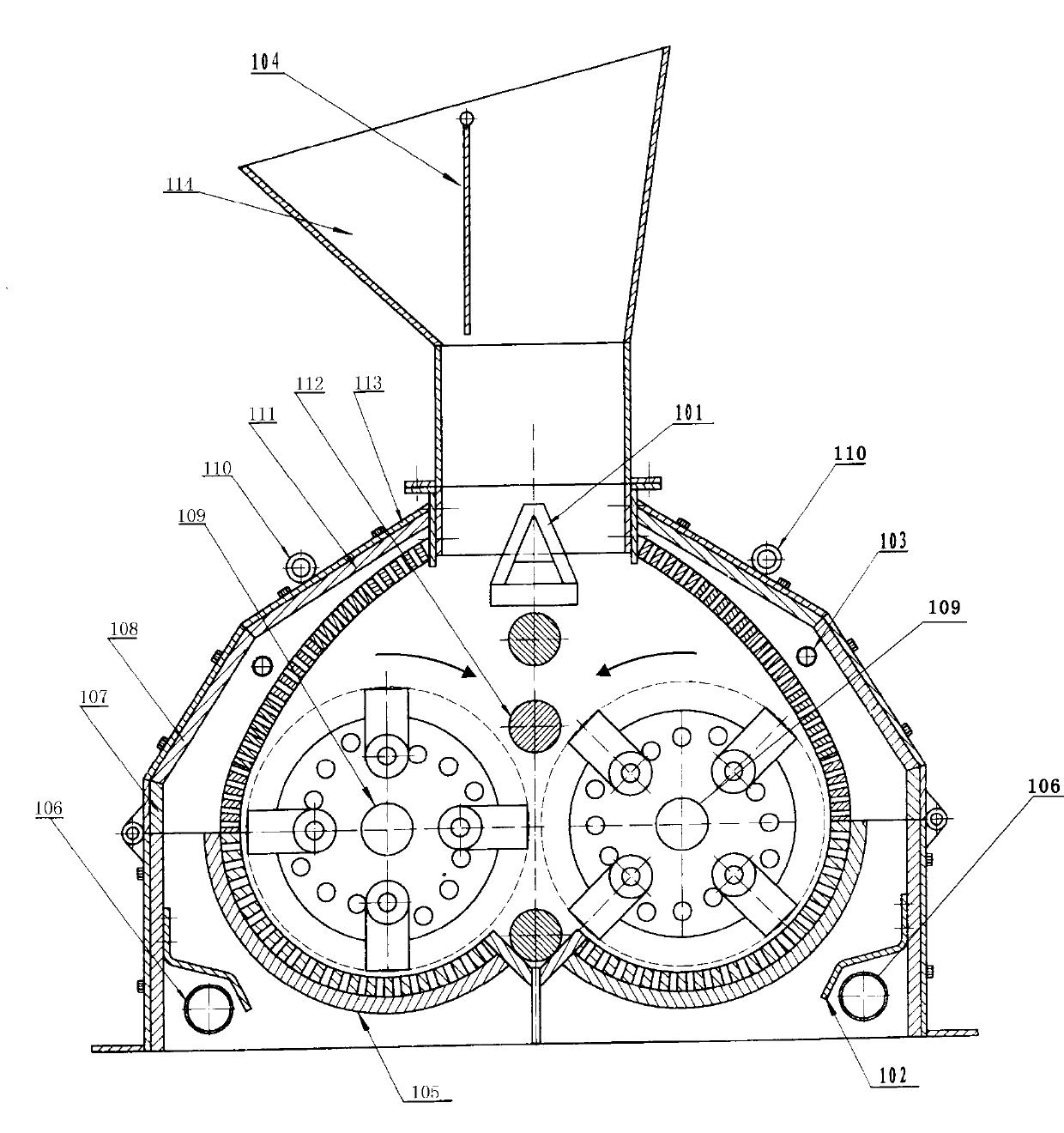

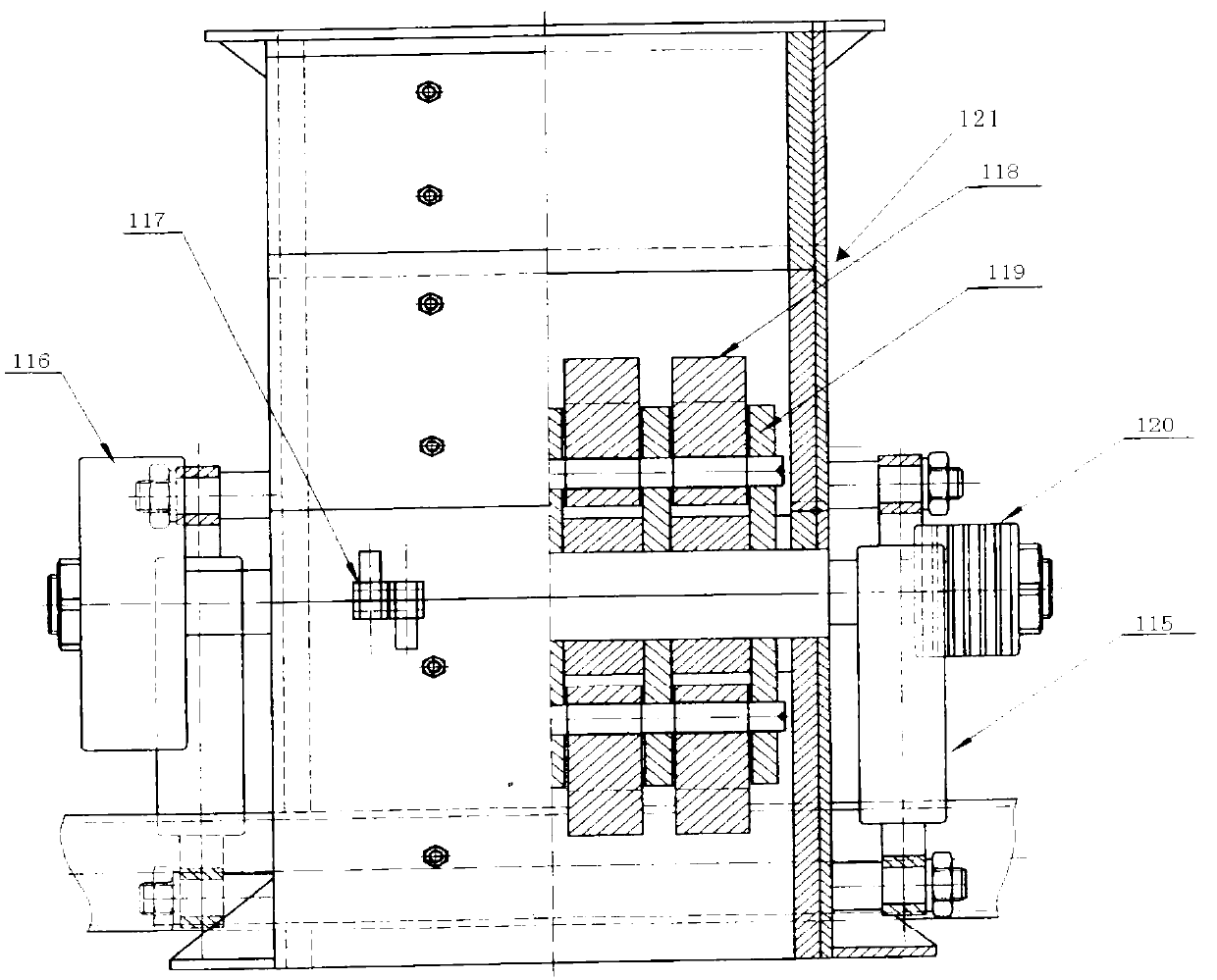

Birotor superfine impacting hammer crusher

The invention relates to a birotor superfine impacting hammer crusher. The birotor superfine impacting hammer crusher comprises a feeding device, a crushing chamber, a grinding chamber, a classification chamber and a feed divider which are connected serially and sequentially, the crushing chamber and the grinding chamber are positioned on two inner sides of a crusher shell symmetrically, the classification chamber is positioned on the upper portion of the grinding chamber, the feeding device is positioned on the upper portion of the crushing cavity, and the crushing cavity and the grinding cavity are connected through the feed divider. The birotor superfine impacting hammer crusher has the advantages of high crushing and grinding efficiency and large material crushing ratio.

Owner:SINOMA TECH & EQUIP GRP +1

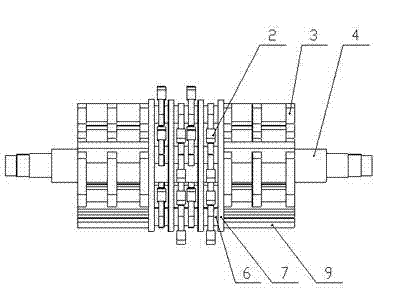

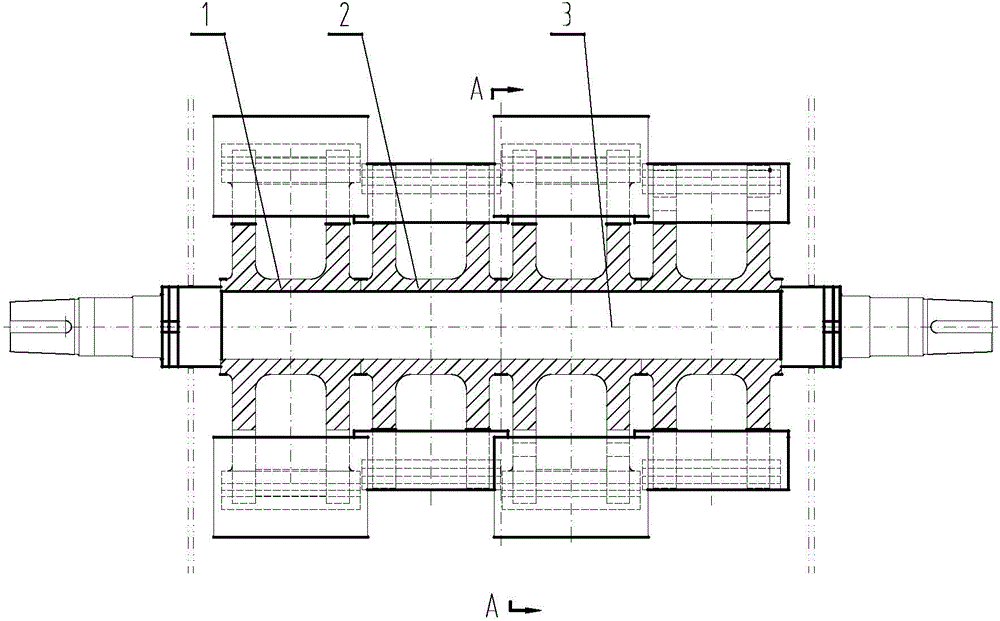

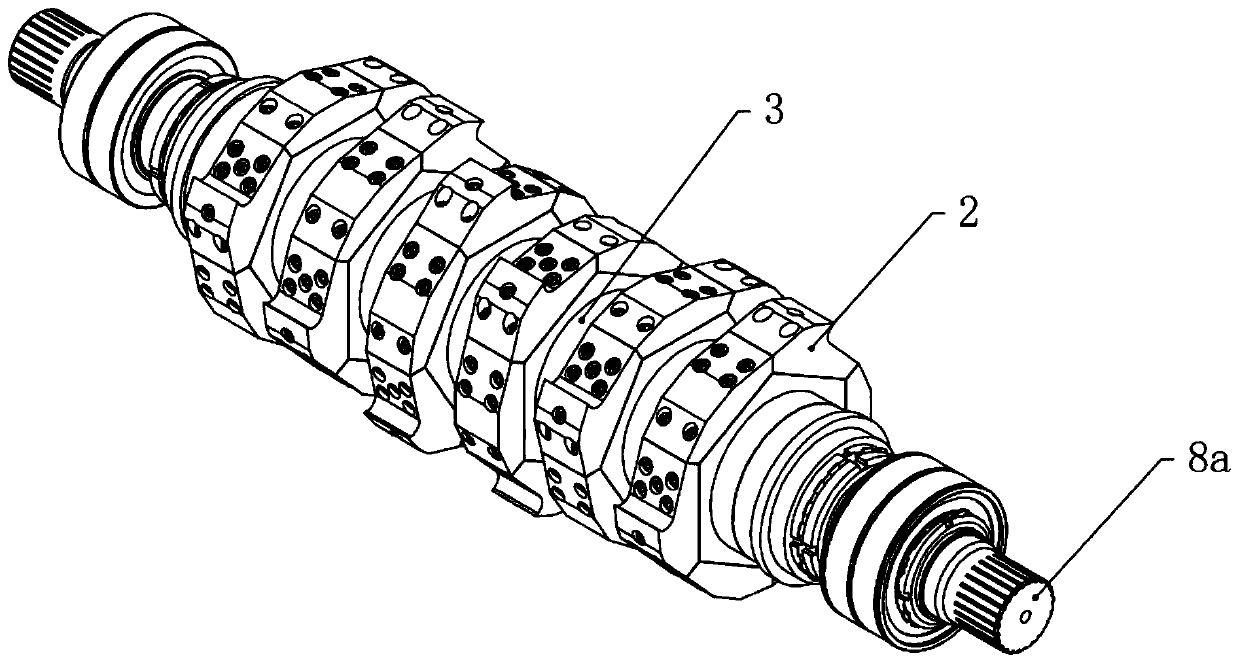

Crusher rotor block and crusher

The invention relates to the field of mining machinery, and discloses a crusher rotor block and a crusher, aiming at overcoming the defects of such as easiness for material blocking, small crushing ratio, quick wear of wearing parts, and short service life in an old-fashioned rotor block. The rotor block consists of multiple sets of rotor disks, wherein each rotor disk is provided with an integrated web plate, and the web plate is provided with multiple sets of plate hammer supporting structures; each rotor disk is fixedly installed on the same shaft, and an angle is formed between two rotor disks. The crusher rotor block and the crusher disclosed by the invention has the advantages that the time when materials enter the crusher and impacted by a plate hammer in high-speed rotation is different, the crushed materials are thrown to a counter-attack plate at the other end of a crushing chamber along the tangential direction at a high speed and crushed again, and then rebounded from the counter-attack plate to the plate hammer, at the moment, the materials can be subjected to crossed impact and crushing between materials with materials crushed later, so that the crushing probability of the materials is increased, the crushing ratio is increased, the crushing efficiency is improved, and the yield is increased.

Owner:朝阳重型机器发展有限公司

Clean jaw crusher with discharging granularity being adjustable and adjusting method of clean jaw crusher

ActiveCN111672558AReduce pollutionReduce the crushing ratioGrain treatmentsRotational axisMoving jaw

The invention discloses a clean jaw crusher with discharging granularity being adjustable and an adjusting method of the clean jaw crusher. The jaw crusher comprises a fixed jaw plate, a moving jaw, amoving jaw plate, a rack, a first rotating shaft, a second rotating shaft, an adjusting seat, a wrist plate, adjusting seat rotating devices, a drive mechanism and a controller. The rack is arrangedon the jaw crusher. The fixed jaw plate is arranged on the rack. The moving jaw is arranged obliquely. The moving jaw plate is fixed to the moving jaw. The first rotating shaft is arranged at one endof the fixed jaw plate and is close to a discharging opening of the jaw crusher. The second rotating shaft is arranged at the other end of the fixed jaw plate and is away from the discharging openingof the jaw crusher. A kidney-shaped hole is formed in one side plate of the rack, and the second rotating shaft rotates on the kidney-shaped hole with the first rotating shaft as a rotating shaft. Theadjusting seat comprises multiple adjusting cushion plates and at least two sets of bolts and nuts. One end of the wrist plate is connected with the moving jaw, and the other end of the wrist plate is connected with the adjusting seat. The at least two adjusting seat rotating devices are mounted on the moving jaw and the adjusting seat correspondingly, and each adjusting seat rotating device comprises multiple self-lubricating joint bearings.

Owner:合肥开比锐精机科技有限公司

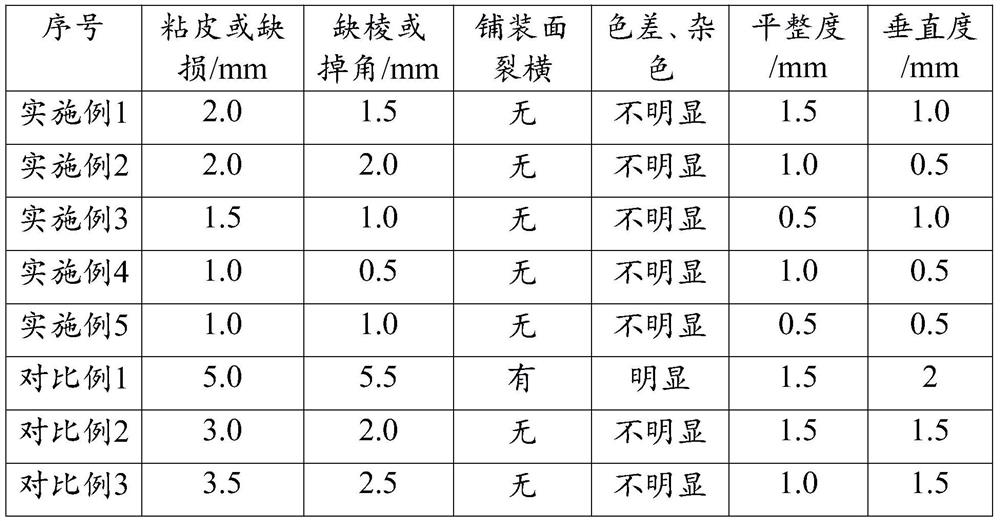

Pavement brick prepared from construction waste recycled aggregate and preparation process thereof

InactiveCN112341091ASolve the difficulty of makingImprove water absorptionSolid waste managementAuxillary shaping apparatusCompressive resistanceBrick

The invention provides a pavement brick prepared from construction waste recycled aggregate and a preparation process of the pavement brick. The pavement brick is a recycled aggregate pavement brick with a surface layer. The surface layer mainly comprises the following raw materials in percentage by mass: 22-29% of cement, 62-70% of natural aggregate and 6-13% of water. And the bottom layer mainlycomprises the following raw materials in percentage by mass: 12-15% of cement, 46-52% of brick-concrete mixed recycled aggregate, 21-29% of concrete recycled aggregate, 3-6% of mineral admixture and8-10% of water. The pavement brick provided by the invention has better appearance quality, higher compressive strength, higher freezing resistance and lower water absorption, the construction waste is fully utilized while the pavement brick with excellent performance is prepared, and the full utilization of resources is ensured.

Owner:BCEG RESOURCES RECYCLING CO LTD

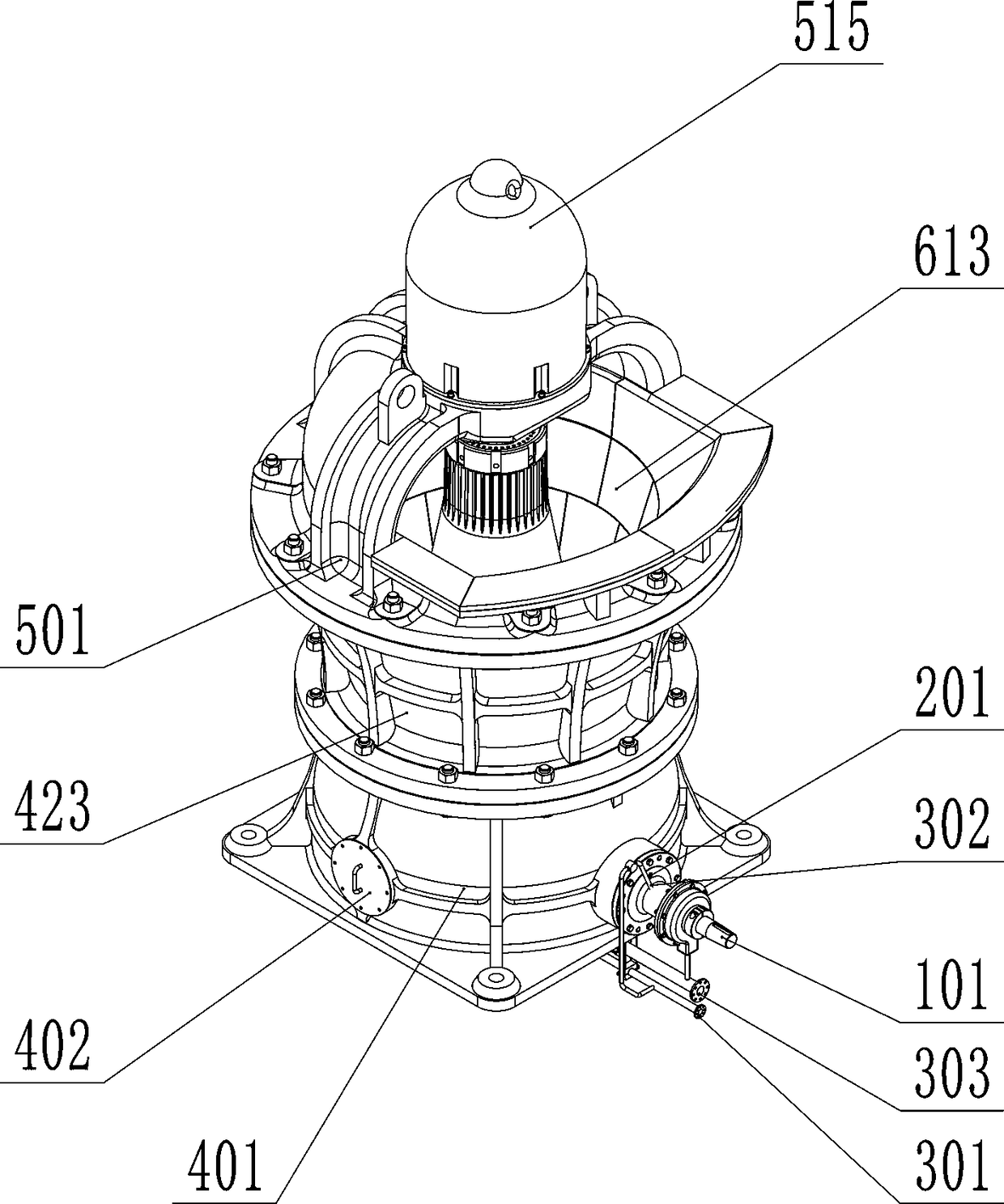

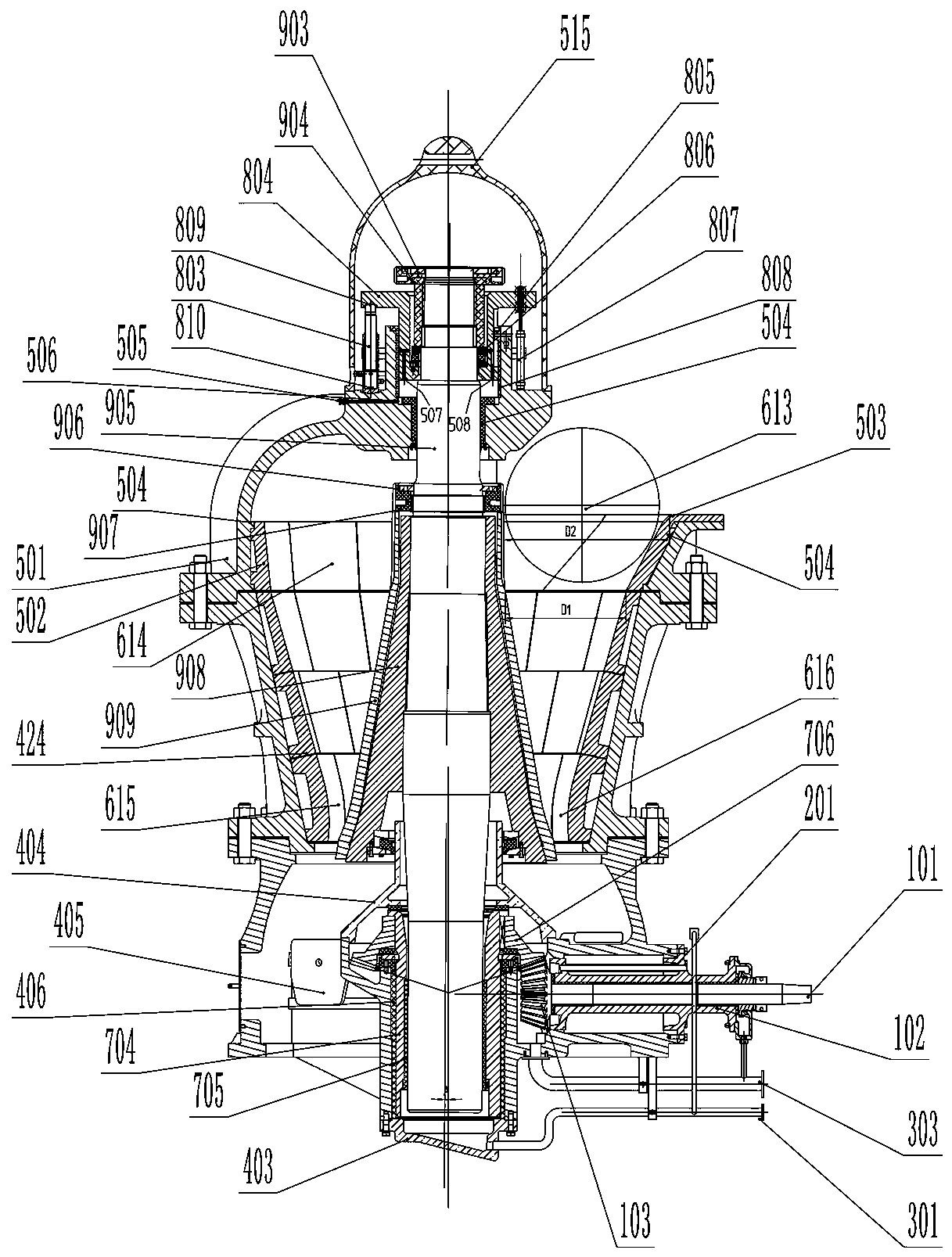

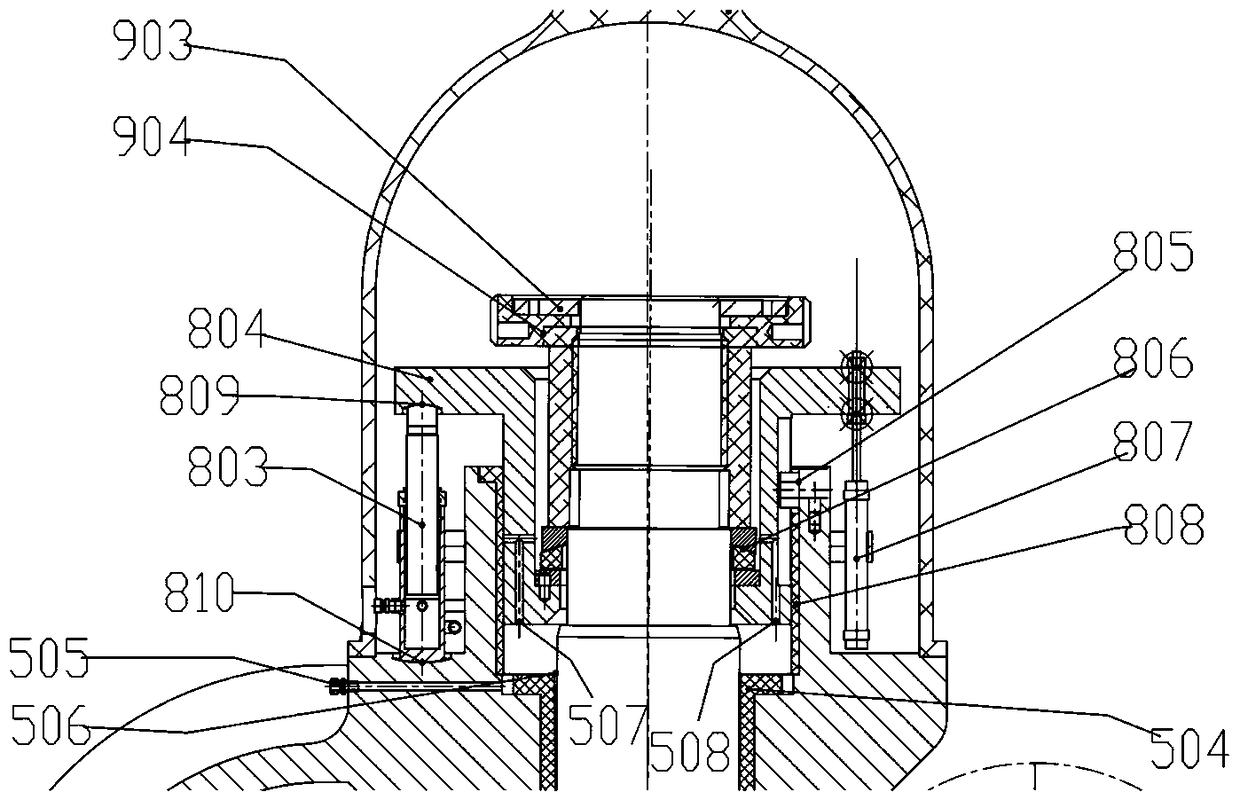

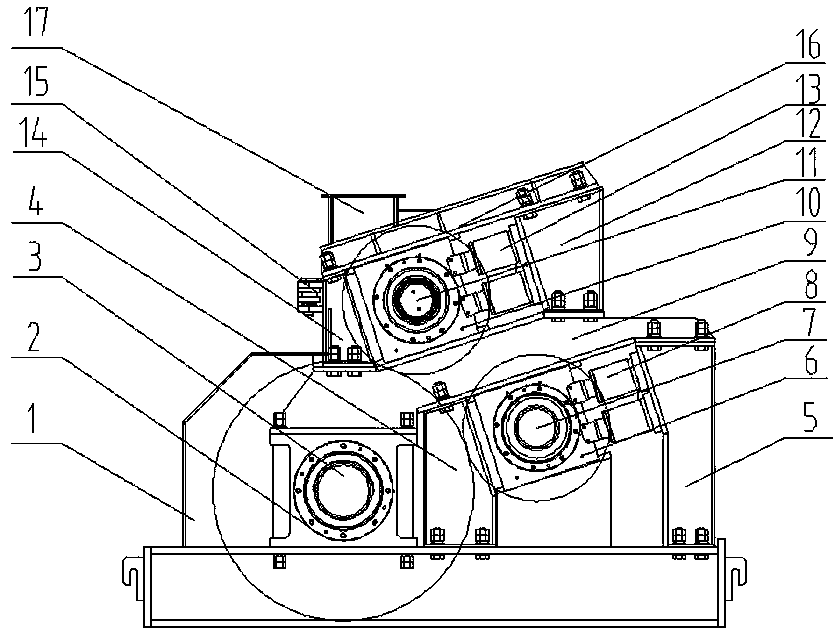

One-sided feeding top hydraulic supporting gyratory crusher

PendingCN108579871ALarge crushing ratioReduce installation difficultyGrain treatmentsGear wheelEngineering

The invention relates to the field of crushing equipment of ores or rocks, in particular to crushing equipment which crushes exploited bulky ores or rocks (the grain sizes are 700mm) to ores or rocks(the grain sizes are smaller than 350mm). The gyratory crusher comprises an upper rack body assembly, a middle rack body assembly and a base assembly as well as a movable cone assembly, a rack wheel eccentric bushing assembly, a pinion transmission assembly and an upper hydraulic supporting lifting suspending assembly in eccentric pendulum movement; a feed inlet is formed in the upper rack body assembly, and a discharge port is formed in the base assembly. The crushing ratio: the proportion of the feeding grain and the discharging grin, of the equipment is increased by enlarging the feed inletand the inner crushing cavity, and the mounting and repair difficulty is reduced by means of upper maintenance and replacement of quick-wear parts.

Owner:沈阳顺达重矿机械制造有限公司

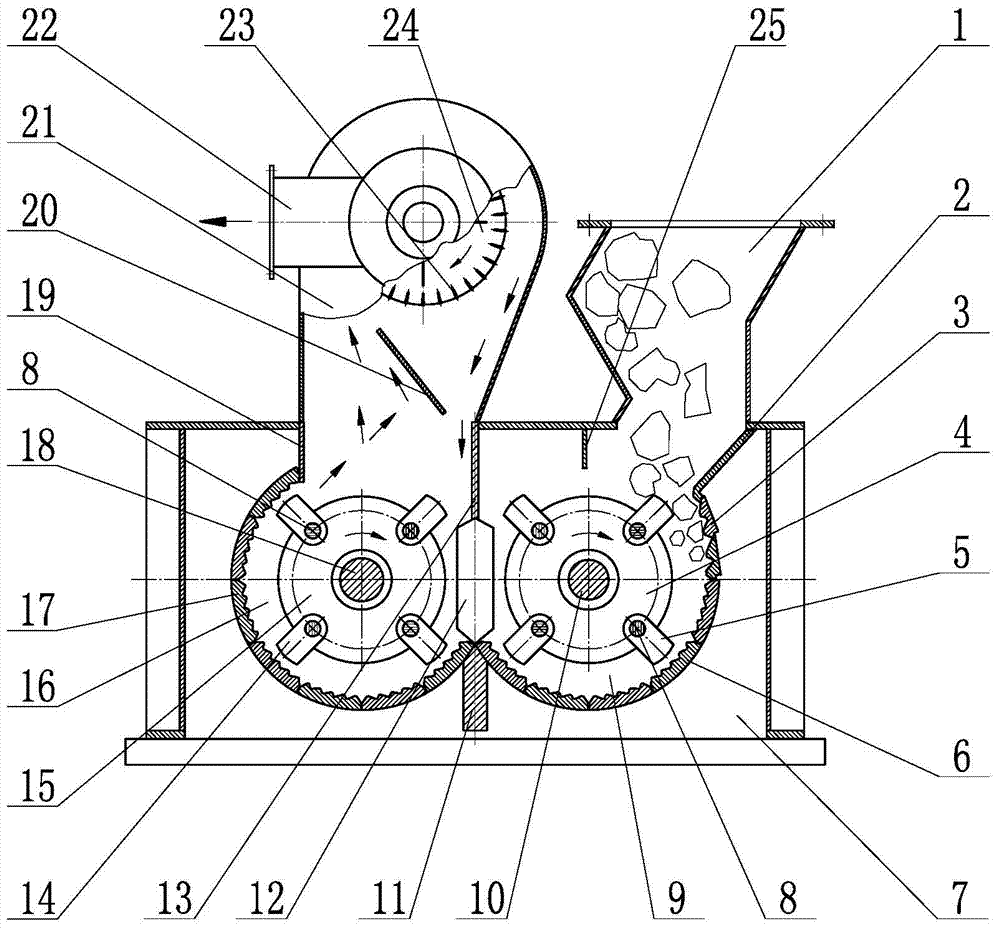

Energy-saving and environment-friendly double-rotor crushing machine

InactiveCN103100464AReasonable structural designImprove utilization efficiencyGrain treatmentsCrusherDistributor

The invention discloses an energy-saving and environment-friendly double-rotor crushing machine which is characterized by comprising an outer protection plate shell, an inner material distributor, a sieve plate supporting ring, double main shafts, crushing rods and a feeding hopper, wherein the feeding hopper is mounted at the upper end of the protection plate shell; the feeding hopper is internally provided with a baffle; the material distributor is located at the lower end position of the feeding hopper so that left and right crushing cavities uniformly supply materials; the sieve plate supporting ring is provided with a circular hole sieve plate device; and the circular hole sieve plate device is internally provided with the double main shafts. The crushing machine disclosed by the invention is improved and has the advantages that 1. the structural design is reasonable, the crushing cavities are in a gradually-opened shape and the crushing effect is increased; 2. except a feeding opening, an inner cavity is nearly a sieve plate so that the passing area of crushed materials is enlarged; the abrasion of a hammer block in an operation process and a steel sieve is reduced; and 3. a plurality of crushing rods are arranged inside the crushing machine so that when two rotors operate relatively from left to right, a hammer head (block) impacts the materials by rotating at a high speed; the materials collide and are beaten back in any direction of the cavity so as to realize a plurality of times of crushing by colliding stones by stones; and finished material products which pass through a circular hole sieve on the sieve plate are polygonal bodies, fewer materials are sheet-shaped, and the yield is high.

Owner:乐山市岷江机器厂

Hydraulic multistage composite roller crusher

PendingCN111450927AImprove efficiencyLarge crushing ratioGrain treatmentsFixed bearingStructural engineering

The invention belongs to the technical field of crushing devices and particularly relates to a hydraulic multistage composite roller crusher which comprises a rack; a fixed roller is fixed and supported on the rack through a fixing bearing; an upper pressing plate and a lower pressing plate are arranged on the outer side of the rack and are slantly fixedly connected with slideways; all slideways are obliquely downwards from one end far away from the fixed roller to the end close to the fixed roller; an upper movable bearing pedestal is arranged in the slideway connected with the upper pressingplate and supports an upper movable roller; a lower movable bearing pedestal is arranged in the slideway connected with the lower pressing plate and supports a lower movable roller; the upper movablebearing pedestal is connected with an upper bidirectional oil cylinder; and the lower movable bearing pedestal is connected with a lower bidirectional oil cylinder. The hydraulic multistage compositeroller crusher can realize composite type crushing operation to greatly improve the crushing efficiency and effectively save energy, and can avoid by self when meeting extremely large or extremely hard material to greatly prolong the service life.

Owner:徐州市诚信破碎机械厂

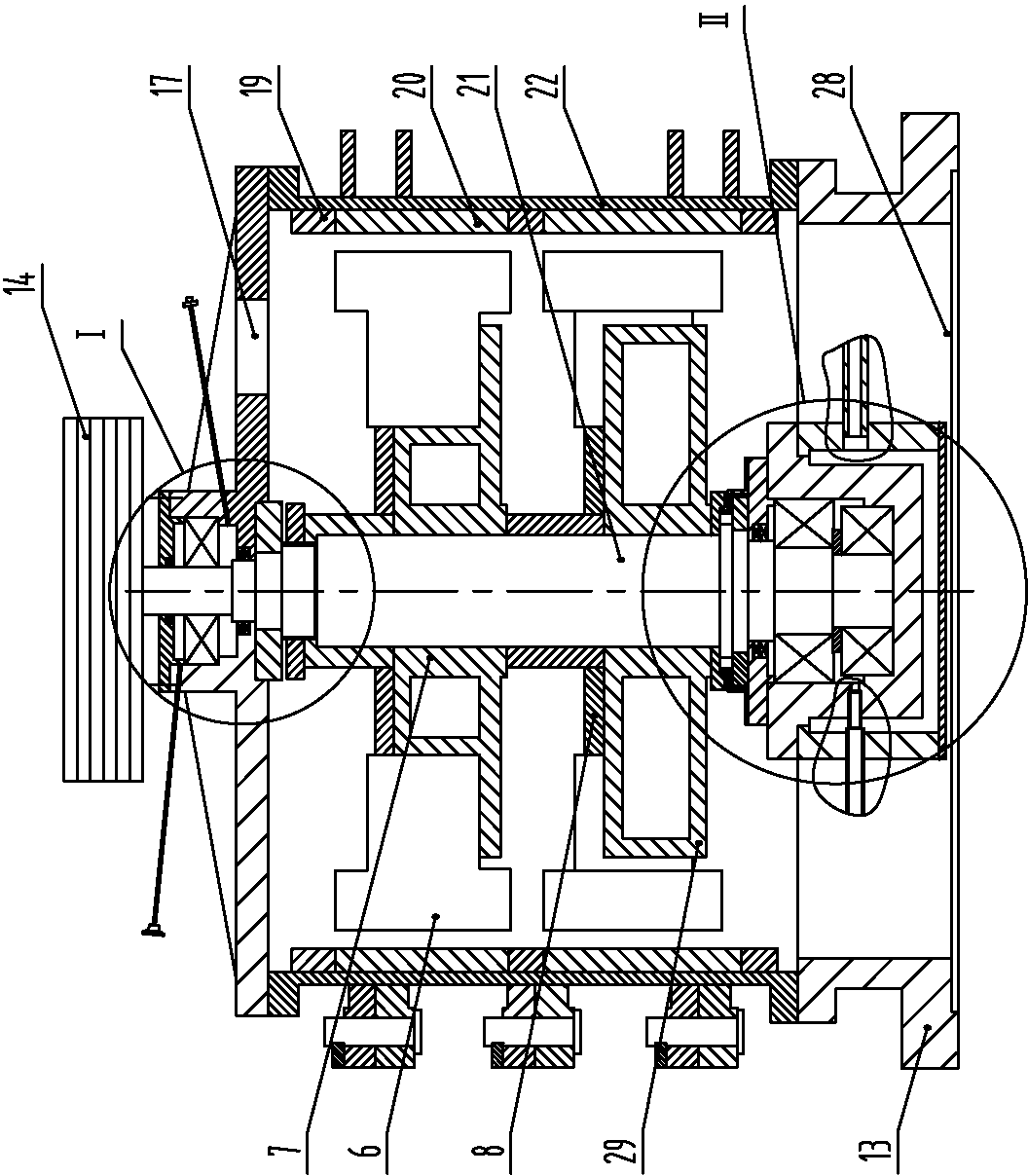

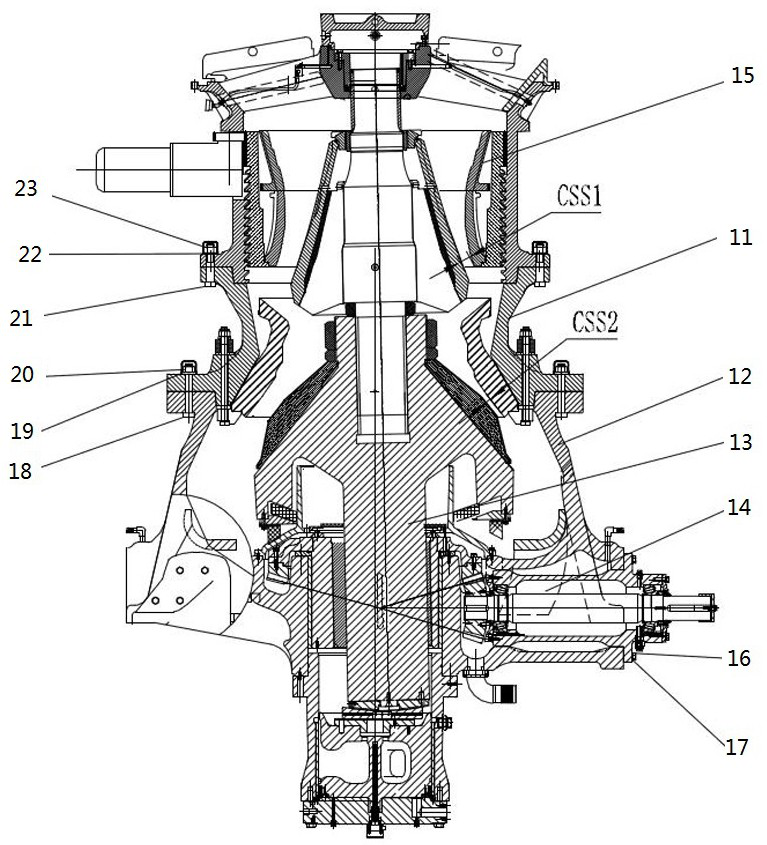

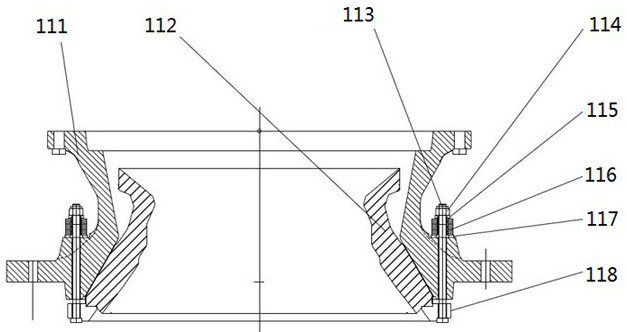

A double-cavity hydraulic cone crusher and its adjustment method

ActiveCN111514964BRealize double-cavity crushingLarge crushing ratioGrain treatmentsCircular coneStructural engineering

The invention discloses a double-cavity hydraulic cone crusher. The double-cavity hydraulic cone crusher comprises a main machine, wherein the main machine comprises an upper frame assembly, a lower frame assembly, a main shaft assembly and a top shell assembly; the upper frame assembly is installed at the upper end of the lower frame assembly; the main shaft assembly is installed into the lower frame assembly; the top shell assembly is installed at the upper end of the upper frame assembly; the main shaft assembly is provided with an upper movable cone and a lower movable cone; the upper frame assembly is internally provided with a lower fixed cone; the top shell assembly is provided with an upper fixed cone; the upper movable cone and the upper fixed cone form a first crushing combination; and the lower movable cone and the lower fixed cone form a second crushing combination. According to the double-cavity hydraulic cone crusher, intermediate crushing in an upper cavity of the main machine and fine crushing in a lower cavity of the main machine are realized in one crusher, so that the super-large crushing ratio is achieved, the process flow is greatly simplified, and the workingefficiency is greatly improved.

Owner:南昌矿机集团股份有限公司

Heavy-duty crushing machine

The invention relates to a heavy-duty crushing machine. According to the invention, a motor and a rotor of the crushing machine are connected by using a belt; a feeding port is arranged on the top of the heavy-duty crushing machine, and is connected to a frame; a discharging port is arranged below the heavy-duty crushing machine; and the rotor is arranged on a bearing pedestal, and is fixed on the frame. With the crushing machine, during a material crushing procedure, adhesion or blocking does not occur, an over crushing rate is low, the noise is low, the vibration is low, a dust amount is low, the energy consumption is low, and the land occupation is low. There is no requirement on the water content of the material requiring crushing.

Owner:广西南宁东创通用机械设备工程有限公司

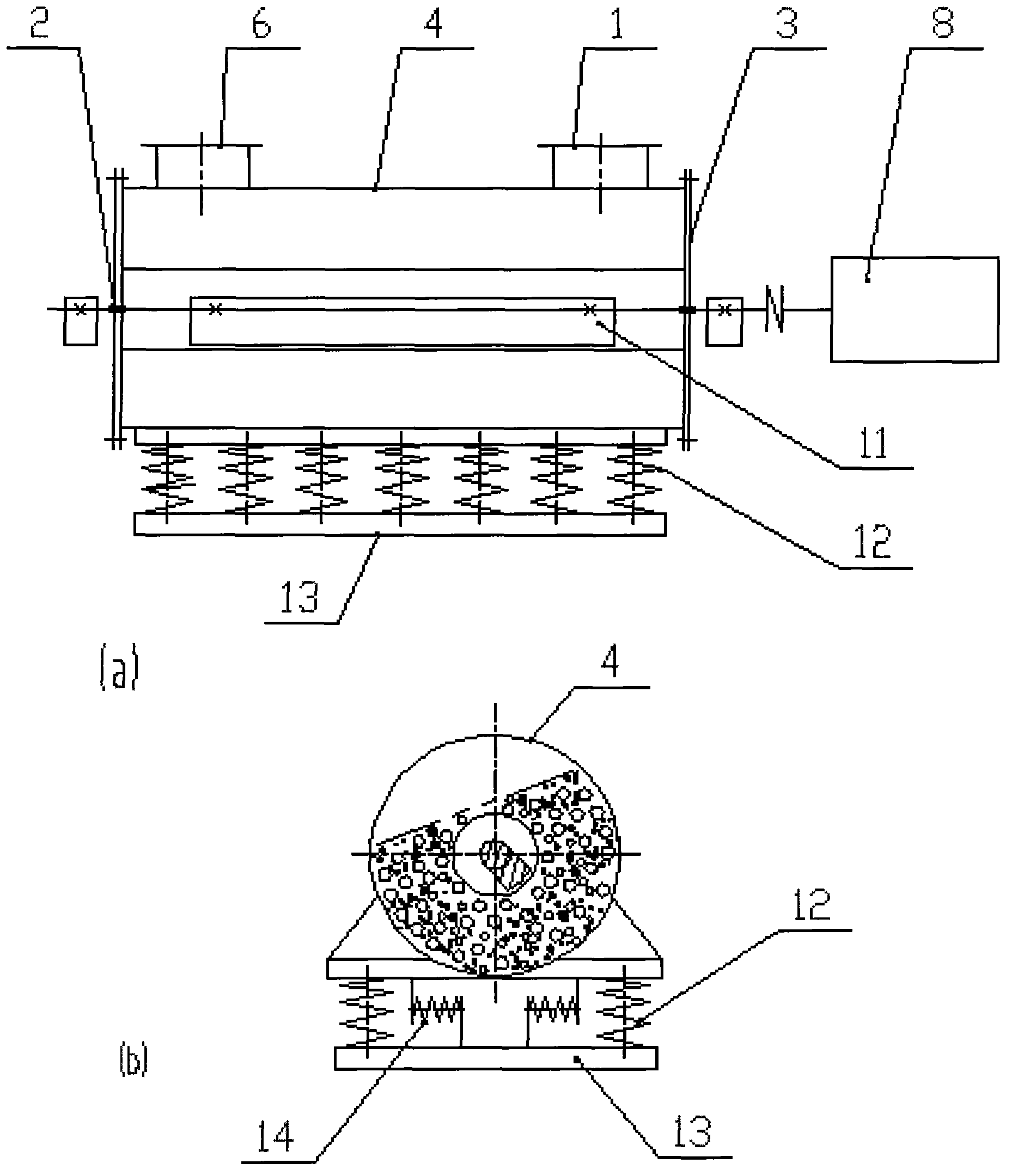

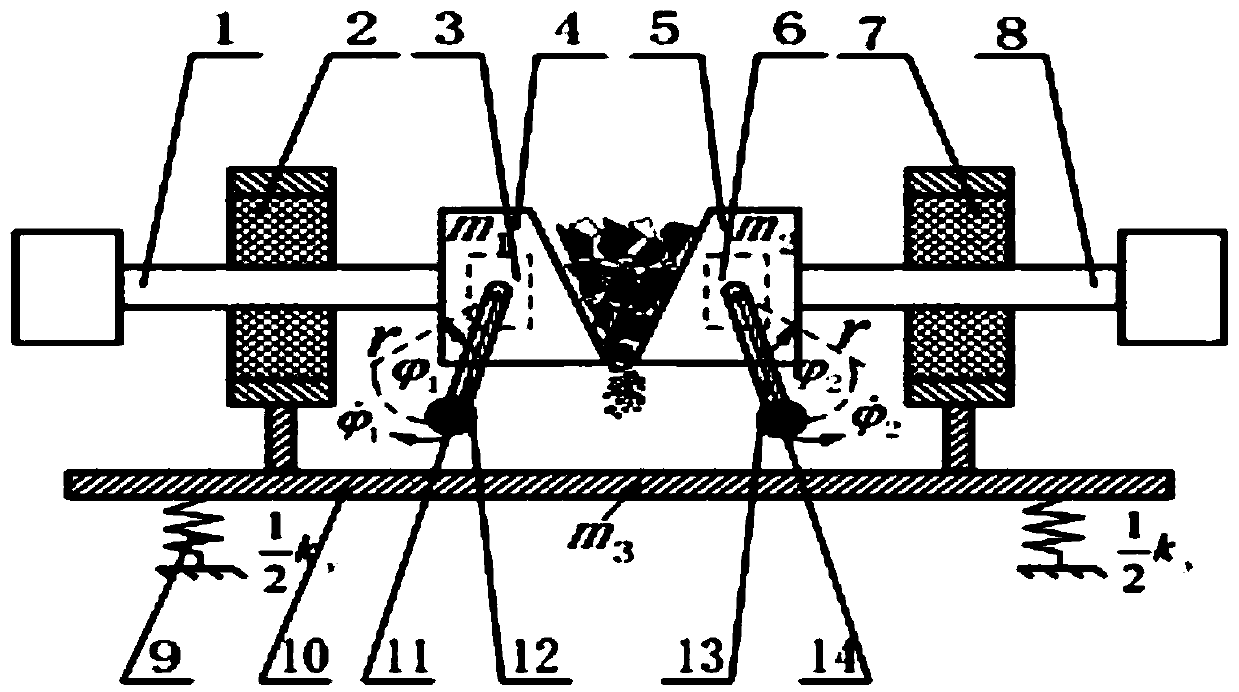

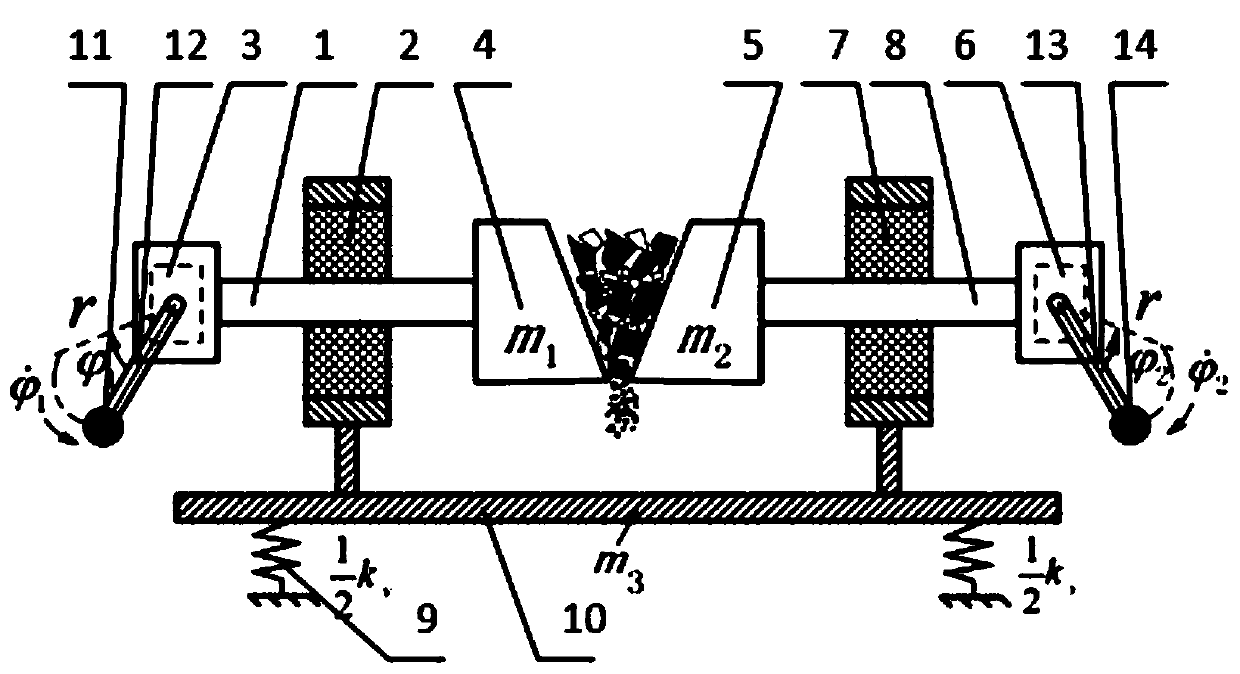

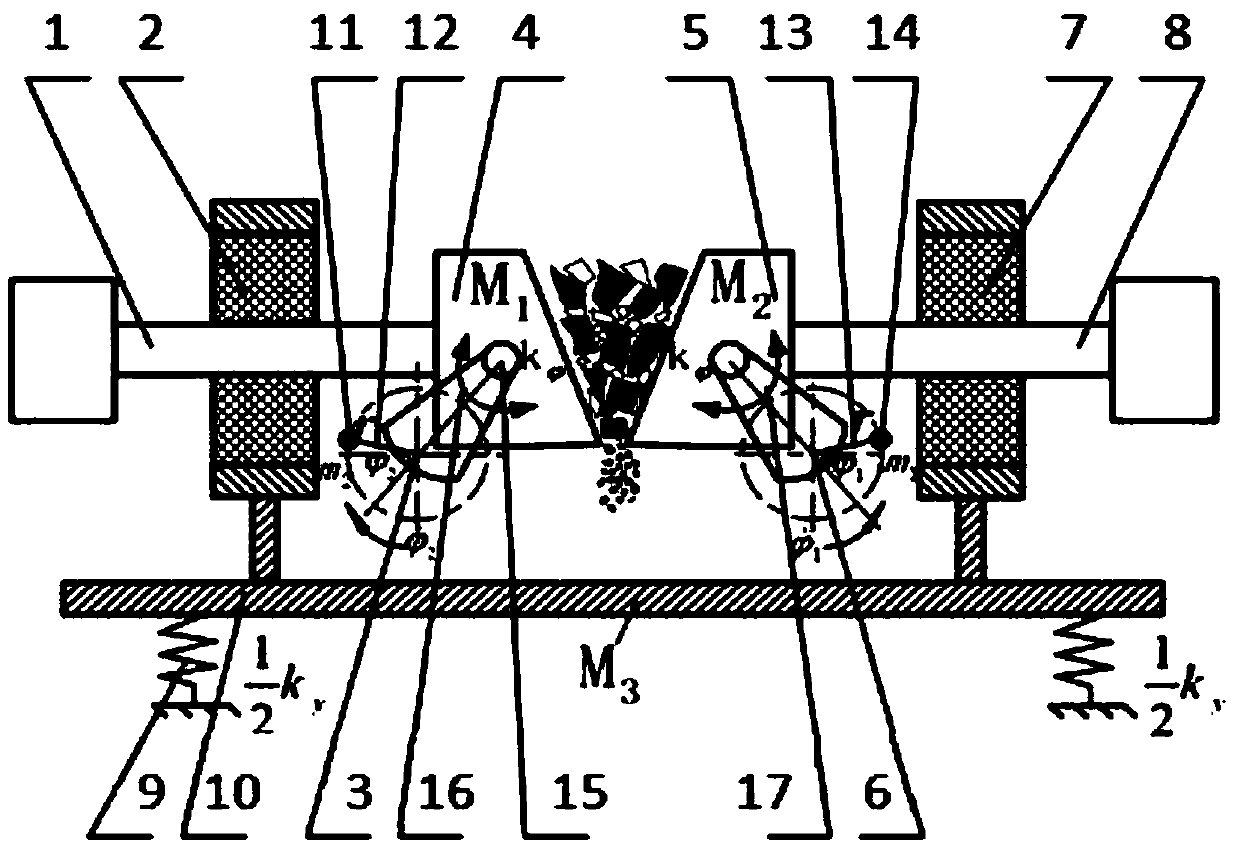

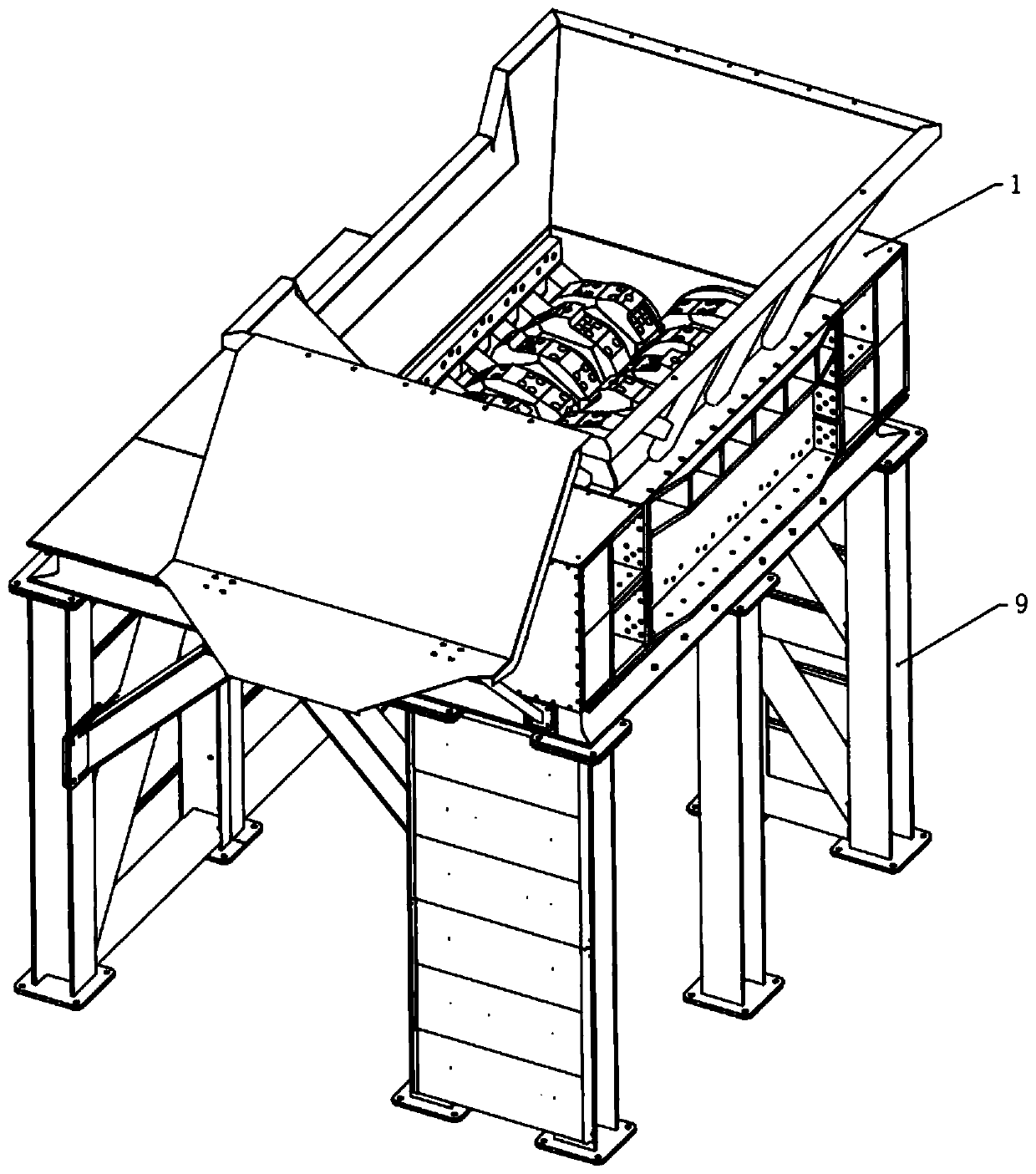

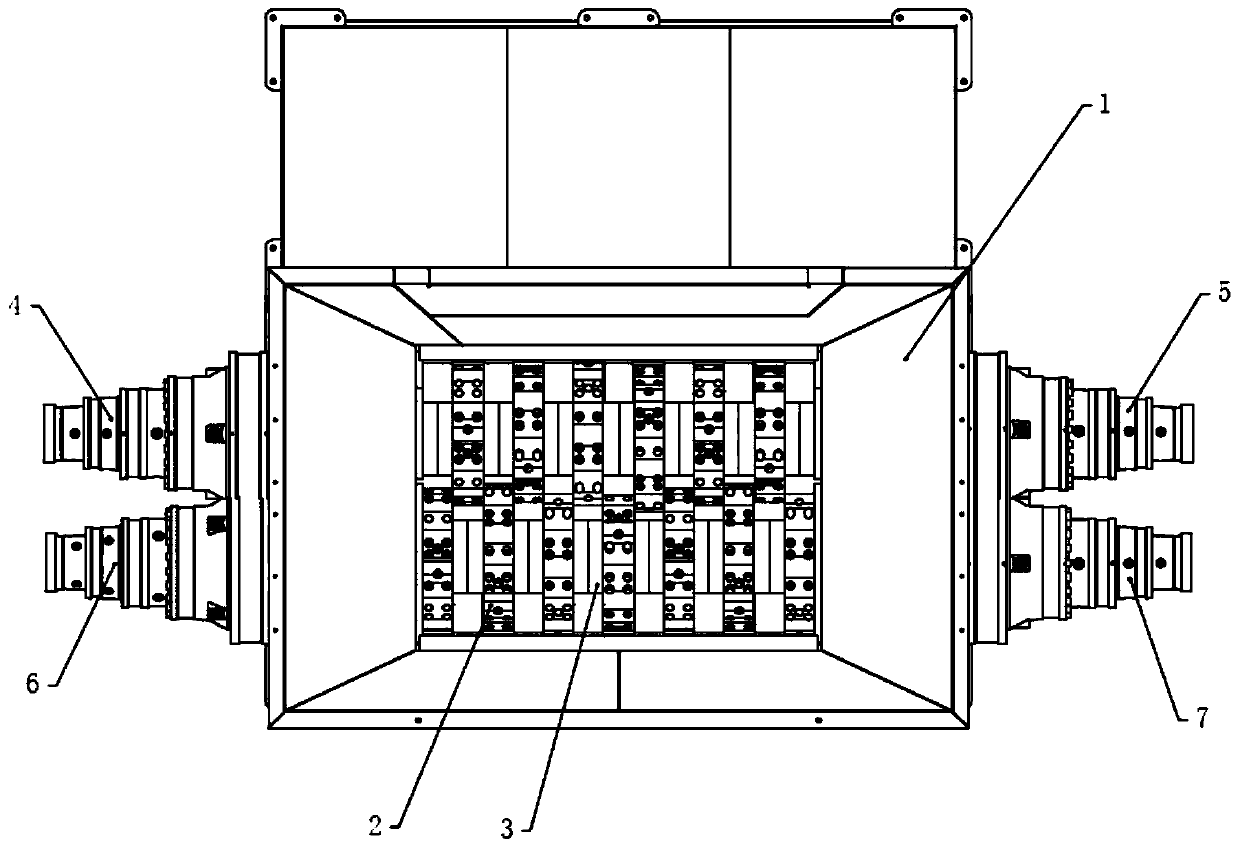

Dual-machine self-synchronous drive balanced type vibration crusher

ActiveCN109622178AIncreased effective crushing strokeIncrease the number of impactsGrain treatmentsMoving jawRelative motion

The invention belongs to the field of self-synchronous machines, and provides a dual-machine self-synchronous drive balanced type vibration crusher. The dual-machine self-synchronous drive balanced type vibration crusher comprises two sets of vibration exciters, two sets of main vibration springs, two supporting bodies, two jaw plates, two sets of damping springs and a vibration isolator; by usinga dual-machine self-synchronous principle to drive, when materials are crushed, eccentric rotors are driven by alternating current motors to enable the two vibration exciters to perform reverse high-speed rotation, the exciting force is generated, and thus two moving jaws are driven to achieve relative motion of antiphase, the force in the horizontal direction of the two moving jaws is counteracted mutually, and a self-balancing state is achieved; and loading transmitted in the horizontal direction is guaranteed to be smallest, and meanwhile material crushing between the two moving jaws is achieved. According to the dual-machine self-synchronous drive balanced type vibration crusher, a subresonance principle and a dual-vibration-exciter self-synchronous principle are combined, a vibrationcrushing way is used for achieving great crushing strength of the crusher, the stability of a system is improved, and the energy conservation of the crusher is achieved. The dual-machine self-synchronous drive balanced type vibration crusher can achieve a relatively large crushing ratio, and can crush ultra-hard materials.

Owner:NORTHEASTERN UNIV

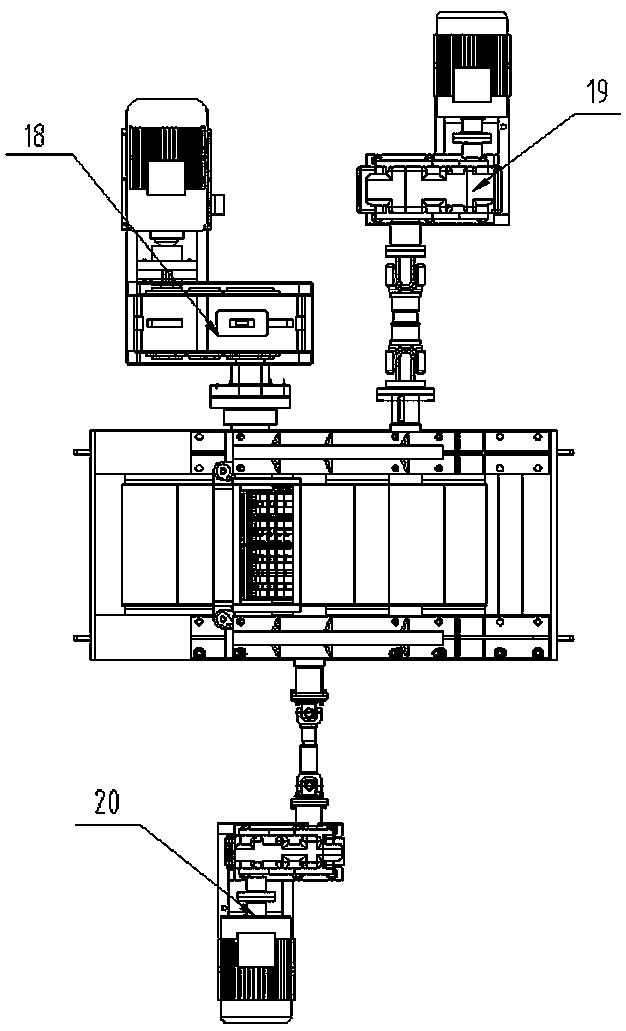

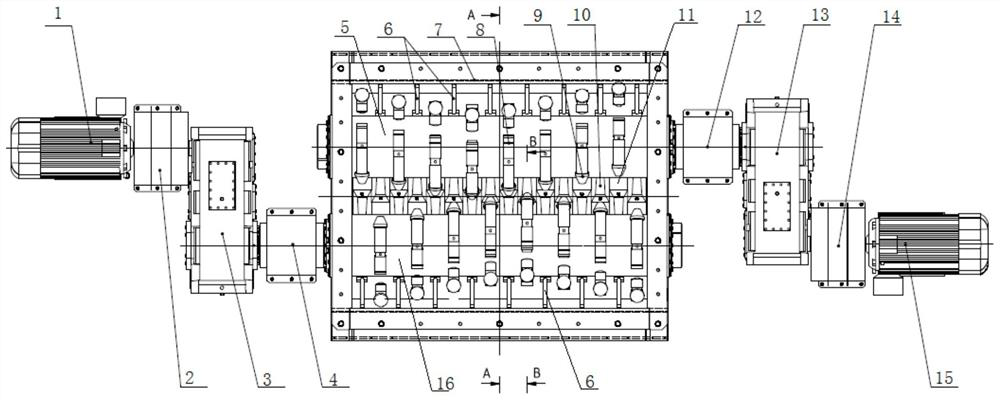

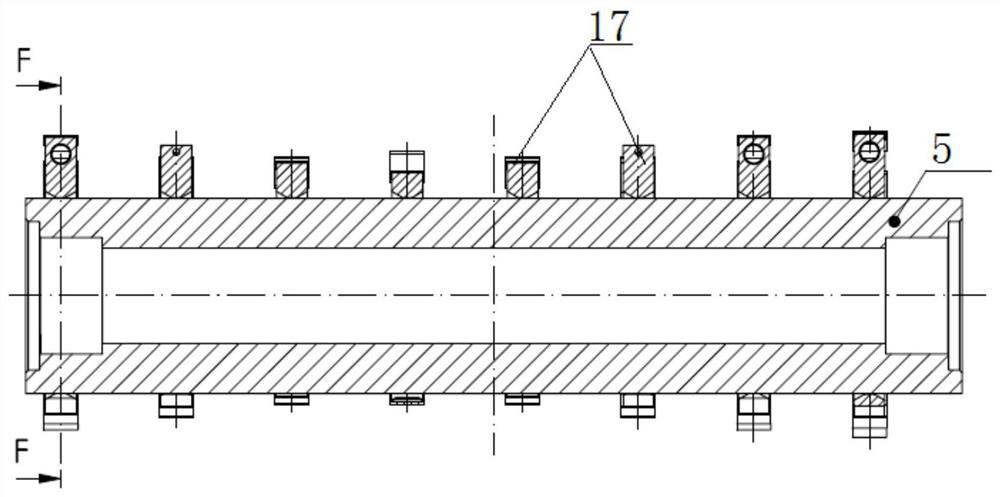

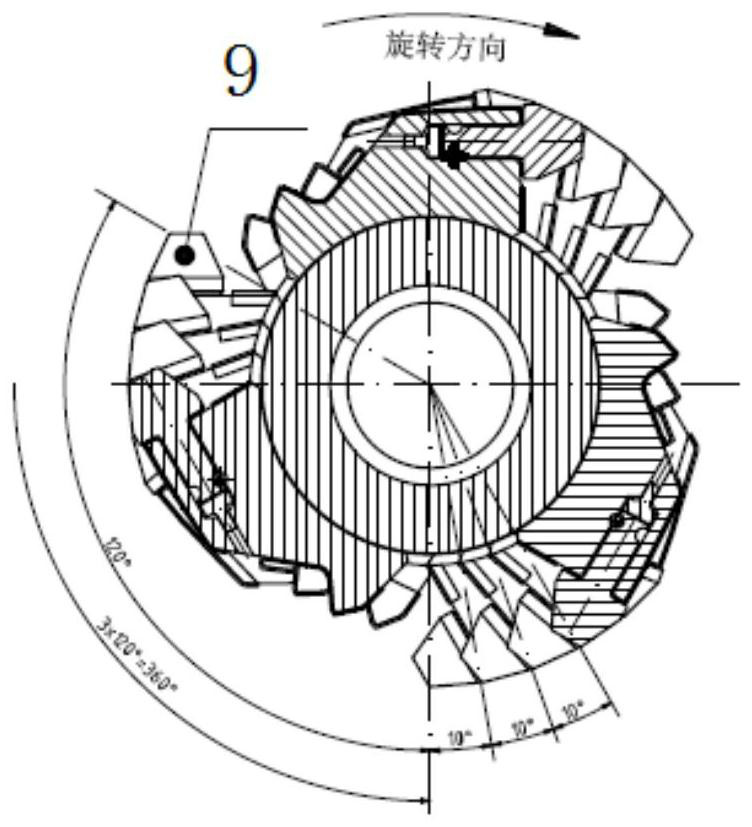

Dual-shaft unpacking and breaking device

PendingCN111229408ALarge transmission torqueLarge crushing ratioGrain treatmentsStructural engineeringSpiral line

The invention discloses a dual-shaft unpacking and breaking device. The dual-shaft unpacking and breaking device comprises a box body, stirring shafts and a driving device, the stirring shafts comprise a first stirring shaft and a second stirring shaft mounted in the box body in a parallel penetrating manner, multiple tools are mounted on the stirring shafts at intervals in the axial direction, the tools on the first stirring shaft and the tools on the second stirring shaft are staggered in the axial direction, each tool comprises multiple tool bodies staggered on the corresponding stirring shaft in the radial direction, blade orientation of the tool bodies on the first stirring shaft and blade orientation of the tool bodies on the second stirring shaft are opposite, blades of the multipletool bodies on each stirring shaft form multi-row spiral line arranging in the axial direction, and the driving device comprises a first driving device directly connected with the first stirring shaft and a second driving device directly connected with the second stirring shaft. Through dual-shaft rollers, low-speed shearing and breaking can be achieved, a large material can be subjected to wholetreatment, and the advantages of being large in breaking strength, high in breaking efficiency, high in yield, low in energy consumption, clean and environment-friendly can be achieved.

Owner:NINGBO HUILONG MACHINERY CO LTD

High-crushing-ratio double-tooth-roller crusher

ActiveCN112871293ALarge crushing ratioIncrease crushing ratioGrain treatmentsElectric machineryEngineering

The invention discloses a high-crushing-ratio double-tooth-roller crusher. The high-crushing-ratio double-tooth-roller crusher comprises a crusher shell, a first tooth roller shaft, a second tooth roller shaft, a first coupler, a second coupler, a first speed reducer, a second speed reducer, a first hydraulic coupler, a second hydraulic coupler, a first motor, a second motor, a hydraulic jack, a bolt support, a crushing beam fixing bolt, a crushing beam and lower crushing teeth, wherein a plurality of rows of roller teeth are distributed on the first tooth roller shaft at equal intervals in the axial direction; a plurality of rows of roller teeth are distributed on the second tooth roller shaft at equal intervals in the axial direction; the first tooth roller shaft and the second tooth roller shaft are arranged in the crusher shell in parallel; and the bolt support is located on the hydraulic jack and connected with an end plate of the crushing beam through the crushing beam fixing bolt. The lower crushing teeth are connected to the crushing beam. The high-crushing-ratio double-tooth-roller crusher can crush materials three times, and the crushing ratio is high; the granularity of finished products can be strictly controlled; large materials can be crushed, and the crushing efficiency is high; and falling on the whole tooth roller shafts is uniform, and the crushing capacity is high.

Owner:江苏羚羊机械有限公司

Stone crusher

The invention discloses a stone crusher. The stone crusher comprises a machine frame; a cavity with an opening in the top and a shell body capable of turning over and covering the opening are arranged on the machine frame; a feeding hole communicating with the cavity is formed in the shell body; a discharging hole communicating with the cavity is formed in the bottom of the cavity; the cavity is internally provided with a screen and a blade assembly capable of rotating relative to the cavity; the blade assembly is positioned above the screen; a second blade matched with the blade assembly to crush stone is arranged on the inner wall, opposite to the blade assembly, of the cavity; a gap communicating with the screen is arranged between the blade assembly and the second blade; and a driving device for driving the blade assembly to rotate is further arranged on the machine frame. The stone crusher has the advantages of being low in noise, small in dust, large in crushing ratio, uniform in product particle size and high in crushing efficiency.

Owner:广东金石建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com