A kind of biofouling cleaning agent and its application

A cleaning agent and biofouling technology, applied in complex/solubilizer treatment, surface active non-soap compound and cleaning composition, detergent composition, etc., can solve the problem of aggravating pipeline oxidation and corrosion, and achieve excellent corrosion and mitigation Corrosion effect, improve oil field safety production, excellent descaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

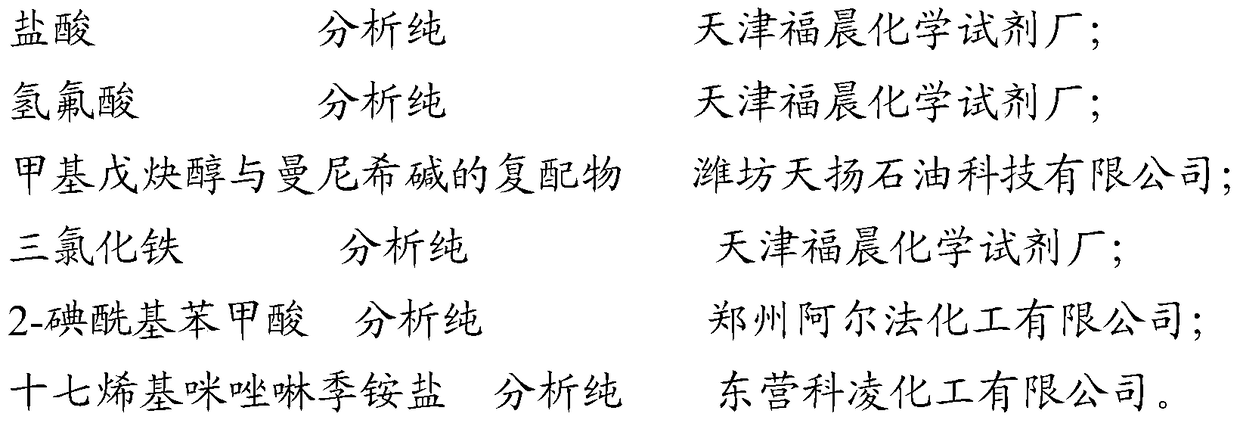

[0029] Specifically, the preparation method of the above biofouling cleaning agent includes: according to the mass percentage of each component in the biofouling cleaning agent, hydrochloric acid, hydrofluoric acid, a compound of methylpentynol and Mannich base, three Ferric chloride, 2-iodobenzoic acid, heptadecenyl imidazoline quaternary ammonium salt, and phosphonoglycolic acid are slowly added into water, and after stirring evenly, a biofouling cleaning agent is obtained.

[0030] On the other hand, an embodiment of the present invention provides an application of the above-mentioned biofouling cleaning agent in treating biofouling in an oil field water injection pipe network.

[0031] Specifically, the steps of using the biofouling cleaning agent provided by the embodiments of the present invention to treat the oilfield water injection pipeline network include:

[0032]101. According to the pipe diameter, length, and fouling degree, determine the concentration and dosage ...

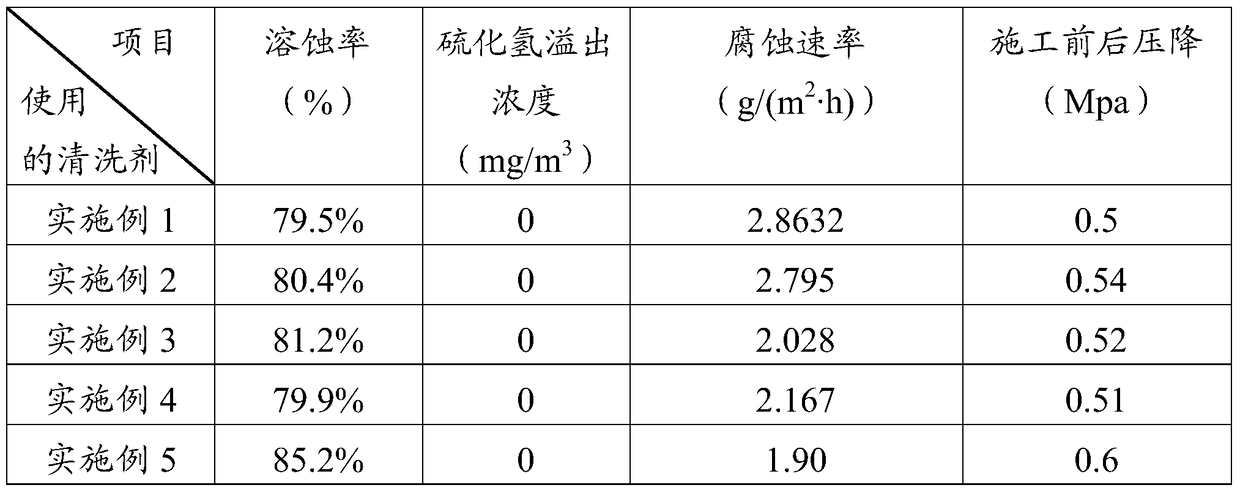

Embodiment 1

[0042] This embodiment provides a biofouling cleaning agent, comprising the following components in mass percentage: 4% hydrochloric acid, 0.6% hydrofluoric acid, 1% compound of methylpentynol and Mannich base, trichlorohydrin 2.5% iron oxide, 1% 2-iodobenzoic acid, 0.6% heptadecenyl imidazoline quaternary ammonium salt, 0.5% phosphonoglycolic acid, and the balance is water. Wherein, in the compound of methylpentynol and Mannich base, the mass ratio of methylpentynol to Mannich base is 1:9.

Embodiment 2

[0044] This embodiment provides a biofouling cleaning agent, comprising the following ingredients in mass percentage: 6% hydrochloric acid, 0.5% hydrofluoric acid, 1% compound of methylpentynol and Mannich base, trichloro 2.8% iron oxide, 0.8% 2-iodobenzoic acid, 0.5% heptadecenyl imidazoline quaternary ammonium salt, 0.4% phosphonoglycolic acid, and the balance is water. Wherein, in the compound of methylpentynol and Mannich base, the mass ratio of methylpentynol to Mannich base is 1:9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com