Five-double full-dry method crushing production line and processing method for high-quality sandstone aggregates

A high-quality, all-dry technology, applied in the field of sand making process and sand making equipment, can solve the problems of high raw material requirements, simple production line, increased energy consumption, etc., to improve sand making efficiency, low raw material requirements, Reduce the effect of powder control pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

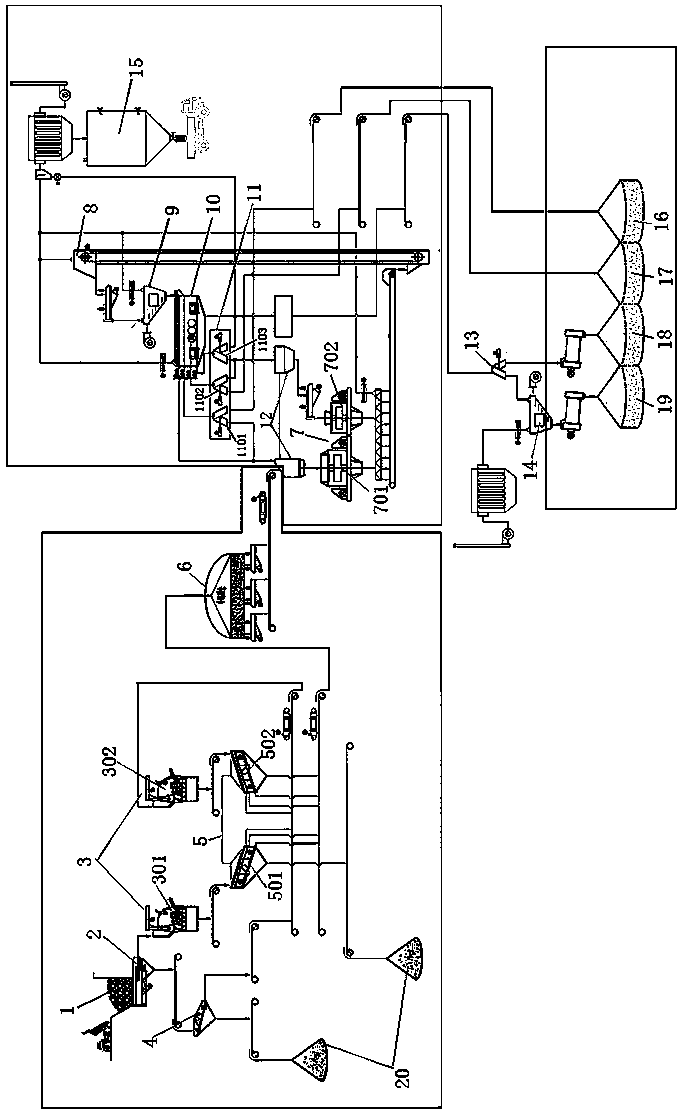

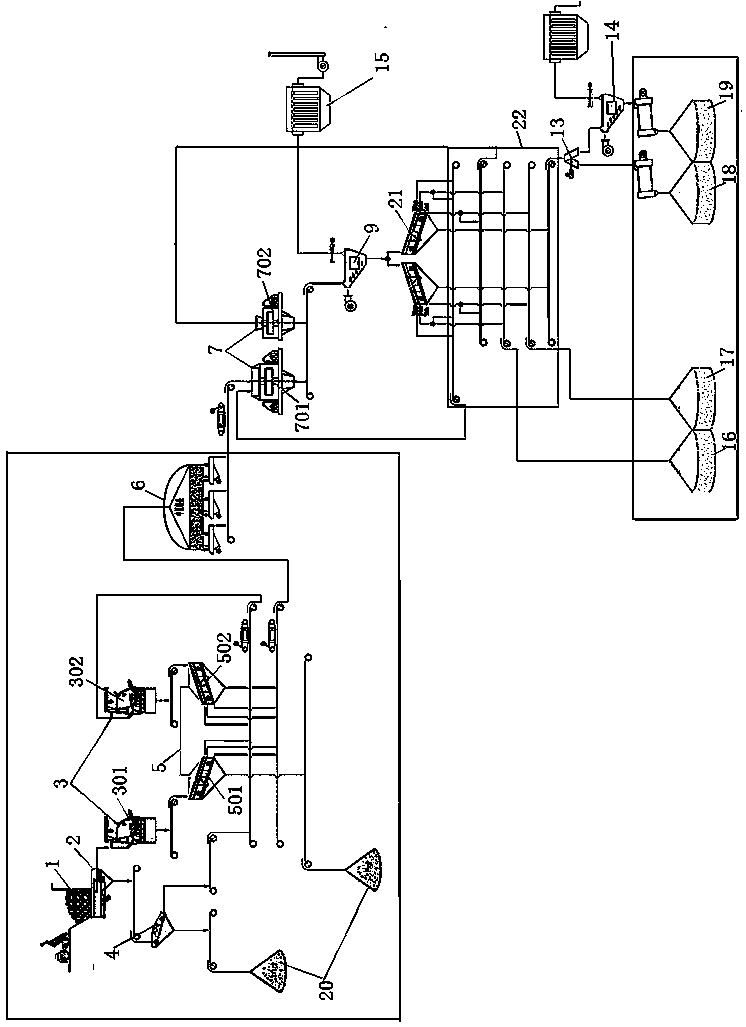

[0037] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

[0038] Such as figure 1 with figure 2 As shown, a high-quality sand and gravel aggregate five pairs of dry crushing production line,

[0039] Including material pretreatment system and high-quality coarse and fine aggregate processing system.

[0040] The material pretreatment system is used for primary desliming, crushing and shaping of raw materials; the high-quality coarse and fine aggregate processing system is used to manufacture high-quality sand and gravel aggregates, which includes double-speed and double-frequency crushing and sand-making equipment 7, finished product screening, Proportional adjustment circulation system, primary powder separator 9, multi-stage powder separator; also includes running belt conveyor for connecting the feed ports of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com