Perovskite solar cell and preparation method thereof

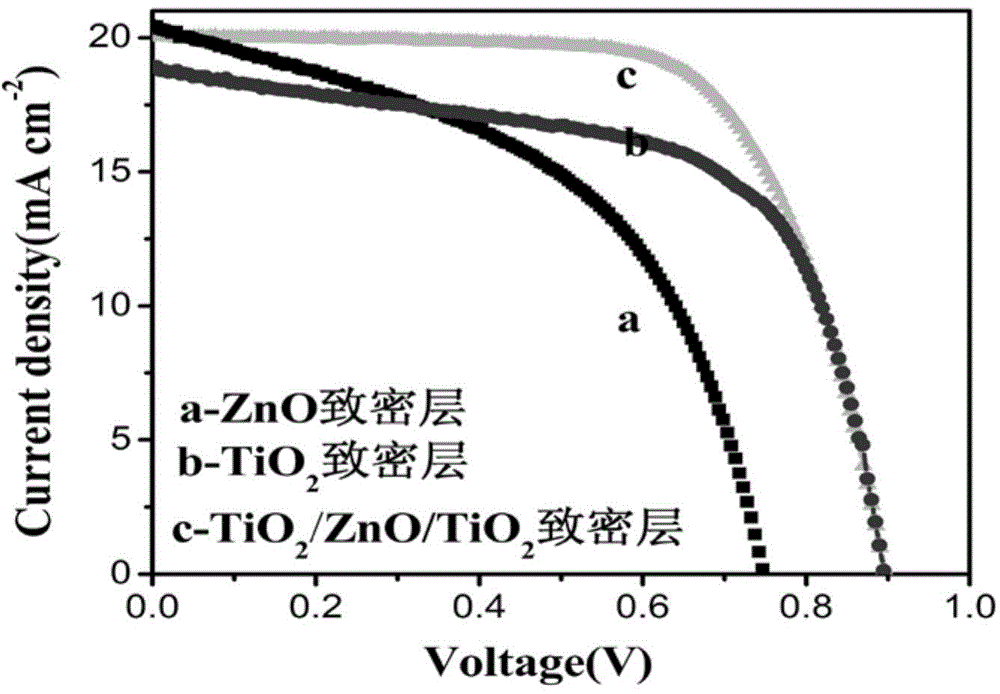

A solar cell and perovskite-type technology, applied in the field of solar cells, can solve the problems of reducing battery performance, insufficient uniformity and density of the film, and increasing electronic recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] Example 1: Preparation of perovskite solar cells

[0101] The implementation steps of this embodiment are as follows:

[0102] A. FTO glass substrate pretreatment

[0103] Use an ultrasonic cleaning machine sold by Kunshan Ultrasonic Instrument Co., Ltd. under the trade name KQ-250E ultrasonic cleaner for ultrasonic cleaning. The surface of the FTO glass is ultrasonically cleaned with deionized water, acetone and alcohol, and then decompressed using a nitrogen cylinder. The self-made connecting device at the outlet of the valve is blown dry with nitrogen, and then uses the ultraviolet light and ozone cleaning machine sold by Novascan Company of the United States under the trade name PSD-UV4 ultraviolet ozone cleaning instrument to perform ultraviolet light and ozone cleaning;

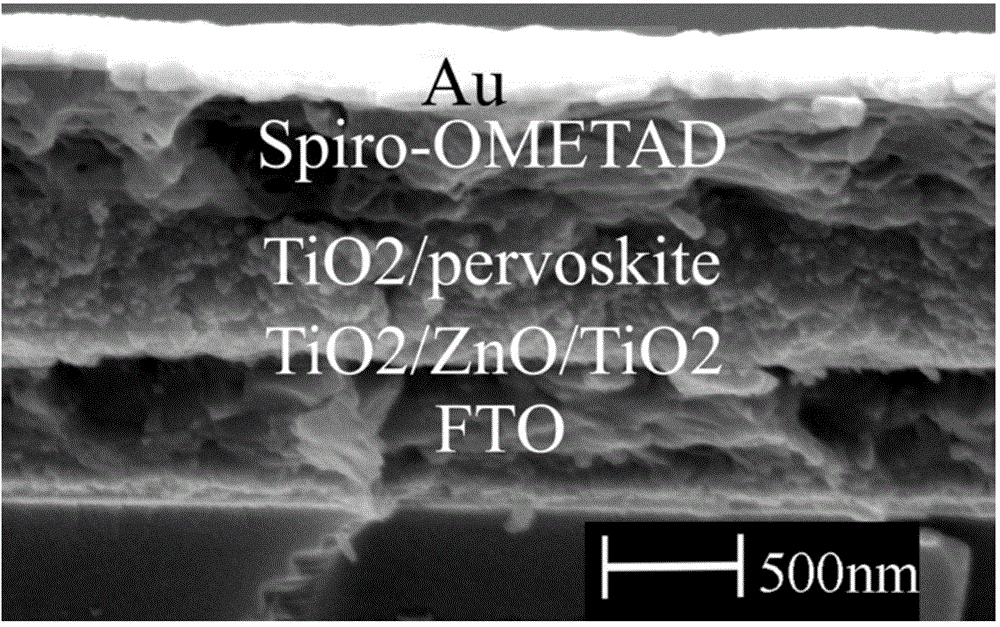

[0104] B. Preparation of Sandwich TiO 2 / ZnO / TiO 2 dense layer

[0105] (i) Preparation of TiO 2 layer

[0106] Use the spin coater sold by the Institute of Microelectronics, Chinese Academ...

Embodiment 2

[0118] Embodiment 2: Preparation of perovskite solar cell

[0119] The implementation steps of this embodiment are as follows:

[0120] A. FTO glass substrate pretreatment

[0121] Using an ultrasonic cleaning machine sold by Kunshan Ultrasonic Instrument Co., Ltd. under the trade name KQ-250E ultrasonic cleaner, the FTO glass surface is ultrasonically cleaned with deionized water, acetone and alcohol, and then the outlet of the pressure reducing valve on the nitrogen cylinder is used to clean the surface of the FTO glass. The self-made connection device is blown dry with nitrogen, and then the ultraviolet light ozone cleaning machine sold by American Novascan Company under the trade name PSD-UV4 type ultraviolet ozone cleaning instrument is used for ultraviolet light ozone cleaning;

[0122] B. Preparation of Sandwich TiO 2 / ZnO / TiO 2 dense layer

[0123] (i) Preparation of TiO 2 layer

[0124] Use the spin coater sold by the Institute of Microelectronics, Chinese Acade...

Embodiment 3

[0136] Embodiment 3: Preparation of perovskite solar cell

[0137] The implementation steps of this embodiment are as follows:

[0138] A. FTO glass substrate pretreatment

[0139] Using an ultrasonic cleaner sold by Kunshan Ultrasonic Instrument Co., Ltd. under the trade name KQ-250E ultrasonic cleaner, the surface of the FTO glass was ultrasonically cleaned with deionized water, acetone and alcohol, and then cleaned with a nitrogen cylinder Dry the self-made connection device at the outlet of the upper pressure reducing valve with nitrogen, and then use the ultraviolet light ozone cleaning machine sold by Novascan Company of the United States under the trade name PSD-UV4 ultraviolet ozone cleaning instrument for ultraviolet light ozone cleaning;

[0140] B. Preparation of Sandwich TiO 2 / ZnO / TiO 2 dense layer

[0141] (i) Preparation of TiO 2 layer

[0142] Use the spin coater sold by the Institute of Microelectronics, Chinese Academy of Sciences under the trade name K...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com