Automobile fuel saving and emission reducing mineral catalyst

A catalyst and mineral technology, applied in the field of automobile fuel-saving and emission-reduction mineral catalyst, can solve the problems of large exhaust pipe loss, no comparability, oil circuit blockage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

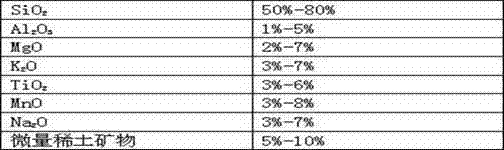

[0027] Embodiment 1: a kind of automobile fuel-saving and emission-reducing mineral catalyst, its composition comprises SiO 2、 Al 2 o 3、 MgO, K 2 O, TiO 2、 MnO, Na 2 O, trace rare earth minerals, the rare earth metal contained in the trace rare earth minerals should reach 0.01% of the total weight of the catalyst system in the whole catalyst, and the specific mass percentage is as follows:

[0028] SiO 2 50% al 2 o 3 5% MgO 7% K 2 o 7% TiO 2 6% MnO 8% Na 2 o 7% Trace Rare Earth Minerals 10%

[0029] After testing, after using this product, the gasoline consumption is reduced by nearly 22%, and the tail gas emission is reduced by more than 30%.

Embodiment 2

[0030] Embodiment two: a kind of automobile fuel-saving and emission-reducing mineral catalyst, its composition comprises SiO 2、 Al 2 o 3、 MgO, K 2 O, TiO 2、 MnO, Na 2 O, trace rare earth minerals, the rare earth metal contained in the trace rare earth minerals should reach 0.05% of the total weight of the catalyst system in the whole catalyst, and the specific mass percentages are as follows:

[0031] SiO 2 80% al 2 o 3 1% MgO 2% K 2 o 3% TiO 2 3% MnO 3% Na 2 o 3% Trace Rare Earth Minerals 5%

[0032] After testing, after using this product, gasoline consumption is reduced by nearly 25%, and tail gas emissions are reduced by more than 30%.

Embodiment 3

[0033] Embodiment three: a kind of automobile fuel-saving and emission-reducing mineral catalyst, its composition comprises SiO 2、 Al 2 o 3、 MgO, K 2 O, TiO 2、 MnO, Na 2 O, trace rare earth minerals, the rare earth metal contained in the trace rare earth minerals should reach 0.1% of the total weight of the catalyst system in the whole catalyst, and the specific mass percentages are as follows:

[0034] SiO2 60% Al2O3 4% MgO 5% K2O 6% TiO2 5% MnO 5% Na2O 6% Trace Rare Earth Minerals 9%

[0035] After testing, after using this product, the gasoline consumption is reduced by nearly 30%, and the tail gas emission is reduced by more than 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com