Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1581 results about "Stepper motor control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

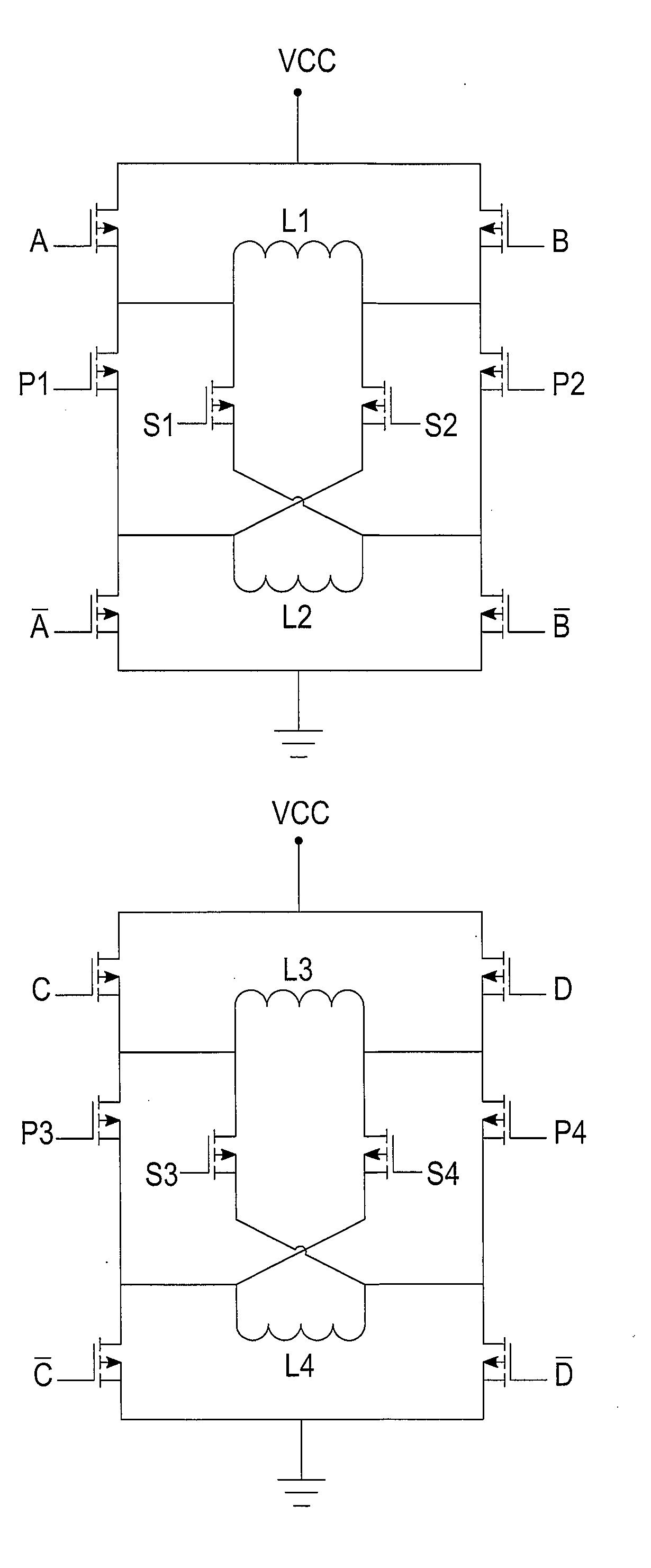

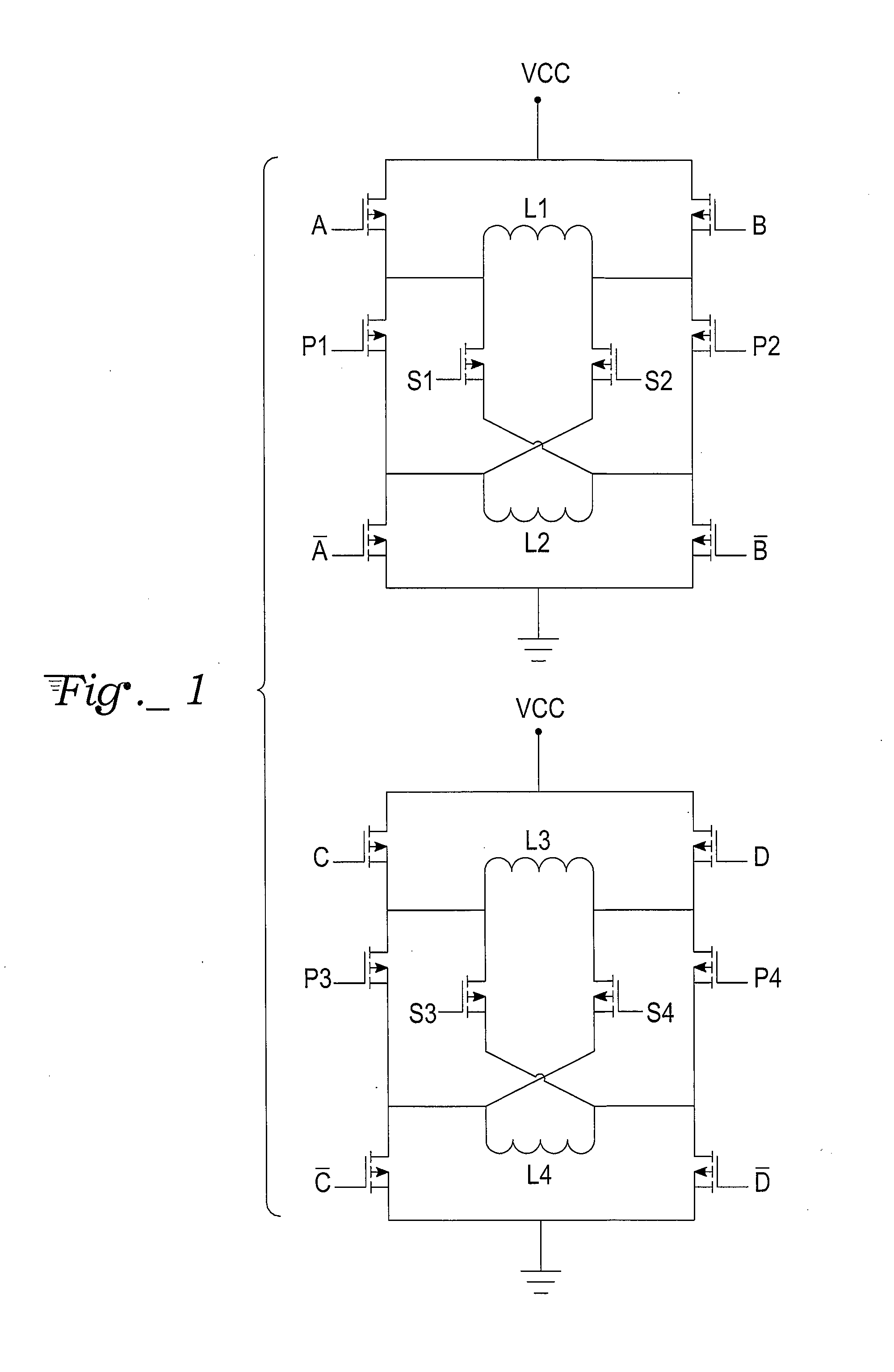

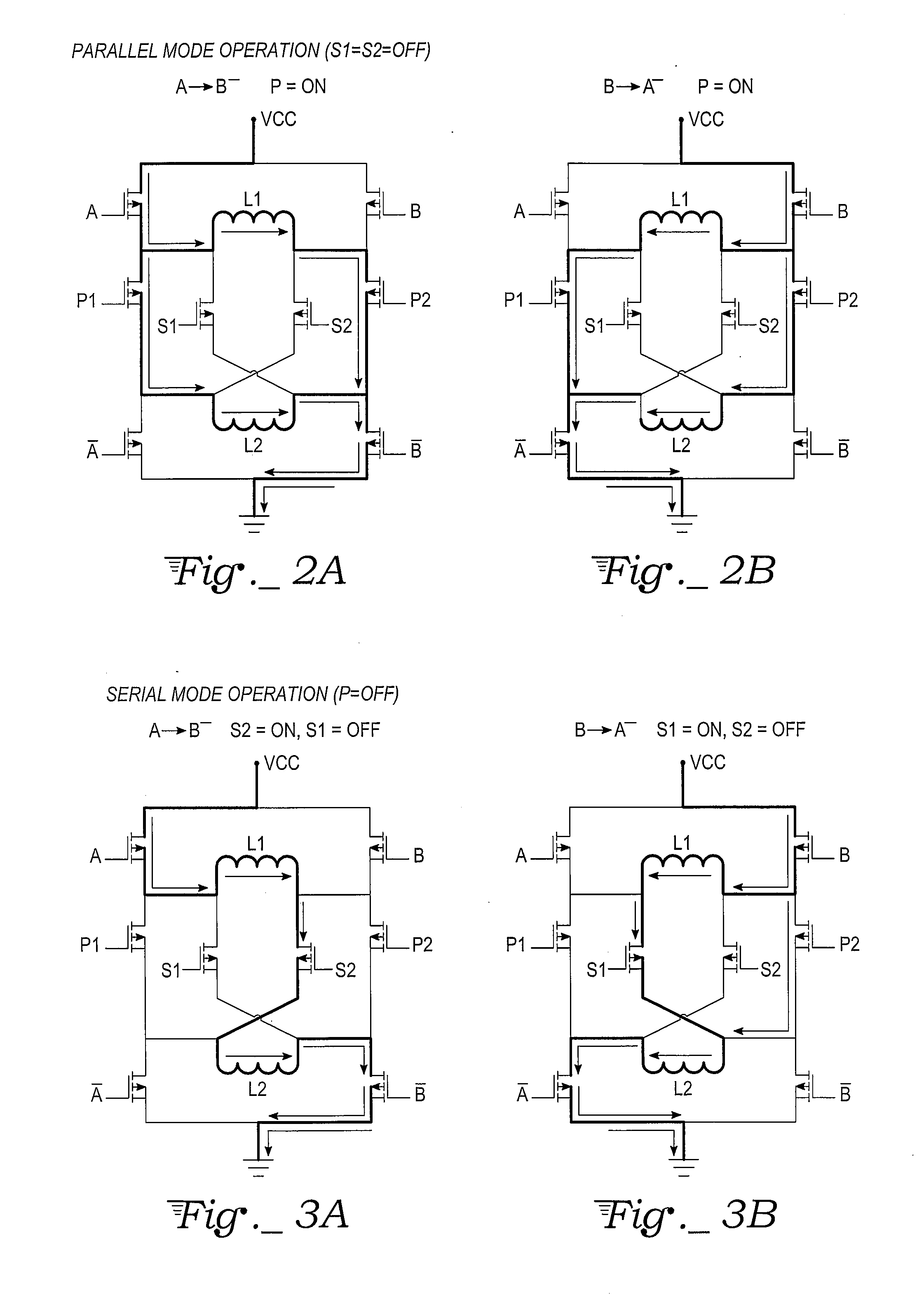

H-bridge drive circuit for step motor control

InactiveUS20110241597A1Improve stand-alone performanceEasy to implementDynamo-electric converter controlMotor speedDriving current

A drive circuit for step motors with bifilar windings is provided in which both parallel and series winding configurations for the stator coils are selectable by a motor controller based on the motor speed. For low speeds a series configuration is selected, while for higher speeds a parallel configuration is selected. Dynamic torque is optimized by the selection for more efficient motor operation with less drive current.

Owner:LIN ENG INC

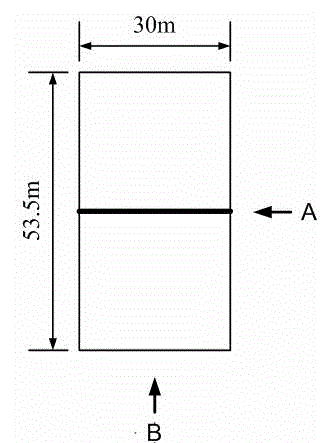

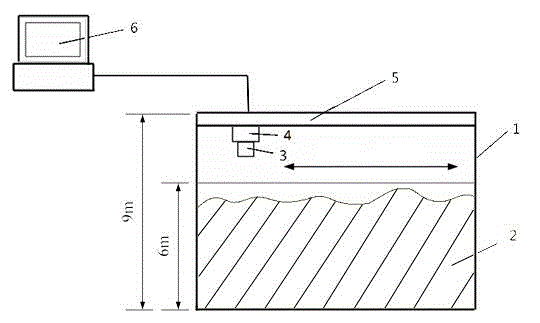

Method for measuring volume of large irregular bulk grain pile based on dynamic three-dimensional laser scanning

The invention relates to a method for measuring the volume of a large irregular bulk grain pile based on dynamic three-dimensional laser scanning. The method comprises the following steps of: arranging a guide rail in the middle of the top of a barn along the width direction, wherein the guide rail is provided with a slide block controlled by a stepping motor, and a laser radar scanner is installed on the slide block; moving the slide block from one end to the other end of the top of the barn at a constant speed to drive the laser radar scanner by the slide block to finish scanning on the surface of the whole bulk grain pile, wherein the laser radar device is a one-dimensional scanning device to realize linear scanning and returning coordinate data, and the master control computer is used for transmitting pulses to the stepping motor and processing the signal; acquiring point cloud data of the surface of the bulk grain pile through the master control computer, determining the distribution density of scanned points for calculating the volume according to an allowed error value of the grain pile measured by the user, and calculating the weight of the grain pile according to the grain density provided by the user; and generating a point cloud graphic matrix attached with coordinates through scanning space morphology by guide rail moving type three-dimensional laser, performing surface fitting to form an irregular bulk grain pile appearance, and thus obtaining the volume of the irregular bulk grain pile. The volume of the large irregular bulk grain pile can be rapidly and effectively measured at high precision, and remote monitoring can be realized; and moreover, the method is low in cost and easy to implement.

Owner:MENG FAN'GANG

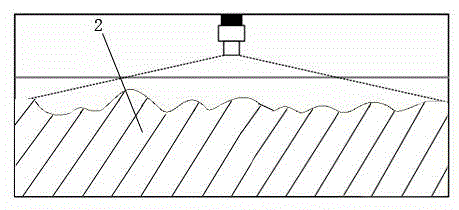

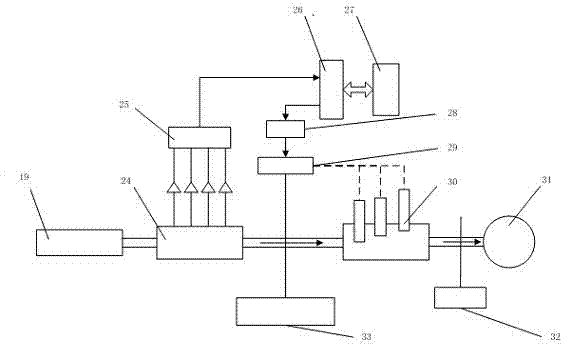

Method and device for curing fiber-reinforced resin-based composite material component by utilizing microwaves

ActiveCN103587130ASolve for uniformitySolve power problemsResin-Based CompositeFiber-reinforced composite

The invention relates to a method and a device for curing a fiber-reinforced resin-based composite material component by utilizing microwaves. The microwaves which are generated by a microwave source with linearly-adjustable power are guided into a resonant cavity, and the microwaves penetrate through and heat the composite material, so that the composite material can be quickly cured and formed. By adopting the advanced octagonal microwave-mode resonant cavity, the uniformity of an electromagnetic field inside the device can be realized; the interference of the reflection wave on the microwave source can be reduced by adopting an automatic impedance matching system, so that the optimal transmission of the microwave power can be realized. A vacuum pipe connector and a temperature sensor are arranged on the inner side wall of the octagonal multi-mode resonant cavity, a glass worktable is arranged inside the resonant cavity, and the rotation of a ball screw is controlled through a stepper motor to control the back-forth movement of the worktable. A choking groove is adopted to prevent the leakage of the microwave. By adopting the method and the device, the problems of the traditional autoclave forming method that the time for manufacturing the fiber-reinforced composite material is long, the energy consumption is high and the heat is non-uniform can be solved, the curing time can be saved, and the quality and performance of the composite material component can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

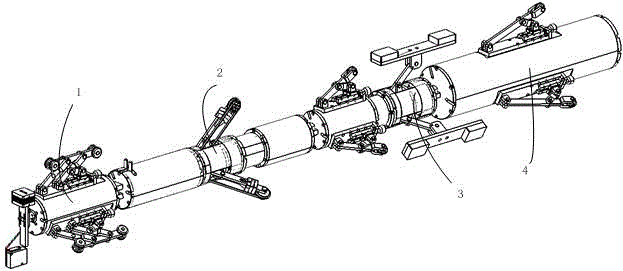

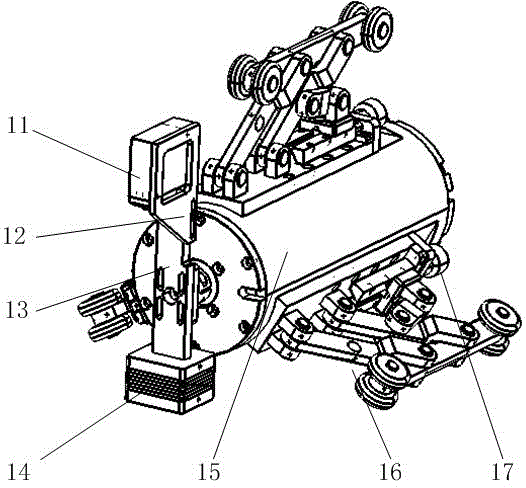

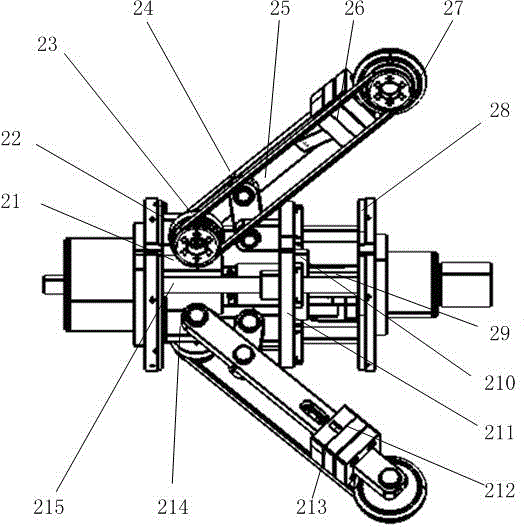

Pipeline detection robot

The invention relates to a pipeline detection robot. The pipeline detection robot mainly comprises a laser detection mechanism (1), a traction mechanism (2), an electromagnetic ultrasonic detection mechanism (3) and an electronic cabin (4), all of which are connected through connecting hinge shafts; the traction mechanism (1) adopts a single-motor all-drive mode and is driven by a turbo-worm synchronous belt to supply a walking power to the robot; the laser detection mechanism (2) comprises a laser displacement sensor, a rotating arm, a counterweight, a support body and the like and is used for measuring surface corrosion and deformation of a pipeline; the electromagnetic ultrasonic detection mechanism (3) comprises a support assembly, a probe and a fixing plate and is used for measuring the wall thickness and the crack defect of the pipeline; the electronic cabin (4) is used for carrying auxiliary components, such as a stepping motor controller, a servo motor driver, a power supply and an FPGA (Field Programmable Gate Array) control panel. The pipeline detection robot disclosed by the invention can be used for finding the defects, such as pipeline corrosion, cracks and deformation, carrying out in-service detection on an oil and gas pipeline in a working process, carrying out targeted repair, maintenance and replacement according to a detection result, reducing the maintenance cost and guaranteeing safe and stable operation of the oil and gas pipeline.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

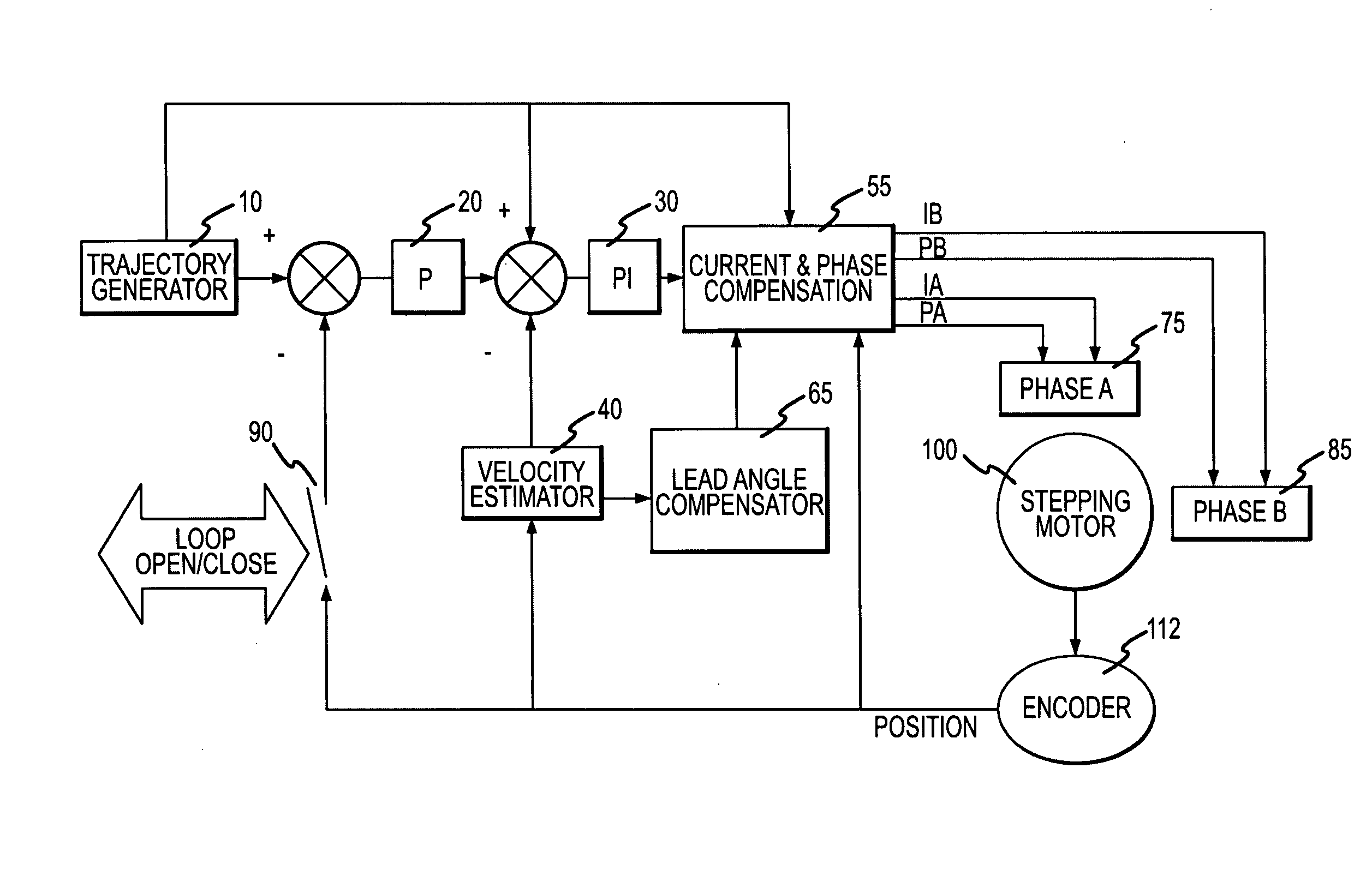

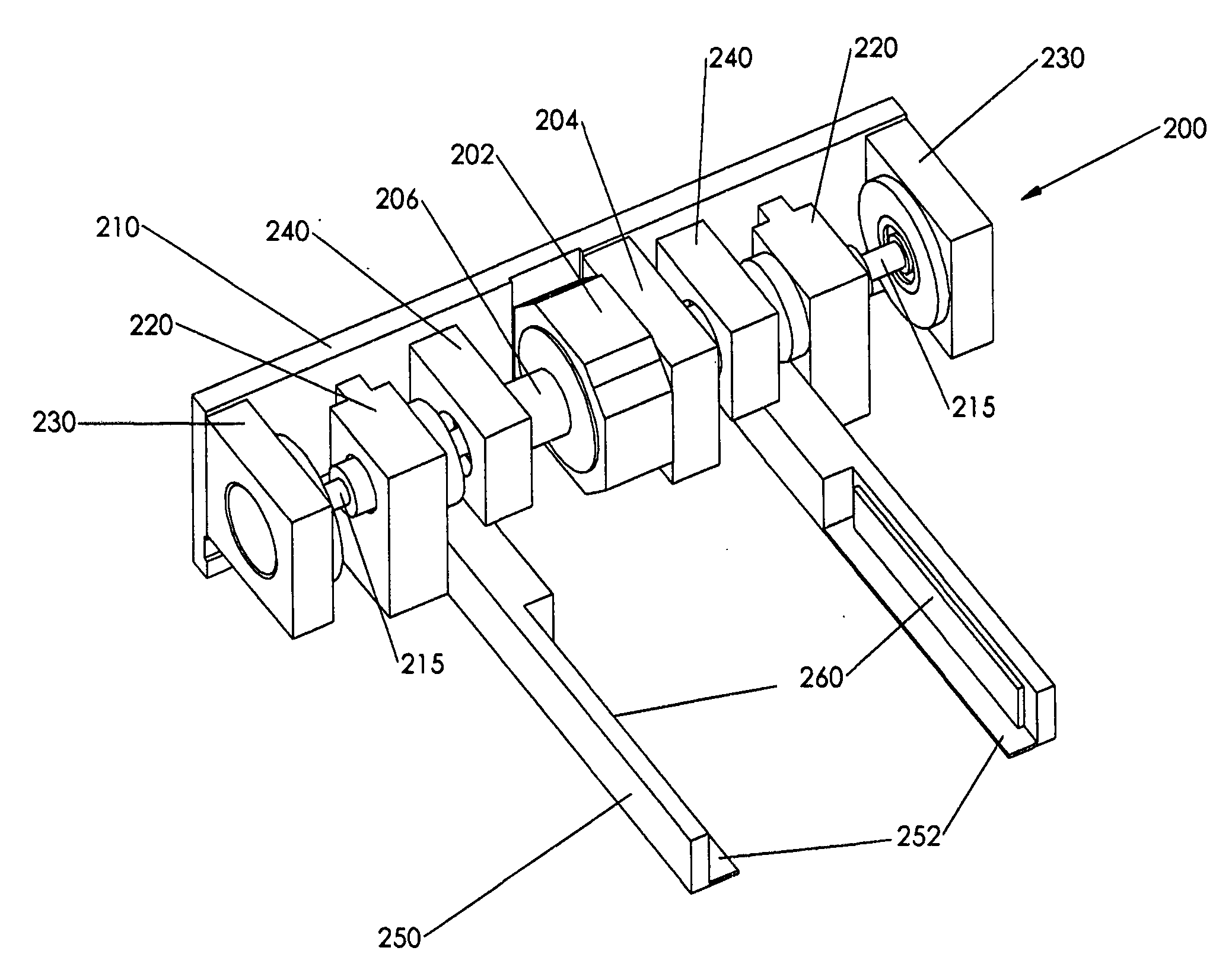

Stepping motor control system and method for controlling a stepping motor using closed and open loop controls

InactiveUS20070040529A1Good for high speedImprove torque performanceComputer controlSimulator controlMotor speedLoop control

A stepping motor is driven in both closed-loop and open-loop modes while initiating microstepping after a predetermined threshold velocity has been reached. A feedback device such as an encoder is mounted on the stepping motor shaft and the encoder keeps track of the mechanical position of the rotor. Based on feedback from the encoder, stator phases are activated to maintain a 90° phase advance and produce maximum torque. A lead angle compensation technique is used to advance the motor lead angle, to allow for the excitation currents to reach maximum even at higher speeds. The stepping motor controller employs this strategy in order to produce maximum torque across a wide range of motor speeds and actuator motions.

Owner:SMC CORP OF AMERICA

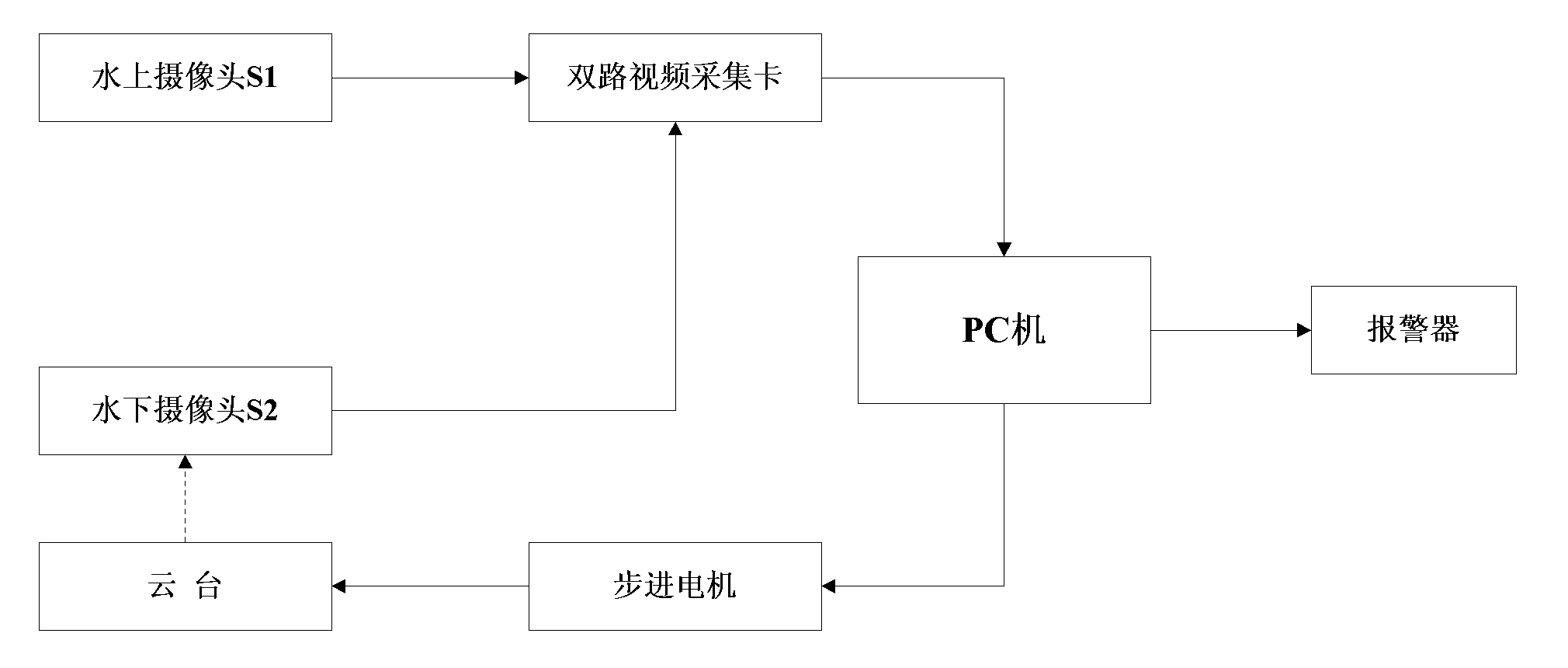

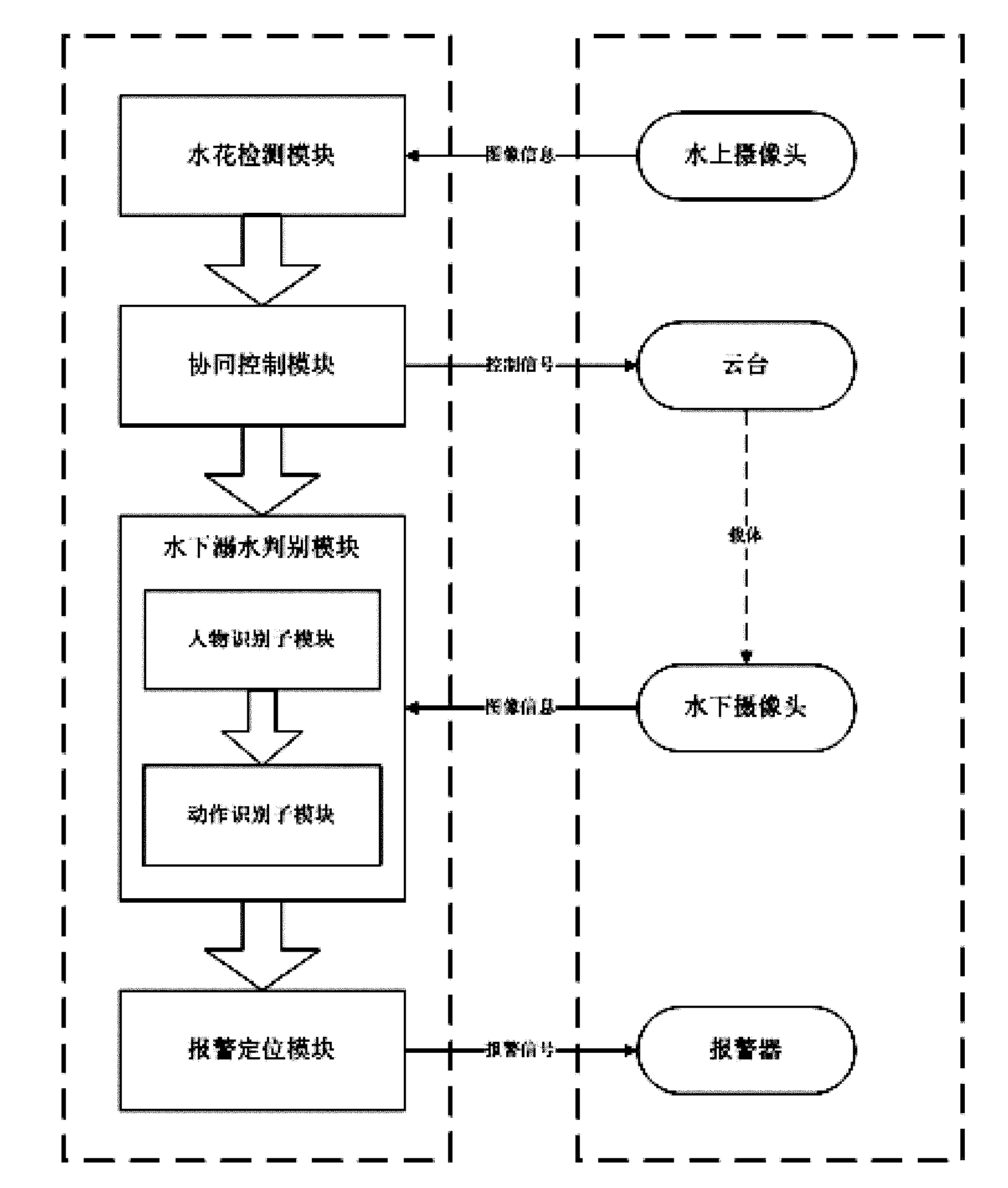

Shooting network-based method and system for warning of drowning prevention in swimming pool

ActiveCN102693606AImprove securityEnsure personal safetyClosed circuit television systemsAlarmsUnderwaterControl signal

The invention relates to a shooting network-based method and system for warning of drowning prevention in a swimming pool. A fixed water camera is installed above a water surface of a swimming pool and a rotatable underwater camera is installed under the water surface of the swimming pool; the water camera and the underwater camera output signals to connect a PC machine or a DSP and a PC machine by video acquisition cards at all paths; the PC machine or the DSP output a control signal to connect an alarm and a stepper motor that controls a cloud platform to make rotations. Besides, the PC machine or the PC machine and the DSP includes / include a spray detection module, a coordinated control module, an underwater drowning determination module and an alarm positioning module. According to the invention, omnibearing and multi-angle warning coverage on a swimming pool can be realized. When a swimmer is drown, the system carries out intelligent determination and emits alarming; and an object position can be provided, so that a lifeguard is warned to carry out rescue at the first time to ensure personal safety of the swimmer.

Owner:NAT UNIV OF DEFENSE TECH

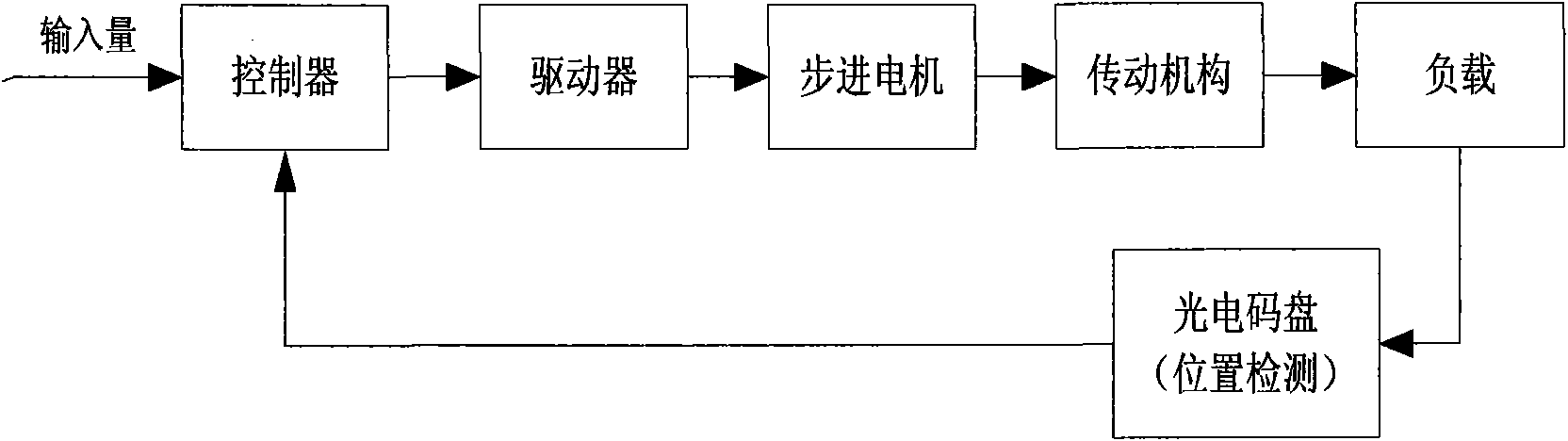

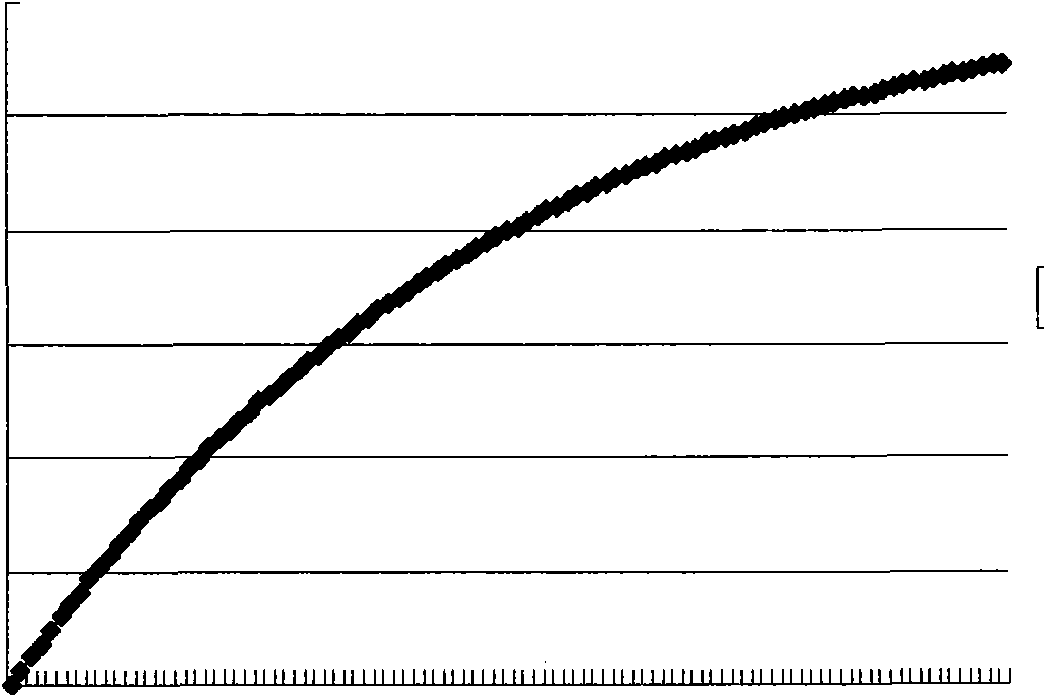

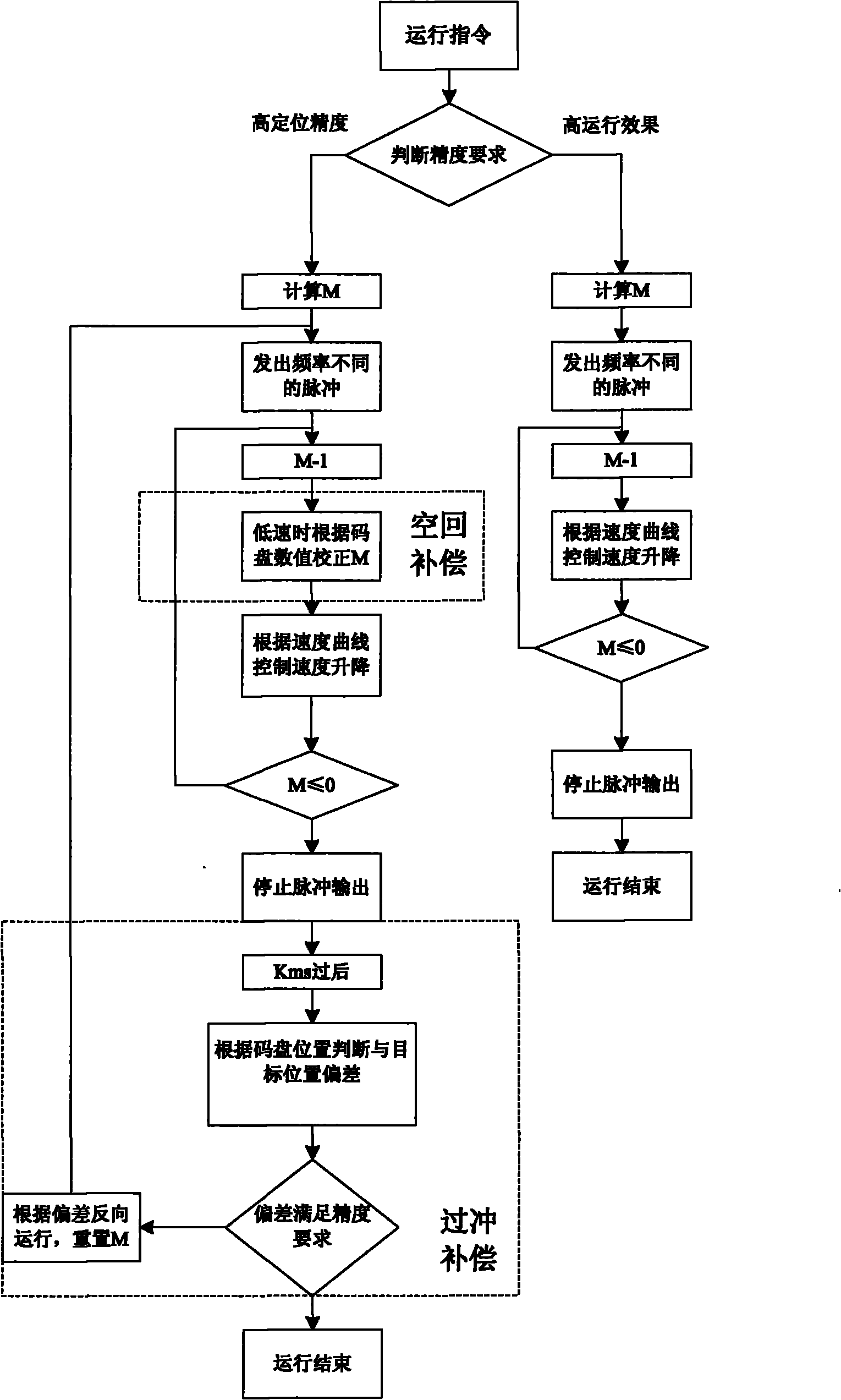

Stepping motor control system and control method thereof

InactiveCN101938241AEasy to findPrevent out of syncDynamo-electric converter controlLoop controlMotor drive

The invention discloses a stepping motor control system and a control method thereof. The stepping motor control system comprises a controller, a stepping motor controller, a stepping motor, a transmission mechanism, a load and a photoelectric encoder, wherein the controller sends a plurality of pulses with a certain frequency and a certain quantity to the driver which receives the pulse information and a direction signal and acts on the stepping motor, the stepping motor drives the load through a driving mechanism, and the photoelectric encoder feeds back and transfers position information to the controller. The invention realizes high-accuracy positioning through a fuzzy control method, achievesprovides higher operation effect by adopting the combination of dual compensation feedback and open-loop control, has the desynchronizing detection function for compensatingrehending and feeding back failure information and also hasprovides higher failure suitability.

Owner:HENAN COSTAR GRP CO LTD

Three-dimensional detection device and method for scanning appearance of a welding seam in high-frequency resistance welding based on linear structured light

ActiveCN107764205AImplement automatic detectionImprove detection efficiencyUsing optical meansSoftware systemWeld seam

The invention provides a three-dimensional detection device and method for scanning the appearance of a welding seam in high-frequency resistance welding based on linear structured light. The three-dimensional detection device comprises a linear structured light sensor, a linear displacement transmission system and a computer, wherein the linear structured light sensor comprises a laser, an industrial camera and a fixed panel; and the linear displacement transmission system comprises a base, a stepping motor and a stepping motor controller. A welded object is placed on the base of the transmission system, scanning is performed by adopting the linear structured light, the industrial camera shoots a laser stripe image of the welding seam, the laser stripe image is processed through a software system to obtain three-dimensional point cloud data of the welding seam, appearance characteristics such as the width and the height of the welding seam are acquired through analysis, and thus judgment can be performed on the quality of the welding seam. The three-dimensional detection device has the advantages of high precision, safety, reliability, real-time detection and the like, improves the efficiency of welding seam quality detection and can achieve automatic detection for the welding seam quality.

Owner:XIAN MASTER ARCHITECTURAL DESIGN CO LTD

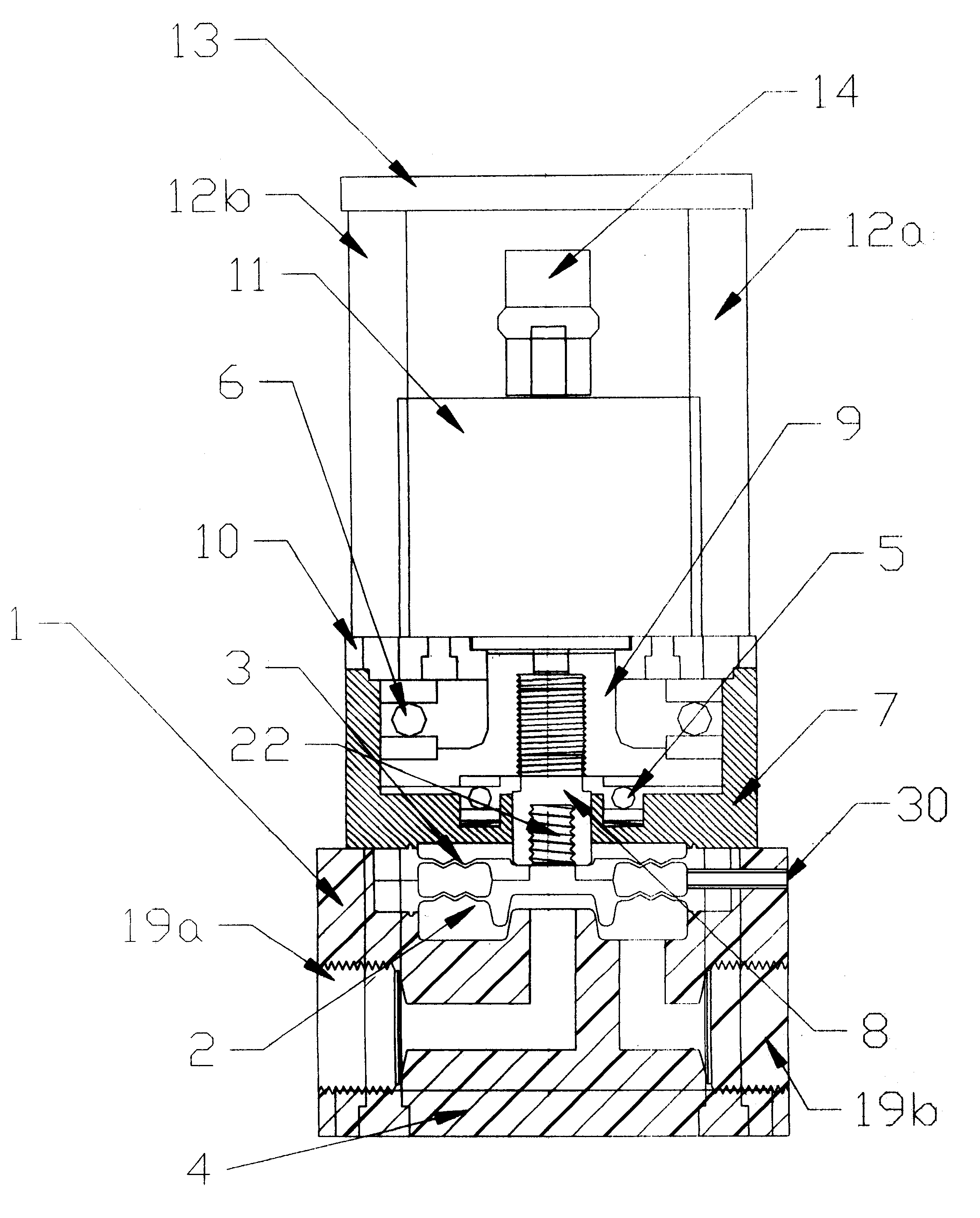

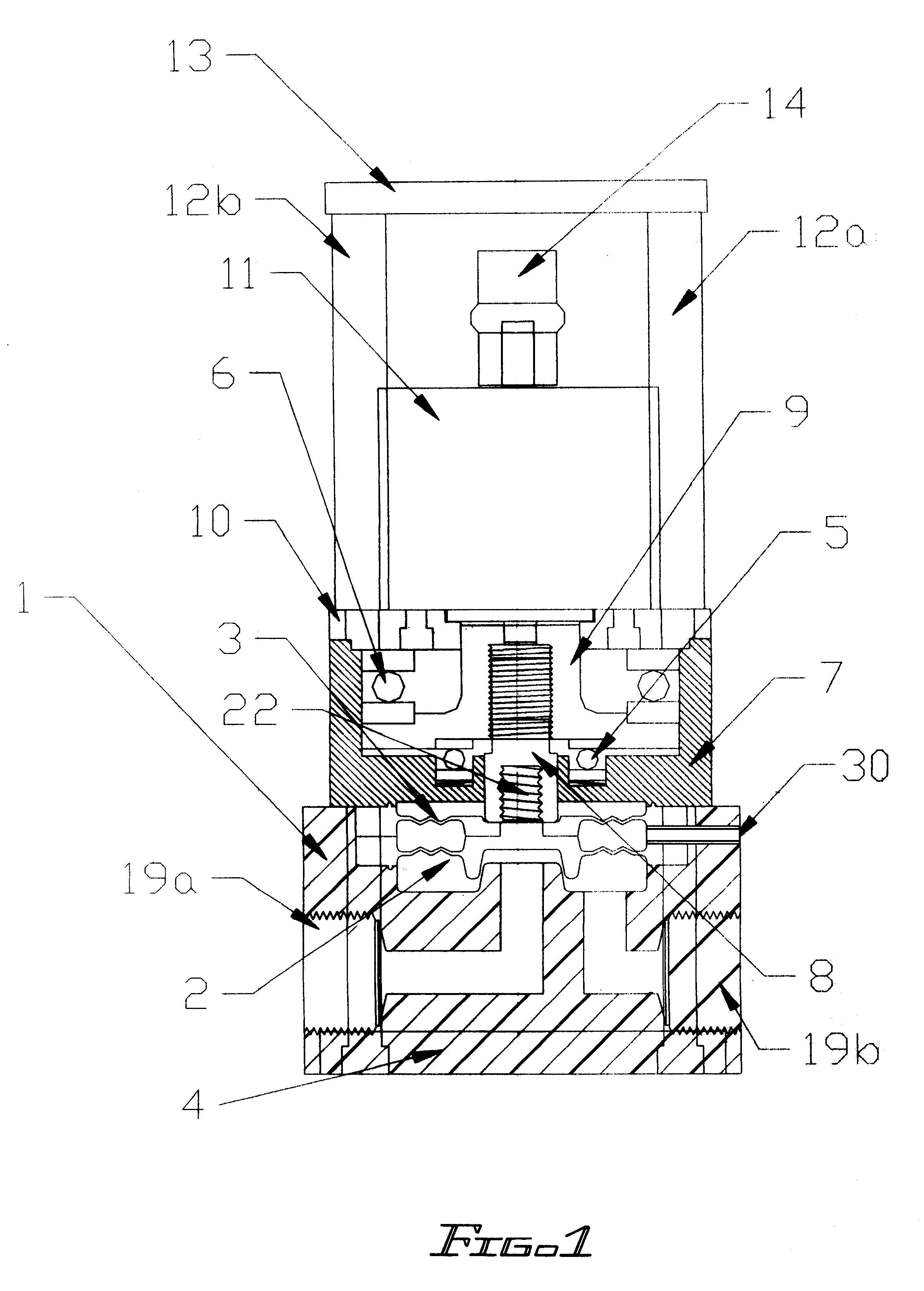

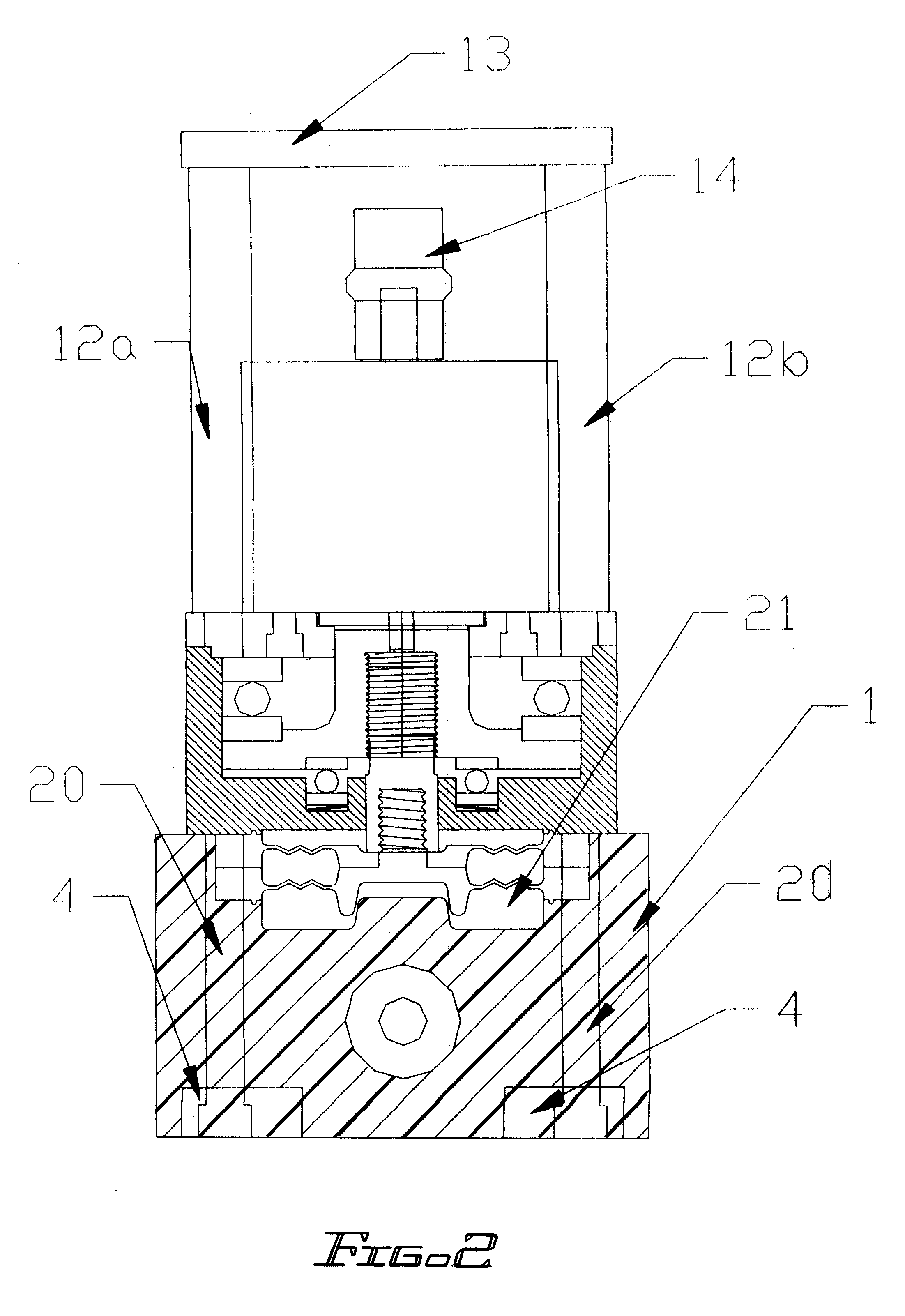

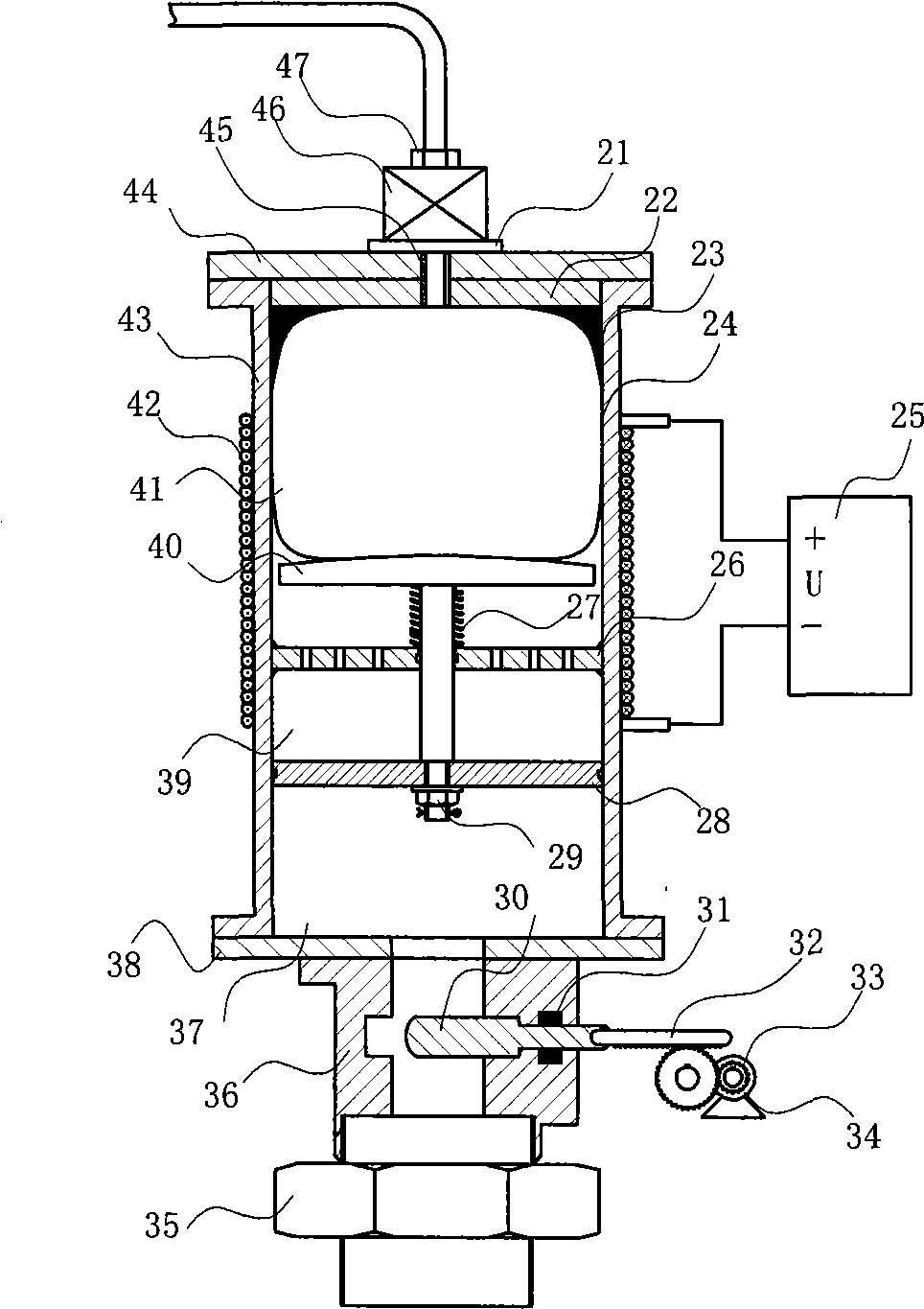

Double diaphragm precision throttling valve

InactiveUS6321776B1Conservative marginMinimize backlashDiaphragm valvesOperating means/releasing devices for valvesFluid controlDiaphragm seal

A throttling valve assembly actuated by a stepper motor having a double diaphragm seal and integral throttling surface. The throttling surface interfaces to a mating orifice and port arrangement to provide a smooth control regime for various process fluids. Because of the unique design of the flow paths the fluids will remain in a laminar flow state throughout the throttling range, thus providing smooth and continuous response to the control input. The valve opening to the fluid controlled by a stepper motor through a direct drive mechanism. The embodiment shown here employees all PTFE construction for the wetting parts, but any material could be used that would be compatible with the process fluid. Additional features are minimal capture of the process fluid, free draining, and no metallic parts in close communication with the process fluid.

Owner:ENTEGRIS INC

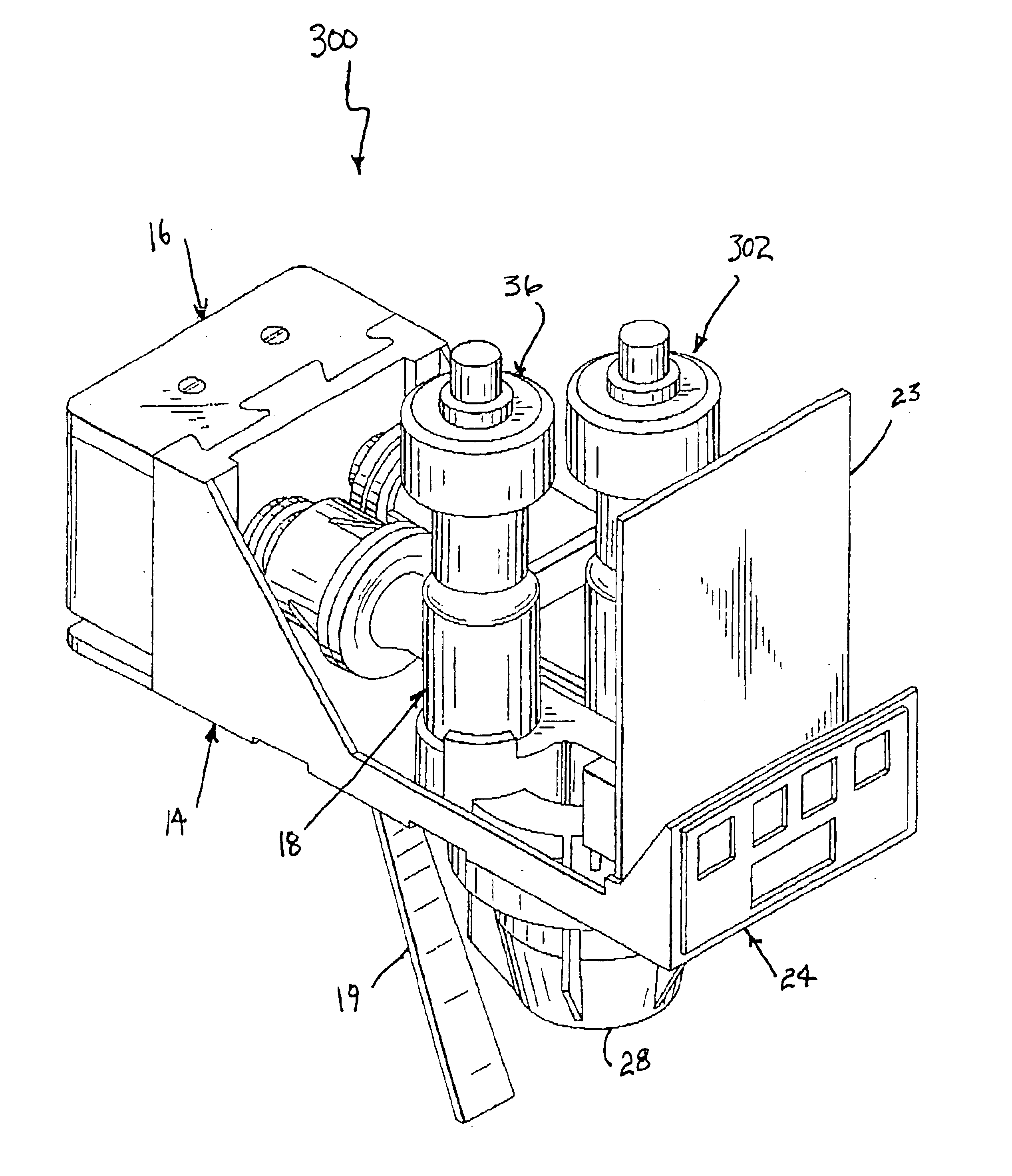

Valve for dispensing two liquids at a predetermined ratio

InactiveUS6845886B2Low costAccurate inductionPlug valvesLiquid transferring devicesMems pressure sensorDifferential pressure

A post-mix beverage valve provides for automatic, accurate beverage ratioing. A valve body can be assembled, and includes a water flow hard body, syrup body and common nozzle body. The water and syrup flow bodies define flow channels and include one end for connection to water and syrup respectively, and opposite ends for fluid connection to the nozzle body. The water flow channel includes a turbine flow sensor connected to a micro-controller determining the water flow rate. The syrup flow channel includes a flow sensor, two MEMS pressure sensors, monitoring the syrup. The sensors are connected to the micro-controller and positioned about an orifice and senses sense a differential pressure indicative of syrup flow rate solenoid regulates flow of syrup through the syrup body. A stepper motor on the water body controls a rod in the flow channel in conjunction with a v-groove.

Owner:IMI VISION LTD

Control method for electronic expansion valve of heat-pump water heater and control device thereof

ActiveCN102374714AFully evaporatedIncrease circulation flowRefrigeration safety arrangementEngineeringElectronic expansion valve

The invention relates to a fluid heater for utilizing a heat pump, in particular to a control method for an electronic expansion valve of a heat-pump water heater and a control device thereof. The control device of the electronic expansion valve comprises a control unit and a stepping motor, wherein the output end of the control unit is connected to the stepping motor, the output shaft of the stepping motor is connected with the electronic expansion valve, the control unit comprises a controller, a driving circuit and a group of temperature sensors, the temperature sensors are fixed in a cooling-medium circulating loop of the heat-pump water heater, and the controller comprises a target superheat-degree setting module, an actual superheat-degree detecting module, a regulating-speed setting module and a driving-signal generating module. In the invention, the exhaust temperature, the water-tank temperature and the environmental temperature are comprehensively judged, a variable target superheat degree is set, the relation of the exhaust temperature and the opening of the electronic expansion valve can be correctly identified, and the requirements of different circulating flow quantities in the state of the variable working condition of the heat-pump water heater are met, thereby the high efficiency, the safety and the stable operation of the heat-pump water heater are achieved.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

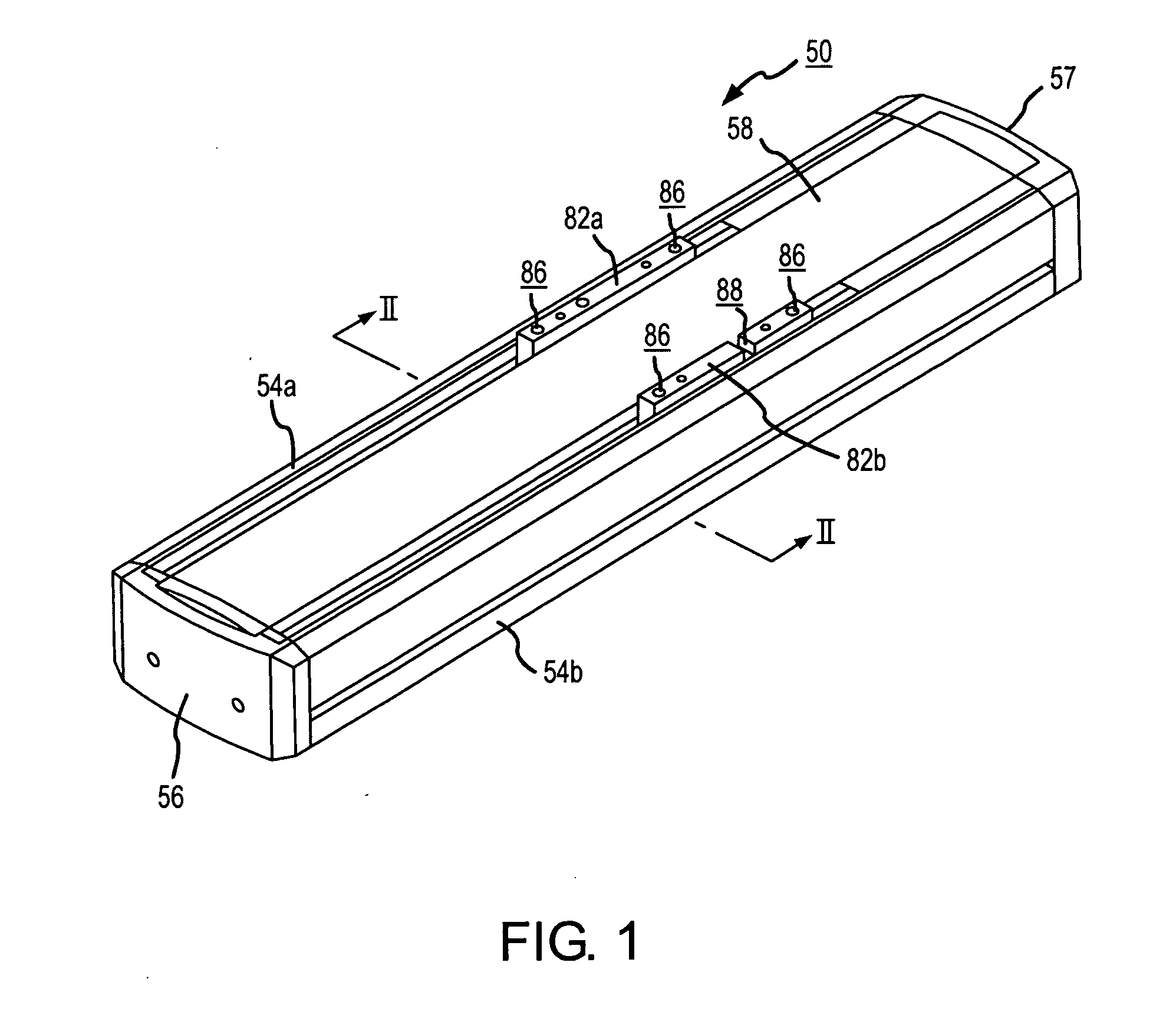

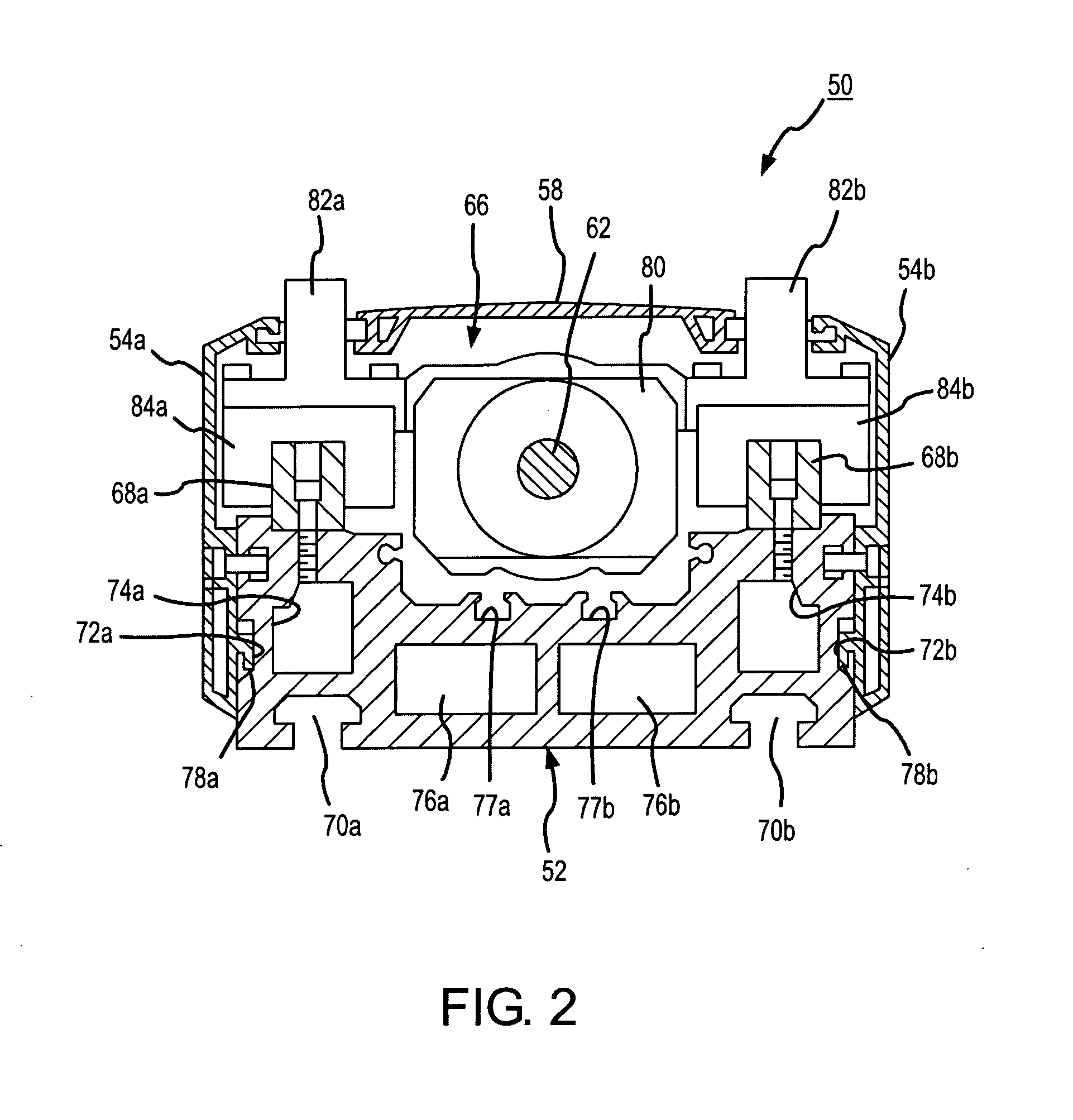

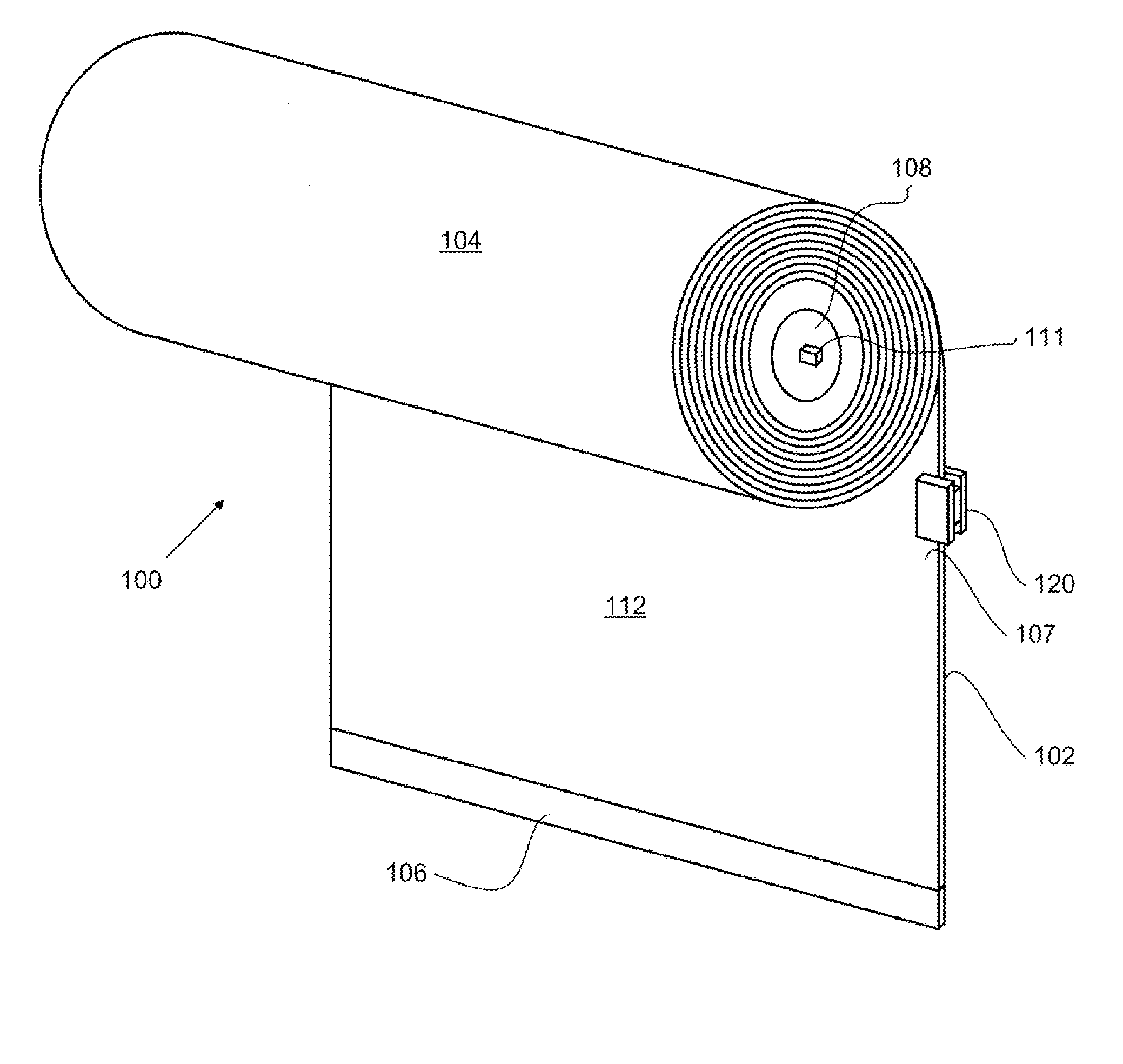

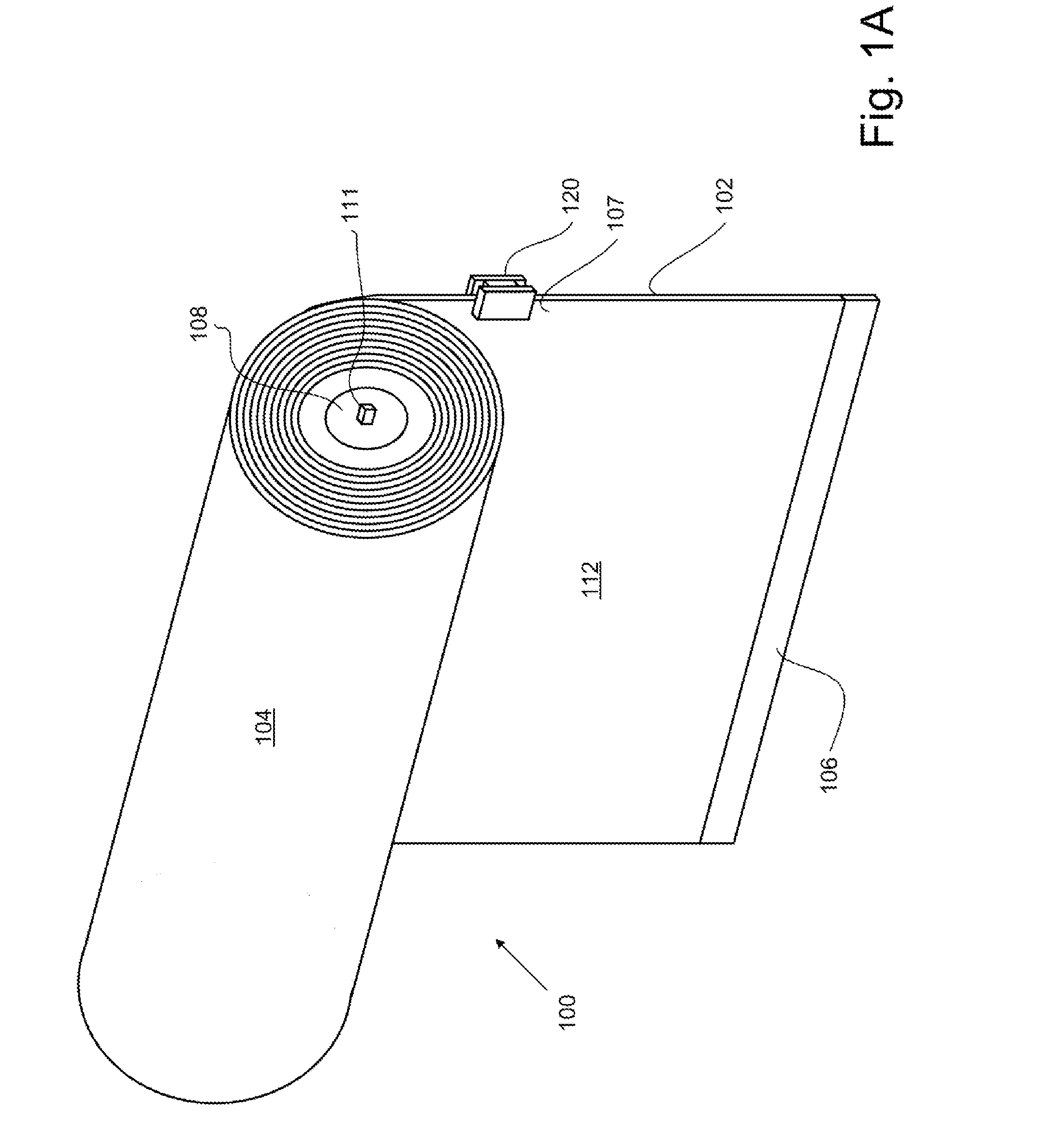

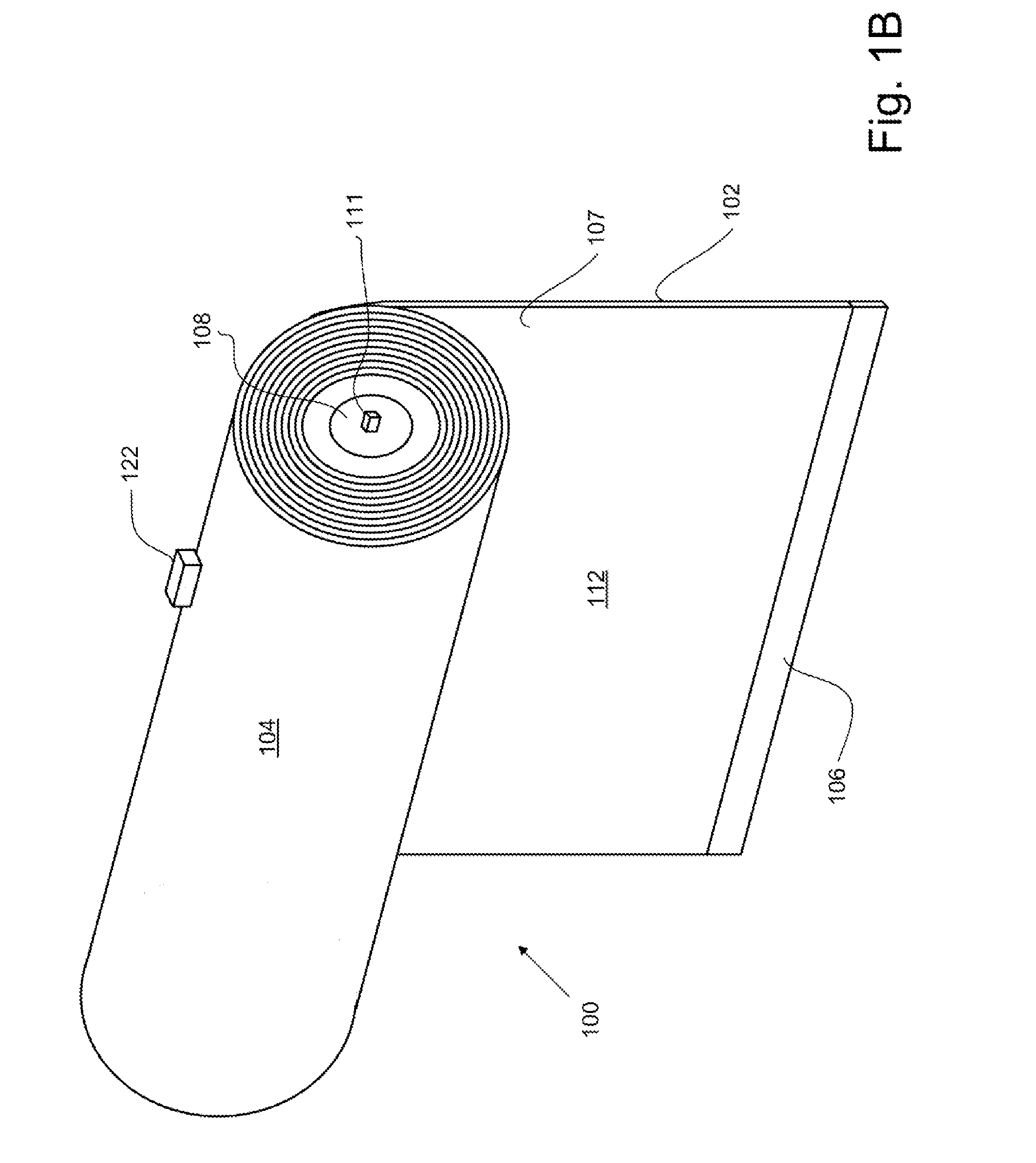

System and method for controlling one or more roller shades

Presented is a roller shade system that includes a flexible shade material having a lower end, a rotatably supported roller tube that windingly receives the shade material, a stepper motor that operably engages the roller tube to rotate the roller tube to move the lower end of the shade material between a first position and a second position, an optical sensor configured for capturing an image frame of the shade material at linear positions along the shade material as the lower end of the flexible shade material moves from the first position to the second position, and a stepper motor controller configured for controlling the frequency of input pulses to the stepper motor to move the lower end of the flexible shade material from the first position to the second position at a substantially constant linear velocity in response to position information obtained from the plurality of captured image frames.

Owner:CRESTRON ELECTRONICS

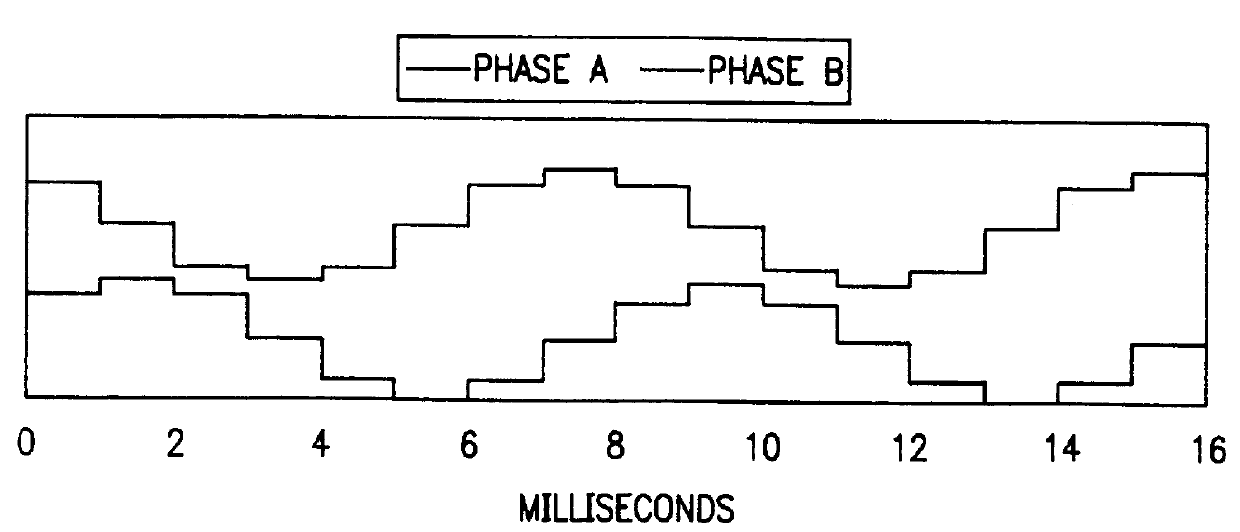

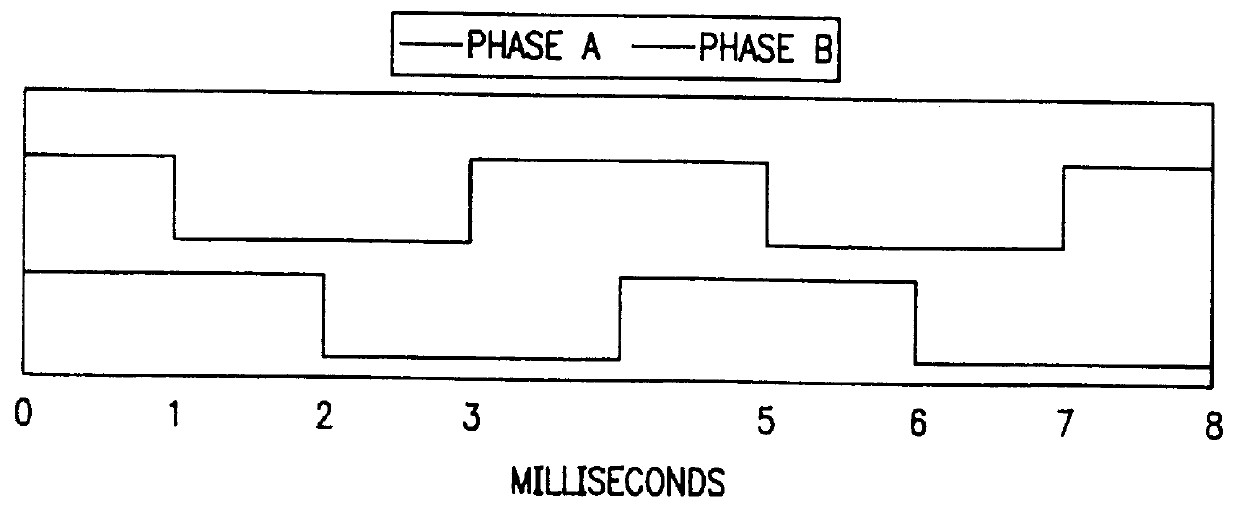

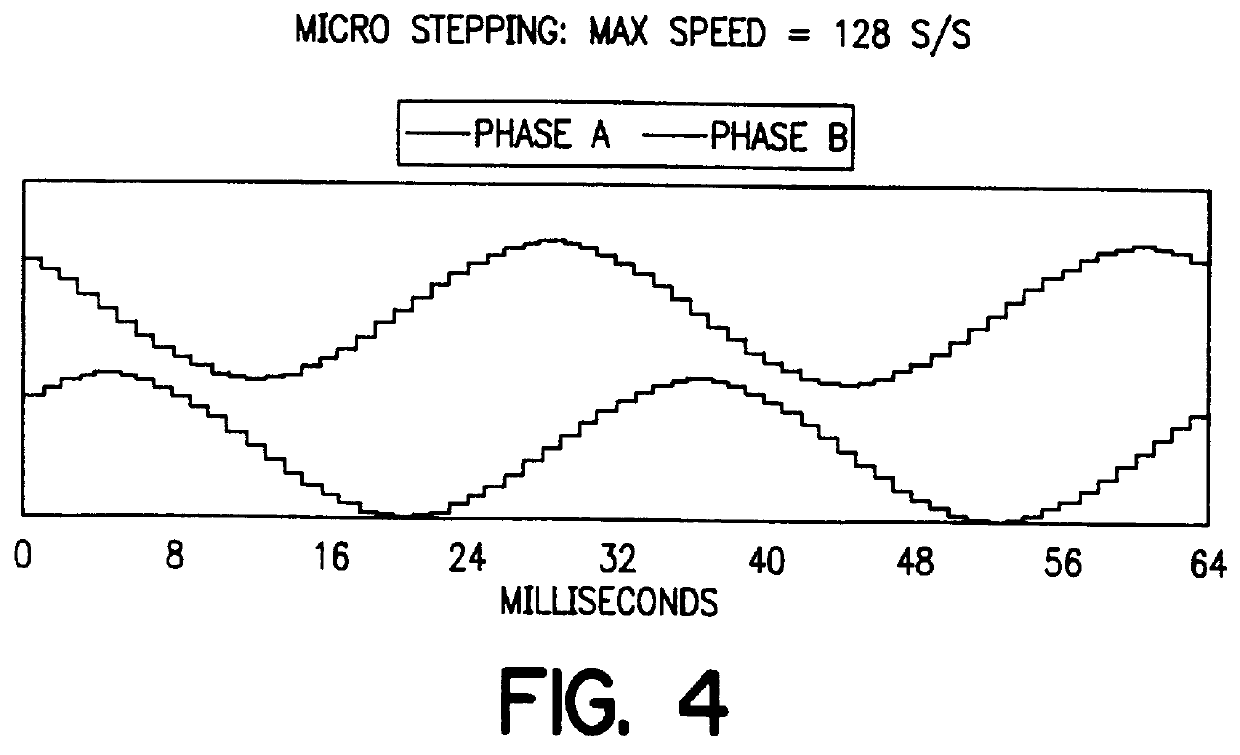

Stepper motor controller for microstepping a stepper motor and a method for microstepping a stepper motor

InactiveUS6140793AReduce overheadGreat step resolutionComputer controlSimulator controlImage resolutionControl theory

A low overhead controller for microstepping a stepper motor and a low overhead method for microstepping a stepper motor. The reduction in overhead in system processor is accomplished by the control circuit which dynamically interpolates motor positions between steps commanded from the processor. Also, the reduction in overhead is accomplished by a microstepping method used to effect microstepping resolution control by employing a stored look-up table which gives a resolution value at a given speed according to a predetermined function.

Owner:BRISTOL MYERS SQUIBB CO

Underwater video camera system based on polarization identification and method thereof

InactiveCN102116997AIncrease contrastImprove clarityTelevision system detailsColor television detailsPolarizerOptical polarization

The invention relates to the technical field of optical instruments, in particular to an underwater video camera system based on polarization identification and a method thereof. The technical scheme is that the underwater video camera system comprises an underwater light source, a polarization modulation part and an image acquisition and processing part, wherein the underwater light source comprises a semiconductor laser, an optical filter, a polarizer, a polarization rotator and a beam expander; the polarization modulation part comprises an analyzer, a stepper motor, a stepper motor controller and an infrared detector; and the image acquisition and processing part comprises a high-frequency CCD (Charge Coupled Device) video camera, an image acquisition system and a computer. The underwater video camera system has the benefits that with the adoption of the underwater camera system and the method, the contrast degree and the definition of target imaging as well as the target detectionand the identification efficiency can be effectively improved; the polarization imaging can utilize the differences of different target back polarizations to eliminate the interference of background light; and as a means for identifying the target from messy background is provided, the method has remarkable advantage as compared with the commoner method for imaging and identifying the target by using light intensity.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

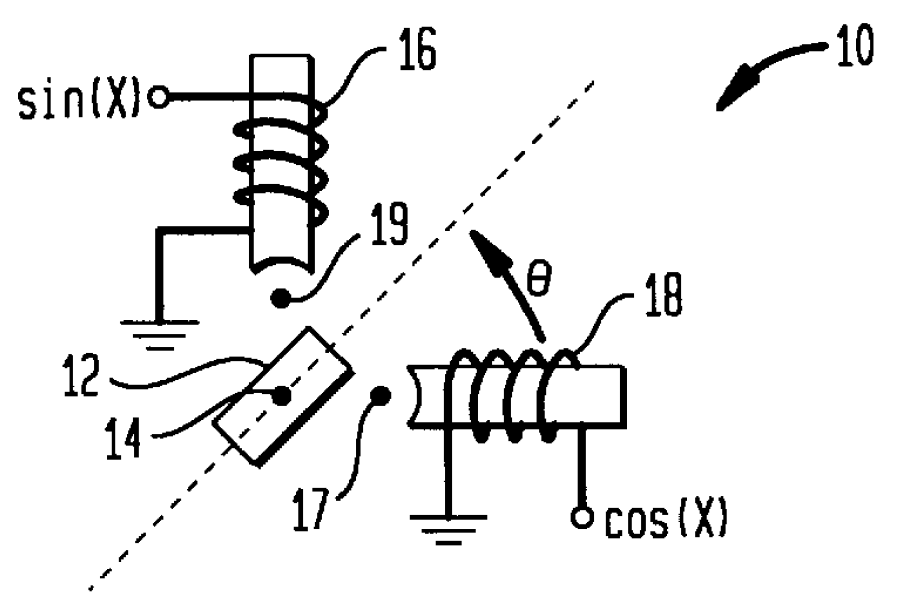

System and method for sensor less magnetic field control of a motor

ActiveUS7116070B2Motor/generator/converter stoppersSynchronous motors startersElectric machineCounter-electromotive force

A system and method for sensor less control of a stepper motor is described. The system and method includes estimation of the position of a rotor of the motor by way of sensing circuitry on the windings of the motor, without the use of positional sensors. The system and method of stepper motor control further includes magnetic field optimization for increasing the torque generating component of a magnetic field generated by stators of the motor, and magnetic field weakening for countering some of the effects of back electromotive force generated by the magnetic rotor.

Owner:ALLIED MOTION CANADA

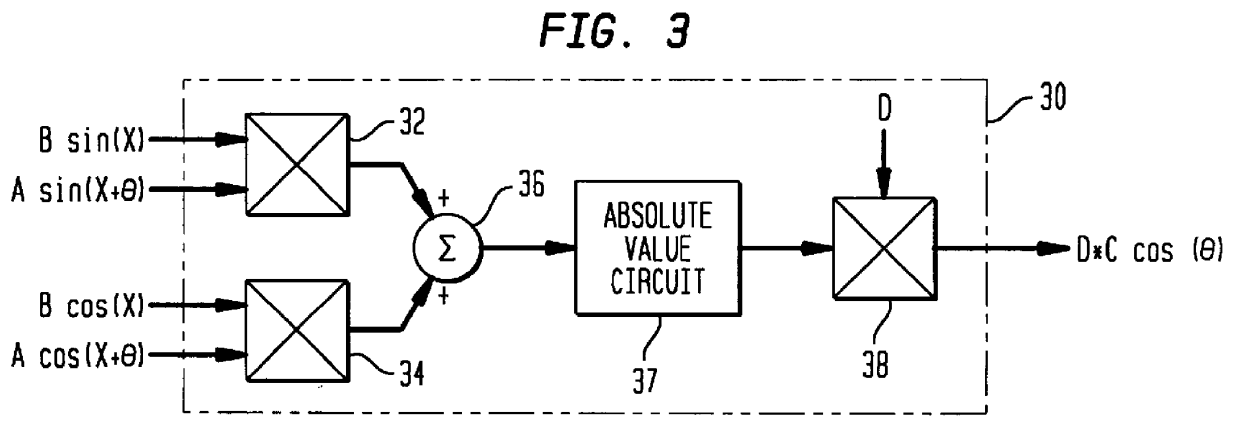

Stepper motor control that adjusts to motor loading

A system and method are provided for controlling a stepper motor having a rotor and a multi-phase stator. Sinusoidal command signals define a commanded position of the motor's rotor. An actual position of the rotor is sensed as a function of an electrical angle between the actual position and the commanded position. The actual position is defined by sinusoidal position signals. An adjustment signal is generated using the sinusoidal command signals and sinusoidal position signals. The adjustment signal is defined as a function of the cosine of the electrical angle. The adjustment signal is multiplied by each sinusoidal command signal to generate a corresponding set of excitation signals, each of which is applied to a corresponding phase of the multi-phase stator.

Owner:NASA

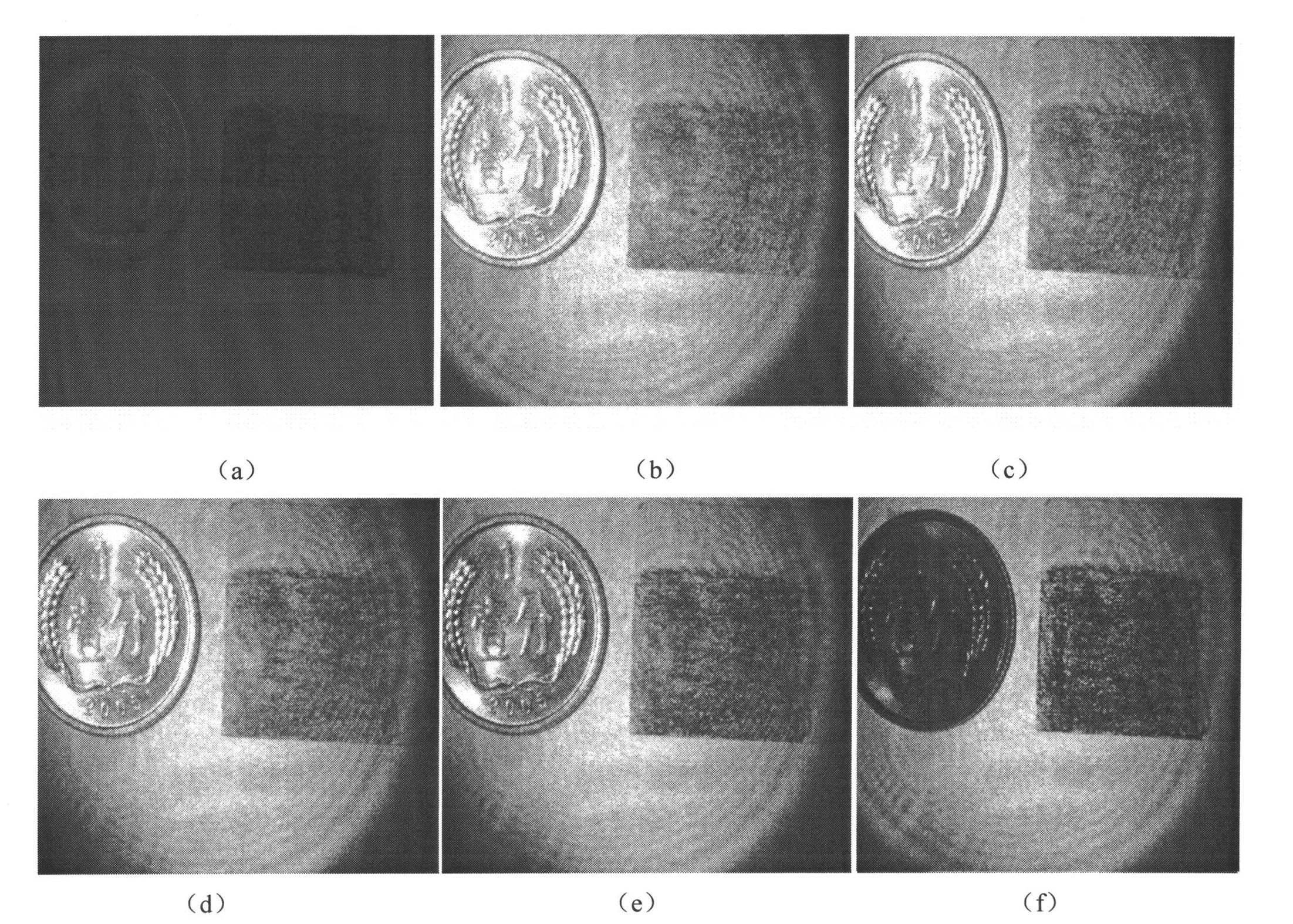

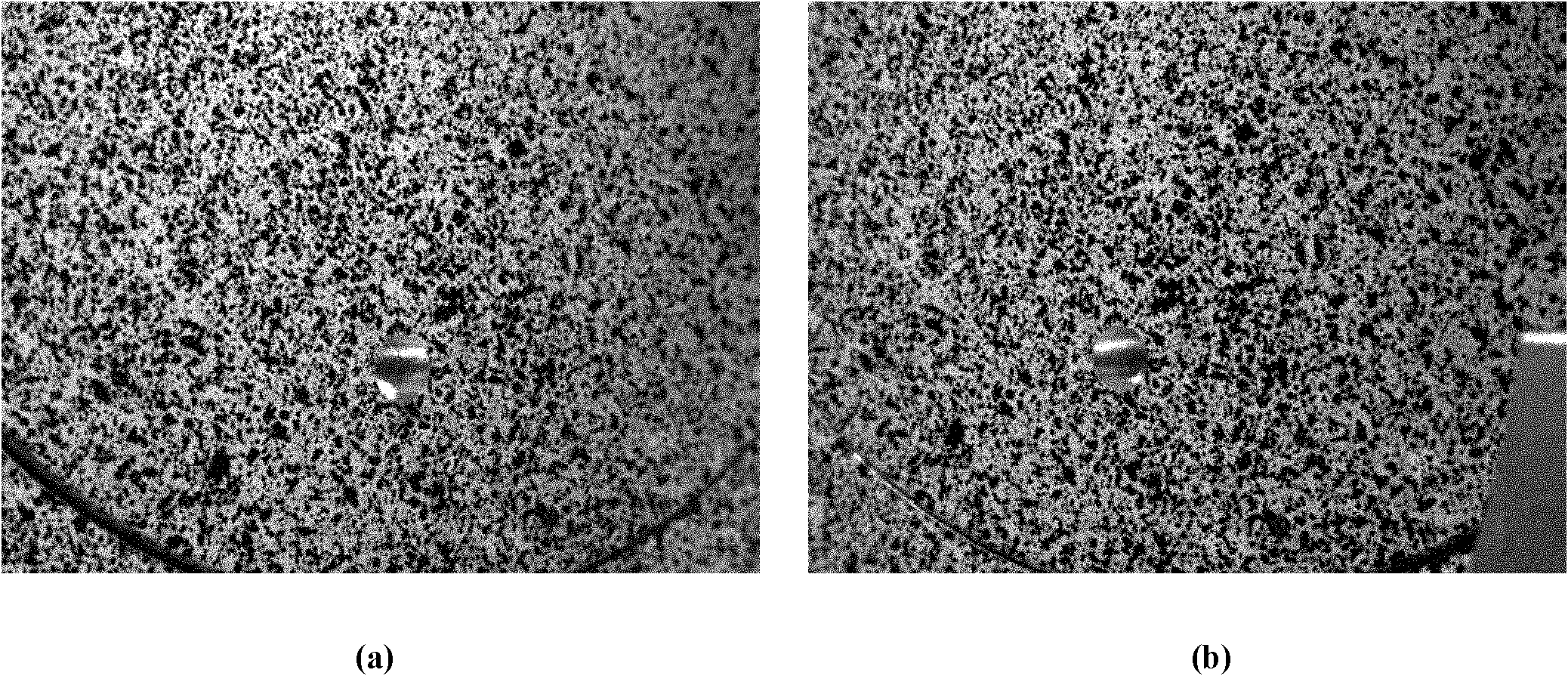

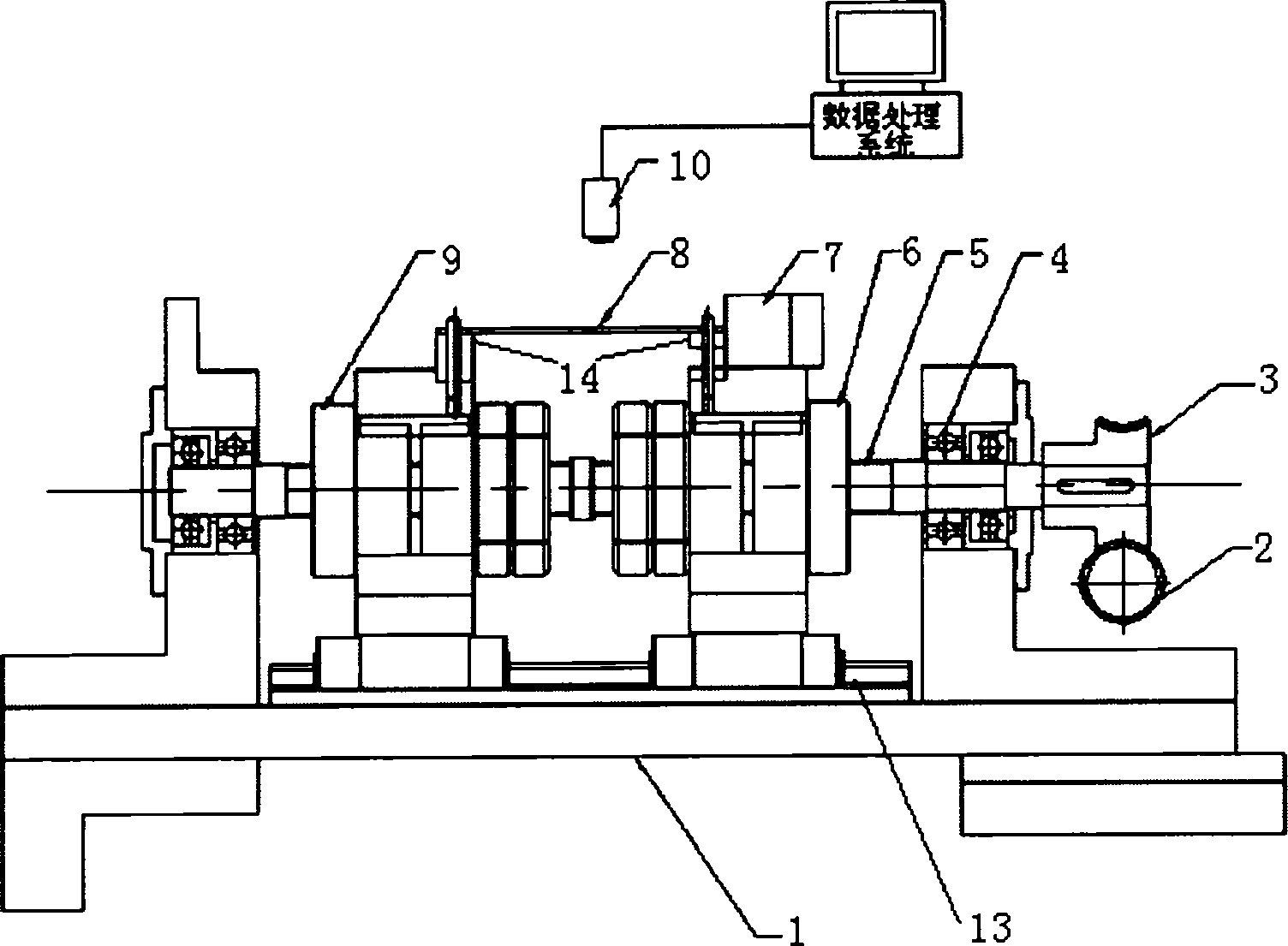

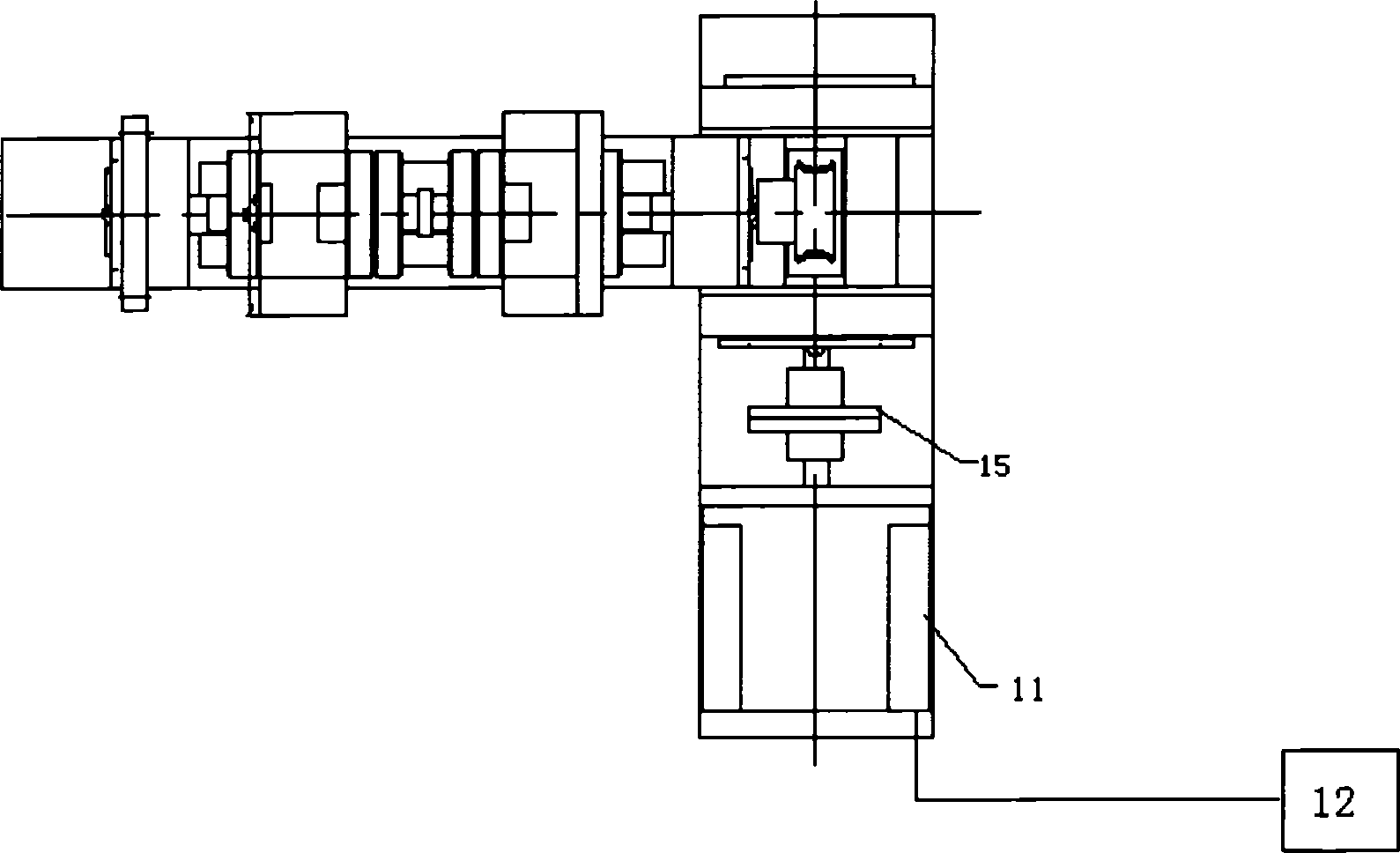

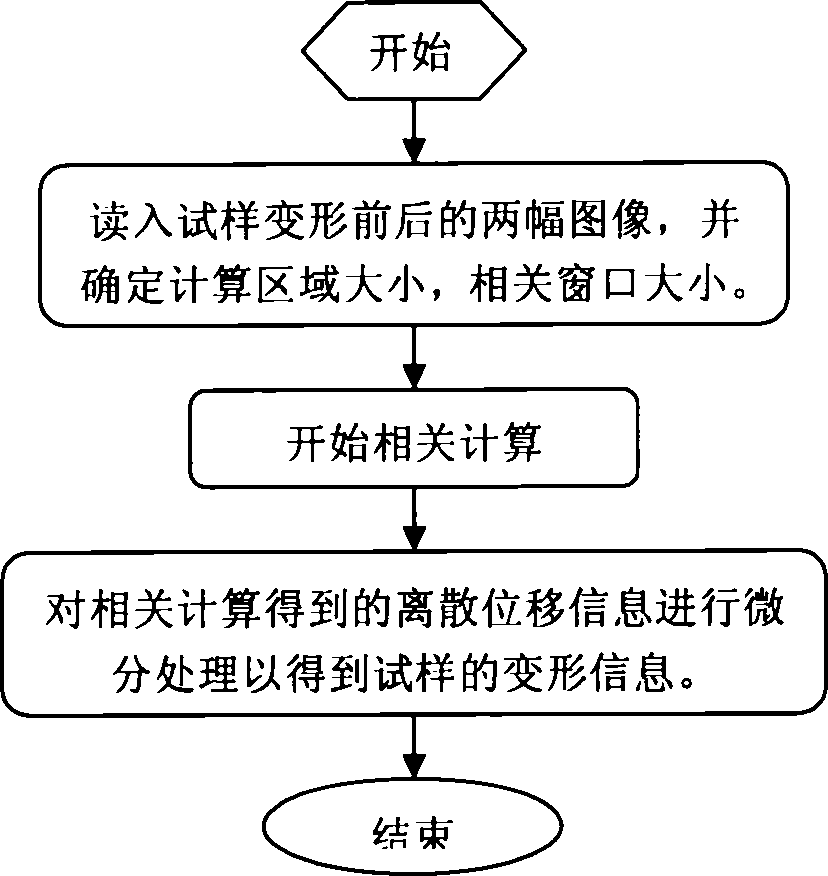

System and method for measuring residual stress in real time

InactiveCN102072877AReal-time online drilling non-contact full-field measurementEasy to operateUsing mechanical meansMaterial analysisElectric machineryEngineering

The invention relates to a system and a method for measuring residual stress in real time. The method comprises the following steps of: performing three-dimensional surface coordinate reconstruction on a test piece by three-dimensional digital image correlation, performing related research on a speckle image at the periphery of a hole before and after drilling the test piece, and calculating a three-dimensional displacement field before and after drilling; automatically feeding an electric spindle precisely through control over a stepping motor by a stepping motor controller and the translation of a worm gear and worm mechanism according to the drilling depth of the test piece; and calculating the residual stress of the test piece according to planar assumption of a drilling area of a curved surface by combining a theoretical formula for measuring the residual stress during drilling. The system can drill the hole precisely in real time, and measures the residual stress of the test piece with depth change in a stepping mode. The system and the method for measuring the residual stress have the advantages of real-time property, high precision, non-contact, whole-field displacement measurement, flexibility and convenience of operation, and the like.

Owner:TSINGHUA UNIV

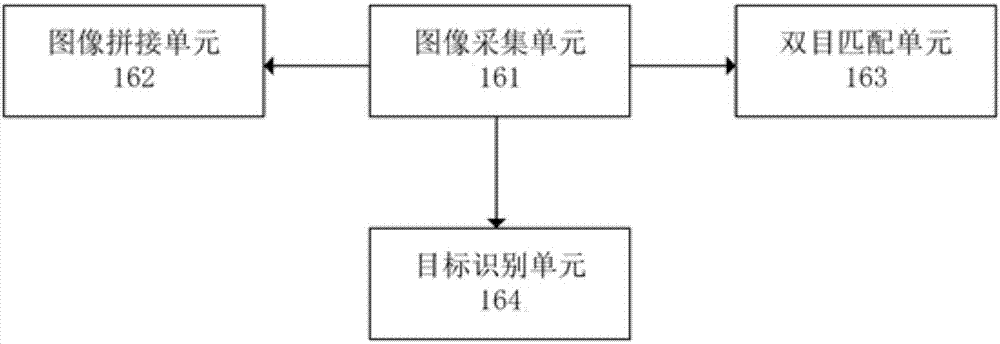

Multi-sensor-based vehicle-mounted environment recognition system and omni-directional vision module

PendingCN106878687ASolve the problem of not being able to obtain all-round environmental information in real timeImprove matching accuracyImage enhancementWave based measurement systemsImaging processingRadar

The invention discloses a multi-sensor-based vehicle-mounted environment recognition system. The system comprises an omni-directional vision module, an IMU module, a GPS module, a radar module and a data fusion module, wherein the omni-directional vision module is used for acquiring environment three-dimensional information in a 360-degree range around a vehicle, the IMU module is used for acquiring accelerated speed and angular speed information of the vehicle, the GPS module and the IMU module jointly work to acquire position and posture information of the vehicle, the radar module is used for acquiring front target position information of the vehicle and has the characteristics of all weather and all time, and the data fusion module is used for fusing environment information acquired by each sensor to more accurately recognize a vehicle driving environment. The invention further discloses an omni-directional vision module, which utilizes each stepping motor to control a corresponding binocular camera to perform a pitching motion in order to acquire omni-directional scene images of an observed environment; and an image processing module is used for in real time collecting and processing scene images acquired by each group of the binocular cameras.

Owner:JILIN UNIV

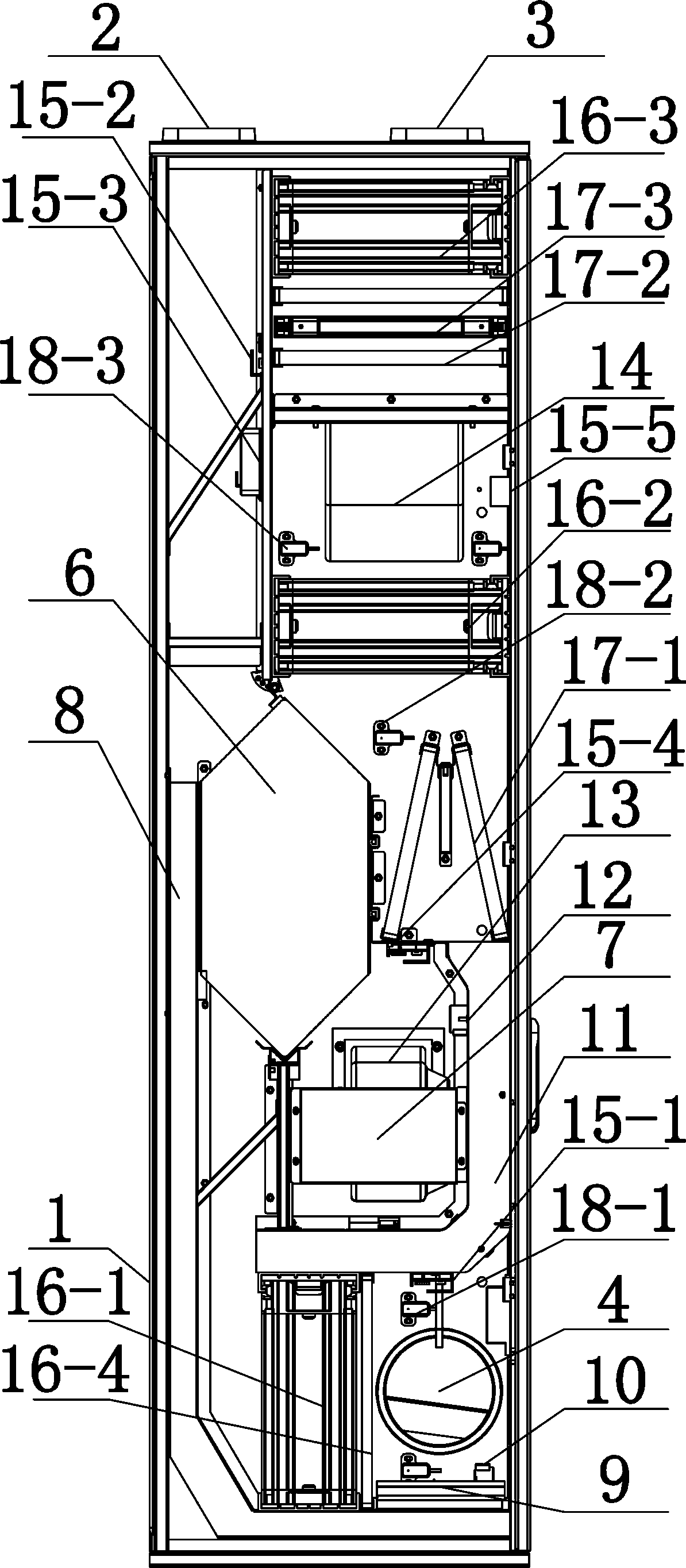

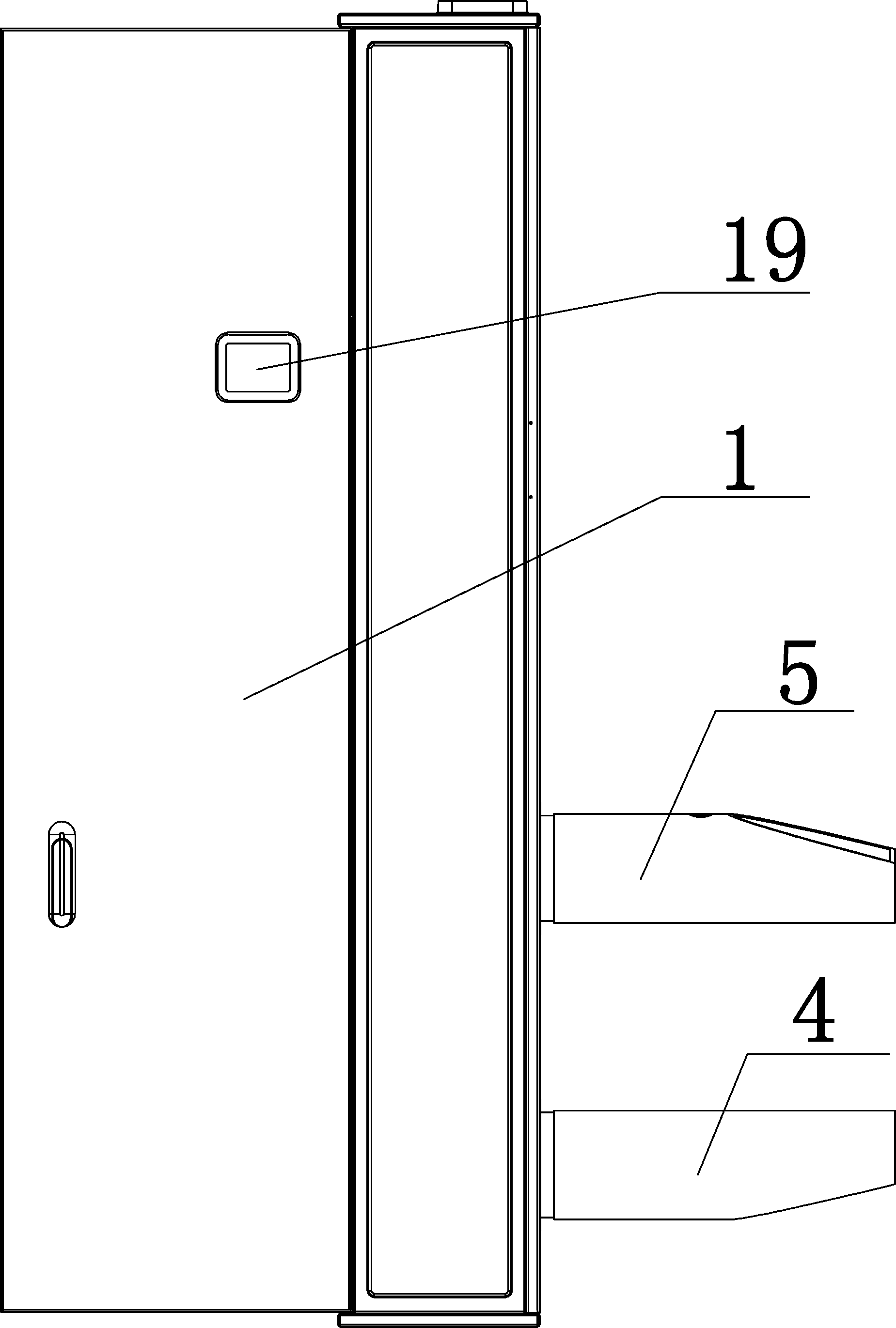

Fresh air machine and control method thereof

ActiveCN104048363AImprove cleanlinessExtended service lifeSpace heating and ventilation safety systemsLighting and heating apparatusFresh airOperation mode

The invention relates to a fresh air machine and a control method of the fresh air machine. Layout of channels in a cabinet is reasonably arranged, an indoor and outdoor air opening and closing plate is controlled to be opened and closed through a first stepping motor, a fresh air bypass channel is controlled to be opened and closed through a second stepping motor, the suitable ventilation channel is selected according to data fed back by a sensing mechanism, and the fresh air machine operates without a heat exchanger on the condition of small difference between indoor temperature and outdoor temperature; a dust removal and sterilization mechanism, an air purification mechanism and a negative ion generator are arranged in the cabinet, bacteria and viruses can be efficiently killed, peculiar smell can be removed, and air entering a room can be purified. According to the control method, a circuit control panel is adopted for controlling an indoor temperature sensor and an outdoor temperature sensor in real time to detect indoor temperature values and outdoor temperature values to obtain the difference value between the indoor temperature and the outdoor temperature, a carbon dioxide sensor is controlled to detect the concentration value of carbon dioxide in the room, three intelligent control operation modes of the fresh air machine are provided, and while the service life of the heat exchanger serving as a key component is prolonged, the requirement for selecting the different air purification modes of a user is met. The fresh air machine is good in purification effect and fresh air effect.

Owner:ZHEJIANG XINGYUE ELECTRICAL APPLIANCE CO LTD

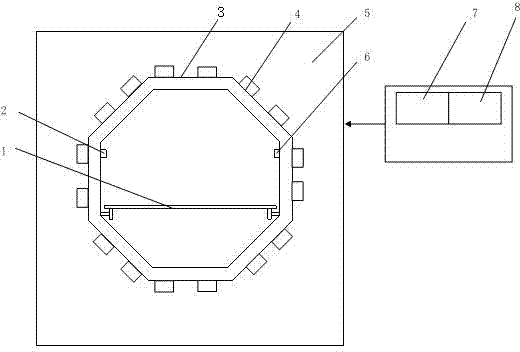

Active reflection compensation servo-type single-board wave making device

InactiveCN101832855AQuality improvementEliminate wavesHydrodynamic testingHydraulic modelsElectric machineReflected waves

The invention provides an active reflection compensation type single-board wave making device which comprises a computer control and drive system, a mechanical system and a wave measurement and feedback system which are sequentially connected. By adopting an active reflection compensation wave making technology, waves meeting the requirement of test precision are made, and meanwhile, waves reflected from a ship model, an opposite pool wall and a wave absorber can be effectively eliminated; and more than 80 percent of reflection waves are absorbed, thus the condition that the reflection waves strike a wave making mechanism to generate reflection waves once again is avoided so as to effectively improve the wave simulation quality of a pool or a water tank. A servo motor is used as a drive device, and a stepper motor control card and an encoder counting card are adopted to carry out two-position control, thereby the frequency response and the wave making control precision are improved, the drive mechanism is simplified and the maintenance cost is greatly reduced.

Owner:中国船舶重工集团公司第七〇二研究所

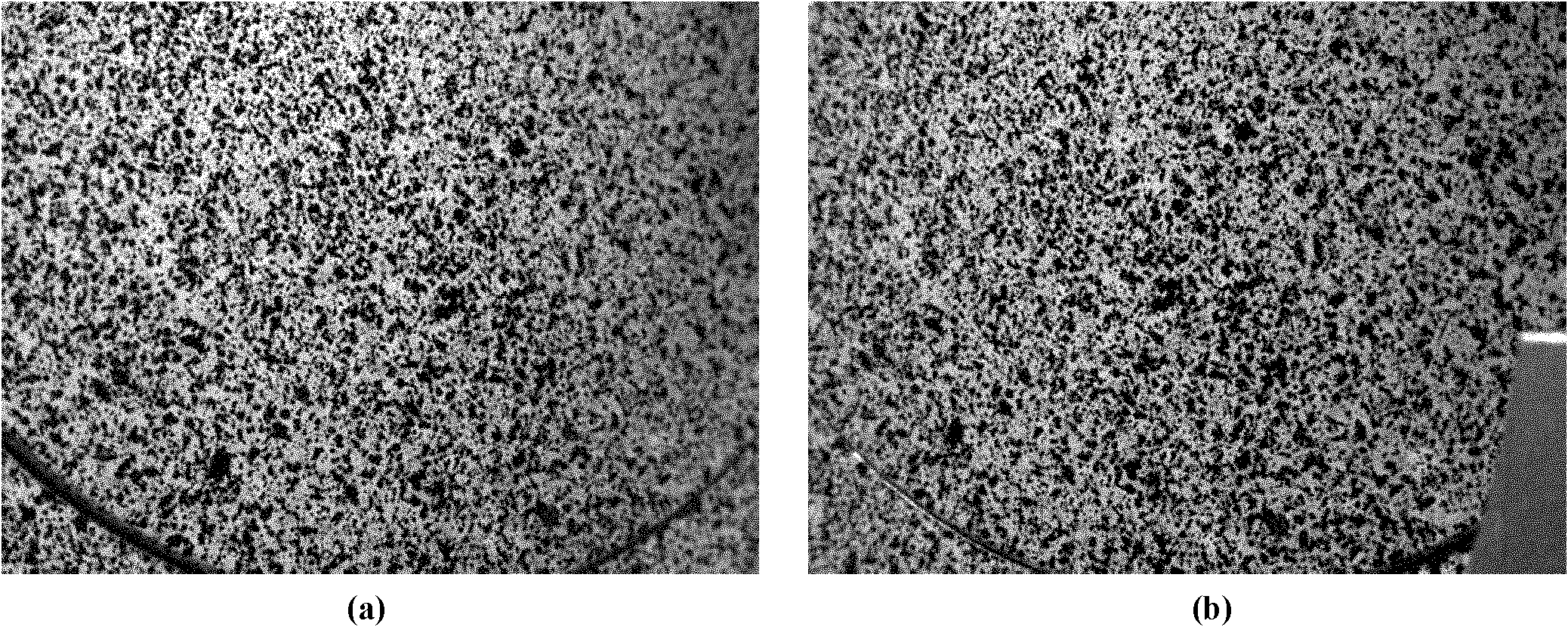

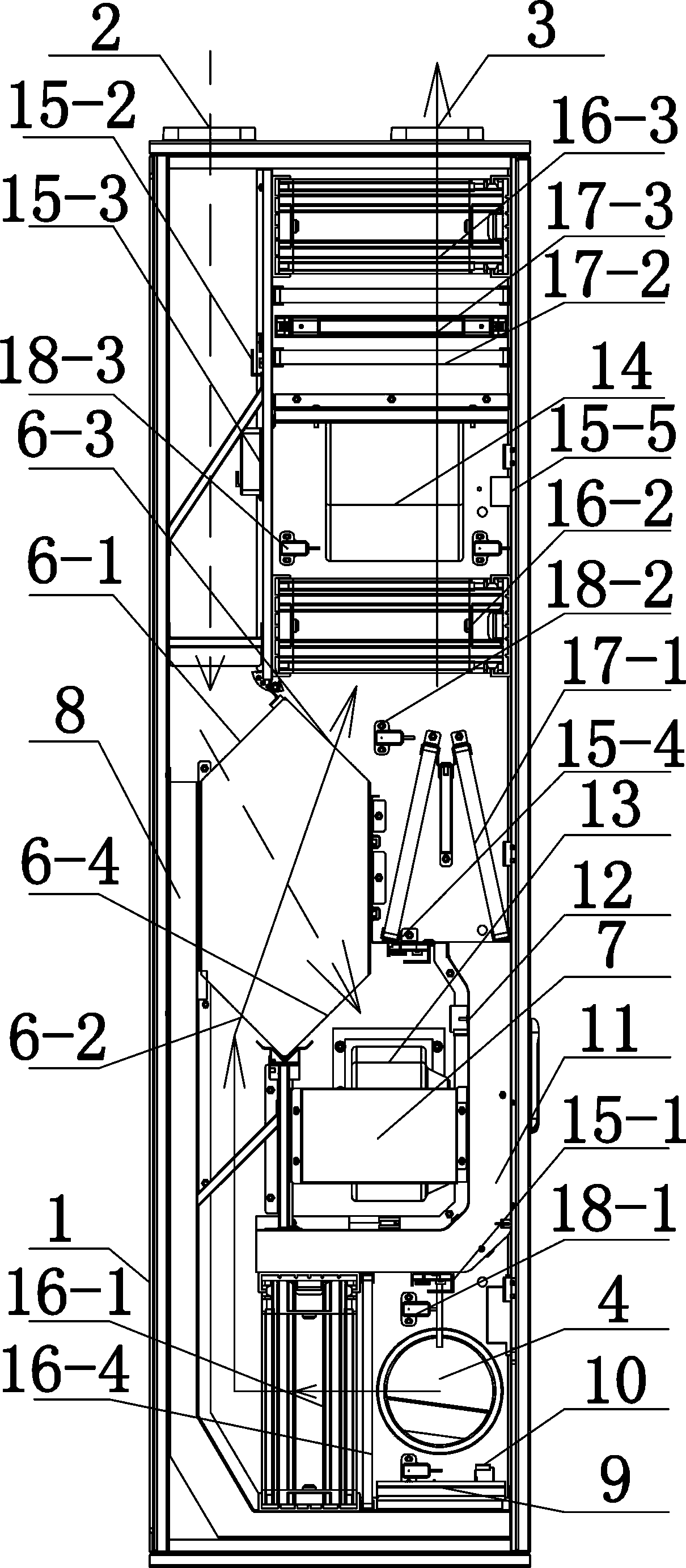

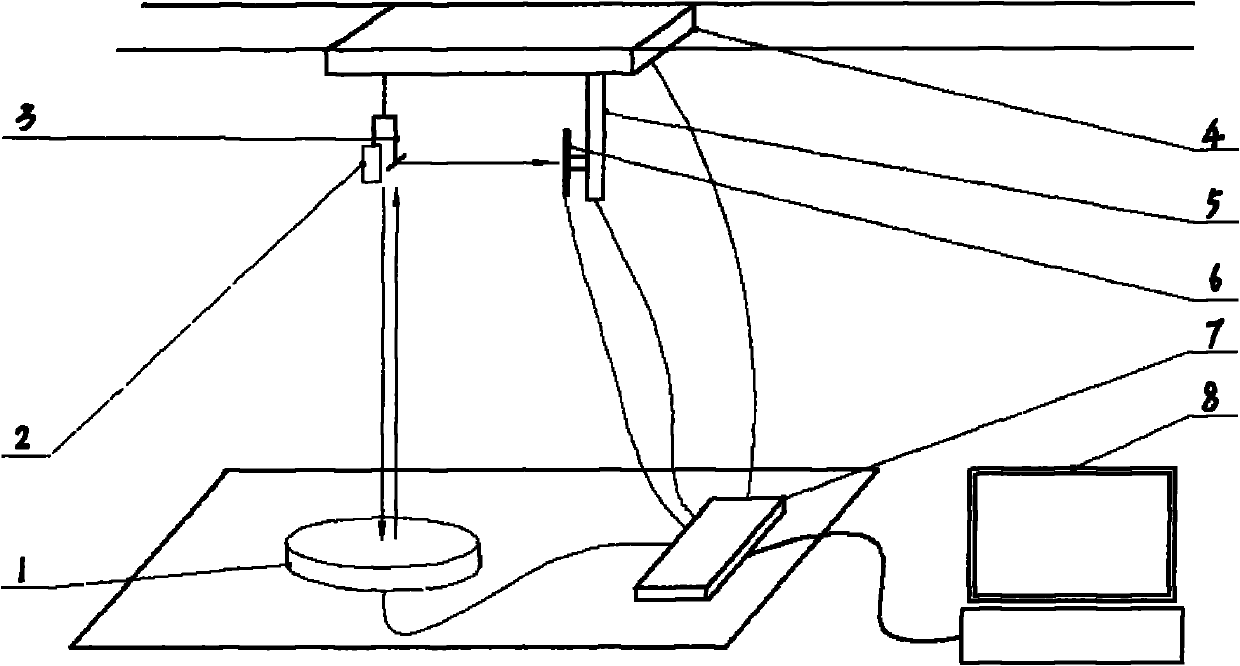

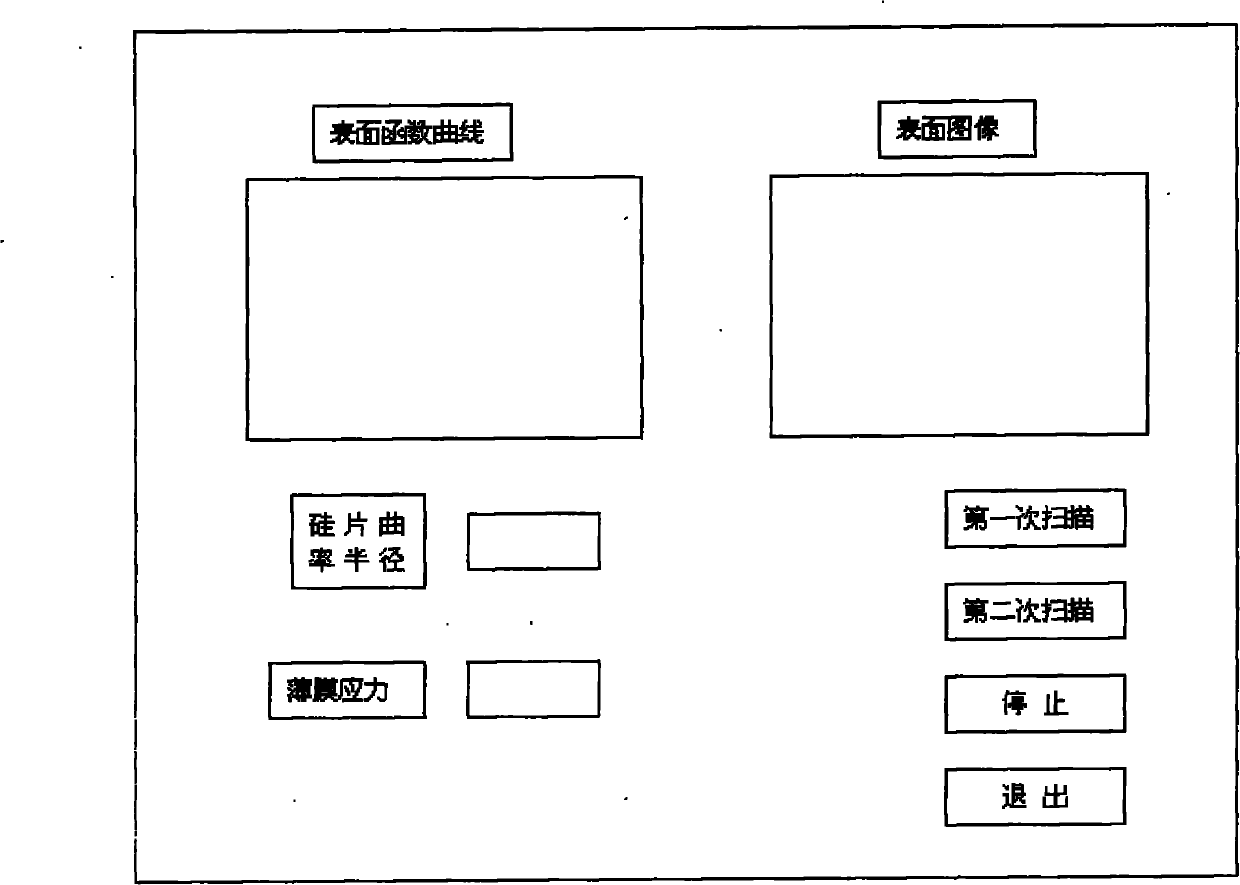

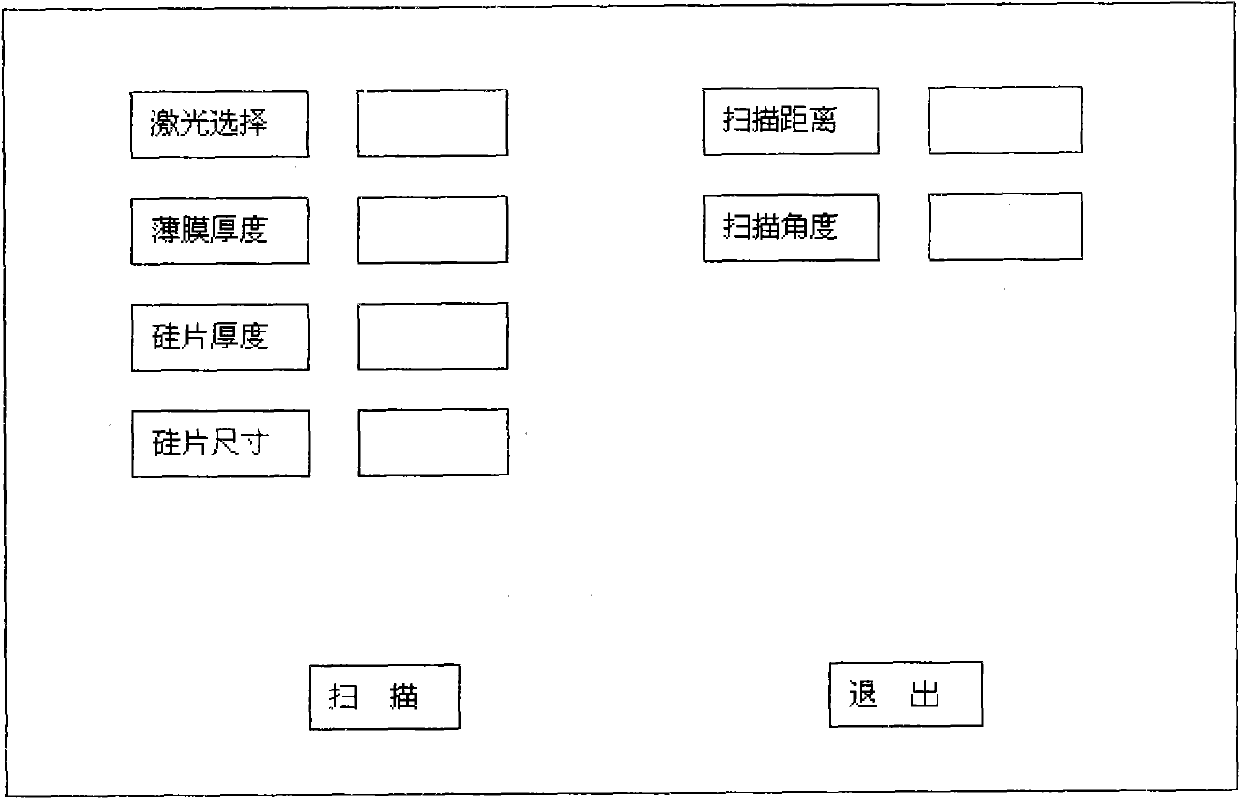

Film stress measuring equipment and film stress measuring method

InactiveCN102023068AUnderstand situationExtension functionForce measurement by measuring optical property variationUsing optical meansStress measuresData acquisition

The invention relates to film stress measuring equipment and a film stress measuring method. In a cuboid equipment case, a laser LED, an optical reflector, a linear sliding rail, a detector and another linear sliding rail all are connected with the top face of the equipment case; the linear sliding rail is arranged below and vertically connected with another sliding rail; a tray and an analog / digital (A / D) data acquisition card are arranged on the internal bottom face of the equipment case; and the tray, the A / D data acquisition card, the linear sliding rail, the detector and the other linear sliding rail are all connected with a computer outside the equipment case through a circuit. In the equipment, a light sensitive electrical detector is used for automatically tracking light path deflection and acquiring a light path deflection displacement signal, a micro step motor is used to control and rotate the tray to quickly generate a silicon chip accurate region curvature and stress change color drawing that helps to get the condition of a thin film on the surface of an entire silicon chip, two-dimensional and three-dimensional images of the surface of the thin film can be obtained, a friendly interface can be written in VC++ language, and it is possible to further expand program functions.

Owner:徐建康

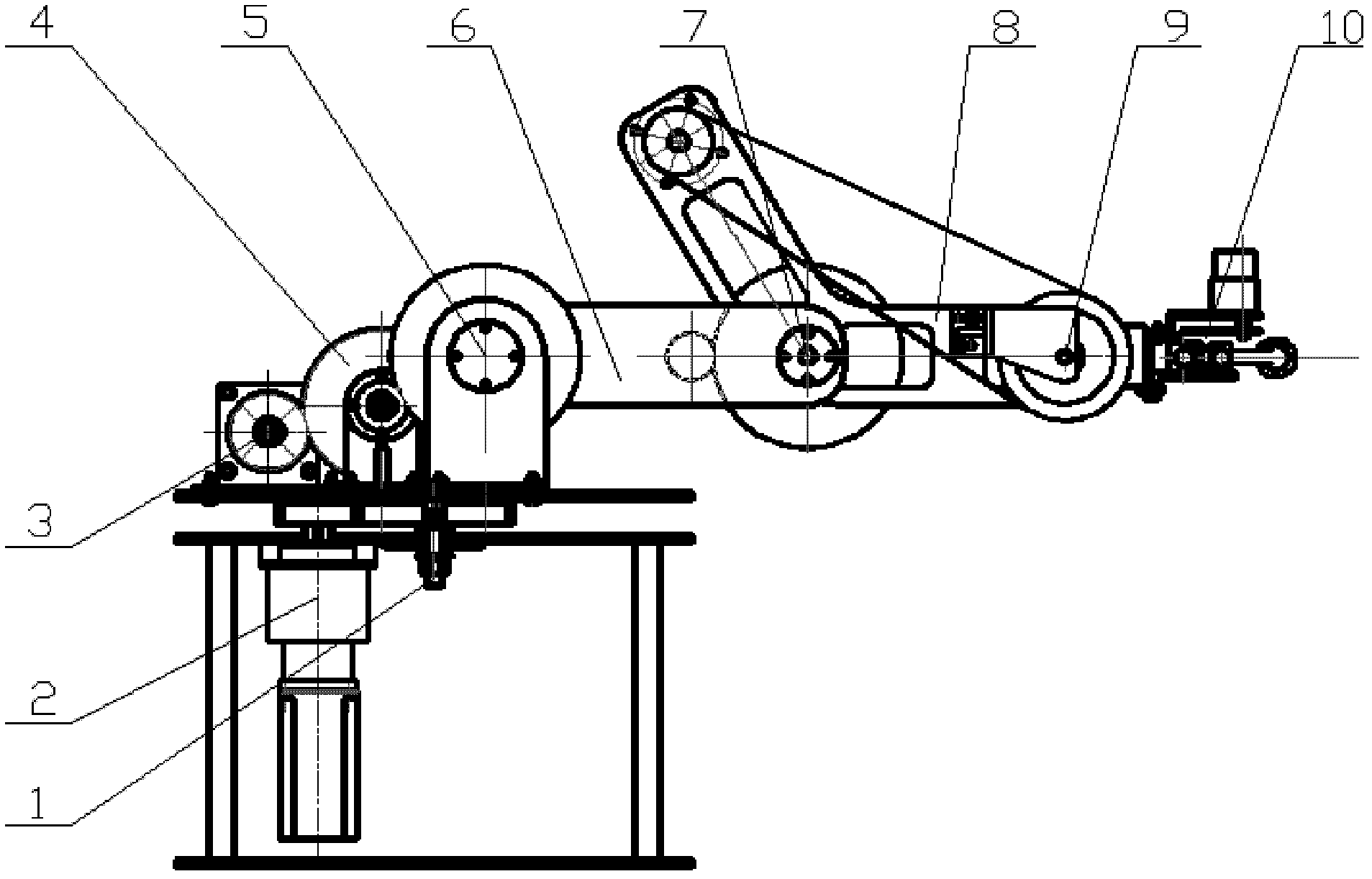

Magnetorheological conformable clamp holder and robot for picking multiple types of fruits and vegetables

The invention discloses a magnetorheological conformable clamp holder and a robot for picking various kinds of fruits and vegetables. The magnetorheological conformable clamp holder comprises a clamping handle, a magnetorheological liquid bag, a shell and a clamping handle translation mechanism; the magnetorheological liquid bag is arranged at the inner side of one end of the clamping handle, is filled with magnetorheological liquid, is connected with a control circuit, and fulfills the function of forming a shape most appropriate for clamping the fruits and vegetables by means of electric magnetization regulation. The robot for picking various kinds of fruits and vegetables comprises a working table, a manipulator and an end effector arranged at the tail end of the manipulator, and the end effector consists of the magnetorheological comformable clamp holder and a shearing mechanism. According to the magnetorheological conformable clamp holder and the robot, when the fruits and vegetables of different kinds are picked, the picking of the fruits can be well performed without replacing clamping devices, and the picking efficiency is high; the picking requirements on different positions within the space can be met, the movement is flexible, and compared with a stepping motor used by the traditional picking manipulator, servo motors can be used for controlling more accurately.

Owner:佛山市中科农业机器人与智慧农业创新研究院

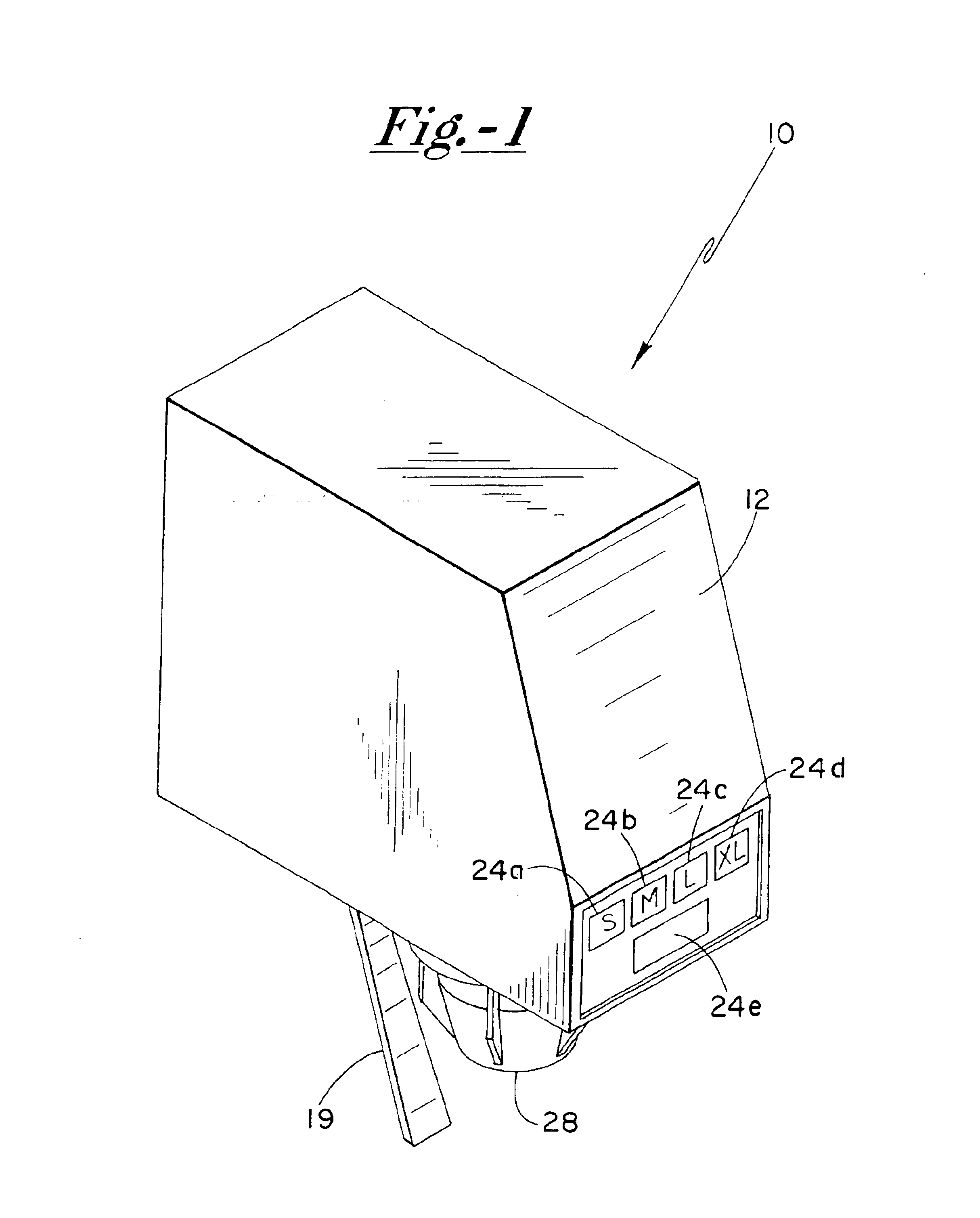

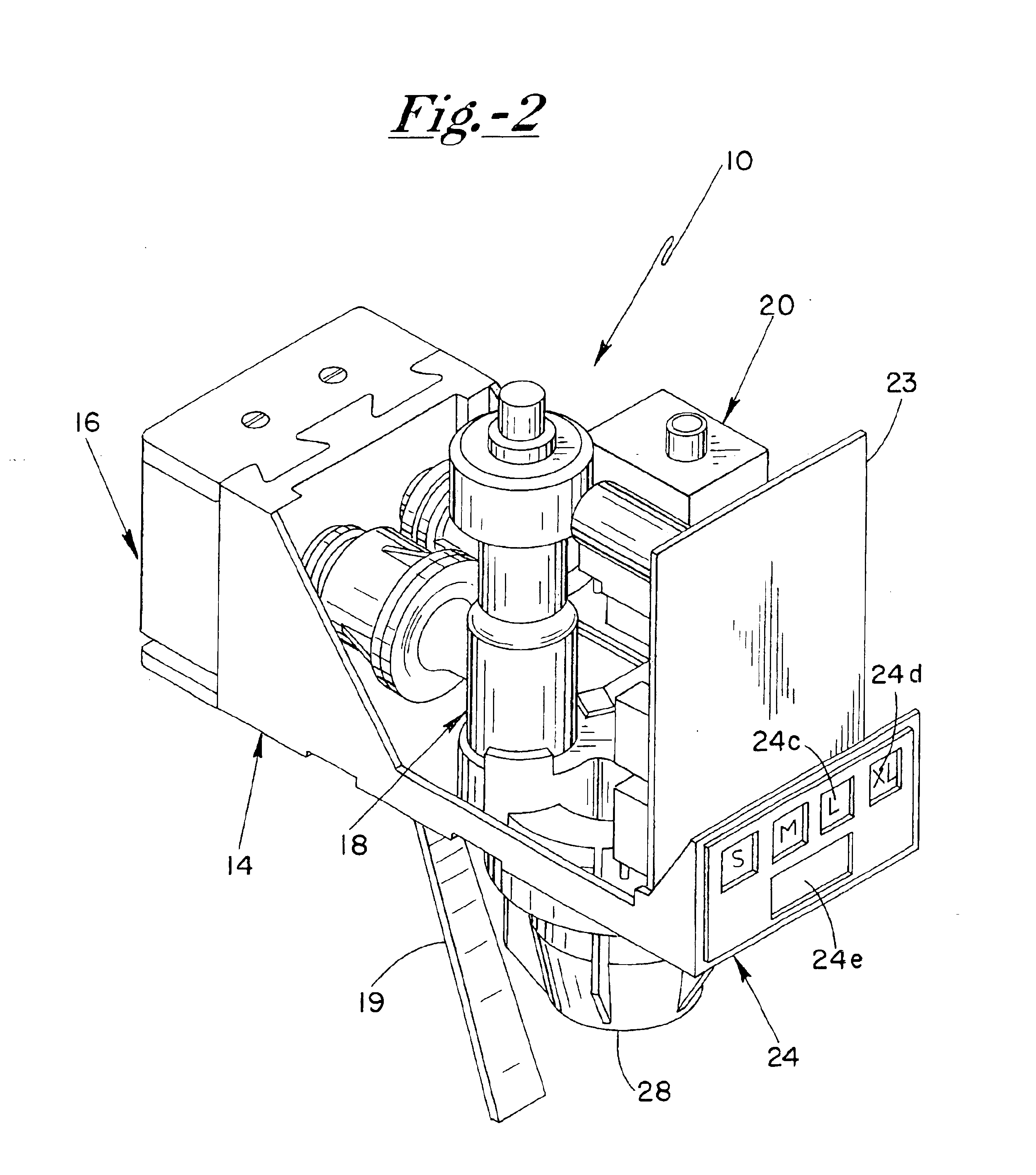

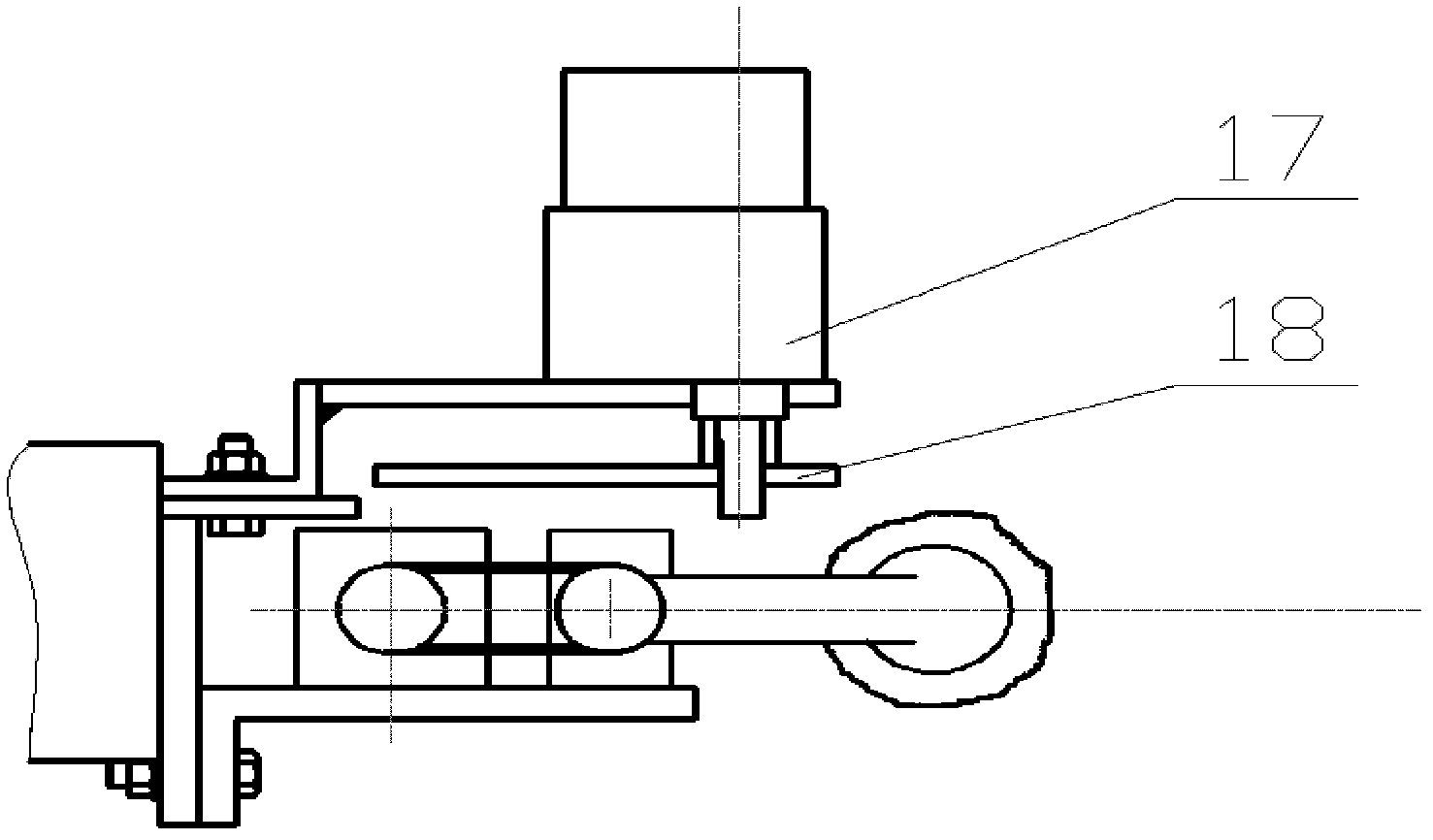

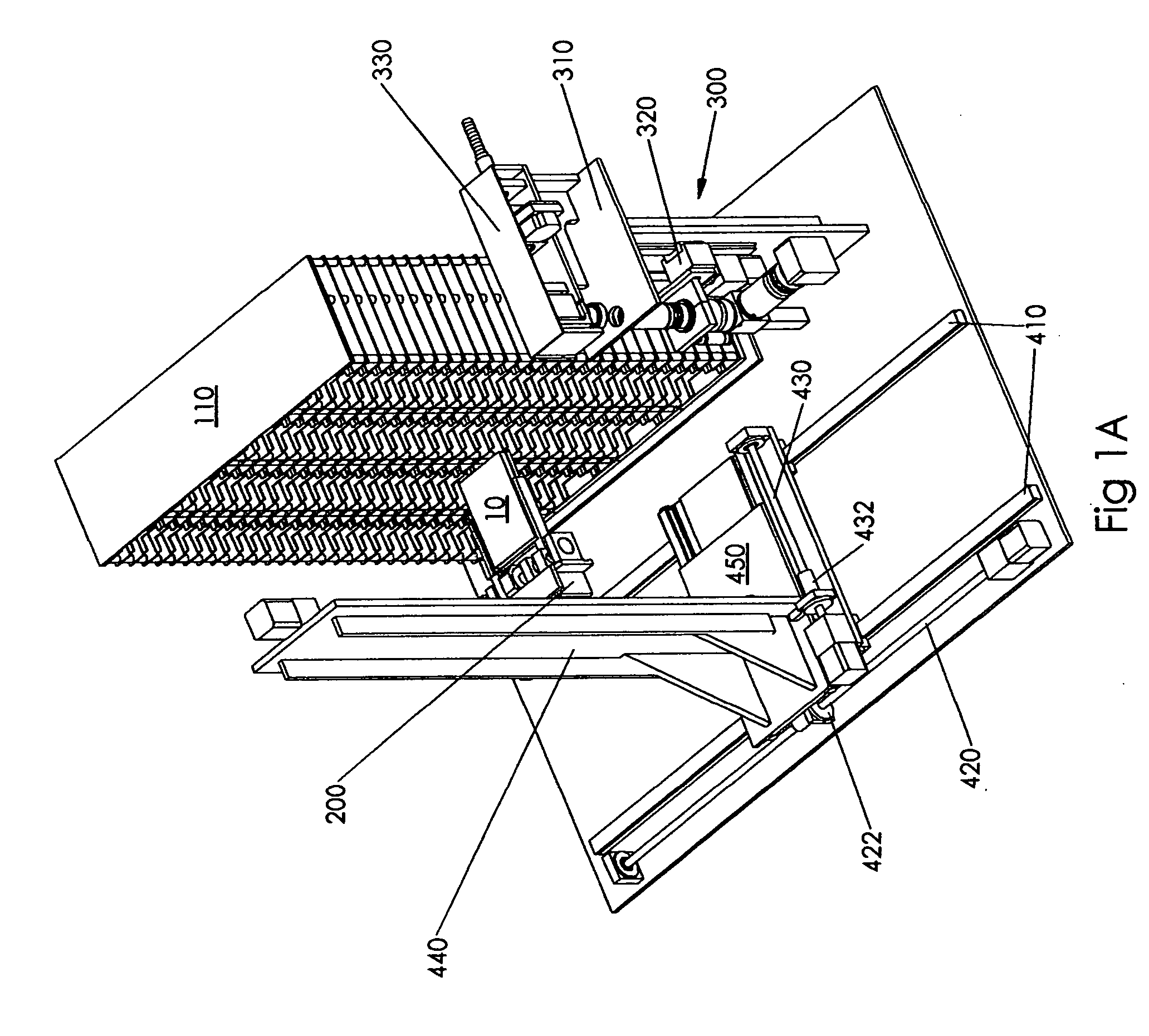

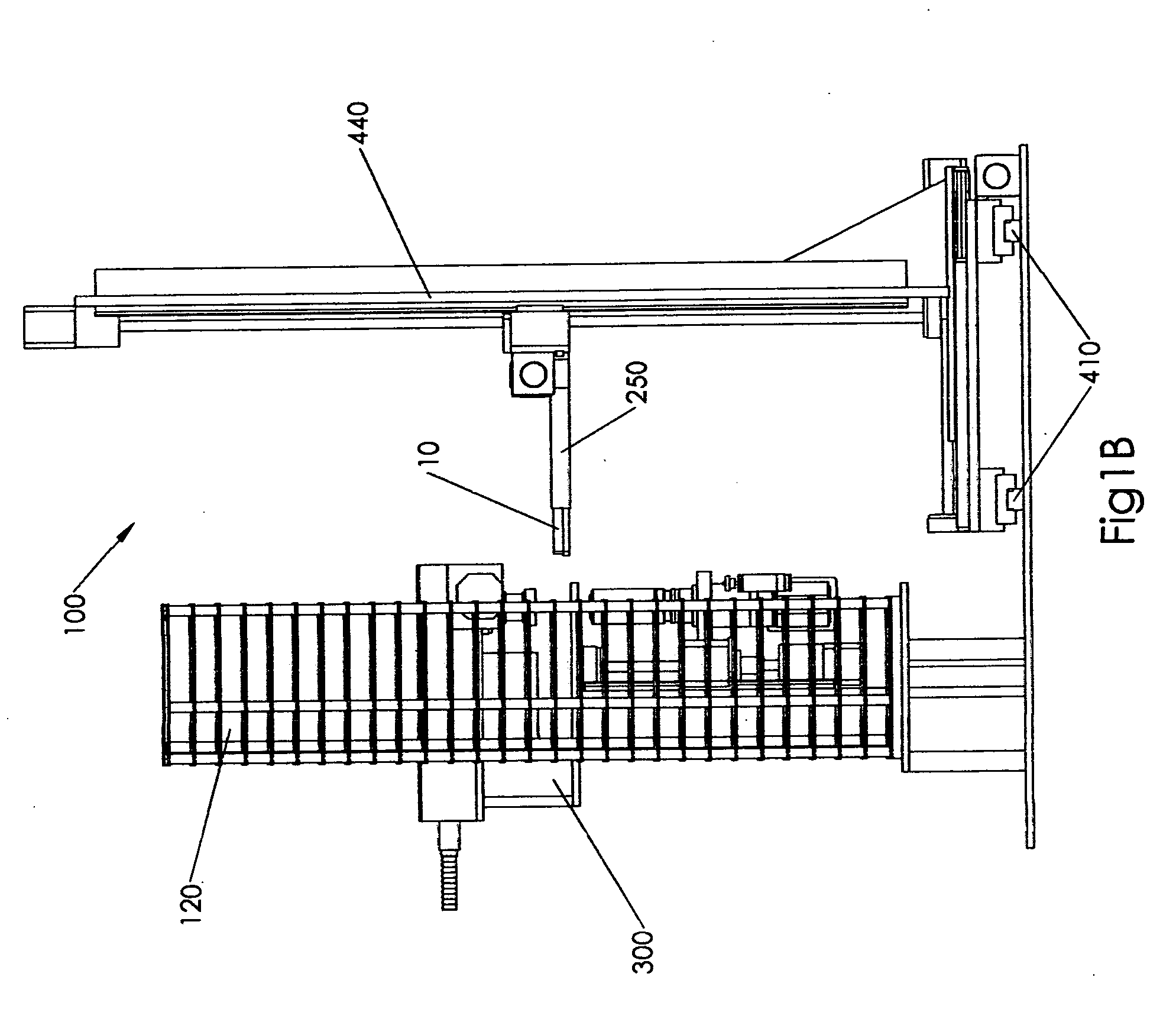

Parallel gripper for handling multiwell plate.

A parallel gripper for handling multiwell plates in an automated analysis system, moves individual multiwell plates between a plate storage array unit (i.e., plate hotel) and an imaging station. More particularly, the gripper has two parallel plate-gripping arms that move in equal, but opposite linear directions and are controlled using a stepper motor. Each of the arms has a shelf that provides support for the corresponding side edge of a multiwell plate.

Owner:HOOVER REX A

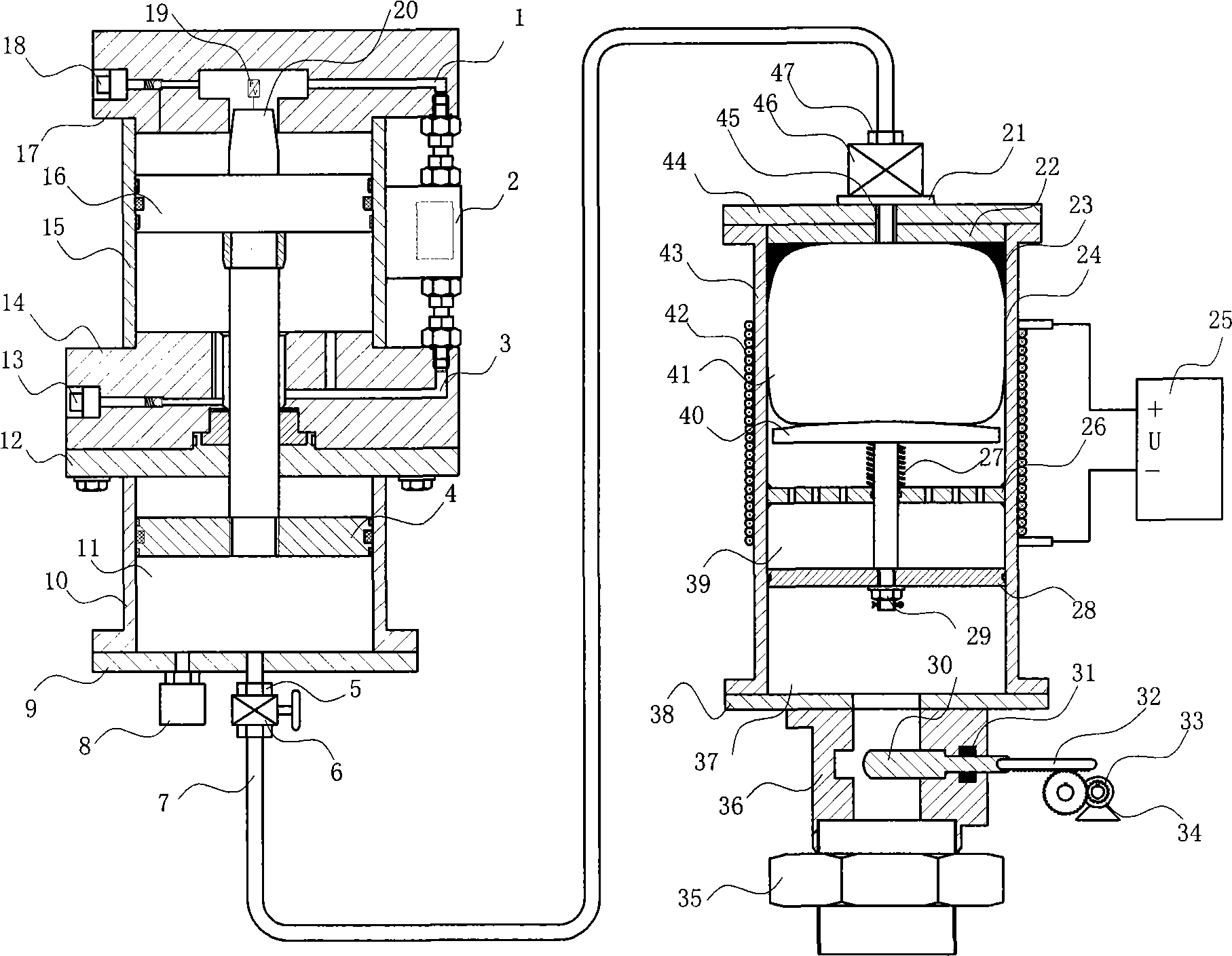

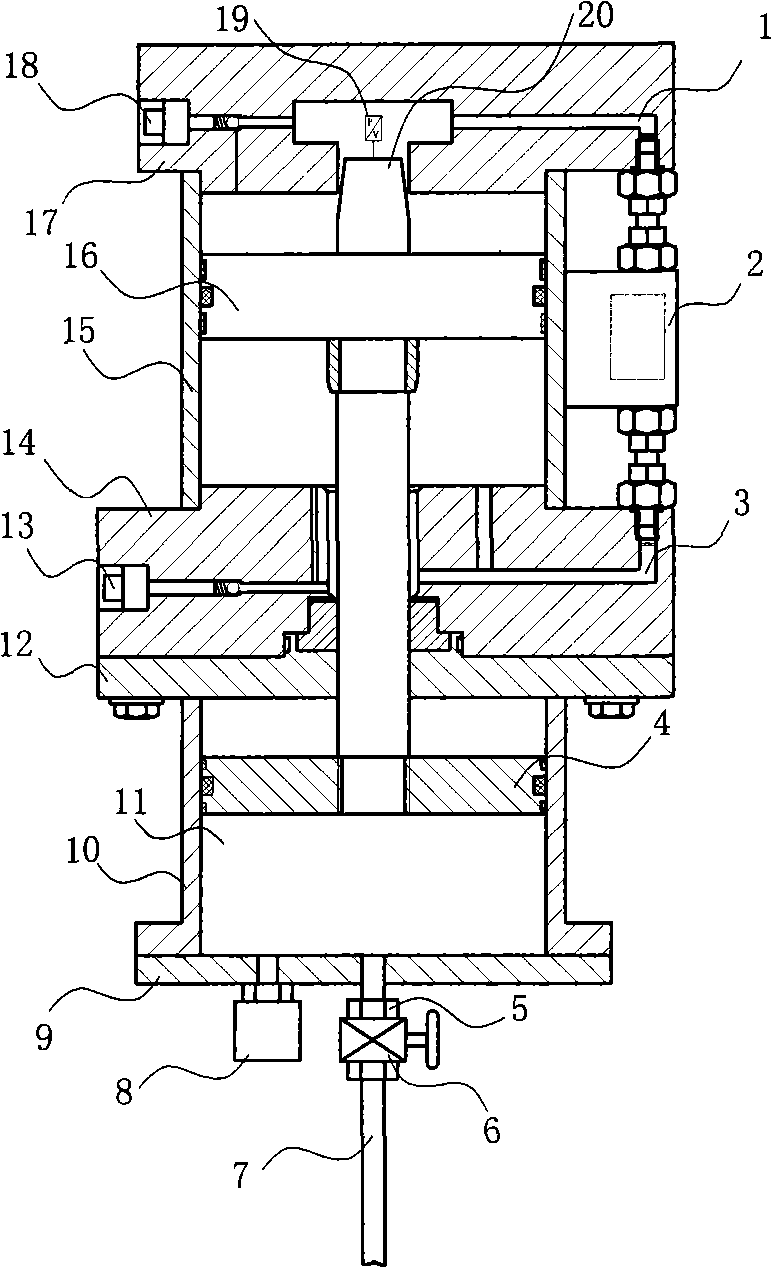

Parameter self-adapting and regulation leather bag type hydraulic accumulator

InactiveCN101476571AChange the application statusImprove air tightnessMechanical apparatusDamping factorSolenoid valve

The invention discloses a parameter adaptive adjustment bag type accumulator. A second air cavity (41) of a parameter variable accumulator device is communicated with a first air cavity (11) of an online adjustment accumulator through a high-pressure electromagnetic valve (46) and a high-pressure gas pipeline (7), and a filling valve cover (36) of the parameter variable accumulator device is communicated with a hydraulic system through a filling valve cover (35). The parameter adaptive adjustment bag type accumulator adopts a valve control hydraulic cylinder to control the air cavity volume and the gas pressure, and a DSP control center to calculate proper parameters so as to achieve automatic adjustment and overcome the defects that the prior accumulator parameter selection is inaccurate and the adjustment is impossible once the accumulator parameter is determined. Because an electromagnetic coil is adopted to adjust the size of the magnetic field in a magnetorheological fluid cavity and a step motor is adopted to control the size of the oil-passing area of an oil inlet, the damping coefficient of the accumulator can be changed dynamically, thus not only the requirement on the speedability and the stability of the compression shock and pulsation of an absorption system is met, but also the requirement on various functions of the same accumulator is met.

Owner:YANSHAN UNIV

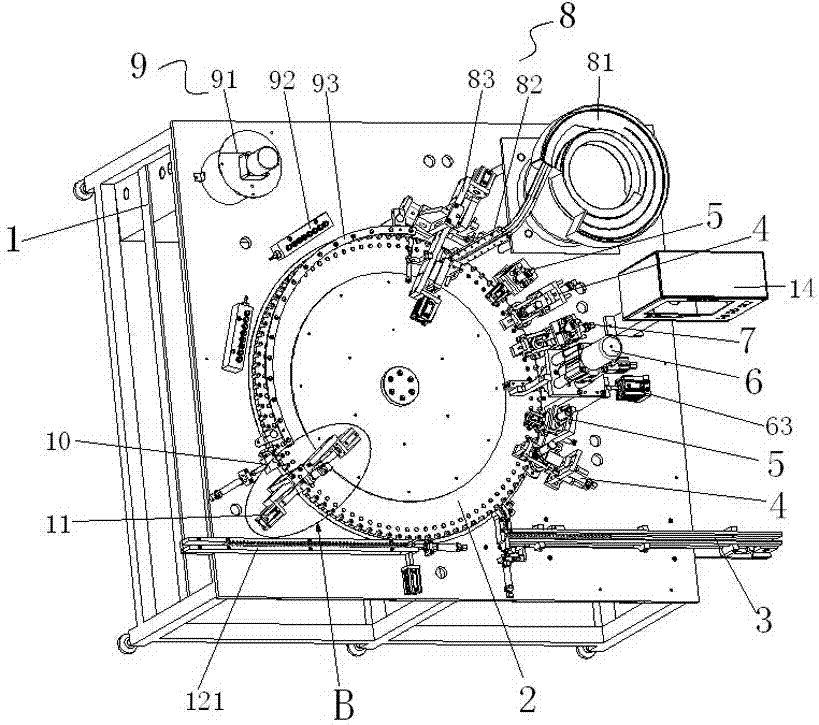

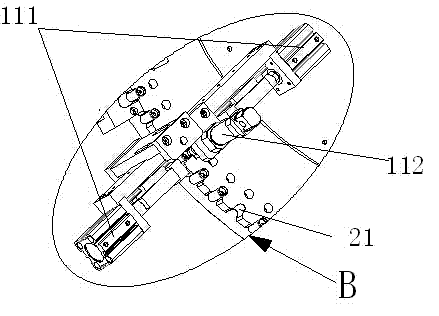

Automatic cylindrical battery assembling machine

ActiveCN104505531ARealize fully automatic assemblyShorten the timePrimary cell manufactureAssembling battery machinesEngineeringAutomatic testing

The invention provides an automatic cylindrical battery assembling machine. The automatic cylindrical battery assembling machine comprises a rack and an indexing plate arranged on the rack and driven to rotate by a divider controlled by a stepping motor, wherein a clamping groove for adsorbing a cylindrical battery to be assembled is arranged on the circumference of the indexing plate according to the dividing angle of the divider; and the automatic cylindrical battery assembling machine also comprises a feeding chute, a tab locating device, a tab shaping device, a groove rolling device, a gluing device, a cap welding device, a liquid injection device, an unqualified product discharging device, a cap pressing device, an automatic sealing machine and a finished product discharging device which are arranged around the indexing plate and sequentially work cooperatively. According to the automatic cylindrical battery assembling machine, the working procedures such as feeding, tab locating, tab shaping, groove rolling, gluing, cap welding, liquid injection, discharging of unqualified products, cap pressing, and automatic sealing and discharging of finished products in the assembling procedures of the cylindrical battery are integrated, the cylindrical battery can be assembled in a full-automatic manner, the whole machine only is required to be monitored by one person, the cost and the time are saved, and the production efficiency is greatly improved.

Owner:惠州亿恒特自动化科技有限公司

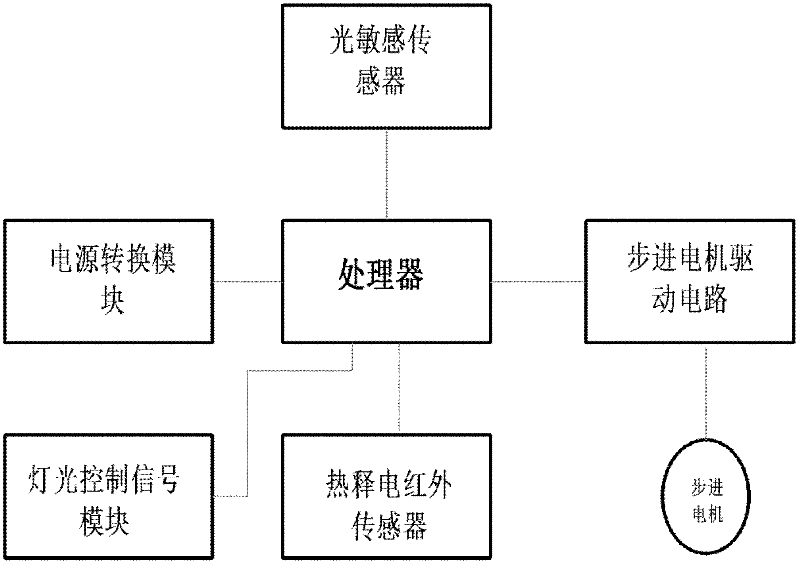

Infrared sensing device for detecting static human bodies

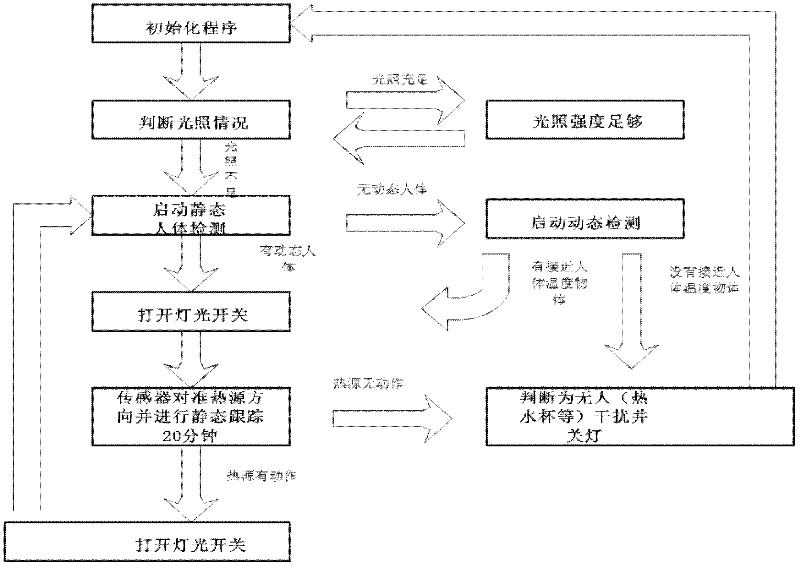

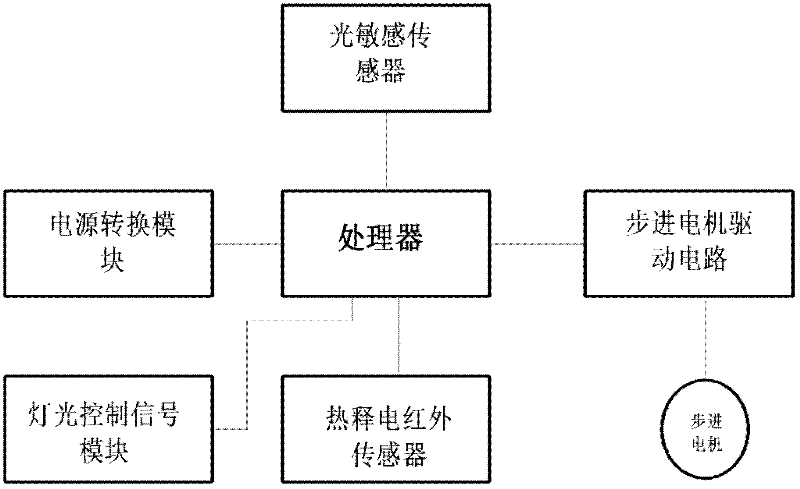

InactiveCN102510601ARotation control is flexible and easy to realizeImprove recognition rateOptical detectionElectric light circuit arrangementHuman bodyControl signal

The invention discloses an infrared sensing device for detecting static human bodies, which comprises a photosensitive sensor, a processor, a light-control signal output module, a stepping motor control module, a stepping motor and a pyroelectric infrared sensor, wherein the light-control signal output module is used for receiving a light-on control signal output by the processor so as to control the light to be on; the stepping motor is used for receiving a rotation control signal output by the stepping motor control module, and driving the pyroelectric infrared sensor installed on the rotating shaft of the stepping motor to rotate according to the control signal; and the pyroelectric infrared sensor is used for scanning a static heat source signal, and controlling the light-control signal output module to output a light-on or light-off signal according to the scanned signal. The device has the advantage of higher recognition rate for human bodies in special locations, such as classrooms and libraries. Since the mechanism is controlled by a program, the speed, angle and forward / reverse rotation of the stepping motor can be rotated, and the rotation control on the sensor is flexible and easy to implement, and the device does not need any complex mechanical structure.

Owner:TIANJIN UNIV

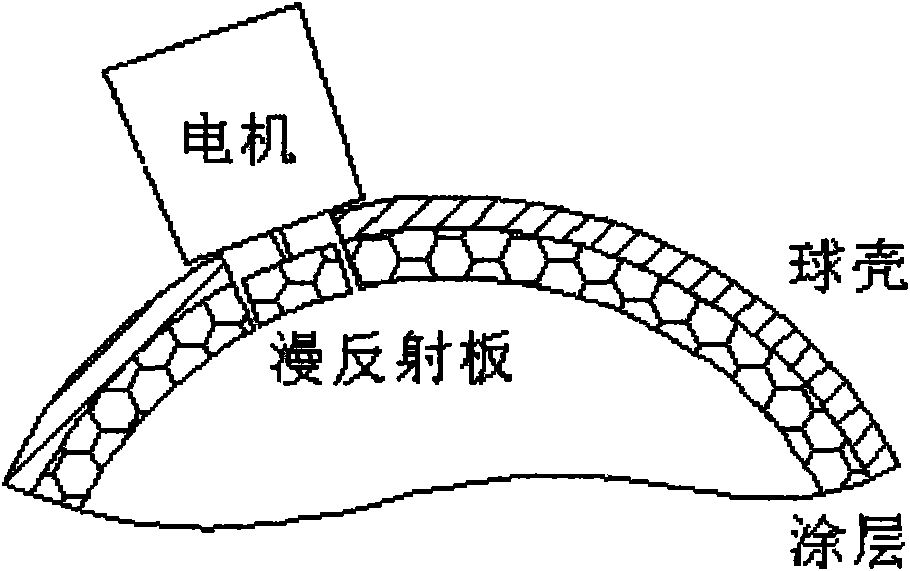

Absolute spectral radiance luminance responsivity calibrating system utilizing wide tunable laser

InactiveCN101650225ASimple structureImprove calibration accuracyRadiation pyrometryResponsivityRadiance

The invention relates to an absolute spectral radiance luminance responsivity calibrating system utilizing a wide tunable laser, which comprises a two-dimensional moving platform, wherein the two-dimensional moving platform is controlled by a computer through a stepping motor control box; a standard detector and a detector to be calibrated are arranged on the two-dimensional moving platform. The absolute spectral radiance luminance responsivity calibrating system also comprises a calibrating light source, wherein the calibrating light source comprises an integrating sphere and a tunable lasersystem; the emitting light of the tunable laser is guided into the integrating sphere and emitted at a light outlet of the integrating sphere to form the calibrating light source; the standard detector and the detector to be calibrated are sequentially aligned to the center of the light outlet of the integrating sphere to detect by the motion of the two-dimensional moving platform; the standard detector calibrates the absolute spectral radiance luminance of the light source of the integrating sphere, and a response signal of the detector to be calibrated is divided by the absolute spectral radiance luminance of the light source of the integrating sphere to obtain the absolute spectral radiance luminance responsivity. The invention can carry out whole machine calibration on a wave band typeradiance luminance detector, the calibrating parameter comprises the absolute spectral radiance luminance responsivity, and the stability and the linearity of the responsivity, and the calibrating precision of the spectral radiance luminance responsivity is effectively improved.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

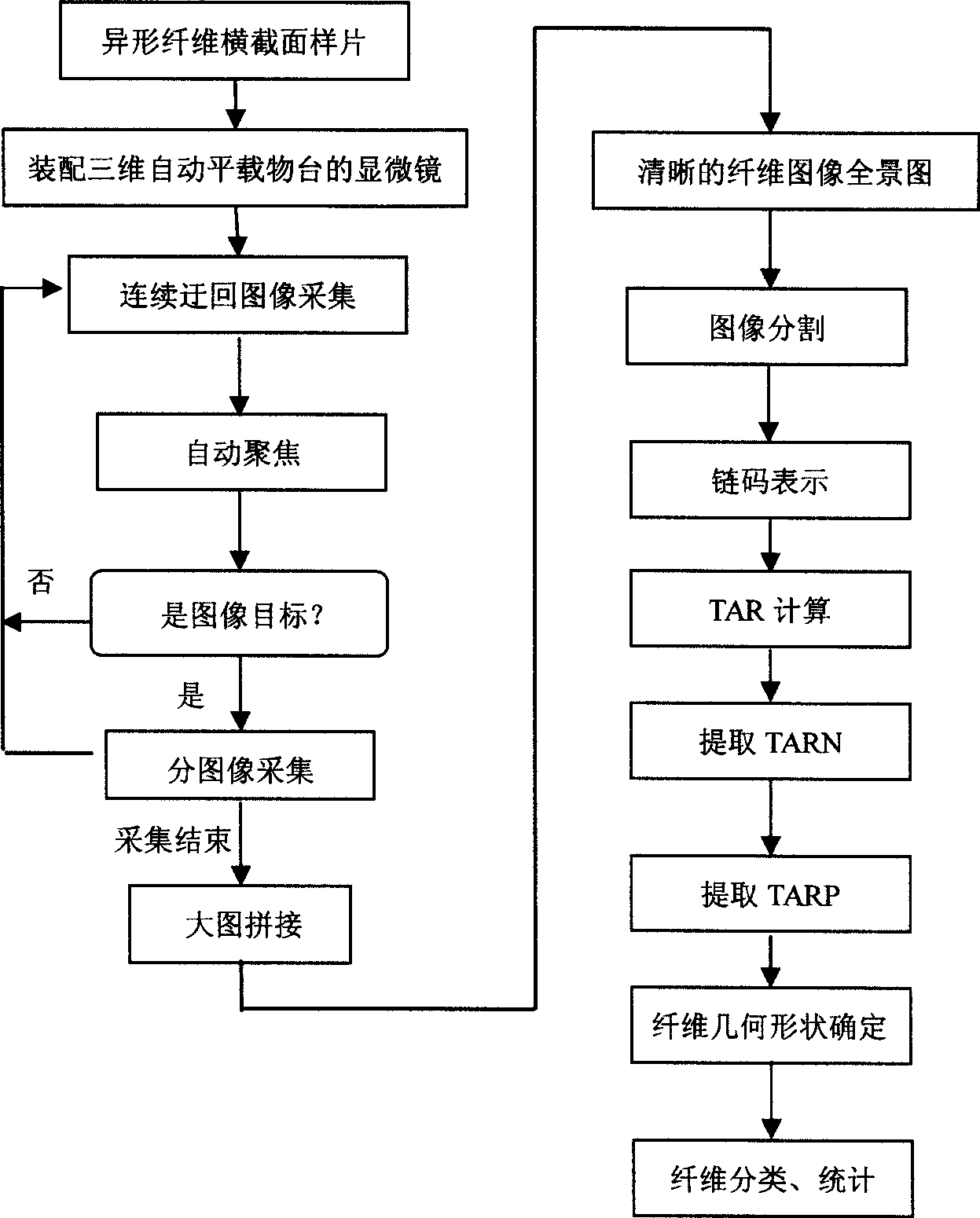

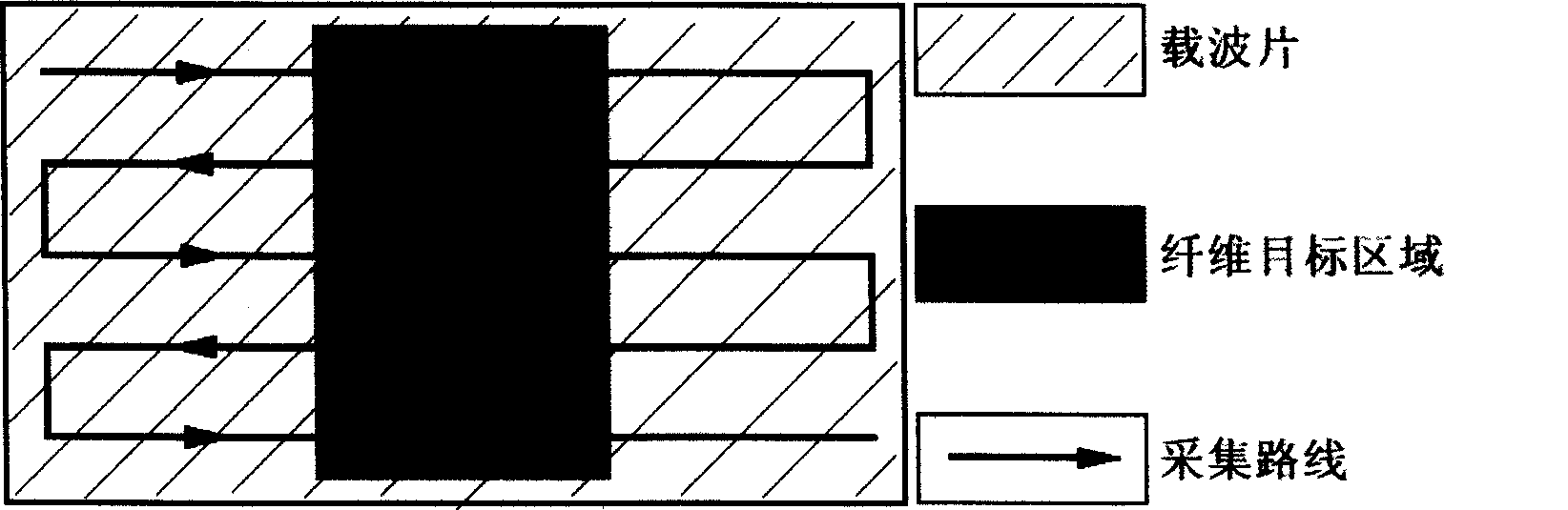

Extraction method for dimension shape characteristics of profiled fiber

InactiveCN101487838AAutomatically obtain classification statistics resultsImprove accuracyImage analysisCharacter and pattern recognitionEngineeringImage segmentation

The invention relates to a method for extracting dimensional shape characteristics of profiled fibers; the stepper motor in XYZ direction of an automatic loading table is controlled through a series port to realize the mobile control in horizontal and vertical directions to cause an optical microscope to work in an optimum focusing state. The extracting method comprises the following steps: giving 'cross-sectional samples of the profiled fibers' and 'microscopes for assembling three-dimensional automatic loading table' to judge through 'continuous indirect image acquisition' and 'automatic focusing'; if not, returning to the 'continuous indirect image acquisition'; if yes, going to 'partial image acquisition', then returning to the 'continuous indirect image acquisition' until the partialimage acquisition is ended; going to 'big image splicing'; obtaining 'clear fiber image panoramagram'; carrying out 'image segmentation', 'chain code representation', 'TAR calculation', 'TARN extraction', 'TARP extraction', and 'fiber geometrical shape determination' on the acquired images; and at last, carrying out 'fiber classification and statistics'.

Owner:DONGHUA UNIV

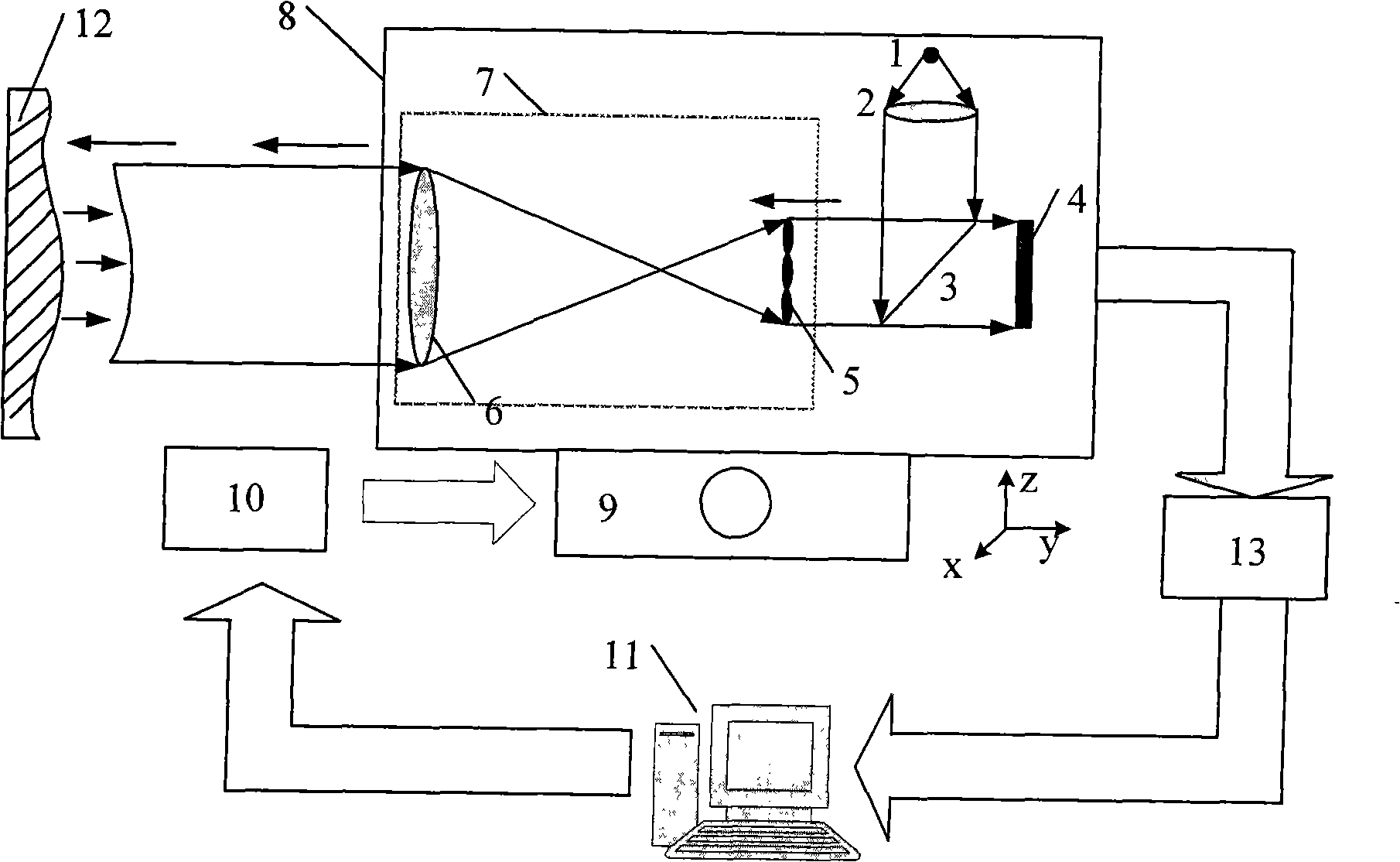

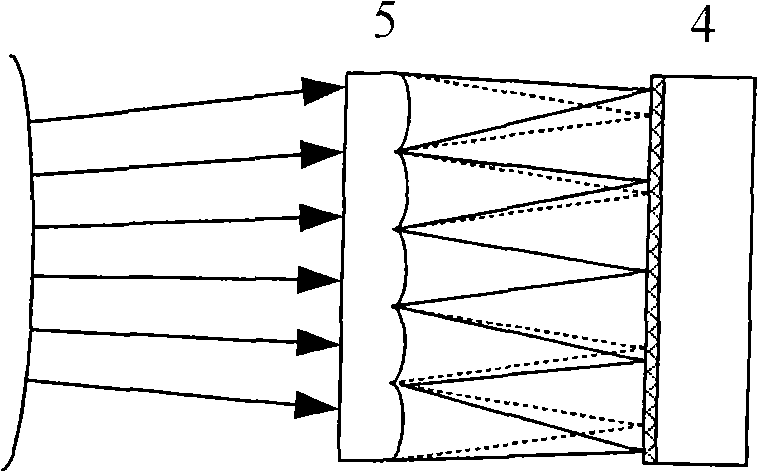

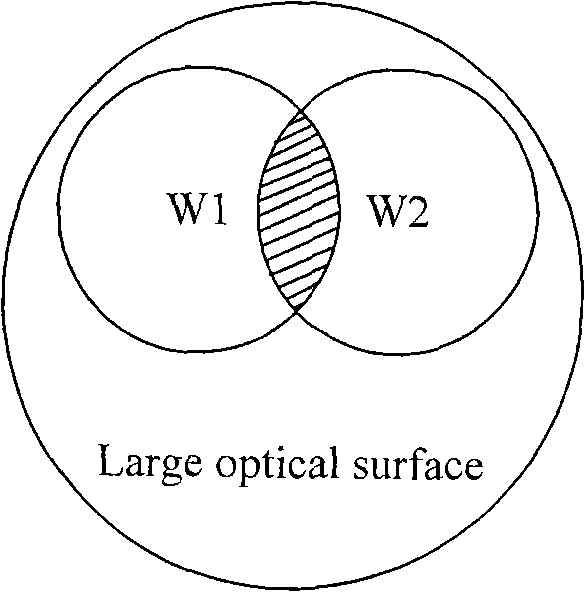

Splicing detection device based on minor caliber circular Shack-Hartmann wavefront sensor

ActiveCN101493375AReduce computational complexityEliminate translation errorsOptical apparatus testingComputation complexityData acquisition

The invention discloses a splicing detection device of a circular Hartmann-Shack wave-front sensor based on a minor caliber. The device is characterized by comprising the Hartmann-Shack wave-front sensor, an x-z 2D electric control translation stage, a step motor controller, a computer, a mirror surface to be detected and a data acquisition card; the Hartmann-Shack wave-front sensor is positioned behind the mirror surface to be detected to detect the mirror surface to be detected, and a facula lattice is formed on the Hartmann-Shack wave-front sensor, and the data acquisition card acquires the facula data and transmits the data to the computer for storing; the computer sends an instruction to the step motor controller, and controls the 2D electric control translation stage to move along an x axis and a z axis to scan and detect the mirror surface to be detected; the data acquisition card sequentially acquires the facula data of a wavelet surface of each frame, and then a wave surface to be detected is obtained by a centroid algorithm, a splicing method and a restoration algorithm. The device and the method help improve a formula by ignoring a defocus error in theoretical analysis, eliminate a principle error of a translation error, improve splicing precision and lower computation complexity of solving splicing parameters.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

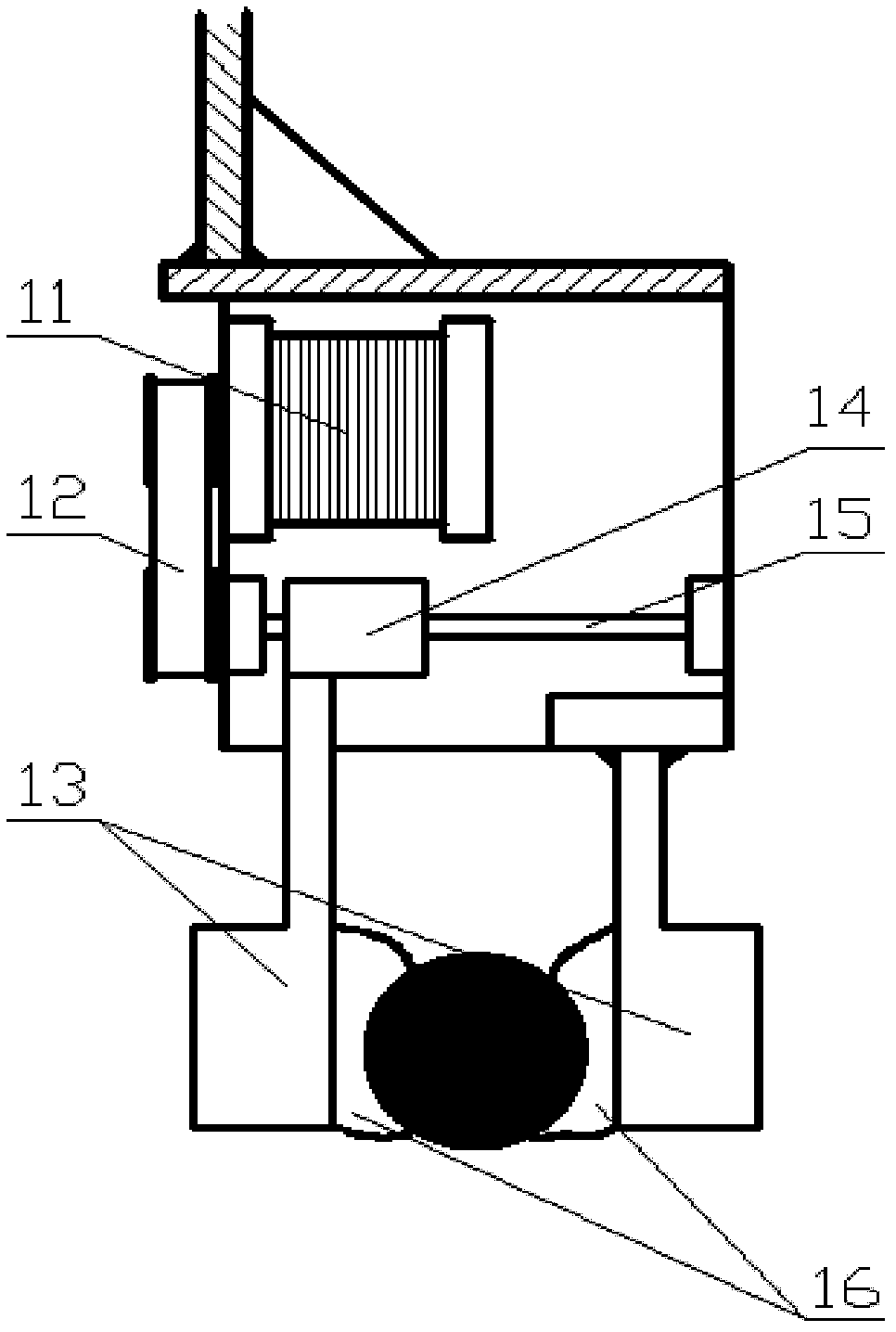

Single-axle double-direction symmetric stretching experimental machine

InactiveCN1888855ARealize displacement loadingIncrease diversityMaterial strength using tensile/compressive forcesBall bearingCoupling

A single axle bidirectional symmetry stretch testing machine belongs to the experimental mechanics equipment technology field, including: the step-by-steps motor 11, the step-by-steps motor controller, the strength sensor, the wormwheel, the worm, the ball bearing screw mandre, the left nut, the right nut, the linear slideway, the axletree, the base 1, the shaft coupling, the testing sample holding device; the step-by-steps motor connects with the worms by the shaft coupling; the wormwheel cooperates with the worm, the linear slideway and the axletree locates on the base; the strength sensor fixes on the right nut of the ball bearing screw mandrel, spreads the one side of the testing sample holding device, the other side of the testing sample holding device fixes on the left nut. The invention is: uses the machine transmission to improve the transmitting precision; uses the step-by-steps motor to load; the distortion measure can use the step-by-steps motor to compute or uses the non-touch photics displacement measure system.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com