Pumping type centrifugation oil-water separator

An oil-water separator and pumping technology, used in liquid separation, separation methods, chemical instruments and methods, etc., can solve the problems of complex structure of centrifugal extractors, many wearing parts of seals and bearings, and small centrifugal extractors. Achieve the effects of mature and reliable raw materials, low maintenance costs, and significant energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

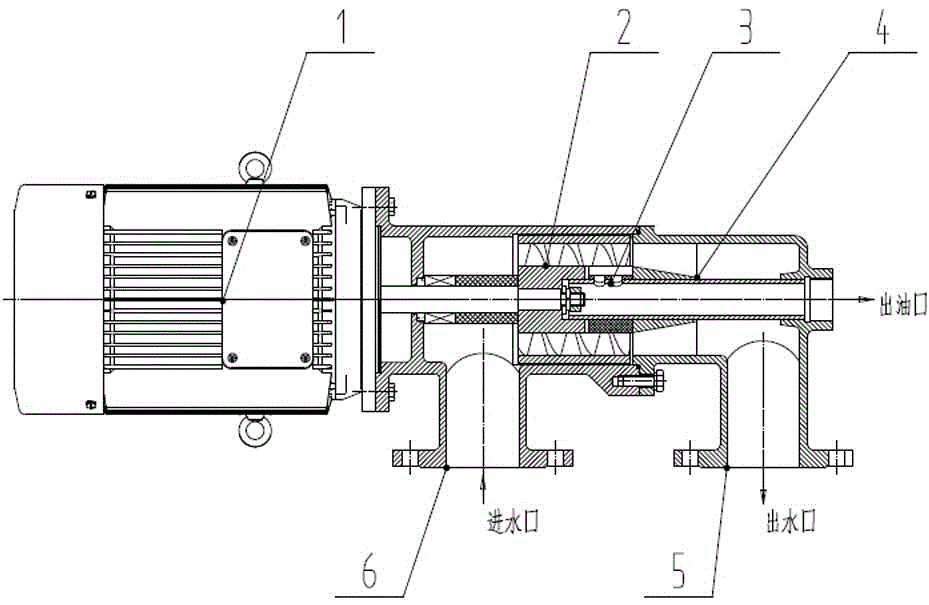

[0014] from figure 1 It can be seen that the present invention comprises a driving device 1, a water inlet section 6 and a water outlet section 5 of a sealed tubular structure; The end of the section 6 is provided with a driving device 1 that can drive the impeller to rotate; the side of the water outlet section 5 is provided with a water outlet, and the end is provided with an oil outlet. The center part is provided with an oil collecting pipe 3, one end of the oil collecting pipe 3 extends into the center of the impeller 2 and has an oil collecting hole, and the other end is connected to the oil outlet; the impeller 2 is in the shape of a hollow cylinder with blades that drive water to rotate inside. The center is provided with a hub connected to the transmission shaft of the driving device 1, and the blades are arranged according to the laws of hydraulic motion. The water inlet and outlet sections are connected by bolts, and the relative positions of the water inlet and ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com