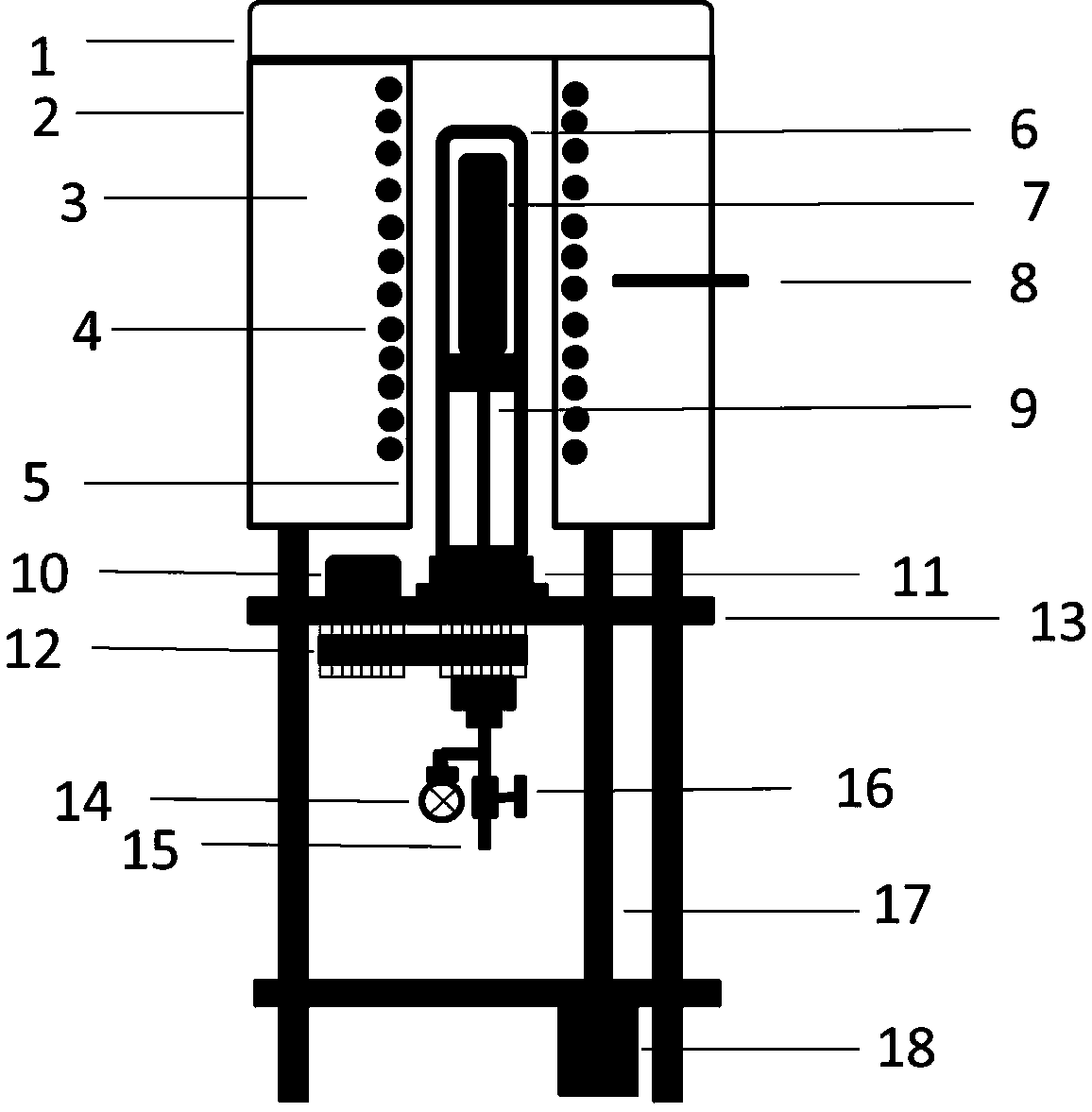

Device and method capable of increasing synthesizing stability of cadmium zinc telluride polycrystals

A cadmium telluride and stability technology is applied in the field of devices for improving the synthesis stability of cadmium zinc telluride polycrystalline, which can solve problems such as quartz tube explosion and tube cracking accident, achieve better synthesis, reduce raw material loss and equipment damage, and avoid Effects of phenomena such as columns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

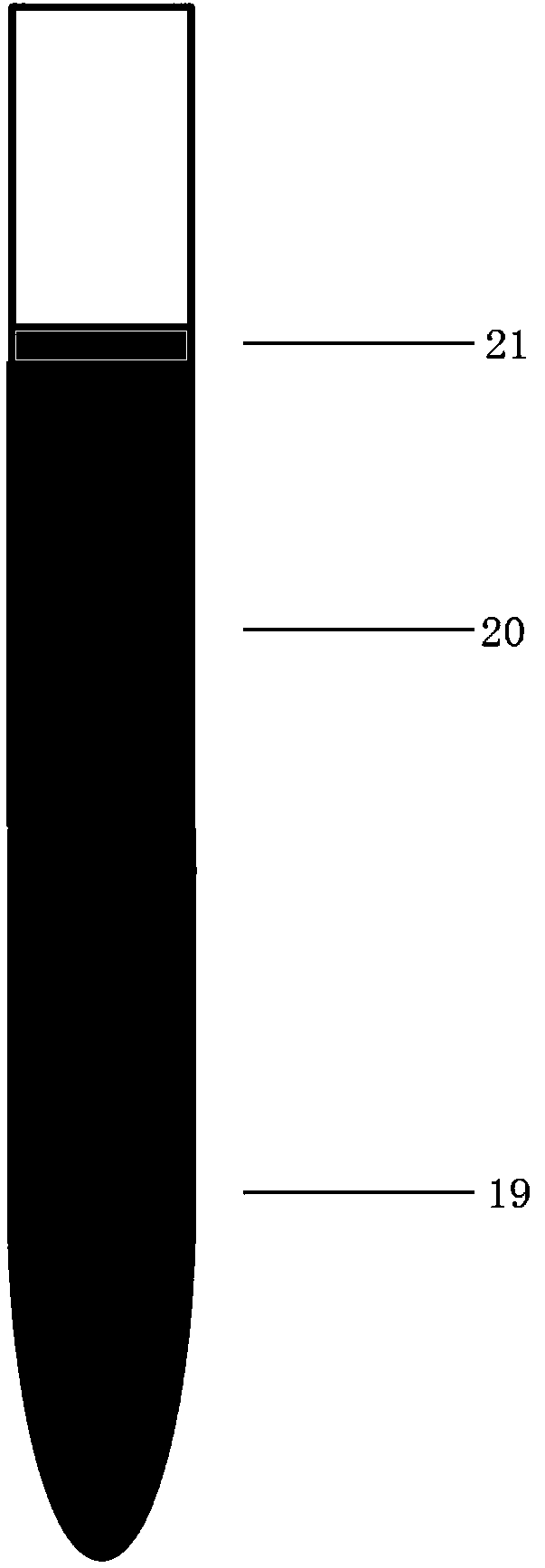

[0073] 1) Decompose acetone at 1000°C on the inner surface of a clean quartz crucible, and coat it with a uniform and firm carbon film;

[0074] 2) Calculate the required high-purity Te, Cd, and Zn raw materials according to the size and composition requirements of the required synthetic ingots. First, put the Te raw materials into the bottom of the quartz crucible. Te blocks of different sizes can be arranged as closely as possible to reduce the gap , then load the Cd raw material in the same way, and finally fill the Zn raw material above the Cd raw material or in the gap;

[0075] 3) Connect the quartz crucible filled with raw materials to the molecular pump group through the flange, put the lower end of the quartz crucible into the degassing furnace, and turn on the vacuum pump to evacuate. When the vacuum degree reaches 1×10 -4 When Pa is below, the degassing furnace starts to heat up. The temperature of the degassing furnace is 200°C. When the vacuum degree reaches 1×10 ...

Embodiment 2

[0084] 1) Decompose acetone at 1000°C on the inner surface of a clean quartz crucible and coat it with a uniform and firm carbon film;

[0085] 2) Calculate the required high-purity Te, Cd, and Zn raw materials according to the size and composition requirements of the required synthetic ingots. First, put the Te raw materials into the bottom of the quartz crucible. Te blocks of different sizes can be arranged as closely as possible to reduce the gap , then load the Cd raw material in the same way, and finally fill the Zn raw material above the Cd raw material or in the gap;

[0086] 3) Connect the quartz crucible filled with raw materials to the molecular pump group through the flange, put the lower end of the quartz crucible into the degassing furnace, and turn on the vacuum pump to evacuate. When the vacuum degree reaches 1×10 -4 When Pa is below, the degassing furnace starts to heat up. The temperature of the degassing furnace is 250°C. When the vacuum degree reaches 1×10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com