Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "Meet welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

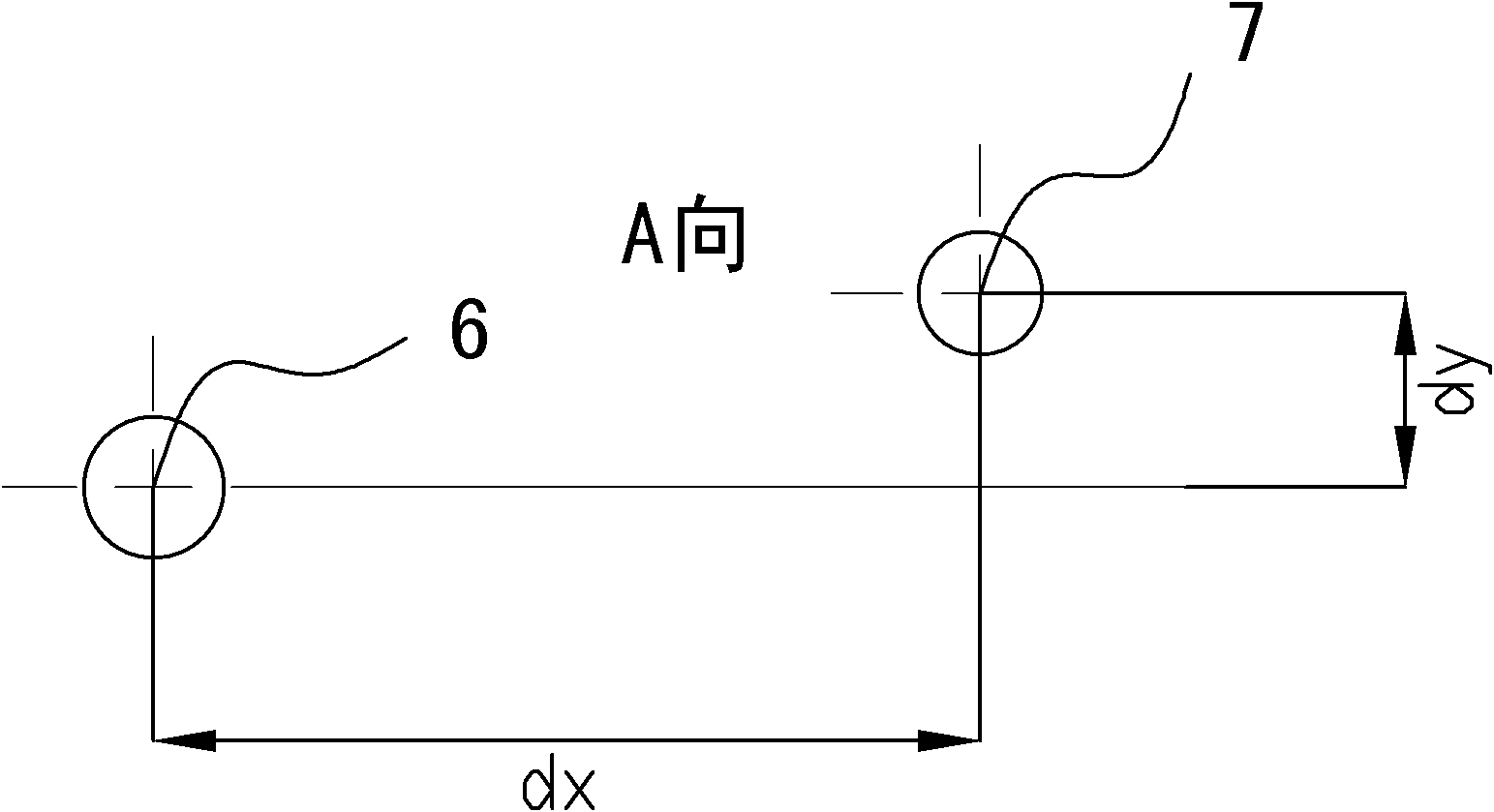

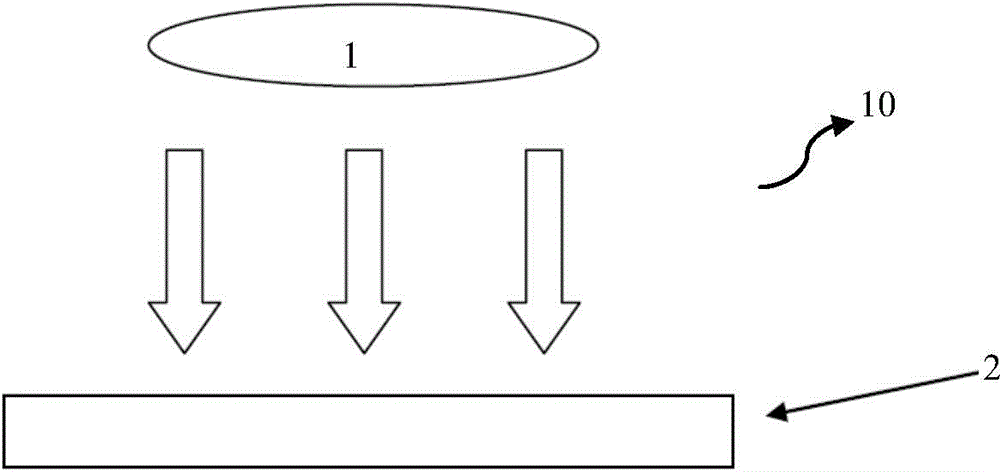

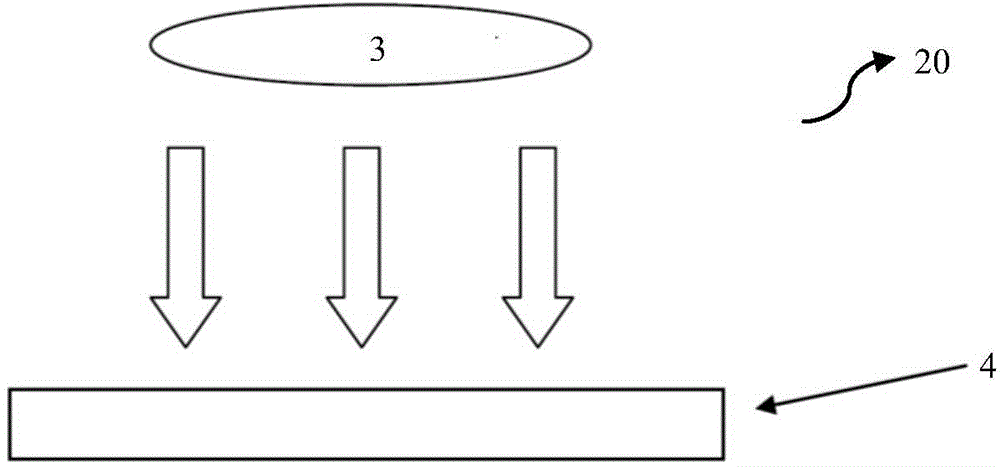

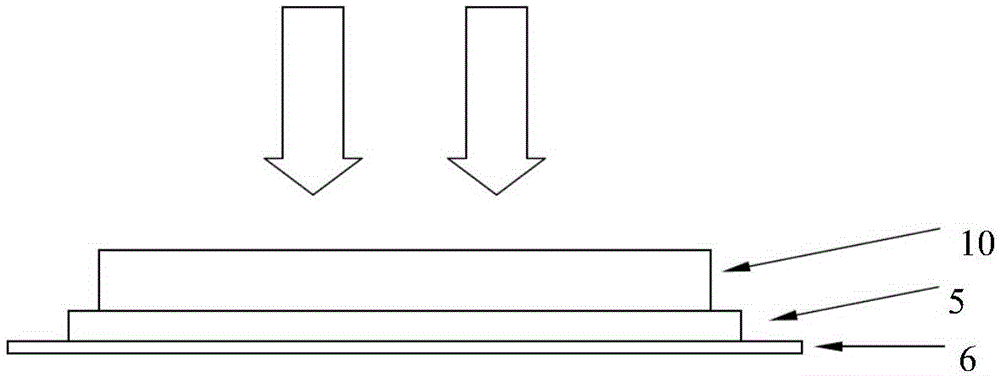

Image centralizing location method for automatic tube plate welding

InactiveCN102152033AReduce consumptionBreak through the positioning problemWelding/cutting auxillary devicesAuxillary welding devicesPosition errorEngineering

An image centralizing location method for automatic tube plate welding is characterized in that a camera is used for picking up the image of the mouth of a tube to be welded; the image is then processed and recognized by a computer system to automatically find the center position of the tube to be welded; and finally, the rotary axial line of a welding torch is translated to the center position of mouth of the tube to be welded by an X-axis moving mechanism and a Y-axis moving mechanism to achieve the location. The method can achieve location of the tube plate by using the image centralizing location method without the need of a core rod and an expansion core, so that the method is a contactless accurate location method, which solves the difficult location problem always puzzling the people for a long time. The method has the following characteristics: (1) the method obviates the position error of the tube mouth caused by machine tooling and welding heat and has high location accuracy; (2) the method can achieve the welding of tube plates with the retracted tubes; and (3) the method can achieve the welding of tube plates with a small diameter (phi3 mm), thereby greatly widening the application range of tube plate welding.

Owner:苏州工业园区华焊科技有限公司 +1

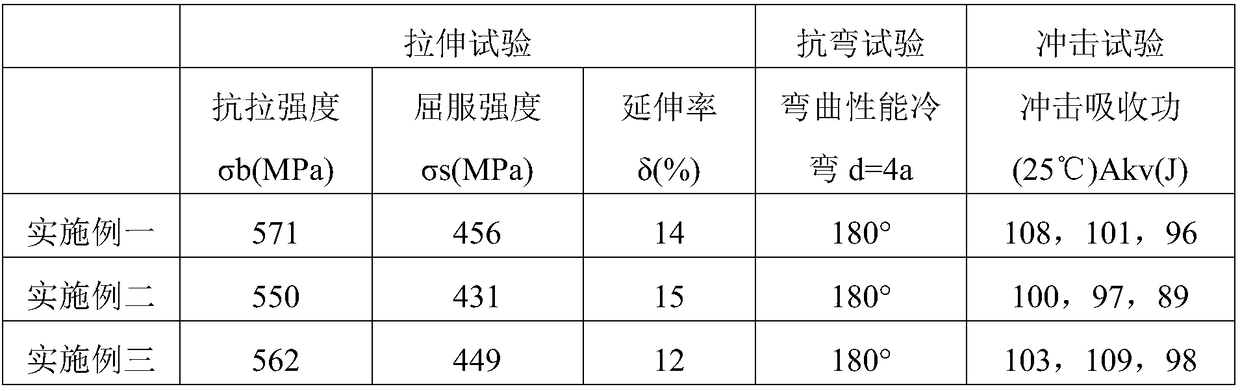

High-strength steel high-ductility gas shielded welding wire

InactiveCN101439446AProcess performance is stableStable welding arcWelding/cutting media/materialsSoldering mediaDuctilityArc welding

The invention relates to a high-tenacity gas-shielded welding wire for high-tensile steel. The welding wire solves problems of 780-850MPa-level low-alloy high-tensile steel welding material, including lack of matching performance and especially poor toughness and high cost. The technical proposal of the invention comprises that the chemical component consists of (counted by weight percentage) 0.05-0.13 percent of C, 1.4-1.9 percent of Mn, 0.4-0.8 percent of Si, 0.4-0.8 percent of Cr, 1.5-1.8 percent of Ni, 0.3-0.8 percent of Mo, 0.06-0.25 percent of Ti, 0-0.60 percent of Cu, not more than 0.025 percent of S, not more than 0.025 percent of P and the balance of Fe and unavoidable impurity elements. When gas-shielded welding is carried out on the welding wire, the welding line has the metal tensile strength of 780-850MPa; the ballistic work AkV at -20 DEG C is not less than 70J, thereby applying to gas-shielded arc welding of 780-850MPa-level low-alloy high-tensile steel.

Owner:SHOUGANG CORPORATION

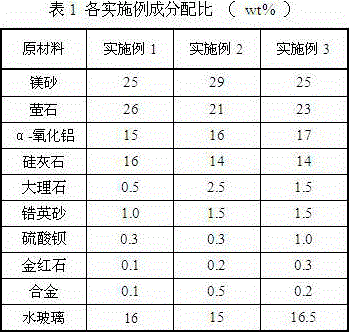

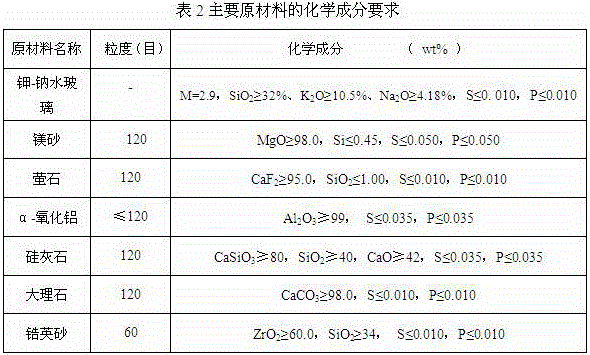

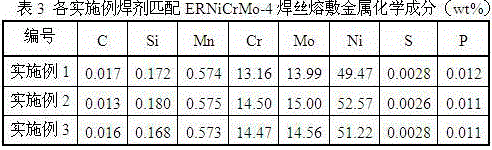

Sintered flux for 9Ni steel welding and preparation method thereof

ActiveCN106238965AImprove low temperature toughnessGood thermal crack resistanceWelding/cutting media/materialsSoldering mediaTO-18Crack resistance

The invention discloses sintered flux for 9Ni steel welding, and relates to the technical field of welding materials. The sintered flux comprises the following components in parts by weight: 20 to 28 parts of CaF2, 23 to 33 parts of MgO, 15 to 18 parts of Al2O3, 8 to 12 parts of CaO, 4 to 10 parts of SiO2, 0.5 to 2 parts of BaO, 0.5 to 2 parts of TiO, 0.5 to 2 parts of ZrO2, 0.5 to 2 parts of alloy and 15 to 20 parts of water glass, wherein the alloy is ferrosilicon or manganese-silicon or a combination of ferrosilicon and manganese-silicon. The preparation method comprises the steps of uniformly mixing the components according to the proportion; carrying out granulation; drying at the low temperature of 300 to 400 DEG C; and sintering at the high temperature of 660 to 750 DEG C, so as to obtain a flux finished product. According to the sintered flux, the flux is matched with a solid welding wire ERNiCrMo-4, the welding manufacturability is relatively good, the mechanical property of weld joints is good, the ultra-low temperature toughness of deposited metals is stable and excellent, the hot crack resistance sensitivity is good, and the sintered flux is applicable to submerged arc flat welding and horizontal welding of 9Ni steel.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

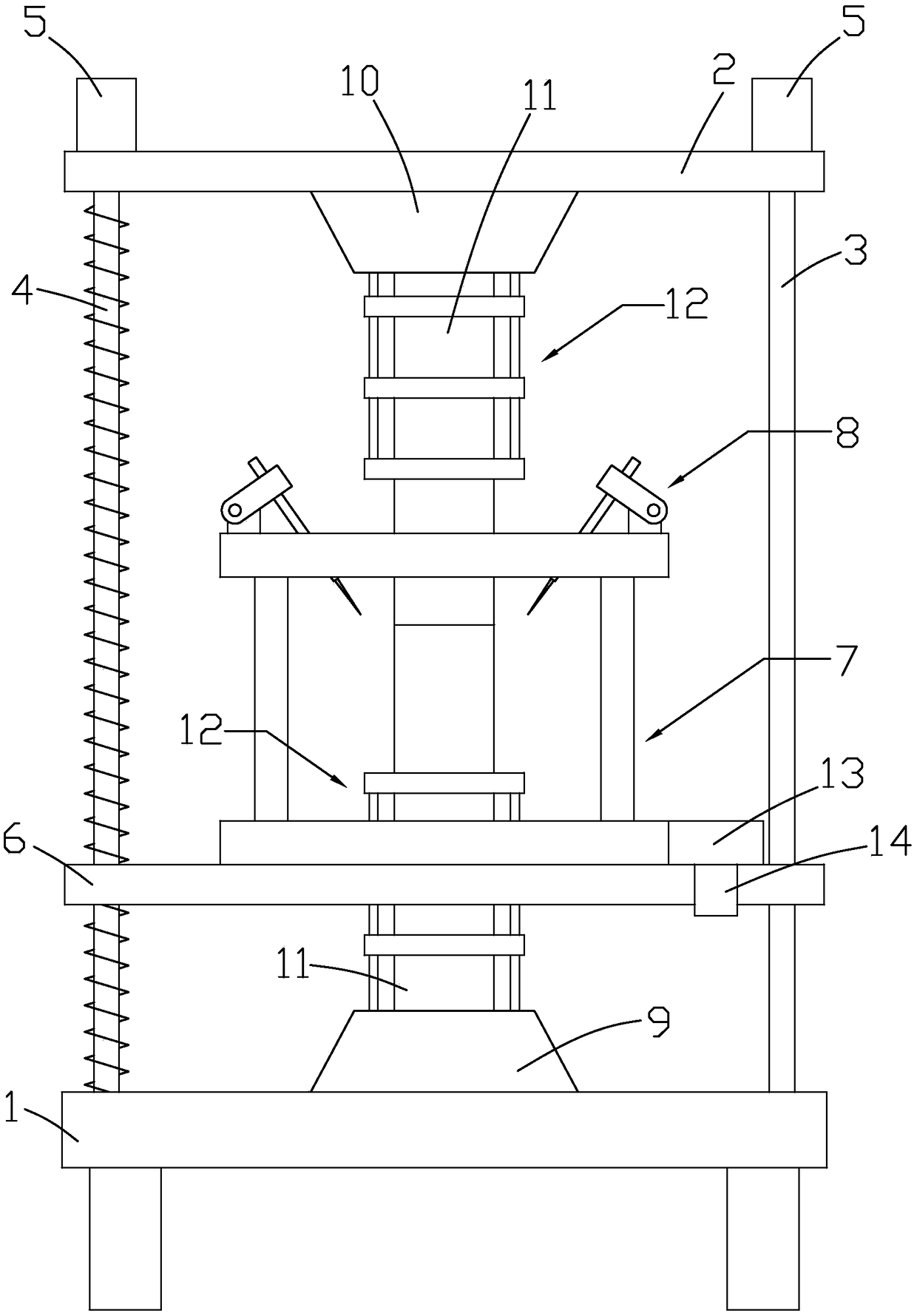

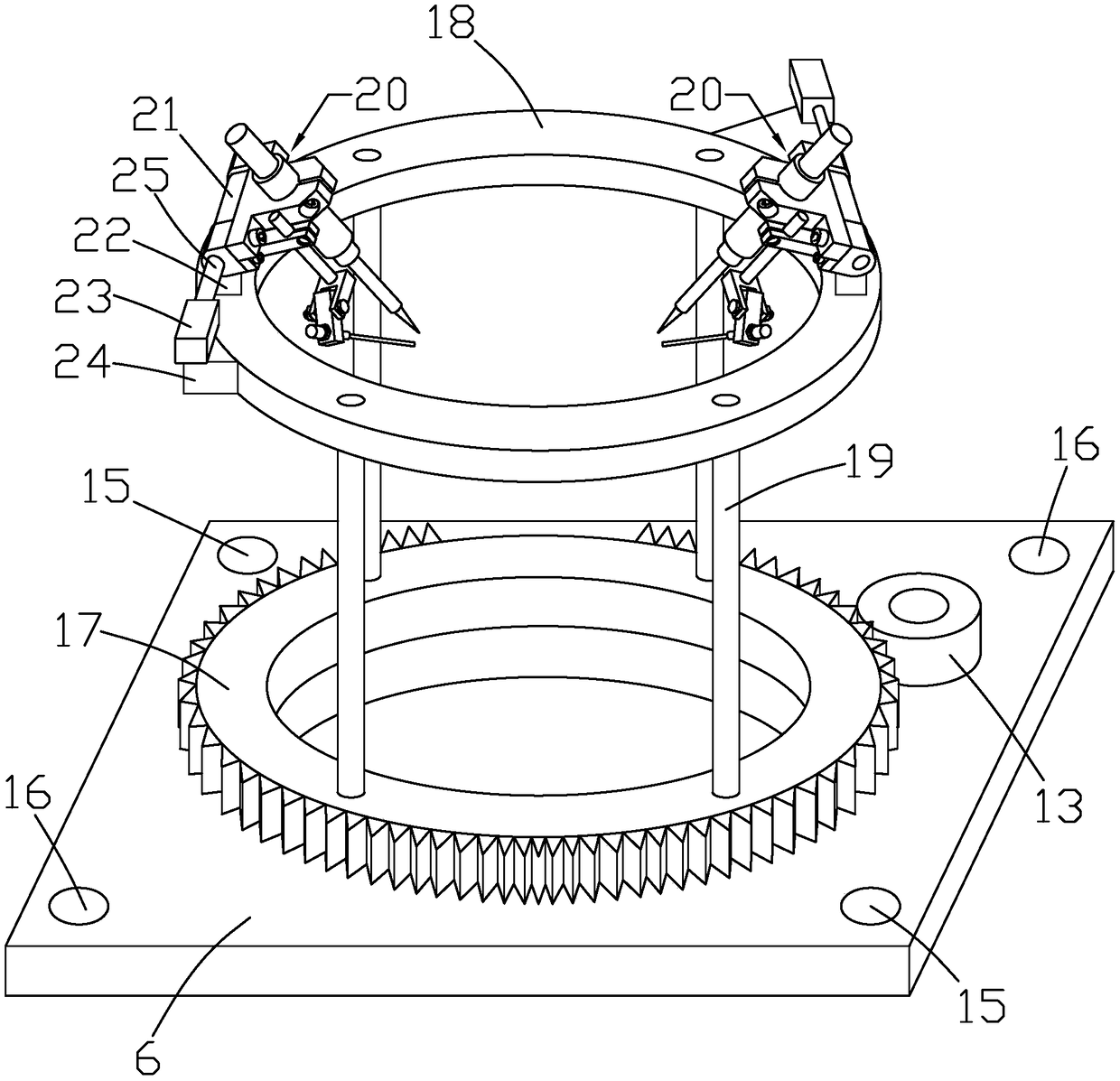

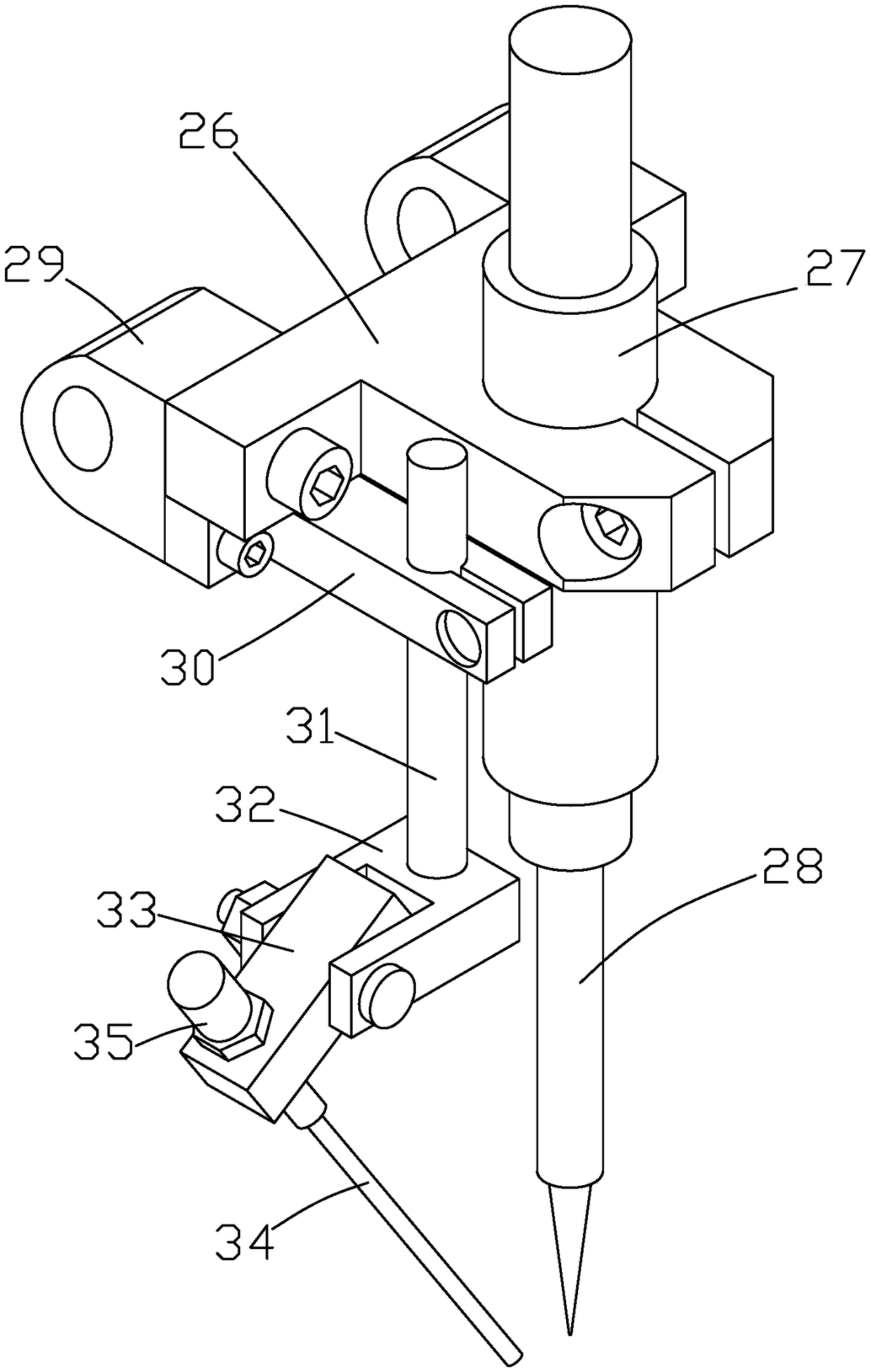

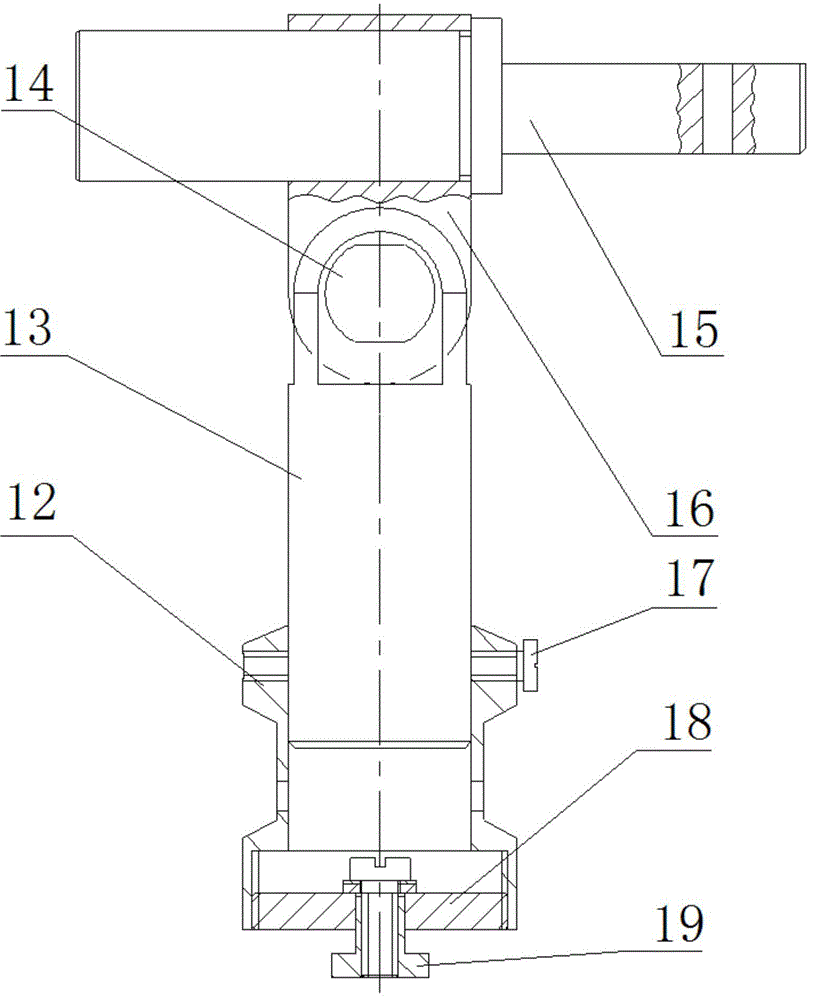

Welding device for pipeline sealing connection

ActiveCN109434341ASmooth rotationImprove stabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThreaded rod

The invention discloses a welding device for pipeline sealing connection. The welding device for pipeline sealing connection comprises a base, a locating plate, a rotating mechanism, a welding mechanism and clamping and locating mechanisms. The base is connected with the locating plate through a stand column and a threaded rod. First motors are arranged at the top end of the threaded rod, and a lifting plate is connected between the stand column and the threaded rod in a moving mode. The rotating mechanism is connected to the lifting plate in a rotating mode, and the welding mechanism is connected to the rotating mechanism. A lower locating platform and an upper locating platform are arranged on the top surface of the base and the bottom surface of the locating plate correspondingly, and the clamping and locating mechanisms are arranged on the lower locating platform and the upper locating platform. Two pipeline test pieces are limited in the upper clamping and locating mechanism and the lower clamping and locating mechanism correspondingly and located on the same vertical straight line. The welding device for pipeline sealing connection is simple in structure and high in practicability, can conduct clamping and locating operation on two pipelines in the up-and-down direction, and can also adjust the height and the position of a welding mechanism, the requirement for sealing welding of pipelines with different lengths is met, the practicability of the welding device is greatly improved, and the working range of the welding device is greatly broadened.

Owner:纳木博(常州)智能装备有限公司

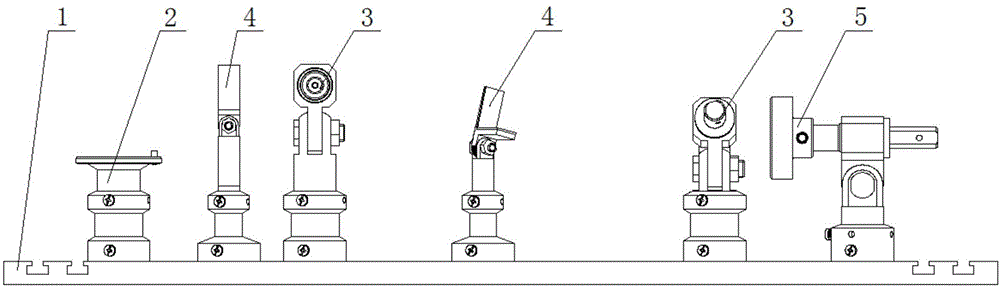

Flexible positioning device for assembling and welding pipelines

InactiveCN103551775AHigh precisionReduce correctionWelding/cutting auxillary devicesPipeline systemsPipe fittingEngineering

The invention relates to a flexible positioning device for assembling and welding pipelines and belongs to the technical field of assembling and welding of pipe parts. A flange positioning assembly, a pipe joint positioning assembly, a pipe fitting bearing assembly and a telescope-feed positioning assembly are all arranged on a foundation plate, and adapting seats of the assemblies are connected with one another through positioning keys and T-shaped grooves. According to the flexible positioning device for assembling and welding the pipelines, by means of matching of the assemblies, accuracy of assembling and welding pipe fittings is improved, shape correction of the pipe fittings during assembling is reduced, manufacture qualities and reliabilities of the pipe fittings are improved, the assemblies can be adjusted, and requirements for assembling and welding the pipe fittings with different sizes and shapes can be well met by adjusting positions and heights of the assemblies when users are confronted with the pipe fittings with different sizes and shapes, so that the applicability of the flexible positioning device is greatly enhanced; the flexible positioning device can be continuously recycled and greatly reduce usage and manufacture costs; defects that medium frames in prior art are low in positioning accuracy, poor in rigidity, easy to deform during using, and long in manufacture period can be overcome.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Self-protective flux-cored wire for all-position underwater wet welding in deep water environment

ActiveCN106964918AMeet weldingEasy arc startWelding/cutting media/materialsSoldering mediaSlagFilling rate

The invention belongs to the technical field of welding materials and discloses a self-protective flux-cored wire for all-position underwater wet welding in a deep water environment. The self-protective flux-cored wire comprises a metal skin and a flux core. The metal skin is formed by rolling an N6 nickel strip. The basic slag system of the flux core is an alkaline calcium fluoride-aluminum-magnesium slag system. The N6 nickel strip comprises, by weight, no smaller than 99.5% of Ni and Co in total, no larger than 0.06% of Cu, no larger than 0.10% of Fe, no larger than 0.05% of Mn, no larger than 0.10% of C, no larger than 0.10% of Si and no larger than 0.005% of S. The flux core comprises, by mass, 52-67% of fluoride, 14-20% of aluminum-magnesium alloy powder, 5-10% of calcium carbonate, 5-15% of ferromanganese, 3-10% of chromium, 4-10% of titanium and 1.5-5% of rare earth. The filling rate of the flux core in the flux-core wire is 24-32%. According to the scheme provided by the invention, the self-protective flux-cored wire can be used for welding under water by 100-200 meters, arcing is easy during welding, arc burning is stable, no arc blowout or breaking phenomenon occurs, an obtained welding seam is attractive in forming, the tensible strength of deposited metal after welding is larger than 500 MPa, and the self-protective flux-cored wire has good impact toughness and meets the all-position welding requirements of medium and low carbon steel and low alloy high strength steel in the deepwater environment.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

Welding method of Q500qE and Q690qE ultra-low carbon bainitic steel heterologous butt joints

ActiveCN109759679ALarge low temperature impact toughness allowanceMeet weldingArc welding apparatusWelding/cutting media/materialsButt jointHigh intensity

The invention discloses a welding method of Q500qE and Q690qE ultra-low carbon bainitic steel heterologous butt joints and belongs to the field of steel bridge manufacture. The welding method comprises the following steps: carrying out thickness reducing processing on a butt joint part of a thicker steel plate in two steel plates different in thickness, processing a transitional bevel edge on thethicker steel plate to enable the thicknesses of the two steel plate to be consistent, wherein the ratio of slope of the transitional bevel edge is 1:(8-10); processing a V-shaped groove in the butt joint part of the two steel plates, wherein the groove angle is 20-22 degrees, and the assembling clearance is 6-8 mm; placing a ceramic liner on one side of the assembling clearance; after preheatingthe steel plates, adopting mixed gas arc welding to weld one to two bottoming welding seams with solid wires at the inner bottom of the groove, and then, adopting solid wires to carry out layer-by-layer filling welding and fill the groove; during the welding process, carrying out interlayer cleaning, wherein the weld bead interlayer temperature is 140-160 DEG C; and after welding, adopting thermalinsulating measures. With adoption of the welding method, high-strength welding of Q500qE and Q690qE with different strengths is realized, and the welding method can be used for welding constructionof bridge structural components.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP +1

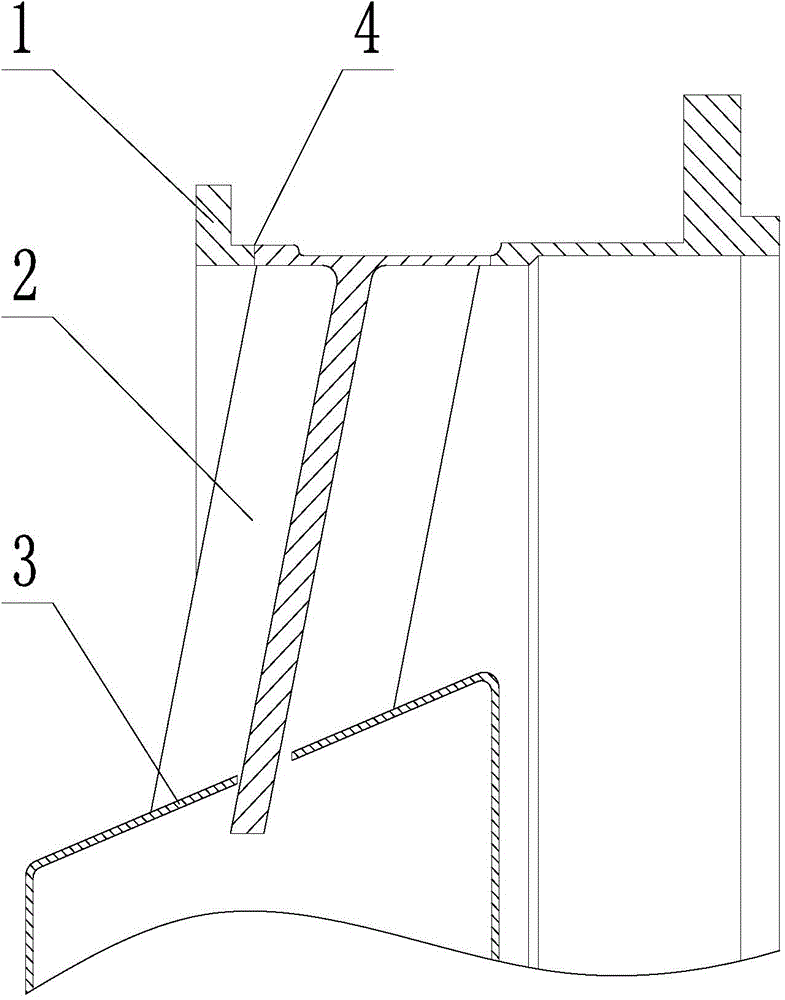

Aero-engine stator assembly vacuum electron beam welding technology

ActiveCN104475959AMeet weldingMeet the performance stability requirements after weldingElectron beam welding apparatusManufacturing technologyDirect effects

The invention discloses an aero-engine stator assembly vacuum electron beam welding technology and belongs to the technical field of aero-engine part manufacturing. Formerly, an aero-engine stator assembly is welded through a brazing method, the brazing intensity is lower than the base metal intensity, the stator assembly performance stability is directly influenced, and a traditional welding method is excessively large in welding deformation. Compared with the prior art, after a large amount of soldering tests, the aero-engine stator assembly vacuum electron beam welding technology has the advantages that welding of the aero-engine stator assembly can be completely satisfied, brand new welding parameters are provided, the welding parameters are obtained after a large amount of welding parameter tests, welding of different thickness weld joints can be satisfied maximally, and thermal input is guaranteed uniform, the welding deformation is effectively controlled, and the requirement for stable postwelding performance of the stator assembly is satisfied due to sequence welding of the two weld joints at symmetrical positions.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Adjustable welding clamp

ActiveCN108544171ASports meetPrevent movementWelding/cutting auxillary devicesAuxillary welding devicesWeldingEngineering

The invention discloses an adjustable welding clamp, and relates to the technical field of mechanical welding clamps. The clamp comprises a movable groove, wherein a moving plate is in sliding connection with one side of the movable groove through a slide rod, and an assembly plate is fixedly connected with the other side of the top of the movable groove; a placement plate is fixedly connected with one sides of the top of the moving plate and top of the assembly plate, while a movable frame is fixedly connected with the other sides of the top of the moving plate and top of the assembly plate;extruding plates are in sliding connection between two sides of the top of the inner wall of the movable frame and two sides of the bottom of the inner wall of the movable frame. The adjustable welding clamp can be used for adjusting the position of a clamp to tightly fasten objects having different sizes, is simple in adjustment, and can better clamp an object through fit between a friction blockand an anti-skid block when a cylindrical object is welded, so that the friction between a clamp and an object can be increased, and reduction of the welding effect caused by movement of the object during working can be avoided.

Owner:WUHU RUITAI PRECISION MACHINERY

Method for welding silicon wafer and molybdenum piece in semiconductor device and application of silicon wafer and molybdenum piece

ActiveCN104538321AImprove mechanical propertiesImprove electrical performanceSolid-state devicesSemiconductor/solid-state device manufacturingWeld strengthUltimate tensile strength

The invention discloses a method for welding a silicon wafer and a molybdenum piece in a semiconductor device. The method comprises the following steps that firstly, a first silver layer is arranged on the molybdenum piece; secondly, a second silver layer is arranged on the anode electrode of the silicon wafer; thirdly, a third silver layer is arranged between the first silver layer and the second silver layer; fourthly, the silicon wafer and the molybdenum piece are welded together by welding the first silver layer, the second silver layer and the third silver layer. According to the method, the technology is simple, the yield and the welding strength are high, the voidage of welding layers is low, the deformation is small, and the performance of the product can be greatly improved. The invention further relates to an application of the silicon wafer / molybdenum piece manufactured through the method.

Owner:ZHUZHOU CRRC TIMES SEMICON CO LTD

Overturning operation table for automobile sheet metal welding six-shaft mechanical hand

ActiveCN106736217AFill in the constraints that the degrees of freedom cannot reachMeet weldingWelding/cutting auxillary devicesAuxillary welding devicesDegrees of freedomEngineering

The invention discloses an overturning operation table for an automobile sheet metal welding six-shaft mechanical hand. The overturning operation table comprises a six-shaft welding mechanical hand body and a welding bottom table, wherein the six-shaft welding mechanical hand body is on one side of the welding bottom table; a left-right moving mechanism is arranged on the welding bottom table; a front-back moving mechanism is arranged on the left-right moving mechanism; an up-down compensation feeding mechanism is arranged on the front-back moving mechanism; an overturning mechanism is arranged on the up-down compensation feeding mechanism; and a clamping mechanism is arranged on the overturning mechanism. The overturning operation table has the beneficial effects that the technical scheme is that a plurality of compensation mechanisms are added at the outer part on the basis of six degrees of freedoms of a six-shaft robot, a plurality of degrees of freedom are added equivalently, the entire device has more than six degrees of freedom, a user can weld various complex parts according to different utilization requirements, limitation of the degree of freedom of the robot is effectively filled, and the working efficiency is improved.

Owner:CHONGQING XINGQIAO IND

Connector for brushless fan of automobile air conditioner

InactiveCN102969631AGuaranteed butt sizeButt meetFixed connectionsCoupling parts mountingWhole bodyInjection moulding

The invention discloses a connector for a brushless fan of an automobile air conditioner. The connector comprises an insulation fixed seat and an L-shaped metal inserting piece, wherein the insulation fixed seat and the L-shaped metal inserting piece are connected with each other to form a whole body; and one end of the metal inserting piece extends out of the insulation fixed seat and is inserted into a slot of an air conditioner wiring harness sheath, and the other end of the metal inserting piece extends out of the insulation fixed seat and is inserted into a welding hole of a circuit board. With adoption of the structure, the connector provided by the invention has the advantages that firstly, as the connector is inserted into the installing hole of the PCB (printed circuit board) and is connected with the PCB in a welding manner, the looseness caused by insufficiency welding is avoided, and contact resistance and reliable welding are guaranteed; secondly, the metal inserting piece and the plastic fixed seat are subjected to secondary injection moulding to guarantee a docking size, and the metal inserting piece is fixed to be prevented from deforming; and thirdly, the connector is simple in structure and can meet the requirements on the docking with the standard sheath at a wiring harness end.

Owner:BONAIRE AUTOMOTIVE ELECTRICAL SYST

Welding technology for large and middle-scale synchronous generator stator bar connection wire

InactiveCN101262154AStrong enoughReduce thicknessLine/current collector detailsManufacturing dynamo-electric machinesUpper jointCopper

The invention relates to a connecting coil welding technique for a stator bar of a large or middle synchronous generator, the technique is characterized in that: the technique comprises the following steps: 1. upper joints of coil bars are welded: (1) the splint of a clamping device is stretched into a part where a lower layer coil is connected with a connecting plate, the splint is stressed, water and power are put through and the connecting plate and the lower layer coil are welded; (2) the splint of the clamping device is backed to the part where an upper layer coil is connected with the connecting plate, the splint is stressed, water and power are put through and the connecting plate and the upper layer coil are welded; (3) connecting coils of all coil slots and interelectrode connecting coils are welded according to the steps (1) and (2) in sequence; 2. lower joints of coil bars are welded according to the step (1). The technique provided by the invention can extend design range of motor windings, reduce the amount of stator winding copper materials and insulation materials, save lots of silver solder, improve welding quality and reduce overall cost of units.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

Image centralizing location method for automatic tube plate welding

InactiveCN102152033BBreak through the positioning problemReduce consumptionWelding/cutting auxillary devicesAuxillary welding devicesComputerized systemEngineering

An image centralizing location method for automatic tube plate welding is characterized in that a camera is used for picking up the image of the mouth of a tube to be welded; the image is then processed and recognized by a computer system to automatically find the center position of the tube to be welded; and finally, the rotary axial line of a welding torch is translated to the center position of mouth of the tube to be welded by an X-axis moving mechanism and a Y-axis moving mechanism to achieve the location. The method can achieve location of the tube plate by using the image centralizing location method without the need of a core rod and an expansion core, so that the method is a contactless accurate location method, which solves the difficult location problem always puzzling the people for a long time. The method has the following characteristics: (1) the method obviates the position error of the tube mouth caused by machine tooling and welding heat and has high location accuracy; (2) the method can achieve the welding of tube plates with the retracted tubes; and (3) the method can achieve the welding of tube plates with a small diameter (phi3 mm), thereby greatly widening the application range of tube plate welding.

Owner:苏州工业园区华焊科技有限公司 +1

Movable welding robot for superconducting welding

PendingCN109551140AMeet weldingIncrease flexibilityWelding/cutting auxillary devicesAuxillary welding devicesStepper motor controlControl theory

The embodiment of the invention discloses a movable welding robot for superconducting welding. The movable welding robot comprises a vehicle body, a stand column arranged on the vehicle body and a welding device arranged on the stand column; the lower part of the vehicle body is provided with a plurality of wheels, and a PLC controller, a stepping motor controller and a stepping motor which are sequentially connected are installed inside the vehicle body; the stand column is fixed to the vehicle body, a direct current servo motor and a transmission device which are connected are arranged inside the stand column, and the direct current servo motor is electrically connected to the PLC controller; the welding device is mounted on the stand column and comprises two first and second branches inparallel, wherein each branch includes two rotating pairs and two connecting rods; a cooling wheel is mounted on the end of the first branch, and a heating wheel is mounted on the end of the second branch; and one rotating pair in each branch is connected with the direct current servo motor through the transmission device. By means of the embodiment, the movable welding robot can be used for superconducting strip welding, can adapt to different welding conditions, and has the good welding effect.

Owner:SHENZHEN POWER SUPPLY BUREAU

SMT welding process for PCB in shell body

ActiveCN112040669ASimple processEasy to operatePrinted circuit assemblingConductive pattern formationEngineeringSolder paste

The invention discloses an SMT welding process for a PCB in a shell body. The process comprises the following steps of: selecting materials of a shell body cover plate and a shell body cavity, and respectively carrying out surface treatment on the shell body cover plate and the shell body cavity; welding the PCB into the shell body cavity ; covering and fixing a frameless steel mesh on the PCB, wherein windows on the frameless steel mesh are in one-to-one correspondence with bonding pads on the PCB; printing solder paste on the bonding pads on the PCB through using the frameless steel mesh, and taking out the frameless steel mesh after printing is completed; using an automatic chip mounter to mount a surface-mount device on the PCB; and welding the surface-mounted device to a correspondingposition of the PCB through reflow soldering. According to the SMT welding process, manual printing and automatic chip mounting processes are adopted, the process is simple, the operability is high,the assembly efficiency is high, and SMT welding of large-batch and high-integration substrates can be met.

Owner:YANGZHOU HAIKE ELECTRONICS TECH CO LTD

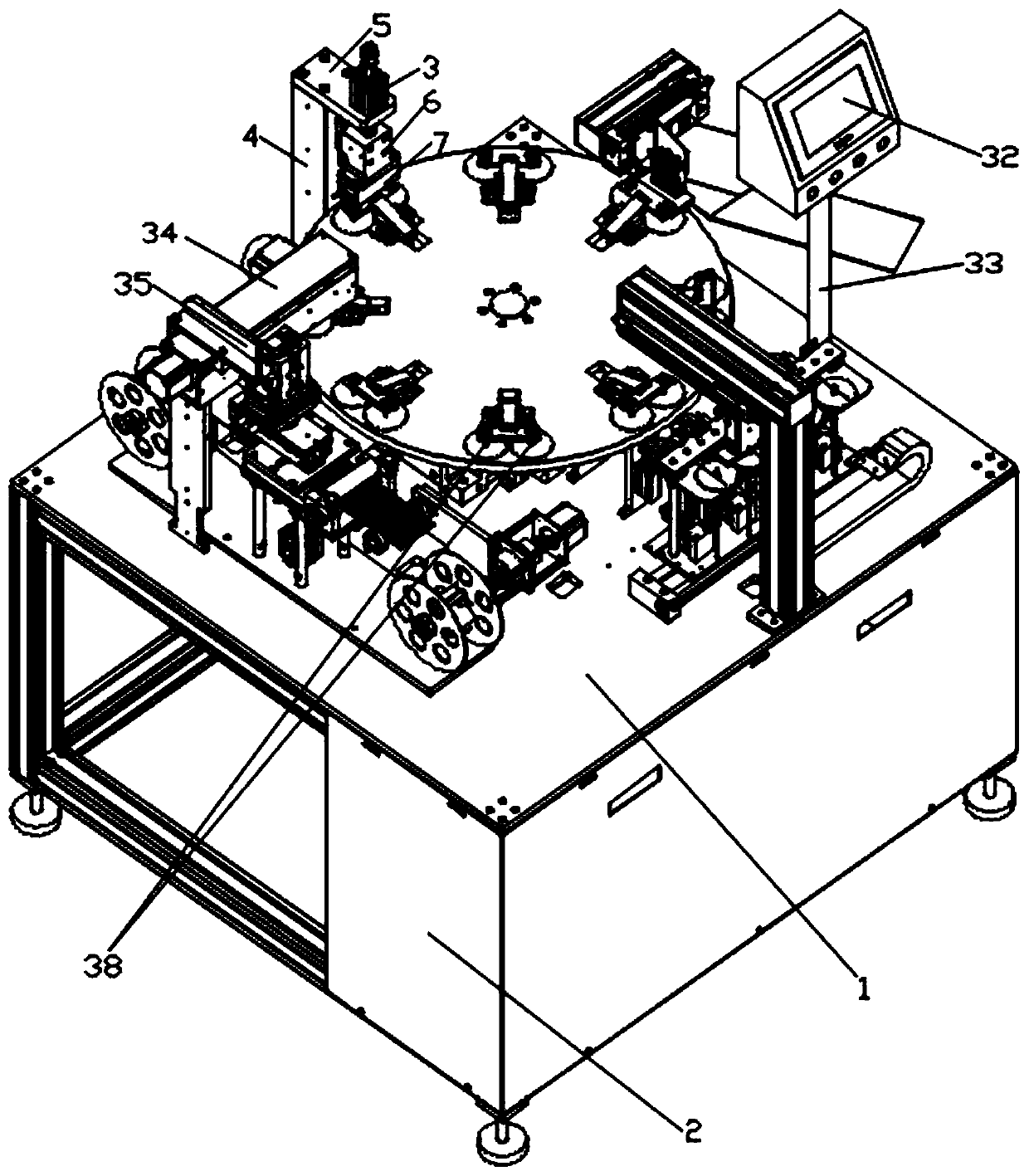

Fully-automatic gasket welding machine

PendingCN110228206ASimple structureSolving Automatic Soldering ProblemsMetal working apparatusEngineeringFully automatic

The invention relates to the technical field of gasket welding machines, in particular to a fully-automatic gasket welding machine. The fully-automatic gasket welding machine has a base, wherein an electric control cabinet is embedded in the base, a turntable mechanism is rotatably arranged in the middle of the upper end of the base, and a plurality of connecting rod mechanisms are uniformly formed on the end face of the turntable mechanism in the peripheral direction; a jacking mechanism, a cutting mechanism, a welding mechanism and a discharging mechanism are sequentially arranged on the periphery of the turntable mechanism clockwise in the peripheral direction; and the welding mechanism comprises a vertical movement air cylinder, a first stand column, a fixed plate, a welding base and awelding head. The fully-automatic gasket welding machine solves the automatic welding problem of gaskets, meets the welding of gaskets with different sizes, reduces the burden of manual operation, improves the overall welding efficiency and the welding quality of the gaskets, and is beneficial for use and wide popularization.

Owner:昆山艾尤诺新材料科技有限公司

Flexible printed circuit board and manufacturing method thereof

ActiveCN106793584AReduced risk of tearingMeet weldingFlexible printed circuitsElectrical connection printed elementsTectorial membranePunching

The present invention provides a flexible printed circuit board and a manufacturing method thereof. The method comprises: performing windowing on a cover film according to the position of a two-sided contact bonding pad in a preset circuit pattern; performing press fit of a first conducting layer at the lower surface of the cover film; processing the first conducting layer to form a first conducting layer circuit pattern; performing press fit of insulation materials and a second conducting layer at the lower surface of the first conducting layer, wherein the upper surface of the second conducting layer is coated with the insulation materials, the insulation materials and the second conducting layer staggered with the position of the two-sided contact bonding pad; processing a blind hole punching through the insulation materials and the second conducting layer at the lower surface of the second conducting layer, and allowing the blind hole to be filled with conducting materials; processing the second conducting layer to form the second conducting layer circuit pattern; attaching a protective film to the lower surface of the second conducting layer; and performing windowing on the protective film according to the position of the two-sided contact bonding pad in the preset circuit pattern. The flexible printed circuit board is provided with a bonding pad which realizes two-sided contact and conduction through the first conducting layer so as to satisfy welding and conduction requirements and reduce the risk of the tearing of the bonding pad.

Owner:VIVO MOBILE COMM CO LTD

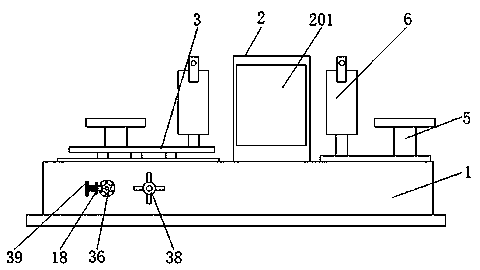

Supporting positioning device and method for laser welding of ribbed wall board

ActiveCN111250880AMeet supportSatisfy supportWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding deformation

The invention relates to a supporting positioning device and method for laser welding of a ribbed wall board. The supporting positioning device for laser welding of the ribbed wall board comprise a bed body, a plurality of positioning tools for positioning the ribbed wall board are arranged on the bed body in the X direction, and the number of the positioning tools is adjusted adaptively accordingto the size and shape of the ribbed wall board. The positioning tools comprise mobile box bodies slidably arranged on the bed body and used for sliding in the X direction, telescopic positioning rodsmoving in the Y direction and the Z direction are arranged on the mobile box bodies, vacuum suction discs for fixing the ribbed wall board are arranged at the top ends of the telescopic positioning rods, and supporting mechanisms for supporting the ribbed wall board are arranged on the mobile box bodies. The welding of ribbed wall board bodies with in various shapes and sizes can be achieved, thewelding process stability is improved, welding deformation is effectively controlled, and assembly efficiency and degree of automation are improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

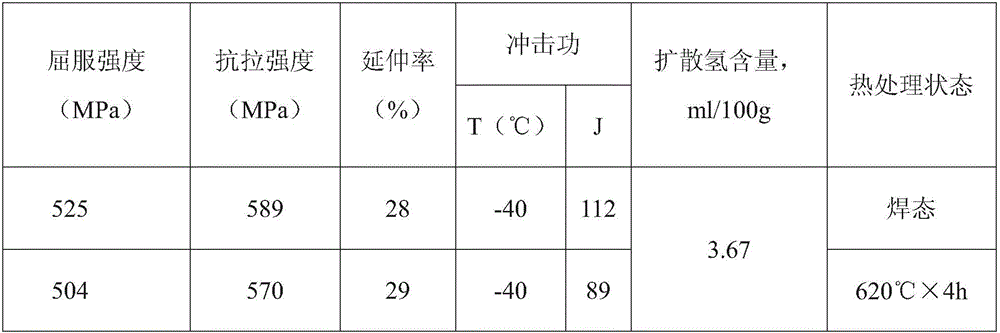

50 kilogram-grade flux-cored wire for relieving stress after welding

InactiveCN106425161AImprove crack resistanceImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaCrack resistanceStress relieving

The invention discloses a 50 kilogram-grade flux-cored wire for relieving stress after welding. The flux-cored wire has excellent crack resistance, weld metal has excellent mechanical property on the as-welded condition and the stress relieving and annealing conditions (620 DEG C * 4 h), the impact value is high (AW is greater than or equal to 100 J and SR is greater than or equal to 80 J) especially at -40 DEG C, and the welding requirement of EH36 can be met.

Owner:KUSN GINTUNE WELDING

Fin type LED radiator

InactiveCN103277767AImplement automatic assemblyMeet automatic assemblyPoint-like light sourceLighting heating/cooling arrangementsHeat conductingEngineering

The invention discloses a fin type LED radiator which comprises a main structure. The main structure comprises a structure seat and a plurality of groups of heat-conducting fins, the heat-conducting fins are arranged on the structure base and are of fin structures which are distributed regularly, and pure aluminum materials are combined with one another and are processed to form the structure seat and the heat-conducting fins. The fin type LED radiator has the advantages that the radiating area is increased by the aid of the fin type heat-conducting fins, the fin type LED radiator is good in radiating effect and low in temperature owing to quick convection, the temperature of the fin type LED radiator is lower than that of the traditional aluminum lamp radiator for a vehicle by 5-11 DEG C, and the fin type LED radiator is made of 1060 series aluminum materials with high heat-conducting performance, so that the heat-conducting coefficient of the fin type LED radiator reaches 53, the fin type LED radiator does not need to be filled with heat-conducting silicon gel, and the integral weight of the fin type LED lamp is reduced by 60-70% as compared with the traditional structure; the fin type LED radiator is simple in structure, can be subjected to various color and surface treatment procedures, is attractive, elegant, superior and exquisite; and a stamped radiating lamp cup can be automatically assembled without being welded, the fin type LED radiator is simple in technique process, and requirements of markets are met.

Owner:东莞金龙电子有限公司

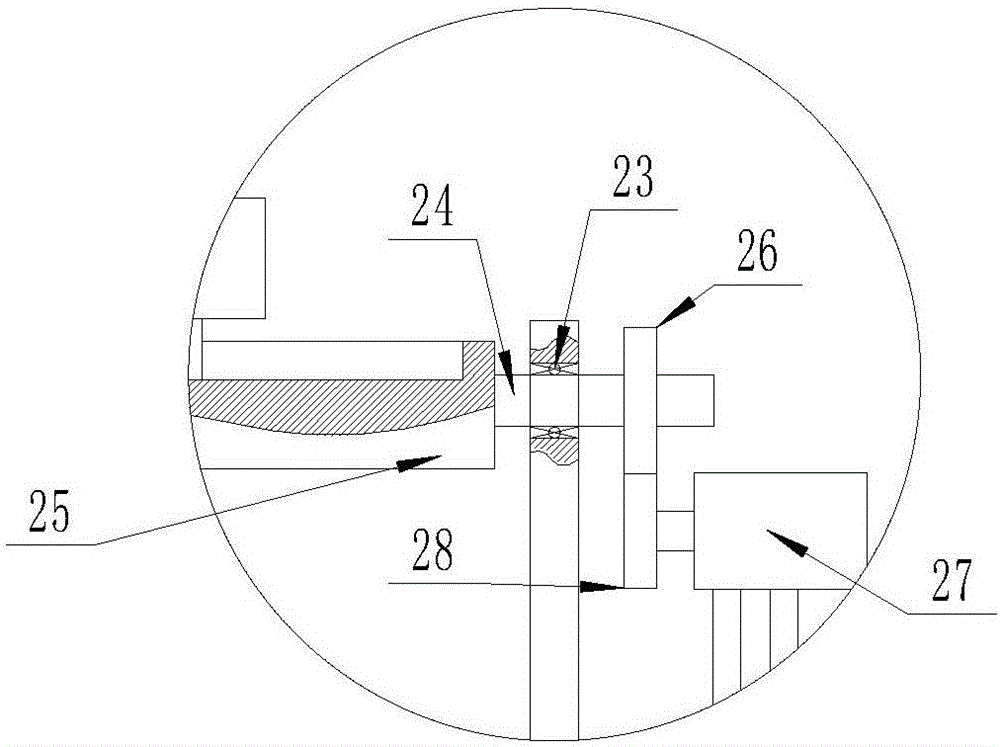

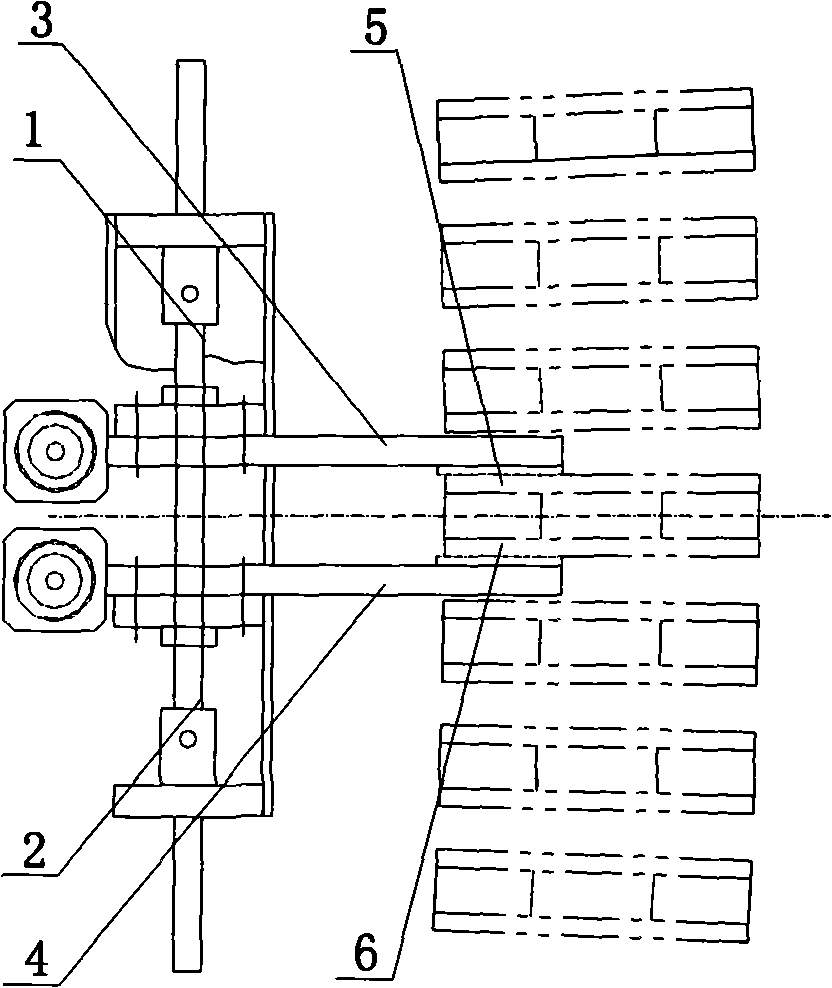

Automatic busbar wire welding system

InactiveCN107891236AImprove processing efficiencyEasy to install and debugWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

An automatic welding system for bus wires, including a station system and a welding robot, the station system includes a feeding mechanism, a positioning welding mechanism, and a discharging mechanism, and the feeding mechanism and the discharging mechanism are respectively arranged on the feeding mechanism of the positioning welding mechanism. The mouth side and the discharge port side are placed perpendicularly to each other. The feeding mechanism and the discharging mechanism are composed of a supporting mechanism and a clamping positioning mechanism connected to each other; The station system and the second station system, a welding robot is installed between the first station system and the second station system; Tight positioning, can meet the welding of various shapes of busbar wire products, and adopts double-station alternate work, high processing efficiency.

Owner:卢光贤

Welding device and process for electrical pipe manufacturing and processing

InactiveCN113369793AMeet weldingNot easy to hurtWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringPipe welding

The invention discloses a welding device and process for electrical pipe manufacturing and processing in the technical field of electrical pipe welding. The welding device comprises a bottom plate, a welding mechanism is arranged at the rear side of the top of the bottom plate, two symmetrically arranged penetrating pipes are arranged above the bottom plate, and the penetrating pipes are fixedly connected with the bottom plate through supporting parts; the inner wall of each penetrating pipe is slidably connected with three fixed clamping plates which are distributed in a circumferential array manner, each fixed clamping plate is fixedly connected with a driving mechanism, the driving mechanisms are used for driving the fixed clamping plates to move and clamp an electrical pipe, the side edges of the fixed clamping plates are provided with turnover mechanisms located in the penetrating pipes, and the turnover mechanisms are used for turning over the electric pipe when the welding mechanism is used for welding. According to the device, the welding of the electrical pipe is more convenient and simpler.

Owner:泰州伟利兴电气有限公司

Intelligent automobile frame welding equipment

PendingCN111673326AMeet weldingWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameWelding

The invention discloses intelligent automobile frame welding equipment. The intelligent automobile frame welding equipment is characterized in that a mounting rail is arranged at the top of a mountingframe, a mounting groove is formed in the middle of the mounting rail, an electric sliding table is arranged in the mounting groove, sliding rails are arranged at the positions, located on the two sides of the mounting groove, of the mounting rail, a sliding block is slidably connected to the sliding rails on the two sides, a connecting rod is arranged at the sliding end of the electric sliding table, the two sides of the connecting rod are fixedly connected with the sliding block, an first electric extendable rod is arranged on the lower surface of the sliding block, a clamping assembly is arranged at the extendable end of the first electric extendable rod, a plurality of welding manipulators are arranged on the two sides of the mounting frame, and welding heads are arranged on the welding manipulators. According to the intelligent automobile frame welding equipment, welding of each position of a vehicle frame can be automatically completed, and meanwhile, by adjusting the welding manipulators, welding of vehicle frames of different models can be completed.

Owner:HUBEI HUAYUE AUTO PARTS

Fused flux used for welding 9Ni steel and preparation method of fused flux

ActiveCN110102933AGood moisture absorptionGood workmanshipWelding/cutting media/materialsSoldering mediaPotassiumMoisture absorption

The invention relates to a fused flux used for welding 9Ni steel and a preparation method of the fused flux, and belongs to the field of welding materials. The fused flux comprises, by weight, 45-47 parts of wollastonite, 15-17 parts of CaF2, 25-27 parts of marble, 12-15 parts of potassium feldspar, 5-7 parts of ZrO2, 5-7 parts of MgO, 0.1-0.5 part of manganese ore, and 2.5-5 parts of BaO. The preparation method comprises the steps of material preparation, smelting, pelletizing, crushing and screening, drying, and packaging, wherein the granularity of the fused flux is 10-80 meshes. The fusedflux has the characteristic of good moisture-absorption resistance and is used in cooperation with an ERNiCrMO-4 nickel-based welding wire according with ASMEIISFA-5.14, the weldability and the mechanical performance of weld joints are good, the tenacity of weld metal at an ultralow temperature is stable and good, and the anti-heat-crack sensitivity is good.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Multifunctional practical welding operation frame

The invention discloses a multifunctional practical welding operation frame. The multifunctional practical welding operation frame comprises a base and a brace vertically and fixedly connected to the base. A plurality of through holes are formed in the four corners of the base, and bolts penetrate through the through holes so that the base can be detachably connected with the ground. A first sleeve, a second sleeve, a third sleeve and a fourth sleeve are connected to the positions, with different heights, of the brace from bottom to top in a sleeved mode, and respectively detachably connected with the brace through bolts, two lug plates are fixedly connected to the third sleeve, and a lug plate is fixedly connected to the fourth sleeve. One end of a cantilever tube is detachably connected with a first clamping end, a second clamping end, a small tube obstacle frame and a contra-aperture combined platform and other structural components through bolts, wherein the first clamping end is used for clamping plates of welder experiment current, and the second clamping end is used for clamping platy test pieces and large-tube-diameter test pieces.

Owner:北京科技高级技术学校

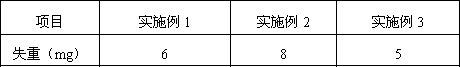

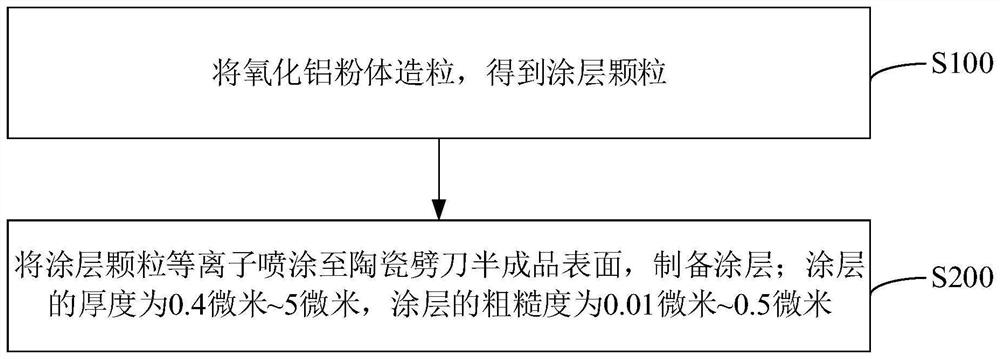

Preparation method of surface coating of ceramic chopper, ceramic chopper and application of ceramic chopper

The invention relates to a preparation method of a surface coating of a ceramic chopper, the ceramic chopper and application of the ceramic chopper. The preparation method of the ceramic chopper surface coating comprises the following steps: granulating aluminum oxide powder to obtain coating particles; and carrying out plasma spraying of the coating particles onto the surface of a ceramic chopper semi-finished product to prepare the coating with the thickness of 0.04-5 [mu] m and the roughness 0.01-0.5 [mu]m. The aluminum oxide coating is formed on the surface of the ceramic chopper through the plasma spraying technology, the process parameters of plasma spraying are adjusted, the ceramic chopper with different surface roughness can be obtained, compared with traditional chemical roughening treatment, welding of different metal wires such as gold wires, silver wires and copper wires can be met, and the service life of the welding wire of the ceramic chopper is long.

Owner:SHENZHEN SUNTECH ADVANCED CERAMICS

Method for preparing new copper-iron welding wires

ActiveCN111745322AGuaranteed purityHigh purityWelding/cutting media/materialsSoldering mediaCopper matrixWelding

The invention provides a method for preparing new copper-iron welding wires. The method specifically comprises the following steps of preparing ingredients: in terms of percentage content, the percentage of Fe in the raw material is 5-15%, and the remainder is Cu; smelting by a method of vacuum melting; casting and taking out of the furnace, wherein the casting speed is first slow, then appropriately accelerated, and finally slowed down; hot forging and machining an excircle; hot rolling and coiling; drawing and intermediate annealing; and straightening, cutting and slitting. The copper-iron welding wires prepared by the invention are fibrous in the iron phase, evenly distributed in a copper matrix, and have uniform overall structure of the alloy. The prepared copper-iron welding wires contains both copper and iron components at the same time, which can well meet the requirements of welding between copper materials and iron materials.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

Welding electrode and coating for welding under wading environment, and preparation methods of welding electrode and coating

ActiveCN108515288ASimple preparation processEasy arc startWelding/cutting media/materialsSoldering mediaYttriumFerrosilicon

The invention discloses a welding electrode and a coating for welding under a wading environment, and preparation methods of the welding electrode and the coating. The coating comprises the followingcomponent raw materials of, by weight, 35-50% of rutile, 10-20% of calcium carbonate, 5-15% of fluorite, 7-18% of mica, 2-9% of ferrosilicon, 3-9% of ferromanganese, 4-10% of titanium and 1.5-5% of yttrium. Potassium sodium water glass with the weight being 18-30% of the total weight of the coating is further added into the coating, and the mass ratio of potassium oxide to sodium oxide in the potassium sodium water glass is 2:1. Meanwhile, the invention further discloses the preparation methods of the welding electrode and the coating. The preparation process is simple, arcing is easy during welding, electric arc combustion is stable, the phenomena of arc quenching and breaking are avoided, an obtained welded seam is attractive in forming, the tensile strength of a butt-joint connector canreach 550 MPa, the thickness of the butt-joint connector is four times that of a plate, cracks are avoided when the cold bending angle is 180 degrees, the advantages of good welding manufacturability, convenient test operation, high welding efficiency and the like are achieved, and welding of workpieces under the wading environment can be met.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

Installing and welding fixture device for upper link of wagon

ActiveCN105149856AGuaranteed angleAvoid working errorsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTruck

The invention provides an installing and welding fixture device for an upper link of a wagon. The device comprises a rack. A sliding groove is formed in the top of the rack. A pull rod support used for being connected with a first pull rod head is arranged on the sliding groove in a sliding manner. The part, at one end of the sliding groove, of the rack is connected with a rotating support assembly. The rotating support assembly comprises a support fixedly connected to the rack. The support is rotationally provided with a rotating pull rod base used for being connected with a second pull rod head. The pull rod support and the rotating pull rod base are located at the same horizontal height. As the pull rod support is arranged at the upper portion of one end of the rack in the sliding manner and the rotating support assembly is arranged at the upper portion of the other end of the rack, components of the upper pull rod can be placed on the device to be fixed and welded at a time, and the work error generated during welding is prevented. As the sliding groove is formed in the upper portion of the rack, and the pull rod support is arranged on the sliding groove in the sliding manner, welding of the upper pull rod with different length requirements can be met by adjusting the position of the pull rod support.

Owner:CRRC QIQIHAR ROLLING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com