Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Avoid secondary crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

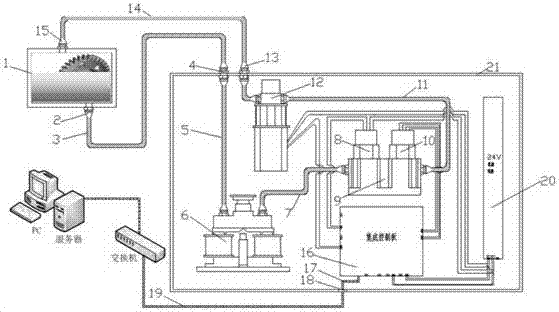

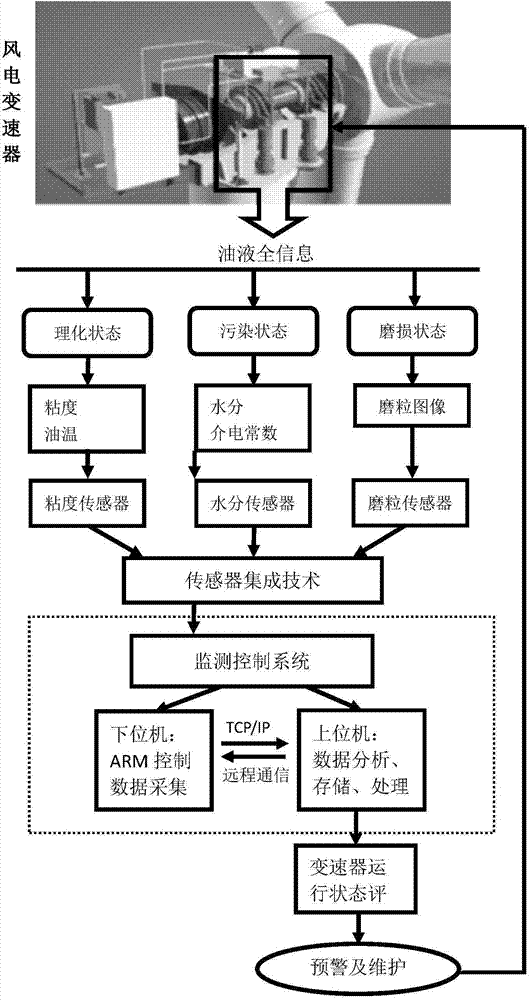

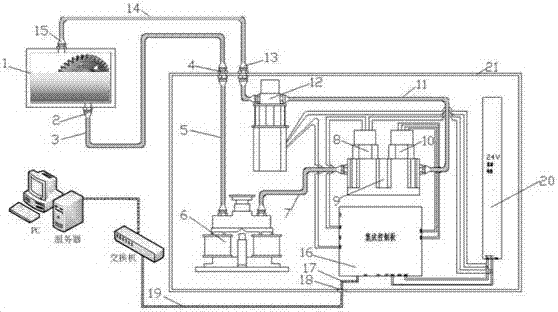

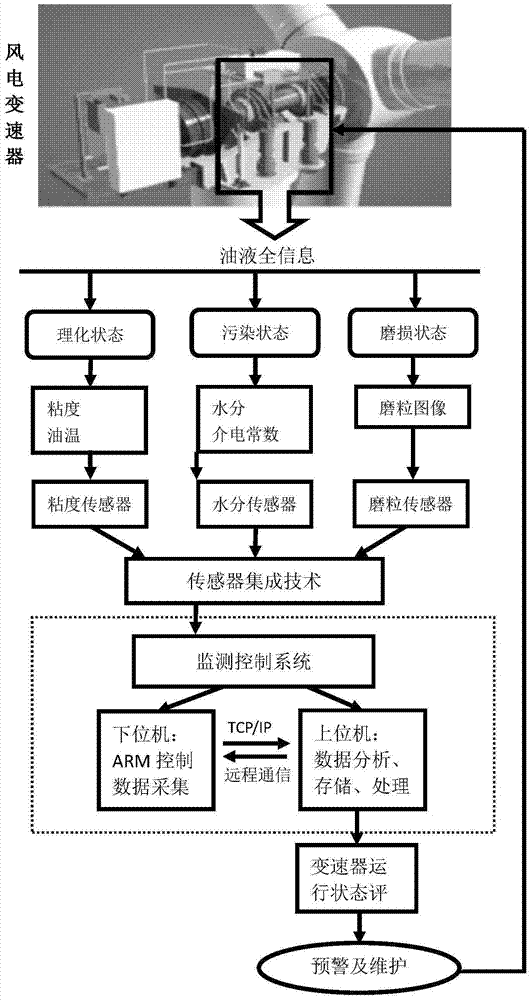

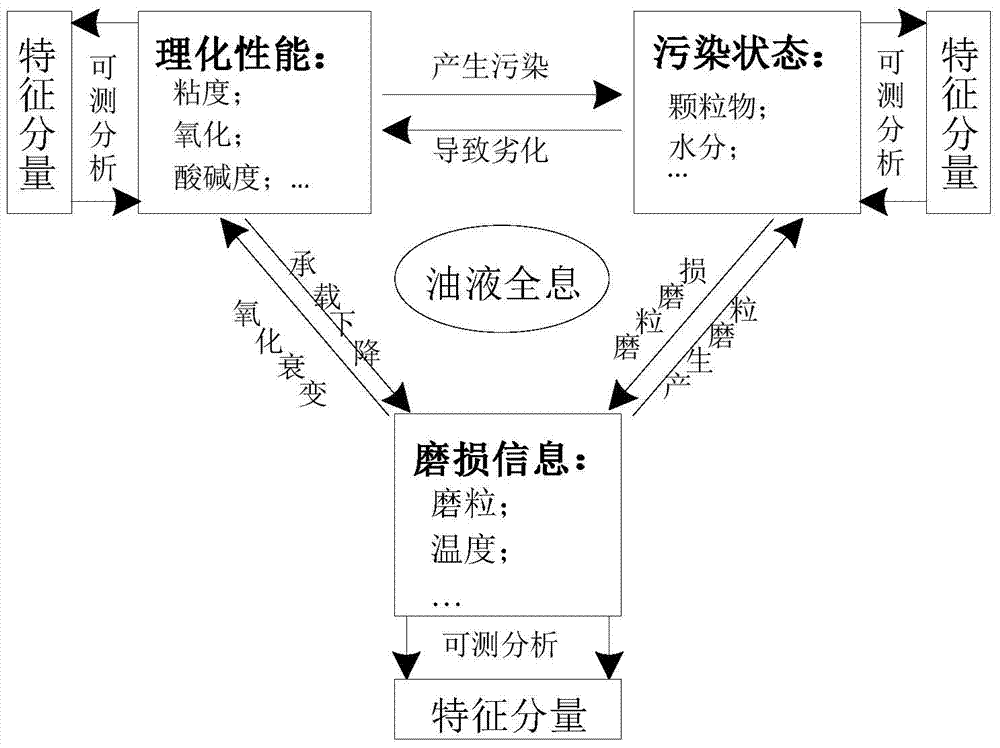

Online monitoring method for lubricating oil of wind-power transmission

ActiveCN104764489AAvoid secondary crushingAvoid interferenceMeasurement devicesElectric power transmissionRelational model

Provided is an online monitoring method for lubricating oil of a wind-power transmission. The online monitoring method for the lubricating oil of the wind-power transmission comprises the following steps that performance analysis is carried out on a tribology system of a gear case of the wind-power transmission, and a comprehensive information monitoring method which is based on three aspects, namely an abrasion, a lubricating oil physical and chemical performance and pollution is proposed; an integral information monitoring system is established through testable analysis, and viscosity, water and an abrasive grain are adopted to be used as testable characteristics corresponding to the three classes of information of the abrasion, the lubricating oil physical and chemical performance and the pollution; by utilizing the embedded type integral sensor technology, real-time obtaining of the information is achieved; by adopting a TCP / IP network communication protocol, remote monitoring is achieved; a relation model of the abrasion, a lubrication oil product and the pollution are established, and inducements of the abrasion or lubricating malfunctions are speculated. Online perfect information obtaining is achieved, the analysis on origins of malfunctions is provided, the effective monitoring method for a running state of the gear case of the wind-power transmission is achieved, and according to positioning of an abrasive malfunction, an oil replacing suggestion and other maintaining suggestions, the important engineering significance for lowering the triology malfunction and prolonging the complete machine service life is achieved.

Owner:XI AN JIAOTONG UNIV

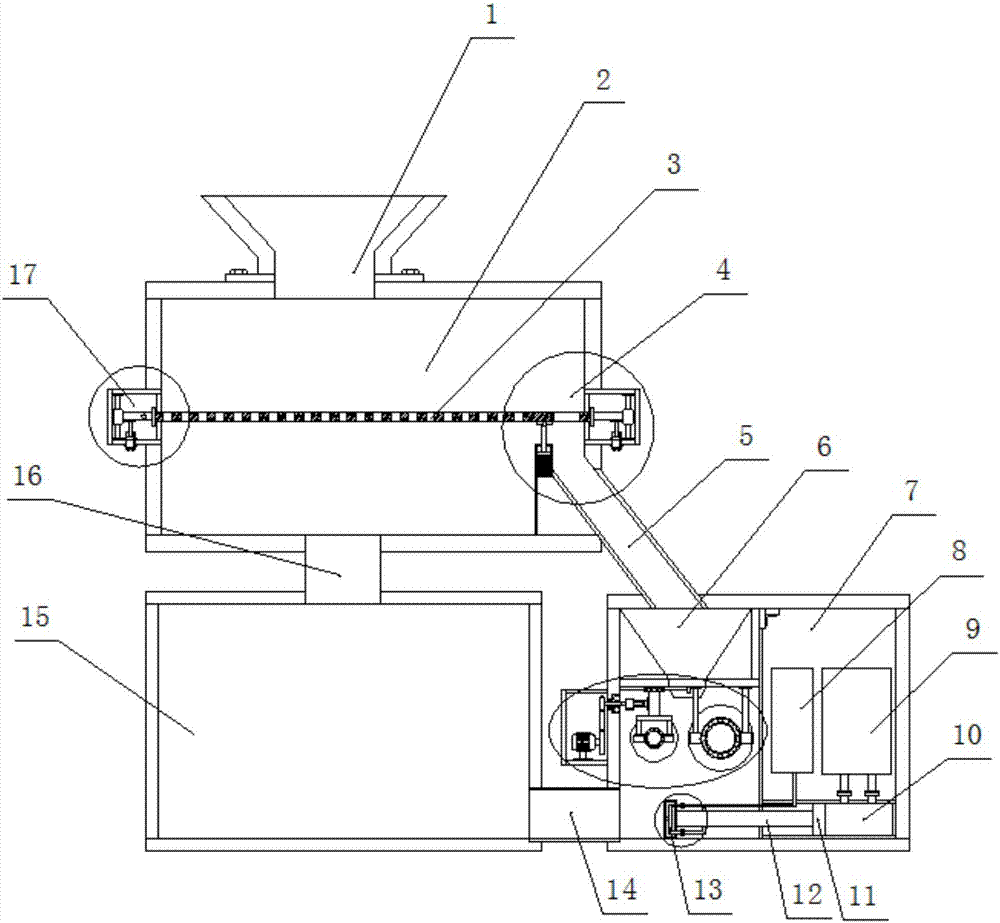

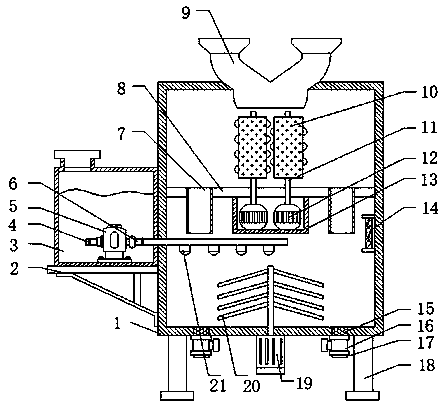

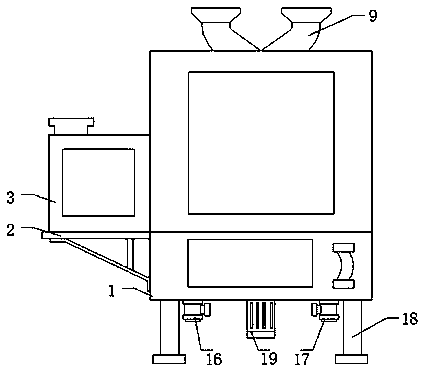

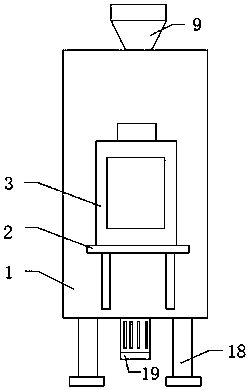

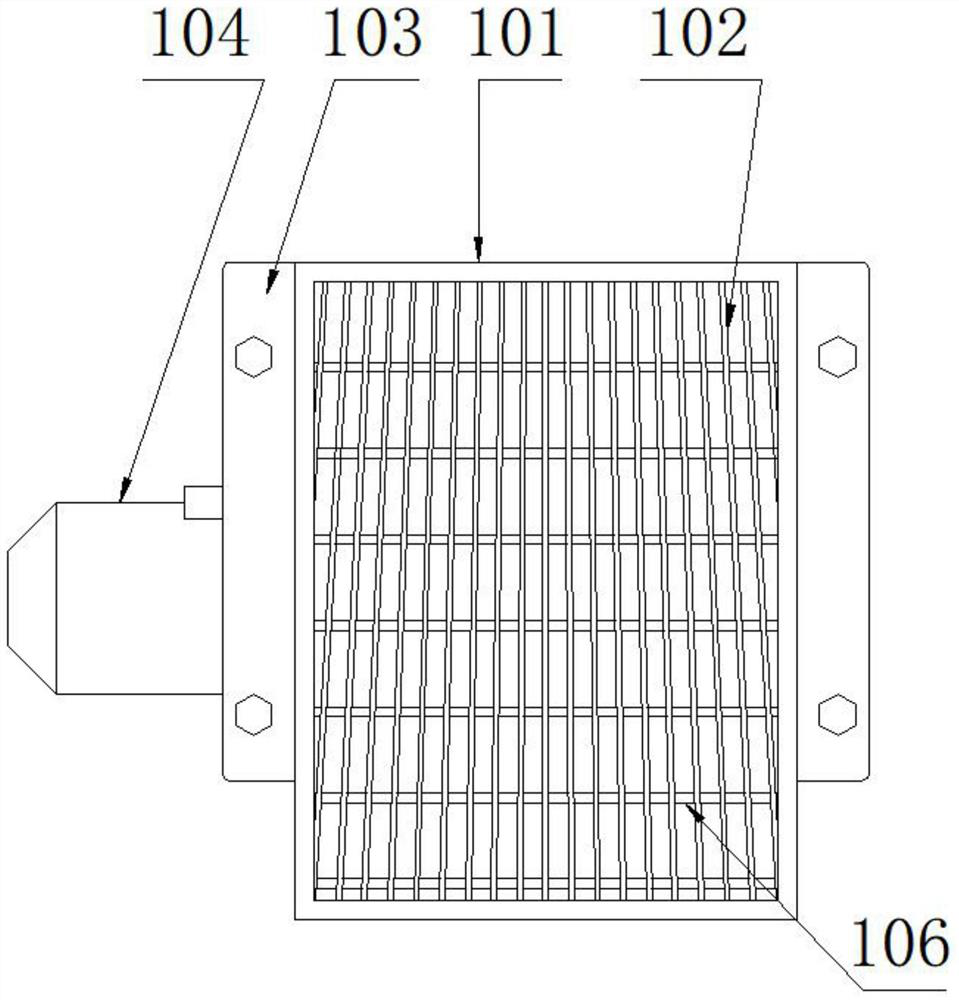

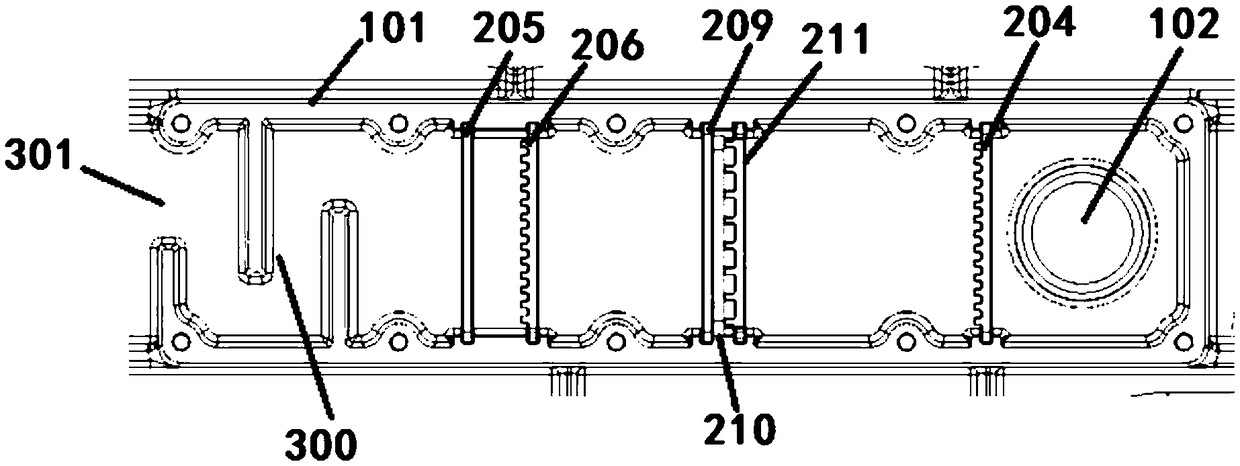

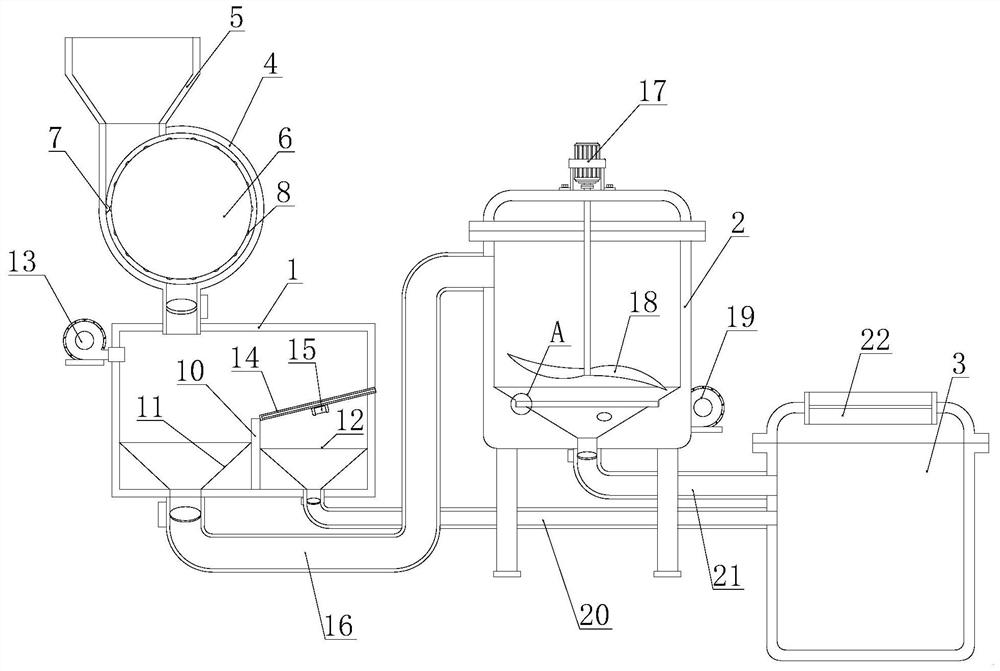

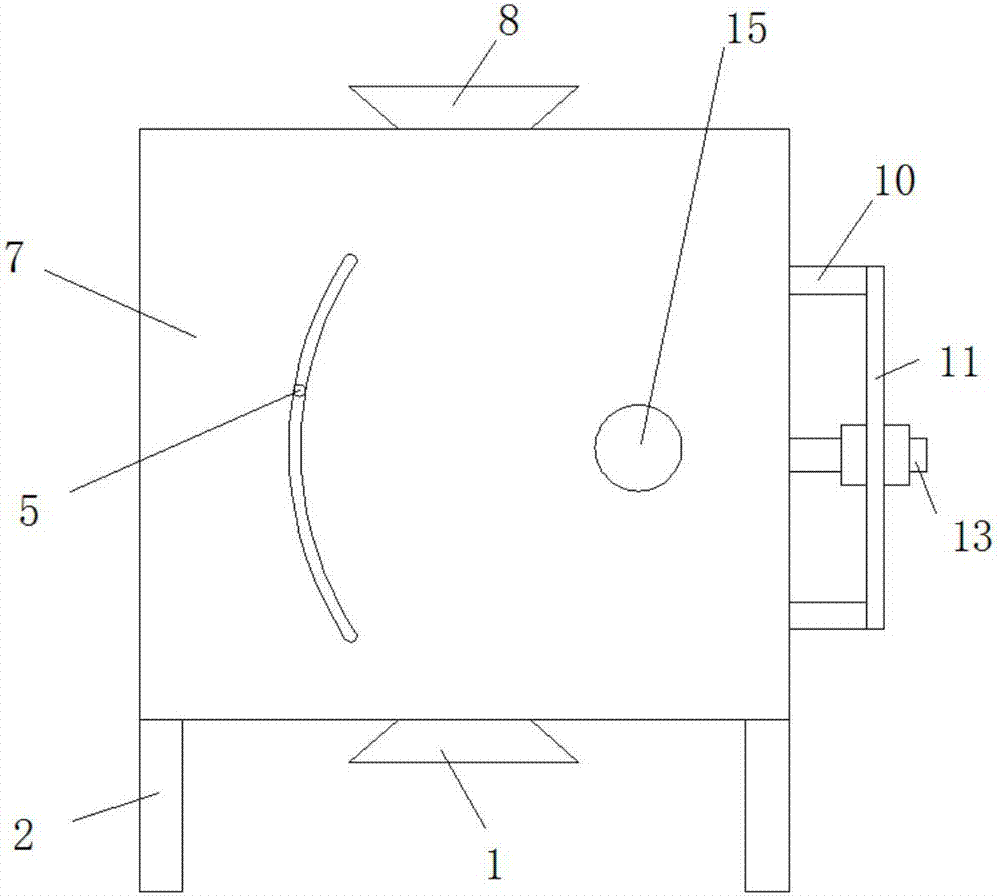

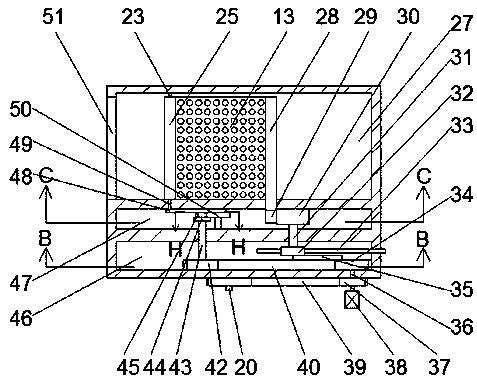

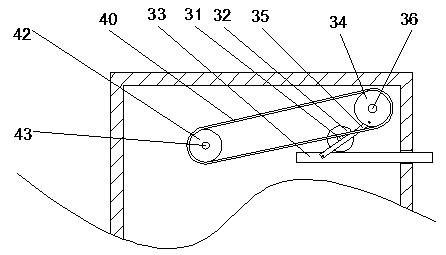

Construction waste separating and crushing treatment device

ActiveCN107486388AAvoid secondary crushingAvoid blockageSievingScreeningHydraulic cylinderEngineering

The invention discloses a construction waste separating and crushing treatment device and relates to a construction waste treatment device and facility. The construction waste separating and crushing treatment device comprises a screening box, a smashing box and a collecting box; the screening box and the smashing box are connected through a smashing pipeline; the screening box is connected with the collecting box through a discharging pipe; the collecting box is connected with the smashing box through a connecting pipe; the top of the screening box is connected with an adding-in port; a screen plate is arranged in the screening box; the left end and the right end of the screen plate are connected with a vibrating device and a downwards-pressing device correspondingly; the smashing box comprises a guiding-in chamber, a machine chamber, an air compressor, a hydraulic machine, a hydraulic cylinder and a smashing device; according to the device, separating and smashing are combined together, separating of materials can be completed on the device, it is avoided that qualified waste is subjected to secondary smashing, unqualified waste can also be smashed, and convenience is brought to a user; and the screen plate in the separating device of the device can move up and down, and the blockage condition in the long time using process can be effectively avoided in the separating process.

Owner:孙勇

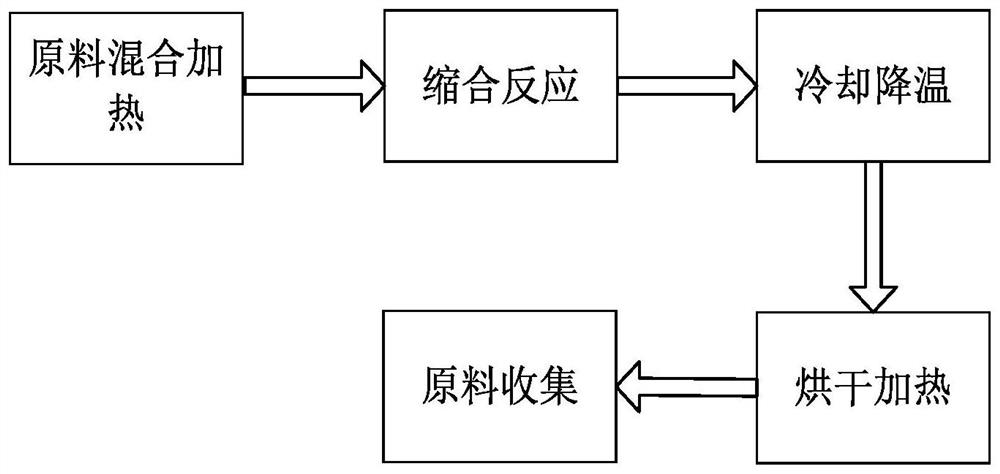

Preparation method of high-quality prebaked anode for 500KA electrolytic cell

The invention relates to a preparation method of a high-quality prebaked anode for a 500KA electrolytic cell. The method comprises the following steps of: (1) storing petroleum coke at different storage locations according to different producing areas; (2) crushing the petroleum coke blocks having the granularity greater than 200mm with a sledge hammer, sieving the petroleum coke blocks with the granularity less than 200mm, delivering the petroleum coke with the granularity less than 70mm into a petroleum coke conveyer belt, recrushing the petroleum coke with the granularity greater than 70mm so as to deliver the petroleum coke with the granularity less than 70mm into the petroleum coke conveyer belt; (3) feeding different petroleum cokes into a specified blending cabin, wherein the petroleum coke of one producing area is placed in each of the four blending cabins, and a belt weigher is arranged at the bottom of each blending cabin; (4) preparing calcined coke; (5) preparing rough coke, middle coke, fine coke and powdery coke; (6) preparing boiler-out thickeners; (7) preparing cooled thickeners; (8) preparing green bodies; (9) feeding the green bodies into a stacking storeroom for stacking; and (10) roasting the green bodies to obtain a prebaked anode. By using the preparation method, the electrolysis preparation requirement can be met, and safe and sable operation of the electrolytic cell is ensured.

Owner:嘉峪关索通预焙阳极有限公司

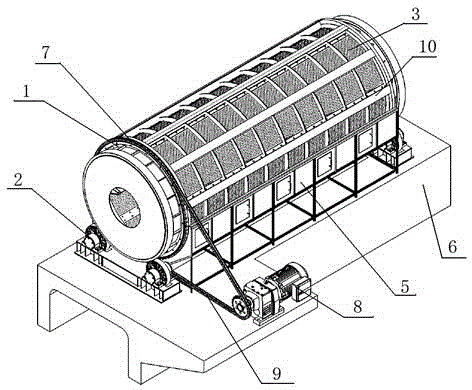

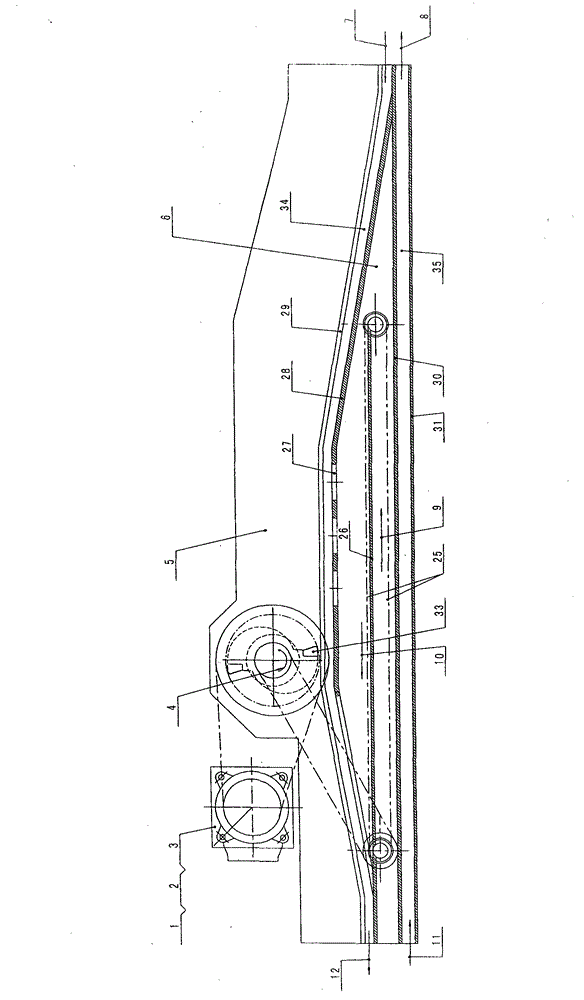

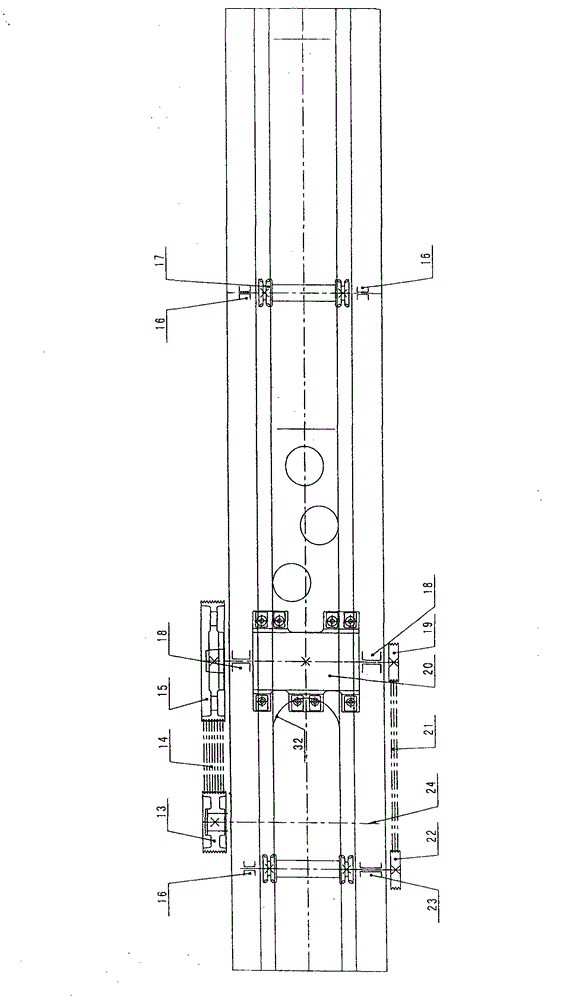

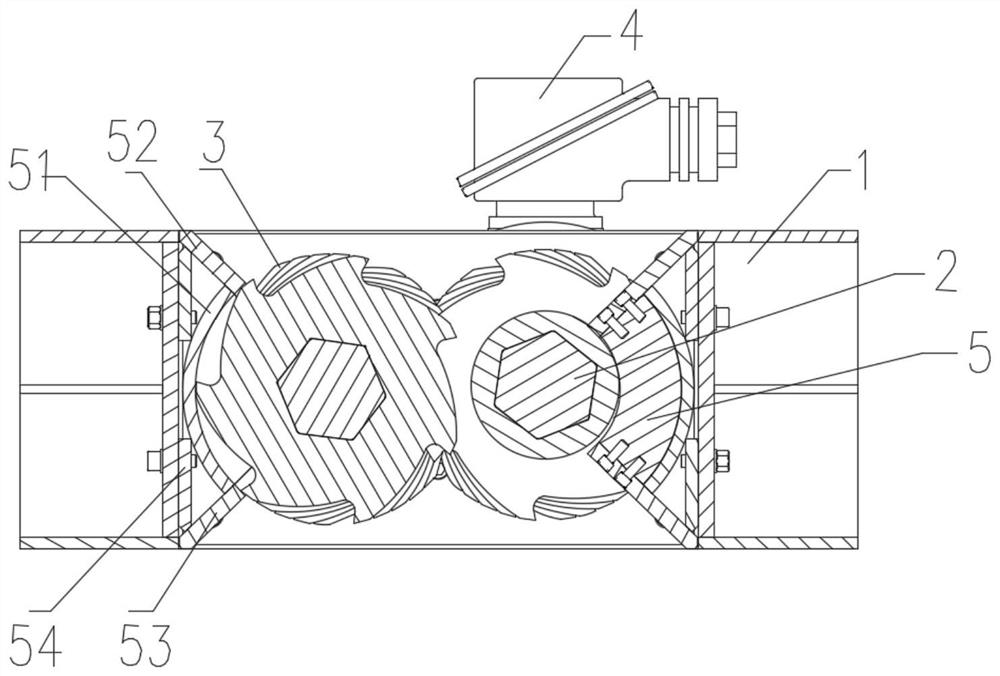

Roller type screening crusher and design method thereof

PendingCN106140400ASmall environment adaptabilityAvoid secondary crushingGrain treatmentsGear wheelProcess engineering

The invention discloses a roller type screening crusher and a design method thereof. The crusher elevates crushed materials to a certain height, and crushing is achieved through mutual impacting and grinding actions of material falling; and after crushing, the materials smaller than screen plate holes fall into a material collecting hopper at the lower portion of the roller type screening crusher through the screen plate holes and are continuously discharged through a conveying device, and therefore the functions of synchronous crushing and screening of the crushed material are achieved. The roller type screening crusher is large in crushing ratio, high in productivity, low in energy consumption and simple in structure, and the product granularity guaranteeing degree is high. The riding wheel supporting design is adopted and is high in environment adaptability, capable of saving investment and low in maintaining difficulty in comparison with a hybrid bearing supporting manner. A chain drive manner is adopted in a roller body and similarly has the beneficial effects of being high in environment adaptability, capable of saving investment and low in maintaining difficulty in comparison with a gear engagement transmission manner. Metal and sundries contained in the materials can be discharged from the tail end of the crusher in a regular material emptying manner, and downstream production and equipment cannot be influenced, wherein the sundries are not prone to breakage.

Owner:贵州莱利斯机械设计制造有限责任公司

A preparation method of a high-compaction high-capacity lithium manganate composite cathode material used for mixing ternary materials

ActiveCN109244450APrecise control of particle size distributionAvoid secondary crushingCell electrodesSecondary cellsGramCrystallite

The invention discloses a preparation method of a high-compaction high-capacity lithium manganate composite cathode material used for mixing ternary materials, which comprises the following steps: 1.Preparing a lithium manganate cathode material with small particle size and narrow particle size distribution; 2, preparing a large-particle, wide-particle-size distribution lithium manganate cathodematerial; 3, mixing that lithium manganate cathode materials with different particle size distribution. The invention finely controls two kinds of manganese source and lithium source with different particle size distribution, taking fully into account the effect of grain growth at high temperature, two kinds of cathode materials with wide and narrow distribution were prepared respectively, At last, the defect of insufficient compaction of single material is solved by mixing according to a certain proportion, and the defect of morphology caused by conventional secondary classification is avoided. Thus, the cathode material with 1C gram capacity of 122- 125 mAh / g and compaction density of 3.15 g / cm3 can be obtained.

Owner:湖南海利锂电科技有限公司

Hammer crusher with screening structure

InactiveCN104096616AReduce energy consumptionChange the installation locationGrain treatmentsPulp and paper industryCrusher

The invention specifically relates to a hammer crusher with a screening structure, which belongs to the technical field of coal mine machinery. The hammer crusher is used for working face crossheading of an underground coal mine and comprises a bottom groove body, a crushing rack body, a drive unit, a hammer shaft assembly and a below-sieve conveying mechanism. Coal conveyed from the tail of a loading machine is conveyed to sieve meshes in the upper middle plate of the crusher through the scraper plate chain of the loading machine for screening; coal with a size smaller than the size of the sieve meshes falls down to the below-sieve conveying mechanism, is then transferred to a U-shaped port and enters coal flow on the scraper plate chain of the loading machine, which enables crushing of the coal when the coal passes through the hammerhead of the crusher to be avoided; coal with a size greater than the size of the sieve meshes is conveyed to the hammerhead of the crusher by the scraper plate chain of the loading machine for crushing, and coal which is crushed to a size smaller than the size of the sieve meshes falls down through the sieve meshes or is transferred by the scraper plate chain of the loading machine so as to prevent secondary crushing; coal with a size greater than the size of the sieve meshes is further crushed with the hammerhead of the crusher, and above-mentioned operation is repeated. The objective of the invention is to crush large coal transported by the loading machine to desired specifications during transporting.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

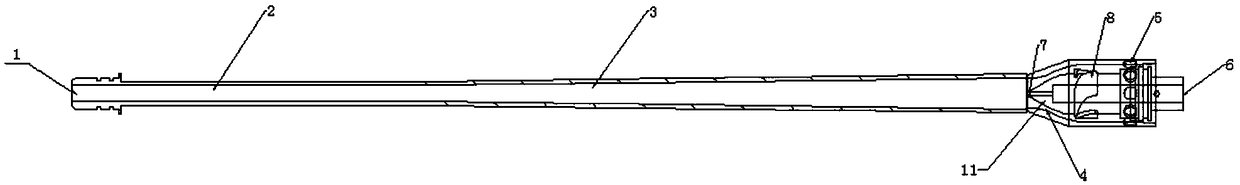

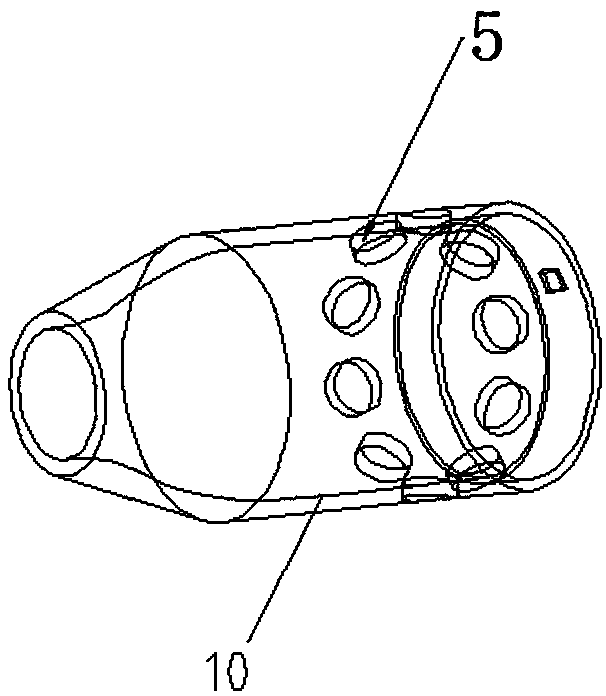

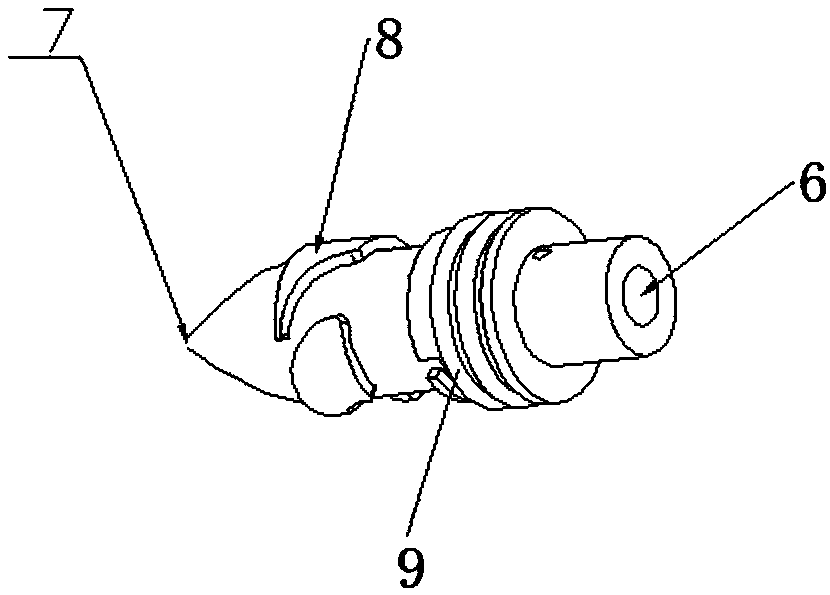

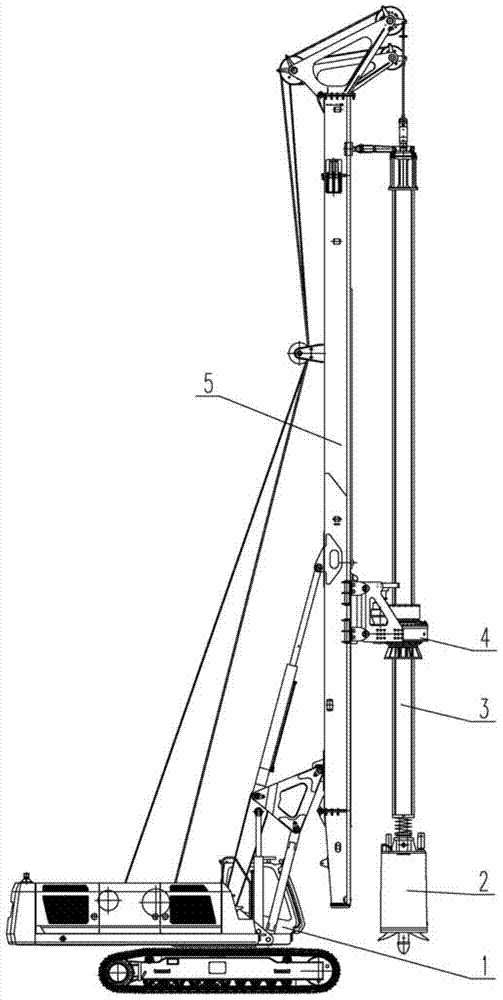

Rotary drilling machine for reverse-circulation pneumatic down hole hammer and construction method for rotary drilling machine

The invention discloses a rotary drilling machine for a reverse-circulation pneumatic down hole hammer and a construction method for the rotary drilling machine. The rotary drilling machine comprises a chassis and a mast arranged on the chassis, wherein a reverse-circulation power head is mounted on a guide rail of the mast; the upper part of the reverse-circulation power head is provided with a water faucet; the water faucet is connected with a slag discharge tube; the lower part of the reverse-circulation power head is provided with a buffer; the buffer is connected with a gas box; the gas box is connected with a gas inlet rubber tube; the lower end of the gas box is connected with a drill stem; and the lower end of the drill stem is connected to the reverse-circulation pneumatic down hole hammer and a drill bit. The rotary drilling machine has the function of constructing the reverse-circulation pneumatic down hole hammer, can realize high-efficiency rock-entering, also can effectively protect hole walls, needs small drilling pressure and small rotary torque, can continuously take a core and can effectively solve orifice dust pollution.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

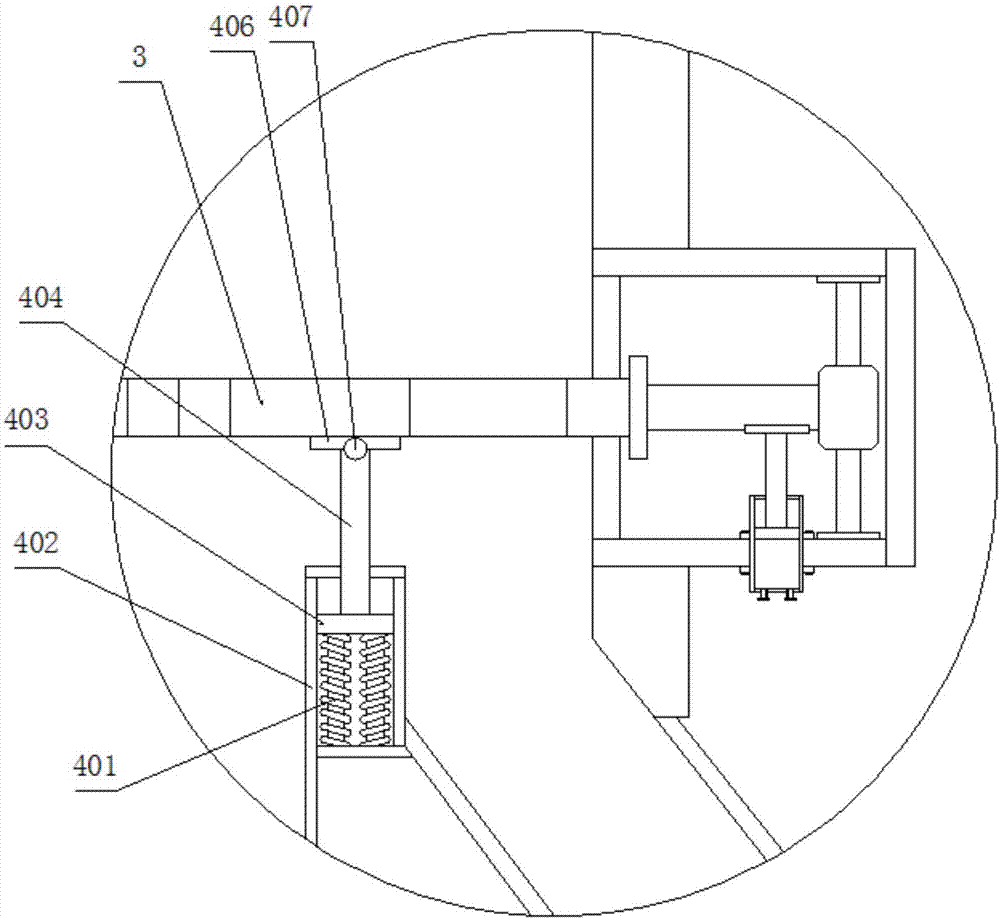

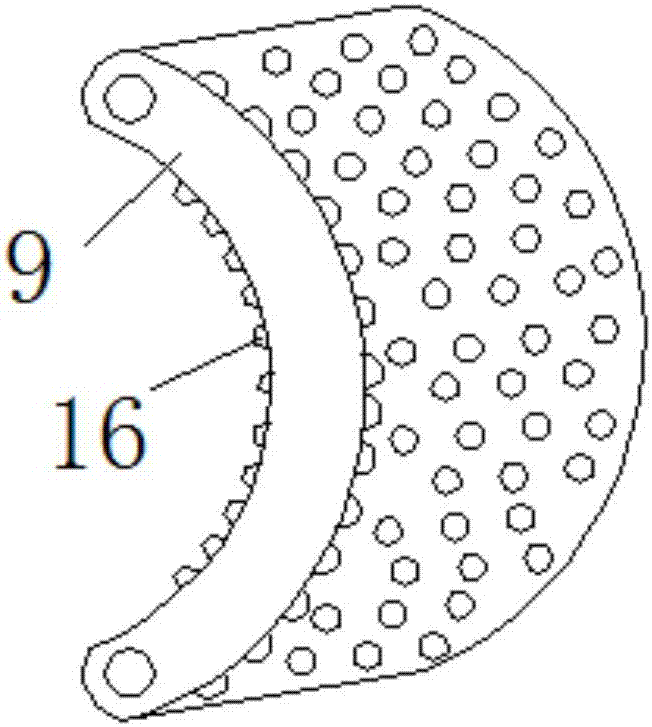

Apparatus for collecting and screening frozen soil fragments in Hopkinson test

ActiveCN106644697AAvoid secondary crushingHelps to movePreparing sample for investigationMaterial strength using single impulsive forceTemperature controlControl power

The invention relates to an apparatus for collecting and screening frozen soil fragments in a Hopkinson test. The apparatus comprises a protective cover which comprises an external layer semicircular protective cover and an internal layer semicircular protective cover by low temperature strong glue bonding; the protective cover is connected to a bracing frame and an internal layer slide plate by a loose-leaf hinge and a positioning pin; air vents are arranged at the lower part of the bracing frame, a channel section is arranged on the bracing frame, and a katathermometer is internally arranged in the bracing frame; a temperature control test box and a protective cover are respectively provided with a pole hole and a rotating wheel hole for a Hopkinson pressure bar and a soil scraping rotating wheel to pass through; the channel, a screw and a support bar are used for connecting the bracing frame and an electric vibrating screen; a control power supply is arranged outside a test box with controllable temperature; a temperature control system is used for controlling the temperature of the test box with controllable temperature. The apparatus can prevent secondary fragmentation of frozen soil fragments, and more frozen soil fragments are collected as possible. The frozen soil fragments are screened and treated at first time after the test, and accuracy of test data is improved.

Owner:ANHUI UNIV OF SCI & TECH

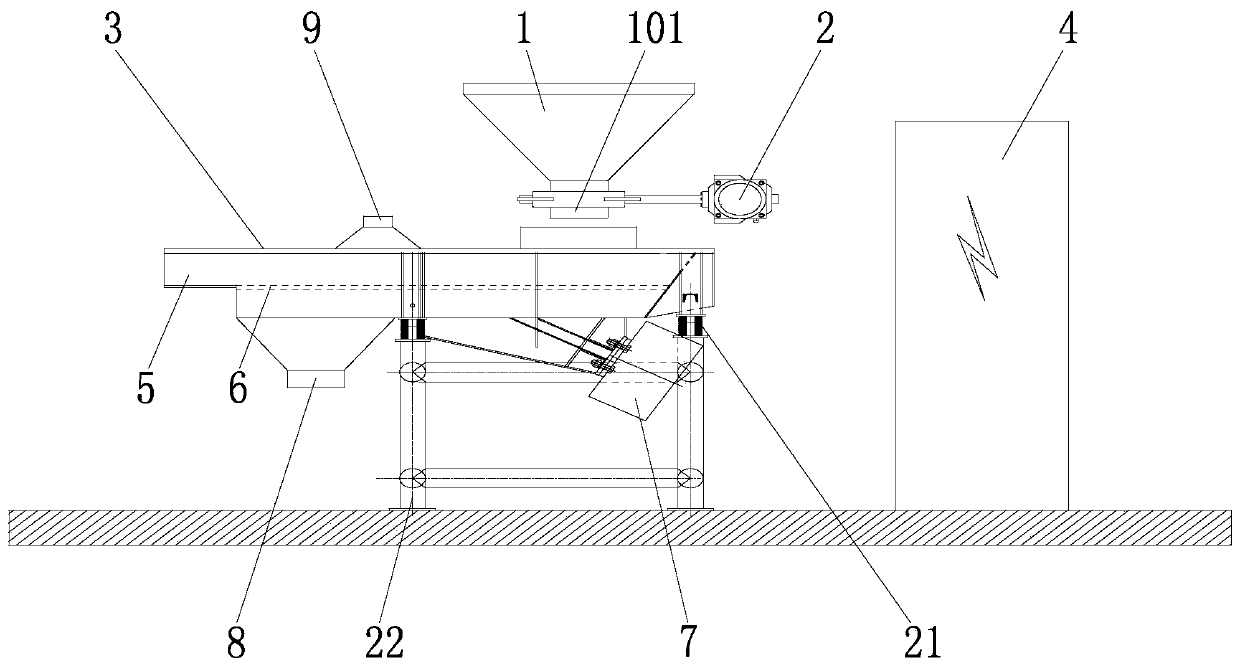

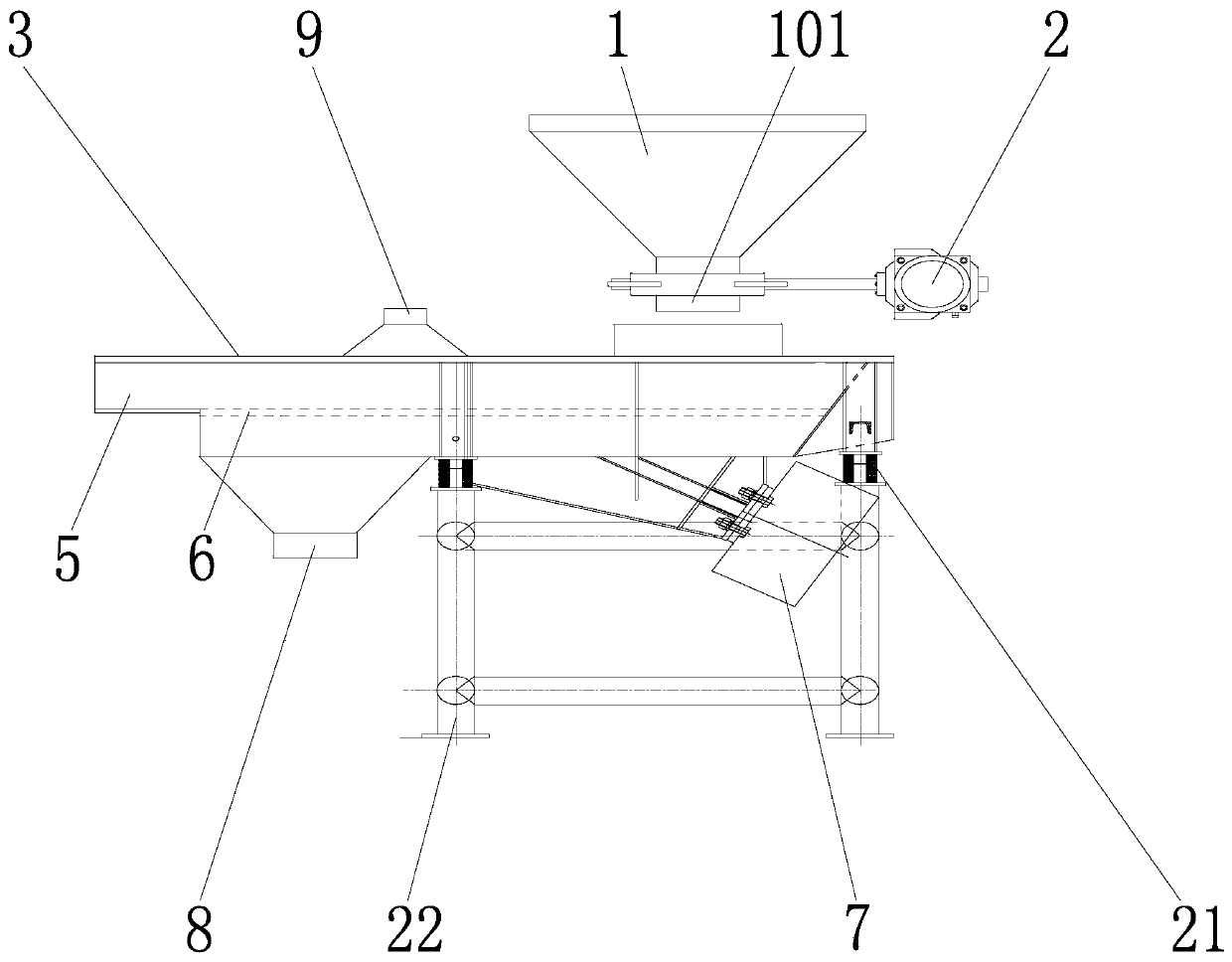

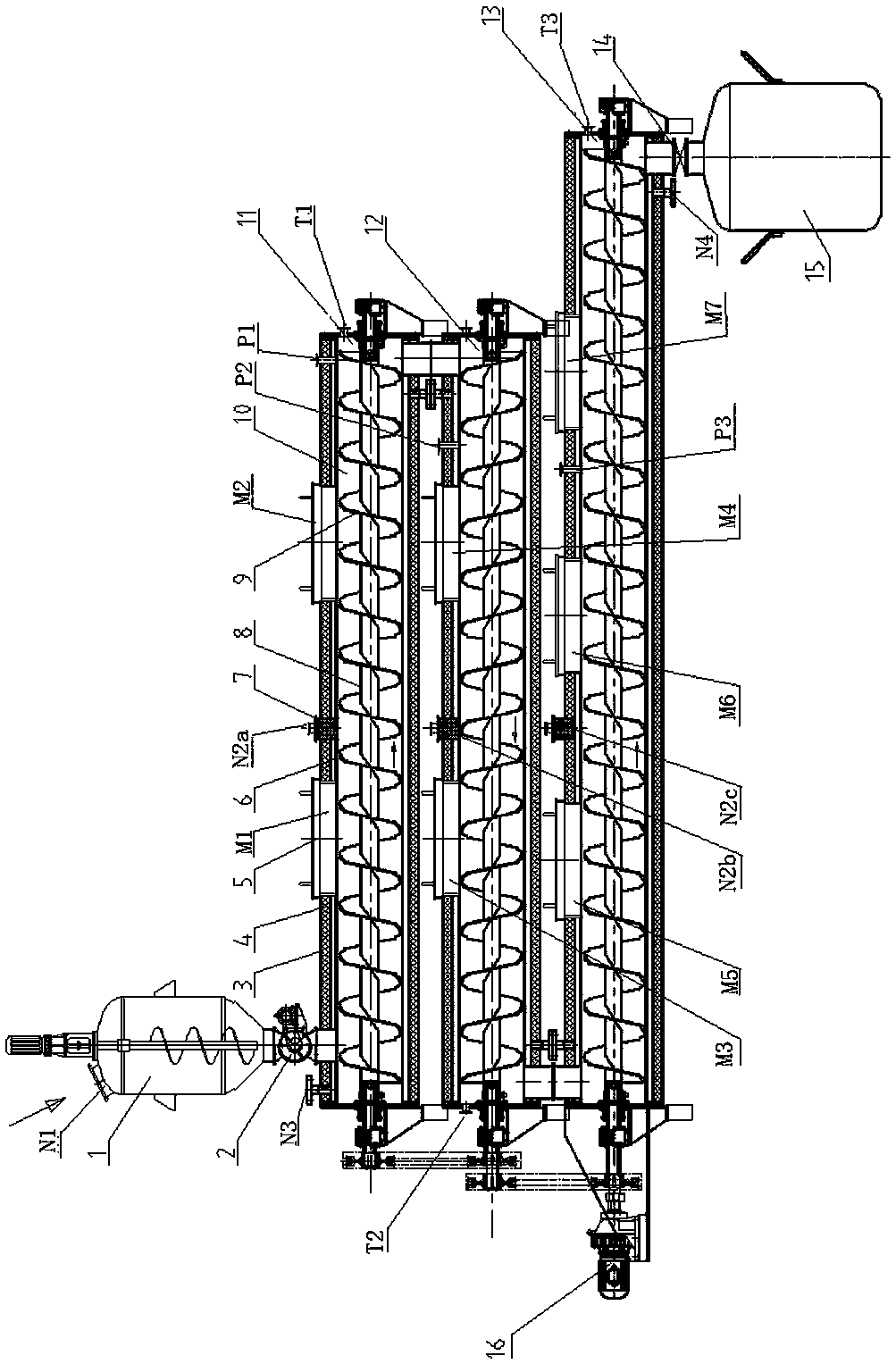

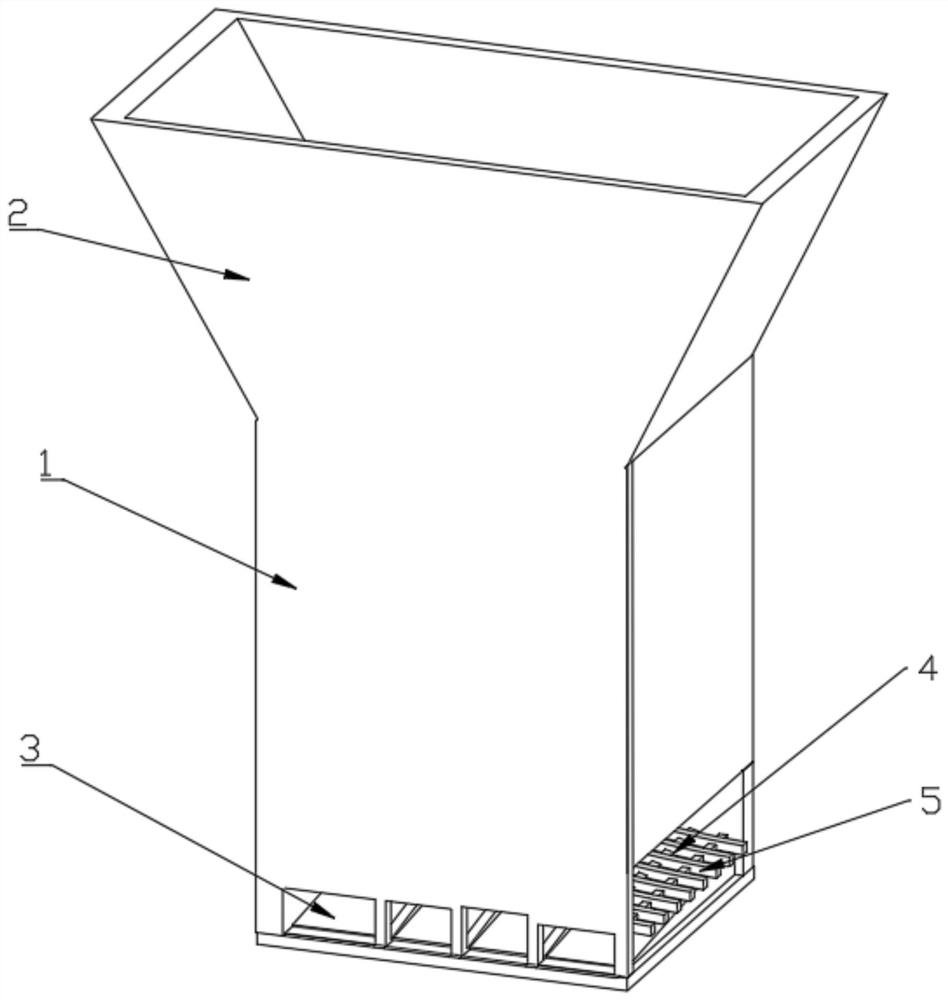

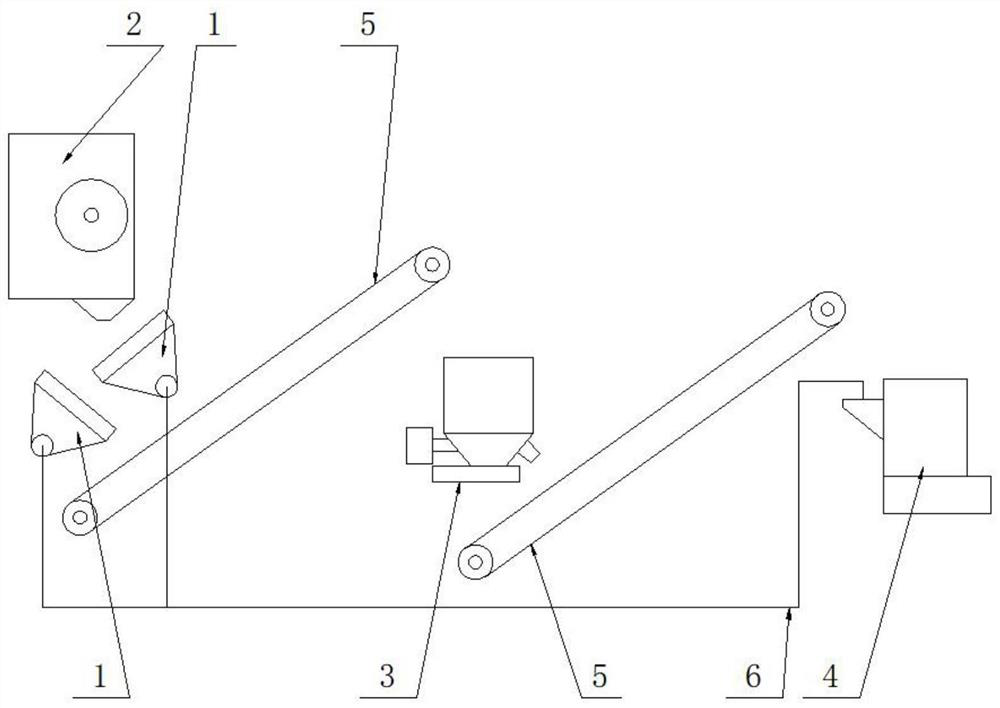

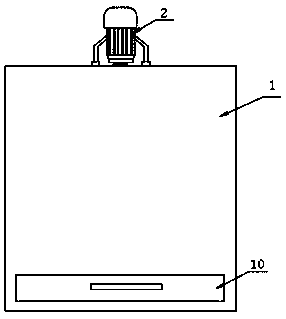

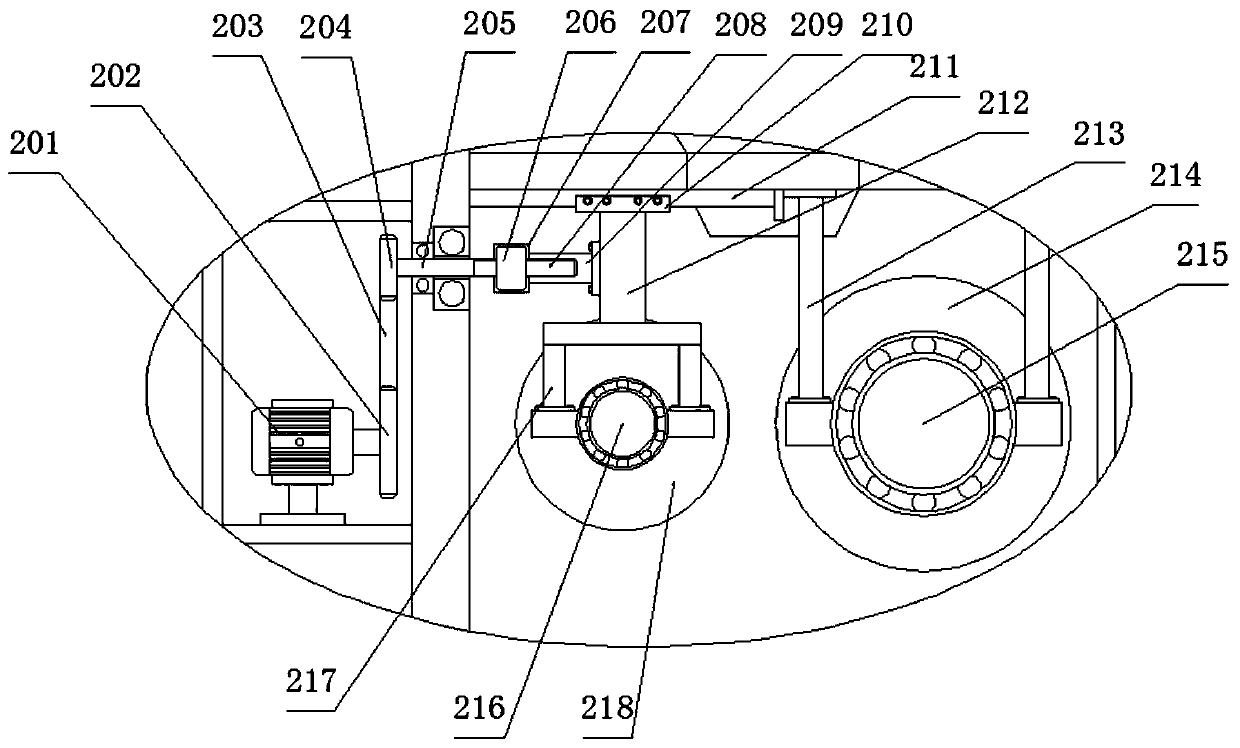

High-efficiency uniform feeding, sieving and crushing system for polysilicon and monocrystalline silicon and method thereof

ActiveCN110918238AAvoid cloggingAvoid secondary crushingSievingScreeningElectric machineryEngineering

The invention discloses a high-efficiency uniform feeding, sieving and crushing system for polysilicon and monocrystalline silicon and a method thereof. The system comprises a material cabin, a feeding machine, a crushing machine, an electronic valve, an accumulation amount detecting device and a control sub-system. The feeding machine comprises a feeding box, a vibrating motor and a screen mesh.The feeding box is provided with a box opening facing an upper discharging hole. One end of the screen mesh is positioned below the box opening; and the other end of the screen mesh faces a discharging end. The vibrating motor is used for moving a silicon material to the other end of the screen mesh in one direction to fall into a lower discharging hole. The accumulation amount detecting device isused for detecting the accumulation amount of the silicon material. The control sub-system is used for reducing the opening / closing frequency or opening / closing amplitude of the electronic valve whenthe accumulation amount is greater than a first preset accumulation amount, and increasing the opening / closing frequency or opening / closing amplitude of the electronic valve when the accumulation amount is smaller than a second preset accumulation amount. According to the high-efficiency uniform feeding, sieving and crushing system for the polysilicon and monocrystalline silicon and the method thereof, the silicon material uniformly falls into the crushing machine for crushing; the overall production efficiency of crushing is improved; the rejection rate of the silicon material is reduced; and the particle size of the finally crushed silicon material is more uniform.

Owner:合肥开比锐精机科技有限公司

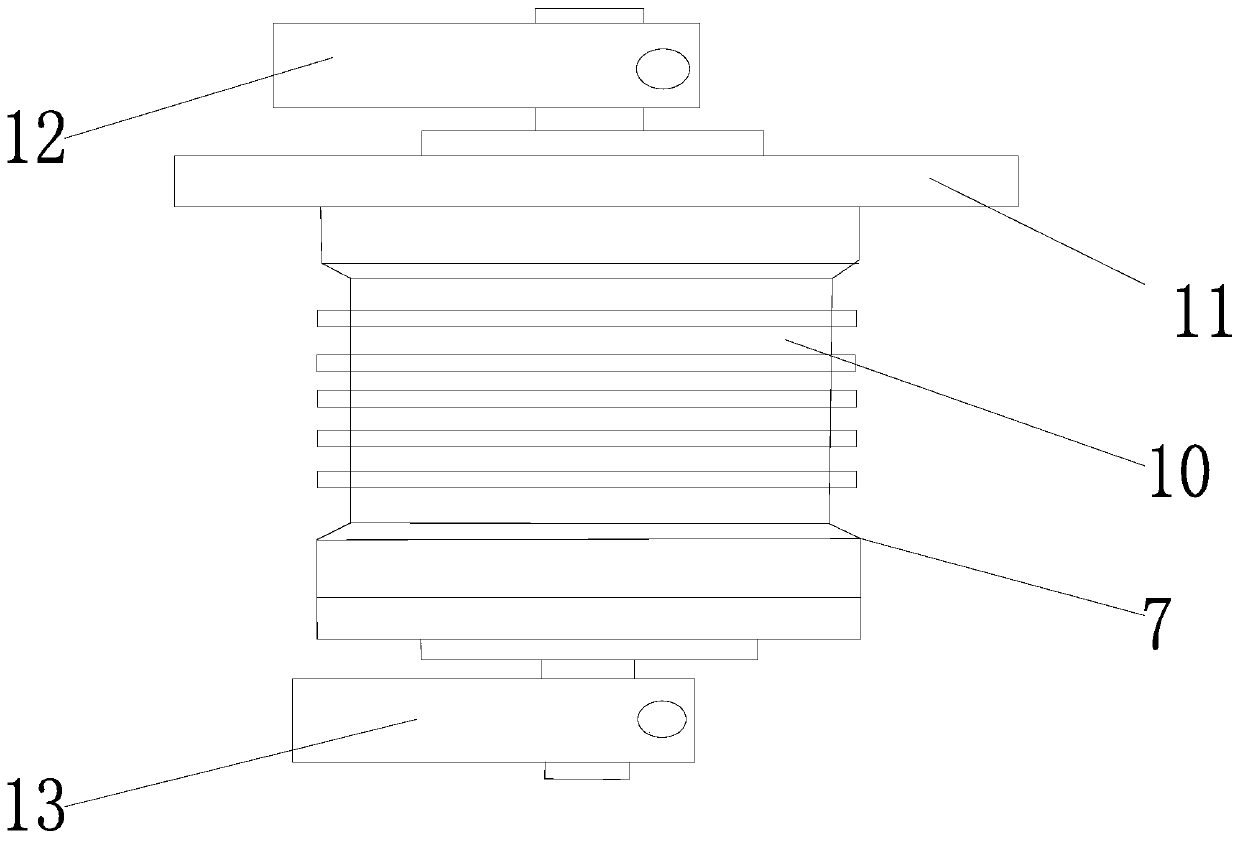

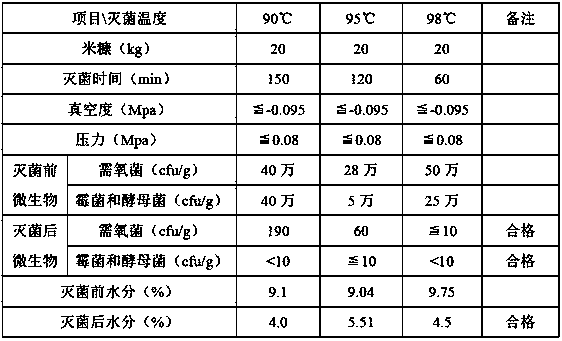

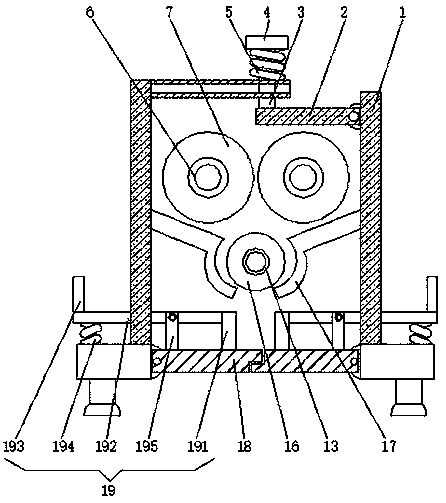

Dry-heat low-pressure continuous sterilization method

ActiveCN110522929AReduce the sterilization temperatureBreak through technical difficulties in the field of sterilizationLavatory sanitoryHeatPositive pressureEngineering

The invention belongs to the technical field of material sterilization. The invention relates to a dry-heat low-pressure continuous sterilization method. A sterilization inner cavity is heated througha heating device; the sterilization inner cavity is vacuumized through a vacuum device; the temperature of the sterilization inner cavity is adjusted and set during sterilization; materials are fed from one end of the tubular sterilization inner cavity, the material is conveyed from a feeding port to a discharging port through a conveying packing auger. In the sterilization process, the maintaining time of the vacuum degree and the pressure is controlled according to the number of microorganisms and the water content of materials, in the material conveying process, sterilization is conductedat the temperature lower than 100 DEG C under the positive-pressure and negative-pressure combined action, and the sterilization time is adjusted by adjusting the staying time of the materials in thesterilization inner cavity by adjusting the rotating speed of the conveying auger. A traditional dry heat sterilization mode is combined with preset positive and negative pressure, a physical sterilization process without any sterilizing agent works under a relatively low temperature condition, the medicine property of the materials is kept, and continuous sterilization is realized.

Owner:江西赫柏康华制药设备有限公司 +1

Glass recovering and breaking device

The invention relates to the technical field of glass recovering and breaking equipment, and discloses a glass recovering and breaking device. The device comprises a box, wherein a baffle I is hingedto one end of the top of an inner cavity of the box, the end, located on the top of the inner cavity of the box, of the baffle I is fixedly connected with the bottom end of a connection rod, the top end of the connection rod extends to the outer portion of the upper surface of the box, and is fixedly connected with the bottom of a pull block, the portion, located between the top of the box and thepull block, of the outer portion of the connection rod is sleeved with a compression spring I, and rotating shafts I are movably sleeved with the inner cavity of the box. According to the glass recovering and breaking device, through action of breaking rollers, glass can be subjected to breaking treatment, the utilization rate of the glass is improved, the cost is saved, meanwhile, under cooperative action of baffle blocks and a grinding roller, the broken glass is ground, therefore, the glass is broken more evenly, the breaking effect is improved, meanwhile, secondary breaking conducted on the broken glass is avoided, and the working efficiency of glass recovery is improved.

Owner:湖南湘潇玻璃纤维有限公司

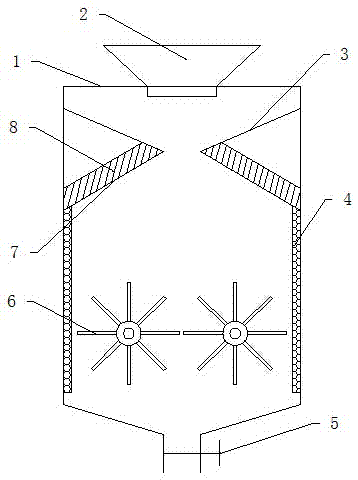

Lotus root starch drying device

ActiveCN105444541AReduce moisture contentImprove drying effectDrying gas arrangementsDrying machines with non-progressive movementsWater contentImpeller

The invention discloses a lotus root starch drying device in the field of lotus root starch processing. The lotus root starch drying device comprises a box body and a feeding hopper. The feeding hopper is fixed to the top end of the box body. Material baffles are arranged on the two opposite side walls in the upper end of the box body. The material baffles are downwards inclined. Condensation plates inclined upwards are arranged below the material baffles. The upper ends of the condensation plates abut against the material baffles. Water absorbing layers are fixed to the upper sides of the condensation plates. A plurality of capillary through holes are formed in the condensation plates. Electric heating plates are fixed to the inner walls of the parts, below the condensation plates, of the box body. Two transversely-parallel rotating shafts are further fixed in the box body. Impellers are fixed to the two rotating shafts respectively and are located below the condensation plates. The lotus root starch drying device is ingenious in concept and compact in structure, water left after drying in the box body can be effectively removed, lotus root starch can be cyclically dried, agglomeration of lotus root starch can be effectively avoided, secondary smashing can be avoided on lotus root starch, production efficiency is improved, and production cost is reduced; the water content of processed lotus root starch is small, agglomeration is avoided, quality is better, and eating is more convenient.

Owner:重庆康养研究院有限责任公司

Construction waste crushing device

InactiveCN112473787AImprove uniformityQuality improvementSievingScreeningDrive wheelStructural engineering

The invention is applicable to the technical field of construction equipment, and provides a construction waste crushing device. The construction waste crushing device comprises a shell; a feeding hopper, wherein the feeding hopper communicates with the top of the shell; an extrusion plate, wherein the upper part of the extrusion plate is rotationally connected to the inside of the shell through arotating shaft; a secondary sieve plate, wherein the secondary sieve plate is arranged inside the shell and is in contact with the bottom of the extrusion plate; and a driving part, wherein the driving part is arranged inside the shell and is connected with the extrusion plate through a transmission part, the transmission part comprises a rotating rod, a fixing rod, a connecting rod and a drivingwheel, the driving wheel is fixedly connected to an output shaft of the driving part, the fixing rod is rotationally connected to the inner wall of the shell, the rotating rod is rotationally connected to the extrusion plate, one end of the connecting rod is eccentrically and rotationally connected to the driving wheel, and the other end of the connecting rod is rotationally connected to the endparts of the rotating rod and the fixing rod, and wave strips are arranged on the secondary sieve plate, and pressing protrusions are arranged at the bottom of the extrusion plate. The construction waste crushing device has the advantages of being simple in structure, convenient to operate, good in crushing uniformity, capable of saving energy and good in synchronism.

Owner:王世梅

Textile broken material recovery device for textiles

PendingCN109234854ALess time to enterEasy to collectTextile disintegration and recoveryFibre disintegrationDrive shaftEngineering

The invention discloses a broken textile material recovery device for textiles. The device comprises a box body, a feeding pipe is welded to the outer wall of the top of the box body, a partition plate is welded to the inner wall of one side of the box body, a motor box is welded to the middle of the outer wall of the bottom of the partition plate, the inner wall of the bottom of the motor box isfixedly provided with first motors equidistantly distributed through bolts, a first transmission shaft is welded to the top of an output shaft of each first motor, first through holes are equidistantly distributed in the portion, close to the first motors, of the outer wall of the bottom of the partition plate, and the first transmission shafts are communicated with the upper portion of the box body through the first through holes. According to the broken textile material recovery device for the textiles, broken materials, leftover materials and the like are crushed into small uniform pieces again, subsequent treatment and placement are facilitated, the occupied area is reduced, more broken textile materials are conveniently stored, the practicability of the device is improved, the brokentextile materials are separated from sundries, debris and the like, cloth is cleaned and dried, storage is facilitated, and the environment is prevented from being contaminated.

Owner:江苏四方纺线有限责任公司

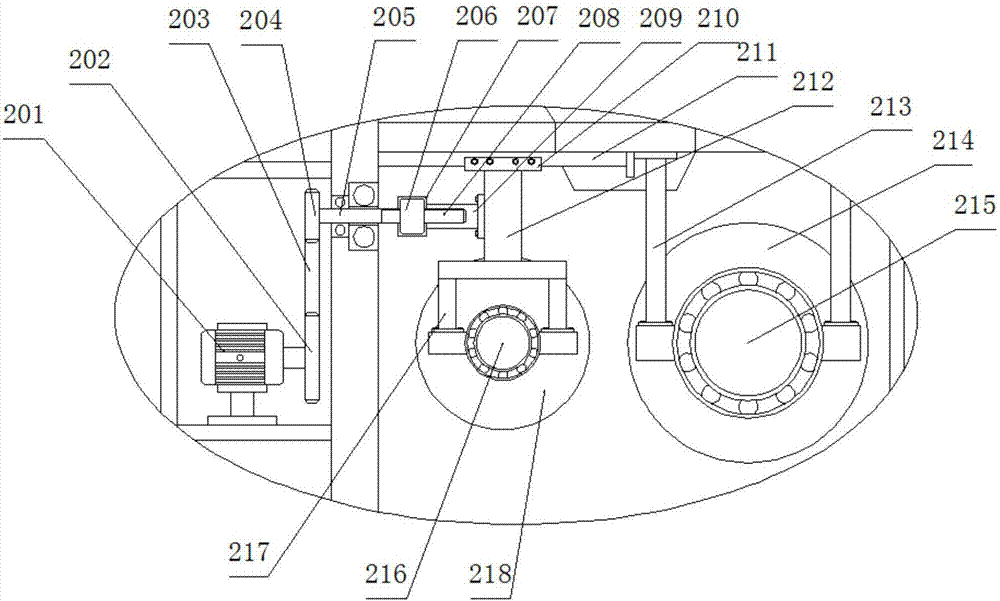

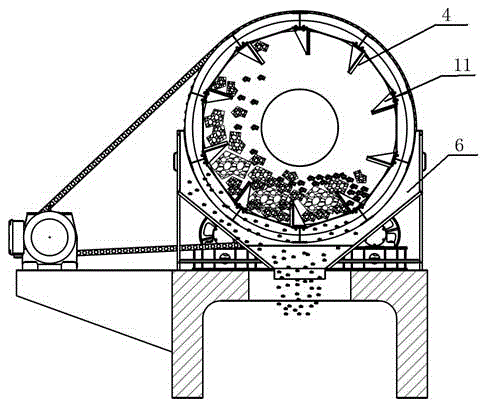

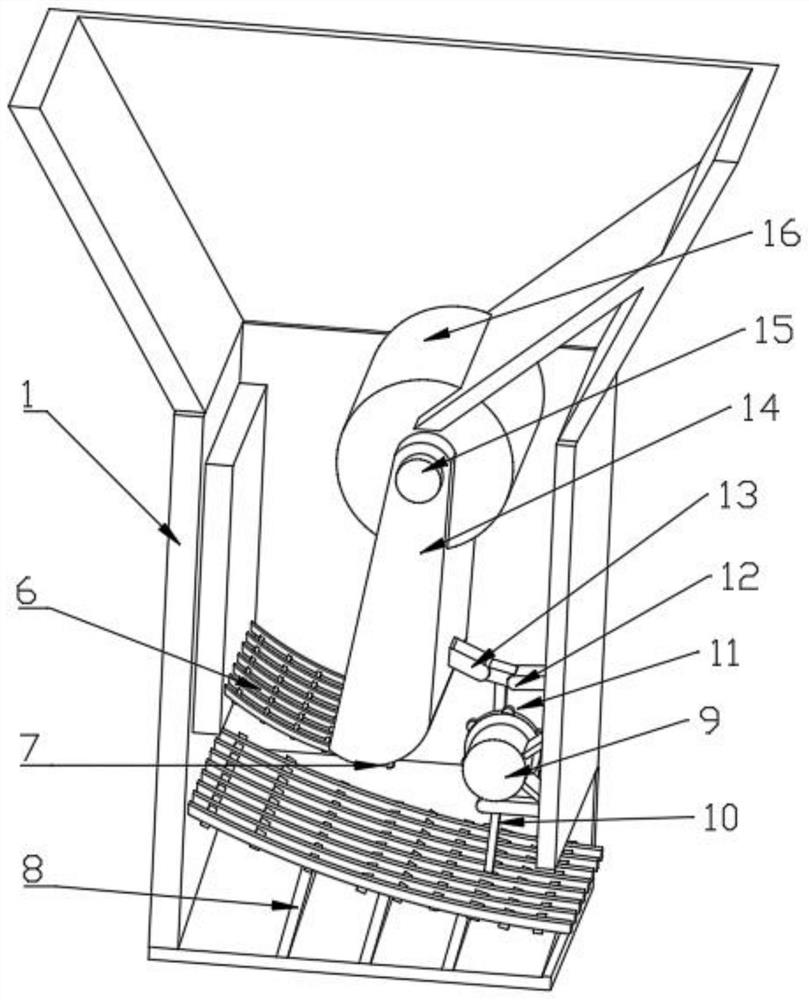

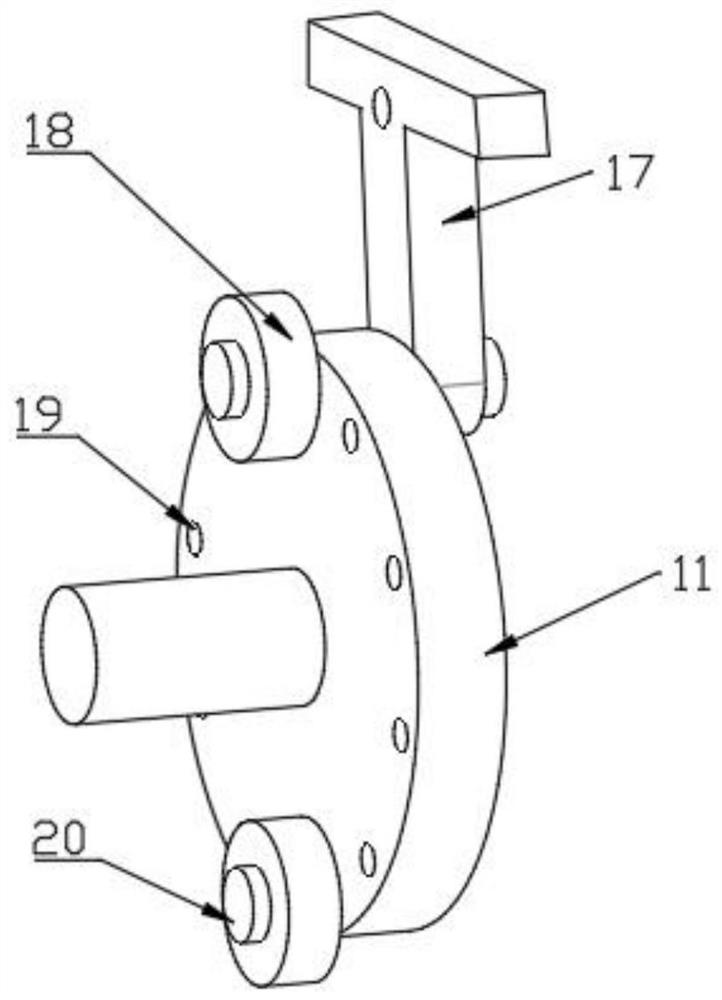

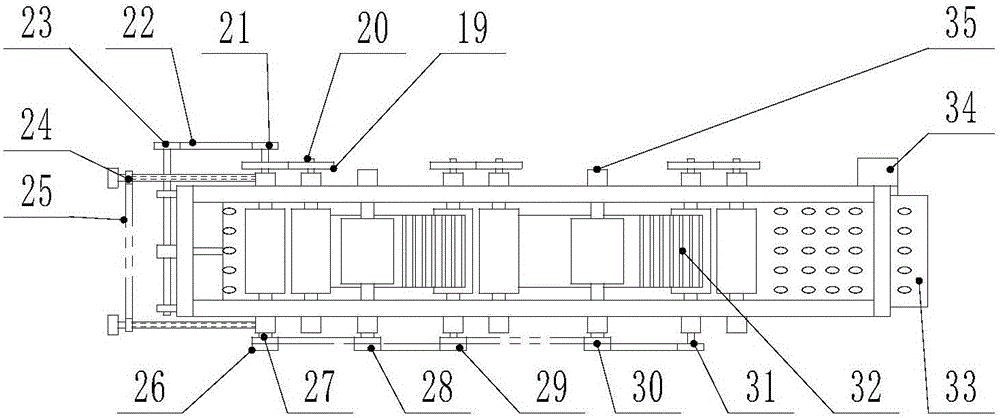

High-efficiency multifunctional badam shell crusher

ActiveCN105707911AImprove shell breaking rateAvoid secondary crushingHuskingHullingGear wheelAgricultural engineering

The invention relates to a high-efficiency multifunctional badam shell crusher. The high-efficiency multifunctional badam shell crusher comprises an electromotor, a motor chain wheel, a frame, a vibrating screen, a crank mechanism, a first separating frame, a screw rod, a handle, a scaleplate, a sliding bearing, a shell-crushing driving roll, a feeding hole, a shell-crushing driven roll, a bearing, a cleaning roll shaft, a cleaning roll, a second separating frame, a gear, a shell-crushing roll shaft, a first chain wheel, a second chain, a second chain wheel, a synchronous chain wheel, a third chain, a third chain wheel, a shell-crushing roll driving shaft, a fourth chain wheel, a fifth chain wheel, a sixth chain wheel, a seventh chain wheel, a grid screen, a shell discharging hole and a kernel discharging hole. The high-efficiency multifunctional badam shell crusher disclosed by the invention has the following beneficial effects: 1, the shell crushing rate is high; 2, the integrity rate of kernels is increased; 3, the high-efficiency multifunctional badam shell crusher is simple in structure and easy to manufacture; 4, the shell crushing speed and the working efficiency are high, and the problems of a nut shell crusher that a shell crushing clearance cannot be adjusted conveniently and a clearance between shell crushing rolls is not uniform are solved.

Owner:INST OF AGRI MECHANIZATION XINJIANG AGRI INST

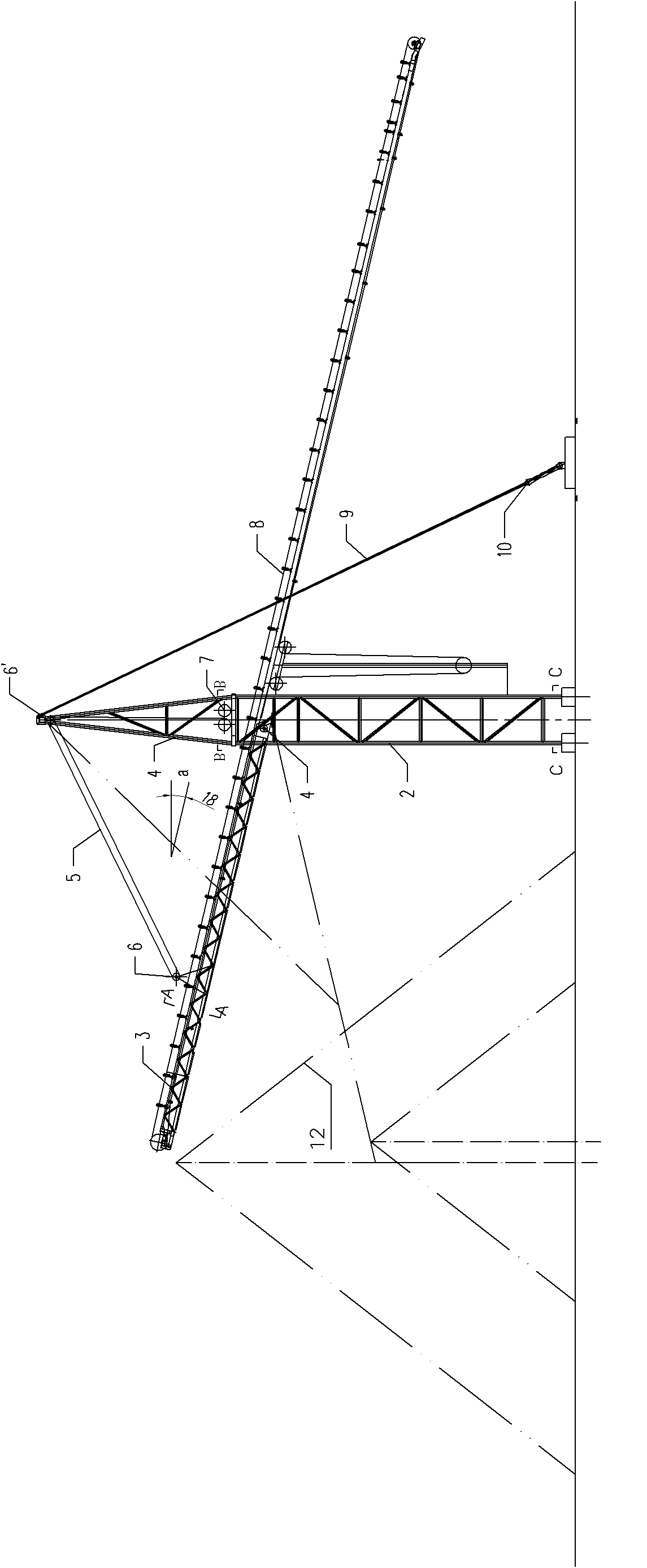

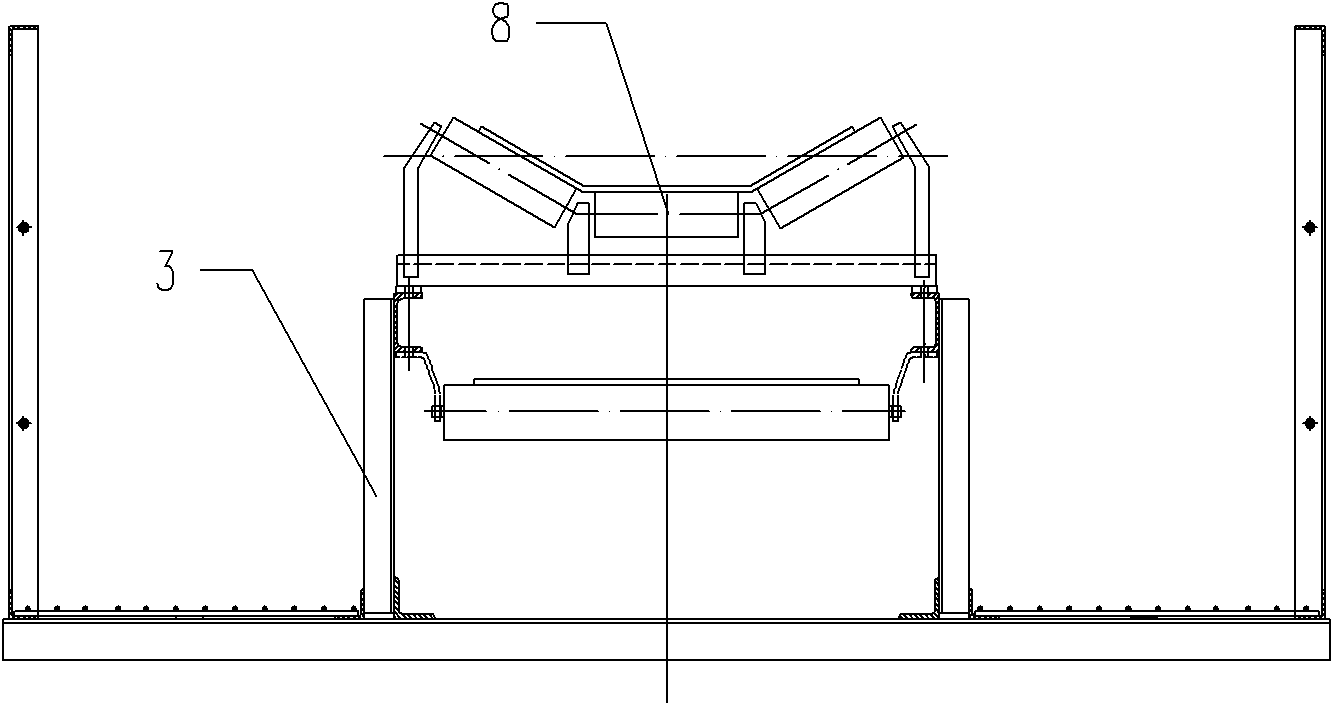

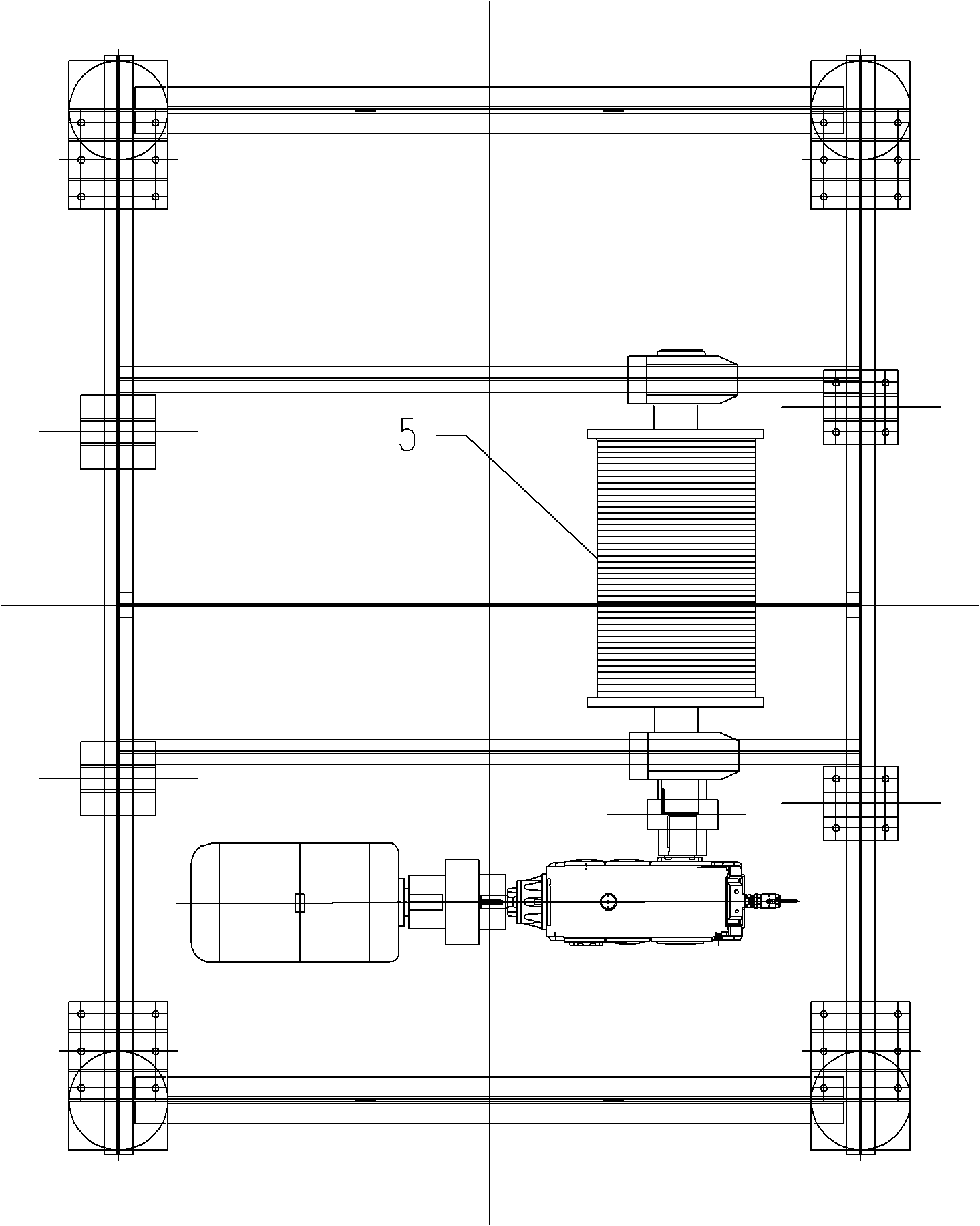

Device for composting concrete aggregate with large particle diameter

Device for composting concrete aggregate with large particle diameter comprises a tower, a steel upright column and a backstay cable, wherein the steel upright column is provided with a hoist workbench, two hinge supports are arranged on the hoist workbench, and a movable cantilever truss girder is connected with the hinge supports via axle pins; a hoist is equipped on the hoist workbench, a sealing-tape machine is arranged on the movable cantilever truss girder, and a steel wire rope of the hoist is connected with the movable cantilever truss girder via two assembly pulleys. Compared with the current scheme of adopting a stocker, the device provided by the invention saves the cost of purchasing stocker equipment, and reduces construction land occupation and civil engineering expense; and compared with the scheme of adopting a sealing-tape machine for blanking and stockpiling at fixed point, the device of the invention can maximally avoid second fragmentation of the aggregate with large particle diameter in stockpiling, and reduces the undersize index of the particle diameter aggregate by 8% to 18%, at the same time, guarantees continuous aggregate grading, avoids aggregate separation, and solves concrete separation problem caused by unreasonable particle diameter of coarse aggregate, so as to reach the quality requirement of concrete aggregate.

Owner:CHINA GEZHOUBA GROUP NO 5 ENG

Crushing and screening device for sepiolite processing and sepiolite breaking and screening process

InactiveCN112871408AIncrease productivityAvoid secondary crushingSievingScreeningGratingCrushed stone

The invention discloses a crushing and screening device for sepiolite processing. The crushing and screening device is arranged under a discharging outlet of a primary crushing machine, and comprises a grating frame, a screen plate and a spiral conveyor mechanism. The screen plate is arranged in the grating frame; the screen plate is obliquely arranged and receives broken stone falling off from the discharging outlet of the primary crushing machine; a collection hopper is arranged on the rear side of the grating frame, and the spiral conveyor mechanism is arranged on the bottom of the collection hopper. According to the crushing and screening device for sepiolite processing and the sepiolite breaking and screening process, the work load of a secondary crushing machine can be reduced; and the production efficiency of the sepiolite powder is greatly improved.

Owner:河北省易县海泡石开发有限公司

Side comb plate mechanism of crusher, and crusher

PendingCN114011547AAvoid secondary crushingAvoid accumulationSolid waste disposalGrain treatmentsStructural engineeringCrusher

The invention provides a side comb plate mechanism of a crusher, and the crusher. The side comb plate mechanism comprises: a mounting part, which is located on the inner wall of a crushing box of the crusher, wherein the mounting part is provided with an inner wall that is matched with the rotary operation track of cutters of the crusher, so when the cutters of the crusher rotate, the inner wall of the mounting part prevents materials from entering the corner parts of the crushing box; and a plurality of comb plates, which are sequentially arranged on the inner wall of the mounting part, wherein gaps between the comb plates are suitable for containing the cutters of the crusher to rotate and operate. According to the side comb plate mechanism of the crusher and the crusher, the materials are prevented from entering the corners of the crushing box through the inner walls of the side comb plates, and the problems of material accumulation and unsmooth discharging are effectively solved.

Owner:SID MACHINERY BEIJING

Rare earth crushing device

InactiveCN110694757AAvoid secondary crushingNo wasteSievingScreeningClassical mechanicsStructural engineering

The invention discloses a rare earth crushing device, and in particular relates to the technical field of rare earth permanent magnet element manufacturing. The rare earth crushing device comprises acrushing box; a motor is arranged at the top of the crushing box; a rotating shaft is arranged at the bottom of the motor; a first crushing cutter is fixedly arranged on the rotating shaft; a first screening plate is arranged at the bottom of the first crushing cutter; a second crushing cutter is arranged at the bottom of the first screening plate; a second screening plate is arranged at the bottom of the second crushing cutter; a third crushing cutter is arranged at the bottom of the second screening plate; a third screening plate is arranged at the bottom of the third crushing cutter; a drawer is arranged at the bottom of the third screening plate; and two feed ports are formed in the top of the crushing box. Three different screening plates are arranged in the crushing box for screeningrare earth, and three crushing cutters are used for crushing each layer of screened rare earth, so that the crushing efficiency is improved, and meanwhile, the secondary crushing of the rare earth iseffectively prevented to save rare earth resources.

Owner:徐州给力磁业有限公司

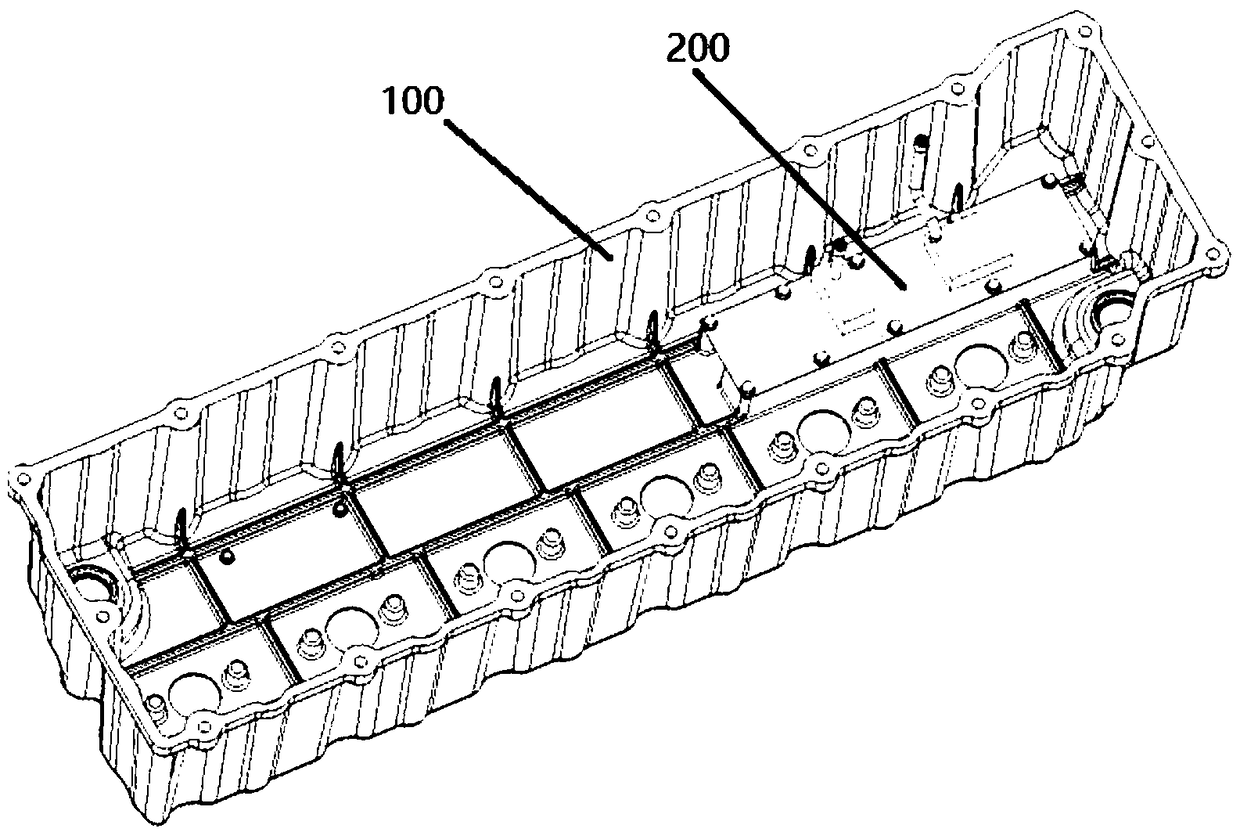

Partition plate oil-driven type engine oil-gas separation device

InactiveCN109139187AAvoid secondary crushingImprove separation efficiencyMachines/enginesCrankcase ventillationCylinder headEngineering

The invention provides a partition plate oil-driven type engine oil-gas separation device. The partition plate oil-driven type engine oil-gas separation device comprises a pre-separation device arranged in a mounting groove of an air cylinder head cover, an initial separation device arranged in the mounting groove of the air cylinder head cover and an oil-driven type oil-gas separator arranged onthe exterior of the air cylinder head cover; an air inlet hole is formed in the mounting groove, the initial separation device is composed of at least two partition plates, an air vent hole is furtherformed in the air cylinder head cover, and an air outlet pipe connected with the oil-driven type oil-gas separator is arranged on the air vent hole; secondary acceleration can be carried out on oil-gas mixture by the partition plate oil-driven type engine oil-gas separation device, large oil drops and small oil drops are separated correspondingly and flow out through an oil return cavity, and theseparation efficiency is high; and in the adsorption of the small oil drops, a filter element do not have residue blocking due to the impact force of the secondary acceleration, therefore, the filterelement does not needed to be replaced at regular intervals, and the problem of replacing and maintenance at the intervals can be solved.

Owner:GUANGXI YUCHAI MASCH CO LTD

Hydraulic cyclone of half-flux internal and external curve channel

PendingCN108816532AImprove coalescenceIncrease settling velocityReversed direction vortexCycloneImpeller

The invention relates to a hydraulic cyclone of a half-flux internal and external curve channel. The hydraulic cyclone is composed of a tail tube segment, a small awl segment, an impeller and an impeller shell. The impeller shell and the small awl segment are connected through a welding mode, a certain quantity of inlets are uniformly dispersed at the impeller shell, the impeller is placed in theimpeller shell, the impeller comprises uniformly distributed axisymmetric wide-sector guide vanes and impeller heads, the impeller is in a hollow structure, a left end outlet of the impeller head is alight-phase overflow mouth, a right side end of the impeller is a light-phase outlet, and a space formed between the impeller head and the impeller shell is a large awl segment; the small awl segmentand the tail tube segment are connected in a welding mode, a penetrating cavity is arranged between the small awl segment and the tail tube segment, the right end of the cavity and the light-phase overflow mouth in the large awl segment are communicated, and the end at the left side of the tail tube segment is a heavy-phase outlet.

Owner:青岛一三一油气科技有限责任公司

A method for online monitoring of lubricating oil in wind power transmission

ActiveCN104764489BAvoid secondary crushingAvoid interferenceMeasurement devicesRelational modelNetwork Communication Protocols

Owner:XI AN JIAOTONG UNIV

Construction method for large-diameter ultra-deep rock borehole bottom-expanding filling pile

ActiveCN100572683CGuarantee the quality of hole formationIncrease the allowable carrying capacityBulkheads/pilesSteel frameGas lift

Owner:CHINA CONSTR SIXTH ENG DIV CORP +1

Pulverizer with screening secondary treatment function

PendingCN113399044AExtended service lifeReduce scrap timeGrain treatmentsElectric machineryStructural engineering

The invention discloses a pulverizer with a screening secondary treatment function. The pulverizer with the screening secondary treatment function comprises a flow dividing box, a secondary pulverizing barrel and a material collecting barrel, a primary pulverizing barrel is arranged at the top of the flow dividing box, the interior of the primary pulverizing barrel is rotatably connected with a grinding roller, and the top of the secondary pulverizing barrel is fixedly connected with a second motor. The output end of the second motor penetrates through the secondary pulverizing barrel to be fixedly connected with a crushing cutter, the bottom of the outer wall of the secondary pulverizing barrel is fixedly connected with a second fan, the output end of the second fan extends to the bottom of the secondary pulverizing barrel, so that raw material blocks are crushed into powder, unqualified raw materials are pulverized through the crushing cutter, direct cutting and pulverizing through the crushing cutter are avoided, and the service life of the crushing cutter is prolonged; and the materials which are ground into powder are blown by the fan when entering the flow dividing box, so that fine powder falls down towards one side of a fine selection barrel, flow dividing of qualified materials and discharged materials is achieved, secondary crushing of the qualified powder is avoided, the crushing time of a crushing cutter is shortened, and the production efficiency is improved.

Owner:王敢闯

Efficient crushing and cleaning equipment for building cement blocks

InactiveCN107185682AAdjustable distanceReduce sizeGrain treatmentsArchitectural engineeringConstruction waste

The invention belongs to the technical field of construction waste treatment, in particular to a high-efficiency crushing and cleaning equipment for construction cement blocks. Aiming at the problems that the existing crushing equipment has high noise when crushed and the size of the crushed cement blocks cannot be controlled, the following solutions are proposed, including shells body, a second motor is installed on the side of the housing, and the output shaft of the second motor is perpendicular to the side wall of the housing, the output shaft of the second motor is inserted into the inside of the housing, and two motors are installed on the output shaft of the second motor There are two parallel rockers, the output shaft of the second motor is perpendicular to the rocker, and the opposite sides of the two rockers are connected with triangular plates, and there is an arc-shaped first crushing plate between the two sets of triangular plates, and the two sets of triangular plates It is connected with the first crushing plate by bolts, the concave arc surface of the first crushing plate is provided with an arc-shaped rack, and the convex arc surface of the first crushing plate is provided with a spherical first protrusion. The invention can well control the size of the crushed cement block, greatly reduces the noise, and maintains people's health.

Owner:HUANGHE S & T COLLEGE

A device for collecting and sieving frozen soil fragments in the Hopkinson test

ActiveCN106644697BAvoid secondary crushingHelps to movePreparing sample for investigationMaterial strength using single impulsive forceTemperature controlControl power

The invention relates to an apparatus for collecting and screening frozen soil fragments in a Hopkinson test. The apparatus comprises a protective cover which comprises an external layer semicircular protective cover and an internal layer semicircular protective cover by low temperature strong glue bonding; the protective cover is connected to a bracing frame and an internal layer slide plate by a loose-leaf hinge and a positioning pin; air vents are arranged at the lower part of the bracing frame, a channel section is arranged on the bracing frame, and a katathermometer is internally arranged in the bracing frame; a temperature control test box and a protective cover are respectively provided with a pole hole and a rotating wheel hole for a Hopkinson pressure bar and a soil scraping rotating wheel to pass through; the channel, a screw and a support bar are used for connecting the bracing frame and an electric vibrating screen; a control power supply is arranged outside a test box with controllable temperature; a temperature control system is used for controlling the temperature of the test box with controllable temperature. The apparatus can prevent secondary fragmentation of frozen soil fragments, and more frozen soil fragments are collected as possible. The frozen soil fragments are screened and treated at first time after the test, and accuracy of test data is improved.

Owner:ANHUI UNIV OF SCI & TECH

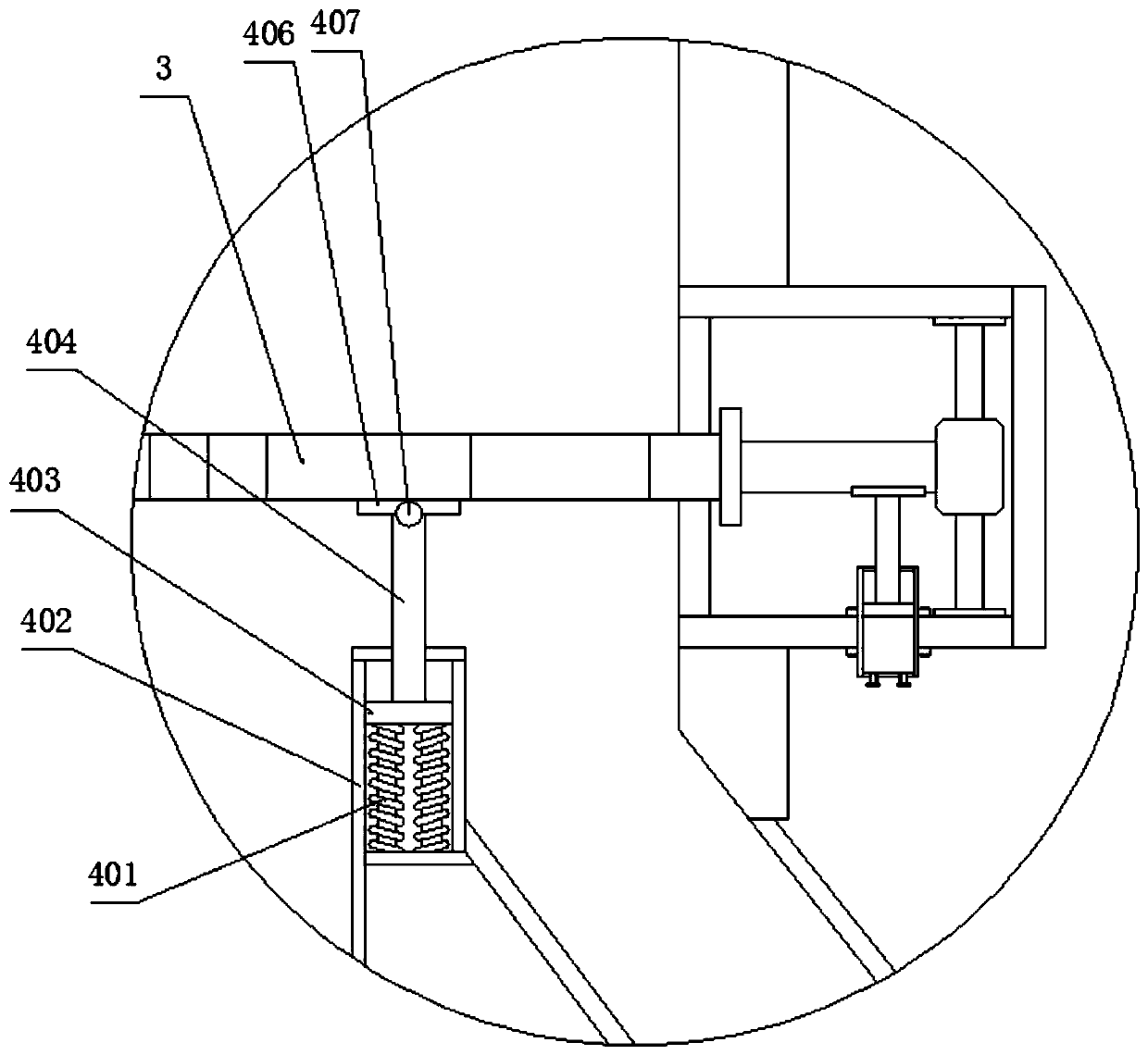

A modified preparation process of water reducing agent

ActiveCN111548468BEffective stirringImprove drying efficiencyRotary stirring mixersTransportation and packagingProcess engineeringWater reducer

The invention relates to a modified preparation process of a water reducer. The modified preparation process of a water reducer adopts the following processing equipment. The processing equipment includes a bottom plate, a drying device and a lifting frame. device, a lifting frame is installed on the upper end of the drying device. The present invention can solve the problem that the existing equipment has poor drying effect and low efficiency when drying the water reducing agent, and cannot quickly stir and heat the raw materials, which leads to slow water loss inside the heated raw materials and affects The processing efficiency of raw materials, and the existing equipment usually cannot crush the raw materials when drying and processing the water reducing agent, resulting in the hardened raw materials after drying in a block structure, which requires secondary crushing of the raw materials, which affects the raw materials. The subsequent use effect and other problems.

Owner:江西富创新材料有限公司

Reverse circulation pneumatic down-the-hole hammer rotary drilling rig and its construction method

The invention discloses a rotary drilling machine for a reverse-circulation pneumatic down hole hammer and a construction method for the rotary drilling machine. The rotary drilling machine comprises a chassis and a mast arranged on the chassis, wherein a reverse-circulation power head is mounted on a guide rail of the mast; the upper part of the reverse-circulation power head is provided with a water faucet; the water faucet is connected with a slag discharge tube; the lower part of the reverse-circulation power head is provided with a buffer; the buffer is connected with a gas box; the gas box is connected with a gas inlet rubber tube; the lower end of the gas box is connected with a drill stem; and the lower end of the drill stem is connected to the reverse-circulation pneumatic down hole hammer and a drill bit. The rotary drilling machine has the function of constructing the reverse-circulation pneumatic down hole hammer, can realize high-efficiency rock-entering, also can effectively protect hole walls, needs small drilling pressure and small rotary torque, can continuously take a core and can effectively solve orifice dust pollution.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

Broken tea separating and crushing device

InactiveCN111570270AAvoid secondary crushingGreat tasteSievingScreeningEngineeringMechanical engineering

Owner:温州兴升环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com