Roller type screening crusher and design method thereof

A design method and crusher technology, applied in grain processing and other directions, can solve the problems of large equipment maintenance and repair workload, unfavorable electrolysis production needs, and high equipment failure rate, achieving low maintenance difficulty, high product granularity guarantee, and investment. The effect of the province

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

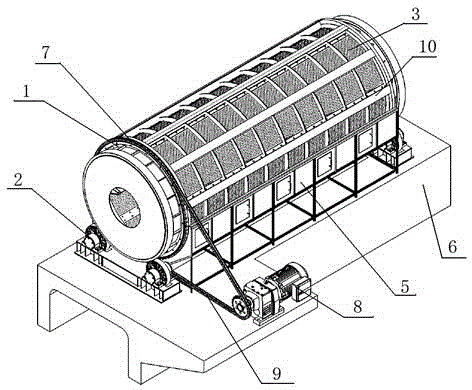

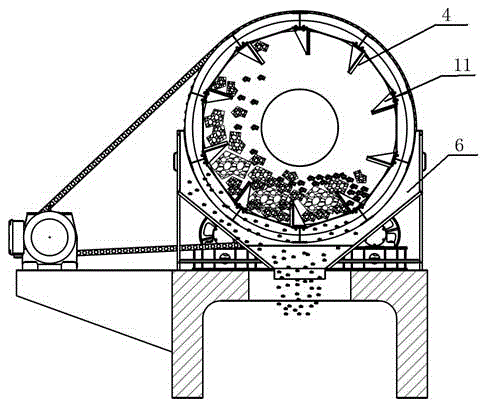

[0021] Embodiment of the present invention: a design method of a drum-type screening crusher. The crusher lifts the crushed material to a certain height, and realizes crushing through the mutual impact and grinding action of the material falling, and the crushed material is smaller than the hole of the sieve plate. It falls into the lower collecting hopper of the drum screening crusher through the sieve plate hole, and is continuously discharged by the conveying equipment, so as to realize the function of simultaneously crushing and screening the crushed materials.

[0022] Among them, the middle part of the rotating drum of the crusher is surrounded by a sieve plate, and the sieve plate bracket is used as a support. The crusher is supported by supporting wheels and driven by a chain to make it rotate. plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com