Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Generation of effective control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

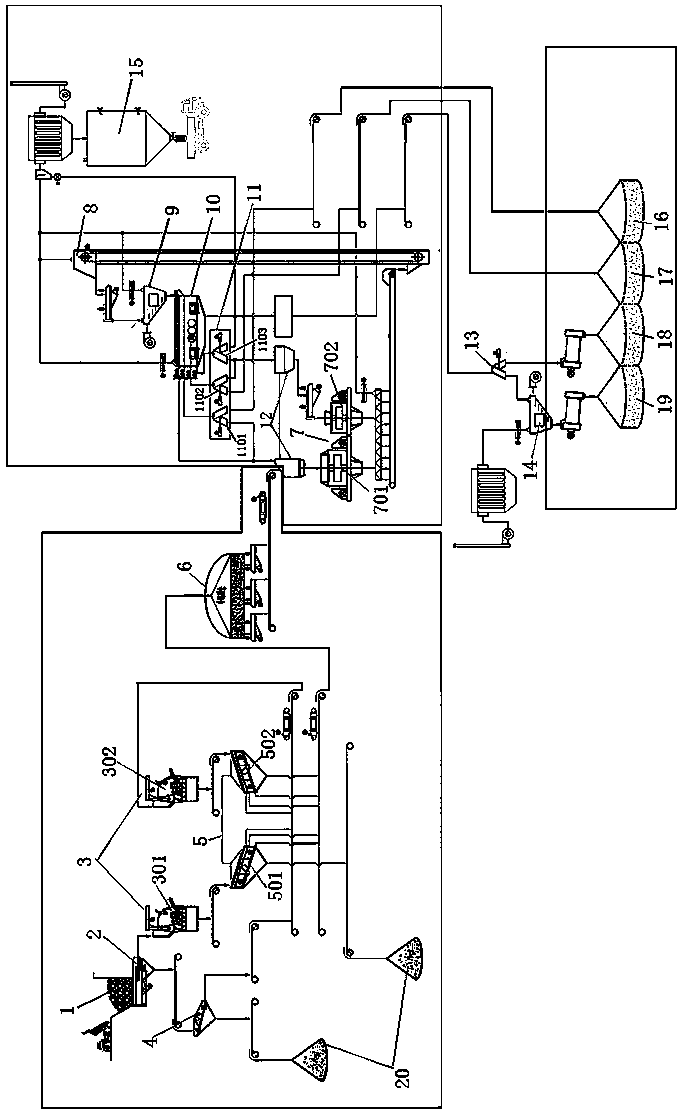

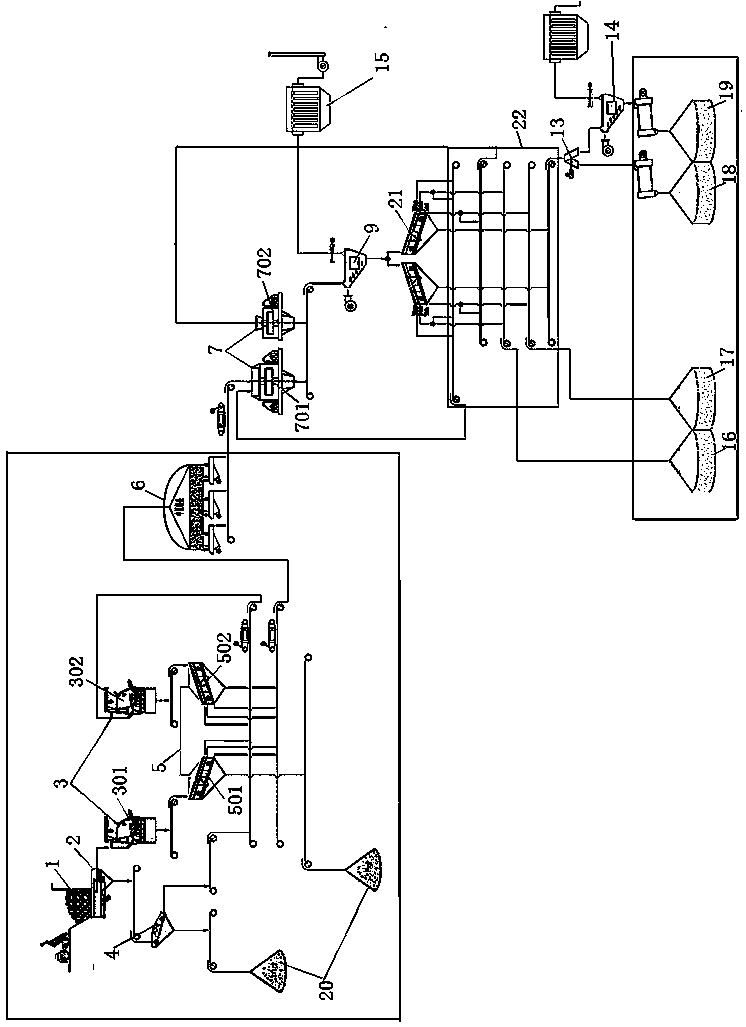

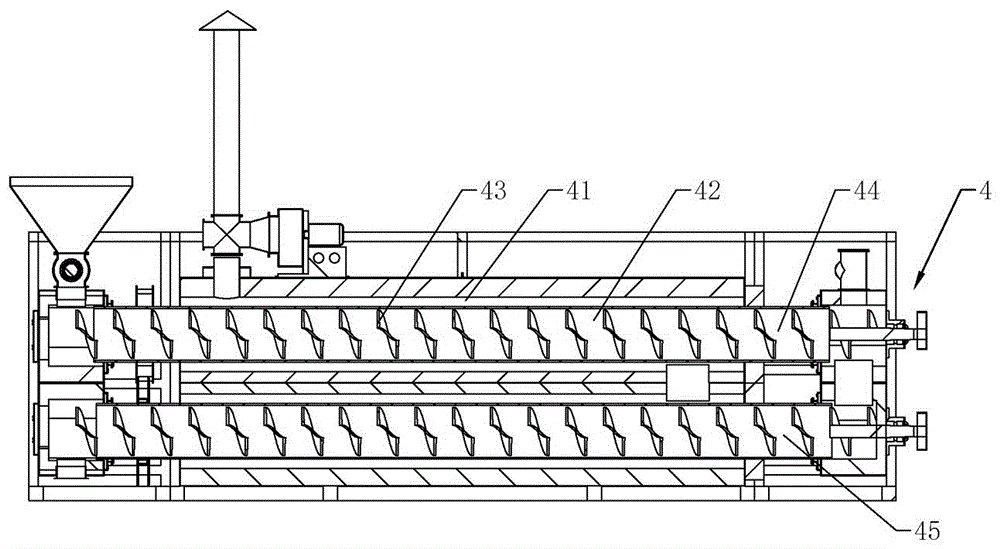

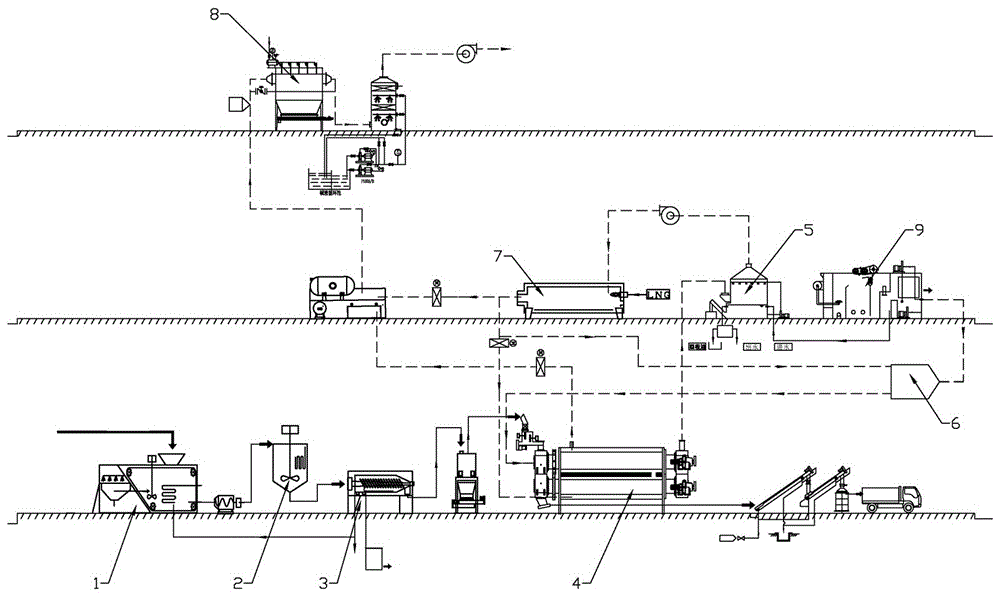

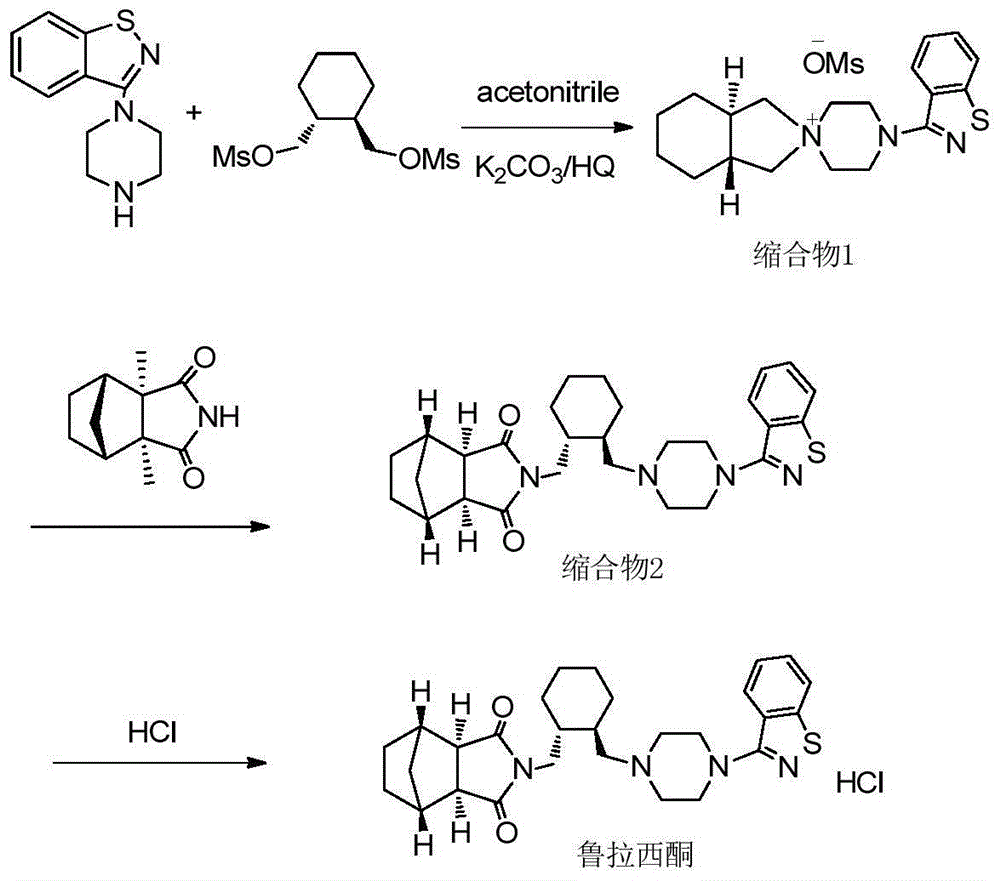

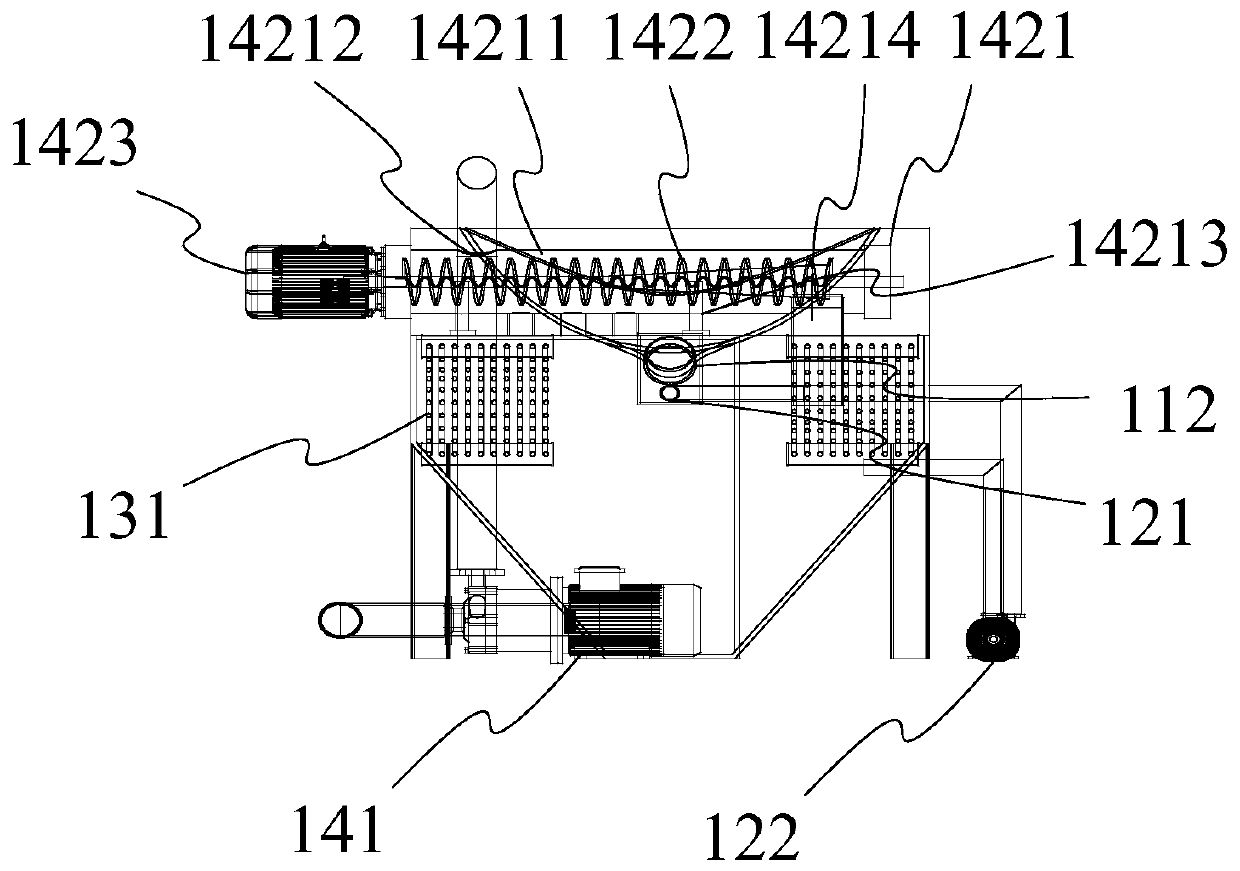

Five-double full-dry method crushing production line and processing method for high-quality sandstone aggregates

PendingCN109731661AGuaranteed cleanlinessGuaranteed growthGrain treatmentsSolid waste managementProduction linePre treatment

The invention discloses a five-double full-dry method crushing production line and processing method for high-quality sand aggregates. The production line comprises a material pretreatment system. A discharge port of the material pretreatment system is connected with a feed port of double-impact crushing equipment of a fine coarse aggregate processing system, a discharge port of the material pretreatment system is connected with a primary classifier, and a discharge port of the primary classifier is connected with a finished product screening and proportion adjusting circulation system. A super-particle-size material outlet of the finished product screening and proportion adjusting circulation system is circularly connected to a feed inlet of double-speed double-frequency crushing sand making equipment. The fine sand aggregates are connected to corresponding finished product bins or are circularly connected to the feed inlet of the double-speed double-frequency crushing sand making equipment, and multi-stage powder selecting equipment is arranged below a fine sand outlet. According to the production line, the production line with multi-stage desliming, double-countering-impact crushing, double-vertical-shaft impact crushing shaping sand making, multi-stage powder selecting and multi-stage circulation is adopted, so that the system productivity and the quality of the finished sand aggregates are improved effectively, the efficient and energy-saving effects are realized, and the practicability is high.

Owner:GUIZHOU CHENGZHI HEAVY IND SCI TECH

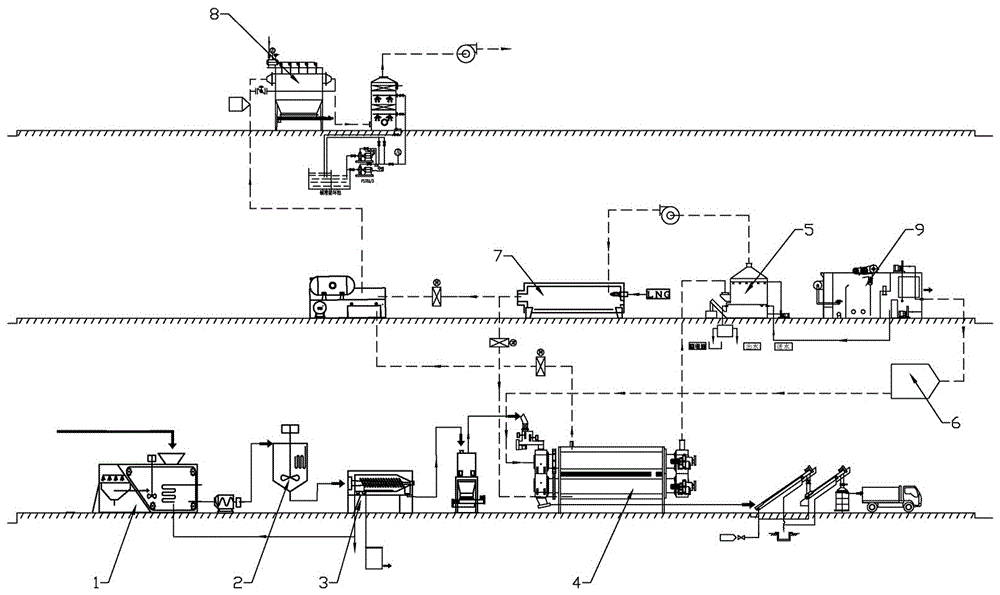

Oil-base mud treatment process

InactiveCN106810038AImprove thermal efficiencyThe treatment effect is thoroughCombination devicesSludge treatment by de-watering/drying/thickeningSimple Organic CompoundsDesorption

The invention relates to the field of sludge treatment, in particular to an oil-base mud treatment process which includes the steps: a, pretreatment: sorting, tempering and initial separation; b, pyrolysis and desorption; c, condensation and oil-water separation; d, utilization of combustible gas; e, flue-gas treatment. The treatment process adopts an internal and external heating pyrolysis and desorption method and is high in heat effectiveness and complete in treatment effect, a pyrolysis gas heat value is sufficiently utilized in the process, oil and conditioners in oil mud without mechanically separating are thoroughly removed, decomposed macromolecular organic compounds are reserved in an inorganic carbon manner, and final products have wide reuse pathways.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

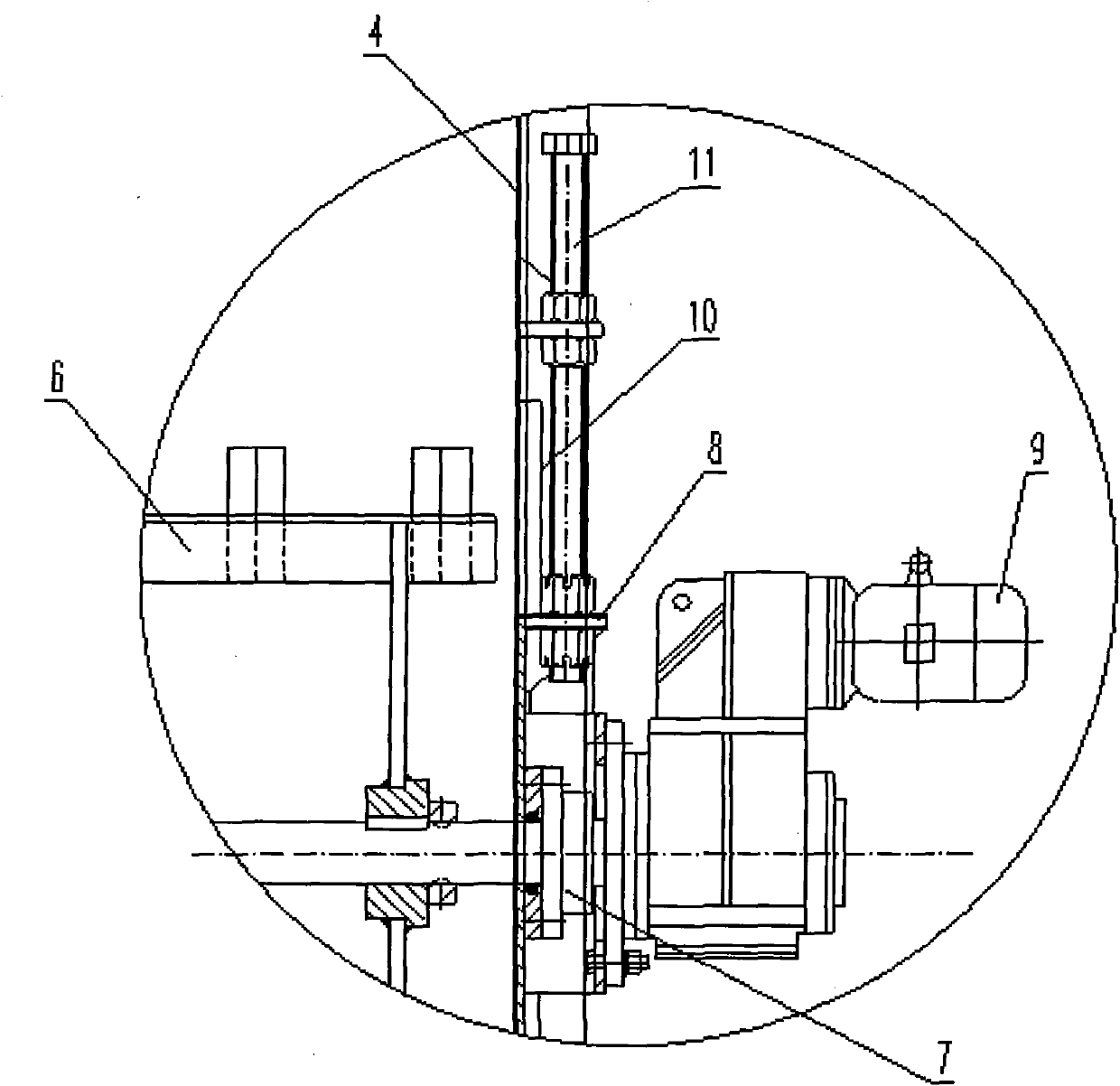

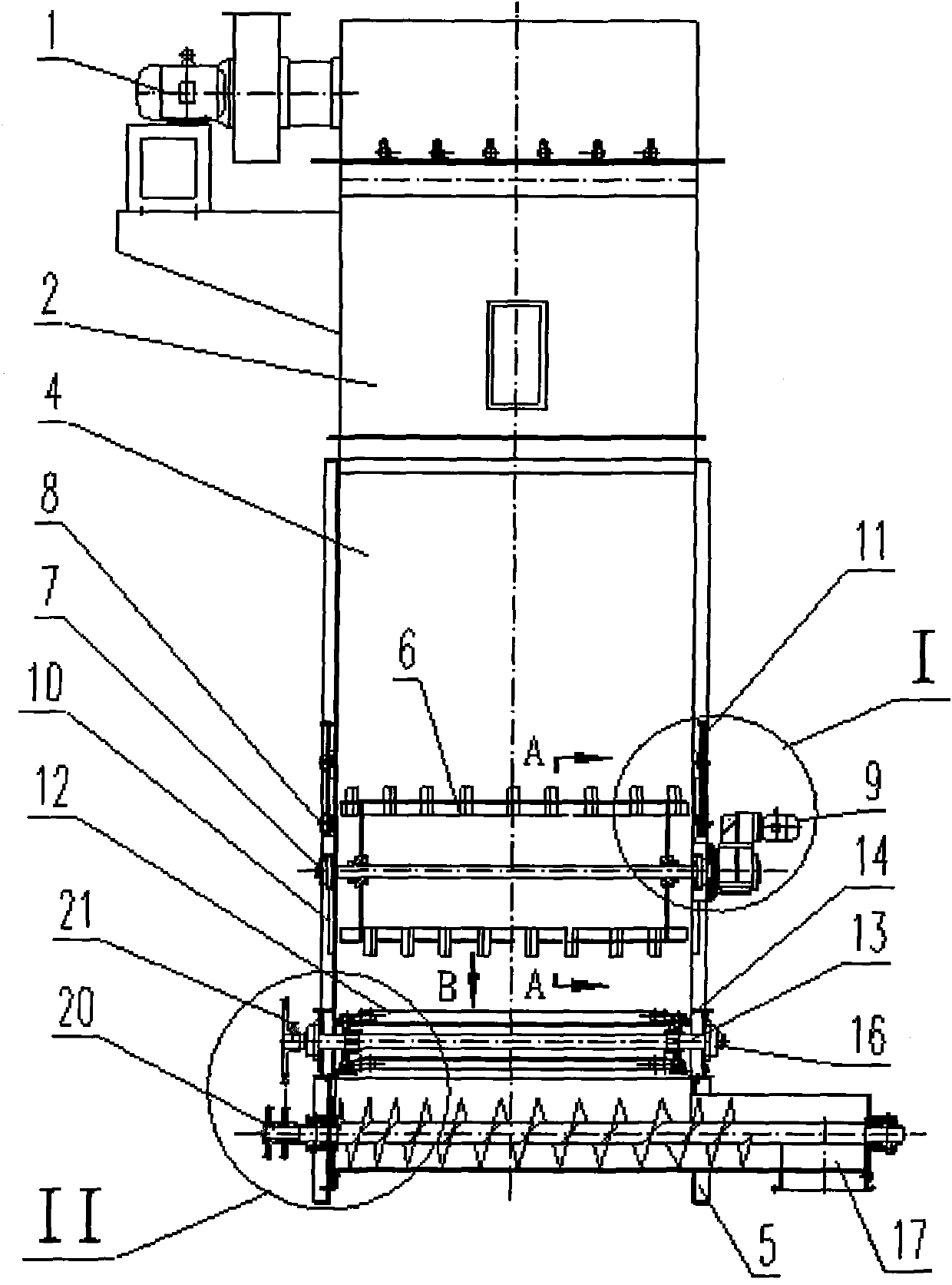

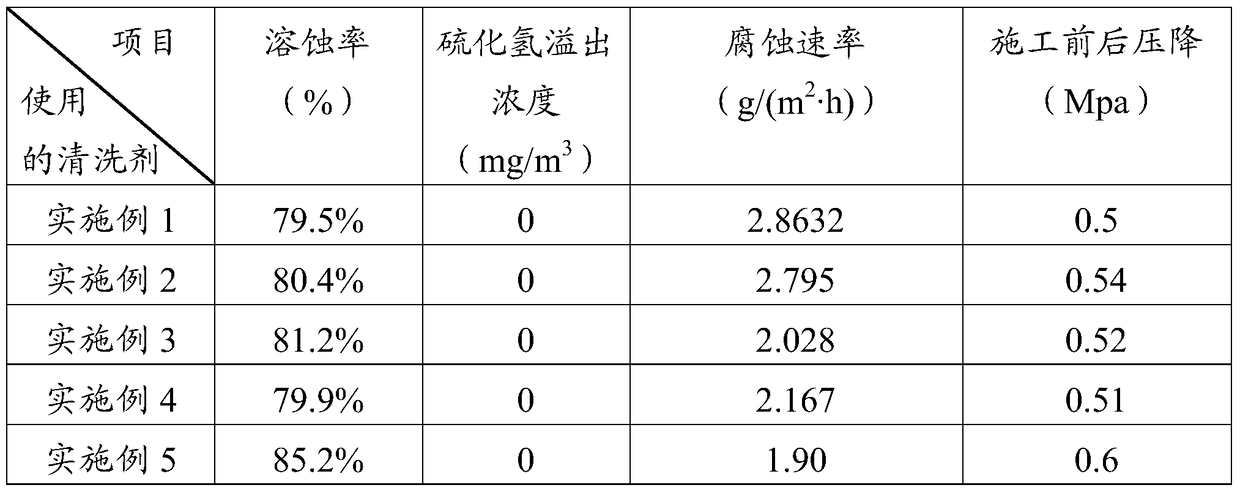

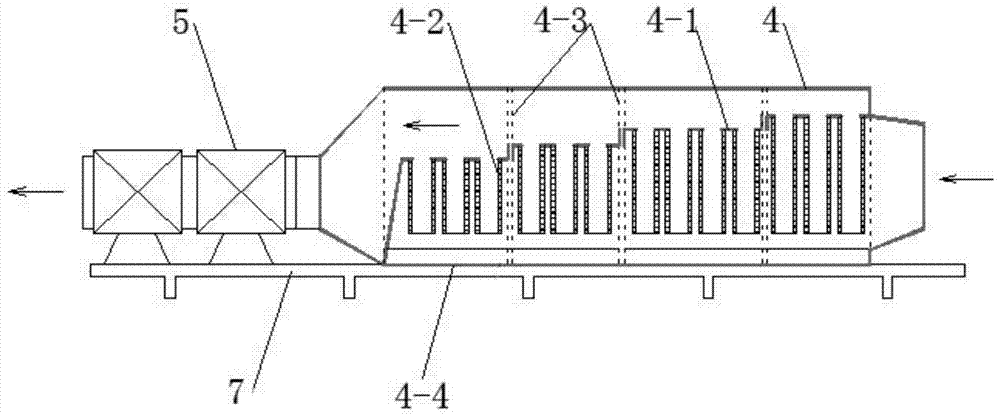

Dry type filtration dust removal system for roadway driving working face

ActiveCN105525939ADoes not affect footage operationsGeneration of effective controlDispersed particle filtrationTransportation and packagingMoving frameRocker arm

The invention provides a dry type filtration dust removal system for a roadway driving working face. Both an extraction fan (5) and a dry type filtration dust remover (4) are fixedly installed on a support (7). The support (7) is arranged on the upper side of a belt conveyor (10) in a nested mode and installed on the upper side of a moving frame (8). The extraction fan (5) is sequentially connected with the dry type filtration dust remover (4), a negative-pressure air barrel (3) and a suction hood (2). The negative-pressure air barrel (3) is suspended on the top of a roadway (1) through a monorail crane (9). The suction hood (2) is supported on a rocker arm (13) at the rear end of a cutting head (14) in a surrounding mode. The dust removal system is high in dust removal efficiency, does not occupy independent moving power, and can operate in cooperation with a driving procedure.

Owner:CHINA UNIV OF MINING & TECH

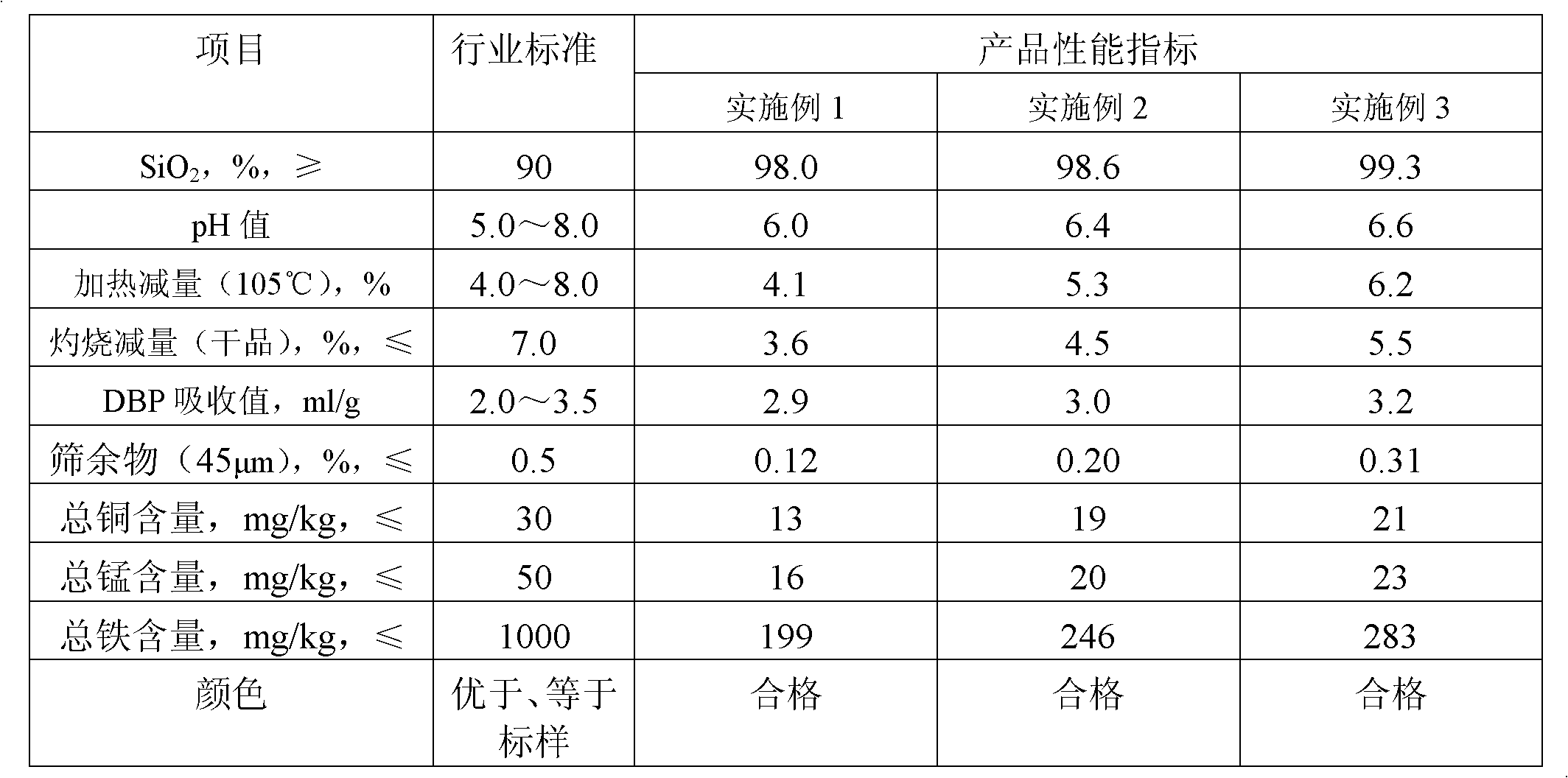

Method for preparing high dispersing white carbon black with ammonia precipitation method

The invention belongs to the field of chemical industry, particularly relates to a method for preparing high dispersing white carbon black with ammonia precipitation method. The method comprises the following steps of: (1) simultaneously adding ammonium hydrogen carbonate, water glass solution and dispering agent to a reaction kettle in a certain proportion, and quickly heating till the temperature of 70-90 DEG C; (2) carrying out heat preservation and stirring, controlling the stirring speed to be 60-100 rpm, simultaneously discharging ammonia gas in the reaction process, and obtaining loose precipitate white carbon black after finishing the reaction; (3) mixing the ammonia gas generated in the reaction and the smoke gas carbon dioxide generated in the process of preparing the water glass solution and simultaneously absorbing with water, and obtaining ammonium hydrogen carbonate solution after the reparation; (4) filtering the obtained precipitate white carbon black after the reaction under the condition of vacuum, wherein the filtrate is recycled to prepare sodium carbonate, and obtaining the high dispersing white carbon black after washing, drying, crashing and filtering the filter cake. The method is simple in technology and environment-friendly, thereby reducing the production cost and improving the product performance; and the quality is stable and reliable.

Owner:廖险峰

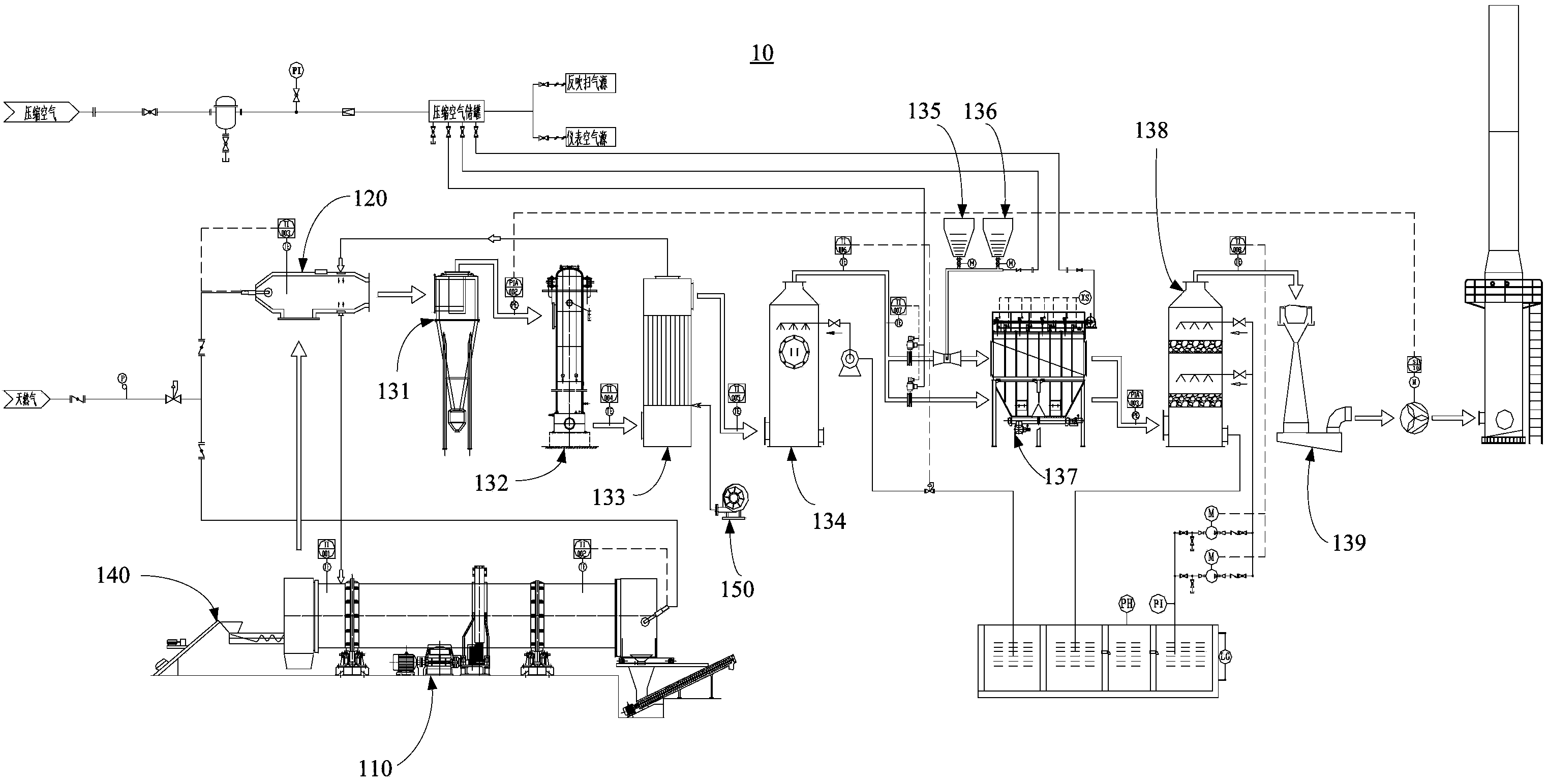

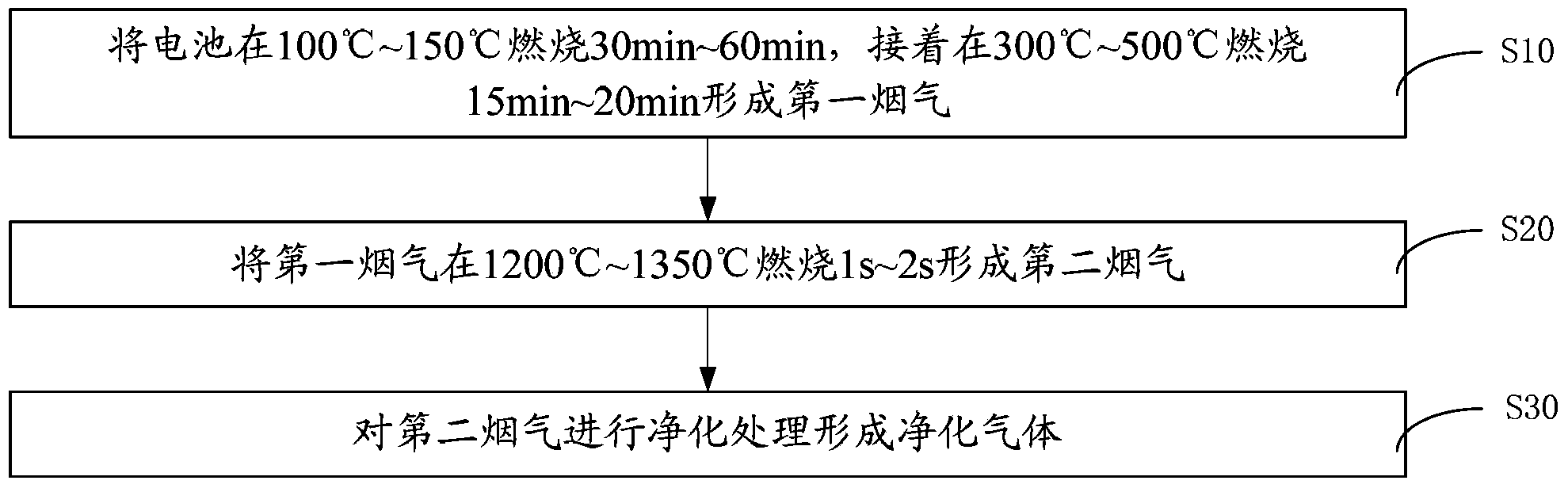

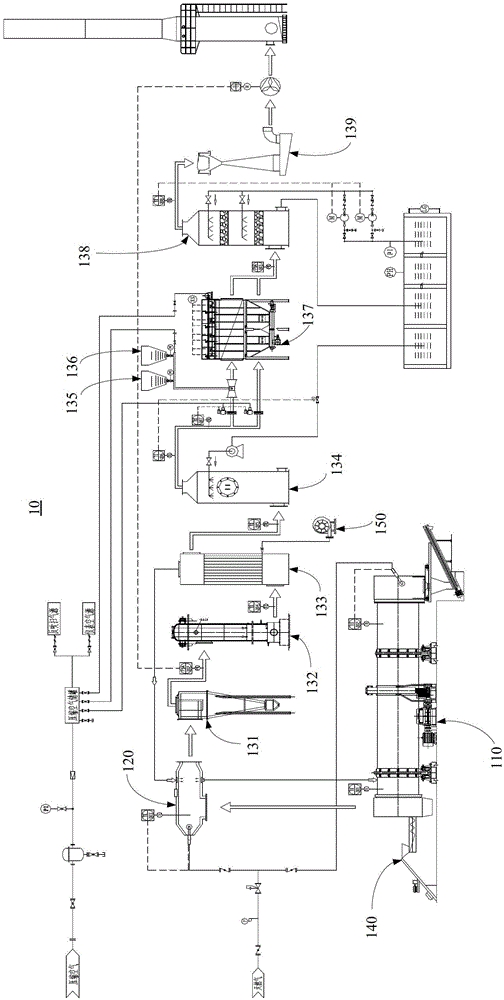

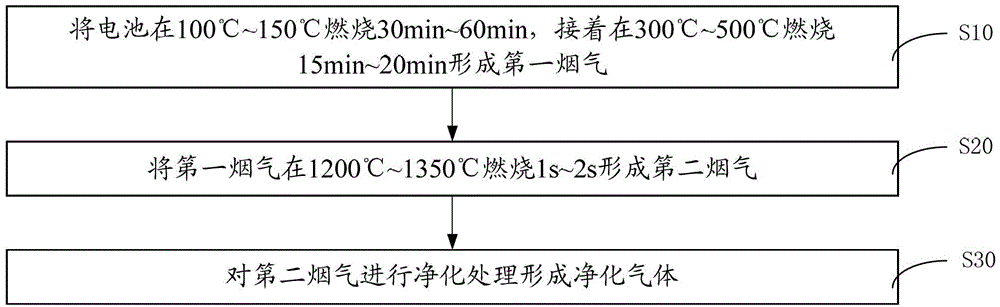

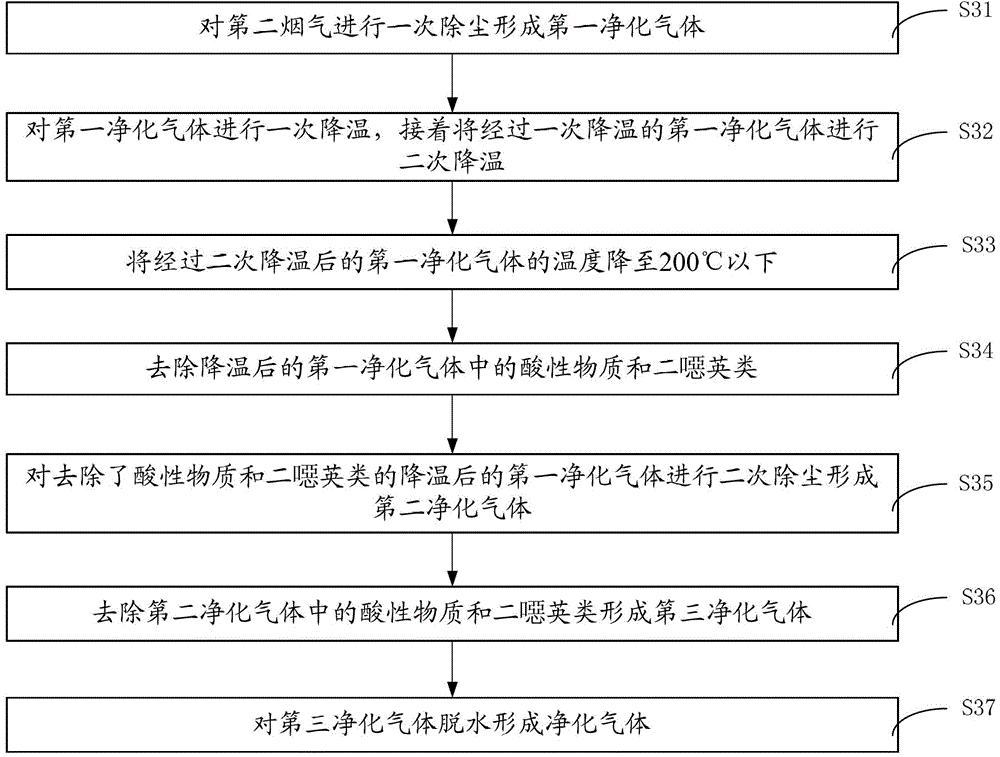

System and method for recycling batteries

ActiveCN103453532AAvoid explosionExplosion won't happenIncinerator apparatusOperational safetyCombustion chamber

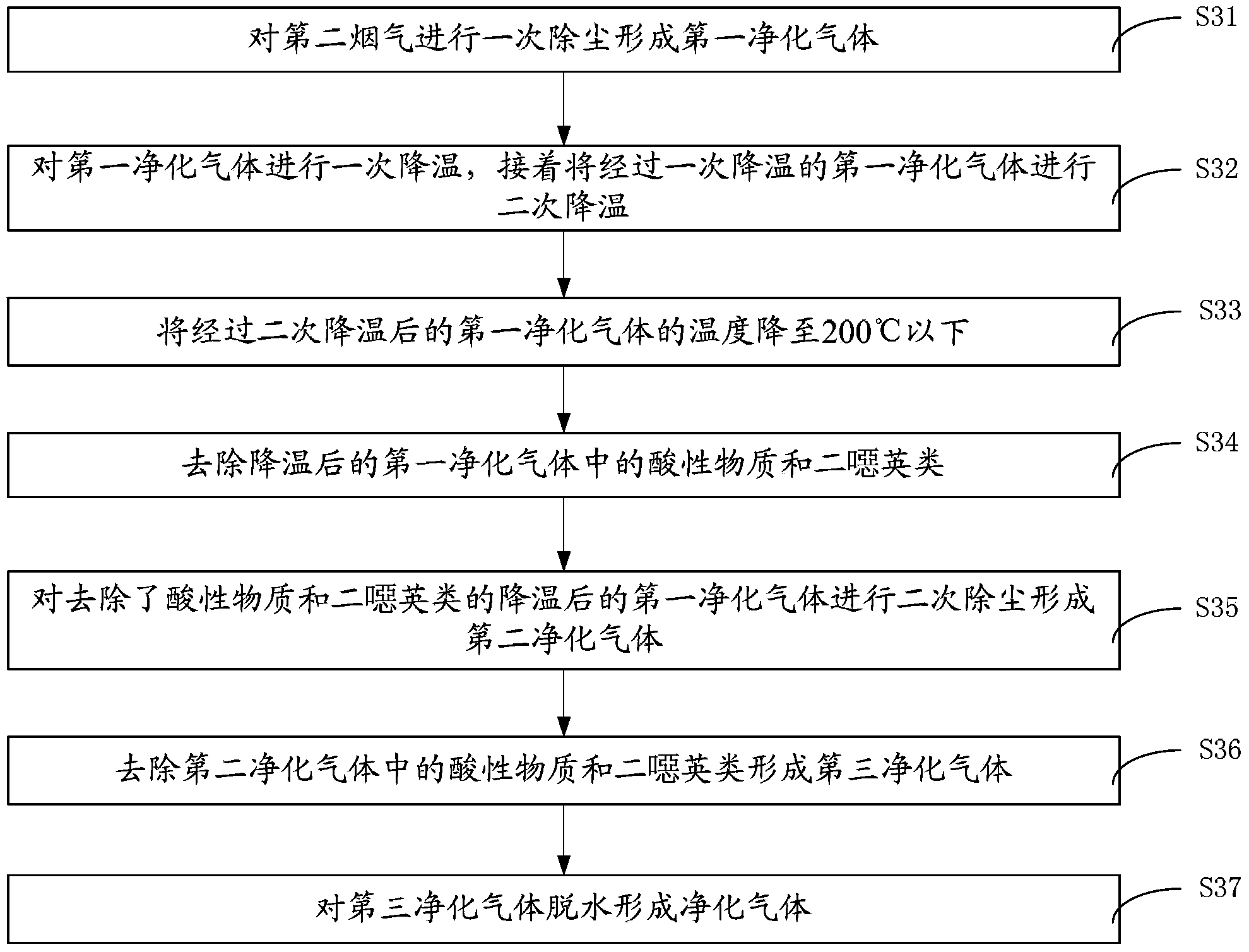

The invention discloses a system for recycling batteries. The system comprises a combustion chamber of a rotary kiln, a secondary combustion chamber and flue gas purification equipment; the combustion chamber of the rotary kiln comprises a first combustion area and a second combustion area; the secondary combustion chamber is communicated with the combustion chamber of the rotary kiln; the flue gas purification equipment is communicated with the secondary combustion chamber. By the aid of the system for recycling the batteries, the batteries are combusted in the first combustion area at the temperature ranging from 100 DEG C to 150 DEG C for 30 to 60 minutes, so that sealing rings of the batteries are sufficiently damaged by means of pyrolysis, hydrogen and organic solvents in the batteries are released and are discharged by negative-pressure devices, and the batteries can be effectively prevented from being exploded at a high temperature; then the batteries are combusted in the secondary combustion area at the temperature ranging from 300 DEG C to 500 DEG C, first flue gas generated when the batteries are combusted is completely combusted in the secondary combustion chamber at the temperature ranging from 1200 DEG C to 1350 DEG C to form second flue gas, the second flue gas is purified by the flue gas purification equipment to form purified gas, and the purified gas is exhausted into the atmosphere. The system for recycling the batteries has the advantages that the batteries are prevented from being exploded, and the system is safe in operation. The invention further provides a method for recycling the batteries.

Owner:GANZHOU HIGHPOWER TECH CO LTD

Curing agent for oily sludge incineration innocent treatment and usage method of curing agent

InactiveCN102676118ARealize harmless treatmentRealize resource processingOther chemical processesSocial benefitsSlag

The invention provides a curing agent for oily sludge incineration innocent treatment and a usage method of the curing agent. The curing agent comprises, by mass, 1-20% of cement, 1-20% of a fluxing agent and 60-98% of water. The curing agent which accounts for 10-50% of the mass of the oily sludge is added in the oily sludge, the flying ash generated by the oily sludge incineration can be restrained effectively, the incinerated products are agglomerated, and the effect of slagging control is achieved. The curing agent is low is cost, convenient to use and capable of solving the secondary pollution problem caused by the oily sludge incineration effectively, so that the heating energy can be used fully and cleanly and furnace slags produced by the oily sludge incineration can be used for paving roadbeds and serve as building materials, and the harmless and recycling treatment of the oily sludge is achieved truly. Besides, the curing agent is beneficial to environmental protection and has good economic and social benefits.

Owner:XINJIANG UNIVERSITY

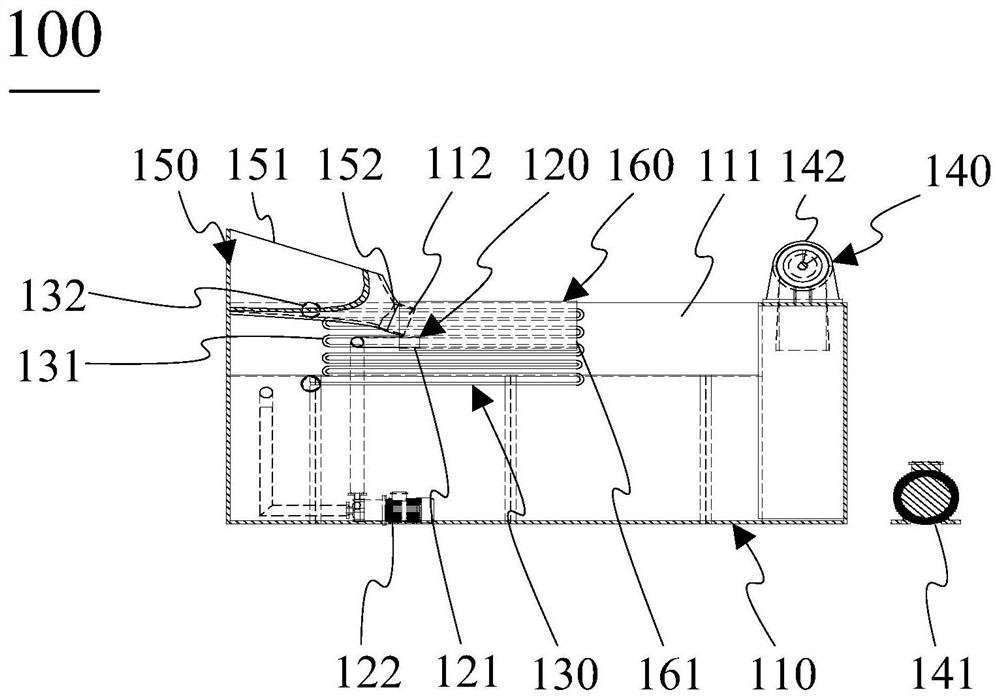

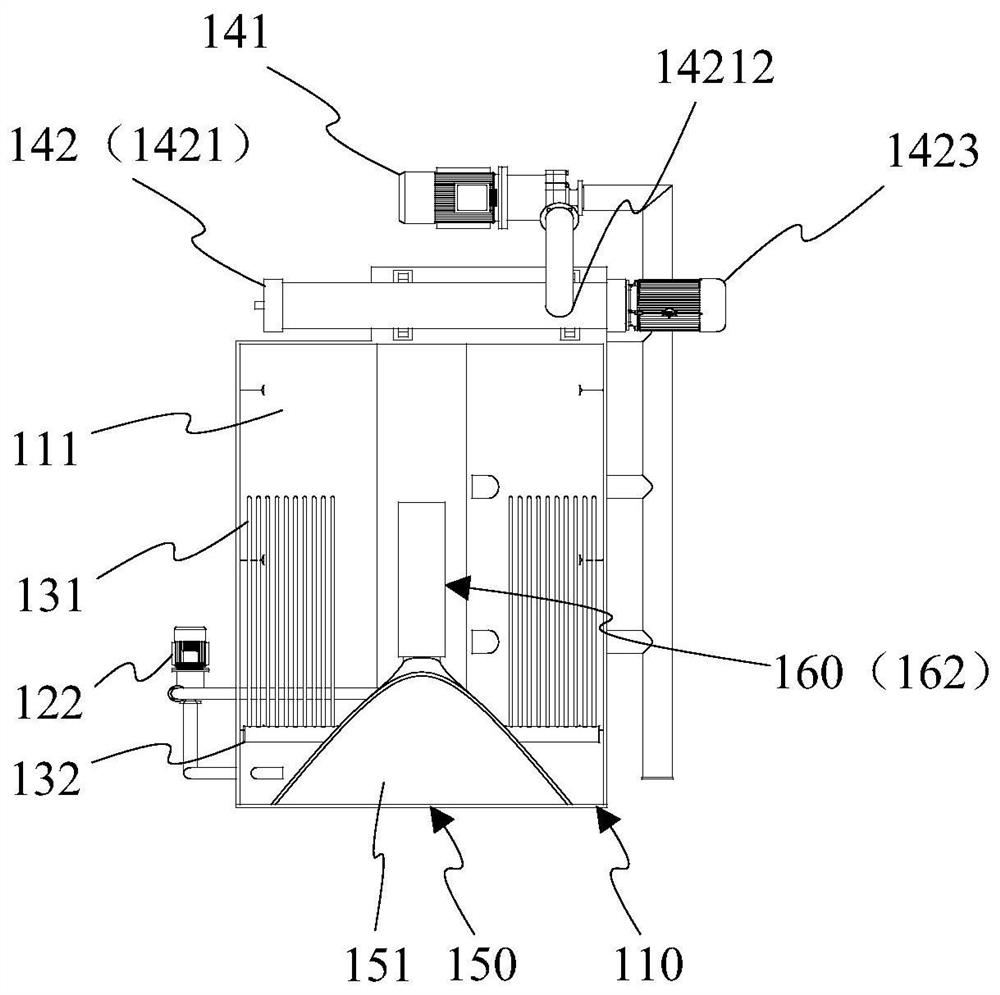

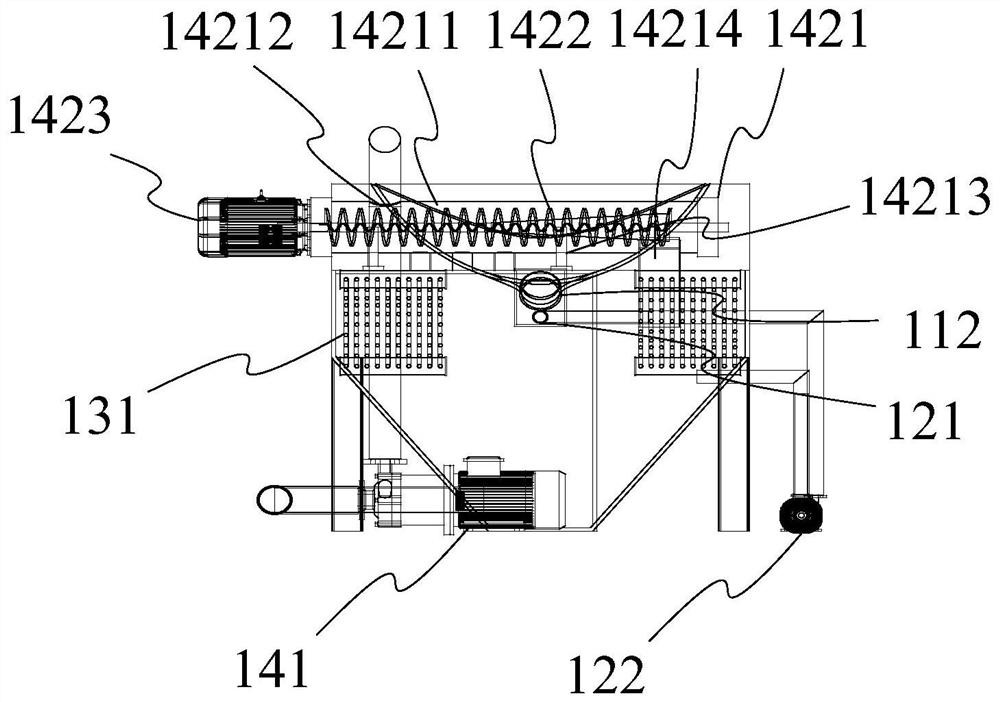

Horizontal cooling silo

InactiveCN101948048ASimple structureReasonable structureTank wagonsLoading/unloadingCooling effectEngineering

A horizontal cooling silo comprises a cooling fan, a silo, a material conveying bed and a spiral conveyer for discharged materials, wherein the cooling fan is arranged above the rear part of the silo; the suction opening of the cooling fan is connected with the silo; a feed opening is arranged on the front part of the silo; the material conveying bed is arranged below the silo and is provided with a conveying scraper chain assembly; the materials flow from the front part of the silo to the rear part of the silo on the material conveying bed; and the spiral conveyer for discharged materials is arranged below the tail end of the material conveying bed. The cooling silo integrates storage and cooling, has better cooling effect especially on the fibrous materials and has simple structure and low cost.

Owner:LIYANG YUDA MASCH CO LTD

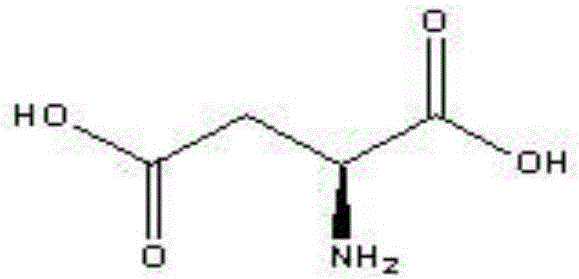

Method for preparing L-aspartic acid and L-alanine by using maleic anhydride

InactiveCN106755157ASimple processRealize circular productionFermentationHydration reactionMaleopimaric acid

The invention provides a method for preparing L-aspartic acid and L-alanine by using maleic anhydride. The method comprises the following steps: heating the maleic anhydride as the raw material to obtain a maleic acid solution through hydration reaction; adding maleate isomerase and L-aspartase; after filtering and concentrating obtained liquid of enzymatic reaction to deaminize, regulating the pH value until the isoelectric point of the L-aspartic acid is equal to 2.8 by using the maleic acid solution as an acidifying agent; crystallizing to separate out the L-aspartic acid; and converting the L-aspartic acid into the L-alanine by further using aspartate decarboxylase. The L-aspartic acid is prepared through one-step reaction by a two-enzyme method, the process is simple and convenient, the conversion ratio is high, production of malic acid as a by-product can be controlled effectively, and the quality of the product is good; and maleic acid is used as the acidifying agent to prepare the L-aspartic acid in an isoelectric point crystallization manner, crystallization mother liquor can be used as an enzyme reaction substrate and then is recycled, the discharge amount of waste water is greatly reduced, and the method conforms to the idea of environmental protection. In addition, the L-aspartic acid is further converted into the L-alanine by an enzymic method, so that products obtained by a whole process are diversified; and the market competitiveness is high.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

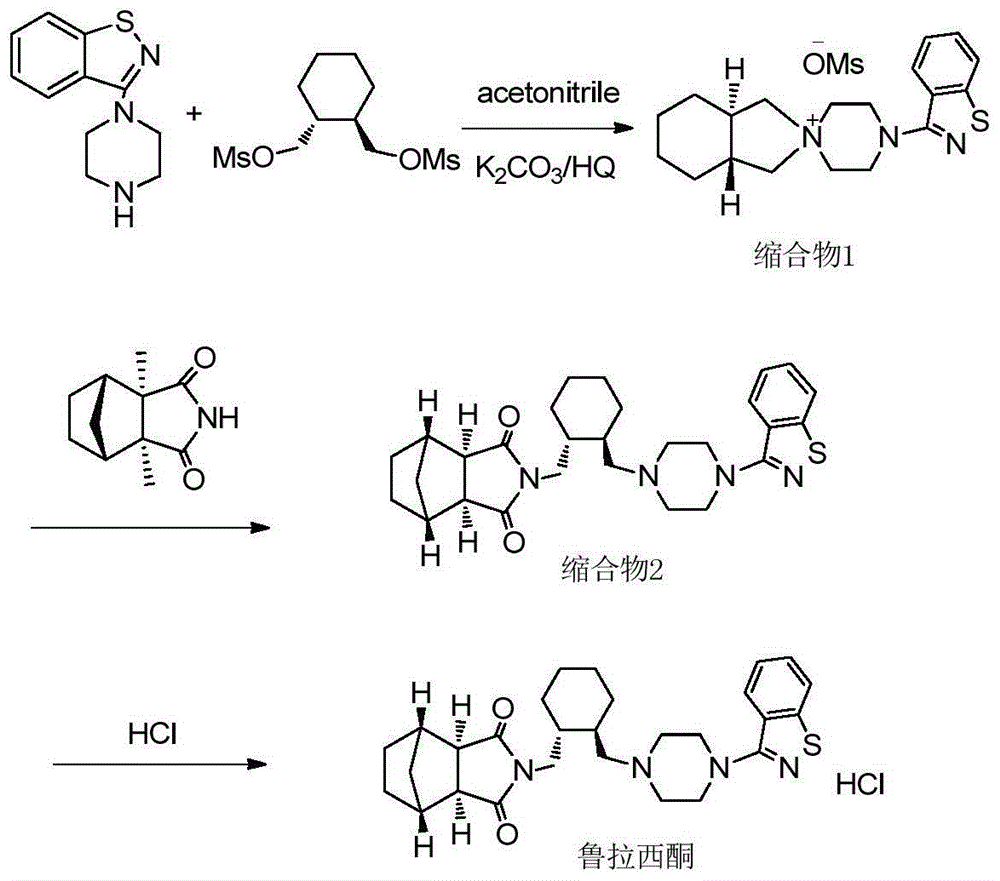

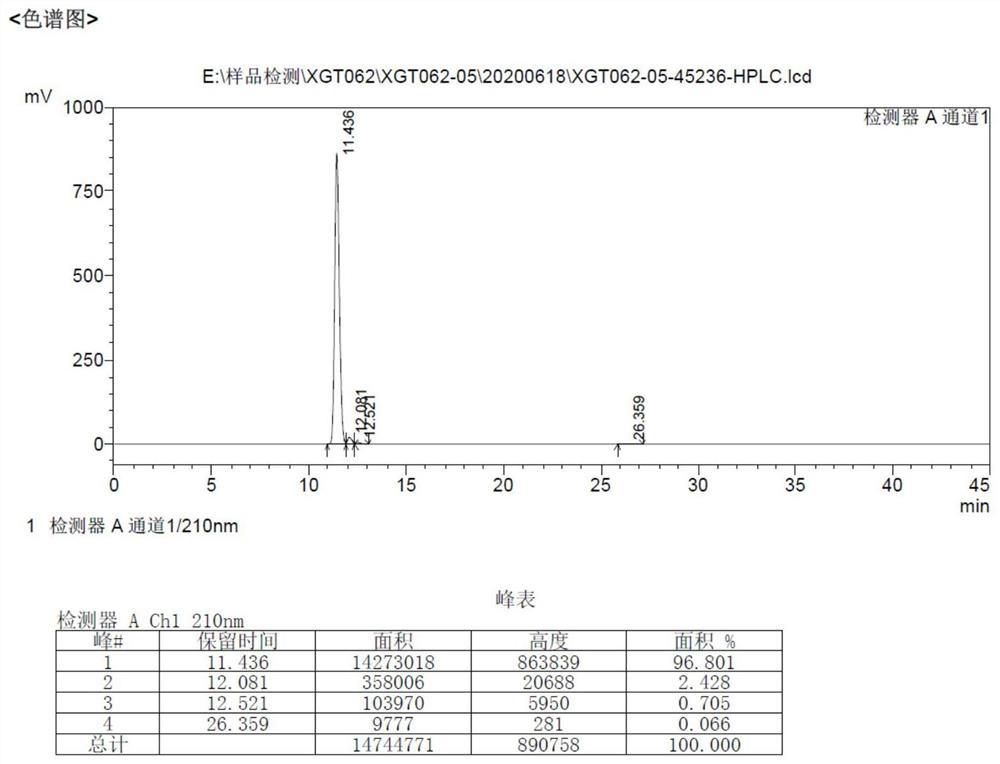

Method for preparing lurasidone with high purity and high yield

InactiveCN106146486ALower the reaction reflux temperatureControl reaction impuritiesOrganic chemistryChemistryProtic solvent

The invention provides a method for preparing lurasidone with high purity and high yield. On the basis of an existing lurasidone preparation method, a small quantity of specific protic solvent is added in the preparation process of (R,R)-3a,7a-9H-isoindole-2-1'-[4'-(1,2-benzisothiazole-3-yl)] piperazine mesylate, so that the reaction rate is greatly increased, the time is shortened to 3 h from 23 h in the prior art, the yield is increased from 82% to 90%, the total yield is up to 71%, and the prepared finished product has the consistent quality with original drugs.

Owner:SHANGAI PHARMA GRP CO LTD

Novel gene necessary for production of conidium from Magnaporthe grisea and its uses

The invention discloses a new necessary MgCON1 gene and utility generated by pear spore bacterium, which is characterized by the following: the gene and its cDNA and coding product possess the sequence in the SEQ ID No.:1, No.:2 and No.:3; the protein of coded gene possesses homeo structural region, which is not similar to known functional protein; the gene removes abnormal and matured attaching cell, which reduces forming frequency of infecting tin and extending infecting hypha without pathogenic ability for rice; the MgCON1 can be important candidate target, which can be applied to design and sieve new drug to prevent fungus.

Owner:CHINA AGRI UNIV

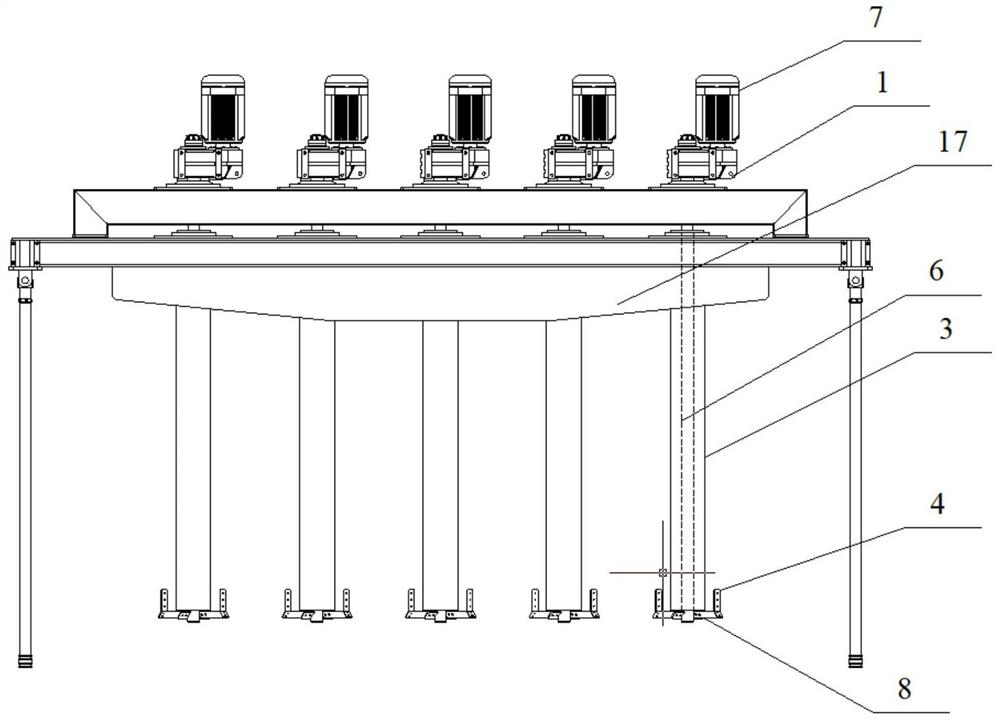

Dust-free automatic discharging device for graphite crucibles

ActiveCN113428653ANo pollution in the processAvoid pollutionVortex flow apparatusSolid materialCrusherGraphite crucible

The invention discloses a dust-free automatic discharging device for graphite crucibles. The dust-free automatic discharging device for the graphite crucibles comprises a material suction crushing mechanism and a material collection filtering mechanism which are connected with each other, wherein the material suction crushing mechanism comprises a plurality of material suction pipes, crushers are arranged below the material suction pipes, when the material suction pipes are inserted into the corresponding crucibles, the crushers break and crush graphite in the crucibles, and the crushed graphite is sucked in by negative pressure in the material suction pipes and transferred to the material collection filtering mechanism; and each crusher comprises a stirring rod, the tops of the stirring rods are connected with a power mechanism, the bottoms of the stirring rods penetrate through the material suction pipes and then are located below the material suction pipes, crushing blades are arranged at the bottoms of the stirring rods, and the power mechanism drives the stirring rods and the crushing blades to rotate so as to crush the graphite. The dust-free automatic discharging device for the graphite crucibles is high in material suction efficiency and stable in product quality.

Owner:贵州东岛新能源材料有限公司

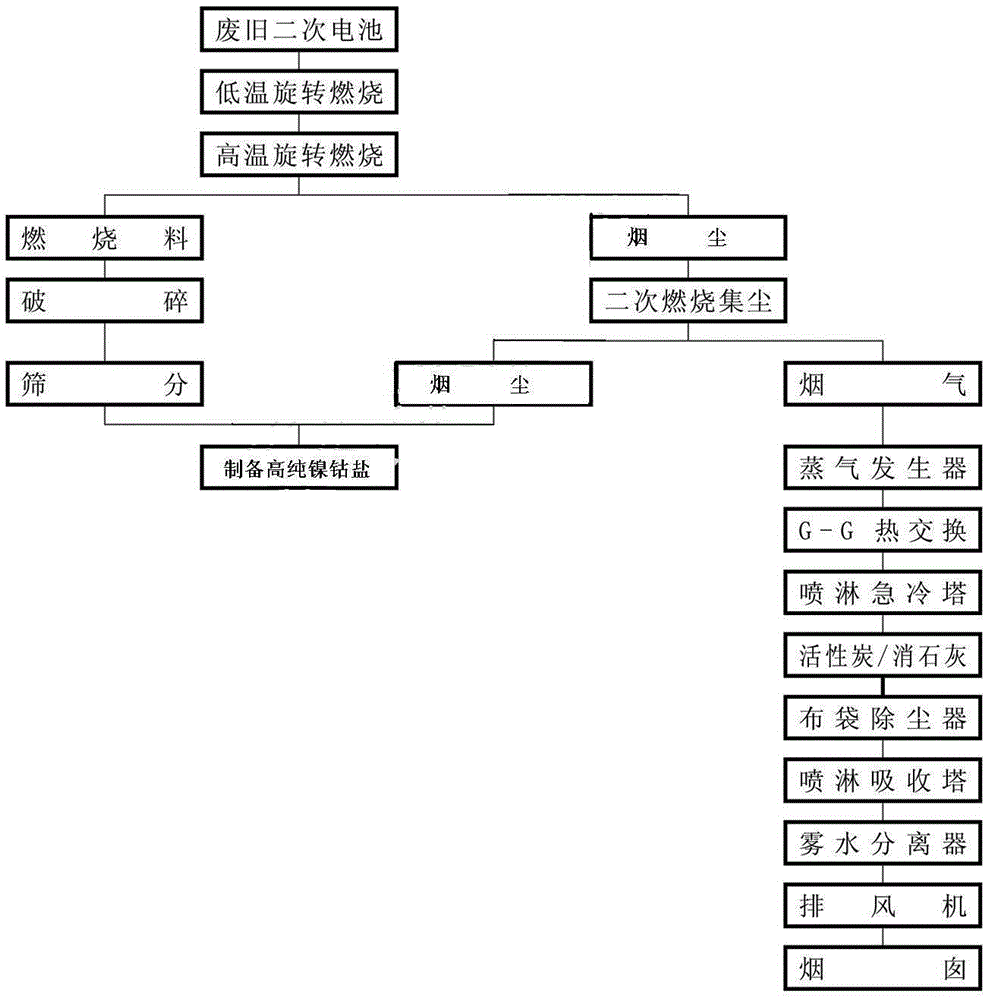

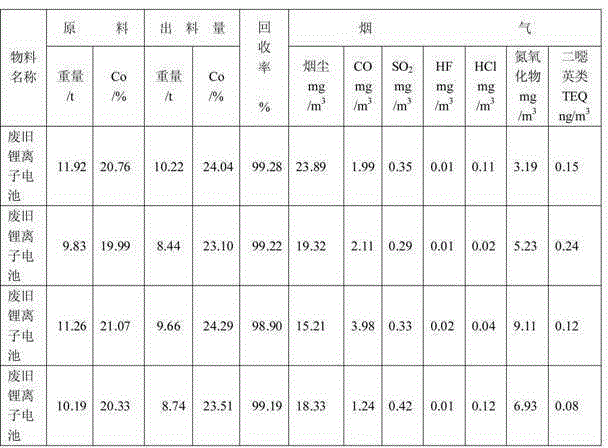

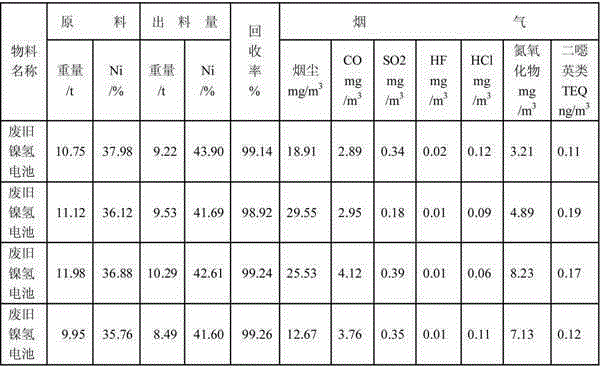

A kind of treatment method of waste secondary battery

ActiveCN103730704BAvoid explosionFully oxidative combustionWaste accumulators reclaimingBattery recyclingNitrogen oxidesElectrical battery

The invention belongs to the technical field of hydrometallurgy and chemical production, and discloses a method for treating waste secondary batteries. By burning in two stages in a rotary kiln, the furnace temperature is first maintained at 100-150°C, and the waste secondary batteries are The front part of the furnace is roasted for 30-60 minutes to ensure that the sealing ring of the waste secondary battery is fully pyrolyzed and destroyed, so that the hydrogen and organic solvent in the battery can be released; Maintain at 300~500°C to fully oxidize, pyrolyze, and burn the organic matter in the waste, and effectively control the generation of odor and nitrogen oxides, so that the generated gas can achieve the effect of no peculiar smell, no foul smell, and complete combustion. The treatment method provided by the invention has a reasonable design, is incinerated first and then crushed, has a high crushing rate, a high recovery rate of valuable elements, can avoid high-temperature incineration and explosion accidents, is safe and pollution-free, and is suitable for popularization.

Owner:GANZHOU HIGHPOWER TECH CO LTD

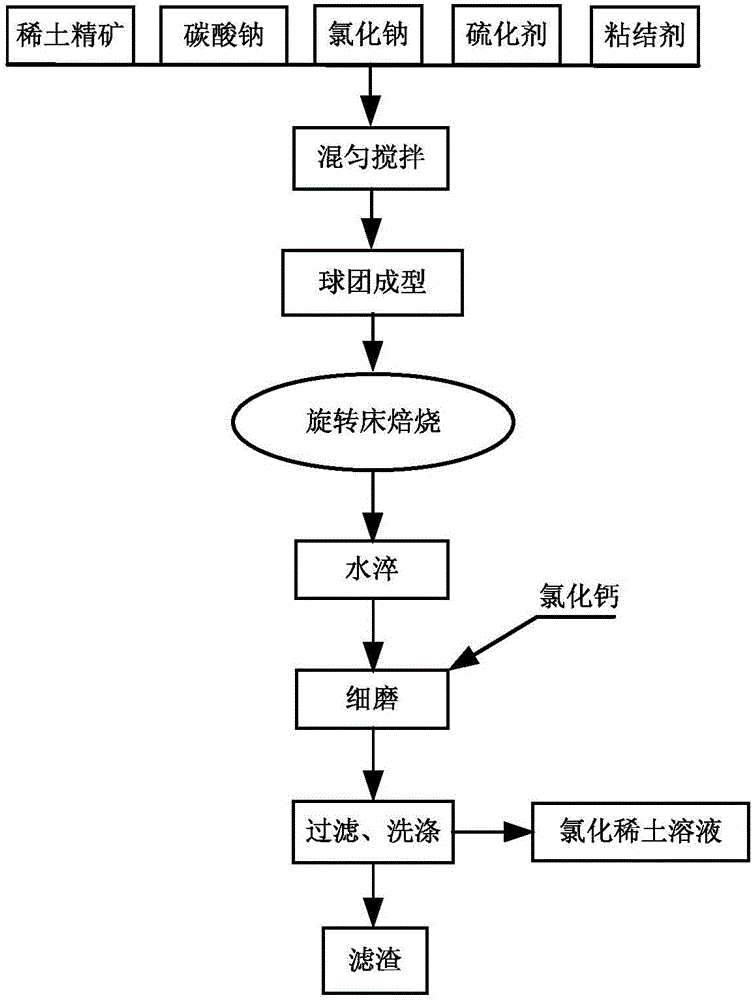

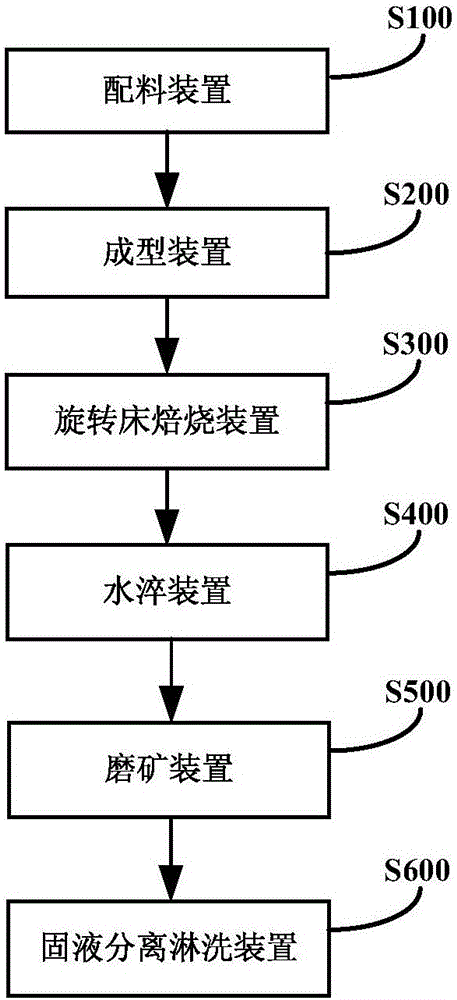

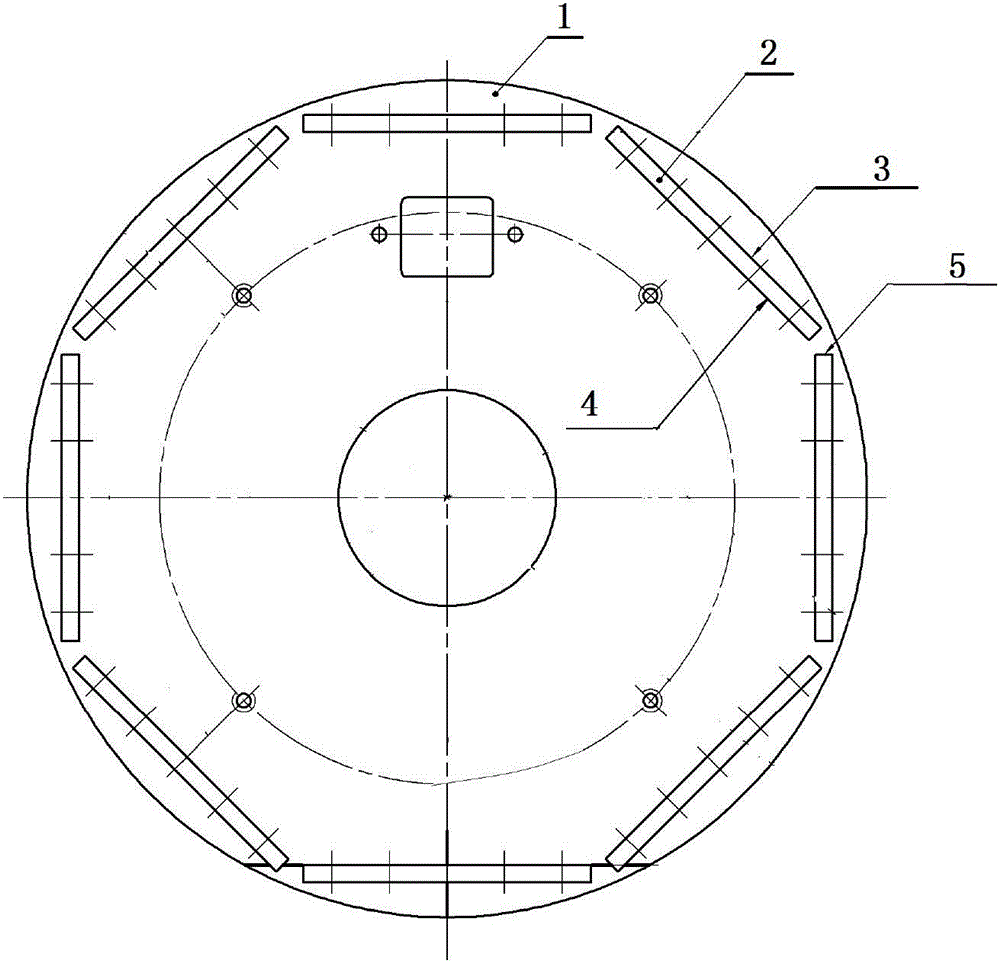

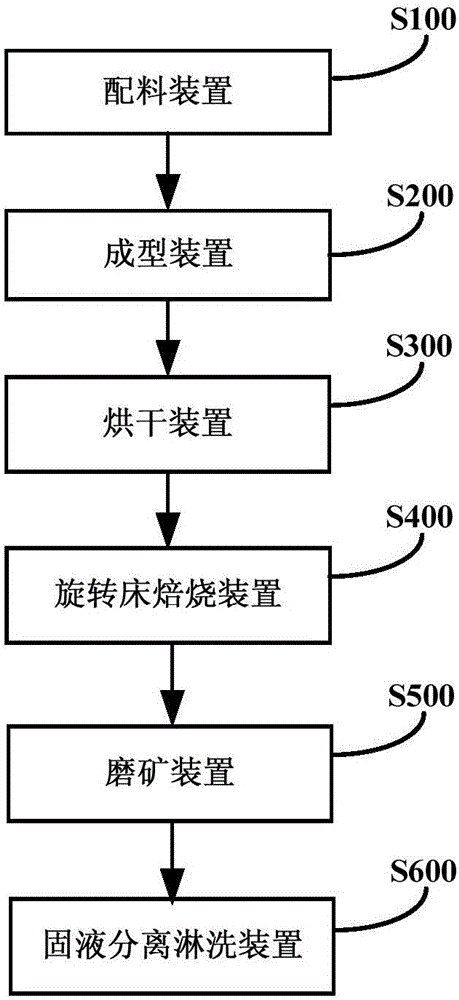

System and method for processing rare earth concentrates

InactiveCN106636626AGeneration of effective controlEffective control and prevention of escapeProcess efficiency improvementFiltrationRare earth

The invention discloses a system and method for processing rare earth concentrates. The method comprises the steps that the rare earth concentrates, sodium carbonate, a chloridizing agent, a vulcanizing agent and a bonding agent are blended in a blending device; then mixed materials are prepared into rare earth green pellets in a forming device; the rare earth green pellets are fed into a rotating packed bed to be calcinated to obtain hot pellets; then the hot pellets are subjected to water quenching, and calcium chloride is added for wet ore grinding in an ore grinding device to obtain ore pulp; and the ore pulp is subjected to filtration or suction filtration in a solid-liquid separation leaching device to obtain filter residues and a chloridized rare earth solution. By adoption of the system and method for processing the rare earth concentrates, the problems that in the prior art, three waste pollution is serious, caustic soda is large in dosage and high in cost, and a large amount of acid is needed for dissolution in subsequent processes are solved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Method for preparing peanut milk

InactiveCN101695347BExtended shelf lifeFully emulsified and dispersedFood preparationMilk substitutesFood additiveMonoglyceride

The invention belongs to the technical field of peanut food additive and peanut beverage processing, and provides a composite emulsifying agent for peanut milk, which is formed by mixing isolated soybean protein, fatty acid monoglyceride, sucrose fatty acid ester, sorbitan fatty acid ester and sodium alga acid in a mass ratio of 1: 1: 1: 1: 1, wherein the mass percentage concentration of the composite emulsifying agent in the peanut milk is 0.05 to 0.15 percent. The invention also provides a method for preparing the peanut milk by adopting the emulsifying agent. The method comprises the following steps: low-temperature cold pressing, soaking, filtering and mixing, grinding, centrifugal separation, emulsifying agent addition, homogenizing, super-high temperature instant sterilization, canning and sealing, and high-temperature sterilization. The fat in the peanut milk prepared by adopting the composite emulsifying agent can be fully emulsified and dispersed, so the generation of a fat ring can be effectively controlled; and meanwhile the shelf life of the peanut milk can be prolonged, and adverse phenomena such as settling, elutriation, demixing and the like of the peanut milk during storage and transportation are prevented.

Owner:QINGDAO HUINENGDUO AGRI DEV

Method for welding outgoing line terminal of nuclear power half-speed turbine generator

InactiveCN106271466AImprove thermal conductivityGuaranteed dimensional tolerance requirementsArc welding apparatusMetal working apparatusNuclear powerShielding gas

The invention relates to a method for welding an outgoing line terminal of a nuclear power half-speed turbine generator. The method solves the problem of the prior art that since the process of manual metal-arc welding or gas shielded arc welding or the like is adopted for welding an outgoing line terminal, the welding deformation is serious, the welding size is difficult to guarantee, welding lines are difficult to form, the welding quality is poor and the welding is difficult in passing flaw detection at a single time. The method comprises the following steps: 1, preparing materials; 2, scribing; 3, assembling; 4, performing spot welding; 5, installing a tool fixture; 6, preheating before welding; 7, performing metal-inert gas welding (MIG) on a workpiece to be welded, wherein the welding current is 370-420A, the welding voltage is 24-34V, the welding speed is 350-500 mm / min, the protection gas is high-purity argon having the purity of more than 99.996%, and the flow rate of gas is 10-15 L / min; 8, performing modification welding; and 9, performing non-destructive inspection. The method is used for welding an outgoing line terminal of a nuclear power half-speed turbine generator.

Owner:HARBIN ELECTRIC MASCH CO LTD

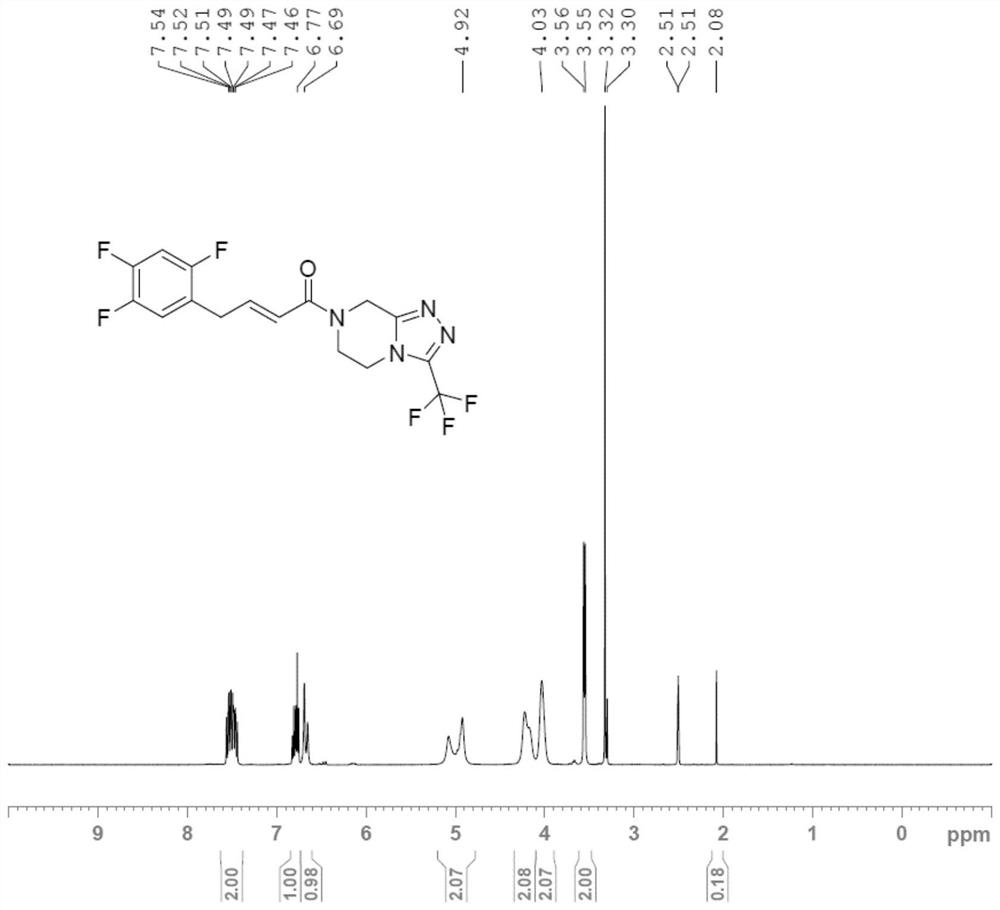

Preparation method of sitagliptin impurity

ActiveCN114075201ATo meet preparation needsGeneration of effective controlOrganic chemistryBulk chemical productionSitagliptinChemical compound

The invention provides a preparation method of a sitagliptin impurity compound, belonging to the field of chemical pharmacy. According to the method, racemic and / or chiral sitagliptin is taken as a substrate, reductive amination is performed firstly, and then Cpe elimination is performed, so the sitagliptin impurity compound is obtained; and the starting material is easy to obtain, operation is simple, generation of double-bond isomeric impurities in a reaction process can be effectively controlled, and purification is convenient. The method is rigorous, practical, scientific and reliable in operation, the required materials are easy to store and free of harm, the product is easy to purify, the yield and the purity of the product are high, the preparation requirements of the impurity can be met, a new thought is provided for synthesis of the sitagliptin impurity (XGT062-05), and the method has important significance in research of the sitagliptin impurity.

Owner:北京新康哌森医药科技有限公司

Battery recycling system and method

The invention discloses a system for recycling batteries. The system comprises a combustion chamber of a rotary kiln, a secondary combustion chamber and flue gas purification equipment; the combustion chamber of the rotary kiln comprises a first combustion area and a second combustion area; the secondary combustion chamber is communicated with the combustion chamber of the rotary kiln; the flue gas purification equipment is communicated with the secondary combustion chamber. By the aid of the system for recycling the batteries, the batteries are combusted in the first combustion area at the temperature ranging from 100 DEG C to 150 DEG C for 30 to 60 minutes, so that sealing rings of the batteries are sufficiently damaged by means of pyrolysis, hydrogen and organic solvents in the batteries are released and are discharged by negative-pressure devices, and the batteries can be effectively prevented from being exploded at a high temperature; then the batteries are combusted in the secondary combustion area at the temperature ranging from 300 DEG C to 500 DEG C, first flue gas generated when the batteries are combusted is completely combusted in the secondary combustion chamber at the temperature ranging from 1200 DEG C to 1350 DEG C to form second flue gas, the second flue gas is purified by the flue gas purification equipment to form purified gas, and the purified gas is exhausted into the atmosphere. The system for recycling the batteries has the advantages that the batteries are prevented from being exploded, and the system is safe in operation. The invention further provides a method for recycling the batteries.

Owner:GANZHOU HIGHPOWER TECH CO LTD

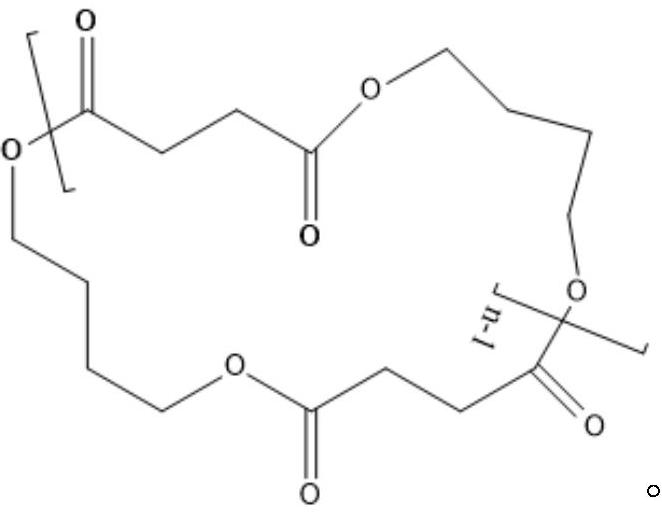

Preparation method of poly (butylene succinate) with low cyclic byproduct

PendingCN114507338AGeneration of effective controlReduce processing stepsBio-packagingPolymer scienceButanedioic acid

The invention provides a preparation method of poly (butylene succinate) (PBS) with low cyclic byproducts, which comprises the following steps: adding titanate, succinic acid and 1, 4-butanediol into a reaction kettle for esterification reaction; and adding a solid-loaded tin catalyst and an auxiliary agent crown ether into the reaction kettle, carrying out condensation polymerization to obtain a polymer melt, and granulating to obtain the poly (butylene succinate) polymer. The content of PBS cyclic by-products is less than or equal to 1wt%, and the PBS has excellent mechanical properties.

Owner:WANHUA CHEM GRP CO LTD

Production method for deep drawing high-carbon steel wire rod

PendingCN113862564AGood billet surface qualityFree from billet grindingCarbon steelHeat conservation

The invention relates to a production method for a deep drawing high-carbon steel wire rod. Steel comprises the following chemical components of 0.69-1.02% of C, 0.15-0.35% of Si, 0.40-0.90% of Mn, less than or equal to 0.35% of Cr, less than or equal to 0.025% of P, less than or equal to 0.025% of S and the balance iron and inevitable impurities. Special casting powder and a large-chamfer crystallizer are adopted for continuous casting, high temperature is adopted for high-speed wire heating, the heat preservation time is controlled, the burning loss of the surface of a steel billet in a heating furnace is increased by adopting oxidizing atmosphere, and network cementite on the surface of the wire rod is smaller than or equal to 0.5 grade.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Water quenching device for electric furnace slag

ActiveCN111004878ACompact structureReduce water vapor generationRecycling and recovery technologiesSlagLiquid steel

The invention discloses a water quenching device for electric furnace slag. The device comprises a main shell, a crushing and cooling unit, a heat exchange unit and a dehydration unit, and is compactin structure, simple and reliable, wherein the main shell is provided with a water cavity and a main material inlet located below a liquid level, the crushing and cooling unit is used for crushing andcooling liquid-state steel slag from the main material inlet, the crushing and cooling process is located below the liquid level so as to effectively control the generation of water vapor, the heat exchange unit controls the water temperature of the water cavity so as to further control the generation of steam, and the dehydration unit is used for dehydrating the water-quenched slag deposited atthe bottom of the water cavity so as to obtain dehydrated finished steel slag, so that the generation of water vapor can be effectively reduced so as to achieve the purposes of water saving and emission reducing.

Owner:北京天朗致达节能环保股份有限公司

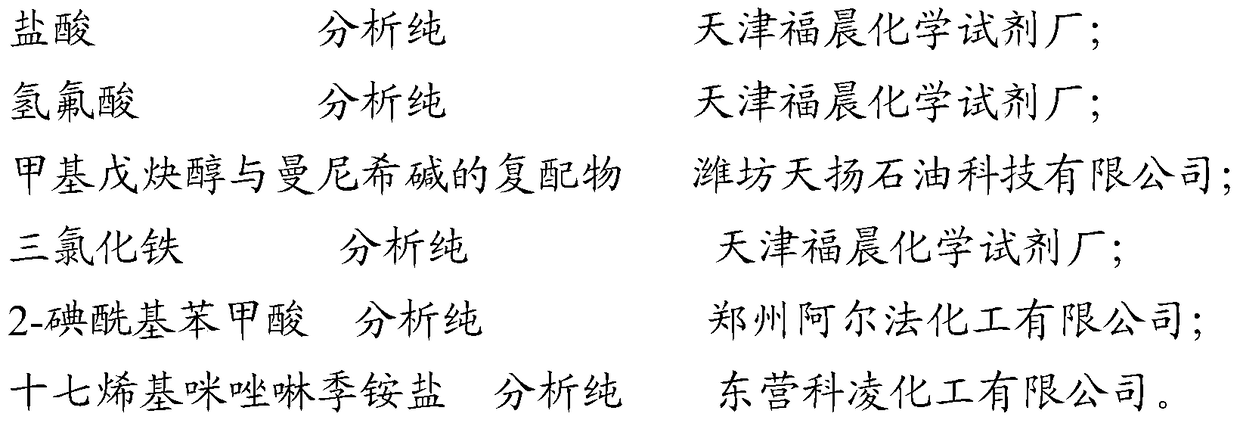

A kind of biofouling cleaning agent and its application

ActiveCN105733858BGood descaling effectPromote safe productionSurface-active non-soap compounds and soap mixture detergentsTreatment using complexing/solubilising chemicalsBenzoic acidBiofouling

The invention discloses a biofouling cleanser and an application thereof and belongs to the field of chemical descaling. The biofouling cleanser includes the following components, by mass, 4-8% of hydrochloric acid, 0.5-1% of hydrofluoric acid, 0.8-1.2% of a compound of methyl pentynol and Mannich base, 2.5-3.5% of ferric chloride, 0.8-1.2% of 2-iodacyl benzoic acid, 0.5-1.2% of heptadecenyl imidazoline quaternary ammonium salt, 0.3-0.6% of hydroxyphosphonoacetic acid, and the balanced being water. The biofouling cleanser has excellent descaling effects and controls the overflow concentration of H2S to be less than 0.2 mg / m<3> without aggravation on oxidizing corrosion and generation of heavy metal pollution. The biofouling cleanser is safe and environment-friendly and is beneficial to safety production in oil fields.

Owner:PETROCHINA CO LTD

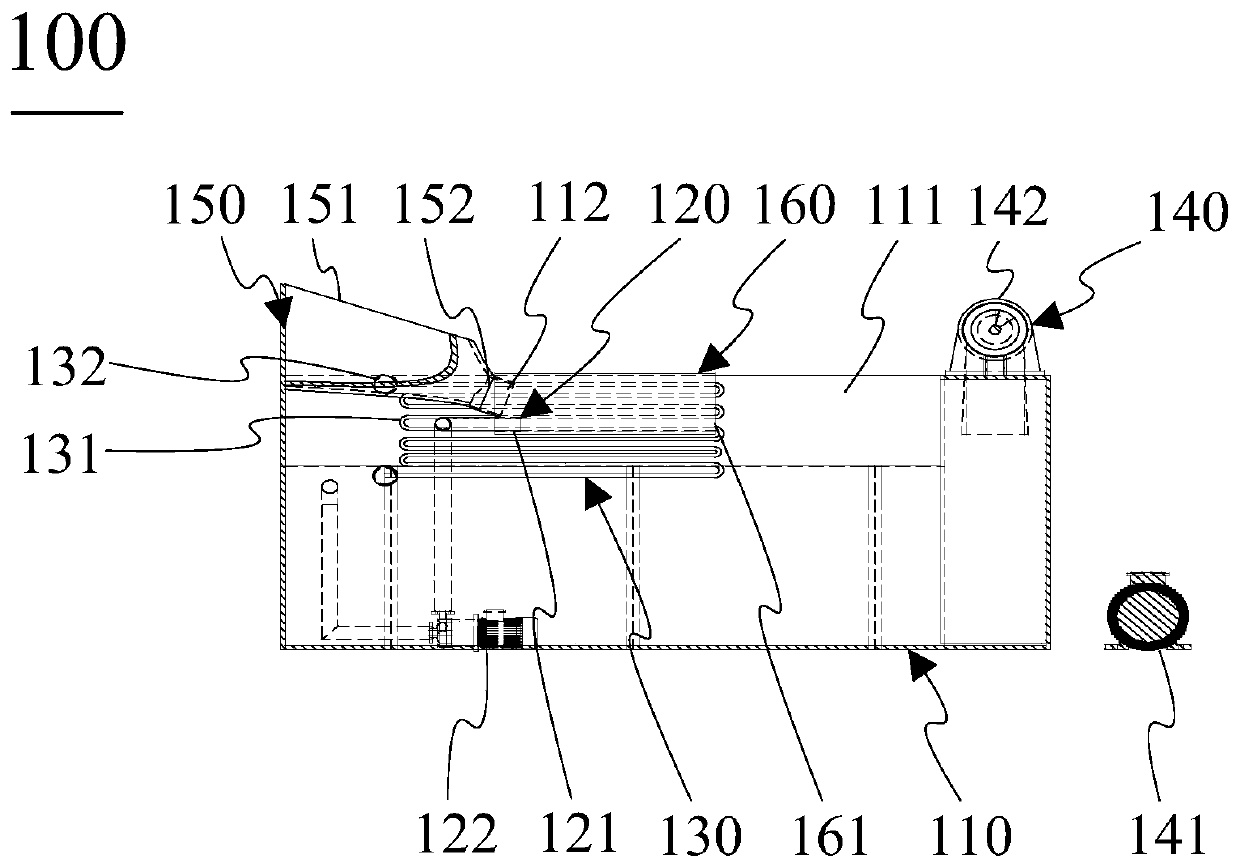

A dry filter and dust removal system for roadway excavation working face

ActiveCN105525939BDoes not affect footage operationsGeneration of effective controlDispersed particle filtrationTransportation and packagingEngineeringRocker arm

The invention provides a dry filter and dust removal system for roadway excavation working face, in which the draw-out fan (5) and the dry filter dust collector (4) are fixedly installed on the bracket (7), and the bracket (7) is nested on the belt conveyor (10) above and installed on the mobile frame (8); the draw-out fan (5) is connected to the dry filter dust collector (4), the negative pressure air cylinder (3), and the dust suction cover (2); the negative pressure air cylinder (3) hang on the top of the tunnel (1) by a monorail crane (9); the dust suction cover (2) is supported on the rocker arm (13) at the rear end of the cutting head (14) in an encircling manner. The dust removal system has high dust removal efficiency, does not occupy a separate mobile power, and can be coordinated with the tunneling process.

Owner:CHINA UNIV OF MINING & TECH

Method of treating rare earth ore concentrate by adopting revolving bed

ActiveCN106755968AGeneration of effective controlPrevent escapeProcess efficiency improvementThermal stateFiltration

The invention relates to a method of treating rare earth ore concentrate by adopting a revolving bed. The method comprises the following steps: compounding rare earth ore concentrate, sodium carbonate, a chlorinating agent and an adhesive according to weight proportion, and uniformly stirring to obtain a mixed material; forming the mixed material in palletizing manner to prepare water-containing green pellets; drying or airing the water-containing green pellets to obtain dried rare earth pellets; adopting the revolving bed to roast the dried rare earth pellets to obtain thermal-state pellets; water quenching the thermal-state pellets, and adding calcium chloride for wet-type ore grinding to obtain ore pulp; and filtering or carrying out suction filtration on the ore pulp, and carrying out elution to separate solid and liquid so as to obtain filter residue and rare earth chloride solution. According to the method, plenty of alkali is not needed during the roasting process, and when rare earth is extracted from the roasted product, water can be directly added for leaching without introducing acid or alkali, so that the cost is low, the economic benefit is excellent, and the environmental protection index is excellent. In addition, the invention further relates to a system capable of adopting the method to treat rare earth ore concentrate.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

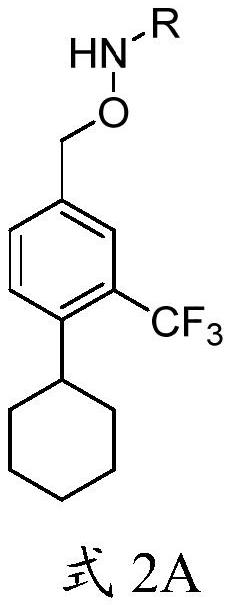

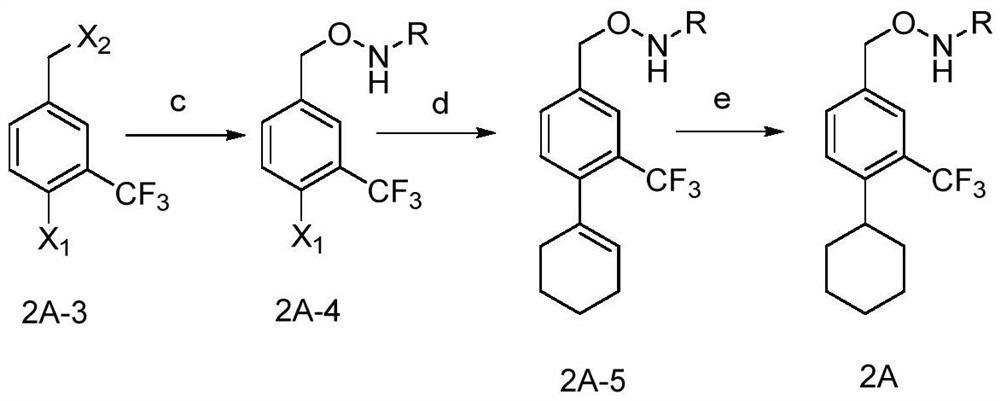

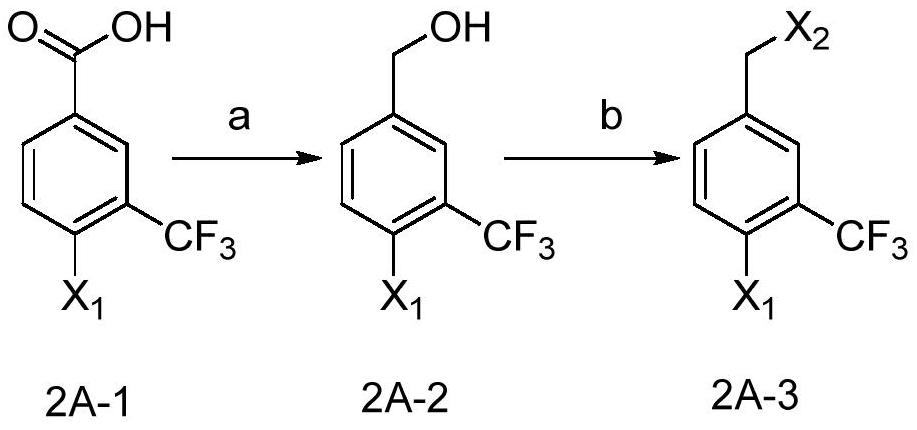

Intermediate of siponimod and synthesis method thereof

The invention relates to a novel intermediate compound (a compound as shown in a formula 2A) of siponimod, a synthesis method of the novel intermediate compound, and a method for synthesizing siponimod by adopting the compound as shown in the formula 2A. Specifically, 3-trifluoromethyl-4-halogenated benzoic acid or 3-trifluoromethyl-4-halogenated toluene is taken as an initial raw material and is subjected to reduction, bromination, coupling, substitution and reduction to obtain a compound as shown in a formula 2A, and R is Boc or Ac.

Owner:SUZHOU KELUN PHARMA RES CO LTD

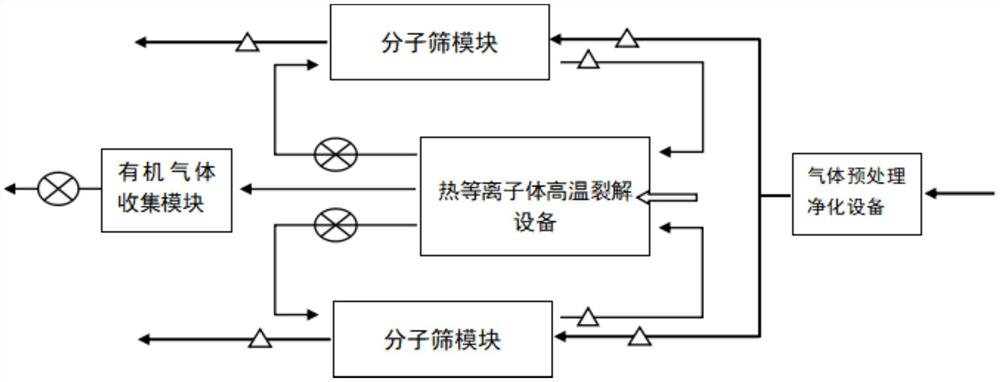

A method of using thermal plasma to heat treat organic waste gas

ActiveCN111495115BLysis completelyGeneration of effective controlHuman health protectionGas treatmentMolecular sieveNitrogen oxides

The invention relates to the technical field of organic waste gas treatment, in particular to a method for using thermal plasma to heat treat organic waste gas. It includes the following steps: gas pretreatment and purification, molecular sieve adsorption and desorption, gas ultra-high temperature cracking and combustion, and tail gas treatment. The thermal plasma pyrolysis equipment provided by the present invention has a high temperature in the combustion working area, a heating block, and a more thorough exhaust gas cracking and combustion effect; when the thermal plasma pyrolysis equipment is working, it does not need external air to supplement the air for combustion, which greatly reduces the gas intake and The tail gas treatment capacity greatly reduces the cost of use; the core area of the thermal plasma pyrolysis equipment can be fed with protective gas as needed, and the protective gas can realize high-temperature anaerobic pyrolysis of organic waste gas, thereby effectively controlling the generation of nitrogen oxides, and can Completely avoid the risk of explosion.

Owner:江苏先竞等离子体技术研究院有限公司

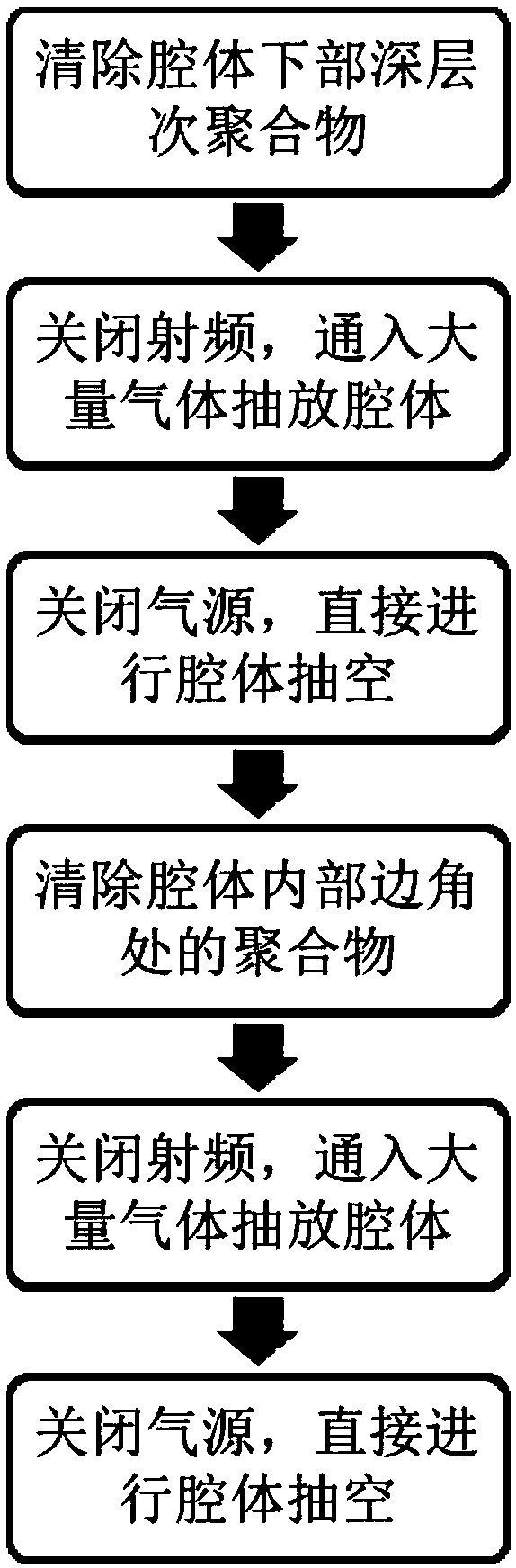

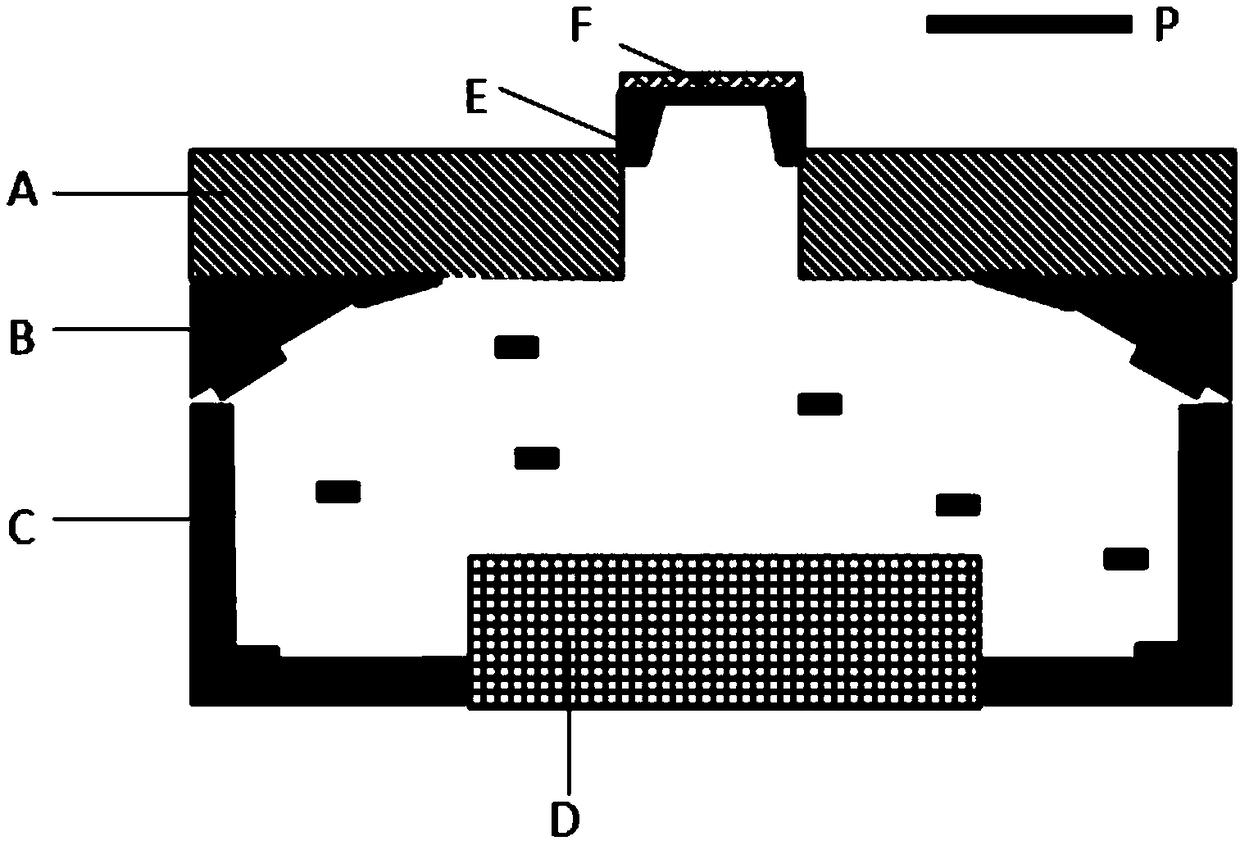

A maintenance method for prolonging the maintenance time interval of etching cavity opening

ActiveCN106449345BGeneration of effective controlGeneration of controlElectric discharge tubesManufacturing cost reductionThermodynamics

The invention discloses a maintenance method for prolonging a time interval of opening maintenance of an etching cavity. The polymer accumulated in the cavity is removed under the closed state of the etching cavity. The method comprises the following steps: utilizing low-pressure high-flow high-power gas and high-pressure low-flow high-power isotropous plasma etching to respectively remove the polymers from the lower part and inner corner of the cavity, and then discharging the suspending grains generated by etching reaction from the cavity by pumping the high-flow gas and under the effect of the subsequent pumping. The plasma cleaning technology is periodically applied to the cavity; the lower level of the accumulation volume of the polymers in the etching cavity can be guaranteed; the generation of the grains can be effectively controlled; the product defects generated by the grain production can be reduced; the time interval of the opening maintenance can be obviously prolonged; the purposes of further increasing the production capacity and lowering the manufacturing cost are achieved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

An electric furnace slag water purification device

ActiveCN111004878BGeneration of effective controlGeneration of controlRecycling and recovery technologiesWater savingThermodynamics

The invention discloses an electric furnace slag water purifying device. Wherein, the electric furnace slag water purifying device includes a main casing, a crushing cooling unit, a heat exchange unit and a dehydration unit, and has a compact, simple and reliable structure. Among them, the main shell has a water cavity and a main feed port below the liquid level. The crushing and cooling unit crushes and cools the liquid steel slag from the main feed port. Since the crushing and cooling process is below the liquid level, the water vapor can be effectively controlled In addition, the heat exchange unit controls the water temperature of the water cavity to further control the generation of steam; the dehydration unit dehydrates the water quenched slag deposited at the bottom of the water cavity to obtain dehydrated finished steel slag. Thus, the generation of water vapor can be effectively reduced, thereby achieving the goal of water saving and emission reduction.

Owner:北京天朗致达节能环保股份有限公司

Novel gene necessary for production of conidium from Magnaporthe grisea and its uses

The invention provides a new gene MgCON1 necessary for the production of pyrosporium conidia and its use. The gene and its cDNA, encoded protein and promoter respectively have the nucleotide or amino acid sequences of SEQ ID No.: 1, No.: 2, No.: 3 and No.: 4 in the sequence table. The encoded product of this gene has a C2H2 zinc finger domain, is localized in the nucleus, and is specifically expressed in conidiophores, conidiophores, and appresses; its knockout results in complete inability to produce conidia in Pyrosporium and loss of ability to infect rice leaves. The expression of MgCON1, the cleavage of transcripts and the expression, modification and localization of the encoded protein, as well as the signaling pathways involved in the gene can be used as important candidate targets for the design and screening of new antifungal agents.

Owner:CHINA AGRI UNIV

Compound concrete and preparation method thereof

The invention relates to the technical field of concrete, and provides a compound concrete and a preparation method thereof, wherein the compound concrete is high in strength, good in crack-resisting effect, excellent in anti-bending performance, strong in freezing resistance, resistant to corrosion and low in cost. The compound concrete comprises the following raw materials in parts by weight: 70 to 80 parts of water, 150 to 160 parts of cement, 490 to 500 parts of recycled coarse aggregate with the particle diameter between 5 and 40mm, 180 to 190 parts of recycled fine aggregate with the particle diameter between 0.15 and 4.75mm, 65 to 75 parts of stone slurry powder, 1 to 3 parts of fluidizer, 5 to 15 parts of water glass and 3 to 7 parts of ethylene polypropylene monofilament fibers. The preparation method comprises the following steps: (1) preparing the recycled coarse aggregate and the recycled fine aggregate; (2) preparing the stone slurry powder; and (3) stirring the mixed raw materials.

Owner:董发达

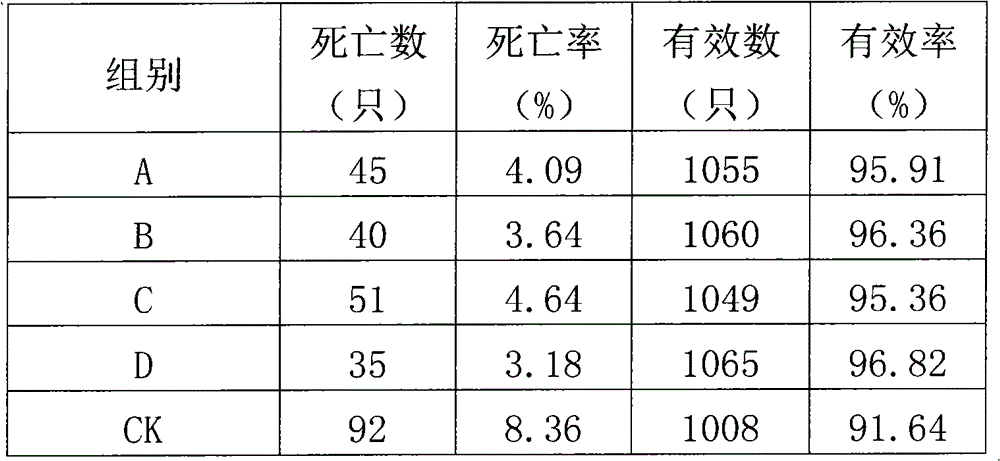

Medicine composition used for controlling poultry airsacculitis, and preparation method thereof

ActiveCN102813910BImprove efficacyEasy to useTetracycline active ingredientsCyclic peptide ingredientsDiseaseEscherichia coli

Owner:NANJING AGRICULTURAL UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com