Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

194results about How to "To meet preparation needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

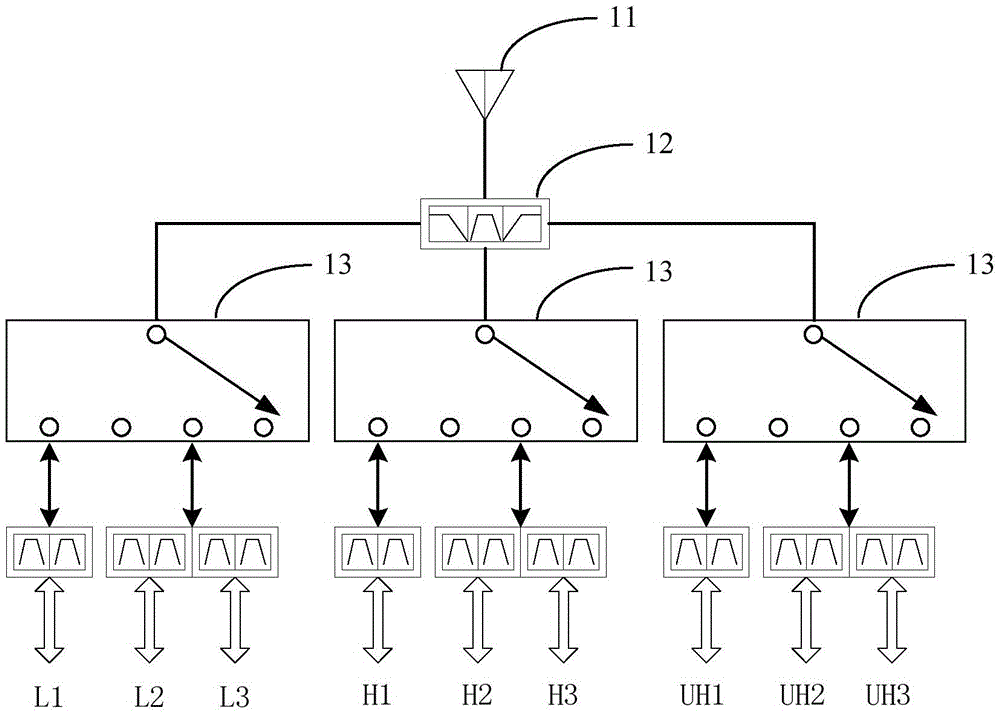

Radio frequency circuit of LTE carrier wave polymerization technology and communication equipment thereof

ActiveCN106712795ASmall insertion lossEnsure wireless communication effectTransmission path sub-channels allocationCarrier signalPolymerization

The invention discloses a radio frequency circuit of an LTE carrier wave polymerization technology and communication equipment thereof. The radio frequency circuit comprises at least one L*M switch, a combiner and a 1*N switch. When the L*M switch is in a carrier wave polymerization mode, switch logic of the L*M switch is selectively connected to a radio frequency path of the combiner. During non-carrier-wave polymerization mode work, through an L*M switch device and one 1*N switch, the combiner is bypassed so that performance in a non-carrier-wave polymerization work mode is guaranteed. In the invention, the radio frequency circuit of a new LTE carrier wave polymerization technology is adopted, circuit insertion losses of a communication terminal under the non-carrier-wave polymerization work mode are effectively reduced, simultaneously a large occupation space problem of a plurality of antenna circuits is avoided, and through flexibly applying the L*M switch device, the radio frequency circuit can satisfy more scene applications.

Owner:HUAWEI DEVICE CO LTD

Laser-electric arc compound welding gun

The invention discloses a laser-electric arc compound welding gun which is characterized in that the welding gun respectively adopts ball screw linear guide rail mechanisms driven by three stepping motors or servo motors to precisely adjust the space positions of a laser focal point and an electric arc electrode along x, y and z three right-angle coordinate axis directions, and meanwhile, a gear pair rotation adjustment mechanism driven by one stepping motor or one servo motor to enable the electric arc electrode to freely rotate around the axial line of a laser beam within a 360-degree range; furthermore, by additional arrangement of an electromagnetic anti-splashing device fed with high-frequency alternating current, the compound welding gun controls a moving path of welding splashing under the mutual action between a magnetic field and a vortex, so that pollution caused by the welding splashing to a laser optical system and an electric arc welding gun protection system can be reduced. Due to the structural design, the compound welding gun disclosed by the invention can meet the requirements on efficient digitalized welding of complicated parts and manufacturing of complicated part additives.

Owner:DALIAN UNIV OF TECH

Method and device for realizing liquid crystal arbitrary orientation control through numerical control micromirror array photoetching

InactiveCN102768472AReduce manufacturing costAvoid graphic distortionPhotomechanical exposure apparatusMicrolithography exposure apparatusNumerical controlUltraviolet

A method for realizing liquid crystal arbitrary orientation control through numerical control micromirror array photoetching utilizes a set of projection photoetching system based on a digital micromirror device (DMD), so the collimated ultraviolet or blue light beams are uniformly irradiated to the surface of the numerical control micromirror array DMD, a computer outputs a shape signal to control all the DMD pixels, i.e. single micromirrors are in different reflection states for realizing intermediate photomask, so the all the DMD pixel reflected lights carry out the shape signal control; the beams are demagnified by a microobjective, and then are projected onto a substrate which has the surface coated with a light-operated orientation material through a polarizing film, exposure is completed through controlling the light intensity and time, and the liquid crystal of an exposure pattern area is reorientated; and another substrate is utilized to form a liquid crystal cell, the liquid crystal cell is filled with the liquid crystal, so preset orientation is realized. The method realizes the control and production of arbitrary patterns and orientation directions, and has a potential important application in the fields of wide viewing angle liquid crystal display, adjustable optical communication devices, wavefront correction, light beam control and the like.

Owner:NANJING UNIV

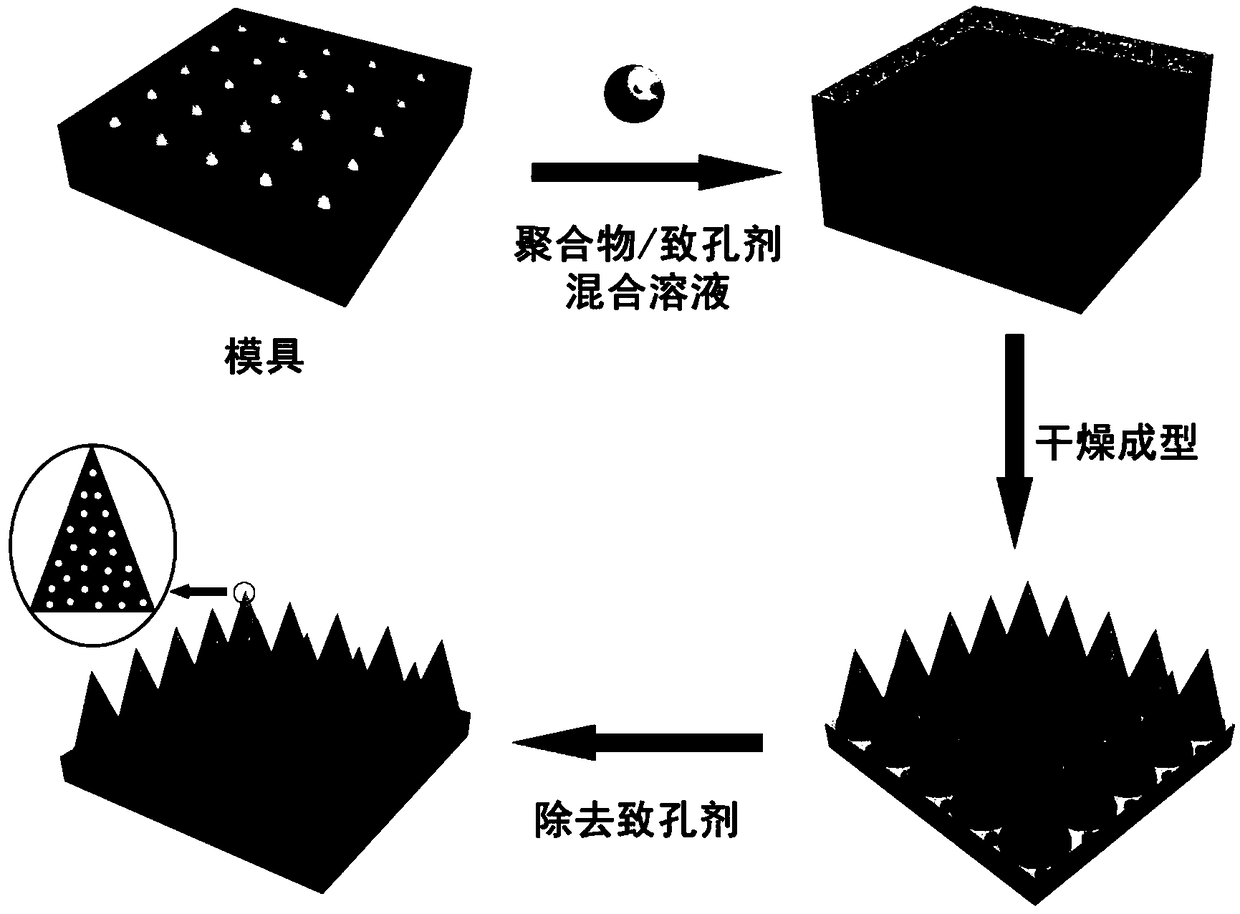

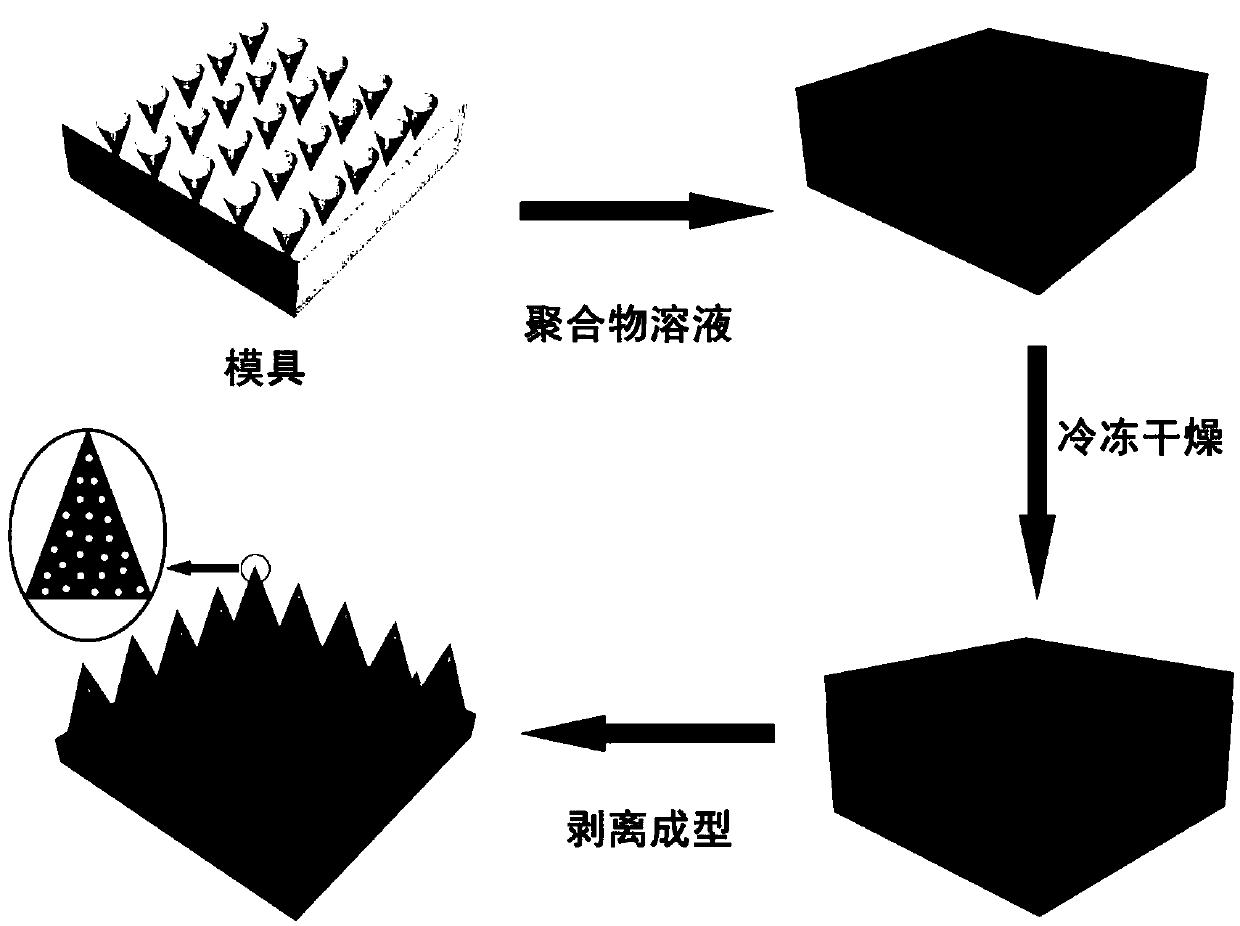

Method for preparing porous polymer micro needle by using template method and application thereof

InactiveCN109364366AOvercome the cumbersome preparation processOvercome the conditionsMicroneedlesPharmaceutical delivery mechanismTissue fluidHair growth

The invention discloses a method for preparing a porous polymer micro needle by using a template method and an application thereof. The method comprises the following steps of: (1) dissolving a polymer and a template agent in a solvent to prepare a polymer solution; (2) filling the polymer solution into a micro needle mould; (3) removing the solvent in the obtained micro needle mould to obtain a solid micro needle; (4) removing the template agent in the obtained solid micro needle to obtain the porous polymer micro needle. By improving the overall process flow design of the preparation method,the method can solve the technical problems of a complex preparation process, harsh conditions, a complicated process, high price, difficult control of the pore structure and size, difficult large-scale production and application and the like of the porous polymer micro needle, the obtained porous polymer micro needle can be used for tissue fluid extraction and transdermal administration, such asskin tissue fluid and blood extraction and transdermal administration of proteins, polypeptides and small molecular drugs in cosmetic, hair growth, immunity, treatment and other applications.

Owner:HUAZHONG UNIV OF SCI & TECH +1

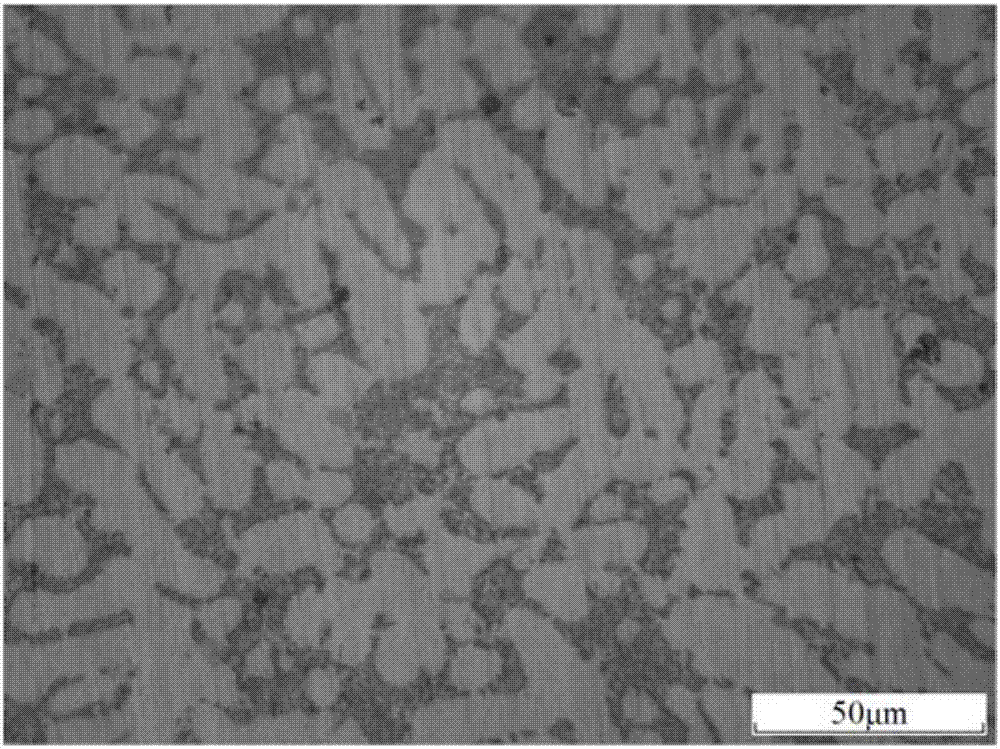

Short-process thermal treatment method of large 35CrNi3MoV steel forgings

The invention discloses a short-process thermal treatment method of large 35CrNi3MoV steel forgings. The short-process thermal treatment method of the large 35CrNi3MoV steel forgings comprises the steps of: slow cooling after forging, isothermal annealing, quenching (or normalizing) and tempering which are carried out sequentially, wherein the slow cooling after the forging is carried out by adopting a hole cooling or furnace cooling mode; in the isothermal annealing, the forgings are cooled to be at the nose temperature (640 DEG C) of a perlitic transformation zone after being austenitized at the velocity not higher than 30 DEG C / h as a furnace for isothermality for 48-66 hours, and pearlites are subjected to the isothermal decomposition and then are cooled to be at the room temperature; as the quenching is carried out, the recrystallization refining is achieve, and crystalline grains is equalized; finally, the tempering at high temperature can eb carried out to obtain a favorable comprehensive mechanical property. The short-process thermal treatment method of the large 35CrNi3MoV steel forgings, provided by the invention, is short in technology process (the total time lasts for about 120 hours), also can be used for obtaining the original austenite mean grain size above ASTMN0.8, can meet the manufacture requirement on power station equipment of thermal power, nuclear power and the like and also can meet the manufacture requirement on large force bearing and transmission structure components large metallurgy, mine and transportation equipment of our country.

Owner:JIANGYIN HENGYE FORGING

A method for prepare a positive electrode material precursor by using waste ternary lithium battery

ActiveCN109193057ALow costSimultaneous recyclingWaste accumulators reclaimingProcess efficiency improvementManganeseCobalt

The invention provides a method for preparing a positive electrode material precursor by using a waste ternary lithium battery, which adopts a first stage leaching as a pressurized ammonia leaching torealize simultaneous recovery of lithium, nickel and cobalt. The second stage leaching is atmospheric pressure acid leaching to realize the recovery of doped metal (manganese or aluminum). The invention realizes low cost of waste ternary positive electrode material, Short-process recovery and reuse, in which nickel is leached by ammonia under pressure, the comprehensive leaching rate of valuablemetals such as cobalt and lithium reaches 92%. The comprehensive recovery of valuable metals such as nickel, cobalt, lithium, manganese and aluminum is over 95% by two-stage leaching. Ammonia and leaching acid can be recycled in closed circuit. The precursor of ternary positive electrode materials prepared by regeneration can meet the needs of preparation of different series of ternary positive electrode materials, and has a good prospect of industrial application.

Owner:KUNMING UNIV OF SCI & TECH

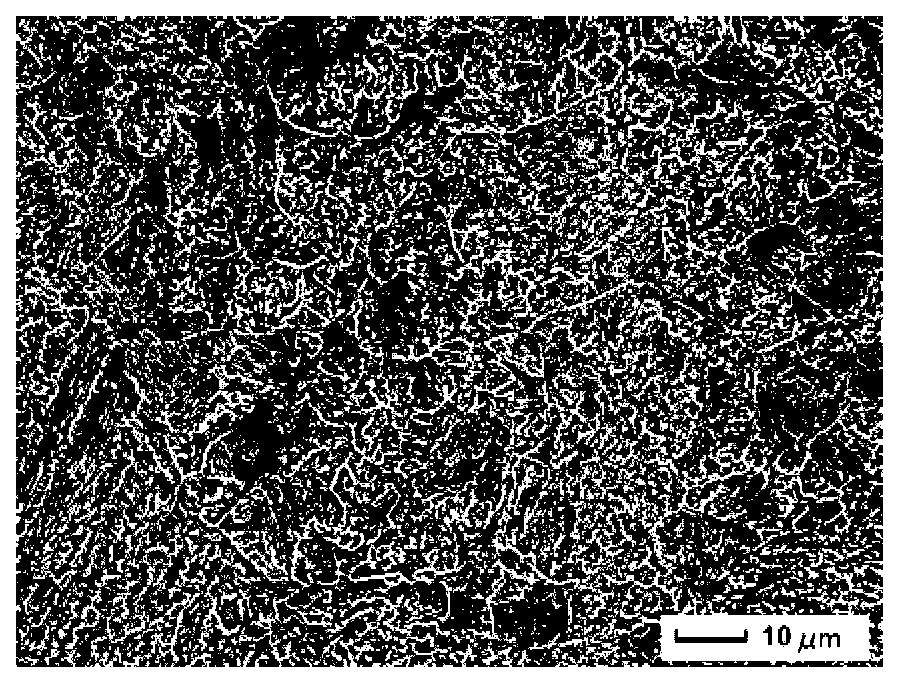

Novel skin/core-layer composite fiber as well as preparation method and application thereof

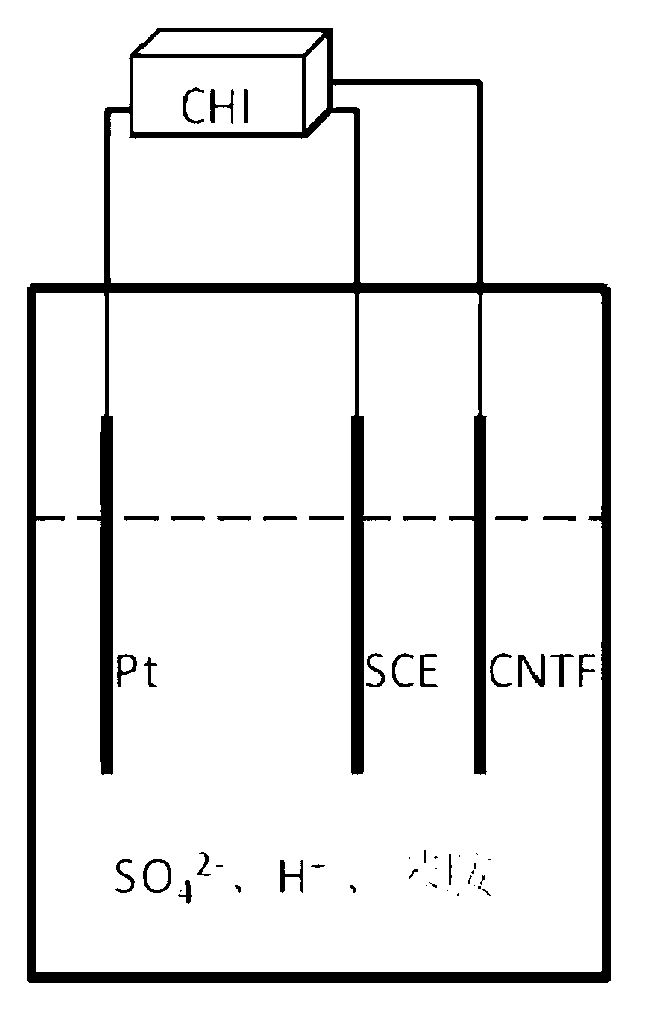

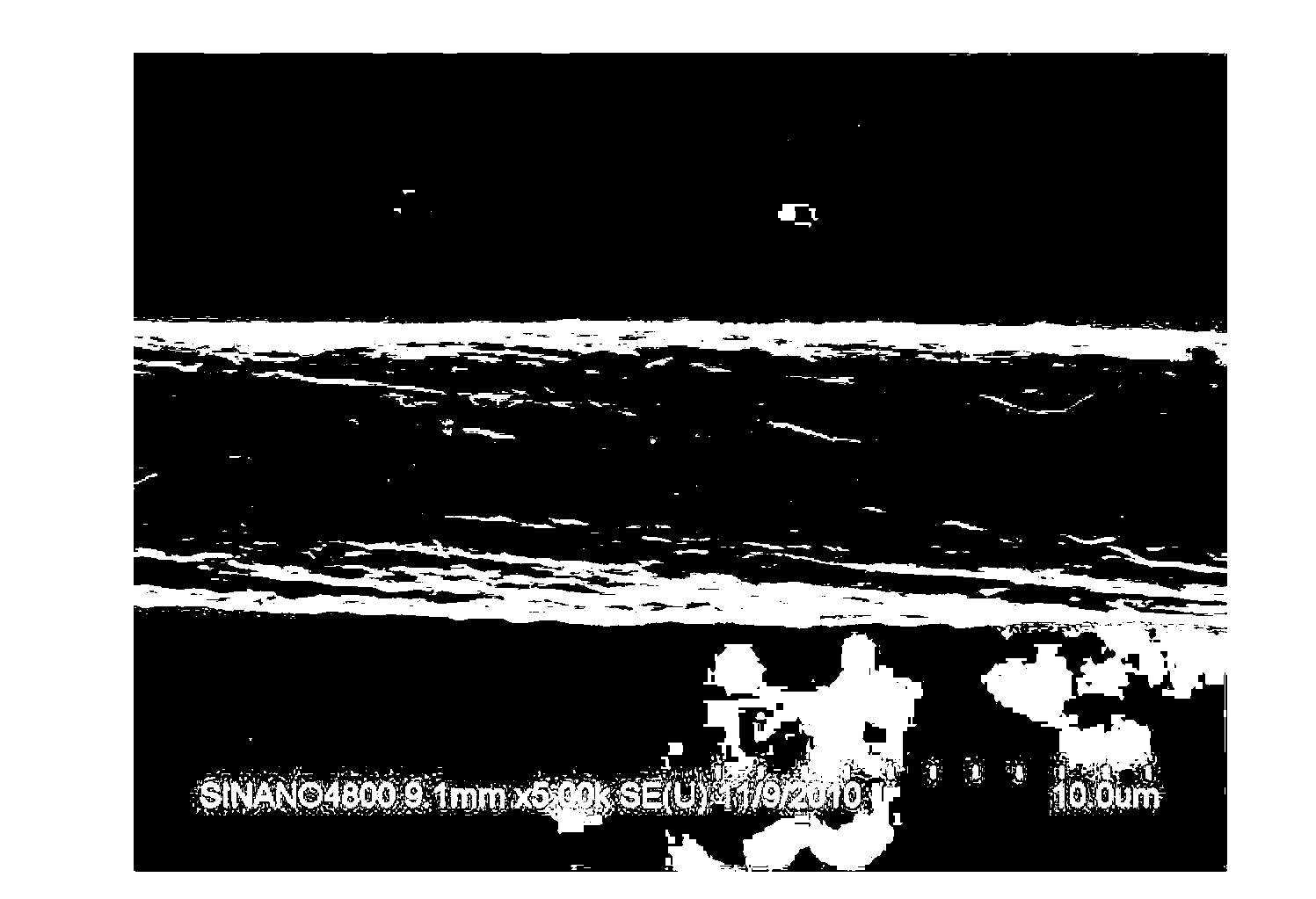

ActiveCN102995162AGood mechanical propertiesHigh strengthCarbon fibresElectrolytic capacitorsFiberPolymer science

The invention discloses a novel skin / core-layer composite fiber as well as a preparation method and application thereof. The novel skin / core-layer composite fiber comprises a carbon nanotube fiber and an electroconductive polymer coated on the carbon nanotube fiber. The preparation method comprises the following steps: firstly, preparing the carbon nanotube fiber by using an array spinning method, a floating catalytic spinning method, a solvent spinning method or the like, then acidizing the carbon nanotube fiber, and depositing the electroconductive polymer on the surface of the acidized carbon nanotube fiber to obtain the bicompoent composite fiber with electroconductive polymer as a skin layer and carbon nanotube fiber as a core layer. The composite fiber has the characteristics of good linear capacitance characteristic, light weight, high strength and the like, is simple, convenient and rapid in preparation method, and is formed through two steps, and the whole preparation process is performed at normal temperature and normal pressure and is low in energy consumption, high in efficiency and convenient to operate.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

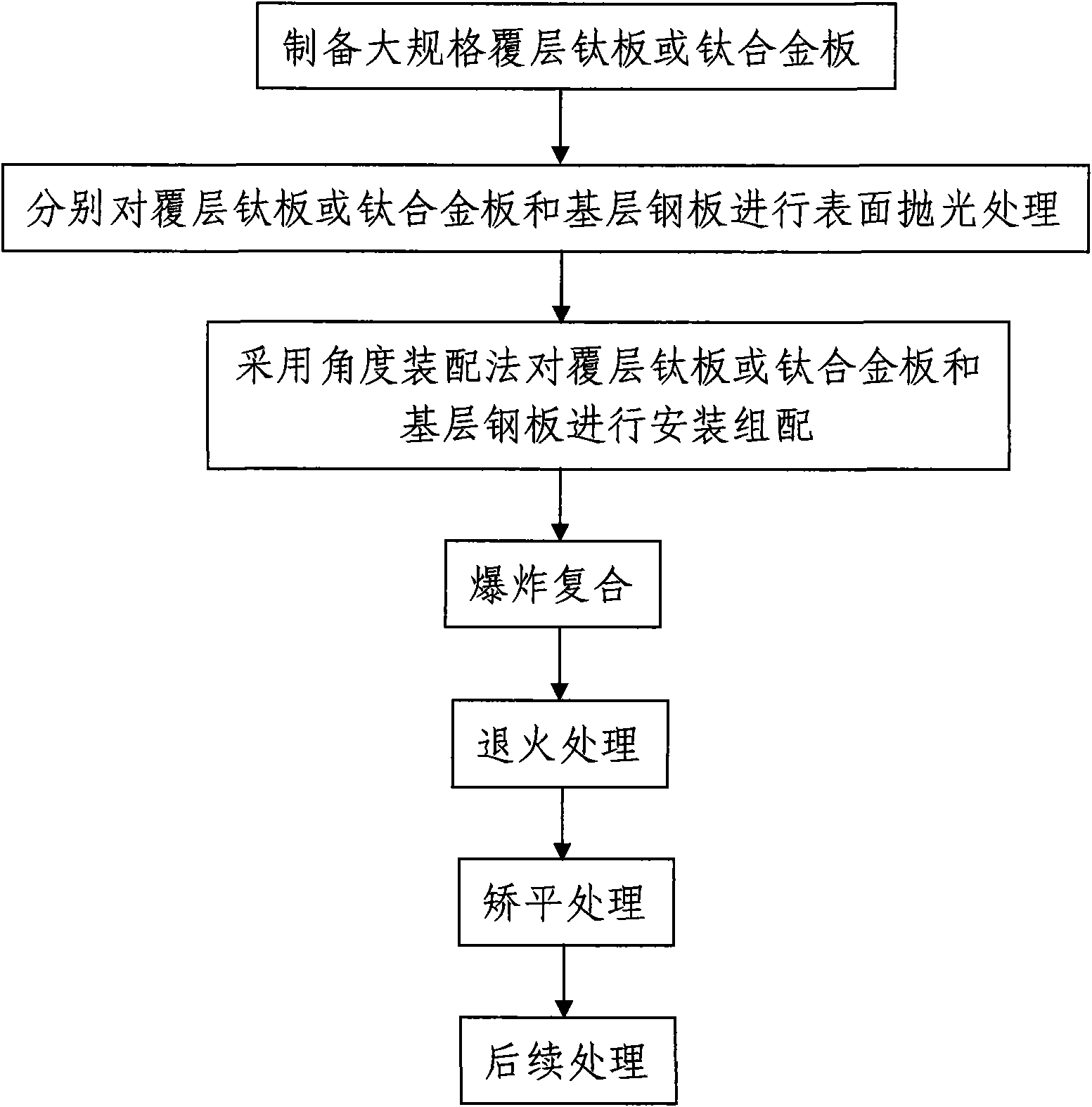

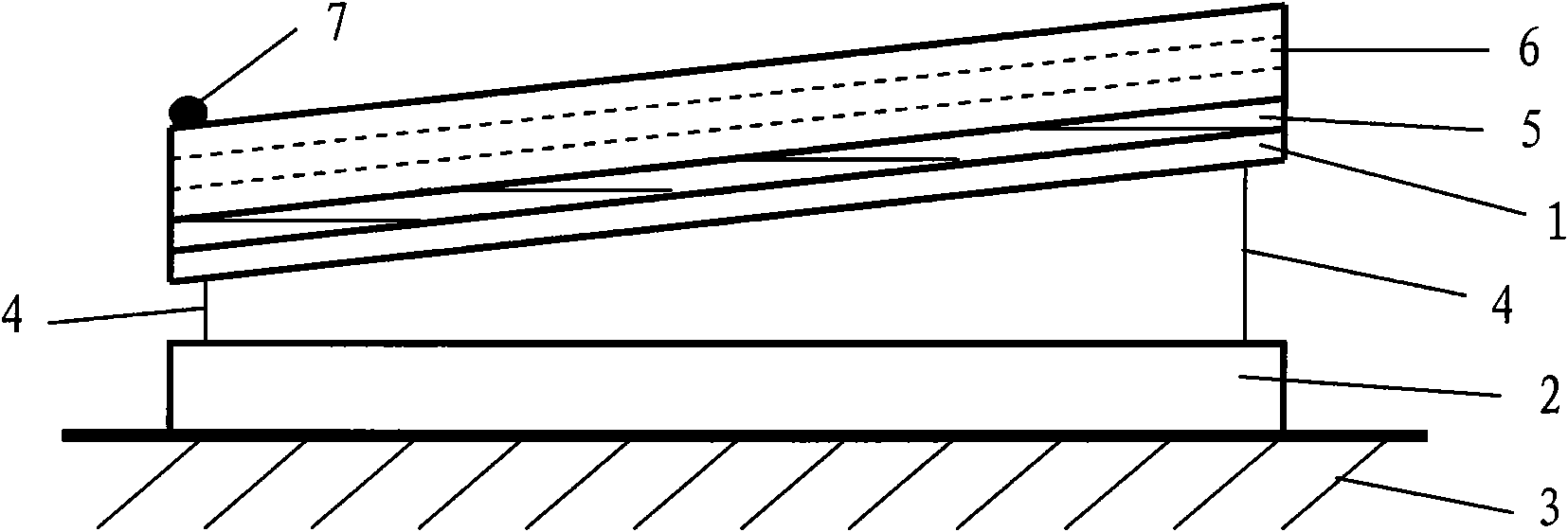

Method for preparing large titanium steel composite plates for nuclear power and thermal power

InactiveCN101590597ASimple preparation processReasonable designOther manufacturing equipments/toolsSheet steelNuclear power

The invention discloses a method for preparing large titanium steel composite plates for nuclear power and thermal power, which comprises the following steps: 1, preparing large cladding titanium plates or titanium alloy plates; 2, respectively performing surface polishing treatment on the cladding titanium plates or the titanium alloy plates and base steel plates; 3, assembling the cladding titanium plates or the titanium alloy plates and the base steel plates by an angle assembly method; 4, performing explosion composition on the cladding titanium plates or the titanium alloy plates and the base steel plates to manufacture preliminary products of large titanium steel composite plates; 5, performing annealing treatment; 6, performing flattening treatment; and 7, performing subsequent treatment, namely performing ultrasonic flaw detection, flamecutting of plate edges, machining of four sides, surface polishing treatment and conventional performance examination on the flattened preliminary products of large titanium steel composite plates. The method has simple operation, convenient implementation and low cost; and the produced large titanium steel composite plates have good quality, and can meet the manufacturing requirement of multiple kinds of large industrial equipment and components on the titanium steel composite plates.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method for manufacturing fine-grain 35CrNi3MoV steel large forging stock

The invention provides a method for manufacturing a fine-grain 35CrNi3MoV steel large forging stock. The method is composed of large-forging ratio forging, isothermal annealing and normalizing which are carried out sequentially, wherein a large-forging ratio is realized through repeated forging; the isothermal annealing comprises the steps of austenitizing the forging stock, then cooling the forging stock in a furnace at a rate of not higher than 30 DEG C / h until the temperature of the forging stock reaches the nasal tip temperature (640 DEG C) of a pearlite transition zone, and then keeping the temperature for 60h, thereby realizing isothermal decomposition of the pearlite; and then cooling the forging stock to room temperature; in addition, the crystalline grains are fined and homogenized through normal normalization, so that an excellent tissue is provided for subsequent production processing. The method provided by the invention is efficient and reliable, and capable of obtaining original austenite mean grain size being above ASTM No.8; and therefore, the method is capable of meeting the manufacture requirements of large load-bearing and transmission structural parts in equipment of fire power station, nuclear power station and the like and in large-scale metallurgy, mine and transportation equipment.

Owner:JIANGYIN HENGYE FORGING

Laser-dipulse MIG (metal-inert gas welding) composite heat source arc AM (additive manufacturing) method for aluminum alloy and workpieces

InactiveCN109079327APerfectly realize the effect of one plus one greater than twoReduce energy consumptionLaser beam welding apparatusMelting tankLiquid metal

The invention provides a laser-dipulse MIG (metal-inert gas welding) composite heat source arc AM (additive manufacturing) method for an aluminum alloy and workpieces. According to the method, low-power pulse laser and dipulse MIG arc are adopted as composite heat sources, an aluminum alloy welding wire is molten to perform surfacing on a substrate according to a designated path, surfacing layersare overlapped layer by layer, and a required aluminum alloy structural member is formed. According to the laser-dipulse MIG composite heat source arc AM method for the aluminum alloy and the workpieces, the low-power pulse laser and the dipulse MIG arc are composited, characteristics of two technologies of laser welding and arc welding are achieved, after the laser and the dipulse MIG are composited, pulse laser with high-peak power acts on a molten pool periodically, so that liquid metal in the molten pool is in a circulation of backward flowing-forward refilling, and equivalently, a strongstirring effect is realized; by means of the impact effect of dipulse waveform, the pore defect in a formed sample can be effectively reduced and even eliminated.

Owner:DALIAN UNIV OF TECH

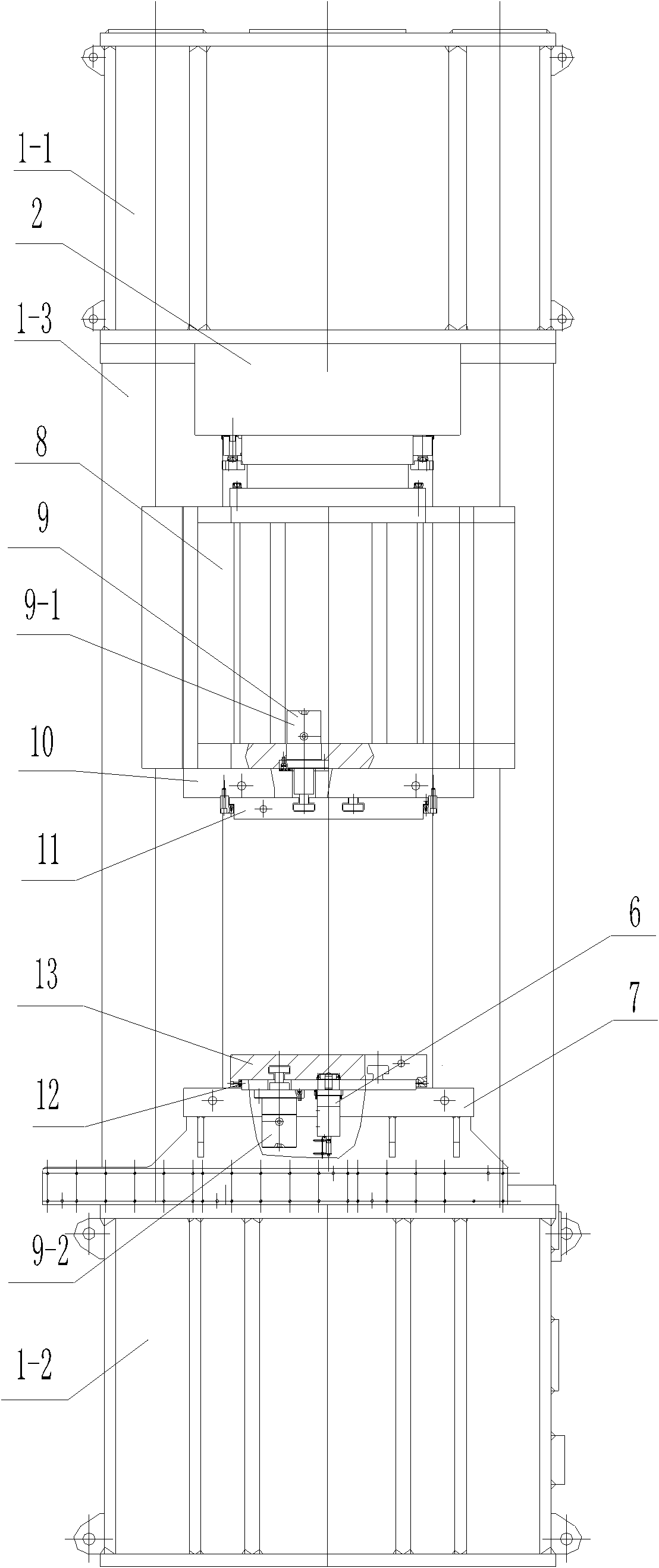

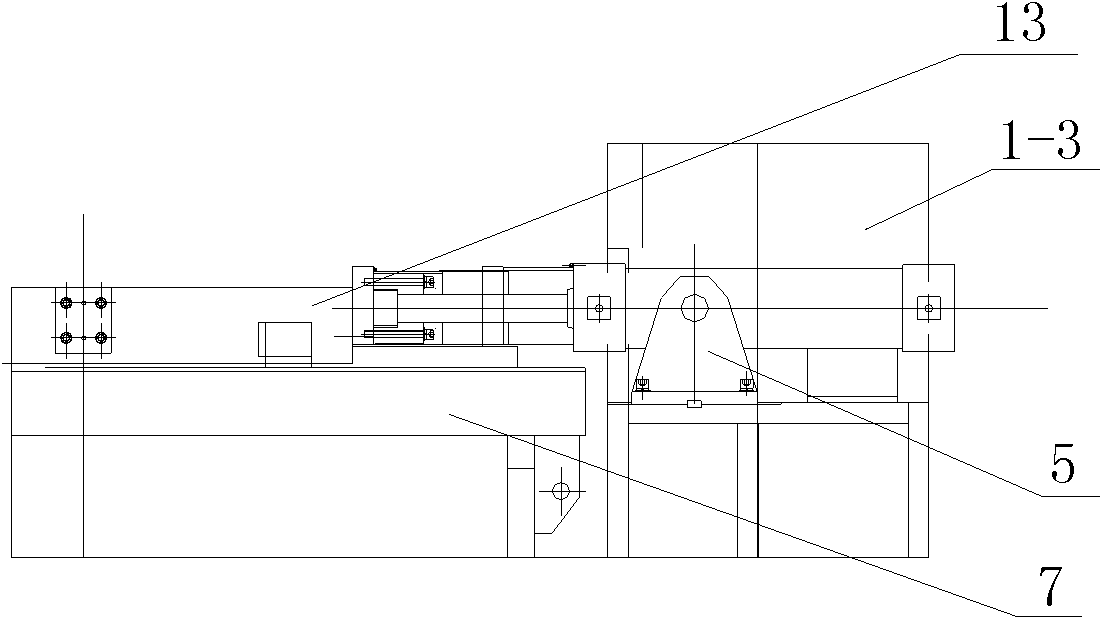

High-accuracy railhead forging hydraulic machine

ActiveCN102059316AReduce labor intensityTo meet manufacturing needsRailway componentsForging/hammering/pressing machinesCompression moldingSlide plate

The invention relates to a high-accuracy railhead forging hydraulic machine which comprises a combined frame type machine body, a main cylinder, a side cylinder, a sliding block and a movable work table, wherein the combined frame type machine body consists of an upper beam, a lower beam and four upright posts, and the sliding block is connected with the main cylinder and the side cylinder. The high-accuracy railhead forging hydraulic machine is characterized in that an upper cushion plate and an upper sliding plate are arranged at the bottom of the sliding block; the upper sliding plate is fastened with the sliding block through an upper clamping cylinder; a lower cushion plate and a lower sliding plate are arranged on the movable work table; the lower sliding plate is tightly clamped with the movable work table through the lower clamping cylinder, wherein a mould pushing device is arranged between two upright posts at one side, and a mould positioning device is arranged in the middle of the movable work table. The invention has the advantages that the hydraulic machine is not only suitable for the hot compression molding process of an AT rail heel-end, but also applied to the pressing forming process of plasticity materials according to demands. Because the accuracy retentivity of the heated and pressed high-accuracy railhead forging hydraulic machine is good, the mould pushing device and the mould positioning device can not only realize multi-station pressing and accurate positioning in the multi-station pressing process, and can ensure the high-accuracy pressing of workpieces.

Owner:TIANJIN TIANDUAN PRESS CO LTD

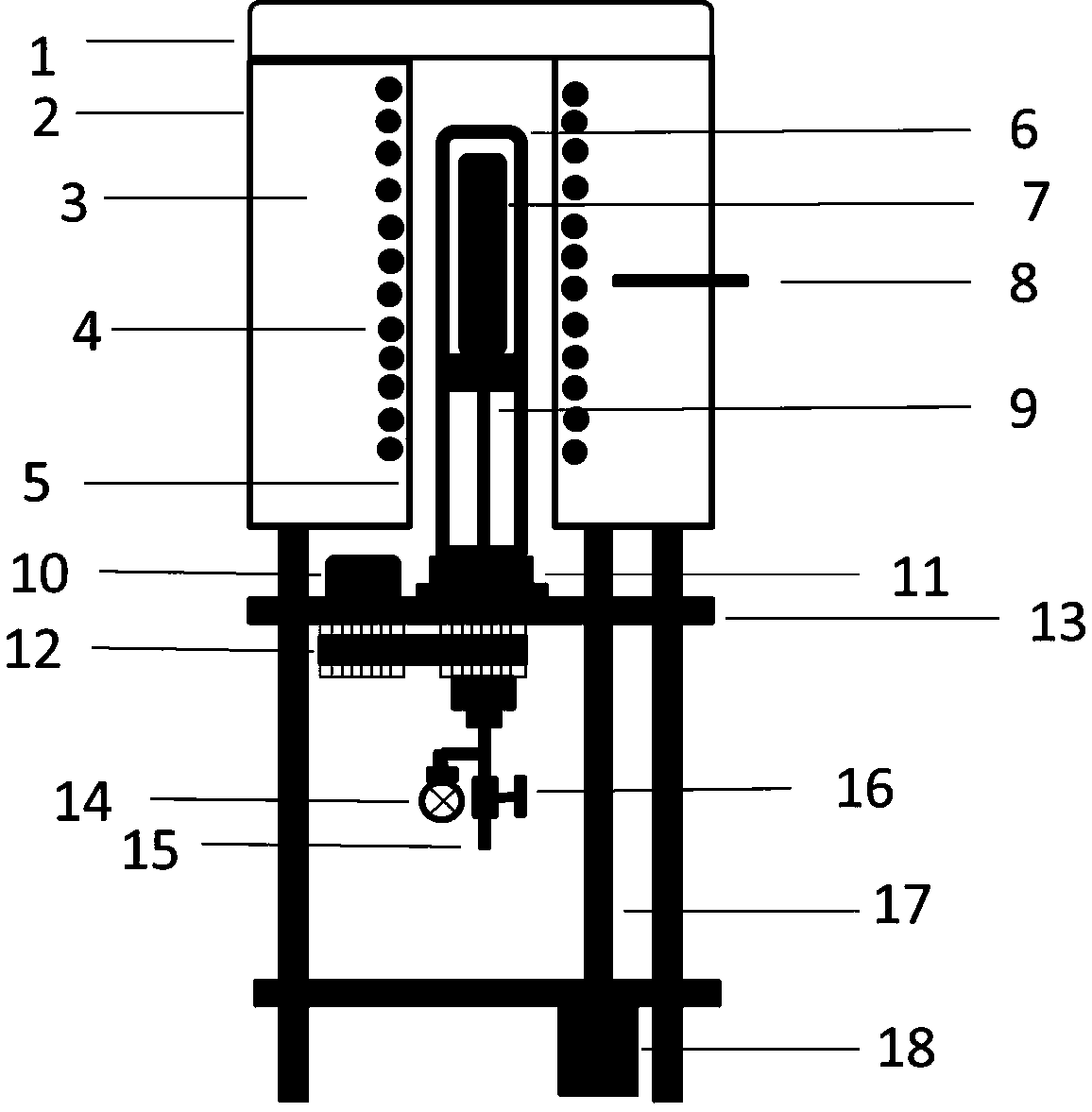

Device and method capable of increasing synthesizing stability of cadmium zinc telluride polycrystals

ActiveCN107904662AReduce pressure difference between inside and outsideAvoid explosive situationsPolycrystalline material growthSingle crystal growth detailsShielding gasCadmium zinc telluride

The invention discloses a device and method capable of increasing the synthesizing stability of cadmium zinc telluride polycrystals and aims to solve the problem that quartz tube explosion occurs easily during the synthesizing of cadmium zinc telluride, and the tube cracking accident is caused. The device and method is characterized in that protective gas is filled into a pressure-maintaining inner container, the internal and external pressure difference of a quartz crucible is balanced or lowered by regulating the gas filling pressure in the pressure-maintaining inner container, raw materialreaction rate is controlled by crystal material distribution, temperature gradient setting or furnace tube ascending and descending, and crystal growth is performed through the temperature gradient setting and the furnace tube ascending and descending. The device and method has the advantages that crucible explosion can be avoided effectively, reaction conditions are mild, phenomena such as tube cracking are avoided effectively, corresponding preparation requirements can be satisfied, and the device and method is promising in application prospect.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

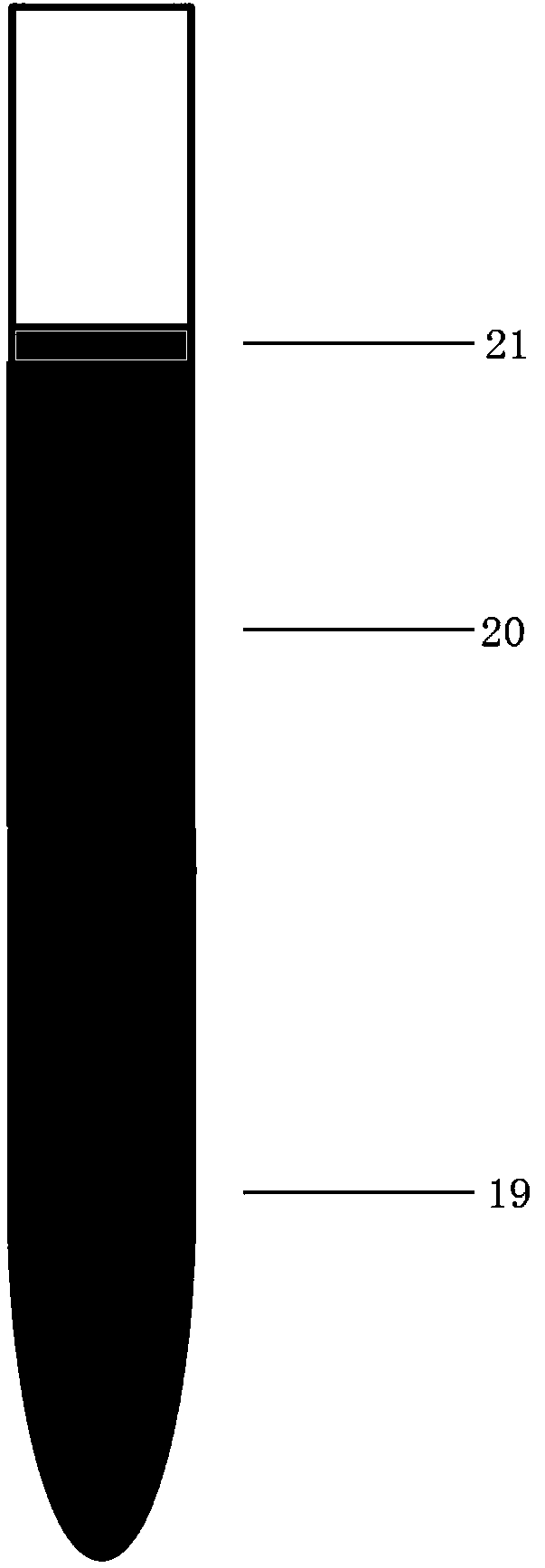

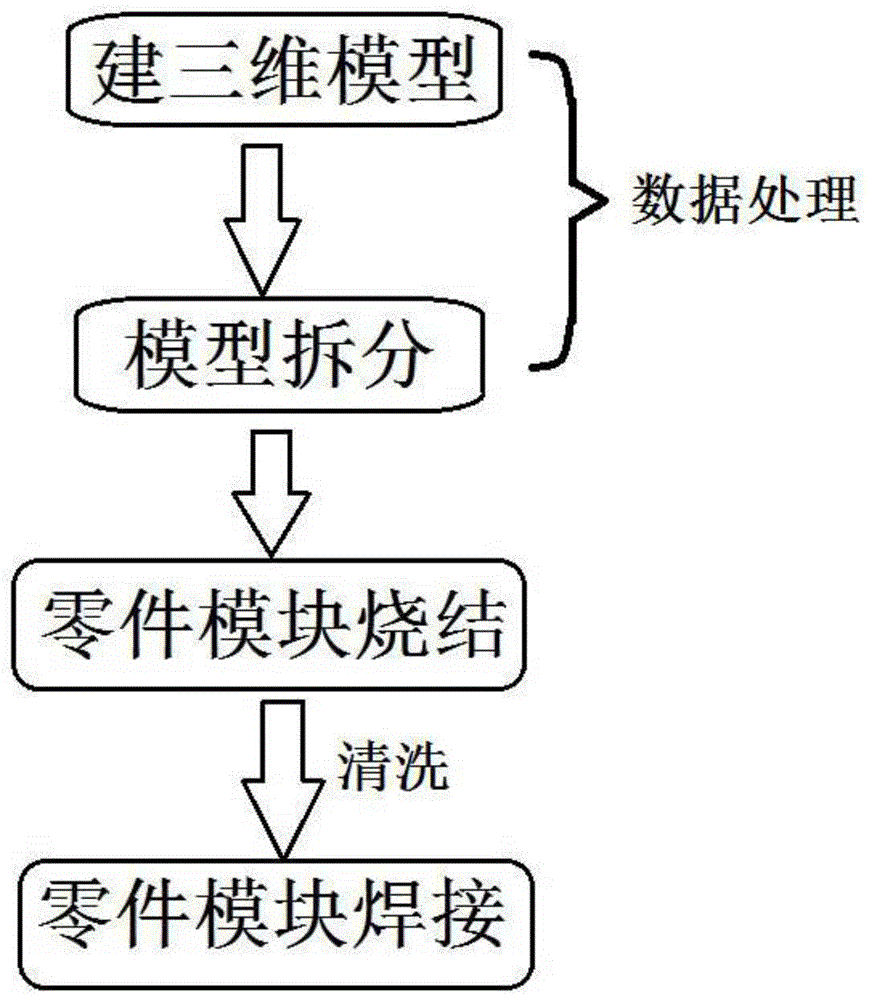

Quick precision mold preparation method

InactiveCN104802339AWide range of mold materialsNo waste of mold materialThree dimensional modelThermoplastic

The invention discloses a quick precision mold preparation method which comprises the following steps: 1, constructing a three-dimensional model, and partitioning into part modules; 2, performing laser sintering to prepare part modules; 3, performing ultrasonic welding on the part modules. By adoption of laser sintering for manufacturing a mold, the mold materials are readily available, waste is avoided, and the cost is low; after 3D modeling, a prototype with complicated structure can be quickly manufactured; by adoption of partitioning design, the whole mold is split and then subjected to ultrasonic welding after laser sintering, so that the preparation requirement of a large-size mold can be met. The ultrasonic plastic welding has the advantages that the welding speed is high, the welding intensity is high, and the sealing property is high; polystyrene is colorless transparent thermoplastic plastic, has glass conversion temperature higher than 100 DEG C, is stable and quick in sintering and small in shrinking percentage fluctuation which is generally 0.2-0.6 percent; ultrasonic welding is pollution-free, and a workpiece cannot be damaged; the welding process is stable.

Owner:SHENZHEN XINLIYANG PRECISION TECH

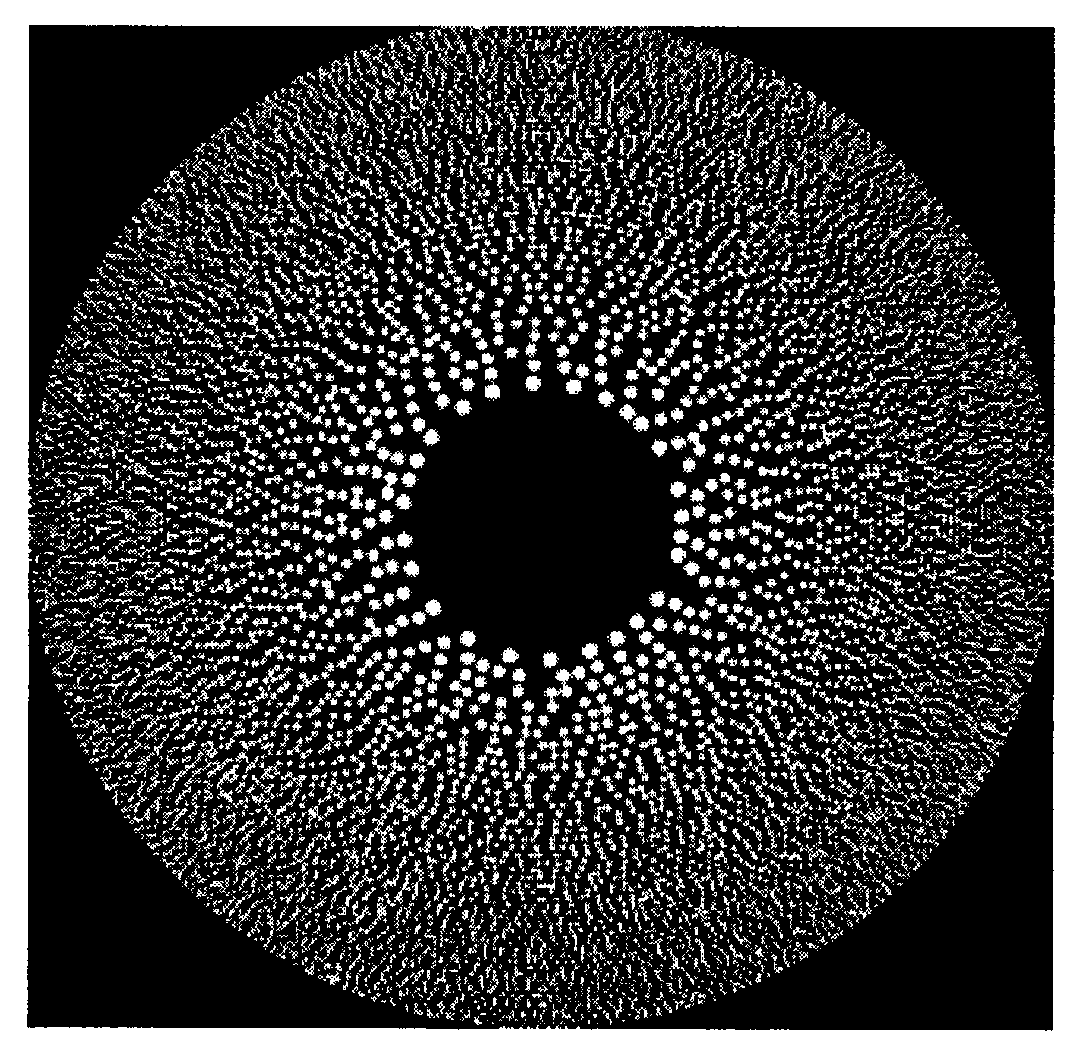

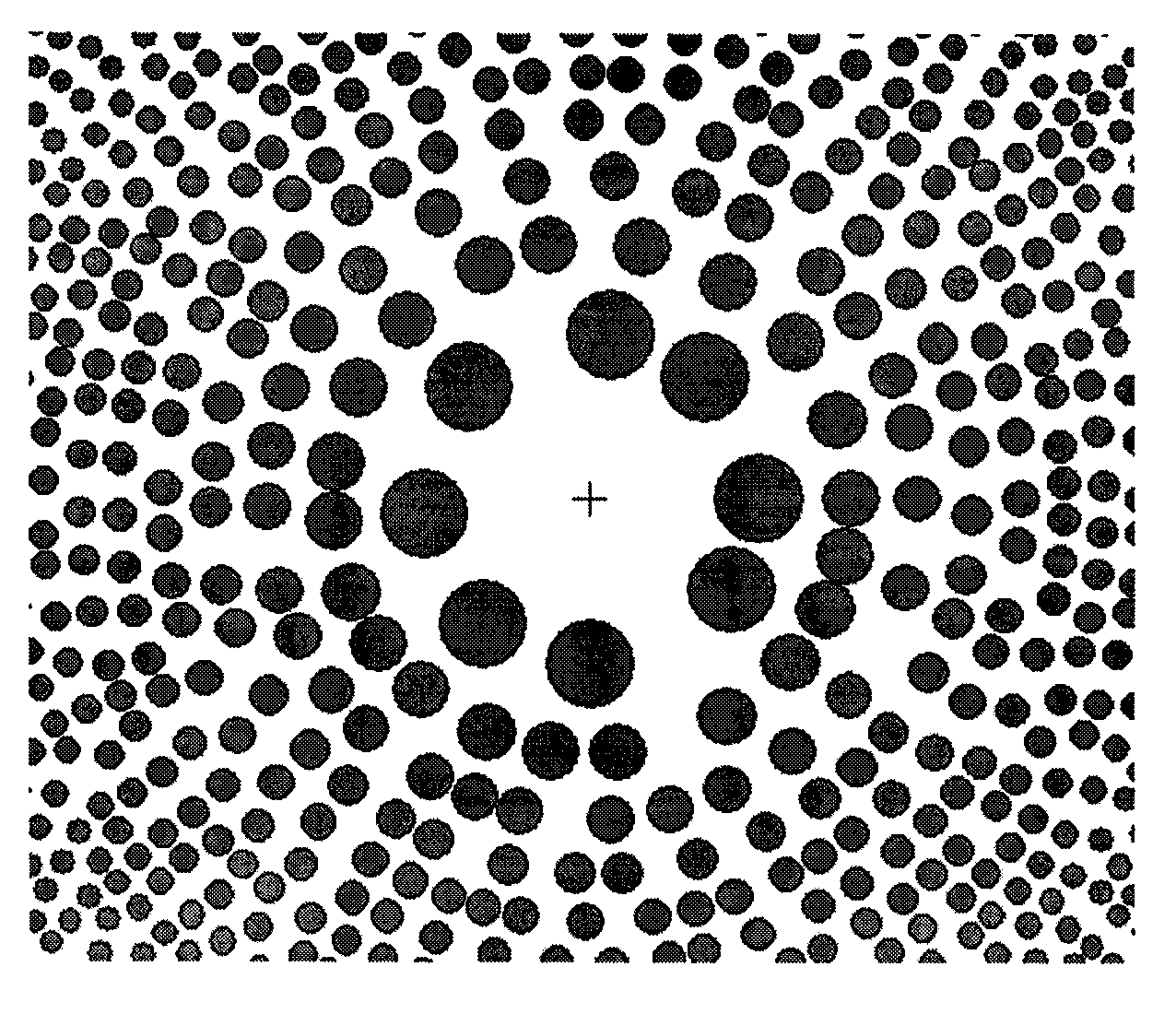

Large-aperture imaging photon sieve and production method thereof

InactiveCN101630027AHigh-resolutionSharp focal spotDiffraction gratingsImage resolutionOptoelectronics

The invention discloses a large-aperture imaging photon sieve and a production method thereof, which belong to the technical field of diffractive optical elements. The large-aperture imaging photon sieve comprises a transparent substrate and an opaque metal thin film plated on the transparent substrate, wherein, a plurality of transparent small holes are randomly distributed on the opaque metal thin film, and the transparent small holes which are randomly distributed lead diffraction light to generate mutual interference, thereby effectively suppressing sidelobe effect and high-level diffraction, improving resolution and obtaining more sharp focal spots. The production method adopts a Connes shaping function for shaping the small holes which are randomly distributed, thereby reducing the number of the holes, reducing the data amount of a layout, optimizing the overall distribution of the small holes, leading the imaging focal spots to be more sharp and leading the level of the existing processing technology to be capable of meeting the manufacturing needs of the large-aperture photon sieve.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

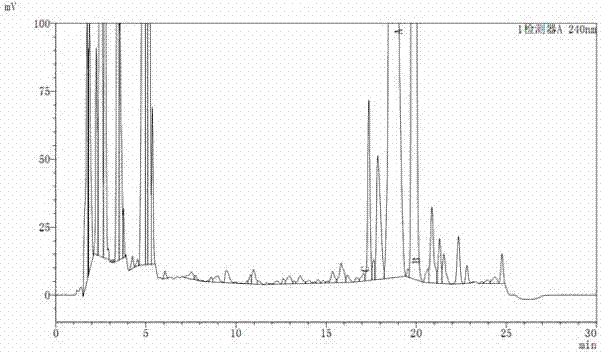

Preparation method of high-purity oritavancin key intermediate A82846B

The invention provides a preparation method of high-purity oritavancin key intermediate A82846B. The preparation method comprises the following steps: separating the oritavancin key intermediate A82846B from a fermented solution, first adjusting a pH, purifying by virtue of macroporous resin, then purifying by virtue of inversed phase chromatography, and finally crystallizing to obtain the high-purity A82846B. The method adopted by the invention is simple in operation, less in consumption of organic solvent, and capable of greatly reducing the generation of waste liquid; and moreover, the defects in the prior art that the adsorption efficiency of cation macroporous resin is low and the product yield is reduced due to the leaked adsorption can be overcome, and the preparation method is suitable for the industrialized production.

Owner:CHONGQING QIANTAI BIOLOGICAL MEDICINE

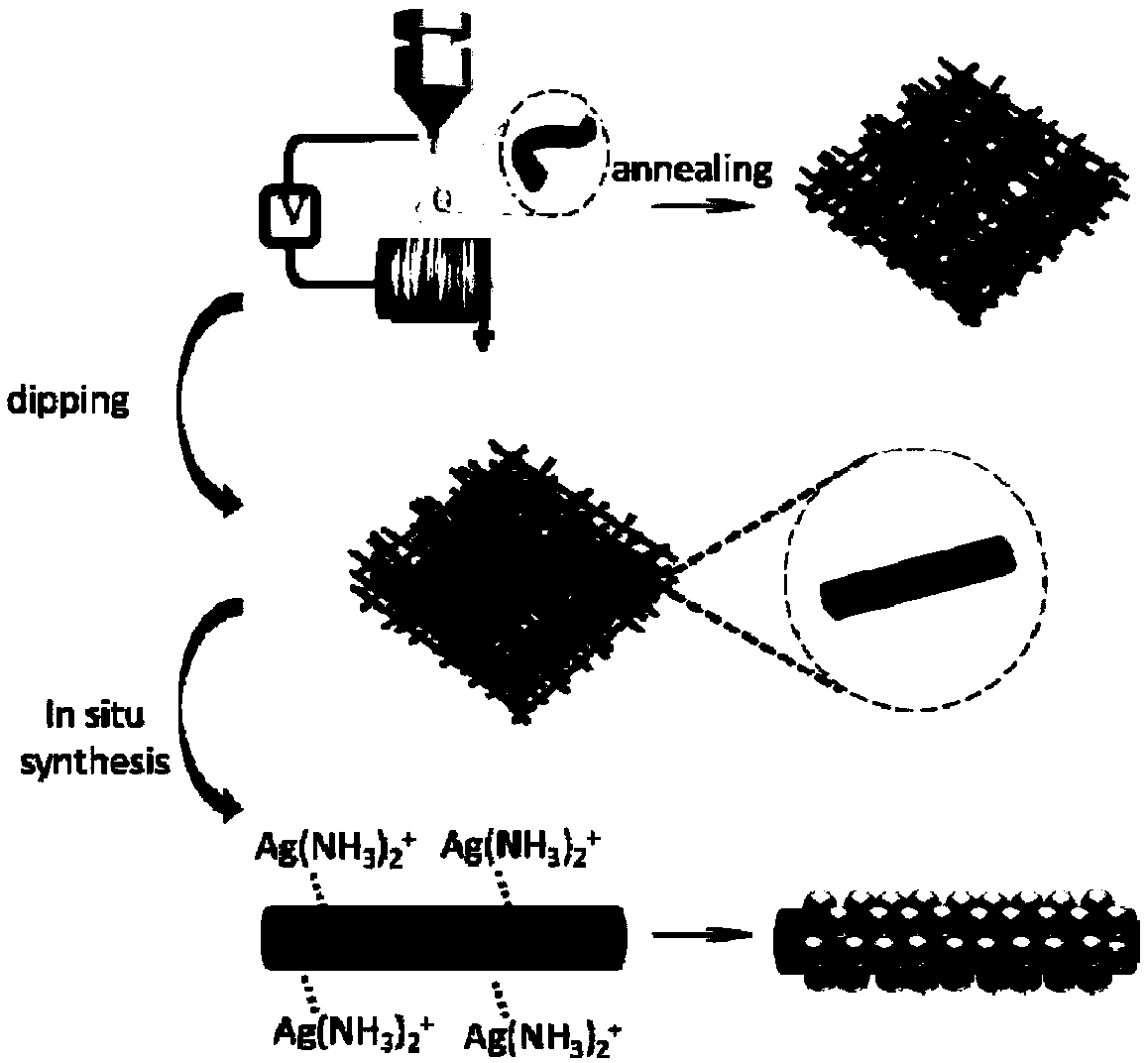

Flexible thermoelectric nanofiber thin film and preparation and application thereof

ActiveCN109295707AExcellent flexibilityGood mechanical strengthFibre typesMonocomponent synthetic polymer artificial filamentElectrospinningNanometre

The invention relates to a flexible thermoelectric nanofiber thin film and preparation and an application thereof, wherein the flexible thermoelectric nanofiber thin film is a PEDOT:PSS-based nanofiber thin film having the surface coated with silver nanoparticles. The preparation includes the steps: the PEDOT:PSS-based nanofiber thin film is obtained by an electrostatic spinning technology; the nanofiber thin film is annealed and then impregnated in a PEDOT:PSS solution, the excess solution on the surface is washed away, and then drying is performed; and the surface of the nanofibers is coatedwith silver nanoparticles by in situ synthesis. The thin film not only has good thermoelectric properties, but also has good mechanical properties and flexibility, and is easily processed into flexible thermoelectric devices. The method provides a new way for preparing the flexible thermoelectric thin film, and has important significance for development of the flexible thermoelectric devices.

Owner:DONGHUA UNIV

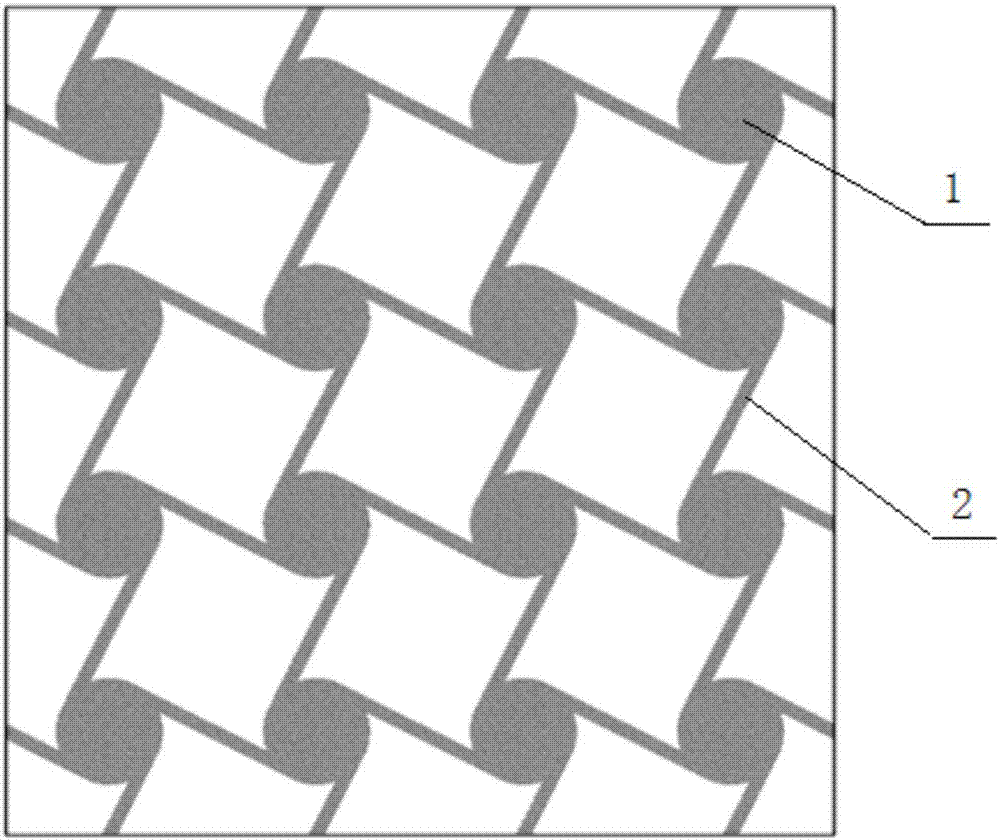

Metal glass metamaterial with chiral microstructure

ActiveCN107012409AIncrease elasticityHigh strengthMaterial nanotechnologyEnergy absorptionMechanical property

The invention provides a metal glass metamaterial with a chiral microstructure. Traditional chiral structural design is applied to a metal glass material. The metal glass metamaterial comprises a cylinder made from the metal glass material and ligaments connected with the cylinder in a tangent mode. The overall mechanical property of the structure can be regulated and controlled by changing the number, the thickness, the length and the arranging mode of the ligaments and the radius of the cylinder. According to the metal glass metamaterial with the chiral microstructure, through perfect combination of the advantages of the chiral structure and the metal glass material, the mechanical properties of a traditional multi-hole material, chiral material and metal glass are greatly improved, the light effect and the negative Poisson ratio can be achieved, the metal glass metamaterial is high in elasticity and strength and large in plasticity, a large-scale metal glass metamaterial is expected to be prepared, and the metal glass metamaterial can be applied to the specific fields such as weight reduction and sound and energy absorption.

Owner:XI AN JIAOTONG UNIV

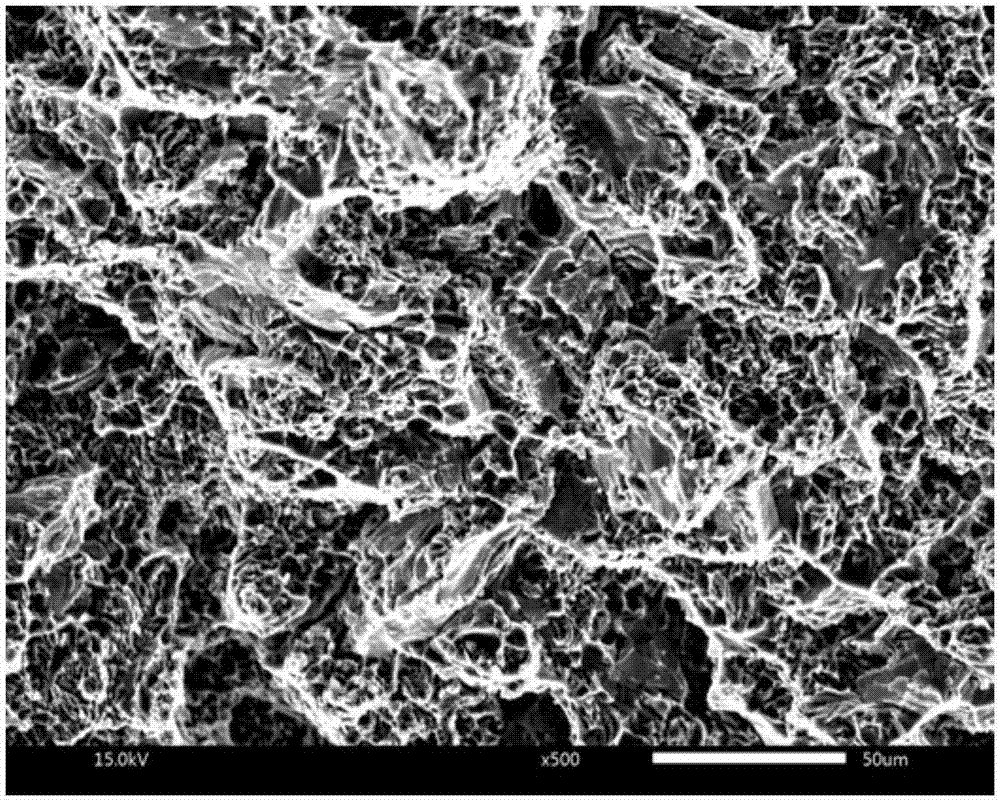

Method and device for improving permeability and homogeneity of resin and reducing pores of prepreg tape

The invention relates to a method and a device for improving permeability and homogeneity of resin and reducing pores of a prepreg tape. The method comprises the steps of firstly rolling for attaching resin adhesive films to the prepreg tape integrated by fiber bundles by a hot pressing roller so as to allow resin to permeate into the prepreg tape preliminarily; and then assisting in pressing through supersonic vibration by a supersonic vibration compressing device so as to obtain the prepreg tape with good permeability and homogeneity of resin and few pores. The device comprises a bundle integrating device for integrating fiber bundles into the prepreg tape, resin adhesive film rolls are arranged at two sides of the bundle integrating device, and the hot pressing roller for rolling for attaching the resin adhesive films at the upper side and the lower side of the prepreg tape to the prepreg tape, the supersonic vibration compressing device for assisting in pressing the rolled attached prepreg tape through supersonic vibration, and a winding device for winding the prepreg tape pressed by supersonic vibration are sequentially arranged in the outlet direction of the bundle integrating device. The method can effectively improve the permeability and the distribution homogeneity of resin in the prepreg tape and overcome the defect of pores in the prepreg tape so as to greatly improve the quality of the prepreg tape.

Owner:XI AN JIAOTONG UNIV

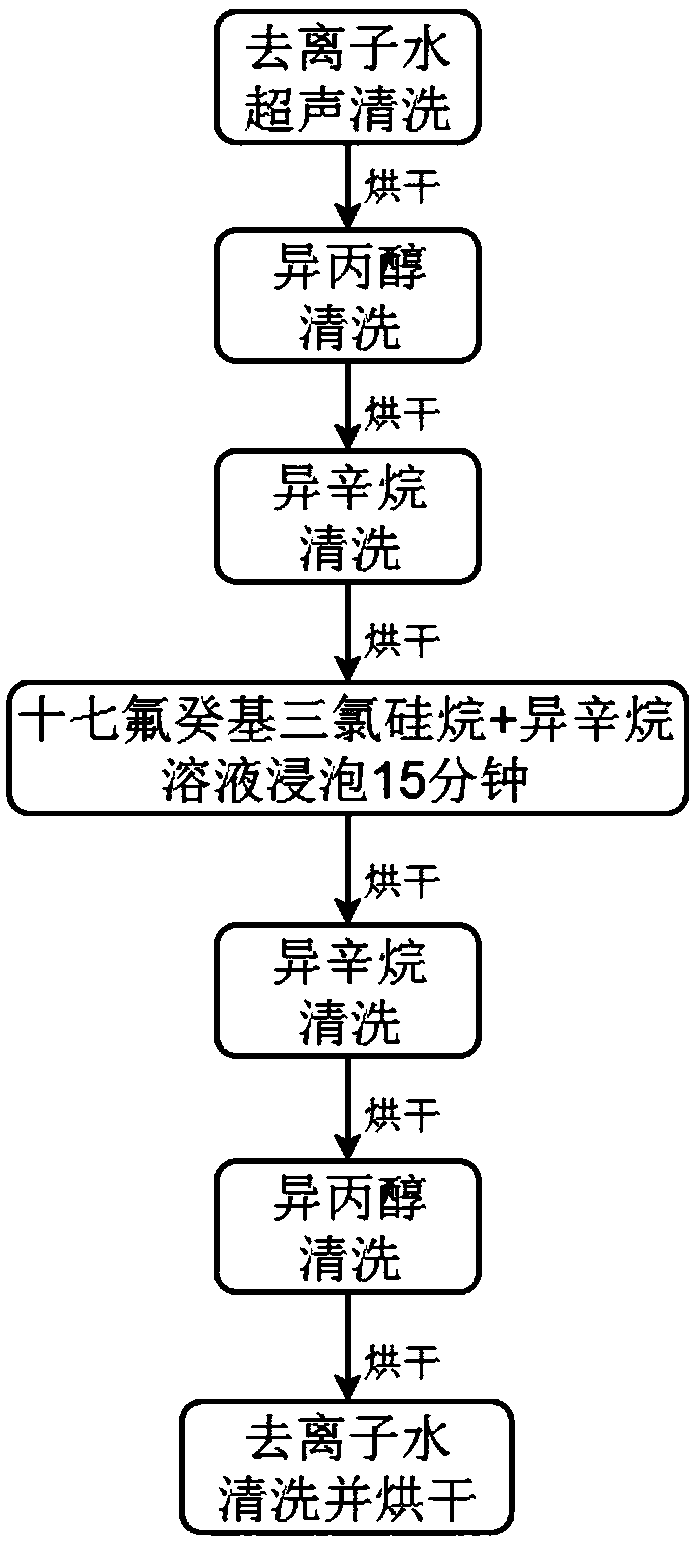

A method for manufacture a flexible transparent electromagnetic shielding film by 3D printing

ActiveCN109041563ASolve the problem of not being able to sinter at high temperatureImprove adhesionAdditive manufacturing apparatusMagnetic/electric field screeningImaging qualityFilm base

A method for manufacture a flexible transparent electromagnetic shielding film by 3D printing includes cleaning and drying a flexible transparent film base material to reduce surface energy; The pretreated flexible transparent film-like substrate is laminated and clamped and fixed on a hard substrate, A 3D spray deposition printing device driven by an electric field is used, a gold spray glass needle is use as a nozzle, a low-temperature sintered non-granular nano silver paste is used as a printing material, and a multi-layer metal mesh is printing on that surface of the pretreated substrate according to a predetermined path to obtain a desired printing height; A substrate of that manufacture metal mesh is vacuum-pumped or an inert gas atmosphere is construct, and a corresponding temperature and a corresponding time are set according to the used prin material, and the conductive treatment of sintering or drying is carried out. The invention not only can realize the manufacture of electromagnetic shielding film influenced by strong electromagnetic shielding efficiency, high light transmittance and low imaging quality, but also can shield electromagnetic waves of different wave bandsby adjusting the mesh period, and has good adaptability and flexibility.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

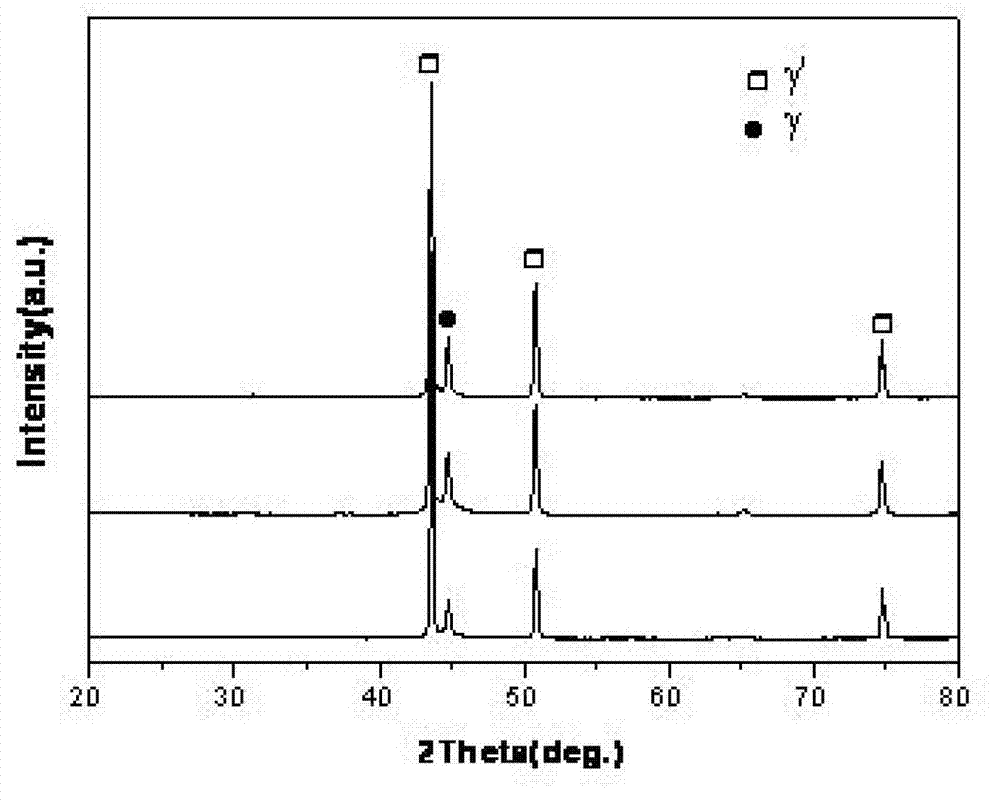

Low-density Ti3Al strengthened super-strength steel and preparing method thereof

The invention relates to low-density Ti3Al strengthened super-strength steel and a preparing method thereof, and belongs to the field of metal materials. The chemical components of the steel comprise, by mass percent, 0.5% to 1.5% of C, 15% to 30% of Mn, 5% to 10% of Al, 5% to 20% of Ti, not larger than 5% of Cr, not larger than 0.2% of Nb, not larger than 2% of Si, not larger than 0.6% of B and the balance Fe and inevitable impurities. Through adding of Ti, Ti3Al is formed, the Ti3Al and k-carbide can jointly generate precipitation strengthening, the steel has the super-high strength and the good plasticity while the density is effectively reduced, the tensile strength reaches above 1350MPa, the ductility reaches above 10%, the density ranges from 6.5 g / cm<3> to 6.9 g / cm / <3>, and the manufacturing requirement of automobile structural parts is met.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

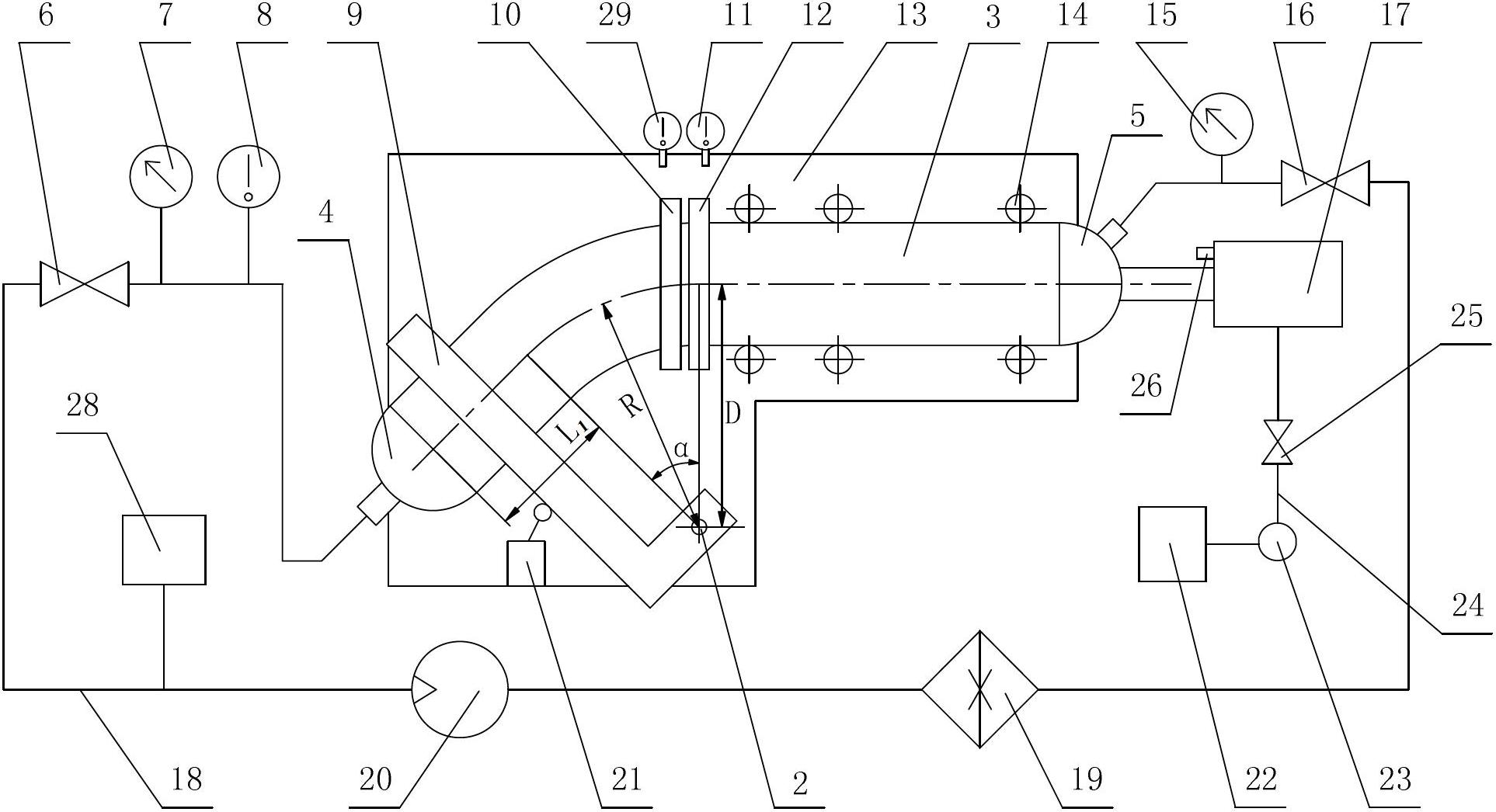

Manufacturing device and method for bimetal composite hot bend

The invention discloses a manufacturing device and a method for a bimetal composite hot bend. The device comprises a thermal induction bend mechanism, an inert gas protecting system and an automatic control system, wherein the thermal induction bend mechanism comprises a rack, a hydraulic cylinder and a hydraulic control system, a rolling wheel, a heating inductor, a limiting stopper, a rotating clamp and a first cooler are arranged on the rack, the inert gas protecting system comprises a gas inlet end socket, an exhausting end socket and a gas circulating pipeline, and a gas inlet end valve, an exhausting end valve, a gas concentration tester, a gas motor and a second cooler are mounted on the gas circulating pipeline. The method includes the steps of intercepting a required bimetal composite pipe, sealing the bimetal composite pipe, installing the bimetal composite pipe on the thermal induction bend mechanism, connecting the inert gas protecting system and roasting and bending. The manufacturing device and the method for the bimetal composite hot bend are reasonable in design, high in intelligent degree, applicability, rate of finished products, product qualities and practicability, and convenient to popularize and apply.

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

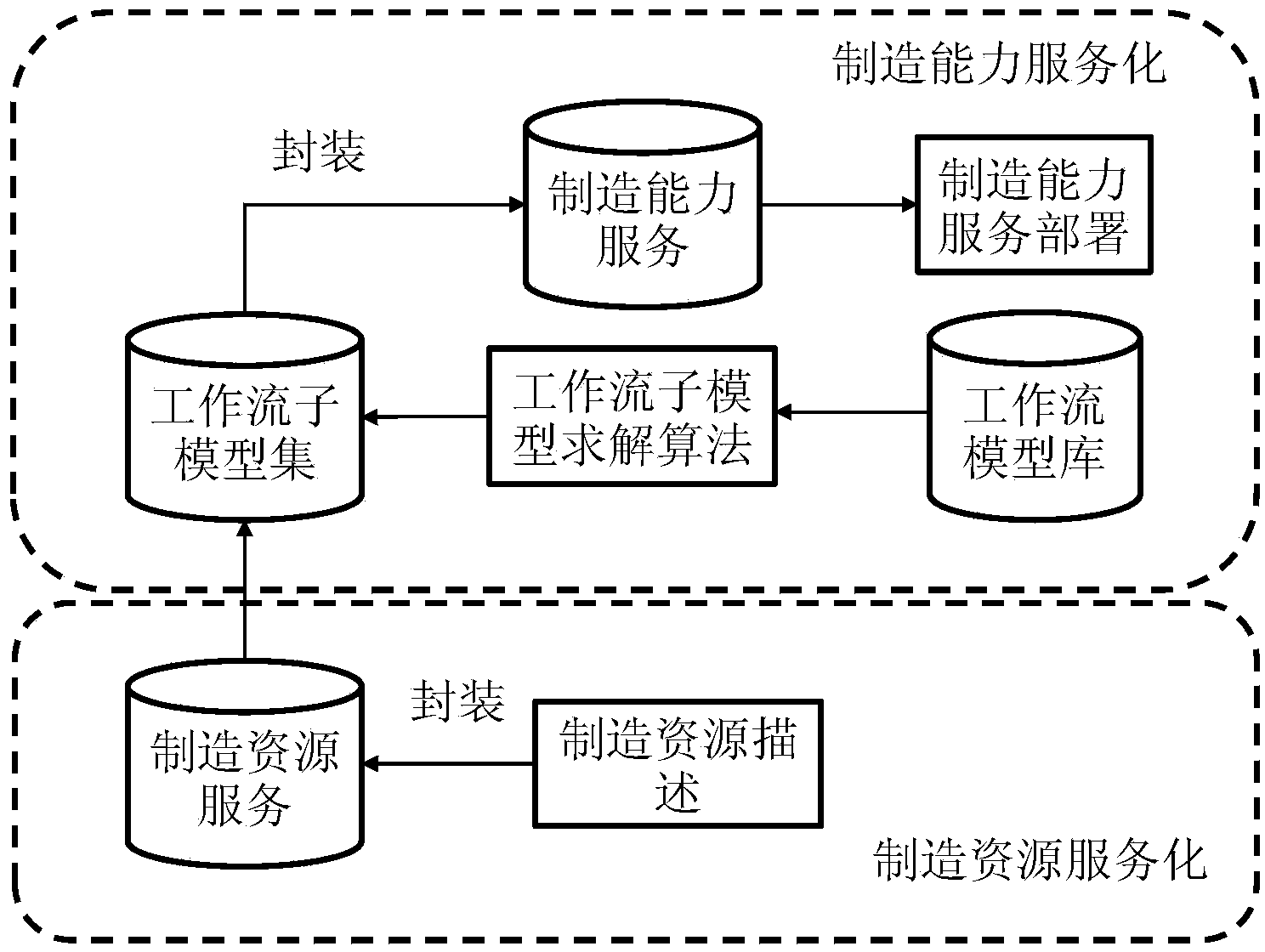

Manufacturing capacity servitization method based on workflow model

ActiveCN103530724ATo meet manufacturing needsFull versatilityResourcesSpecial data processing applicationsRelation graphWorkflow model

The invention discloses a manufacturing capacity servitization method based on a workflow model. The method comprises the following steps: firstly, building a resource input-output model according to the provided workflow model to form a resource relation graph, and describing a relation between resources needed by a service activity and generated resources; secondly, partitioning the workflow model into workflow sub-models of different particle sizes according to the resource relation graph, wherein manufacturing resources converged through the workflow sub-models are the manufacturing capacity; lastly, servicizing the formed manufacturing capacity to obtain manufacturing capacity service. According to the method, dispersed manufacturing resources are integrated into service process capacity by using service process knowledge and are published outwards, so that manufacturing capacities of multiple particle sizes and different functions can be provided for users on a cloud manufacturing service platform, and on-demand use and circulation of the manufacturing capacity are further realized.

Owner:HUAQIAO UNIVERSITY

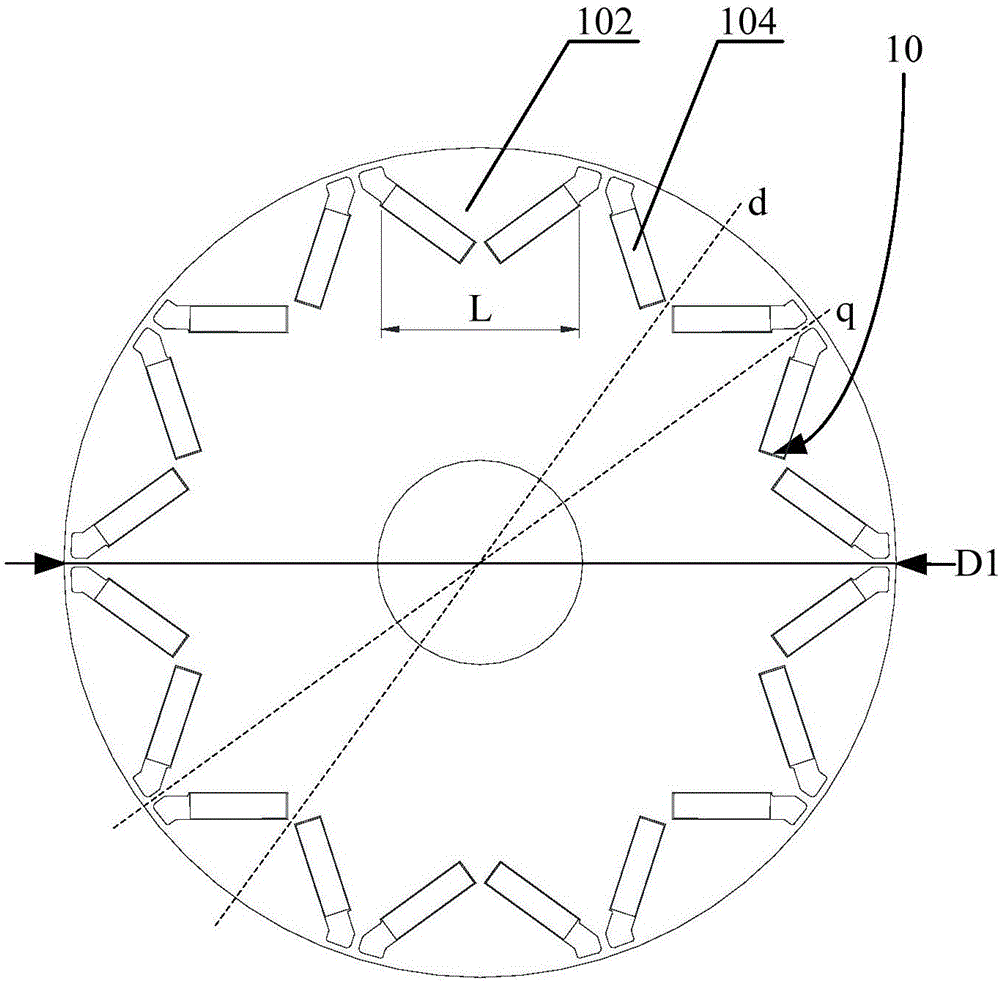

Motor rotor, permanent magnet motor and compressor

ActiveCN107528400AReduce volumeImprove power densityMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsHigh power densityPhysics

The invention provides a motor rotor, a permanent magnet motor and a compressor. The motor rotor comprises a rotor iron core of which the end surface is provided with multiple sets of accommodating slots along the circumferential direction of the rotor iron core; and multiple permanent magnets which are correspondingly embedded in multiple sets of accommodating slots, and the permanent magnets in all sets of accommodating slots form magnetic poles, wherein the number of the magnetic poles is greater than or equal to eight and less than or equal to twelve, the distance between the two ends of the magnetic poles is L, the peripheral diameter of the rotor iron core is D1, and 0.18xD1<=L<=0.28xD1. With application of the technical scheme, the higher power density can be realized by limiting the dimension relationship between the peripheral diameter of the rotor iron core and the distance of the two ends of the magnetic poles with cooperation of increasing of the number of the magnetic poles; besides, the dimension of the motor rotor can be reduced by limiting the number of the magnetic poles so as to realize miniaturization of the motor.

Owner:GUANGDONG MEIZHI COMPRESSOR

Hydrothermal lithium supplement-spray remodeling regeneration method of waste ternary positive electrode material

ActiveCN111129487ADoes not cause processing problemsAvoid the hollowing problem of granulationCell electrodesWaste accumulators reclaimingManganeseSeed crystal

The invention discloses a hydrothermal lithium supplement-spray remodeling regeneration method for a waste ternary positive electrode material. The method comprises the following steps: deeply discharging, disassembling and separating the waste ternary lithium battery; putting a positive electrode aluminum foil into a sodium hydroxide solution, and drying, calcining and grinding the stripped wasteternary lithium battery positive electrode material to obtain powder; adding the powder into organic acid for surface activation, then adding a lithium salt solution for hydro-thermal treatment, andthen taking the mixture as a seed crystal to be mixed with a nickel source, a manganese source and a cobalt source to obtain turbid liquid with uniform components; carrying out spray granulation remodeling on the turbid liquid to obtain an NCM precursor, and carrying out two-stage sintering on the NCM precursor and industrial oxygen to obtain a regenerated ternary positive electrode material. According to the invention, the environment-friendly and short-process recycling of the waste ternary positive electrode material is achieved, wherein in-situ repair of lithium can be rapidly achieved inthe hydrothermal lithium supplementing process, and the ternary positive electrode waste obtained after lithium supplementing serves as a seed crystal; in combination with the spray granulation technology, structure remodeling and controllable preparation of the ternary positive electrode material can be achieved.

Owner:KUNMING UNIV OF SCI & TECH

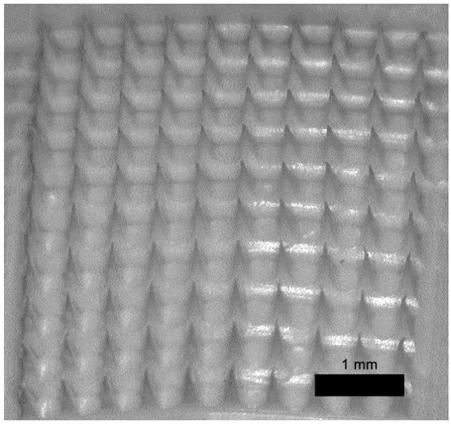

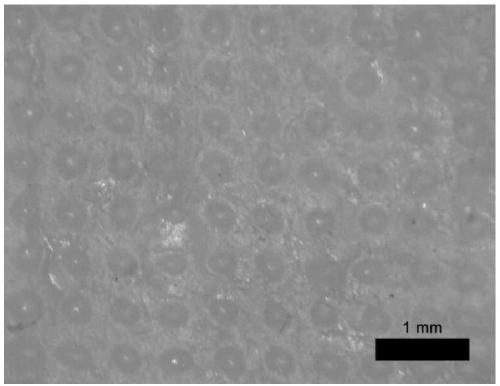

Production method and application of porous polymer microneedle

ActiveCN110840822ALow costGood biocompatibilityMetabolism disorderMicroneedlesPolymer dissolutionPolymer science

The invention discloses a production method and application of a porous polymer microneedle. The production method includes the steps of firstly, dissolving polymer into a solvent to obtain a polymersolution; secondly, filling the polymer solution into a microneedle mould; thirdly, freezing the whole microneedle mould filled with the polymer solution; fourthly, using freeze drying treatment to remove the solvent contained in the frozen microneedle to obtain the porous polymer microneedle, wherein the freeze drying treatment is performed under the pressure intensity of 0-100Pa. The productionmethod has the advantages that large-scale porous polymer microneedle production can be achieved by the simple and mild freeze drying technology, the technical problems that the production process ofthe porous polymer microneedle is complex, harsh in conditions, expensive, hard in pore structure, size and distribution control and difficult in large-scale production and application and the like can be solved; the produced porous polymer microneedle is applicable to tissue fluid extraction and transdermal drug delivery.

Owner:HUAZHONG UNIV OF SCI & TECH +1

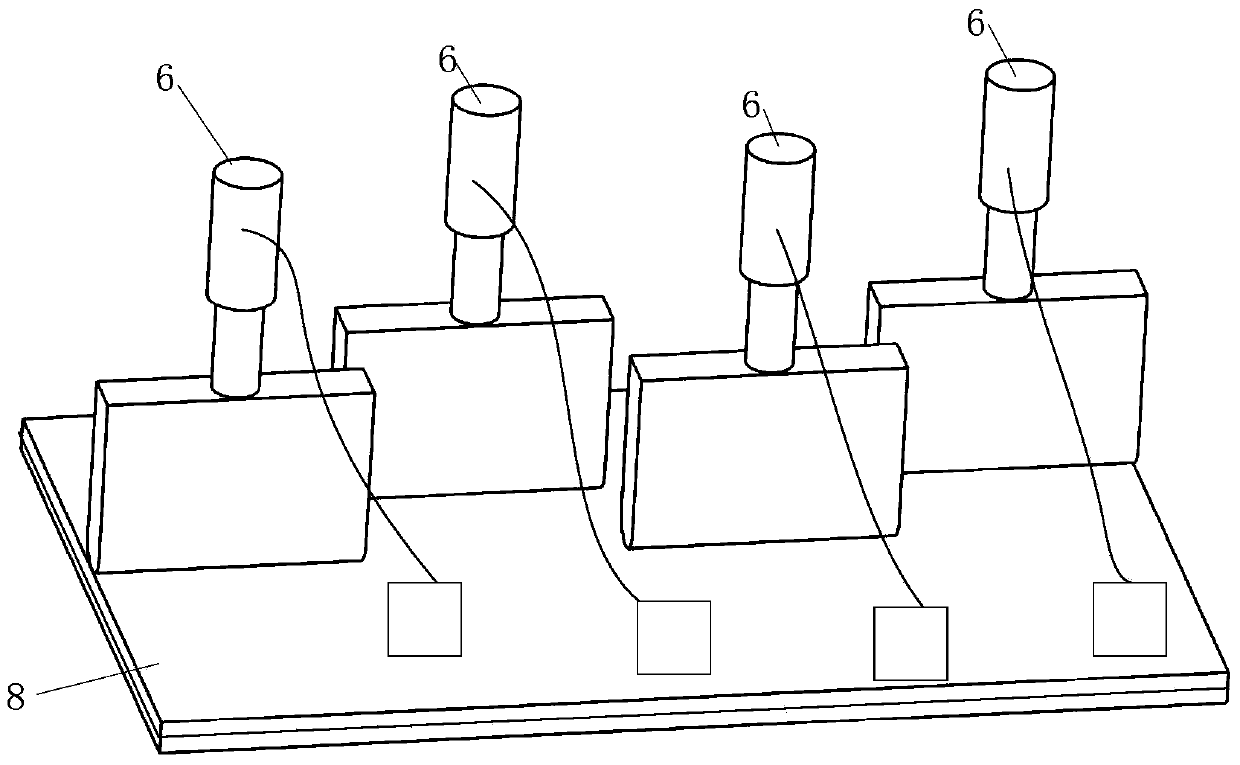

Three-dimensional braided prefab with pre-set thread and manufacturing method thereof

The invention discloses a three-dimensional braided prefab with a pre-set thread and a manufacturing method thereof. The three-dimensional braided prefab is characterized in that the prefab is of a skin-core structure; a core layer is formed by core yarns and a round three-dimensional braided structure which is braided through a four-step method and is provided with shaft yarns; a skin layer is ofa diagonal three-directional structure formed by arraying braiding yarns at the same side of the shaft yarns. The braiding yarns, which are located on the outermost layer of the core layer, are usedas diagonal three-directional shaft yarns, so that whole braiding of the skin-core structure is realized. The prefab is subjected to four-step cycle to obtain a prefab pitch length and the prefab witha target length is braided according to requirements. According to the manufacturing method of the prefab, the direction of the braiding yarns, the thickness of a skin-core layer and a diagonal three-directional pitch length can be flexibly designed and the difficulty that fibers are damaged when the three-dimensional braided prefab with the pre-set thread is used for wholly braiding and processing the thread is overcome; the whole mechanical properties of the prefab are easy to improve; meanwhile, the method has the advantages of simplicity in operation, stability in manufacturing and the like; the manufacturing requirements of high-performance and low-cost composite materials can be met.

Owner:TIANJIN GONGDA AEROTECH COMPOSITE MATERIALS

High-hardness corrosion-resistance aluminum-silicon-copper series cast aluminum alloy obtained through zirconium-strontium composite microalloying and magnesium alloying and preparing method

Disclosed is a high-hardness corrosion-resistance Al-Si-Cu series cast aluminum alloy obtained through Zr-Sr composite microalloying and Mg alloying. The high-hardness corrosion-resistance aluminum-copper-silicon cast aluminum alloy of the zirconium strontium composite microalloying and the magnesium alloying is characterized in that the aluminum alloy is mainly composed of aluminum (Al), silicon (Si), cuprum (Cu), magnesium (Mg), zirconium (Zr), strontium (Sr) and ferrum (Fe). A preparing method comprises sequentially the following steps that (1), pure Al and Al-Si intermediate alloy are molten and then are heated to 850 DEG C, and then Al-Cu, Al-Zr and Al-Sr intermediate alloy are added in sequence; and (2), after all intermediate alloys and metals are molten, the temperature is adjusted to 750 DEG C, and pure Mg is added; and after the pure Mg is molten, hexachloroethane is added for refining and degassing until no gas escapes, the melt is deslagged and cast into an ingot after standing and heat preservation for 5-10 min. According to the high-hardness corrosion-resistance aluminum-silicon-copper series cast aluminum alloy obtained through the zirconium-strontium composite microalloying and the magnesium alloying and the preparing method, the casting-state texture of the aluminum alloy is compact, the indoor temperature non-notch impacting tenacity average value is 16.35 J / cm2, the tensile strength is 262.132 MPa, the ductility is 5.645%, and meanwhile, the uniform corrosion rate is 0.321081508 mm / y when the aluminum alloy is soaked for 93 h in 3.5% NaCl water solution under the temperature of 37 DEG C.

Owner:JIANGSU UNIV

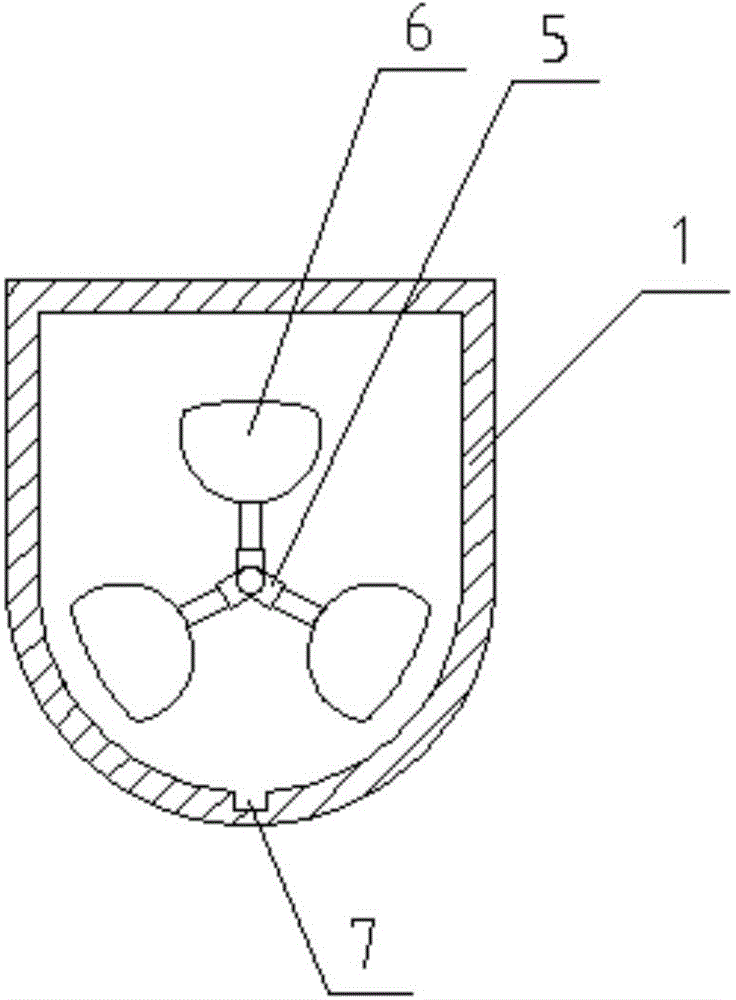

Stirrer

InactiveCN104084071AWell mixedPure tasteRotary stirring mixersMixer accessoriesDrive wheelSpiral blade

The invention discloses a stirrer. The stirrer comprises a stirring container, a driving mechanism and a stirring mechanism, wherein the upper part and the lower part of the stirrer are respectively provided with a material inlet and a material outlet; the driving mechanism comprises a driven wheel, a driving wheel, a speed regulator, a motor and an electric control cabinet; the stirring mechanism comprises a main shaft, spiral blades and blades; the spiral blades and the blades are fixedly connected to the main shaft; the stirrer can enable materials to be stirred relatively uniformly; the materials are relatively pure in flavor; the percent of pass of foods is ensured; secondarily, the spiral blades not only enable the materials to be mixed relatively fully, but also can push and guide the materials; the material discharge is convenient; the production efficiency is improved greatly; manufacturing needs of the different foods can be met by replacing the dismountable blades; hobbing cutter wheels with cutting blades are installed at the lower part of the material inlet, and can be used for cutting the raw materials entering a stirring groove, and then the cut raw materials are stirred, and the stirring effect is improved greatly.

Owner:SUZHOU CHUANGWEISHENG AUTOMATION SCI & TECH

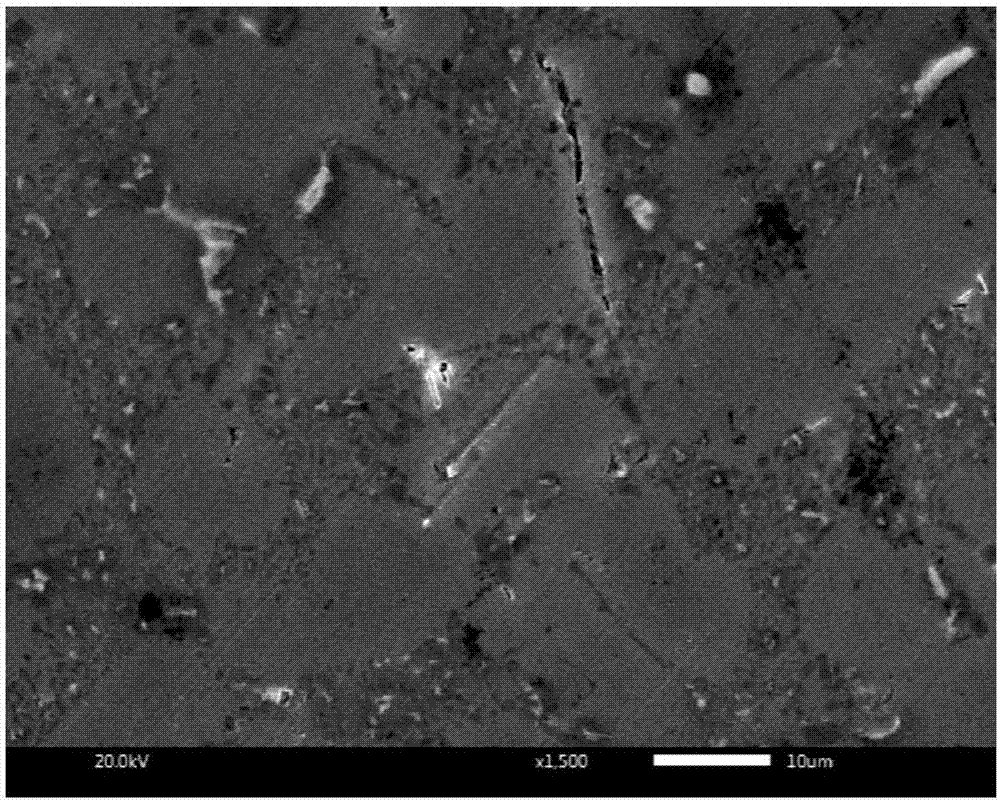

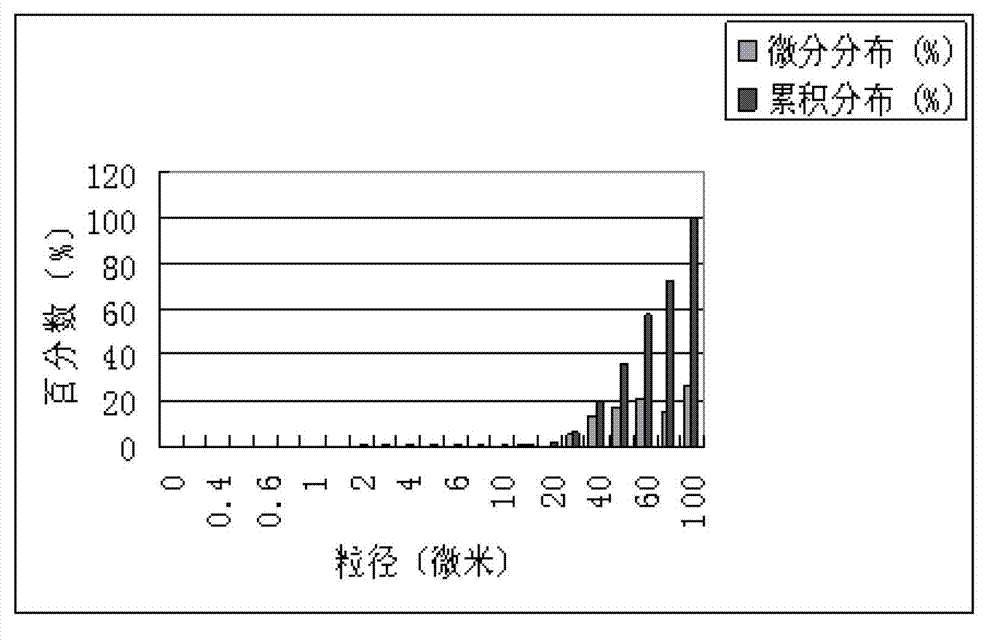

Preparation method of NiCrAlYSi powder spraying material

InactiveCN103045909AGood qualityRealize engineering applicationMolten spray coatingChemical compositionCrucible

The invention aims at provides a preparation method of an NiCrAlYSi powder spraying material. The method adopts a technology of 'mother alloy pre-preparation and ultrasonic gas atomization' and a purpose of uniform control for chemical components of powder is achieved. The method comprises the specific steps that (1), a mother alloy is pre-prepared by a vacuum induction heating method; raw materials are placed into a magnesia crucible, with forvacuum degree higher than 2Pa, refining temperature of 1390-1430 DEG C, refining period of 15-20min, and casting temperature of 1420-1460 DEG C; the raw materials are cooled and cast to an alloy bar with a diameter of 70-100mm; (2) component analysis is conducted on the obtained mother alloy; if components of the obtained alloy exceed a proportion of the chemical components of the NiCrAlYSi powder, secondary stock preparation is conducted according to the proportion; (3), gas atomization pulverization is conducted, with atomization temperature of 1500-1530 DEG C, atomization pressure of 8-10MPa, gas flow of 10-15m<3> / min, alloy liquid flow of 2-4kg / min, and an atomization medium of pure argon.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Moisturizing, anti-ageing and skin-whitening gel mask and preparation method thereof

InactiveCN107970174AGood skin careImprove antibacterial propertiesCosmetic preparationsToilet preparationsTremellaMethylisothiazolinone

The invention relates to a moisturizing, anti-ageing and skin-whitening gel mask and a preparation method thereof. The mask comprises the following preparation raw materials: a macromolecular wettingagent, a micromolecular wetting agent, a tremella polysaccharide extract, a lagerstroemia speciosa polyphenol extract, diguanosine tetraphosphate, polyglycerol-2, a supermolecular hydrogel matrix anddeionized water. The supermolecular hydrogel matrix is prepared from the following raw materials: guar hydroxypropyl trimethylammonium chloride, phytic acid and methylisothiazolinone. The mask provided by the invention replaces the conventionally used thickening agents such as xanthan gum and sodium alginate by using the self-made supermolecular hydrogel matrix, has excellent antibacterial property, has viscosity lower than that of the conventional thickening agent, is easy to coat, does not stick and pull fine hair when needing to be removed, avoids skin discomfort and improves the comfortable sensation of users; the mask has remarkable moisturizing, anti-ageing and skin-whitening effects, and avoids pore blockage and avoids phenomena of blackhead, acne and enlarged pore after long-time use.

Owner:广东安康德美化妆品有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com