Pulverizer with screening secondary treatment function

A mill and milling technology, applied in grain processing and other directions, can solve the problems of dull blade, long grinding time, and increase processing time, so as to avoid secondary crushing, reduce crushing time, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

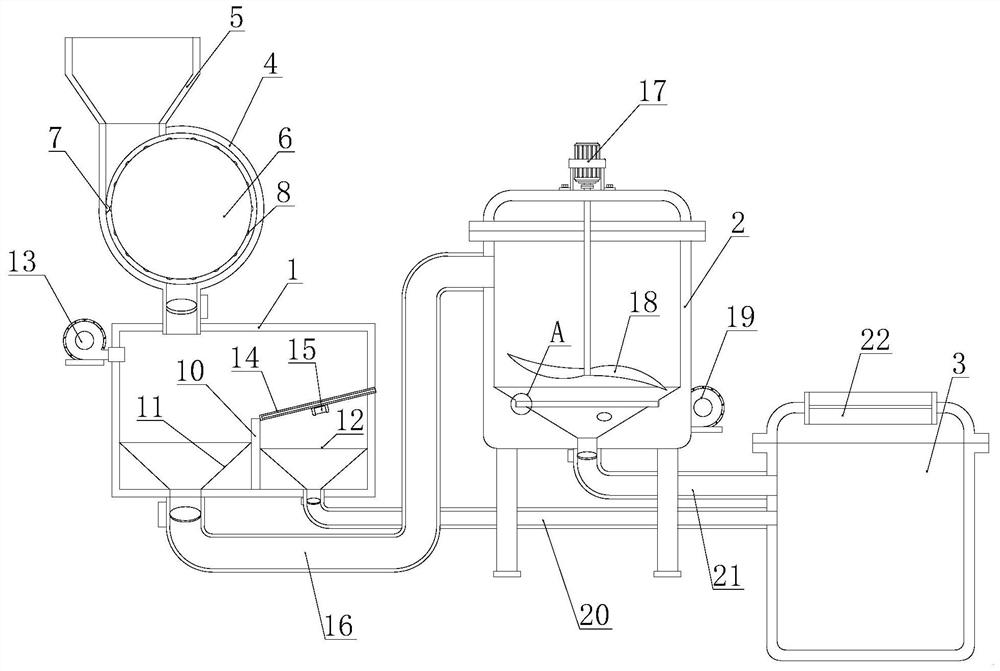

[0019] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical scheme: a kind of pulverizer with sieving secondary treatment function, comprising a split box 1, a secondary grinding bucket 2 and a collection bucket 3, the split box 1 The top is provided with a primary grinding barrel 4, and the inside of the primary grinding barrel 4 is rotatably connected with a grinding roller 6, and the top of the secondary grinding barrel 2 is fixedly connected with a No. 2 motor 17, and the No. 2 motor 17 The output end passes through the secondary grinding barrel 2 and is fixedly connected with a crushing knife 18, and the bottom of the outer wall of the secondary grinding barrel 2 is fixedly connected with a No. 2 fan 19, and the output end of the No. 2 fan 19 extends to the secondary The bottom of the milling barrel 2, the bottom of the diverter box 1 is fixedly connected with a No. 1 feeding pipe 16 and a No. 2 feeding pipe 20, and the bottom of the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com