Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

301results about How to "Big pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Perovskite solar cell and preparation method thereof

InactiveCN104091888AEasy to prepareControllable parametersSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellFill factor

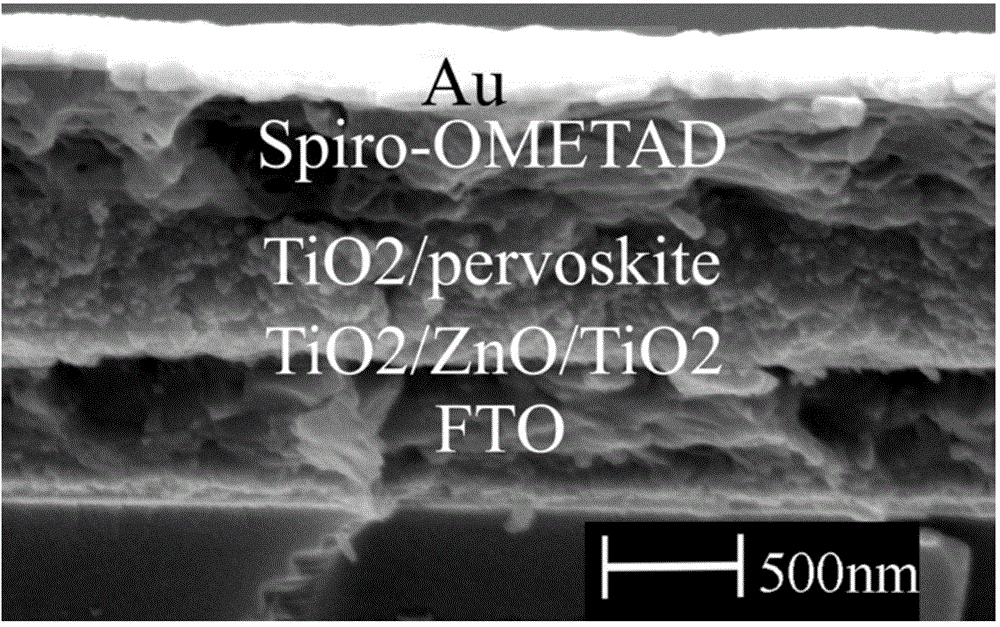

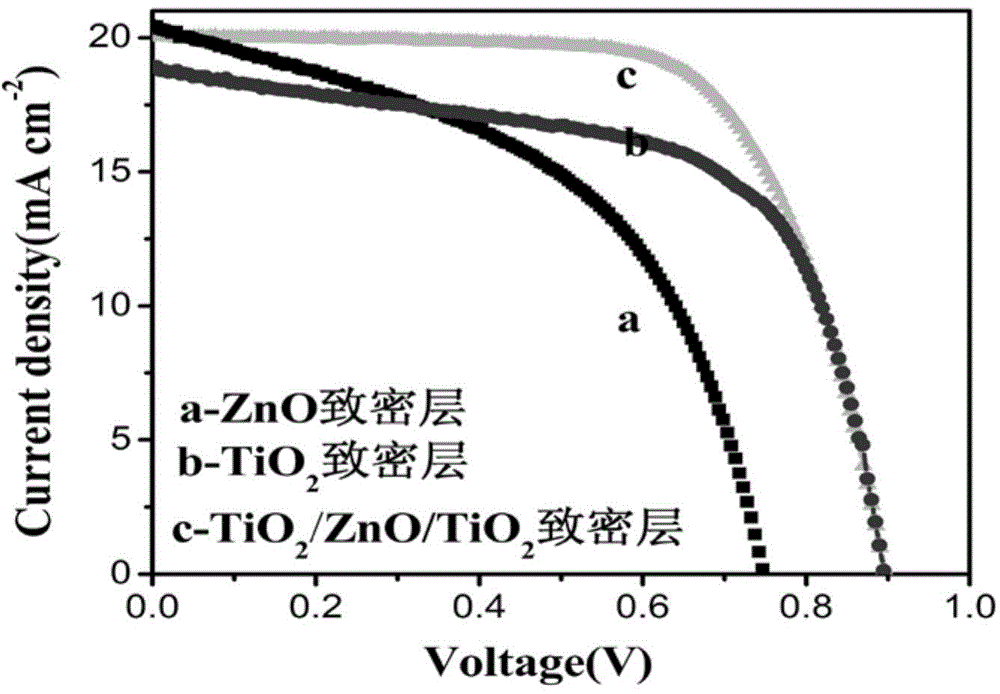

The invention relates to a perovskite solar cell and a preparation method thereof. The perovskite solar cell is composed of an FTO glass substrate, a sandwich structure TiO2 / ZnO / TiO2 compact layer, a TiO2 mesoporous / perovskite structure material active light absorption layer, a spiro-OMeTAD hole transferring layer and a gold electrode. Compared with the prior art, the sandwich structure TiO2 / ZnO / TiO2 compact layer combines with the advantages and disadvantages of TiO2 and ZnO, so that fill factors of the perovskite solar cell are improved to 70%, and the photoelectric conversion efficiency reaches 12.6%. Equipment for preparing the perovskite solar cell is simple, the preparing process is simple, control is easy, the cost is low, and the perovskite solar cell has a very good industrial application prospect.

Owner:HUBEI UNIV

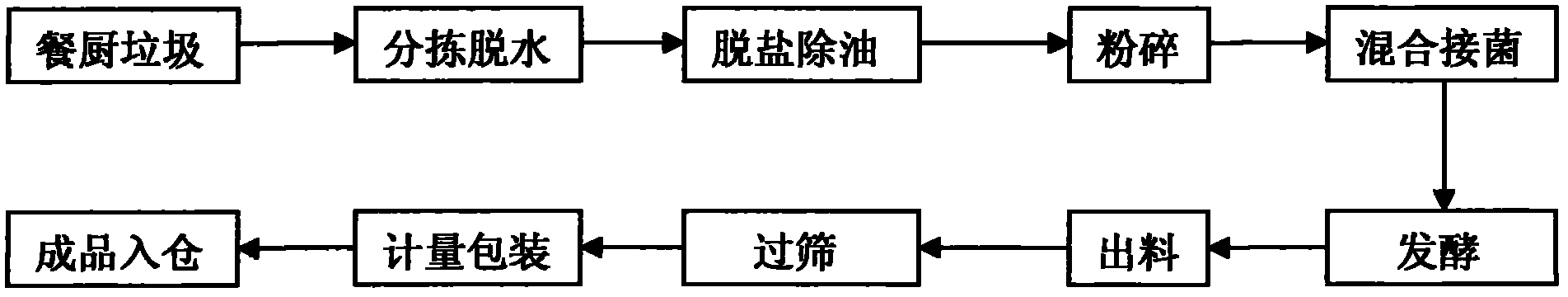

Microbial organic fertilizer prepared from restaurant-kitchen garbage and preparation method thereof

InactiveCN102320871ABig pollutionIncrease available nutrientsBio-organic fraction processingOrganic fertiliser preparationChemical structureOrganic manure

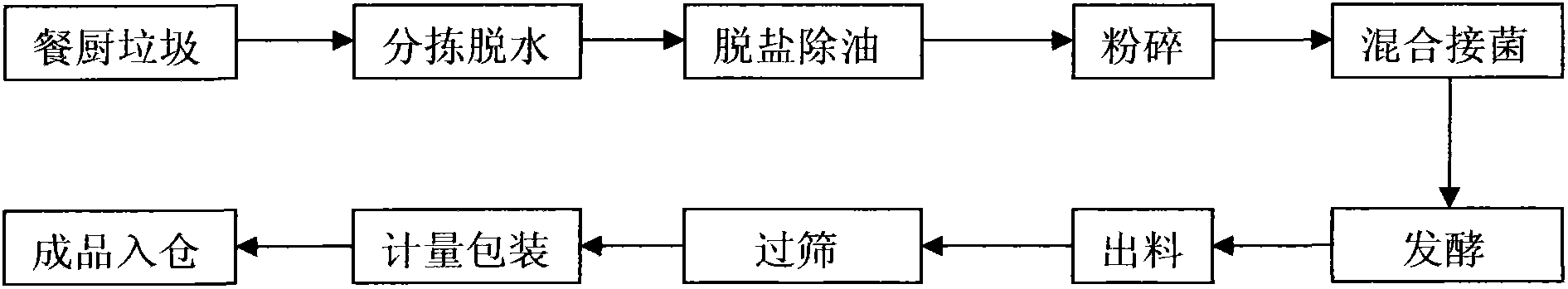

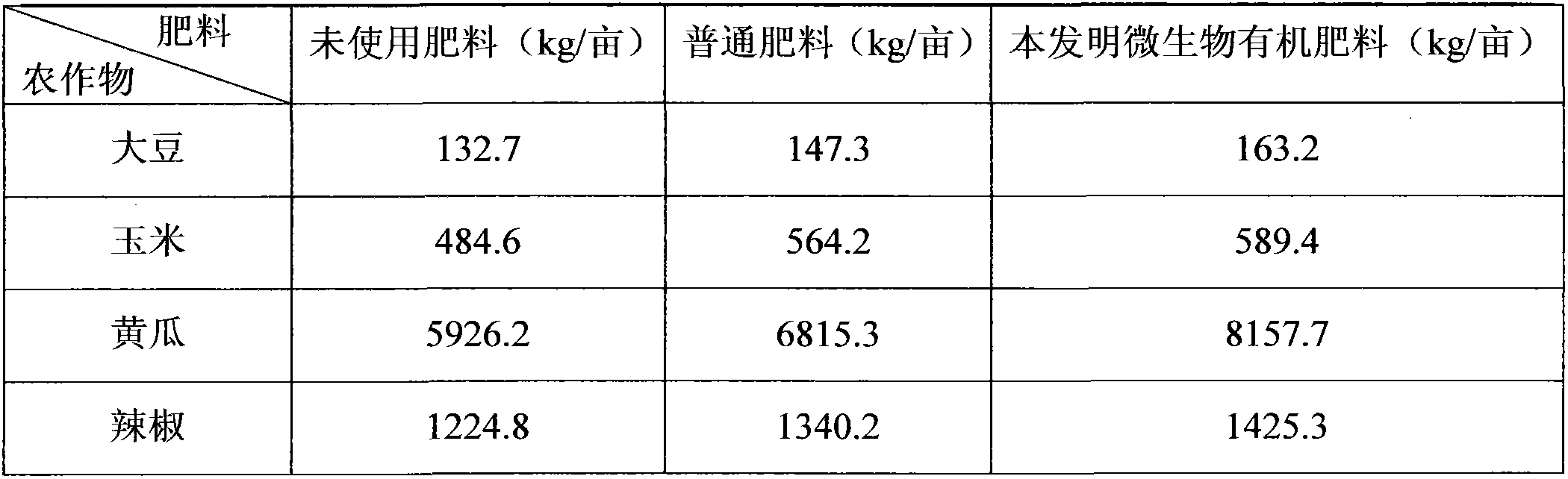

The invention relates to a microbial organic fertilizer prepared from restaurant-kitchen garbage, and relates to a soil improvement technique. The microbial organic fertilizer is prepared by taking the restaurant-kitchen garbage as the main raw material supplemented with additives, wherein the additives include subsidiary agricultural product waste, inorganic material and microbial composite bacteria groups, and the microbial organic fertilizer comprises the following components in percentage by weight: 60-75% of restaurant-kitchen garbage, 10-30% of subsidiary agricultural product waste, 1-10% of inorganic material and 1-5% of microbial composite bacteria groups. In the microbial organic fertilizer, the restaurant-kitchen garbage is adopted as the main raw material, so nutrition constituents in the restaurant-kitchen garbage can be effectively recycled, the problems of environment pollution and resource waste of the restaurant-kitchen garbage are solved, the physical and chemical structures of soil can be conditioned, the quality of agricultural products is improved, and the integrated fertility level of the soil is improved.

Owner:焦社杰

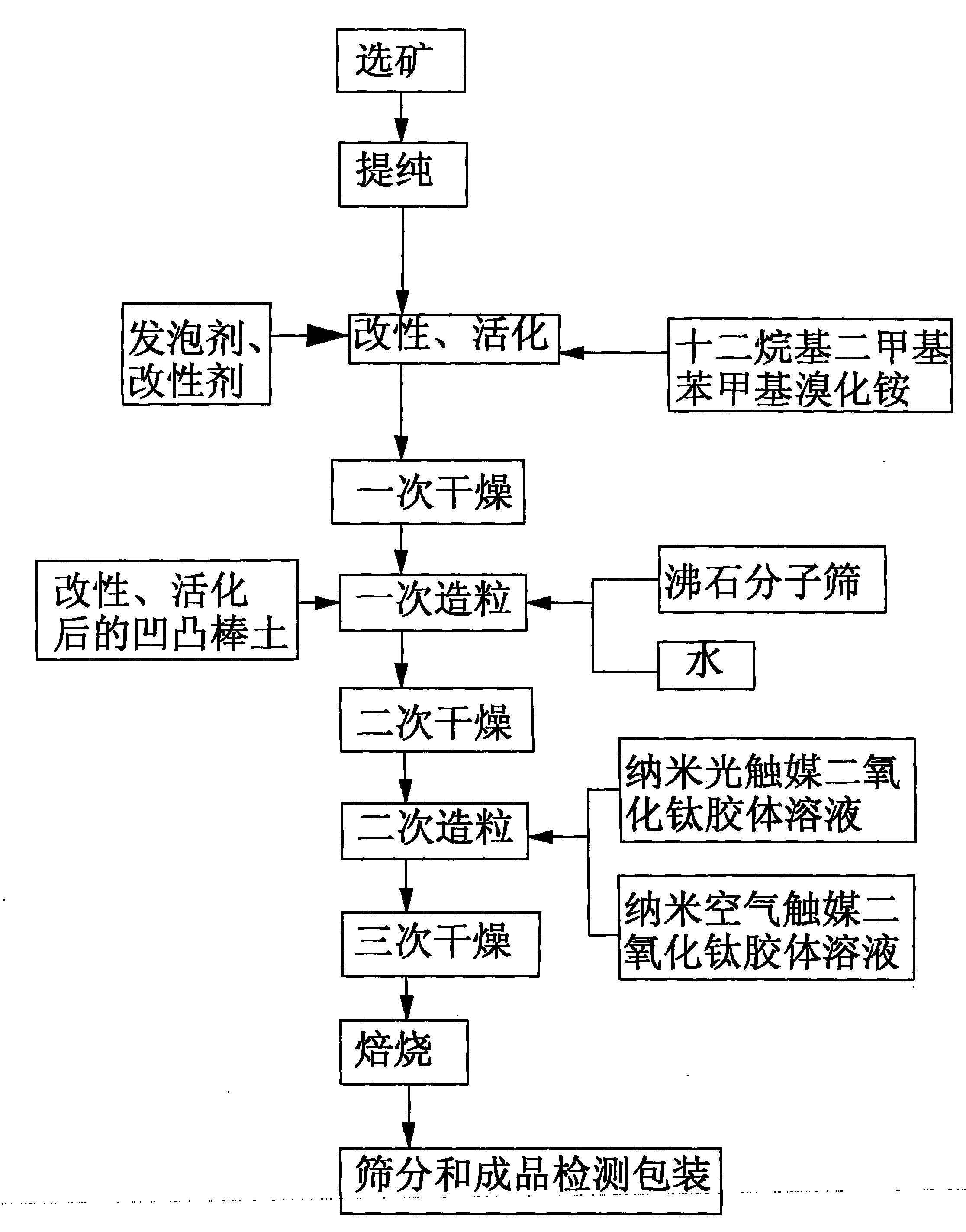

Composite air purificant containing nanometer mineral matters and preparation method thereof

ActiveCN101780288AWill not polluteProcess environmental protectionPhysical/chemical process catalystsDispersed particle separationSodium bicarbonateDecomposition

The invention provides a composite air purificant containing nanometer mineral matters, which contains 47wt% to 78wt% of attapulgite as a natural mineral, 20wt% to 50wt% of synthetic zeolite molecular sieve as a molecular sieve, 0.5wt% to 5wt% of sodium carbonate or sodium chloride or sodium fluoride or sodium hydrogensulfite as a modifier, 0.5wt% to 5wt% of ammonium bicarbonate or sodium bicarbonate or aluminum sulfate as a foaming agent, 0.5wt% to 2wt% of dodecyldimethylbenzylammonium chloride as a surface active agent, 0.2wt% to 2wt% of nanometer photocatalyst titanium dioxide colloidal solution as a photocatalyst and 0.1wt% to 1wt% of nanometer aircatalyst titanium dioxide colloidal solution as photochemical catalysts. The composite air purificant is prepared by first drying, first pelleting, second drying, second pelleting, third drying, baking and finish product detection and package. The invention has high alternative adsorbability and high decomposition efficiency for organic pollutants in the air.

Owner:宁波市沧海新材料开发有限公司

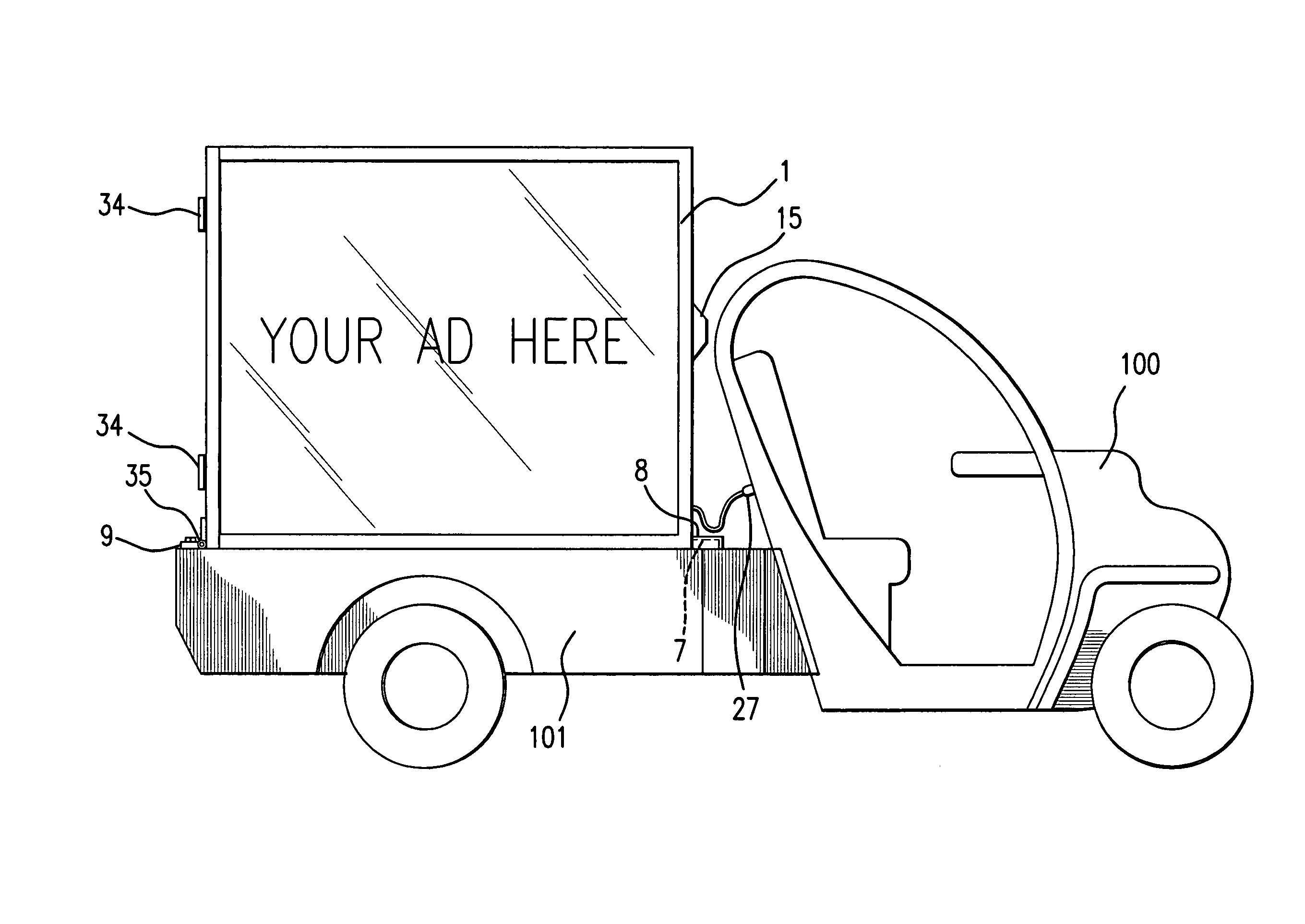

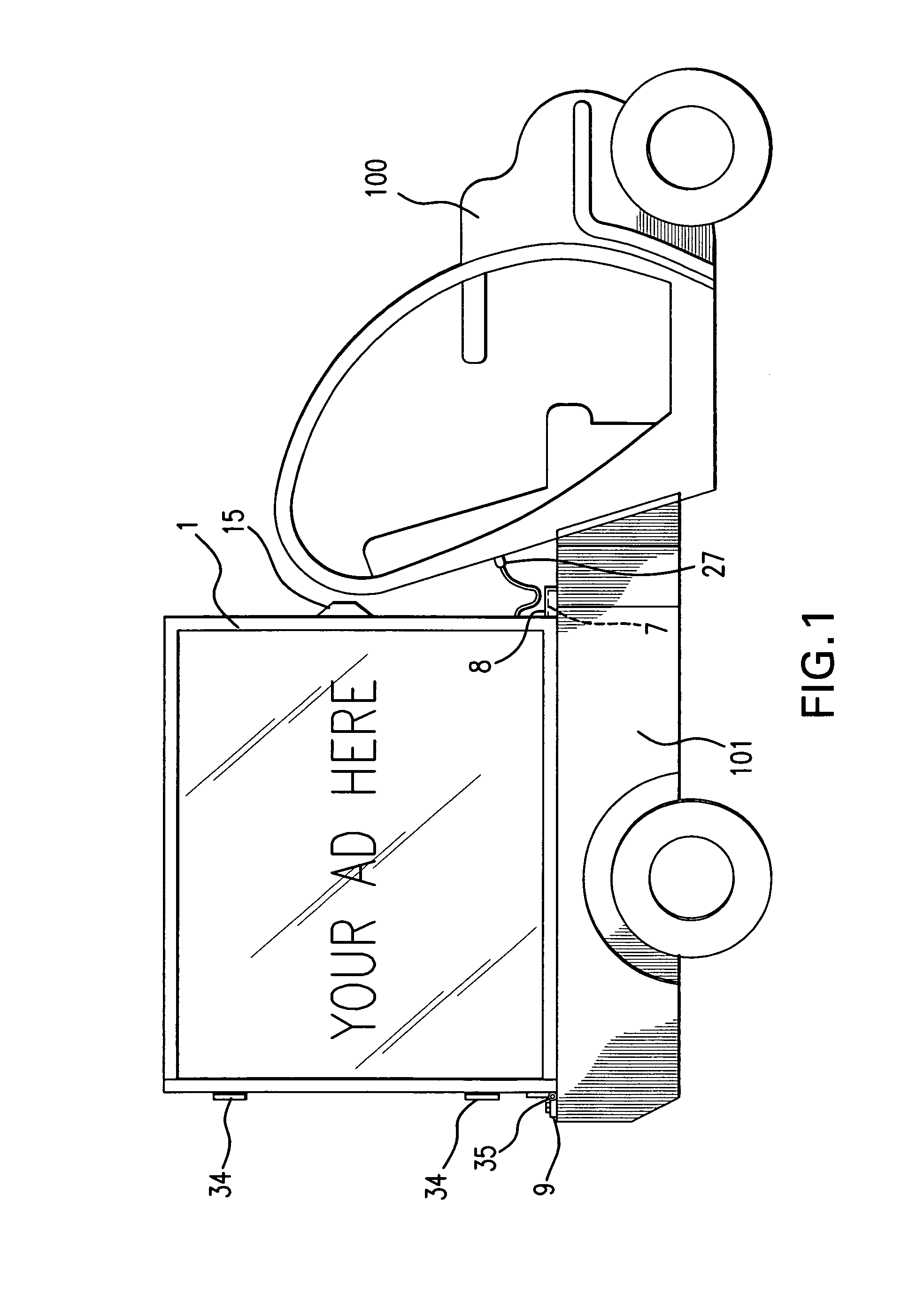

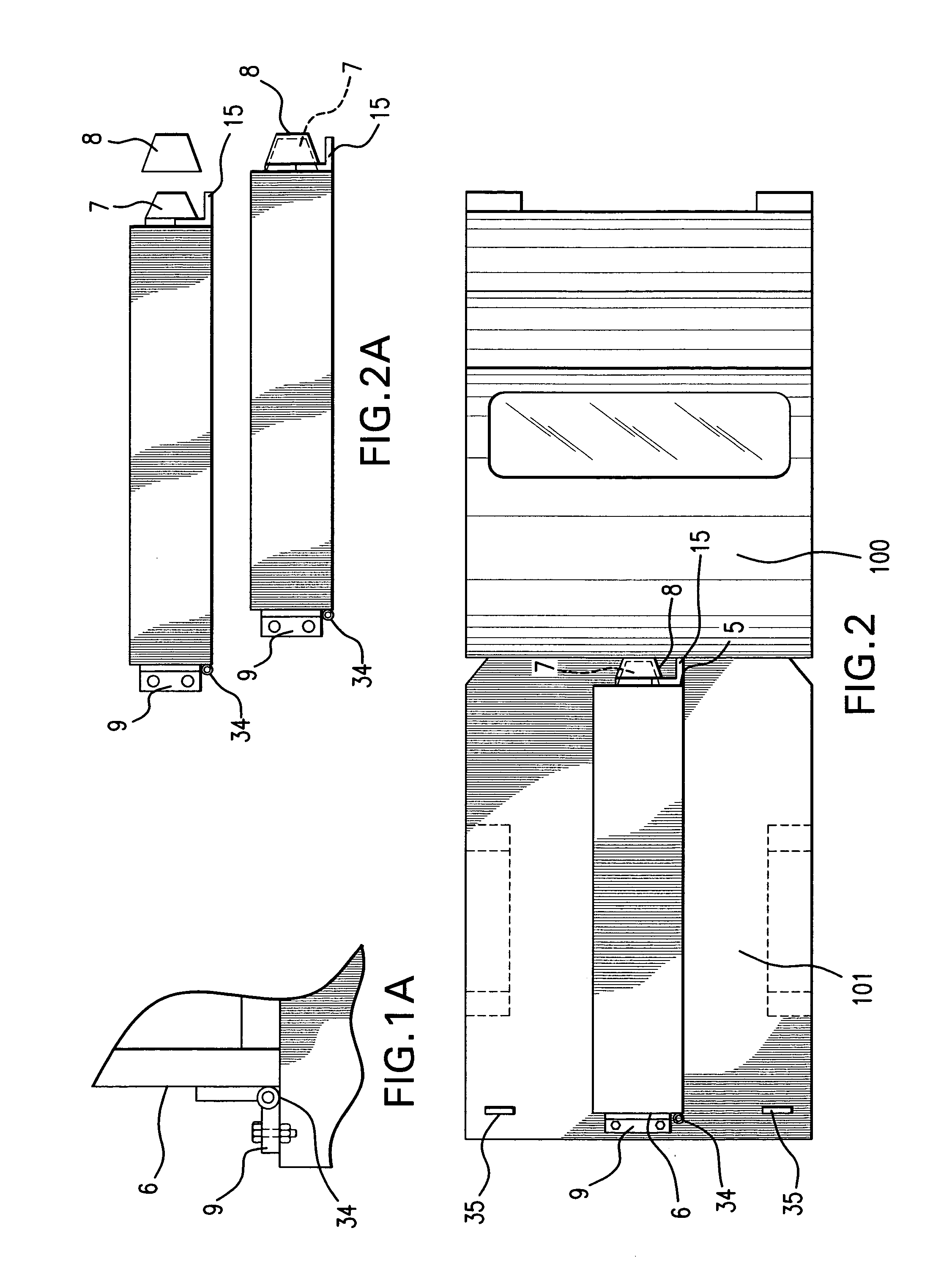

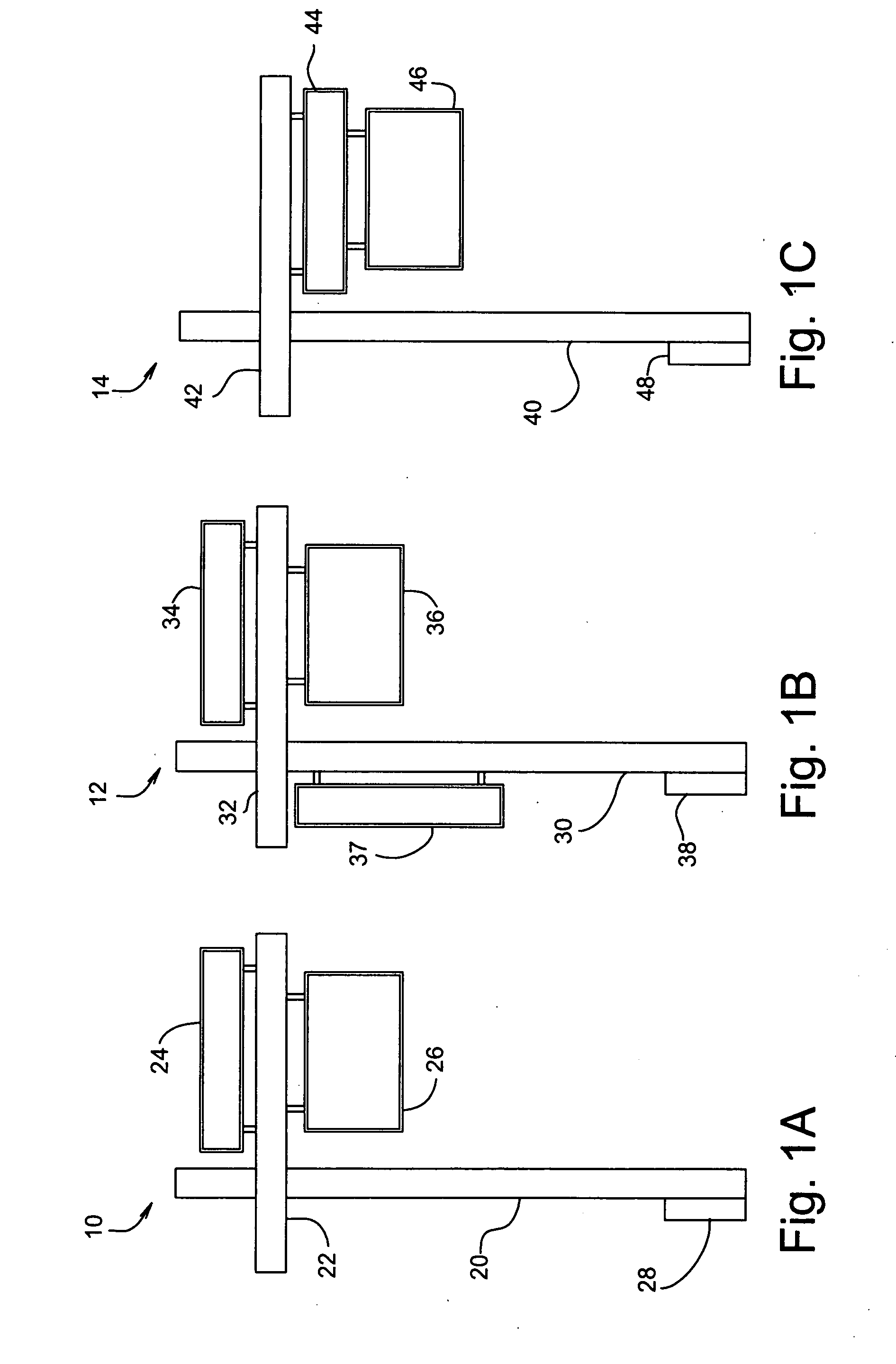

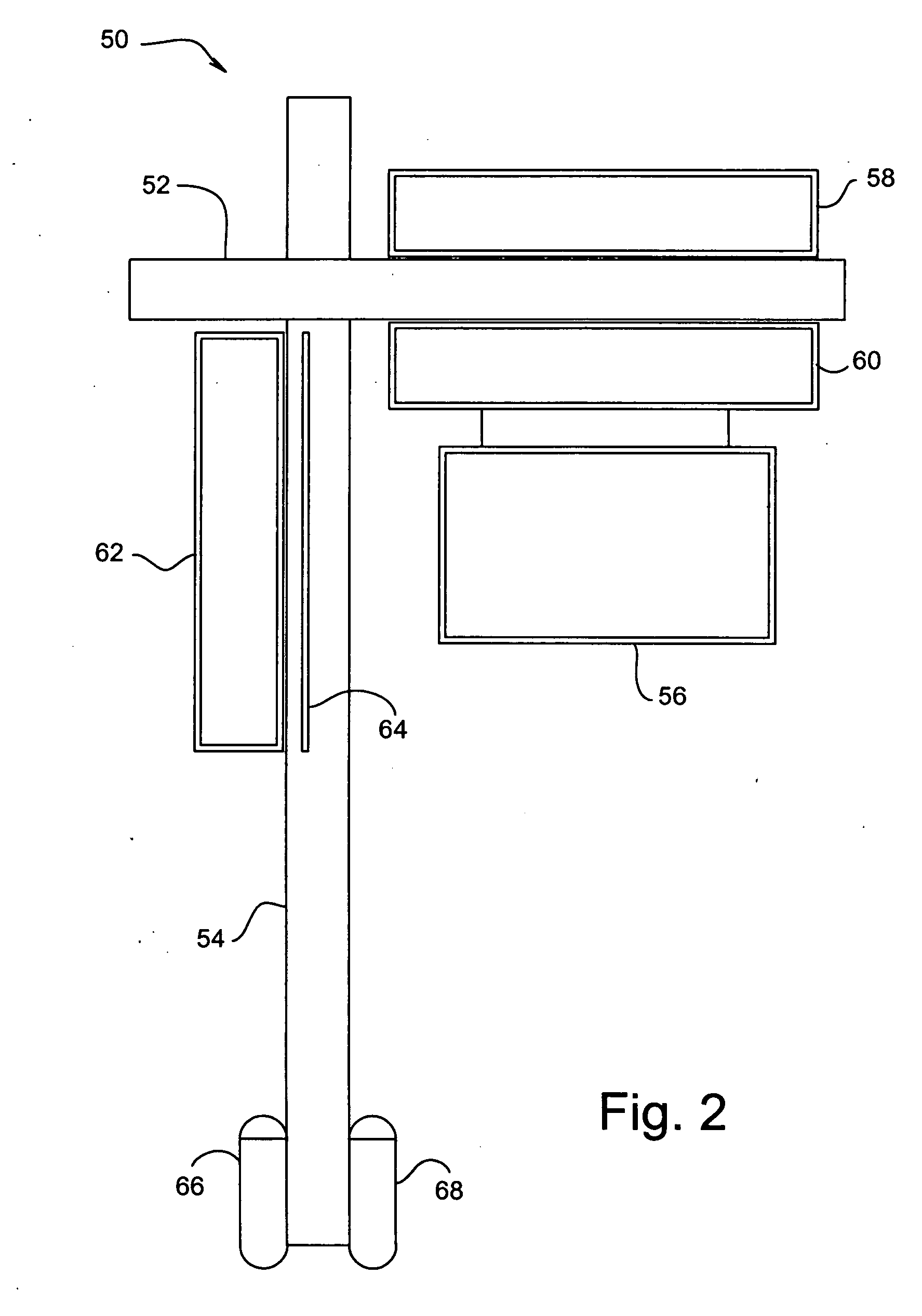

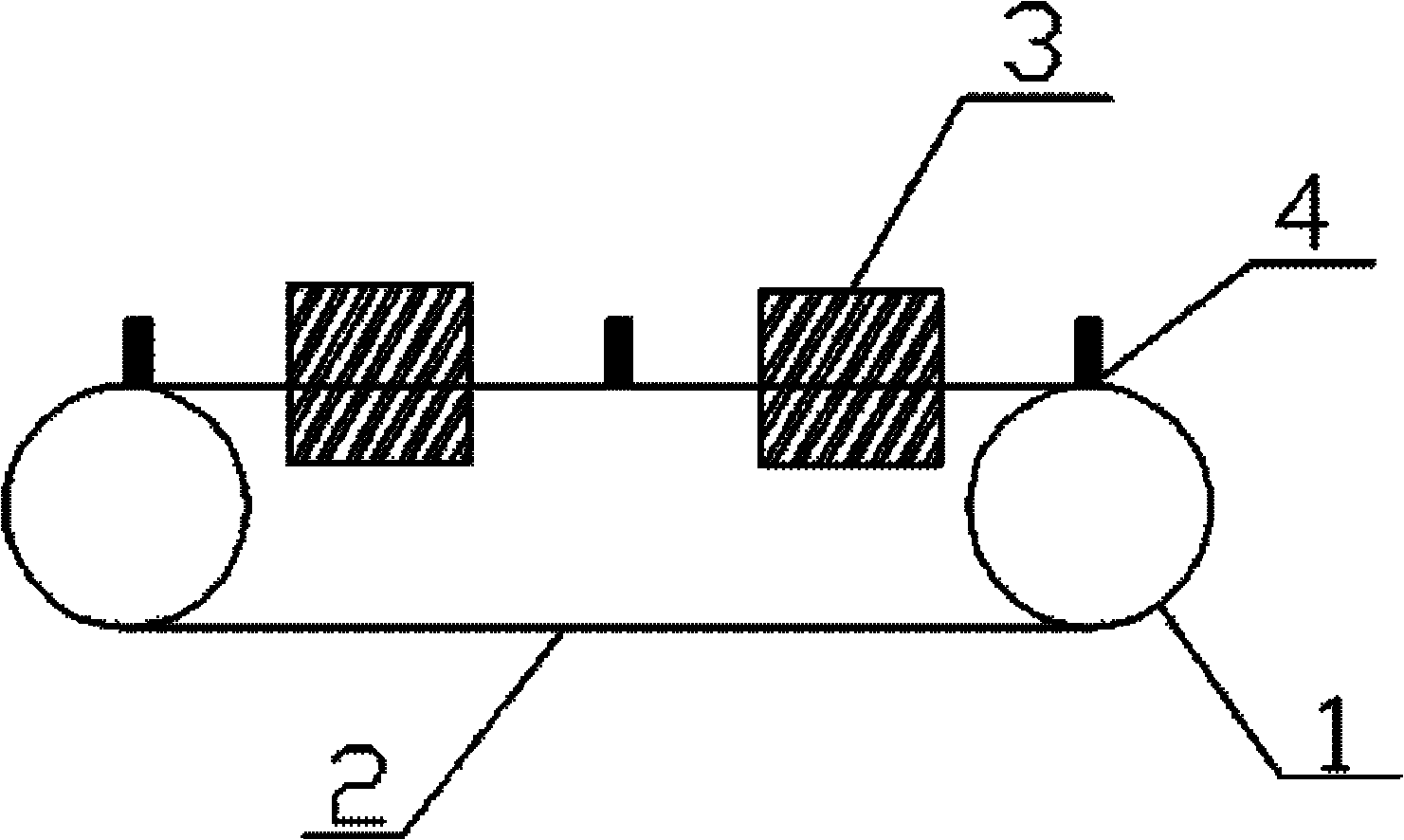

Low speed electric vehicle mobile advertising system

InactiveUS7287349B1Improve the level ofLittle noiseMobile visual advertisingMonocoque constructionsLow speedDisplay device

This system comprises a small advertising assembly that can be easily mounted onto the bed of a Low-Speed Electric Vehicle. The assembly includes an advertising display and a frame. The system allows for the advertising display to be attached in multiple positions such as: upright for viewing and stowed flat for transport. The advertising display has an internal light source and removable translucent advertising panels. This Low Speed Electric Vehicle Mobile Advertising System provides an advertising system that is mobile for both on- and off-road conditions, generates little or no noise or air pollution, and operates at pedestrian-friendly speeds to promote maximum exposure of the message being advertised.

Owner:AUTOFLEX

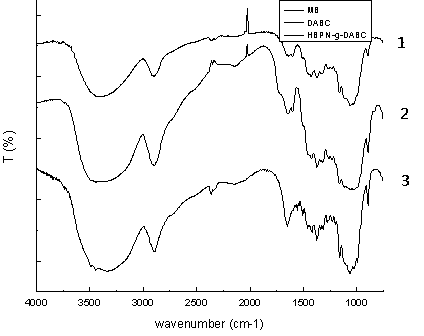

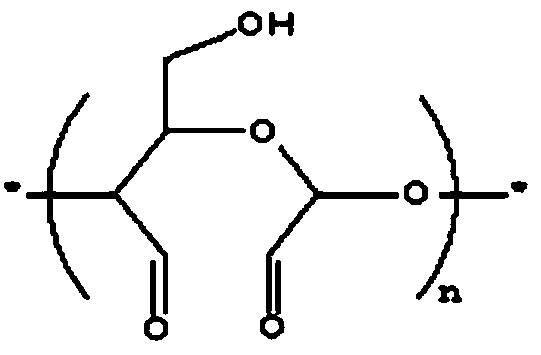

Amino-terminated modified cellulose, and preparation method and application thereof

InactiveCN103554510AIncrease added valueLow added valueWater contaminantsWater/sewage treatment by sorptionEthylenediamineFiber

The invention discloses amino-terminated modified cellulose, and a preparation method and application thereof. The method comprises the following steps: firstly, soaking a bagasse material which is cleaned and dried into constant weight in concentrated alkaline for over 10 hours; washing, carrying out suction filtering and drying to obtain alkaline bagasse fibers; then carrying out an oxidation reaction on the alkaline bagasse fibers and a strong oxidant in a dark condition, so as to obtain dialdehyde bagasse cellulose; with methyl methacrylate and ethanediamine as raw materials, stirring in an organic solvent under dark and oxygen-isolated conditions to carry out a polymerization reaction, so as to obtain an amino-terminated hyperbranched polymer; and finally carrying out a reflux reaction after dissolving the dialdehyde bagasse cellulose and the amino-terminated hyperbranched polymer into the organic solvent, so as to obtain the amino-terminated hyperbranched grafted dialdehyde cellulose. The modified cellulose not only has good adsorptive property on heavy metal ions in a wastewater solution, but also is easy to separate after adsorption. Thus, the amino-terminated modified cellulose has the water purification effects of simple method and low cost.

Owner:GUANGXI UNIV FOR NATITIES

Additive used for monocrystalline silicon wafer alkaline flocking and application method thereof

InactiveCN102312294AExtended failure cycleIncrease contact rateAfter-treatment detailsTO-18Temperature control

The invention relates to an additive used for monocrystalline silicon wafer alkaline flocking and an application method thereof, belonging to the technical field of solar batteries. The additive is prepared by the following components: ethanolamine, polyphosphate, sodium dodecylbenzene sulfonate, sodium hydroxide and water. A flocking agent is prepared through the following steps: (1) dissolving sodium hydroxide in deionized water so as to obtain alkaline flocking liquid; (2) adding the additive motioned above into the alkaline flocking liquid to obtain the flocking agent. During flocking, monocrystalline silicon wafers used for solar batteries are immersed in the flocking agent with temperature controlled to be 75 to 85 DEG C and flocking time controlled to be 15 to 18 minutes. The additive used for monocrystalline silicon wafer alkaline flocking in the invention enables flocking reaction time to be shortened and productivity to be enhanced; prepared texture surface pyramids have a uniform size and low reflectivity; the additive is applicable to solar battery silicon wafer alkaline flocking of different specifications and meets the purpose of industrial production.

Owner:浙江向日葵聚辉新能源科技有限公司

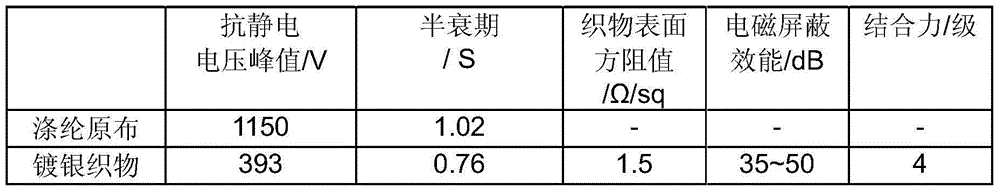

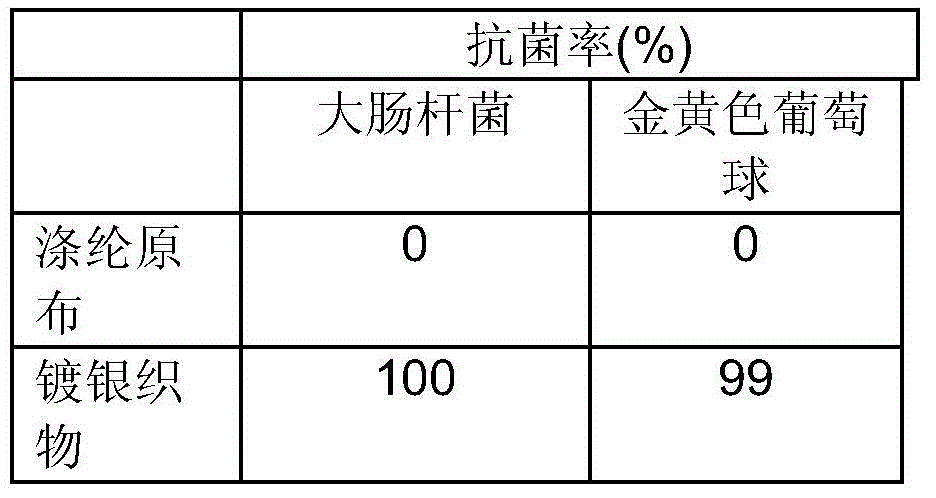

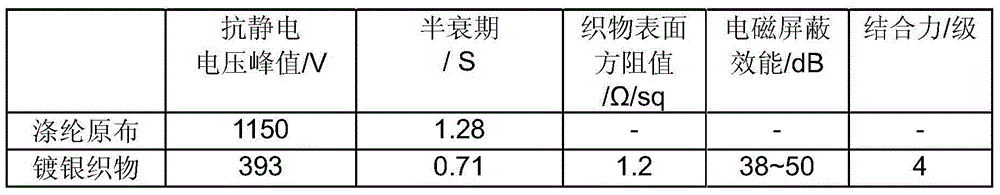

Method for making conductive fabric through polyaniline-triggered chemical slivering

InactiveCN104452309ABig pollutionReduce pollutionVegetal fibresAnimal fibresElectromagnetic shieldingBiological activation

The invention relates to a method for making conductive fabric through polyaniline-triggered chemical slivering. Fabric is soaked in a mixed solution of aniline and protonic acid, ammonium persulfate is added to the mixed solution, a reaction is carried out for 2-10 hours, and then the processed fabric is obtained after washing; the processed fabric is soaked in a silver nitrate solution, washed, dried, and then soaked in a silvering solution for being silvered for 30-60 min at the temperature of 30-40 DEG C, then the processed fabric is washed and dried, and finally the conductive fabric is obtained. According to the method, the process conditions of sensitization and activation are omitted, polyaniline and silver nitrate replace stannous chloride and palladium chloride high in price, cost is lowered, and environment pollution is reduced. The conductive fabric obtained through the method is good in conductivity, the binding strength of metal and fabric is high, the electromagnetic shielding performance is excellent, and the conductive fabric has an antistatic function, an antibacterial function and the like.

Owner:DONGHUA UNIV

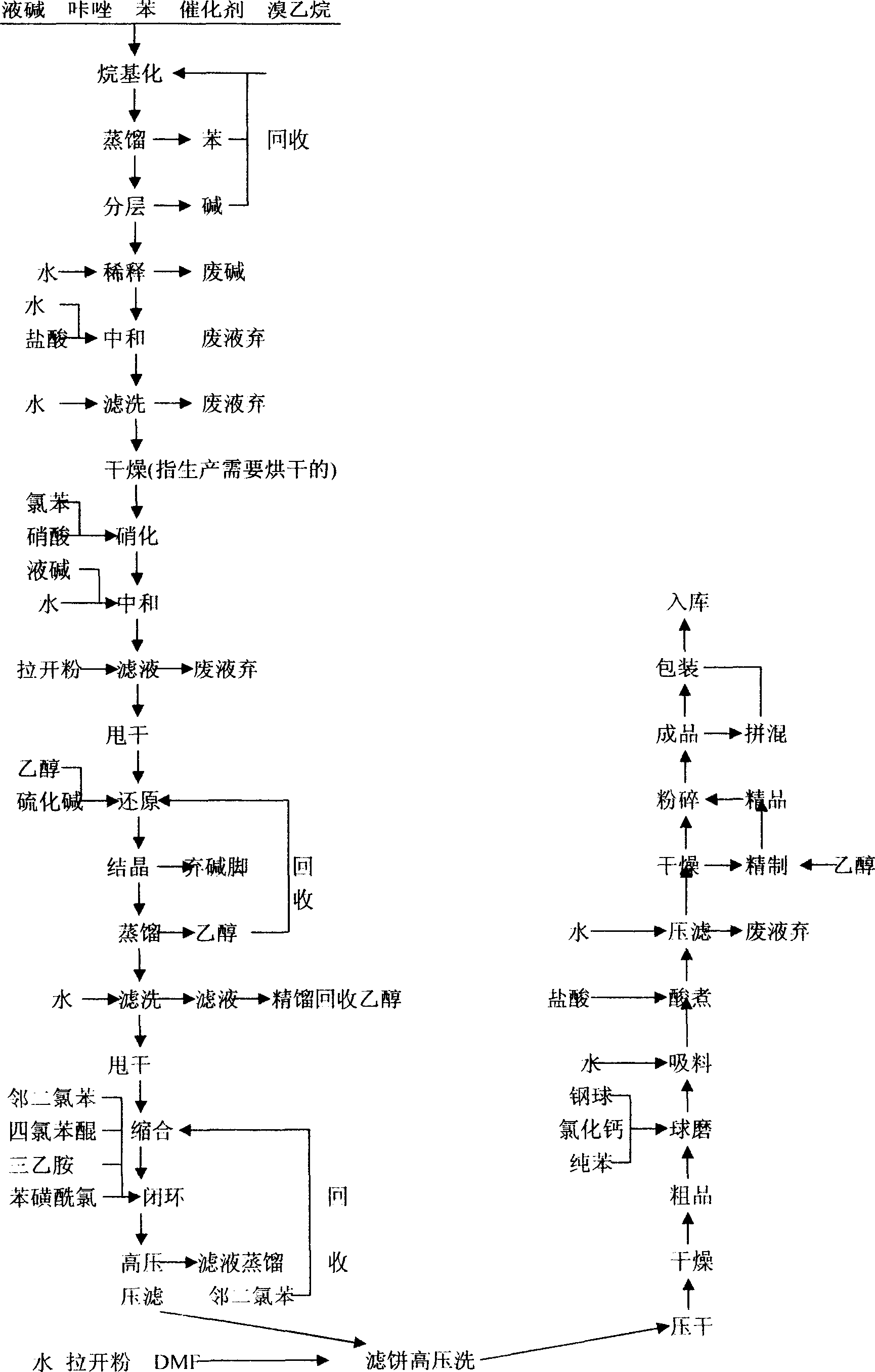

Technique for producing sumitone fast violet RL

This invention discloses a method for producing semitone fast violet RL. The method uses carbazole as the raw material, and comprises alkylating, nitrifying, reducing, condensing, ring closing and ball-milling. The method makes improvement on the present nitrifying and ring closing techniques. After improvement, the nitrifying technique has a short reaction time and a high recovery rate of solvent o-dichlorobenzene. The method has such advantages as little pollution, little harm to operators and stable product quality.

Owner:南通龙晨新材料科技有限公司

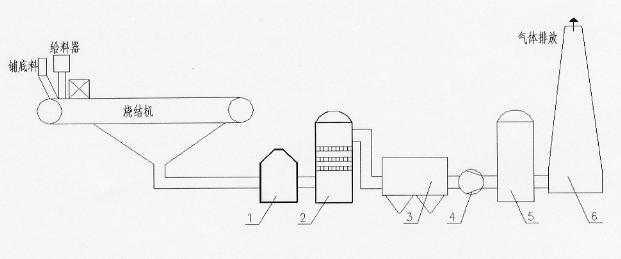

Denitration system and method for sintering flue gas without ammonia reducing agent

InactiveCN102188904ASimple processSimple process equipmentLighting and heating apparatusDispersed particle separationChemical equationProcess engineering

The invention relates to a denitration system and method for sintering flue gas without using ammonia as a reducing agent. The system comprises a sintering machine, and a heater, a denitration reactor, a deduster, a blower fan, a desulfurization tower and a chimney sequentially connected with the sintering machine. The denitration reactor is arranged before the deduster; that is, the deduster is arranged between the heater and the denitration reactor. A catalyst layer is provided in the denitration reactor. The method comprises the following steps that: sintering flue gas is heated by the heater to an appropriate temperature before the deduster and is sent to the denitration reactor; NOx is removed by a catalytic reduction in the denitration reactor under the influence of a catalyst, wherein the chemical equation for the removing of NOx is 2NO +2CO =N2 + 2CO2; the reacted sintering flue gas is emitted into the atmosphere after dedusting and desulphurization. According to the invention, the ammonia reducing agent needs not to be added, the catalyst is widely available and cheap, and investment and operation cost needed is low; the reducing agent used in the invention is CO reduction ingredients in the sintering flue gas instead of ammonia, thereby avoiding many problems resulting from the utilization of an ammonia reducing agent.

Owner:BAOSTEEL ENG & TECH GRP

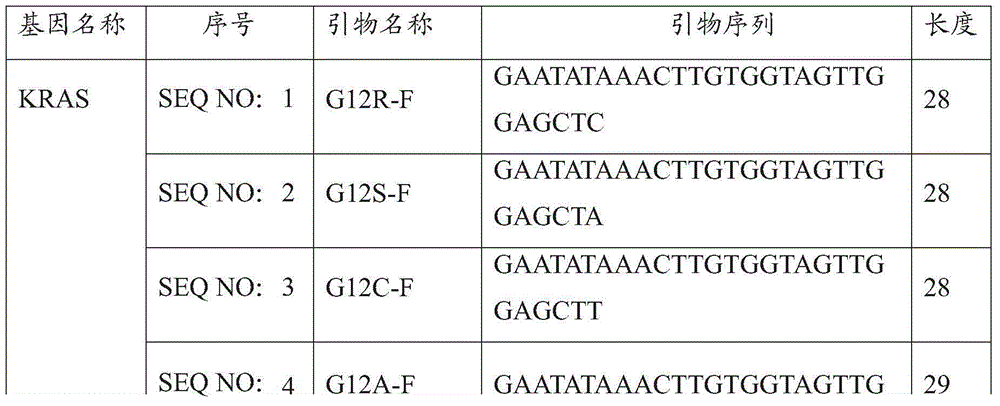

Composition for detecting colorectal cancer hotspot gene mutation sites and using method of composition

ActiveCN104099422AReal-time diagnosisImprove accuracyMicrobiological testing/measurementDNA/RNA fragmentationCurative effectBody fluid

The invention discloses composition for detecting colorectal cancer hotspot gene mutation sites. The composition comprises primer sequences from SEQ NO:1 to SEQ NO:17 as well as block sequences from SEQ NO:18 to SEQ NO:21. The detecting method for mutations related to colorectal cancer has the advantages of high specificity, high sensitivity, low pollution, simplicity and rapidness in operation, safety and the like, detection results are better in accuracy and repeatability, the method is particularly suitable for detection of hotspot mutations of colorectal cancer driving genes from body fluids such as plasma and the like, real-time and non-invasive diagnosis, recurrence monitoring and curative effect evaluation can be performed on colorectal cancer patients, and the method has important values.

Owner:JIANGSU MICRODIAG BIOMEDICINE TECH CO LTD

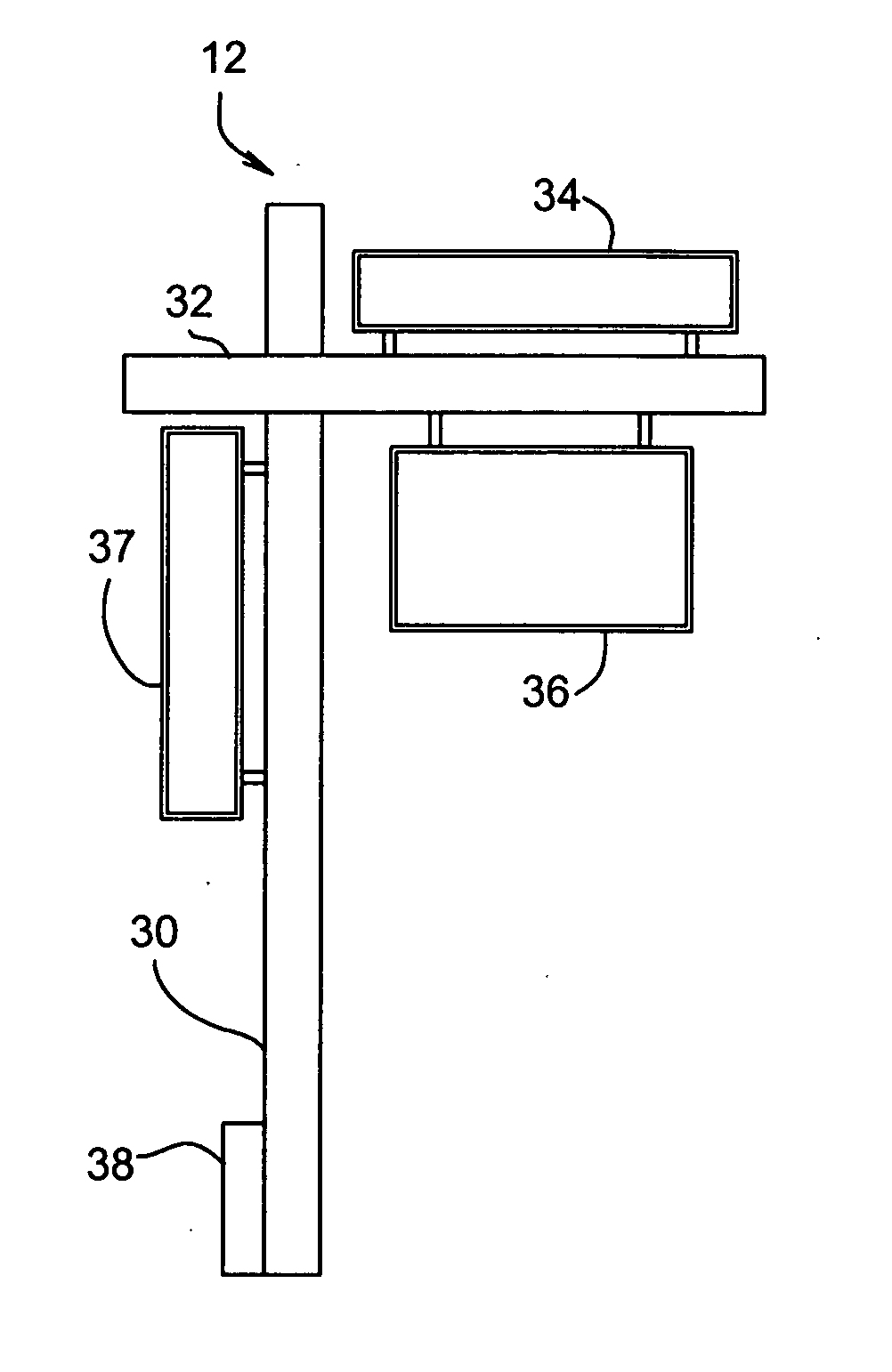

Electric sign with flat light source

InactiveUS20070193088A1Little and no light pollutionIncrease costIlluminated signsDisplay devicePortable power

An electrically powered sign is provided having a flat transparent sign display panel containing an alphanumeric sign message, a flat light source placed in close proximity, or directly affixed, to the sign display panel, a frame of varying configurations supporting the flat light source and the sign display such that the flat light source, when powered on, shines light through the sign display making the sign message visible in low light conditions, and a serviceable portable power source to provide electrical power to the flat light source, attached to the frame, whereby the electrically powered sign is self-contained and portable, and capable of being placed anywhere for displaying the sign displays alphanumeric sign message.

Owner:LYNN TERRY L +1

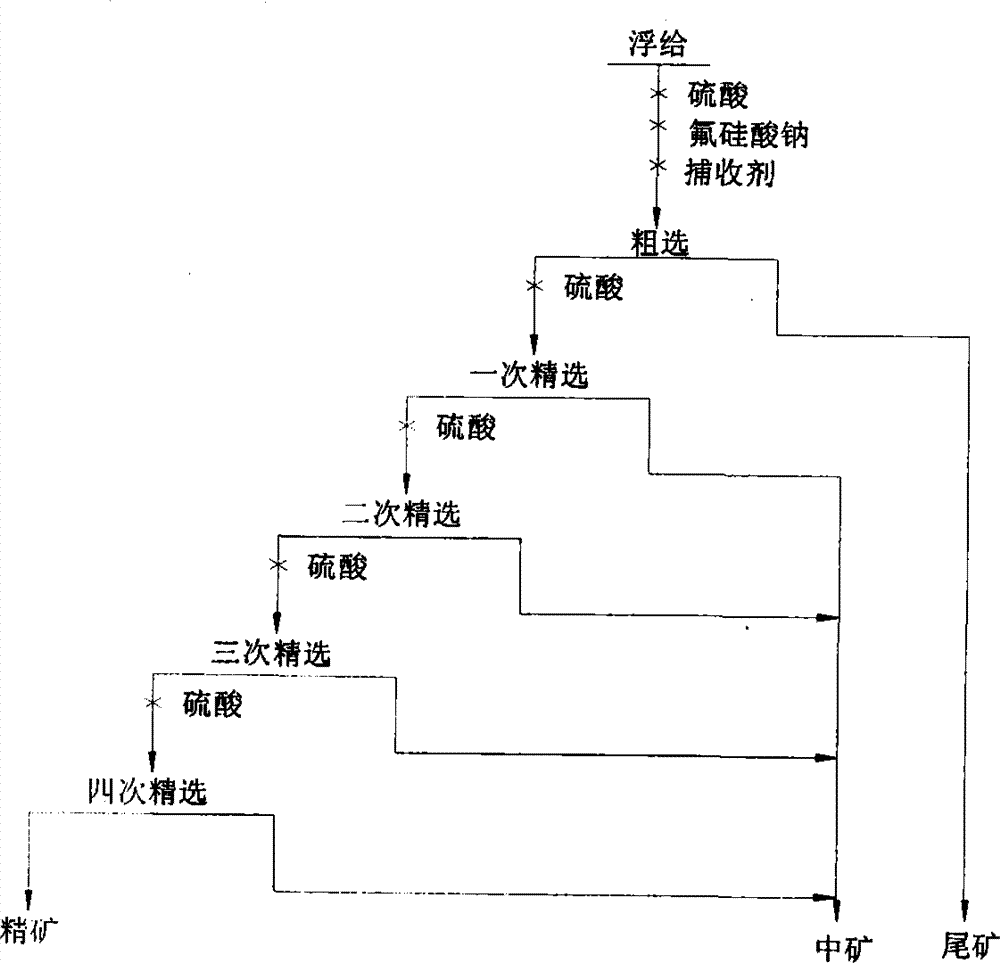

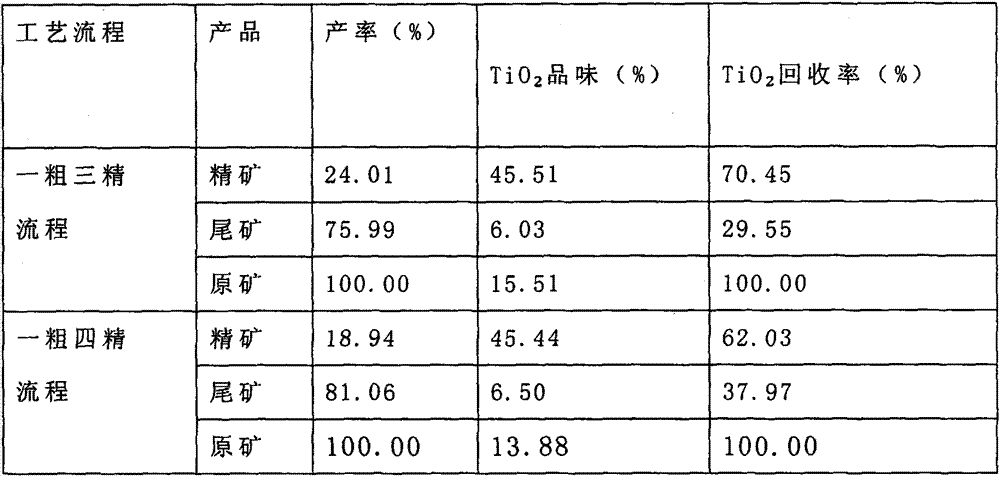

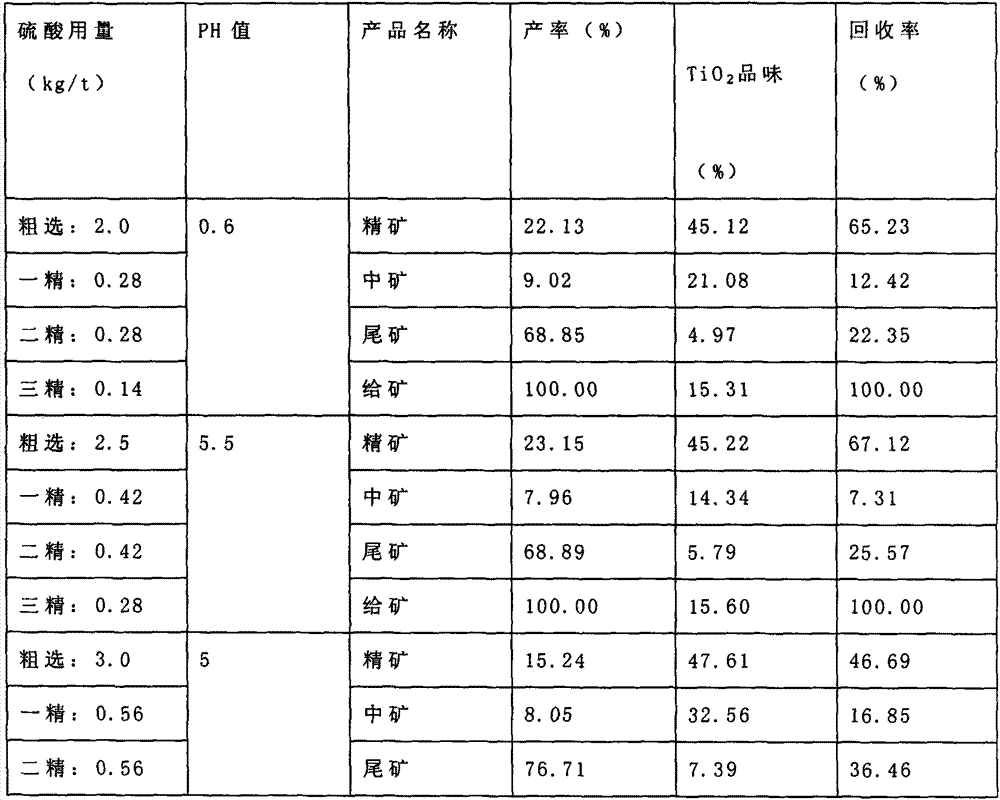

Preparation method for titanic iron ore floatation collecting agent

The invention discloses a preparation method for a titanic iron ore floatation collecting agent. The preparation method includes the following steps that vacuum gas oil No.5 dewaxing oil serves as raw oil; a fuming sulphuric acid solution serves as a sulfonating agent, and sulfonating reaction is performed on the raw oil and the sulfonating agent to obtain a sulfonated product; an NaOH solution is used for performing primary saponification on the sulfonated product to obtain sulfonate; the prepared sulfonate, soybean oleic acid and styryl phosphonic acid are compounded to be a mixture; secondary saponification is performed on the mixture after compounding through NaOH solution to obtain the anionic collecting agent. Compared with an existing titanium concentration collecting agent, the prepared titanic iron ore floatation collecting agent is simple in floatation agent rule, small in usage quantity of agents, excellent in floatation index and good in low-temperature floatation performance; the main components of the collecting agent are sulfonic acid and fatty acid, so that the collecting agent is small in influence on the environment and is a green product.

Owner:THE ZHANGJIAKOU KAISHENG BENEFICIATION PHARMACY

Silicon block cutting method

InactiveCN102350741AImprove cutting abilityImprove cutting efficiencyFine working devicesHardnessCooling fluid

The embodiment of the invention discloses a silicon block cutting method which comprises the following steps: driving a cooling fluid into a mortar jar; sequentially winding a diamond steel wire on a pulley and a guide pulley to knit a wire mesh; putting a silicon block on a machine tool, and setting a machine tool zero point and technological parameters in the silicon block cutting process; and cutting the silicon block by using the diamond steel wire. In the cutting method disclosed by the invention, the diamond steel wire is knitted into the wire mesh, and the wire mesh is used for cutting the silicon block, thereby replacing the method for cutting a silicon block by driving mortar with a steel wire in the prior art. Since the diamond grains have high hardness and strong cutting power, the cutting power of the diamond steel wire is stronger than that of the mortar-carrying steel wire, thereby greatly enhancing the cutting efficiency of the silicon block, increasing the cutting speed of the silicon block and lowering the cutting cost.

Owner:YINGLI ENERGY CHINA

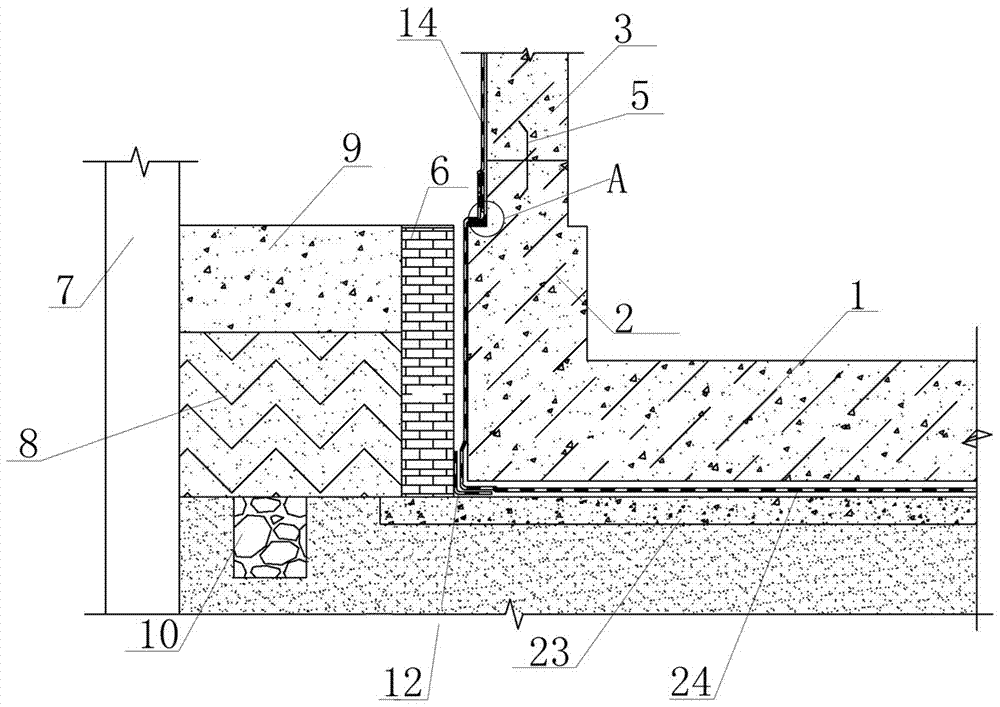

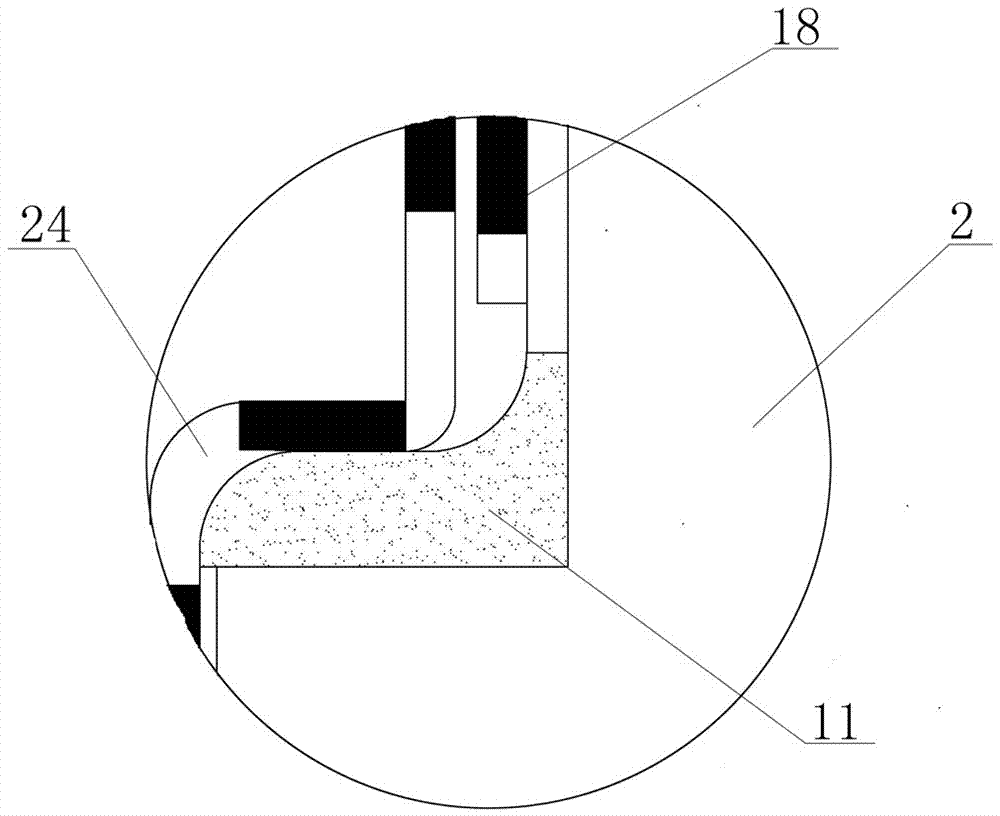

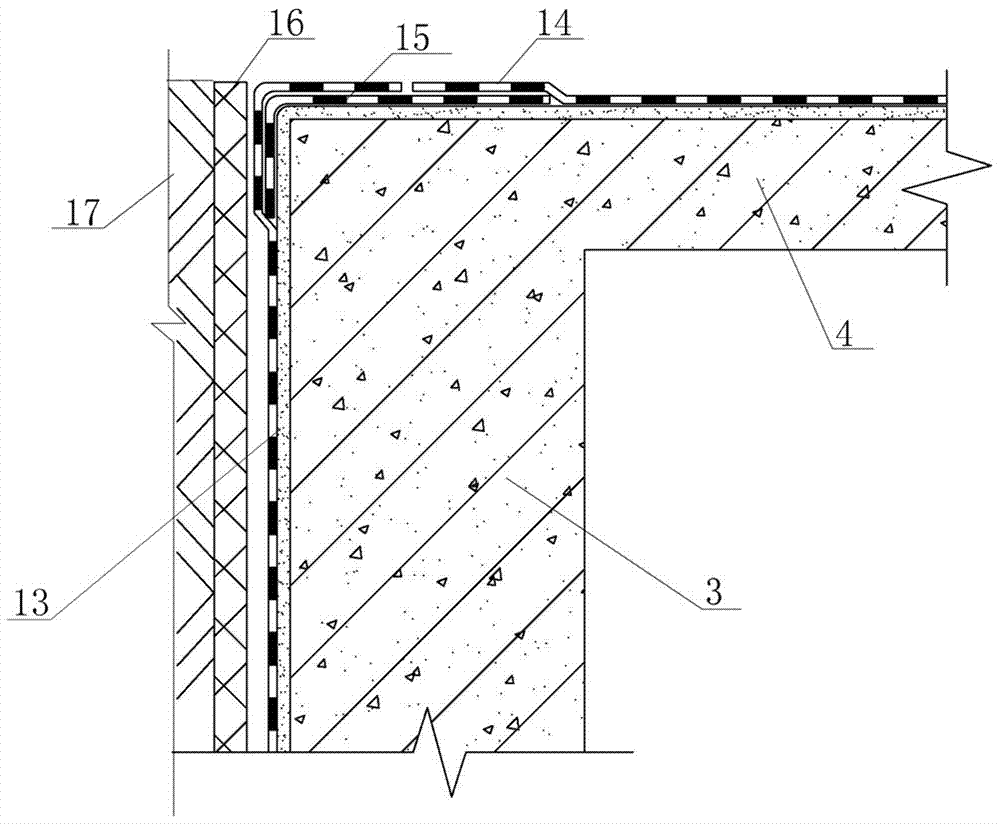

Basement water-proof structure and construction method for basement outer wall water-proof structure thereof

PendingCN107190783AImprove the weak bondEffective waterproof barrierProtective foundationGasketsBasementEconomic benefits

Provided are a basement water-proof structure and a construction method for a basement outer wall water-proof structure thereof. A basement comprises a basic bottom plate, a basement wall body and a basement top plate. Wall bushings are formed in the basement wall body. The basement wall body comprises a guiding wall and a basement outer wall. Construction joints between the guiding wall and the basement outer wall are connected and fixed through water-stop steel plates. A concrete gel layer and a cross film water-proof layer are arranged at the periphery, from inside to outside in sequence, of the basement outer wall and the basement top plate. A second additional cross film water-proof layer is arranged in the portion, located at the inside corner position between the wall bushings and the basement wall body, of the cross film water-proof layer. The tail ends of the cross film water-proof layer and the second additional cross film water-proof layer are fixed to the wall bushings through metal hoops, and are sealed by applying polyurethane. The basement water-proof structure and the construction method for the basement outer wall water-proof structure have the characteristics of being safe and applicable, have good popularization and use value, and can generate good economic benefits after being widely popularized and applied.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Annealing process of martensitic stainless steel cold-rolled strip steel for tool

InactiveCN107674946ASmall footprintEasy to operateProcess efficiency improvementRough surfaceProduction line

The invention discloses an annealing process of martensitic stainless steel cold-rolled strip steel for a tool, and belongs to the technical field of stainless steel machining. The problems that according to existing processes, strip breaking and oxidization are prone to occurring, oxide skins are uneven, the phenomena of oxidized residues, poor pickling, color difference and rough surfaces are prone to occurring, annealing raw materials pollute the environment and are high in cost, moreover, equipment is complex, the production line is long, and scratching is prone to occurring are solved. The annealing process comprises the following steps of raw material hot rolling, hot rolling annealing, hot line pickling, rolling, bell type annealing, and cutting and packaging. According to the annealing process, compared with common 2D production equipment, a bell type annealing furnace is simple in equipment, small in occupied area, low in equipment cost and easy to operate, a production methodis simple and easy to implement, manufactured strip steel is bright in surface, high in plasticity, toughness and quenching hardness, slitting machining, forming machining, surface machining and surface grinding are facilitated, and the tool with a small specification can be rolled and produced conveniently.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Refining method of raw material gas containing ethene in process of preparing ethylbenzene from ethene

InactiveCN101659590AEasy to implementSimple processGaseous fuelsLiquid carbonaceous fuelsEthyleneChemistry

The invention discloses a refining method of raw material gas containing ethene in the process of preparing ethylbenzene from ethene, comprising the steps: raw material gas containing ethene and dilute ethene gas returned by a catalytic cracking or splitting device are mixed or respectively enter from the lower part of an absorbing device, are contacted with an absorbent entering from the upper part of the absorbing device for refining, the refined raw material gas enters a reaction part of an ethylbenzene device to react with benzene to prepare the ethylbenzene, the saturated absorbent is desorbed and then recycled, and desorbed gas enters a catalytic cracking or catalytic splitting device. The method has simple flow, low investment and favorable refining effect, and ensures that the unreacted rate of propylene is as high as 98.1-99.9 percent.

Owner:CHINA PETROCHEMICAL CORP +1

Agaricus bisporus film-free preservative and use thereof

InactiveCN102177960ANo pollution in the processChange colorFruit and vegetables preservationVitamin CAdditive ingredient

The invention discloses an agaricus bisporus film-free preservative and use thereof. The agaricus bisporus film-free preservative is an aqueous solution of the following components in percentage by mass: 1.2 to 2.5 percent of low-molecular-weight(1,000 to 3,000) chitosan oligosaccharide, 0.4 to 0.6 percent of citric acid, 0.4 to 0.6 percent of sodium chloride, 0.2 to 0.3 percent of vitamin C, 0.0001 to 0.0003 percent of cysteine. Compared with the agaricus bisporus preservative in the prior art, the agaricus bisporus film-free preservative disclosed by the invention has the prominent advantages that: the edible low-molecular-weight chitosan oligosaccharide is used as a main ingredient; film is not formed; color is not changed; the operation is convenient; the shelf period can be prolonged by 3 to 5 days at normal temperature (25 DEG C) and by 15 to 20 days at a low temperature (5 DEG C); and the preservative is edible, pollution-free, environment-friendly and low in cost.

Owner:LIANYUNGANG ACAD OF AGRI SCI

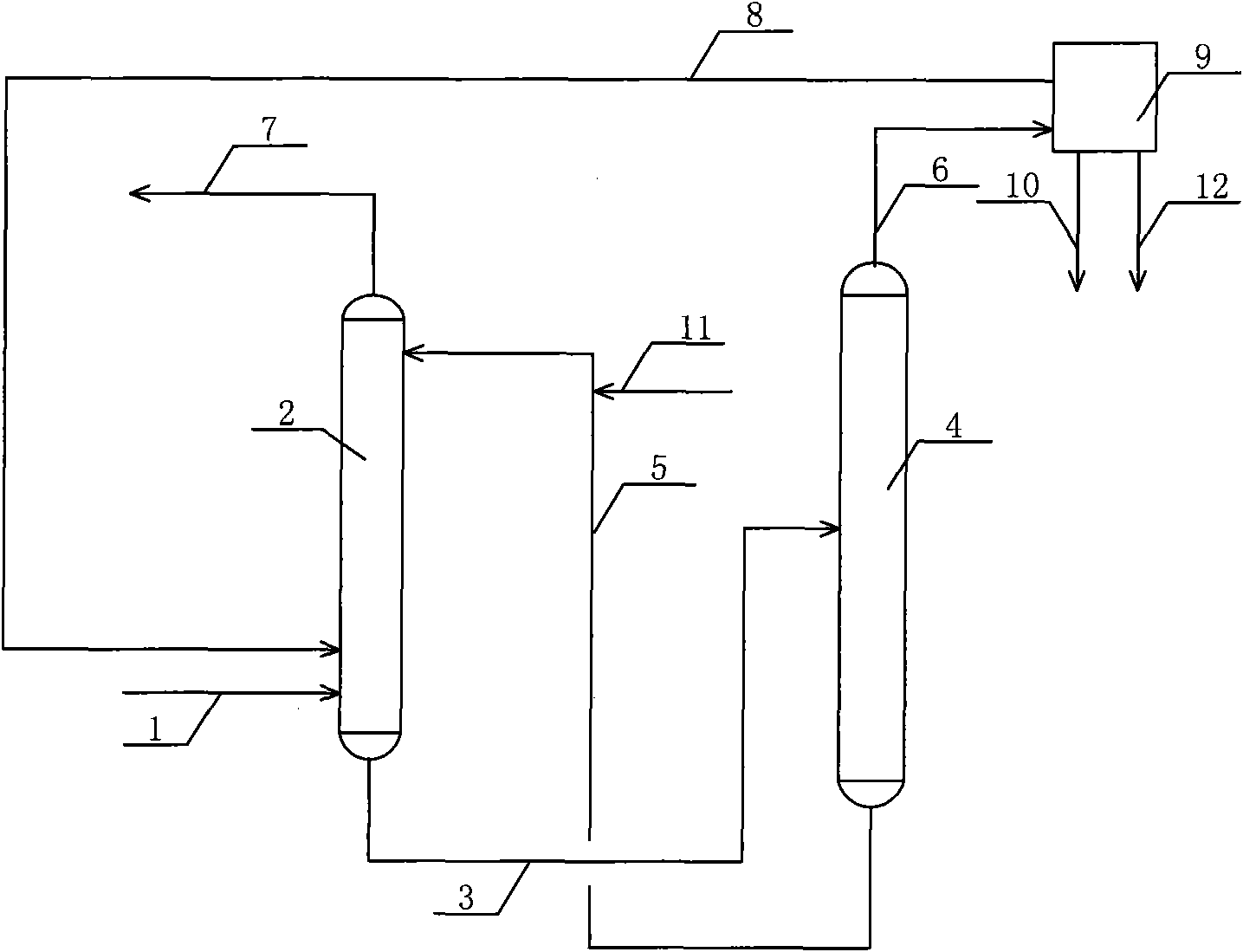

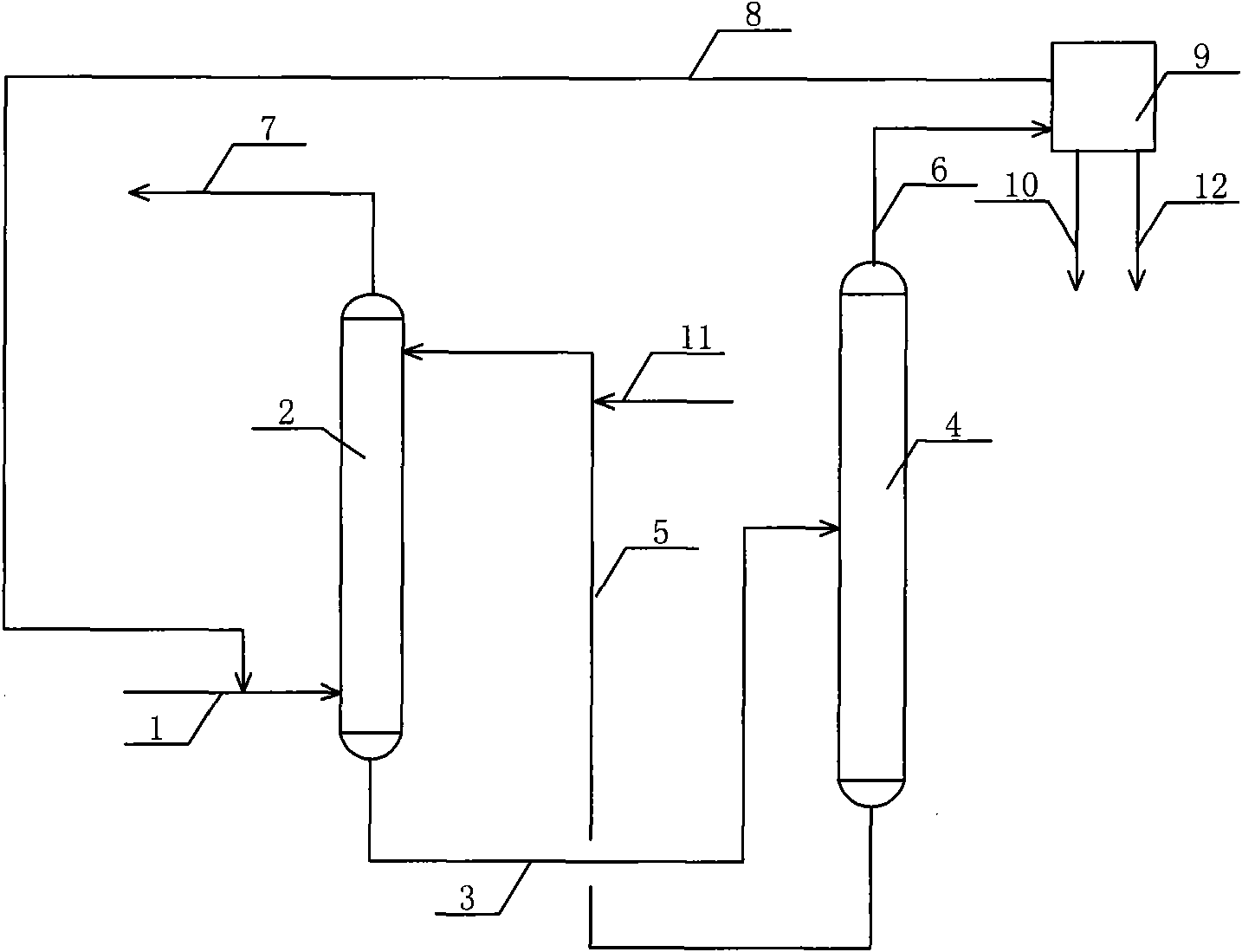

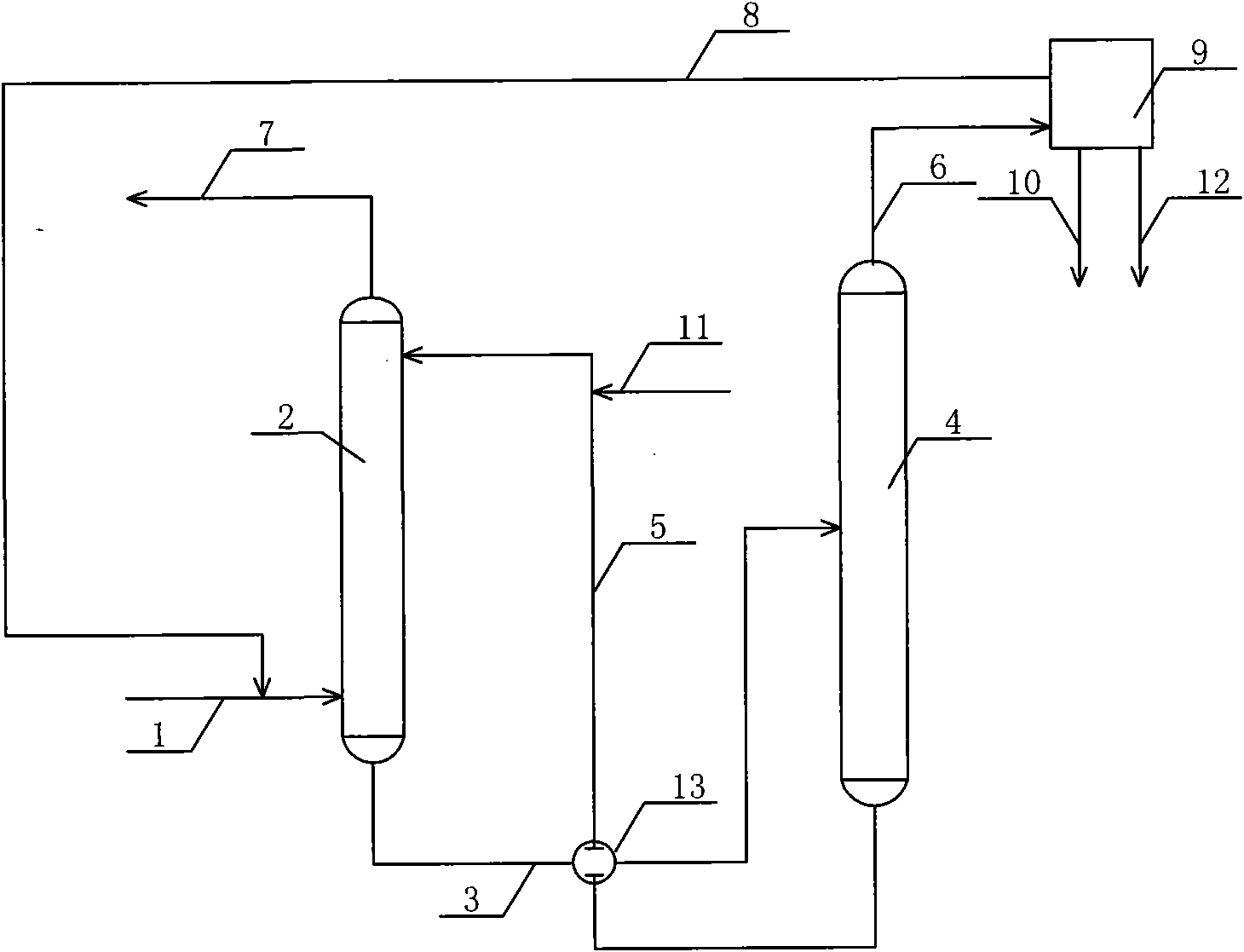

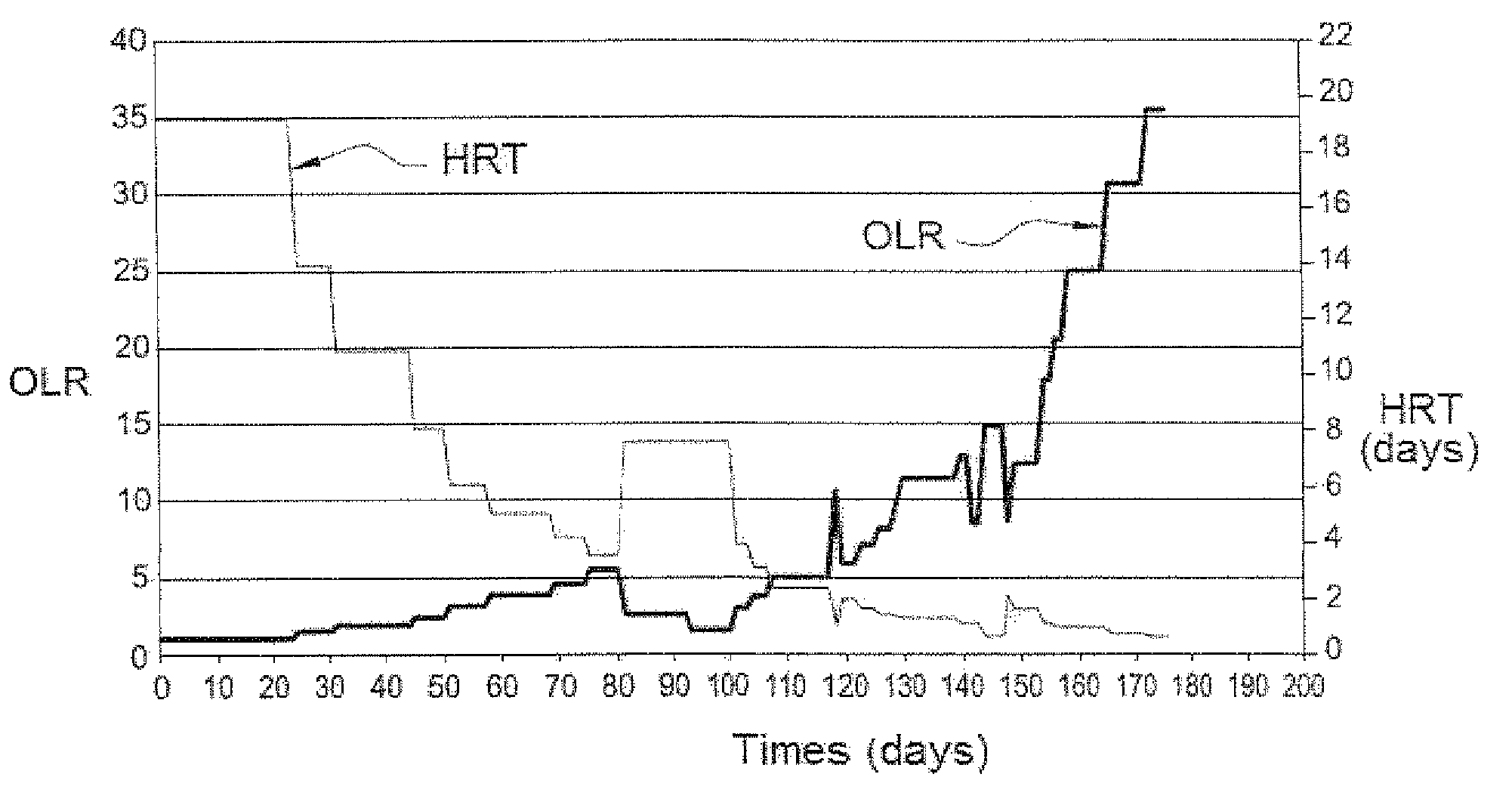

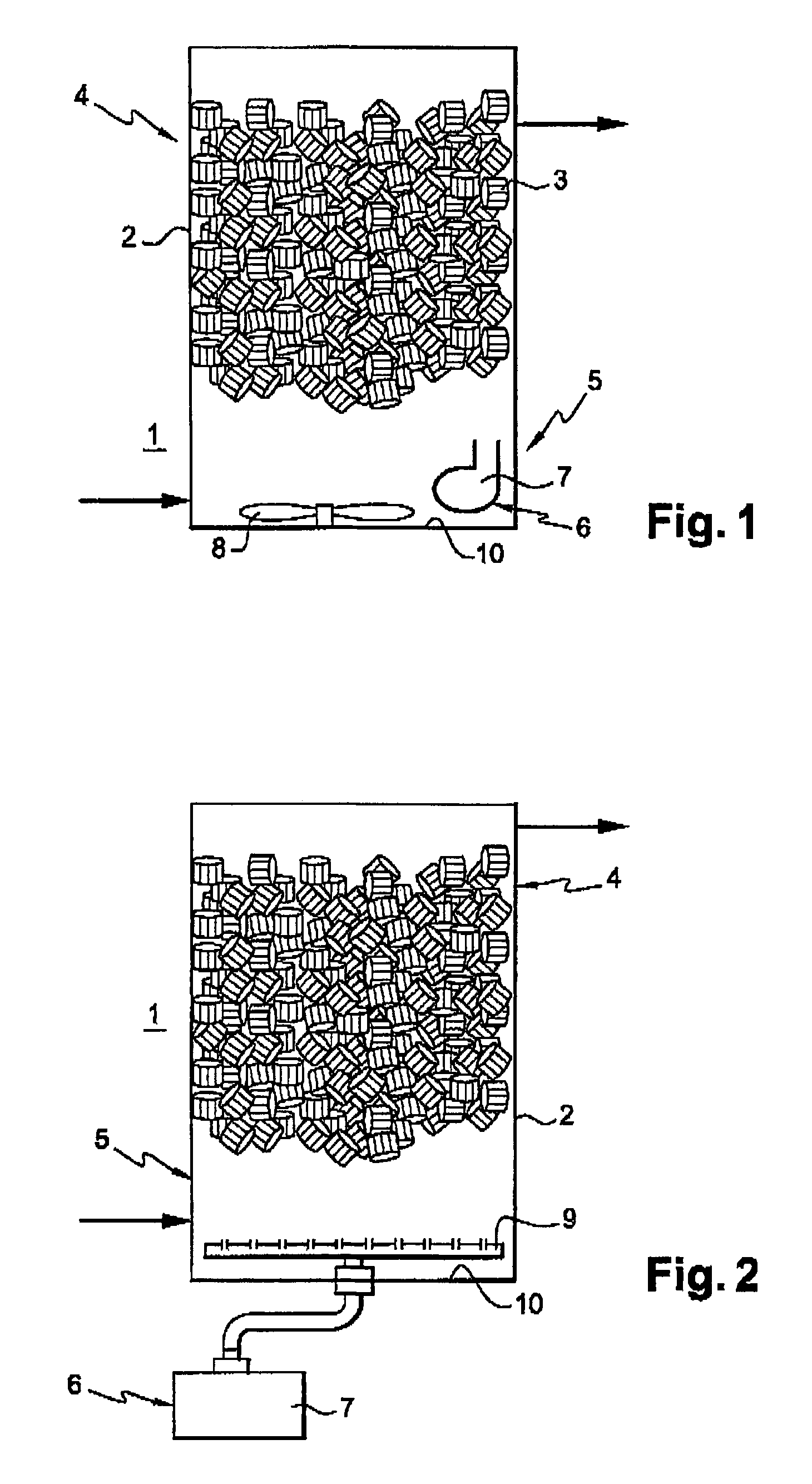

Method for purifying effluent in an anaerobic reactor

InactiveUS7670489B2Big pollutionRaise the level of performanceWaste based fuelTreatment with anaerobic digestion processesProcess engineeringAnaerobic reactor

The invention relates to a method for purifying effluents in an anaerobic reactor (1) in which the micro-organisms are held by supports, the supports forming a bed which is fixed in a part (4, 5) of the reactor. The inventive method is characterized in that it includes a step wherein the reactor is backwashed once it has been at least partially clogged, by temporarily suspending the supports. Advantageously, the method includes an initial step for starting the reactor, during which the load of the reactor is increased with a short and constant hydraulic residence time.

Owner:INSTITUT NATIONAL DE LA RECHERCHE AGRONOMIQUE

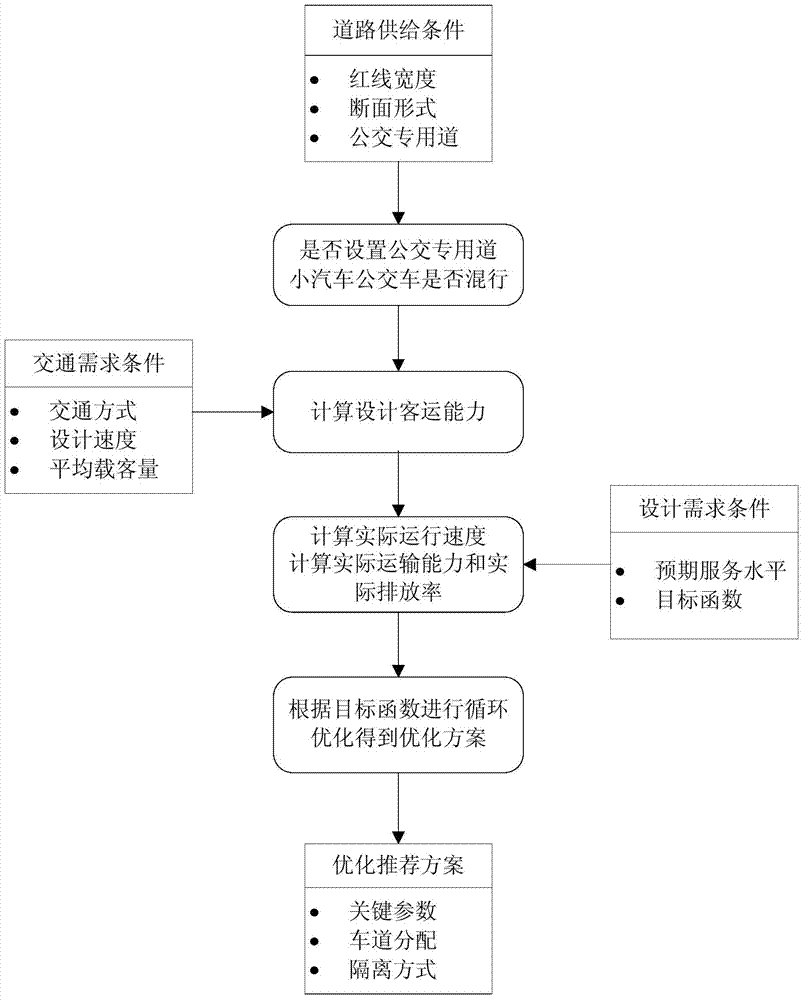

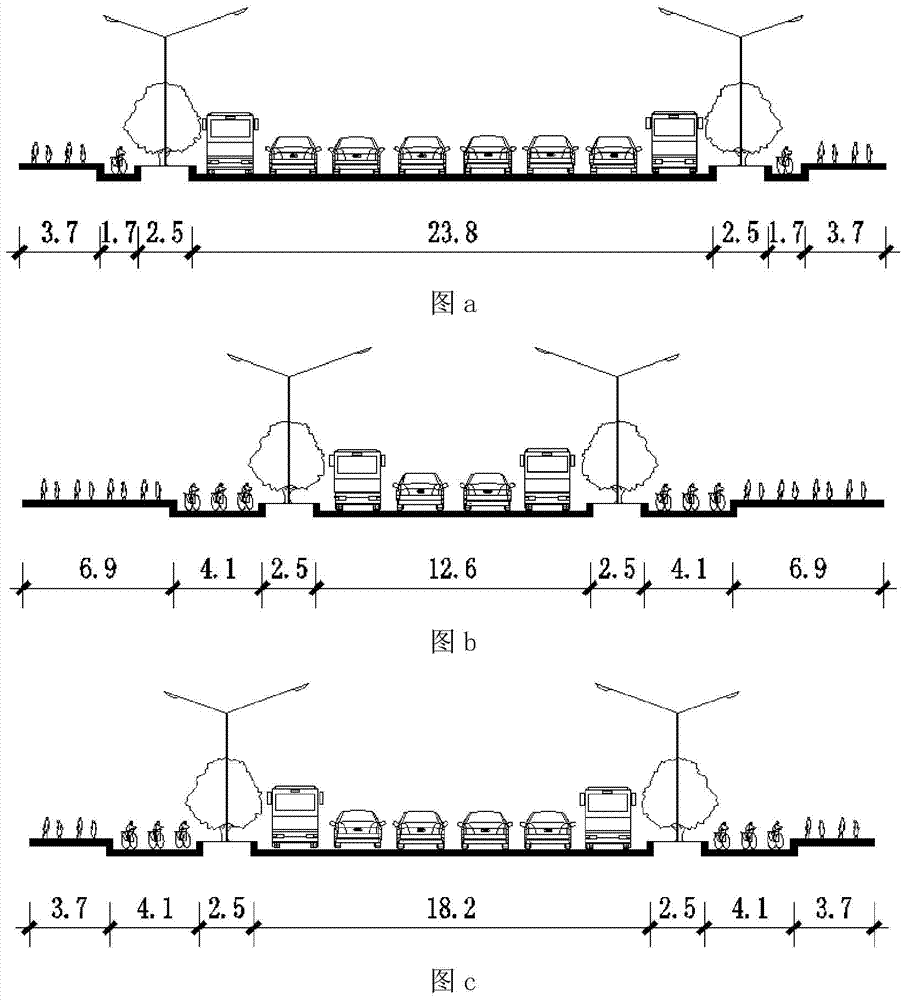

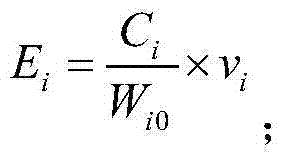

Multimode city road cross section resource coordinated configuration method

ActiveCN104778832ABig pollutionImprove Passenger Transport EfficiencyRoad vehicles traffic controlForecastingBus laneTraffic conditions

The invention discloses a multimode city road cross section resource coordinated configuration method. The method includes the steps that firstly, whether a bus-only lane is set and what cross section form is adopted are determined according to set red line width and design requirements; then, road supply conditions of motor vehicles are determined, whether mixing of cars and buses occurs and the width of each motor way are determined, traffic conditions are determined, the passenger transport efficiency and emission rate of each transport means per standard unit width are determined again, and then an objective function with the highest cross section passenger transport efficiency and the smallest emission rate and corresponding constraint conditions are established; finally, the objective function is solved to obtain key parameters in the optimization process and a cross section resource allocation result. Under the road conditions and traffic conditions of the set red line width, a cross section layout design scheme achieving the high road cross section passenger transport capacity and the small emission quantity can be provided.

Owner:SOUTHEAST UNIV

Wall cement laying equipment used in construction site

The invention relates to cement laying equipment, in particular to cement laying equipment used in a construction site. The cement laying equipment achieves the purposes that the cement sheds little when laid, the laying process saves both time and labor, dangerousness to a worker is small and the contamination of the clothes of the worker is small. The cement laying equipment comprises a base plate, a first supporting leg, an electric wire winding wheel, a guide rail, a second supporting leg, a fixed pulley, a guide sleeve, a pulling line, a placing board, a third supporting leg, a driving wheel, a driven wheel and the like. The upper side of the base plate is provided with the first supporting leg in a welding mode, and the electric wire winding wheel is rotatably connected to the first supporting leg. According to the wall cement laying equipment used in the construction site, the effects that the cement sheds little when laid, the laying process saves both time and labor, dangerousness to the worker is small and the contamination of the clothes of the worker is small are achieved.

Owner:广东龙越建筑工程有限公司

Nanofiber membrane with heavy metal adsorbing function and preparation method of nanofiber membrane

InactiveCN104587981ASimple processLow costOther chemical processesWater contaminantsSorbentNanofiber

The invention relates to a nanofiber membrane with a heavy metal adsorbing function and a preparation method of the nanofiber membrane. The nanofiber membrane comprises a matrix and macromolecules self-assembled on the surface of the matrix. The preparation method comprises the following step: self-assembling the macromolecules carrying amino groups on a thermoplastic nanofiber membrane by virtue of a chemical oxidative polymerization method to obtain the nanofiber membrane. The nanofiber membrane is simple in preparation process and low in cost, and is capable of efficiently adsorbing heavy metal ions; the defect that a conventional heavy metal ion adsorbing agent requires to be separated for the second time is avoided; the effective removal of hexavalent chromium ions is realized by using a principle of first adsorption and then reduction; meanwhile, the macromolecules have a strong hydrogen bond function among hydrophilic nanofiber membranes, cannot drop from the membranes, and can be recycled.

Owner:DONGHUA UNIV

Method for recovering alkali and organic substance from pomace and waste liquid

InactiveCN1450227ADischarge volume reductionReduce total pollutionRegeneration of alkali lyeLiquid wasteAdditional values

The method for covering alkali and organic substance from pulp waste liquor includes the following steps: under the condition of that temp. is 20-60 deg.c and pressure is 1.5-3.0 MPa the pulp waste liquor is passed through the fixed membrane separation system to make separation to obtain the trapped liquor in which the concentration of organic substance is 90g / l and transmitted liquor containing sodium hydroxide, said transmitted liquor containing sodium hydroxide can be recovered, and can be used in pulp production, and the described trapped liquor containing organic substance can be evaporated and concentrated, and can be used for preparing products with high additional value after it is treated by means of modification process.

Owner:凯能高科技工程(上海)有限公司

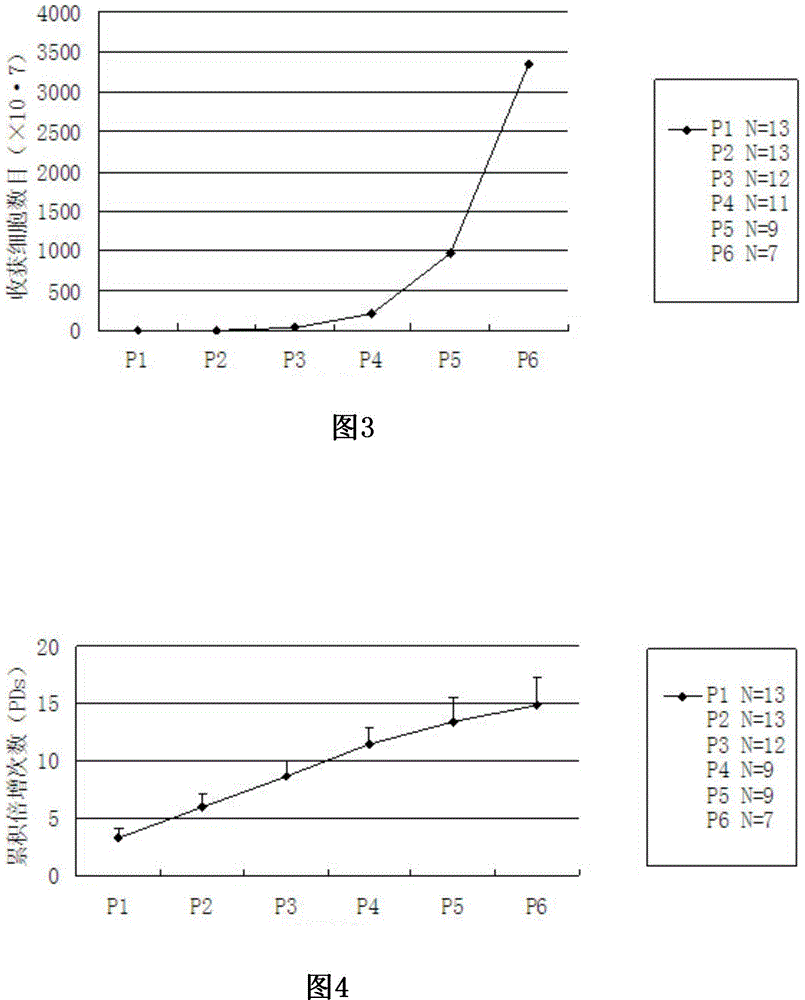

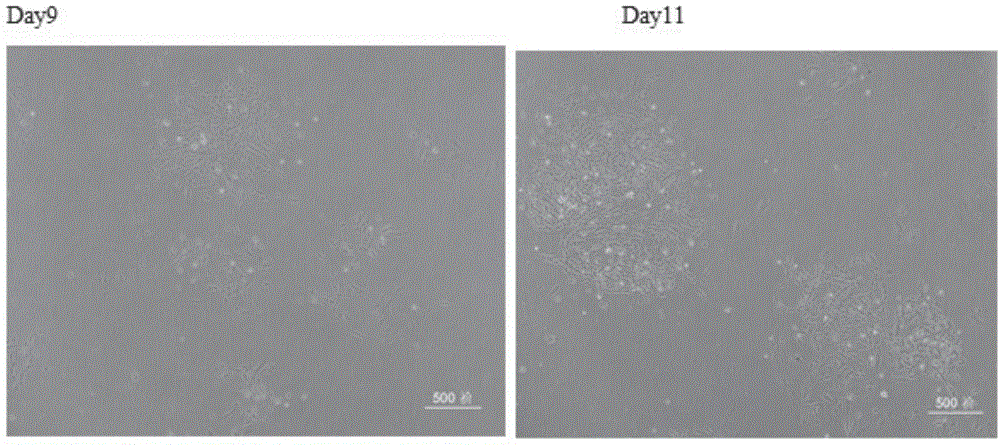

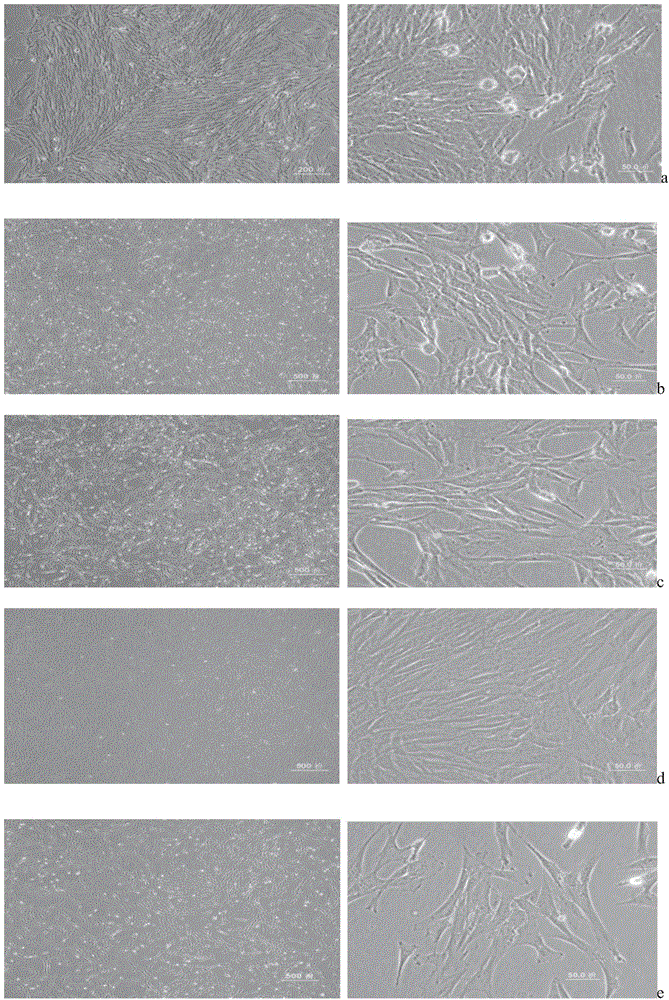

In-vitro separation and cultivation method for tooth-sourced mesenchymal stem cells

InactiveCN104560872ASolve the problem of prone to agingSingle ingredientSkeletal/connective tissue cellsSingle cell suspensionCell mass

The invention discloses an in-vitro separation and cultivation method for tooth-sourced mesenchymal stem cells. The in-vitro separation and cultivation method comprises the following steps: (A), gingiva on a tooth surface and surrounding tissue are scraped off, and the tooth is stored in tooth preserving fluid; (B), a culture solution is added to a centrifuge tube, dental pulp is collected to the centrifuge tube and cut into pieces by scissors; (C), collagenase type I and dispase are added to digest dental pulp tissue; (D), single-cell suspension is prepared; (E), the obtained single cell is subjected to primary culture, and the planting density of primary cells is (1-5)*10<4> / cm<2>; and (F), the cells are subjected to subculturing. The tooth is crushed with a physical method to obtain the dental pulp tissue, the collagenase type I and the dispase are used for digestion, the single-cell suspension is obtained, primary planting and culturing are performed for 10-15 days, and then passage is performed; and the problems that the primary cells are mixed with other components of the tooth and aging occurs probably in a cell mass culture process are solved effectively.

Owner:SHENZHEN BEIKE BIOTECH

Methylamino emamectin benzoate dispersible oil-based suspension and preparation method thereof

ActiveCN102805086ANot easy to decomposeEasy to useBiocideAnimal repellantsEmamectin benzoateSuspending Agents

The invention discloses methylamino emamectin benzoate dispersible oil-based suspension and a preparation method thereof. The methylamino emamectin benzoate dispersible oil-based suspension comprises, by weight percent, 0.5-30% of methylamino emamectin benzoate, 0.5-30% of thickener, 10-12% of emulsifier, 2-8% of dispersant and the like, 0.1-3% of stabilizer, and the balance of vegetable oil. The preparation method includes mixing well the components proportionally, and using a sand mill for sanding to make the dispersible oil-based suspension. The methylamino emamectin benzoate dispersible oil-based suspension is environment-friendly. The vegetable oil is used as the dispersant, so that the suspension is high in viscosity and permeability, resistant to rain wash and long in duration. The vegetable oil has synergistic effect for the methylamino emamectin benzoate, the effect of the methylamino emamectin benzoate is given to full play, and usage of effective ingredients is reduced. The invention belongs to the technical field of processing of chemical pesticide preparations.

Owner:SHANDONG LVBANG CROP SCI CO LTD

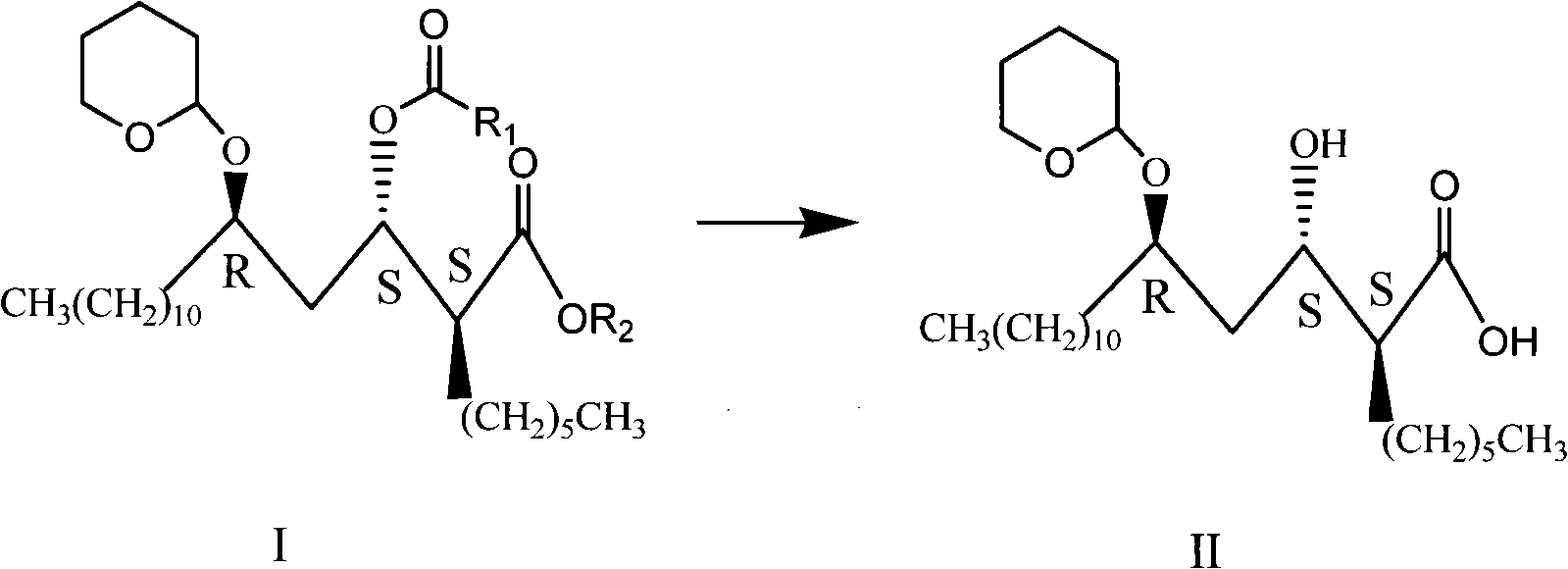

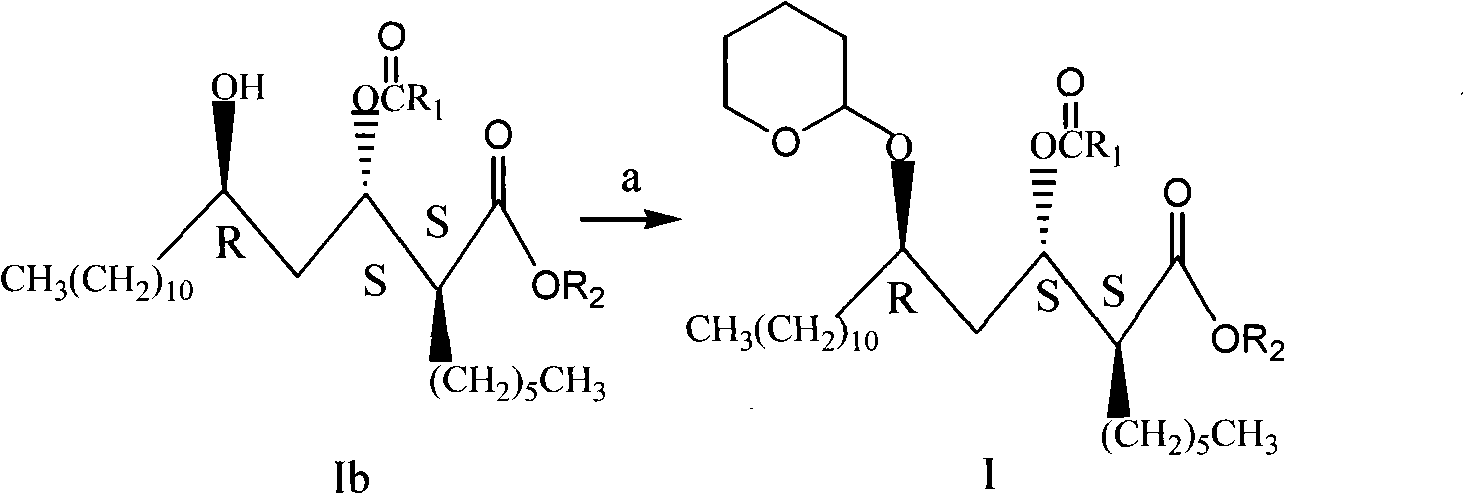

Novel method for synthesizing orlistat, intermediate compound and preparation thereof

ActiveCN101348475ABig pollutionHigh optical purityOrganic chemistryBulk chemical productionSynthesis methodsProcess conditions

The invention discloses a novel method for synthesizing Orlistat, as well as a novel intermediate compound to which the method relates, i.e. the compound shown in formula (I), wherein the definition of R1 or R2 is detailed in the instruction. The invention also discloses the method for preparing the intermediate compound. The synthesis method disclosed by the invention has cheap and easily available raw material, mild technological condition, simple post treatment, the obtained product with high photic purity, and the whole technology highly is suitable for industrialized production.

Owner:ZEIN BIOTECHNOLOGY CO LTD

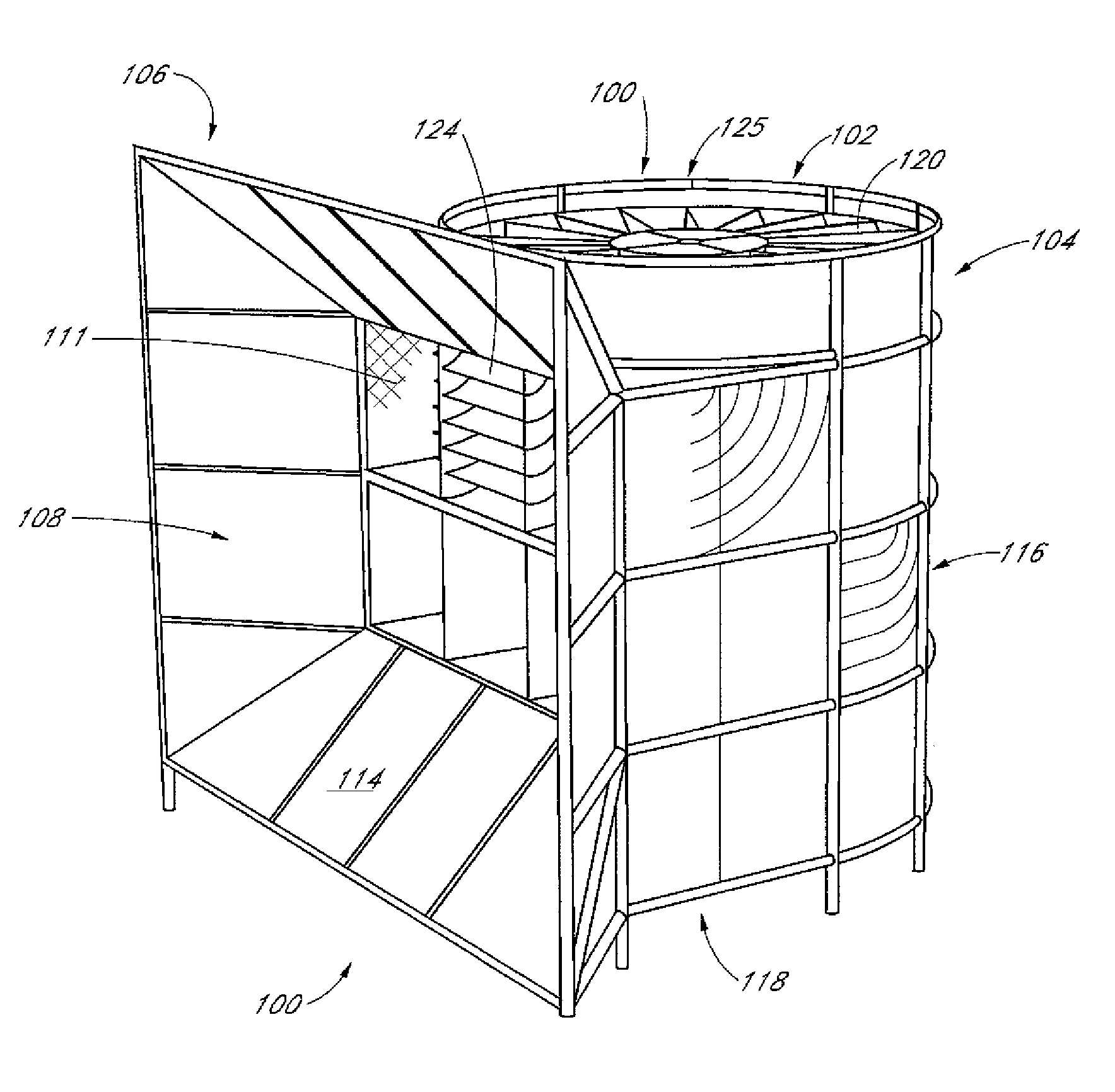

Wind turbine with channels and roof air exhaust

ActiveUS9013054B1Increase wind speedLittle and no noise pollutionWind motor assemblyMachines/enginesKnife bladesTurbine

This wind turbine is enclosed in a housing structure with a bell shaped opening and a stack effect created on the roof. One side of the housing, facing the wind, opens up to receive air. The air that enters the housing is divided into multiple chambers. The chambers and turning vanes guide the air directly to the blades and help in minimizing air turbulence. The blades are angled to receive the maximum amount of the air. The air rotates the blades turning the rotor, converting mechanical rotation into electrical power. There is a horizontal rotor attached to vertical shaft which is used to generate electrical energy. The stack effect on the roof creates a negative air flow aiding in turning the rotor.

Owner:BX POWER

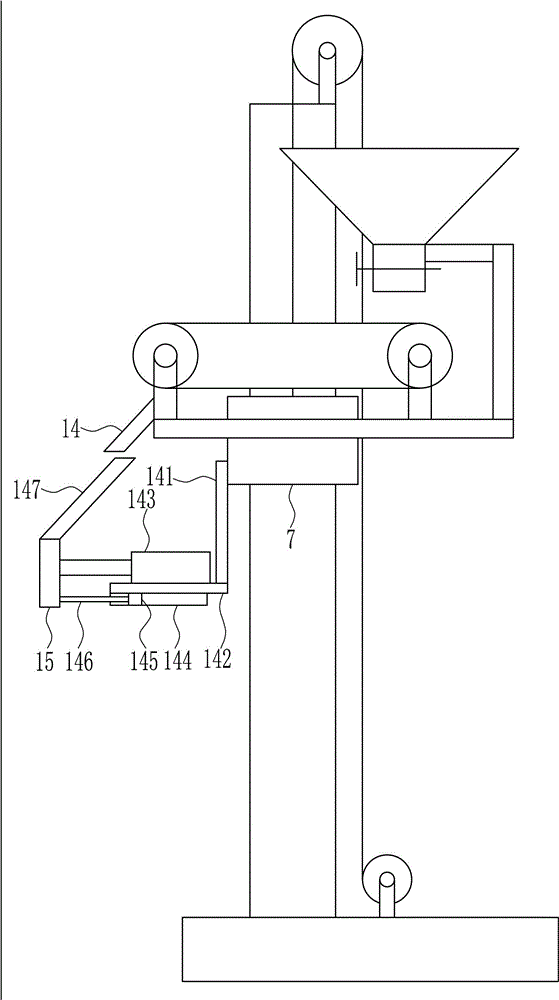

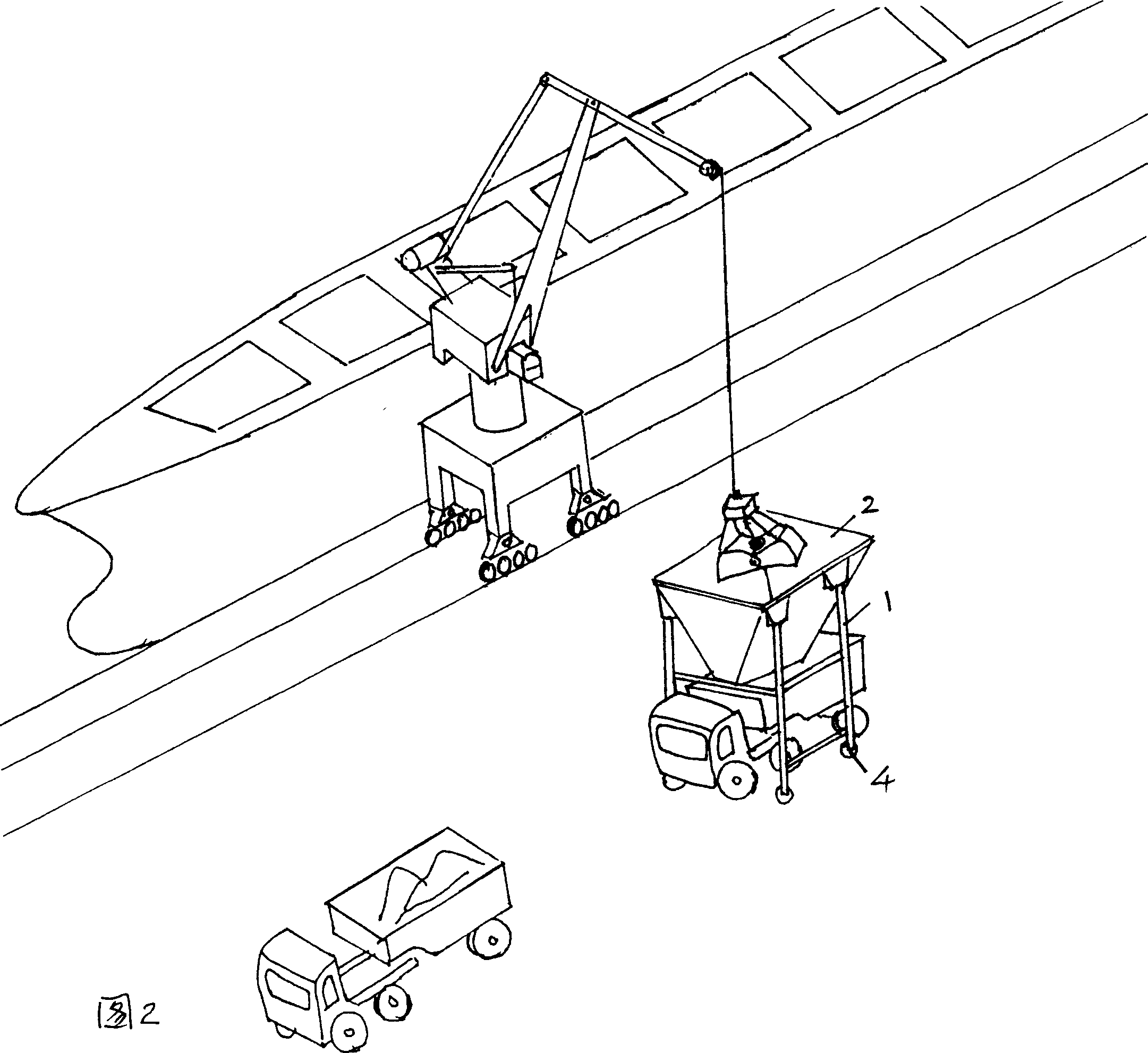

Technical method and facilites for loading and unloading goods at berth in hundred thousand tunnage

InactiveCN1498834AEasy to operateEliminates the need for stockpiling in the dock front yardLarge containersTrolley cranesQuality of workTruck

A loading and unloading method for the one hundred thousands tons class of dock features that the cargo is transported from ship's cabin into a greater hopper with guide plate at its lower opening by the grab bucket of greater hoist, and then loaded in a truck under said greater hopper. Its apparatus is composed of a 4-column supporting frame, and a greater hopper installed on said supporting frame. Its advantages are high efficiency and quality of unloading and loading and less loss.

Owner:天津港第五港埠有限公司

Composition for detecting hot-spot mutation gene of lung cancer and application method thereof

ActiveCN104152551AStrong specificityHigh sensitivityMicrobiological testing/measurementDNA/RNA fragmentationCurative effectTherapeutic effect

The invention discloses a composition for detecting a hot-spot mutation gene of a lung cancer. The composition comprises primer sequences in SEQ NO:1 to SEQ NO:53, and block sequences in SEQ NO:54 to SEQ NO:63. The detection method for lung cancer-related mutation has the advantages of strong specificity, high sensitivity, small pollution, simplicity and rapidity of operation, high safety and the like, the detection result has good accuracy and repeatability, and the detection method is especially suitable for detection of hot-spot mutation of a lung cancer driver gene from body fluid such as plasma, is capable of noninvasively carrying out diagnosis, recurrence monitoring and therapeutic effect evaluation on a patient with the lung cancer in real time, and has an important value.

Owner:JIANGSU MICRODIAG BIOMEDICINE TECH CO LTD

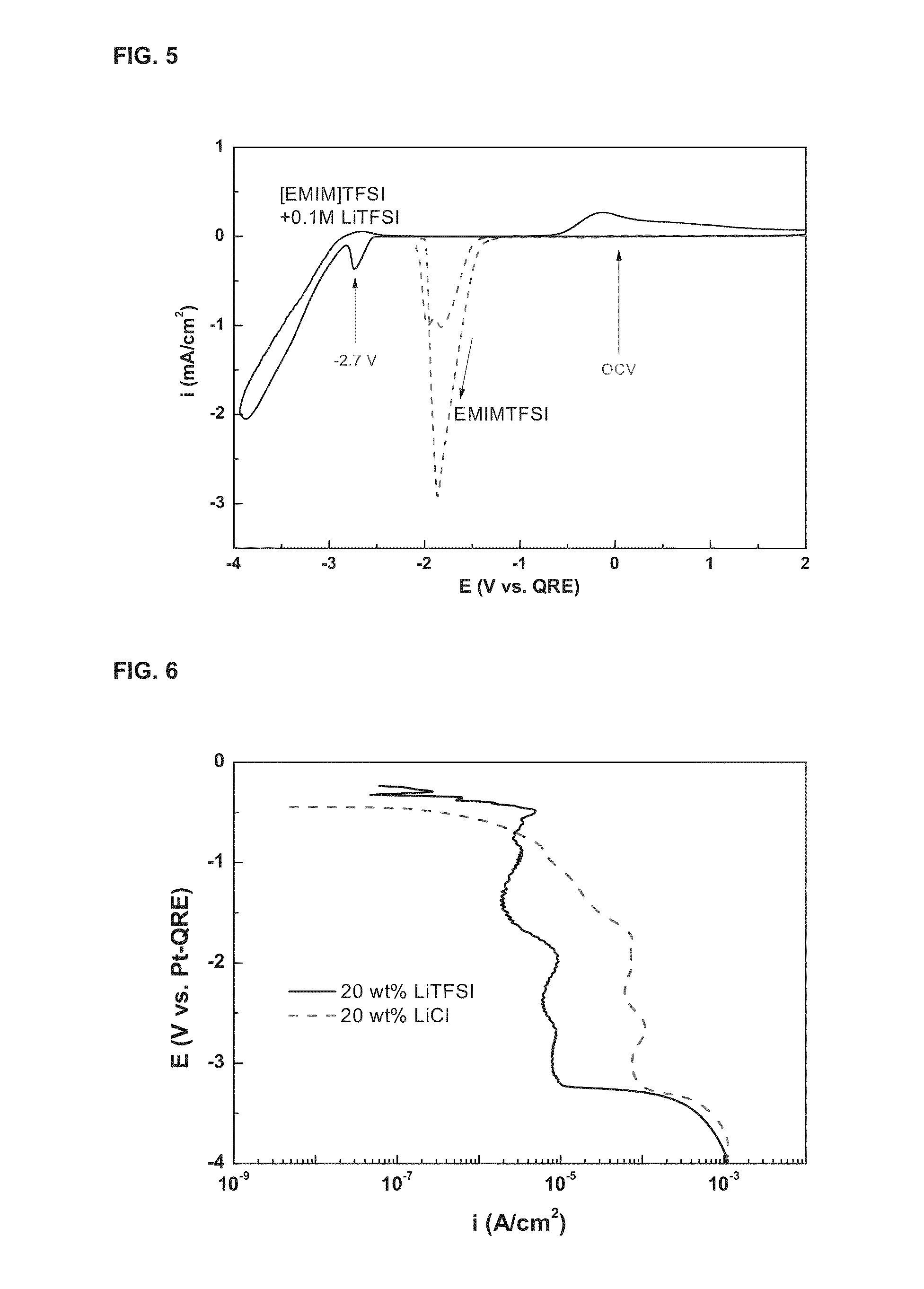

Method for preparing metallic lithium using electrolysis in non-aqueous electrolyte

InactiveUS20140147330A1Improve efficiencyImprove stabilityManufacturing cost reductionMetallic lithium

The present invention provides a method for preparing metallic lithium by electrolysis using a non-aqueous electrolyte at low temperature. The method for preparing metallic lithium according to the present invention can directly prepare metallic lithium by electrolysis at a low temperature, and enable mass production, and reduce the manufacturing cost due to its simple process and easy control of electrolytic conditions, and thus the method for preparing lithium thin films according to the present invention can be applied in the industry.

Owner:KUMOH NAT INST OF TECH IND ACADEMIC COOPERATION FOUND

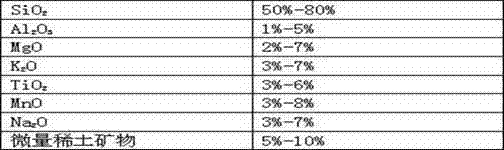

Automobile fuel saving and emission reducing mineral catalyst

InactiveCN103566927AHigh activityBig pollutionLiquid carbonaceous fuelsFuel additivesPtru catalystAir filter

The invention relates to an automobile catalyst and particularly relates to an automobile fuel saving and emission reducing mineral catalyst comprising the following components: SiO2, Al2O3, MgO, K2O, TiO2, MnO, Na2O and trace rare-earth minerals, wherein rear-earth metals contained in the trace rare-earth minerals in the whole catalyst account for 0.01-0.1% of the total weight of a catalytic system. The automobile fuel saving and emission reducing mineral catalyst is an inorganic mineral composition and mainly comprises silicon oxide. The automobile fuel saving and emission reducing mineral catalyst has thermoelectricity and piezoelectricity, can generate charges, release a great number of negative ions and radiation far infrared rays under a convection current condition or when heated, pressurized or excited by other energy, and has a special electromagnetic wave function. The automobile fuel saving and emission reducing mineral catalyst can be placed into an air inlet valve and an air filter, and can be used for improving the activity of an oxygen molecule so that the combustion efficiency is increased.

Owner:黄铂焜 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com