Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Realize all position welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength steel high-ductility gas shielded welding wire

InactiveCN101439446AProcess performance is stableStable welding arcWelding/cutting media/materialsSoldering mediaDuctilityArc welding

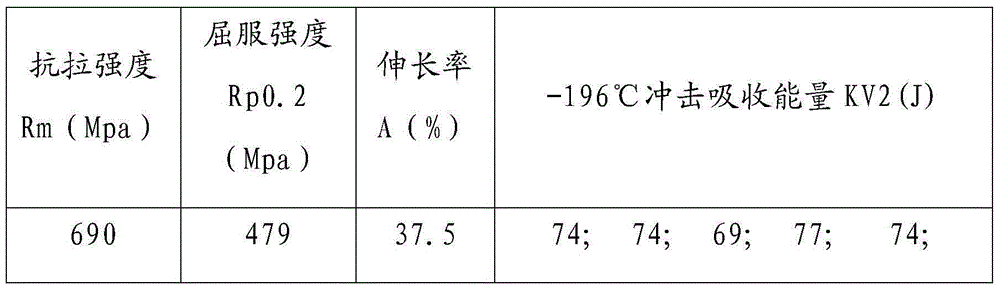

The invention relates to a high-tenacity gas-shielded welding wire for high-tensile steel. The welding wire solves problems of 780-850MPa-level low-alloy high-tensile steel welding material, including lack of matching performance and especially poor toughness and high cost. The technical proposal of the invention comprises that the chemical component consists of (counted by weight percentage) 0.05-0.13 percent of C, 1.4-1.9 percent of Mn, 0.4-0.8 percent of Si, 0.4-0.8 percent of Cr, 1.5-1.8 percent of Ni, 0.3-0.8 percent of Mo, 0.06-0.25 percent of Ti, 0-0.60 percent of Cu, not more than 0.025 percent of S, not more than 0.025 percent of P and the balance of Fe and unavoidable impurity elements. When gas-shielded welding is carried out on the welding wire, the welding line has the metal tensile strength of 780-850MPa; the ballistic work AkV at -20 DEG C is not less than 70J, thereby applying to gas-shielded arc welding of 780-850MPa-level low-alloy high-tensile steel.

Owner:SHOUGANG CORPORATION

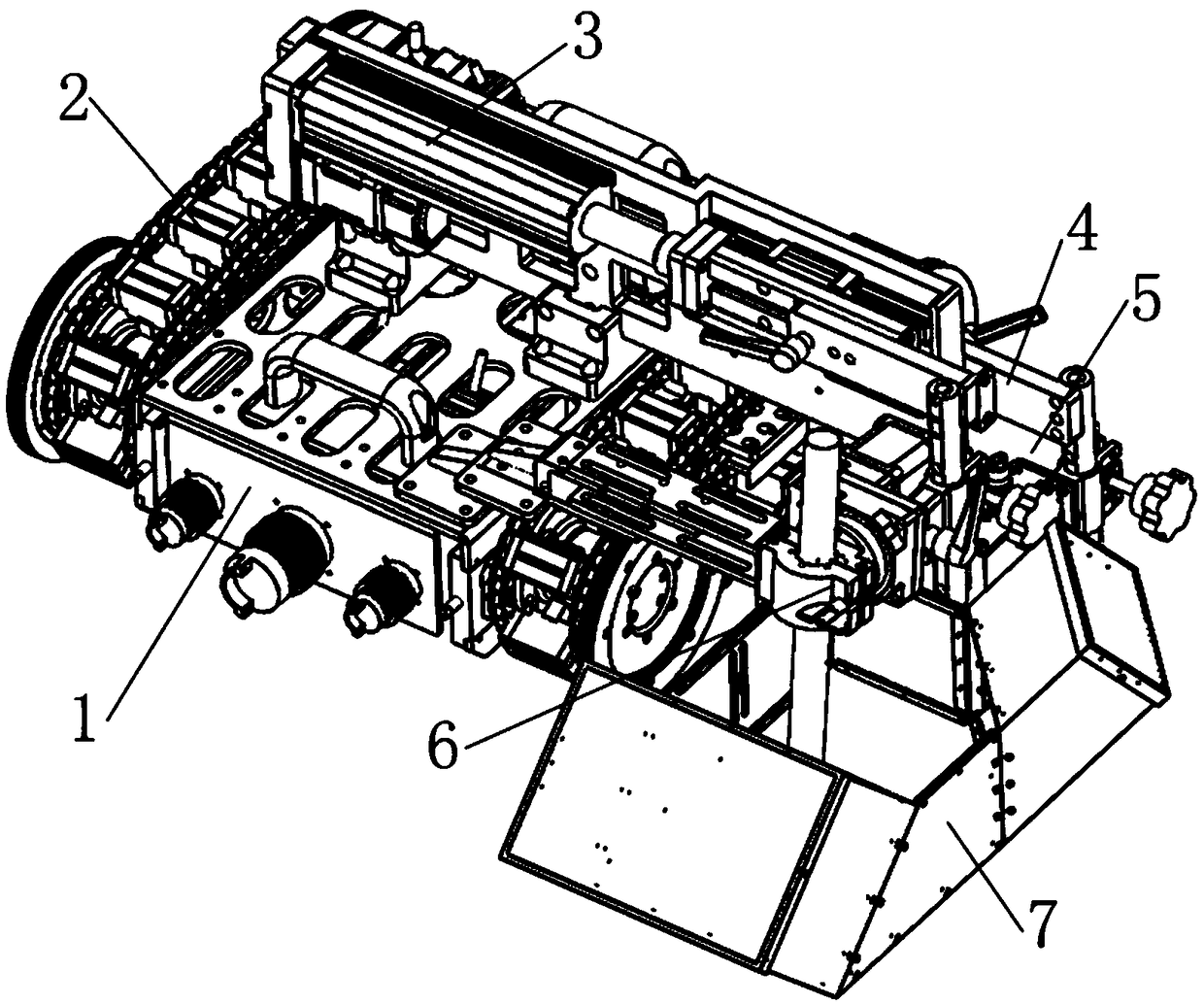

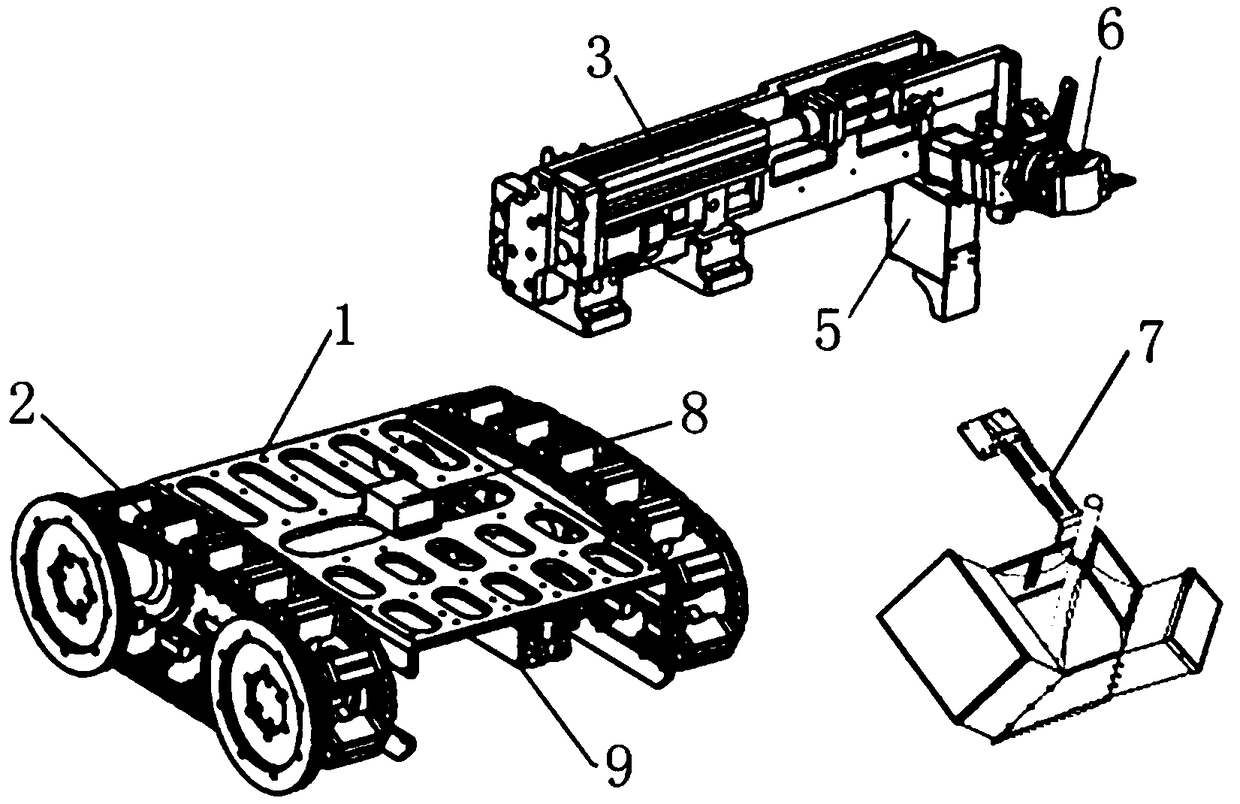

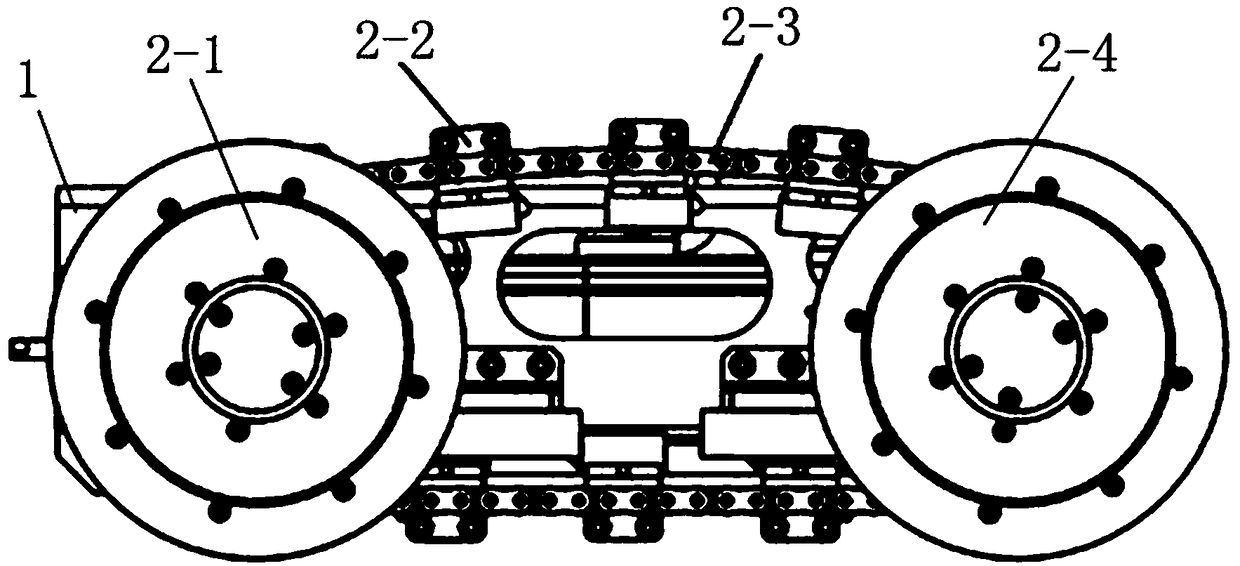

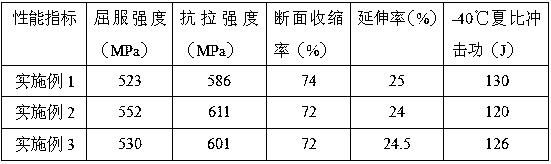

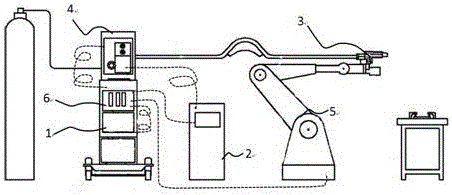

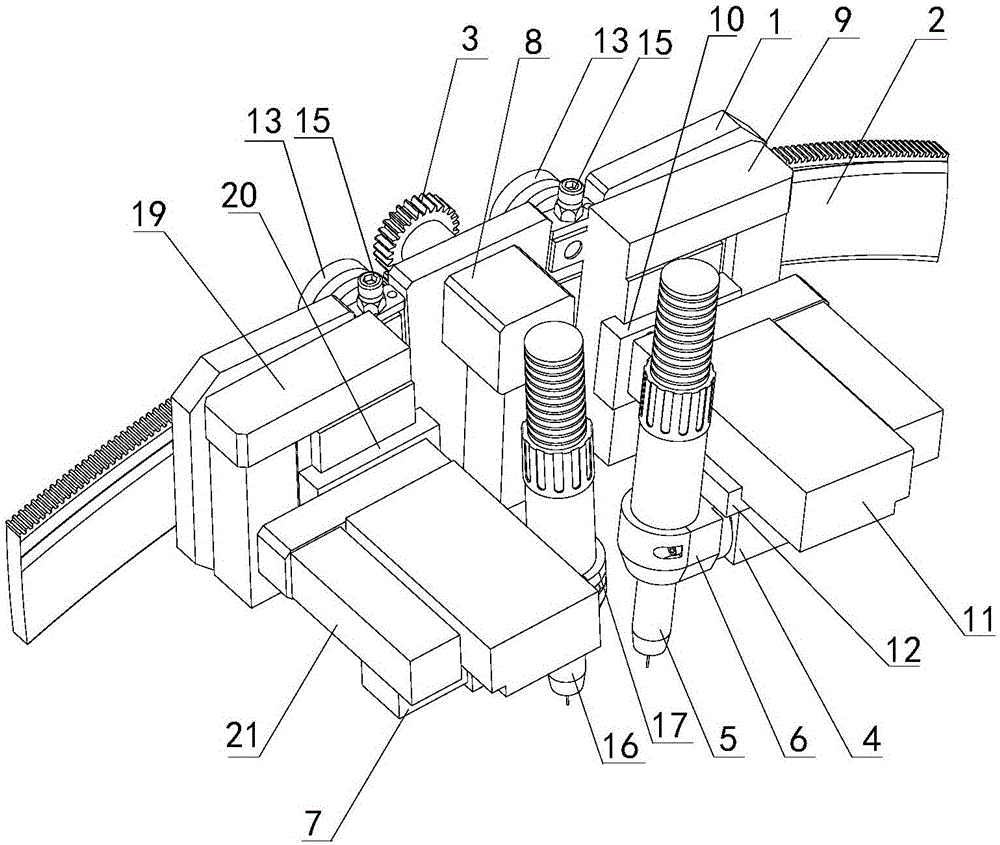

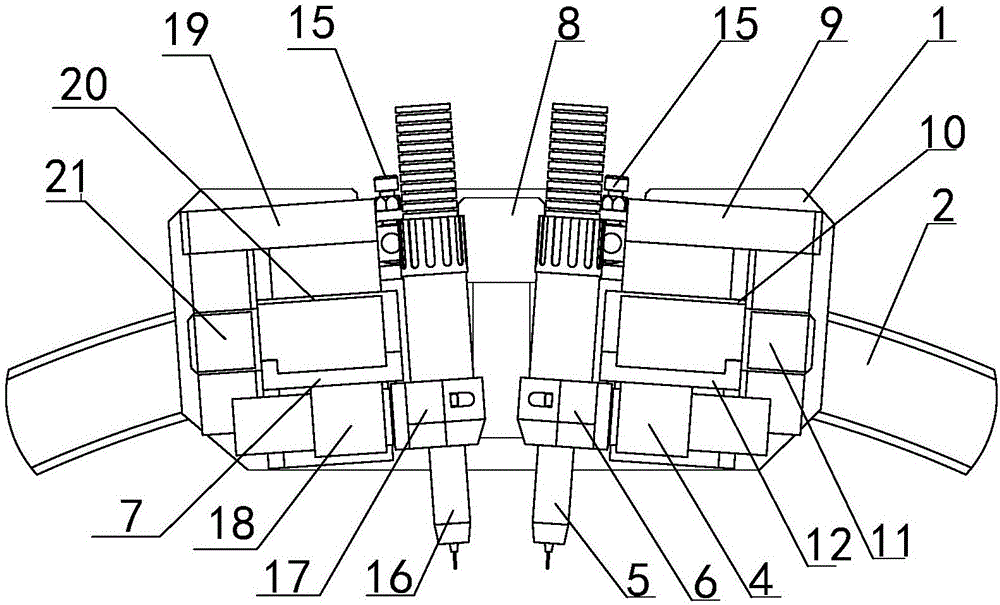

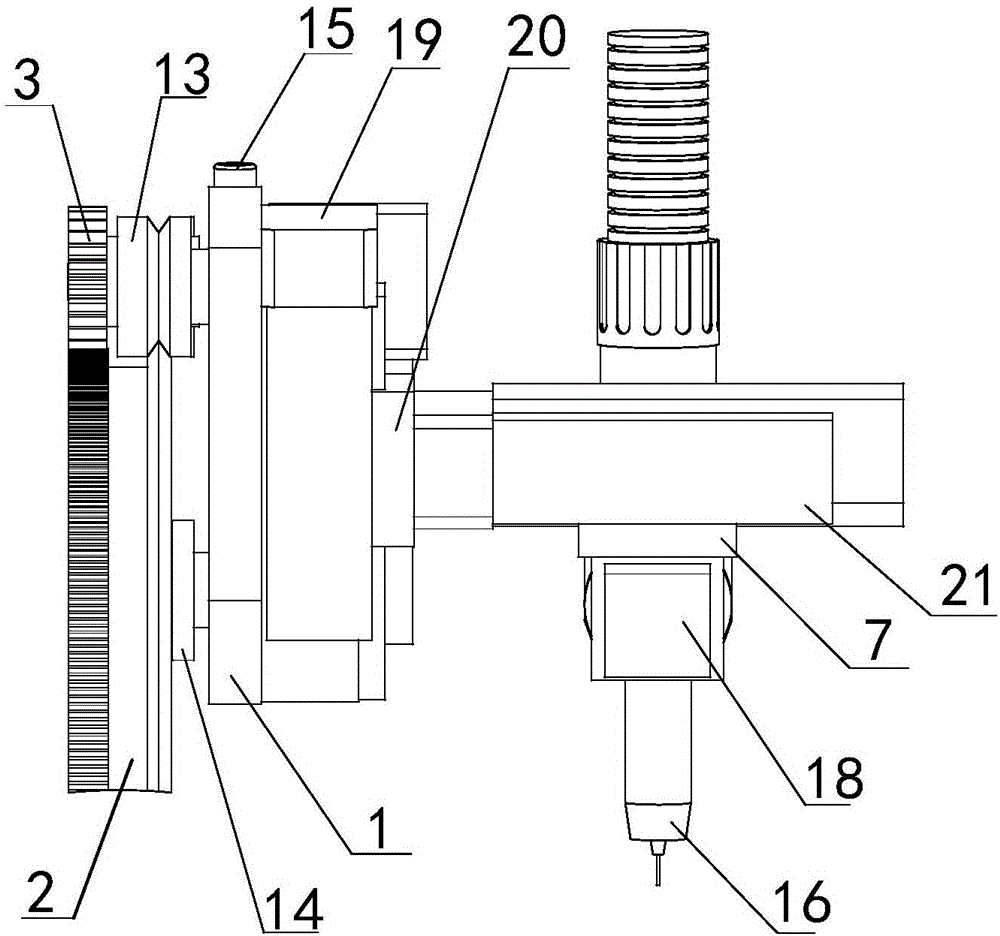

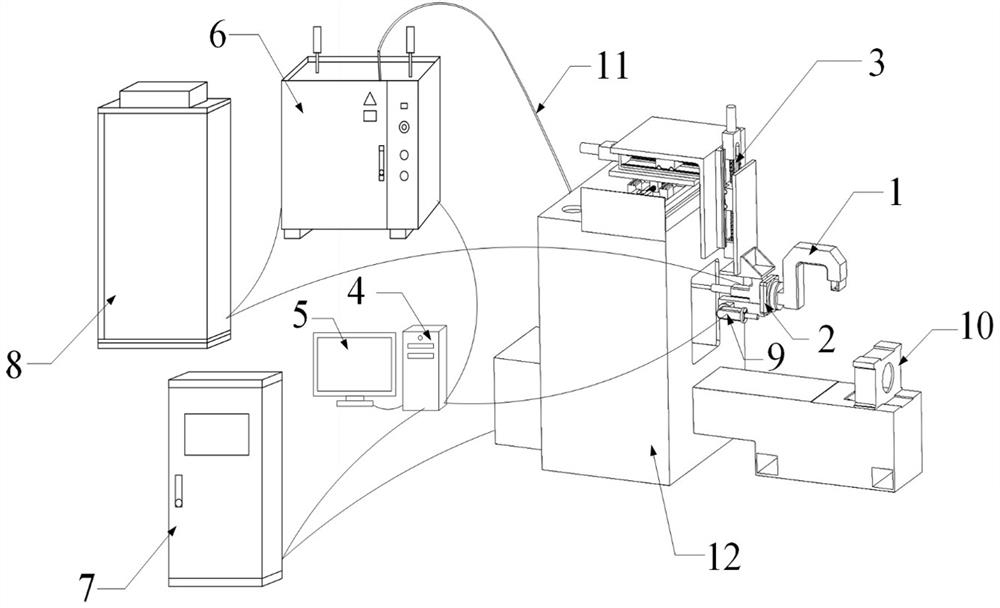

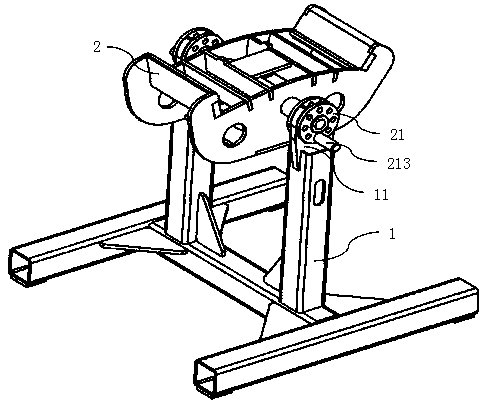

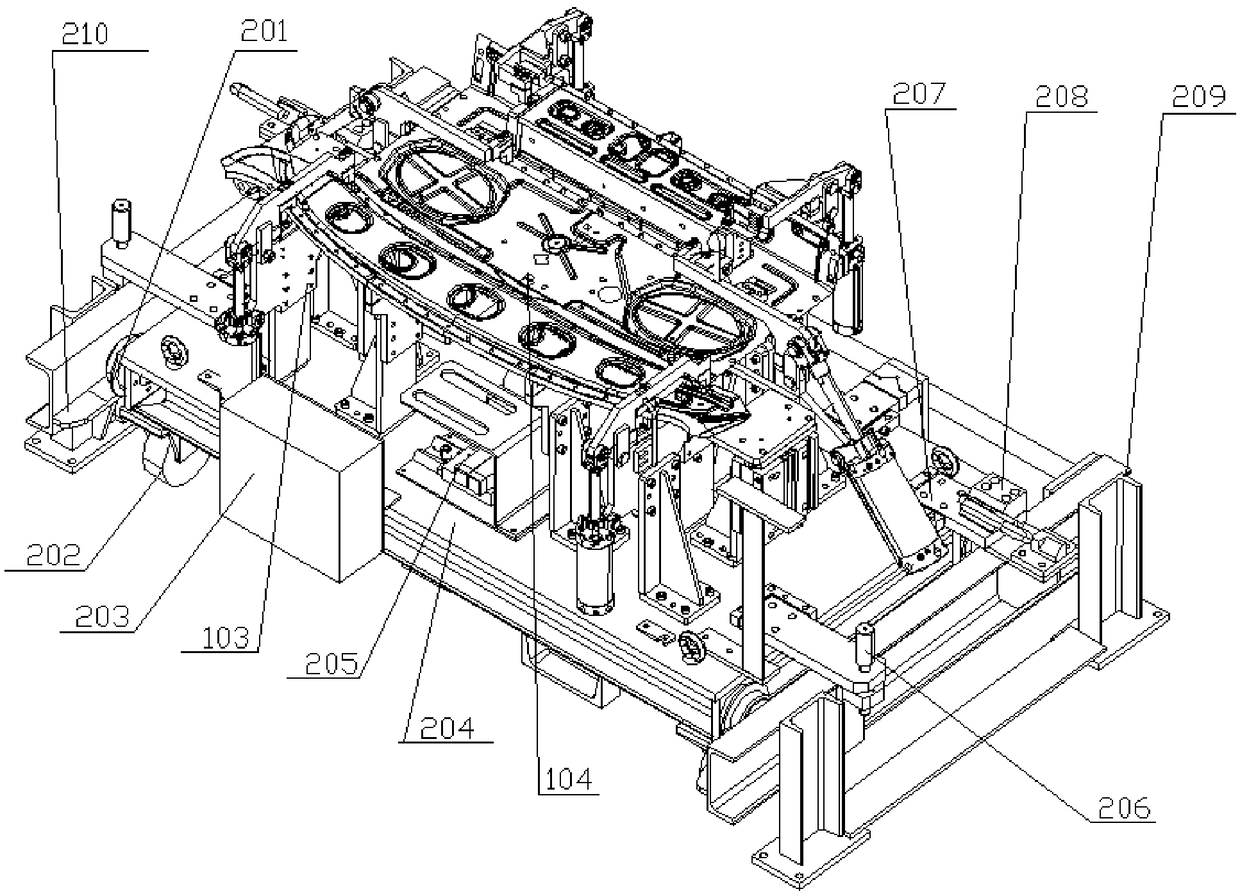

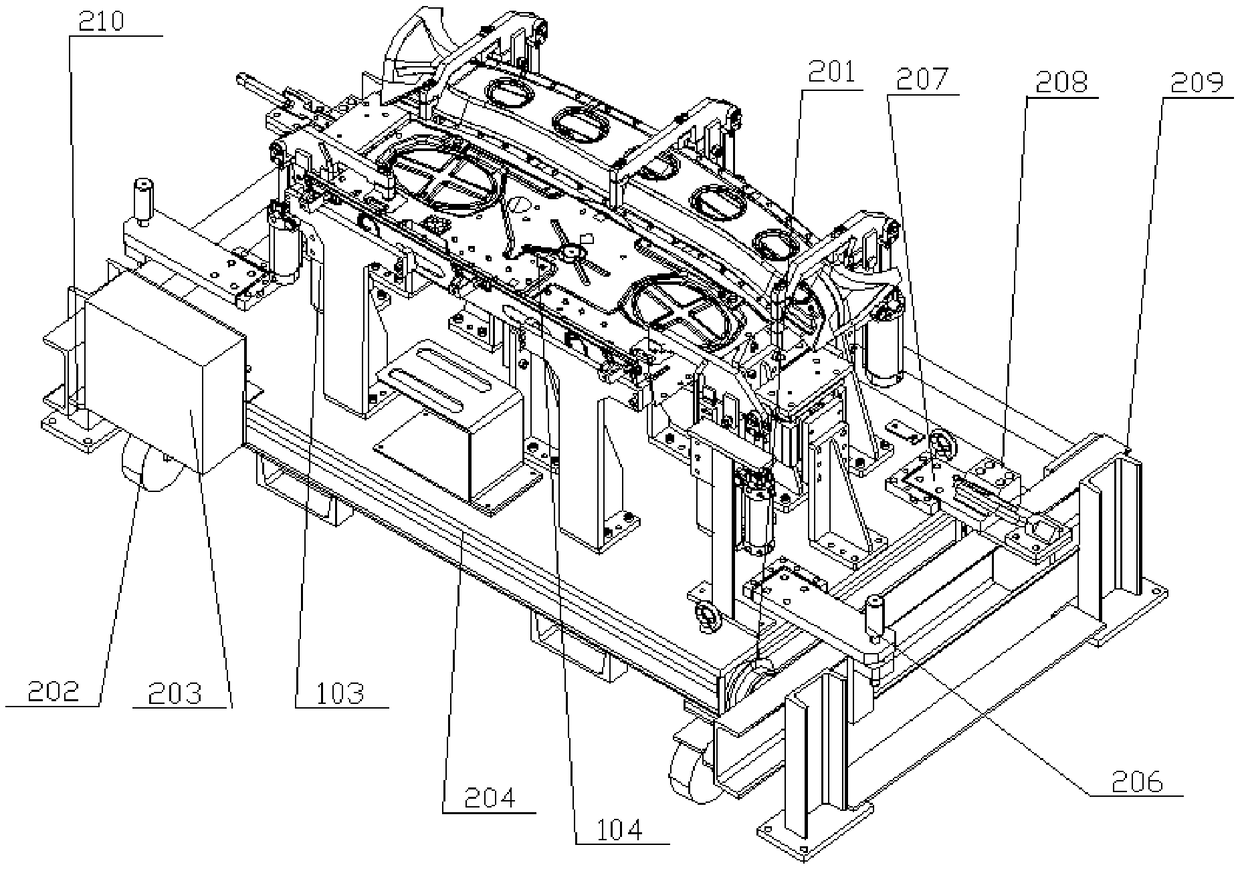

Crawling welding robot and control method thereof

PendingCN109396700ARealize all position weldingLarge welding rangeWelding/cutting auxillary devicesArc welding apparatusVehicle frameWorking environment

The invention relates to the technical field of welding devices, in particular to a crawling welding robot. The robot comprises an adjustable magnetic adsorption module, wheel-covered travelling mechanisms, a crawling machine frame and a welding load device, wherein the welding load device is arranged on the crawling machine frame; the wheel-covered travelling mechanisms are arranged at the two opposite ends of the crawling machine frame and are used for providing crawling power for the crawling machine frame; and the adjustable magnetic adsorption module is arranged on the crawling machine frame and is arranged between the two wheel-covered travelling mechanisms. According to the robot, the wheel-covered travelling mechanisms are arranged so as to realize rail-free and guide-free crawling, moving on a large and medium-sized plane or the surface of a cambered surface welding structural part is realized, vertical crawling on walls is realized, welding operation can be conducted during forward moving or backward moving, full-position welding of large and medium-sized structural parts can be realized, the welding auxiliary time can be obviously reduced, and the production efficiency is high; and the magnetic adsorption force is adjusted through the adjustable magnetic adsorption module, the crawling on flat plates and large-curvature arc plates can be realized, and working environment adaptability is high.

Owner:BEIJING BO TSING TECH CO LTD

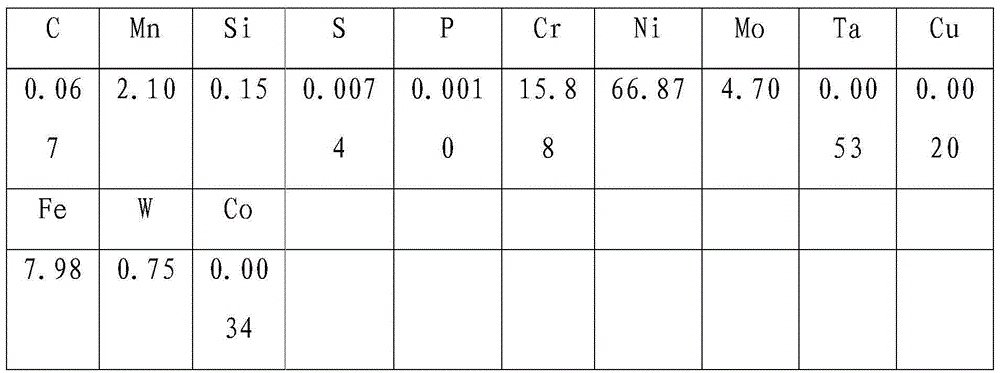

Nickel-based welding rod used for ultralow-temperature steel and preparation method of nickel-based welding rod

ActiveCN105081613AImprove performanceSimple welding processWelding/cutting media/materialsSoldering mediaHeat resistanceMass ratio

The invention belongs to the technical field of welding materials and particularly relates to a nickel-based welding rod used for ultralow-temperature steel and a preparation method of the nickel-based welding rod. The welding rod comprises a welding core wire, chemical powder and an adhesion agent; the mass ratio between the chemical powder and the welding rod is 25-27:100, and the mass ratio between the chemical powder and the adhesion agent is 100:25-30. When the welding rod prepared through the preparation method is welded, the electric arc is stable, the splatter is slight, the sediment separation is good, the form is beautiful, the welding can be conducted through alternate currents or direct currents, and the all-position operation performance is good. The nickel-based welding rod is mainly used for the nickel-based alloy welding with heat resistance and corrosion resistance requirements, and the nickel-based welding rod can also be used for the welding of some alloy hard to weld and dissimilar steel.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +1

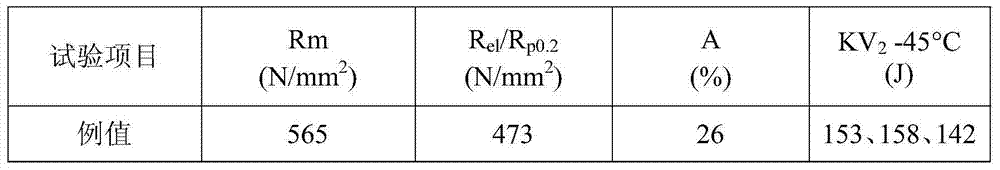

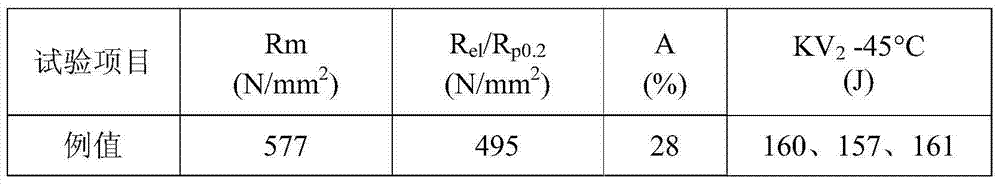

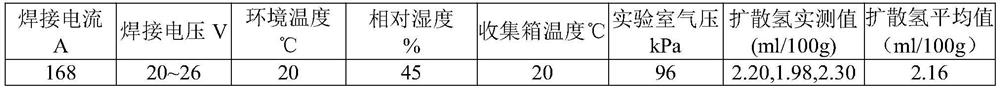

Metal powder-cored wire for welding X80 high-strength low-alloy pipeline steel

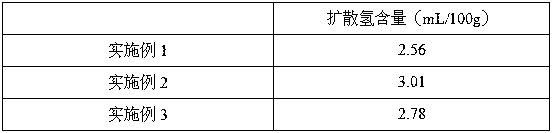

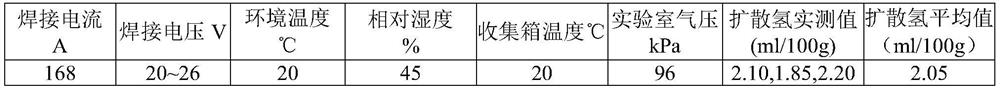

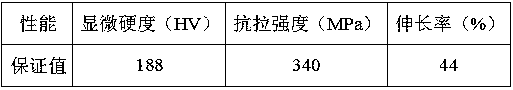

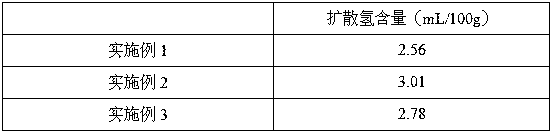

ActiveCN104259687ALow diffusible hydrogen contentImprove deposition efficiencyArc welding apparatusWelding/cutting media/materialsFerrosiliconRare earth

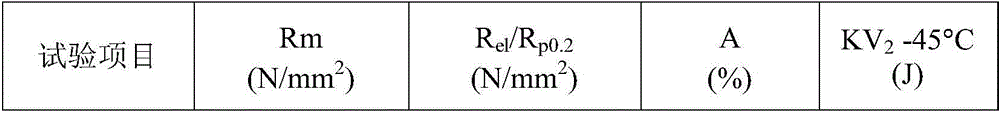

The invention discloses a metal powder-cored wire for welding X80 high-strength low-alloy pipeline steel. The metal powder-cored wire consists of a carbon steel strip and a metal powder core, wherein a formula of metal powder consists of low-carbon ferromanganese, ferrosilicon, ferrotitanium, nickel powder, ferromolybdenum, ferroboron, magnesium powder, rare earth fluoride and the balance of iron powder. The metal powder-cored wire is characterized by adopting an Ni-Mo-Ti-B alloy system to be applied to the root welding, filling and cover surface welding of the X80 high-strength low-alloy pipeline steel, in particular to the backing welding, so that the melting speed is fast, the melting efficiency is high, the all-position welding can be realized, the content of diffusible hydrogen is lower, and KV2(-45 DEG C) is higher than 100 J.

Owner:TIANJIN YONGCHANG WELDING WIRES

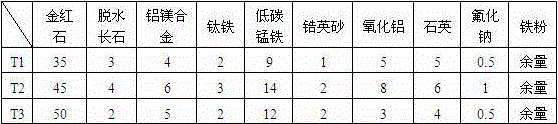

Seamless flux cored wire with good vertical position welding manufacturability

ActiveCN106736049AGood welding wire workmanshipRealize all position weldingWelding/cutting media/materialsSoldering mediaCopper platingMoisture absorption

The invention discloses a seamless flux cored wire with good vertical position welding manufacturability, and relates to the field of welding materials. The seamless flux cored wire is composed of low carbon steel outer skin and flux core powder, and the flux core powder is prepared from the mixing of materials, by mass, 35%-50% of rutile, 2%-4% of dehydrated feldspar, 4%-6% of aluminum magnesium alloy, 2%-3% of ferrotitanium, 9%-14% of low carbon ferromanganese, 1%-2% of zircon sand, 3%-8% of aluminum oxide, 4%-6% of quartz, 0.5%-1% of sodium fluoride and the balance iron powder. According to the seamless flux cored wire with the good vertical position welding manufacturability, the flux core powder is added online synchronously, after the flux core powder is added into the outer skin steel belt, the outer skin steel belt is then subjected to rolling forming and welding seaming, and afterwards subjected to annealing, reducing and copper plating so that the seamless flux cored wire can be prepared. The prepared seamless flux cored wire is stable in mechanical property, low in diffusible hydrogen, high in moisture absorption performance, excellent in antirust performance, and good in welding manufacturability; meanwhile, all-position welding can be conducted, the seamless flux cored wire is particularly applicable to welding of position of vertical welding, and can be used for welding of a D36 level steel plate.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

High-toughness titanium alkaline type seamless flux-cored wire suitable for full-position welding

ActiveCN108406159ASimple processImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaCrack resistanceSlag

The invention discloses a high-toughness titanium alkaline type seamless flux-cored wire suitable for all-position welding. The flux-cored wire is composed of a low-carbon steel strip at the peripheryand flux core powder inside; and the flux core powder comprises the following components, by weight percentage: 30-40% of rutile, 1-2% of aluminum oxide, 2-4% of dehydrated feldspar, 1-3% of quartz,1-3% of zircon sand, 1-2% of rare earth oxide, 1-2% of silicon powder, 0.2-0.4% of ferroboron, 6-8% of nickel powder, 8-15% of metal manganese, 4-9% of magnesium powder and the balance iron powder andinevitable impurities. According to the flux-cored wire, a titanium alkaline slag system is adopted, the proportion of alloy elements is optimized, the content of mineral powder is adjusted, and under the protection of CO2 gas, horizontal, transverse and vertical position welding can be realized; the mechanical property is stable, the impact power at 40 DEG C below zero reaches 100J, the crack resistance is good, diffusible hydrogen is low, the moisture resistance is strong, the seawater corrosion resistance is good, and the anti-cracking ability is good.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Pulsed tungsten argon arc welding method

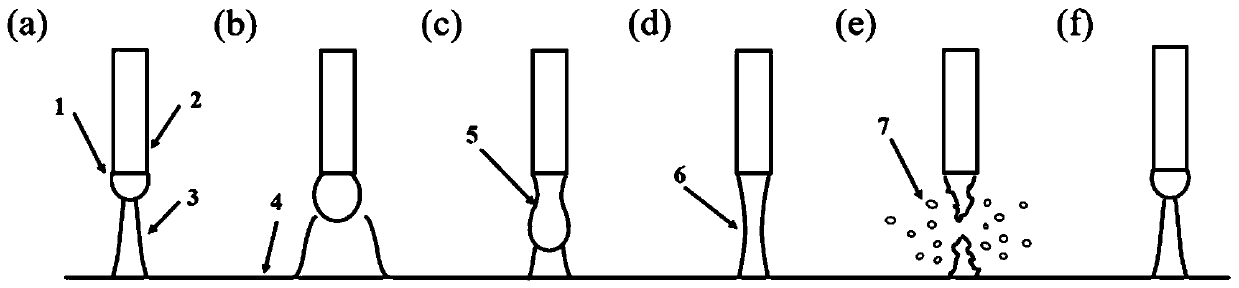

InactiveCN103894709AReduce splashReduce distortionArc welding apparatusWelding/cutting media/materialsCurrent rangeShielding gas

A pulsed tungsten argon arc welding method comprises the following steps that (1) gas proportion of protective gas is determined; (2) composition of parent material is determined; (3) composition and diameter of a soldering wire is determined; (4) the welding is conducted according to the welding process specification. The welding process of the step (4) is characterized in that the requirements of the welding process comprise the steps that (a) the protective gas is the mixed gas of argon and oxygen, wherein at room temperature, the argon is 98% in volume, and the O2, namely the oxygen is 2% in volume; (b) it is guaranteed that the droplet transition is the one-pulse-one-droplet pulse jet flow transition in the welding process. According to the technical scheme, the pulsed tungsten argon arc welding method has the advantages that the welding spatter is small, bond area performance is improved, appearance of weld forms well, all position welding are applicable, and current range is wide.

Owner:SUZHOU JIEDERUI PRECISION MACHINERY

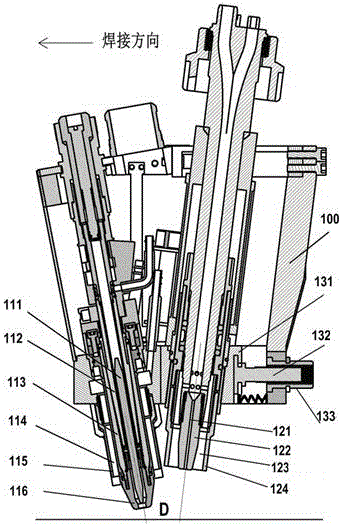

Double heat source hybrid welding torch and welding method

PendingCN106624402ASimplify the build processImprove deposition efficiencyWelding apparatusStable statePower flow

The invention provides a double heat source hybrid welding torch and a welding method. The double heat source hybrid welding torch comprises a consumable electrode and a non-consumable electrode, an acute angle is formed between respective axes of the electrodes, the acute angle is less than 60 degrees, an electric arc is built between the non-consumable electrode and a workpiece and between the consumable electrode and the workpiece, a common melting pool is formed, the distance between electric arc impact points of the two electric arcs on the plane of the workpiece is D, and stable state of the electric arcs is realized by virtue of an adjusting device used for adjusting the distance between the two electrodes and a magnetic shielding part used for applying a transverse magnetic field between the two electrodes. According to the double heat source hybrid welding torch, the influence of an electromagnetic force on the electric arcs can be reduced by virtue of the adjusting device according to parameter conditions of welding operation regardless of the direction and magnitude of an arc current, and the influence of an MIG (Metal-Inert Gas) electric arc on a plasma electric arc is practically reduced, wherein operation for adjusting the distance between the two electrodes by virtue of the adjusting device is more convenient, and effect is more direct.

Owner:王长春

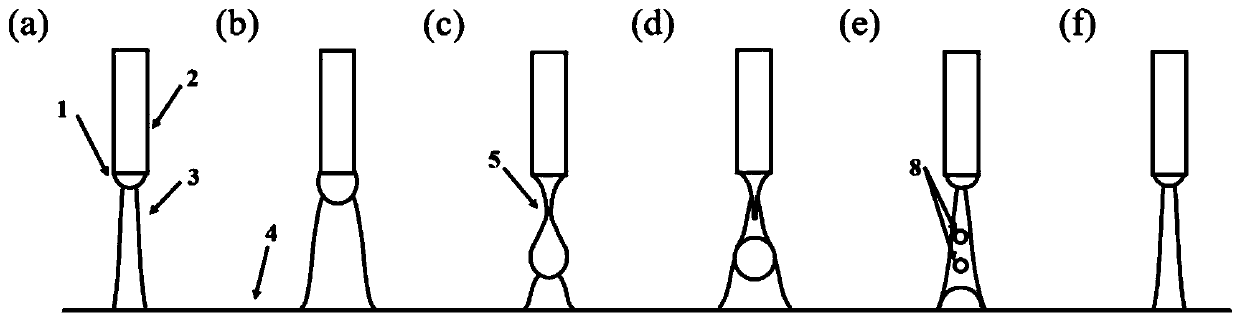

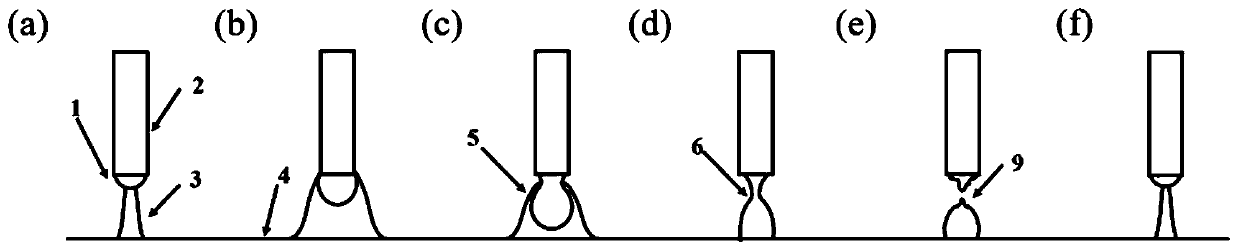

Welding waveform control method for gas metal arc welding of nickel-based alloy

The invention discloses a welding waveform control method for gas metal arc welding of a nickel-based alloy. The method comprises the following steps: a basic value stage: setting a basic valve voltage, a basic valve current and a duration t1; an earlier stage of a pulse stage: setting a first voltage, a first current and a duration t2; a later stage of the pulse stage: setting a second voltage, asecond current and a duration t3; finish of the pulse stage: setting a basic value voltage, a basic value current and a duration t4; a short-circuit current inhibiting stage: setting a third voltage,a third current and a duration 5; and an arcing stage: setting an arcing voltage, an arcing current and a duration t6. The method can solve the problem that it is difficult for P-GMAW globular transfer and it is difficult to pave a molten bath and also can overcome the defect that the side wall is not fused and the root is not penetrated incompletely. The method is favorable for all-position welding and is automatically, and is relatively high in deposition efficiency.

Owner:SHANGHAI JIAO TONG UNIV

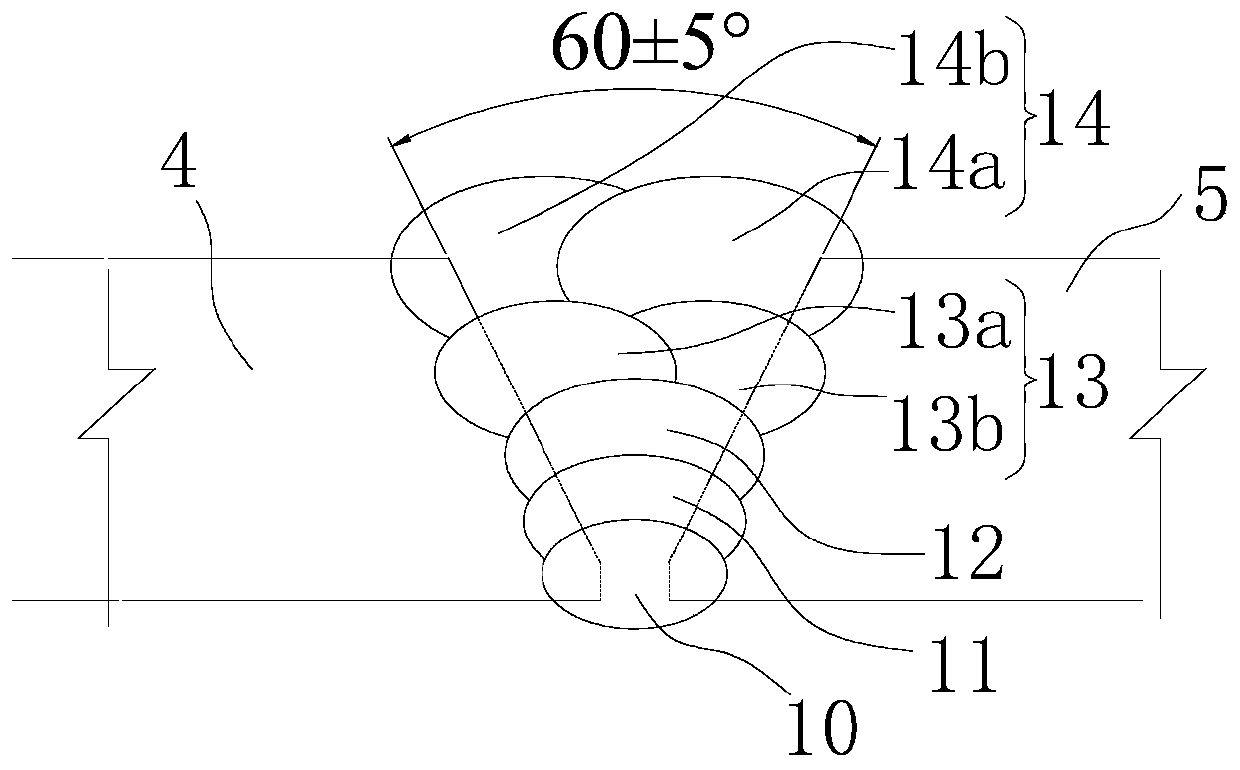

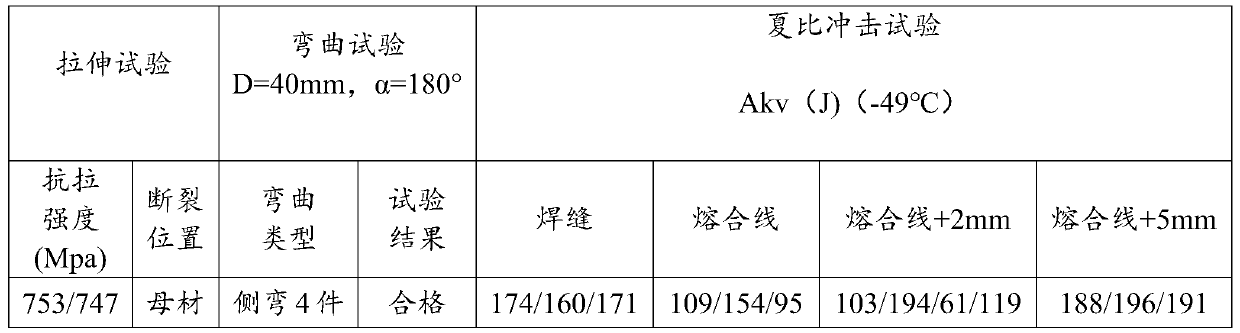

MIG welding solid-core welding wire for high-manganese austenite low-temperature steel and welding process of MIG welding solid-core welding wire

PendingCN114289929AReduce surface tensionRealize all position weldingArc welding apparatusWelding/cutting media/materialsManganeseUltimate tensile strength

The invention relates to an MIG welding solid-core welding wire for high-manganese austenite low-temperature steel and a welding process of the MIG welding solid-core welding wire. According to the technical scheme, the MIG welding solid-core welding wire for the high-manganese austenite low-temperature steel comprises the following chemical components: 0.20-0.60 wt% of C; si is less than or equal to 0.05 wt%; the content of Mn is 20-32 wt%; the content of Ni is 0.1 to 2 weight percent; the content of Cr is 0.1 to 1.8 wt%; the content of Cu is 0.55 to 1.00 wt%; the content of W is 0.5 to 1.9 weight percent; the content of Mo is 1.3 to 3.0 wt%; the content of Al is 0.5 to 2 weight percent; nb + V + Ti + B + RE < = 0.5 wt%; p < = 0.002 wt%; s < = 0.001 wt%; and the balance of Fe and inevitable impurities. Full-automatic and all-position welding can be achieved, the welding efficiency is high, forming is good, and the mechanical property is excellent; the strength of weld metal formed through inert gas protection is matched with that of high-manganese austenite low-temperature steel, the forming performance is good, the low-temperature toughness is excellent, and the technical requirements for the strength and ultralow-temperature toughness of the LNG storage tank at the working temperature of-196 DEG C can be met.

Owner:WUHAN UNIV OF SCI & TECH

TIP TIG welding process of duplex stainless steel

InactiveCN110497068AQuality improvementImprove efficiencyArc welding apparatusWelding/soldering/cutting articlesFriction weldingThermal deformation

The invention provides a TIP TIG welding process of the duplex stainless steel. The TIP TIG welding process comprises the following steps of 1, preparation of welding material and formulation of welding process, 2, welding groove machining, 3, pre-welding preparation. 4, welding of duplex stainless steel, and 5, weld joint detection. According to the TIP TIG welding process , by means of the semi-automatic TIP TIG welding process, the problems that the existing duplex stainless steel manual GTAW welding speed is low, the welding efficiency is low, and the submerged-arc welding SAW welding position is limited are solved, the welding quality can be guaranteed, the welding efficiency can be improved, and semi-automatic full-position welding in the duplex stainless steel high-quality, high-efficiency, full-working-condition and full-thickness range is realized; the welding quality is ensured, the welding current is reduced, the welding heat input is reduced, the heat affected zone is reduced, the welding thermal deformation is low, the surface forming of the weld joint is good, and the operation controllability is high; and the welding efficiency is improved, and the full-position welding of the duplex stainless steel can be realized in a workshop or a field construction site.

Owner:ZHONGHAI FULU HEAVY IND CO LTD

All-position welding machine

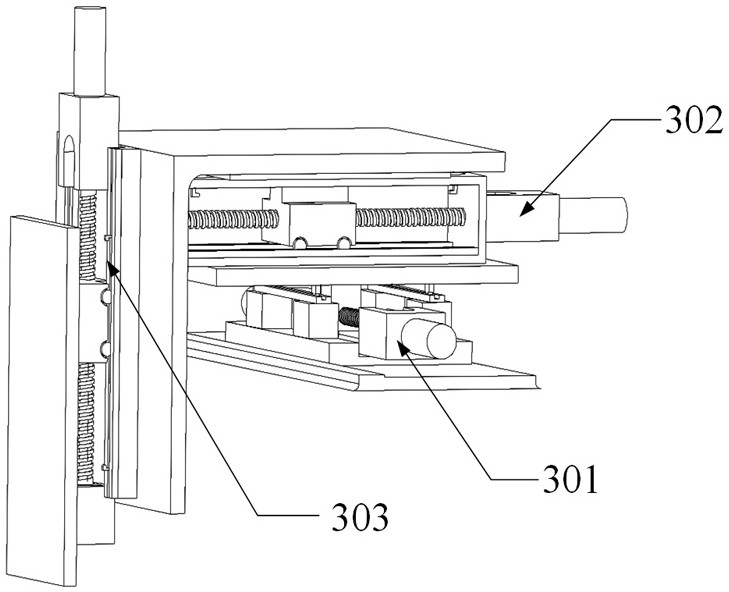

InactiveCN106216902AAll position fastAll position welding fastWelding/cutting auxillary devicesAuxillary welding devicesLinear motionEngineering

The invention discloses an all-position welding machine. A travelling drive unit basal plate is laterally suspended at one side of a rack guide rail through a guide wheel set and a traveling gear; a motion shaft of a first linear motion unit is fixedly arranged on the basal plate; a motion shaft of a second linear motion unit is fixedly arranged on a slide part of the first linear motion unit; a first welding gun is fixedly arranged on a slide part of the second linear motion unit through a first welding gun fixing part; a motion shaft of the first linear motion unit is perpendicular to the motion shaft of the second linear motion unit; a first angle swing shaft drive unit is fixedly arranged on the motion shaft of the second linear motion unit; the output shaft of the first angle swing shaft drive unit is connected with the first welding gun fixing part; and an output shaft of the travelling drive unit is connected with a wheel shaft of the travelling gear. The all-position welding machine effectively solves the technical problem that an existing all-position welding machine for rotary body parts is low in welding efficiency, so that all-position, quick and accurate welding for the rotary body parts is realized, and therefore, welding working efficiency is improved.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

High-nitrogen manual arc welding electrode suitable for high-nitrogen armor steel welding

ActiveCN110181198AHigh strengthImprove purityWelding/cutting media/materialsSoldering mediaImpurityLithium fluoride

The invention relates to a high-nitrogen manual arc welding electrode (hereinafter referred to as welding electrode) suitable for high-nitrogen armor steel welding. According to the technical scheme,the welding electrode comprises a steel core and a coating, wherein the steel core accounts for 70 wt%-90 wt% of the welding electrode and the coating accounts for 10 wt%-30 wt% of the welding electrode. The steel core comprises chemical components as follows: 0.01 wt%-0.06 wt% of C, 0.05 wt%-0.20 wt% of Si, 19.0 wt%-22.0 wt% of Cr, 22.0 wt%-24.0 wt% of Mn, 1.00 wt%-2.00 wt% of Mo, 0.50 wt%-0.90 wt% of N, less than or equal to 0.002 wt% of P, less than or equal to 0.003 wt% of S and the balance Fe and inevitable impurities. The coating comprises chemical components as follows: 25 wt%-28 wt% ofmarble, 17 wt%-20 wt% of fluorite, 3 wt%-5 wt% of lithium fluoride, 40 wt%-45 wt% of manganese nitride, 4 wt%-6 wt% of nickel powder, 2.5 wt%-4.5 wt% of molybdenum powder and the balance iron powder,and 10 wt%-15 wt% of binder is added during preparation of the coating. Weld metal formed by the welding electrode during high-nitrogen armor steel welding has high strength, plasticity and toughnessand can meet technical requirements of a new generation of armored equipment.

Owner:WUHAN UNIV OF SCI & TECH

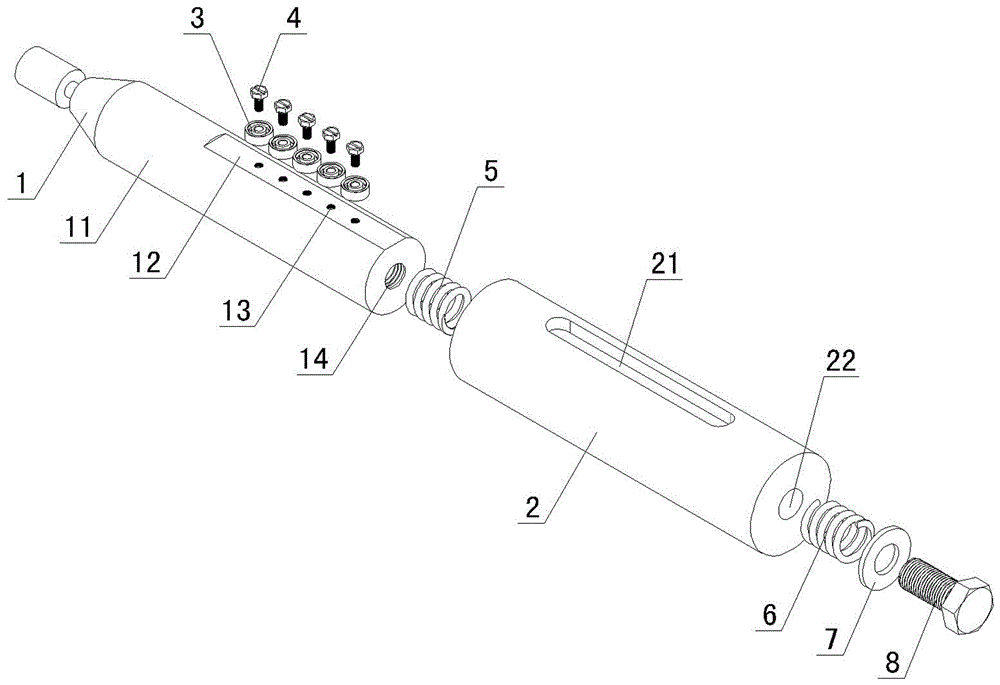

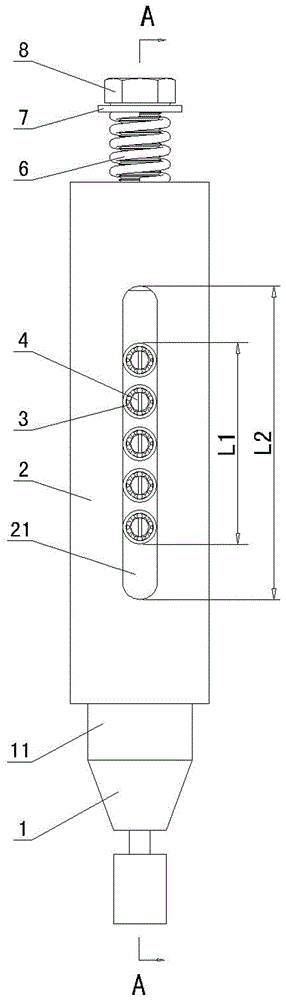

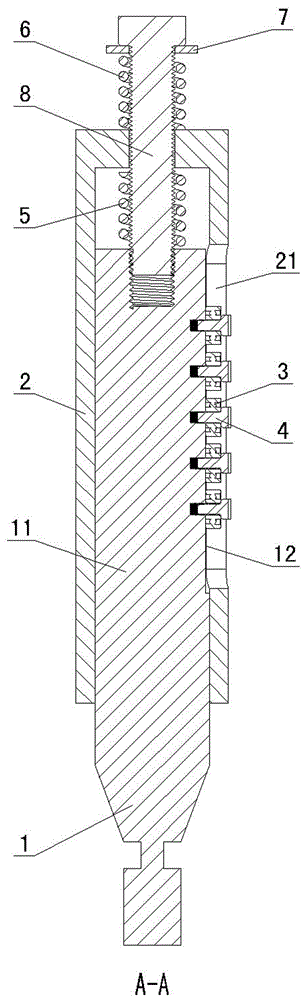

Floating double-shaft shoulder friction stir welding tool and method for space welding

ActiveCN106624340AEasy to slideReduce frictionNon-electric welding apparatusRolling-element bearingEngineering

The invention discloses a floating double-shaft shoulder friction stir welding tool and a method for space welding. The tool comprises a stirring head and a sleeve; at least two rolling bearings are arranged on a connecting shaft of the stirring head; each rolling bearing is connected with the connecting shaft of the stirring head through a locking bolt; U-shaped grooves in clearance fit connection with the rolling bearings are axially formed in the side wall of the sleeve; the length L2 of the U-shaped grooves is larger than the positioning distance L1 of the rolling bearings; an adjusting bolt in threaded connection with the connecting shaft of the stirring head is inserted in the top center of the sleeve; the adjusting bolt is sleeved with a first limiting spring and a second limiting spring; the first limiting spring is positioned in the sleeve; the second limiting spring is positioned out of the sleeve; and the adjusting bolt is screwed to change relative positions of the connecting shaft of the stirring head and the sleeve so as to realize adjustment of the pressing degree of the first limiting spring and the second limiting spring. The tool is simple and reliable in structure, easy to manufacture and excellent in use effect, and can effectively realize floating welding and space all-position welding.

Owner:CHINA-UKRAINE INST OF WELDING GUANGDONG ACAD OF SCI

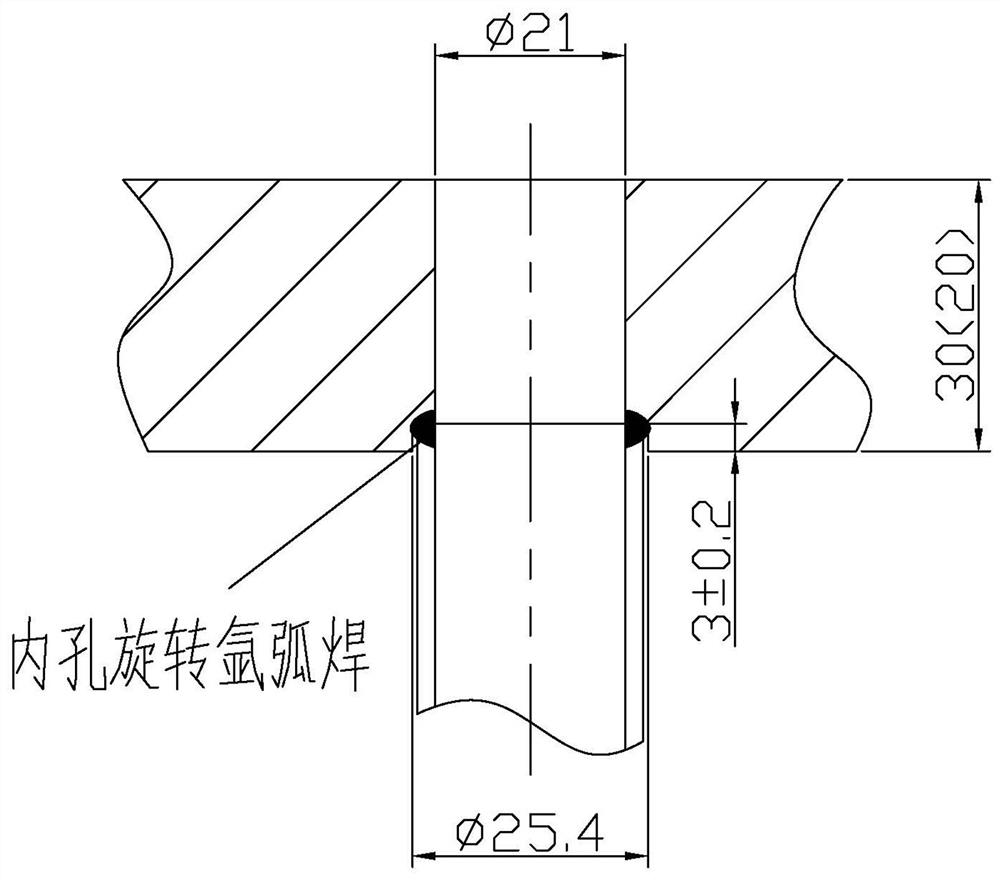

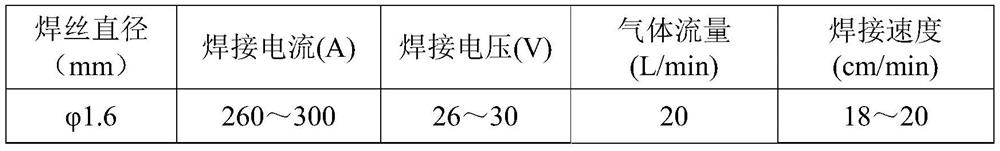

Inner hole rotary argon arc welding gun head of pipe and pipe plate and welding method

PendingCN113102870AImprove insulation performanceAccelerated corrosionSupport devices with shieldingPipe fittingShielding gas

The invention discloses an inner hole rotary argon arc welding gun head of a pipe and a pipe plate and a welding method, and relates to the field of welding of heat exchanger pipe fittings and pipe plates. The gun head is mainly composed of a conductive mandrel, a tungsten electrode, an upper positioning insulation sleeve, a lower positioning insulation sleeve and an adjustable nut, the upper positioning insulation sleeve sleeves the upper part of the exterior of the conductive mandrel, the upper part of the upper positioning insulation sleeve is integrally connected with an annular plate for hanging and fixing the whole gun head, the adjustable nut is in threaded connection with the exterior of the upper positioning insulation sleeve, and a protective gas hole is formed in the conductive mandrel. An inlet of the protective gas hole is formed in the axial direction of the conductive mandrel, an outlet is located in the lower portion of the conductive mandrel and extends to the outer side of the conductive mandrel in the radial direction, the tungsten electrode is located below the protective gas hole, the lower positioning insulation sleeve further sleeves the bottom of the conductive mandrel, and a compression screw is further arranged on the bottom face of the conductive mandrel. An argon protective sleeve is further adopted during welding. According to the inner hole rotary argon arc welding gun head and the welding method, the stress corrosion resistance and crevice corrosion resistance stability of a connector are improved, and the safe use performance of equipment is improved.

Owner:SHANXI FENGXI CHEM EQUIP

Flux-cored wire for 9Ni steel gas shielded welding and welding metal

InactiveCN105643137AReliable welding qualityNarrow down the brittle transition temperature rangeWelding/cutting media/materialsSoldering mediaWeld seamSodium carbonate

The invention discloses a flux-cored wire for 9Ni steel gas shielded welding and welding metal. The flux-cored wire is composed of a metal skin and inner powder. The powder comprises, by weight, 5-25% of molybdenum powder, 5-20% of ferrochromium, 0.50-10.0% of ferromanganese powder, 1.0-10% of ferrotitanium powder, 1.0-10% of potassium fluoride, 0.2-1.5% of sodium carbonate, 0.1-1.5% of potassium oxide, and the balance other alloy. The welding metal prepared by Ar+CO2 mixed shielding gas shielded welding and used for a welding connector comprises 0-0.05% of C, 0.05-0.25% of Si, 1.0-3.5% of Mn, 0-0.008% of P, 0-0.005% of S, 5-15% of Cr, 5-20% of Mo, 5-12% of Fe, 0-0.01% of Nb, and the balance Ni. The tensile strength of the welding metal is greater than or equal to 700 MPa, and the impact toughness of the welding metal at minus 196 DEG C is greater than or equal to 100J.

Owner:HAINING RUIAO METAL TECH CO LTD

High-nitrogen metal powder core flux-cored wire applicable to high-nitrogen armor steel welding

ActiveCN110181197AAvoid deformation hardeningQuality improvementWelding/cutting media/materialsSoldering mediaRare earthChromium nitride

The invention relates to a high-nitrogen metal powder core flux-cored wire applicable to high-nitrogen armor steel welding. According to the technical scheme, the high-nitrogen metal powder core flux-cored wire is composed of a steel band and flux core powder, wherein the steel band and the flux core powder account for 60 to 70 wt% and 30 to 40 wt% of the high-nitrogen metal powder core flux-coredwire in sequence. The steel band is composed of the following chemical components: 0.01 to 0.05 wt% of C, 0.05 to 1.00 wt% of Si, 2.00 to 15.00 wt% of Mn, 14.00 to 17.00 wt% of Cr, less than or equalto 0.002 wt% of P, less than or equal to 0.03 wt% of S and the balance of Fe and unavoidable impurities. The flux core powder is composed of the following chemical components: 0.5 to 1.2 wt% of lithium fluoride, 0.5 to 1.0 wt% of rare earth fluoride, 25 to 30 wt% of chromium nitride, 43 to 48 wt% of manganese powder, 12 to 17 wt% of nickel powder, 8 to 12 wt% of molybdenum powder and the balanceof iron powder. When the high-nitrogen metal powder core flux-cored wire is used, electric arc is stable, the molding performance is good and all-direction welding can be realized; and weld metal forthe high-nitrogen armor steel welding has high strength and high plasticity and toughness and meets the technical requirements of new-generation armored equipment.

Owner:WUHAN UNIV OF SCI & TECH

Gas metal arc welding flux-cored wire used for ultralow-temperature high-manganese steel

InactiveCN112894199AAchieve strength requirementsExcellent ultra-low temperature toughnessWelding/cutting media/materialsSoldering mediaIron powderManganese

The invention relates to a gas metal arc welding flux-cored wire used for ultralow-temperature high-manganese steel. According to the technical scheme, the gas metal arc welding flux-cored wire used for the ultralow-temperature high-manganese steel is composed of 65-70 wt% of a steel strip and 30-35 wt% of flux core powder; the steel strip comprises the following chemical components: 0.10-0.20 wt% of C, 0.01-0.05 wt% of Si, 3-7 wt% of Mn, less than or equal to 0.002 wt% of P, less than or equal to 0.001 wt% of S, and the balance Fe and inevitable impurities; and the flux core powder comprises the following chemical components: 28-34 wt% of rutile, 2-4 wt% of zircon sand, 2-4 wt% of potassium titanate, 20-25 wt% of electrolytic manganese, 8-15 wt% of nickel powder, 8-12 wt% of high-carbon ferro-chrome, and the balance iron powder. According to the gas metal arc welding flux-cored wire used for the ultralow-temperature high-manganese steel, all-position welding can be achieved, and the welding efficiency is high; and formed weld metal is good in forming, low in pore sensitivity and excellent in low-temperature toughness, and the strength matches that of the ultralow-temperature high-manganese steel.

Owner:浙江鸿途焊接科技有限公司 +2

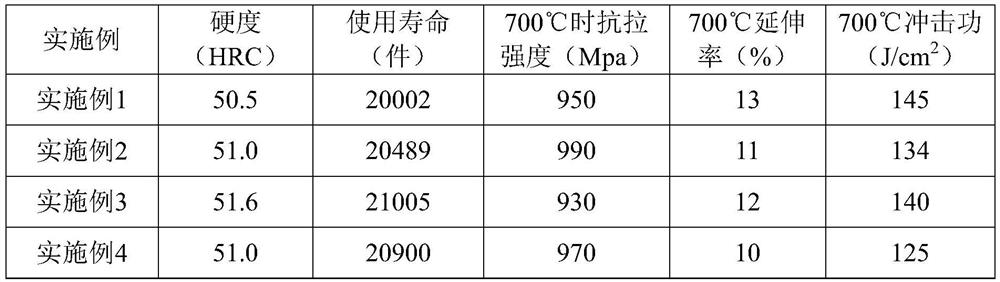

Flux-cored wire for repairing hot forging die and using method of flux-cored wire

ActiveCN113210930AGood wear hardnessGood high temperature strength and toughnessArc welding apparatusWelding/cutting media/materialsAlloy elementSodium fluoride

The invention provides a flux-cored wire for repairing a hot forging die and a using method of the flux-cored wire. The flux-cored wire comprises an alloy steel strip outer skin and flux-cored powder; the alloy steel strip outer skin is prepared from the components including, by mass, 0.20%-0.29% of C, 0.60%-0.70% of Si, 0.5%-0.8% of Mn, less than or equal to 0.01% of S, less than or equal to 0.015% of P, 12%-13% of Cr, 2%-3% of Ni, 4.0%-4.9% of Mo, 0.3%-0.5% of V and the balance Fe; the flux core powder is prepared from the components including, by mass, 55%-60% of rutile, 3%-5% of sodium fluoride, 1%-2% of magnetite, 3%-5% of potassium cryolite, 5%-8% of zircon sand, 4%-7% of potassium titanate, 2%-3% of cerium oxide and the balance Fe. According to the flux-cored wire, main alloy elements are transited through the alloy steel strip outer skin, the transition rate of the alloy elements is increased, so that surfacing metal has good abrasion resistance and impact toughness, and the service life of the hot forging die is prolonged.

Owner:泰安市瑞朗科技有限公司 +1

Direct current welding current adjusting method

InactiveCN104607763AAvoid imbalancePrecise adjustment of welding timeArc welding apparatusPower flowTransformer

The invention discloses a direct current motor improvement method. According to the method, an existing alternating current motor serves as a cylinder, four diodes are additionally arranged on the alternating current motor and are arranged on an aluminum plate to form a single-phase bridge circuit, then the output end of an alternating current welding machine is connected to the input of the bridge circuit, alternation is conducted through the diodes, and breakover is achieved so as to achieve improvement of the alternating current motor. When the electrowelding transformer current is transmitted in from 380 / 220v, the transmitting-out end of an electrowelding transformer is connected to 75 v, and it is presumed that a point A is positive, point A-D1-RL-direct current electric reactor-direct current diverter-D3-75v-negtive electrode is achieved; otherwise, when a point O is positive, O-D2-RL-direct current electric reactor-direct current diverter-D4-point A is achieved, meanwhile the alternating current conducts alternating breakover till ending according to the variable quantity of 50 HZ per second, and thus smooth and steady direct current is shifted in and output.

Owner:陈进

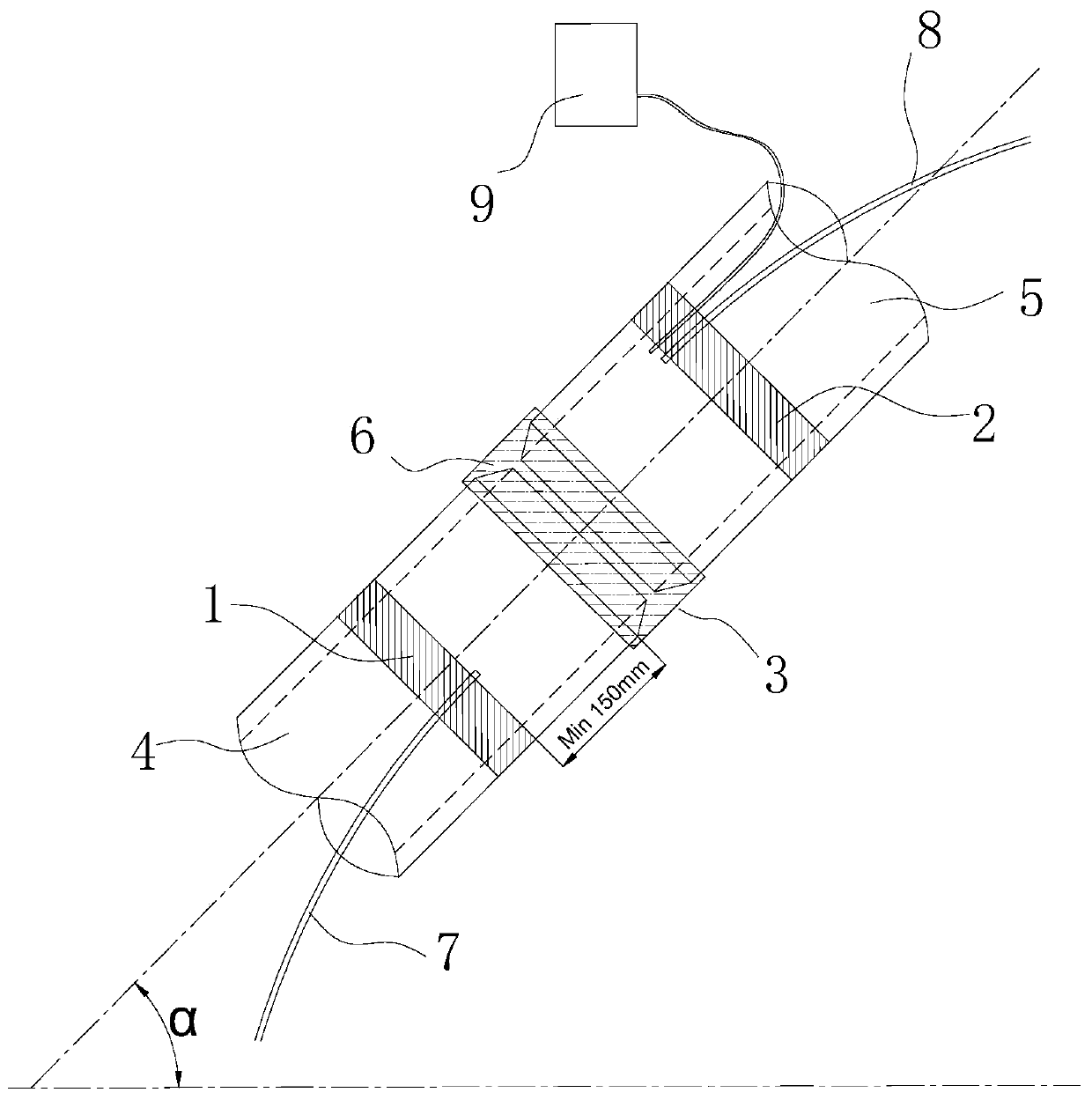

Construction method for all-position automatic welding of hydropower-station super-size pressure steel tube

InactiveCN107252949AReduce labor intensityRealize all position weldingArc welding apparatusFriction weldingButt welding

The invention discloses a construction method for all-position automatic welding of a hydropower-station super-size pressure steel tube. The construction method comprises the following steps that a round steel tube is assembled by steel tube tiles; positioned welding is conducted on the back joint of a steel tube welded joint; cleaning and polishing are conducted on a welded joint groove; weld preheating is conducted; a flexible railway is absorbed on steel tubes along a to-be-welded welded joint; a welding tractor conducts welding while walking on the flexible railway, automatic welding is conducted by the welding tractor through solid core wires, and meanwhile a rich-chlorine gas protective measure is arranged; ribbed ring lobe pieces are welded to the two ends of the steel tube; the steel tube is transported to a previous steel tube, and girth welding is conducted on the two steel tubes; and butt welding of ribbed rings are conducted. According to the construction method for all-position automatic welding of the hydropower-station super-size pressure steel tube, the flexible railway is adopted so that the welding tractor can freely crawl along the surface of the pressure steel tube, thus all-position welding is achieved, the labor intensity of workers is greatly relieved, and the welding efficiency is improved; and the welding tractor automatically completes welding in the whole process, so that the welding quality is stable and reliable.

Owner:CHINA GEZHOUBA GRP MECHANICAL & ELECTRICAL CONSTR

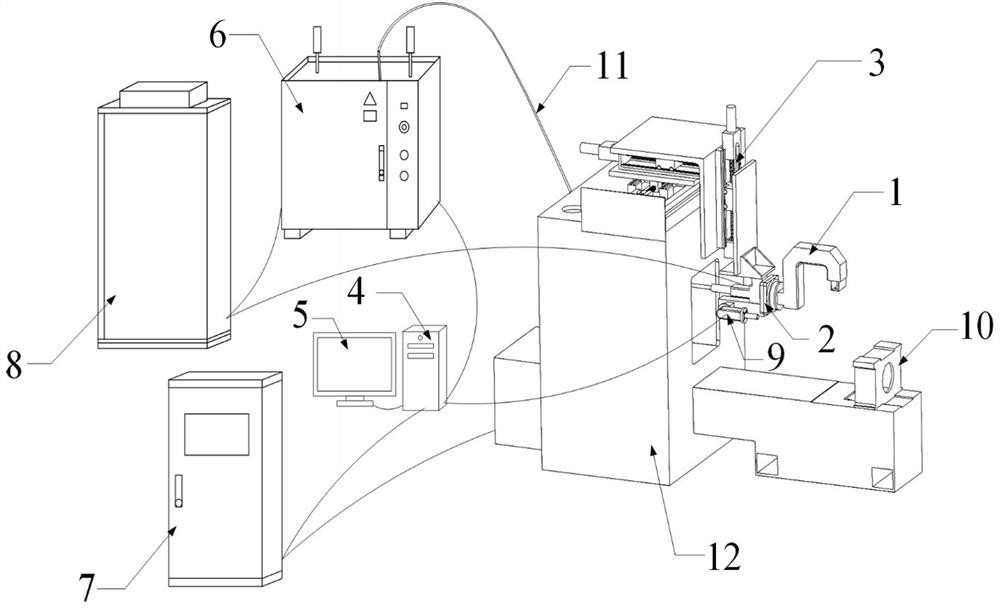

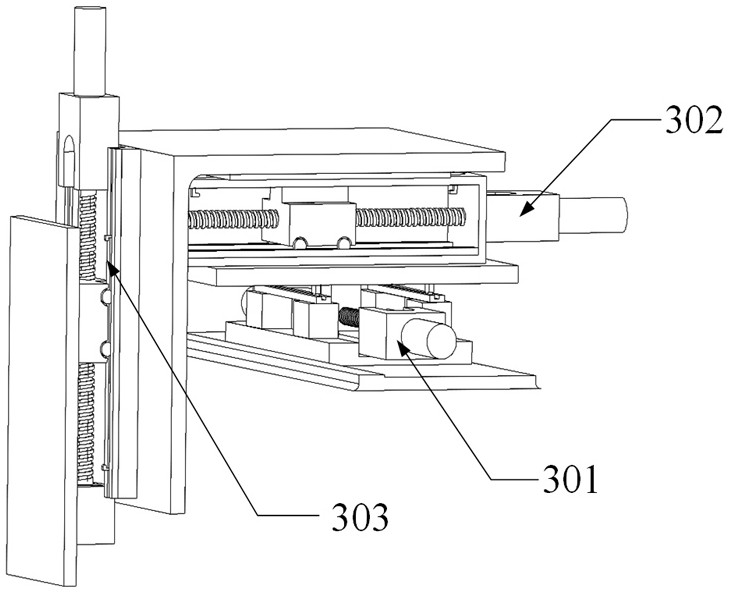

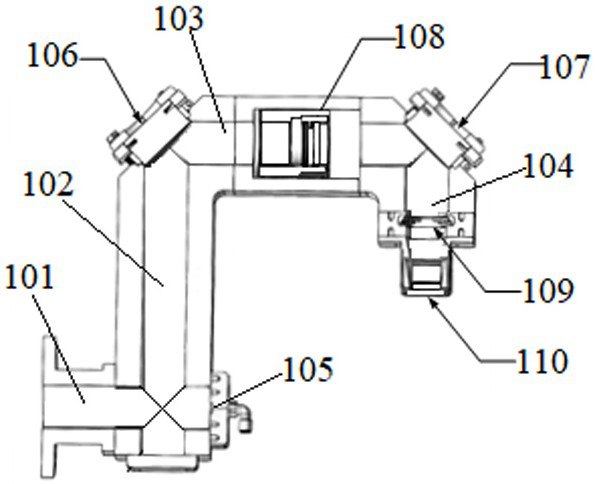

A kind of all-position laser welding system and welding method

ActiveCN114101908BRealize all position butt weldingAdjustable angleWelding/cutting auxillary devicesAuxillary welding devicesLaser transmitterRotational axis

The invention belongs to the technical field of laser welding, and in particular relates to an all-position laser welding system and a welding method, comprising a control system connected with a laser welding head, a tooling platform for carrying welding parts, and a laser transmitter for providing welding energy for the laser welding head ; The incident end is installed on the rotating part of the rotating disk. By setting the incident end on the rotating part of the rotating disk, the laser welding head can be driven by the rotating disk, and when the laser beam is emitted, the laser beam emitted by the laser welding head can rotate ±450 degrees around the rotation axis of the rotating disk , to realize all-position butt welding of thin-walled tubes with a diameter of 5-12 mm; the present invention installs the rotary disk on a position that can drive the laser welding head to perform linear motion on the x-axis, y-axis and z-axis of the three-dimensional coordinate system The moving assembly can adjust the position of the laser welding head, so that the rotation axis of the laser welding head can be on the same line as the axis of the welded pipe.

Owner:SOUTHWEST JIAOTONG UNIV

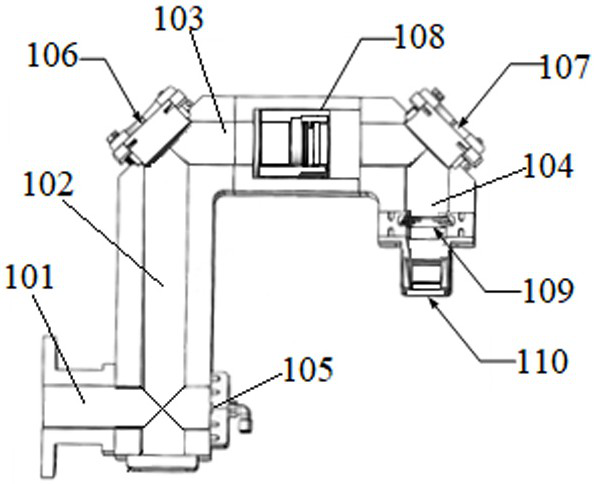

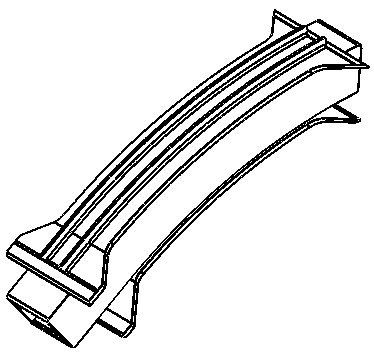

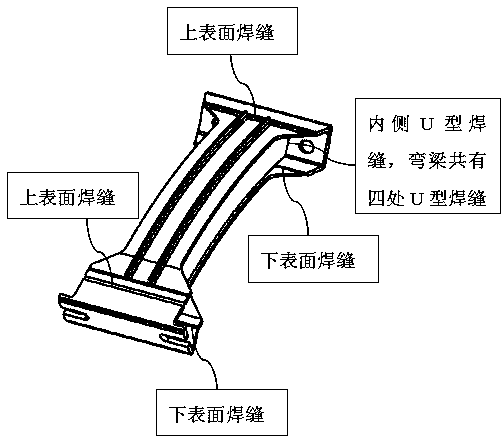

Camber beam installing and welding tool for equipment cabin and welding method thereof

PendingCN109366075AImprove versatilityRealize changing at any timeWelding/cutting auxillary devicesAuxillary welding devicesSoftware engineeringCopying

The invention belongs to the technical field of trains and discloses a camber beam installing and welding tool for an equipment cabin and a welding method thereof. The camber beam installing and welding tool comprises a bracket with a supporting leg and a copying module arranged above the bracket to accommodate a camber beam. The radian of the upper surface of the copying module is matched with the bending radian of the camber beam. A supporting mechanism which can be inserted into the supporting leg of the bracket to enable the copying module to be in different angle states is arranged on theperipheral surface of the copying module. According to the installing and welding tool, the copying module and the bracket are designed in detachable connection, so that the copying module can be replaced anytime. A proper copying module can be mounted to the bracket according to the model specification of the camber beam, so that the universality of the tool is improved. Meanwhile, the copying module is adjusted at different angles for welding by arranging the supporting mechanism, so that the welding precision is controlled favorably.

Owner:ZHUZHOU LINCE GRP +1

All-position laser welding system and welding method

ActiveCN114101908AAvoid monotonyAvoid pitsWelding/cutting auxillary devicesAuxillary welding devicesLaser solderingThin walled

The invention belongs to the technical field of laser welding, and particularly relates to an all-position laser welding system and welding method.The all-position laser welding system comprises a control system connected with a laser welding head, a tool platform for bearing a welding piece and a laser transmitter for providing energy for welding for the laser welding head; and the incident end is mounted on the rotating part of the rotating disc. The incident end is arranged on the rotating part of the rotating disc; the laser welding head can be driven by the rotating disc, when laser beams are emitted, the laser beams emitted by the laser welding head can rotate by + / -450 degrees around a rotating shaft of the rotating disc, and all-position butt welding of the thin-walled pipe with the diameter being 5-12 mm is achieved. The rotating disc is installed on the moving assembly capable of driving the laser welding head to do linear motion on the x axis, the y axis and the z axis of the three-dimensional coordinate system, so that the moving assembly adjusts the position of the laser welding head, and the rotating axis of the laser welding head and the axis of the pipeline to be welded can be located on the same straight line.

Owner:SOUTHWEST JIAOTONG UNIV

Gas-shielded flux-cored welding wire for arc welding

InactiveCN103962746BReduce slag contentRealize all position weldingArc welding apparatusWelding/cutting media/materialsHydrogen contentMaterials science

Owner:GUANGDONG PROVINCIAL INST OF WELDING TECH GUANGDONG PROVINCIAL ACADEMY OF UKRAINE

A metal powder-cored flux-cored welding wire for x80 low-alloy high-strength pipeline steel welding

ActiveCN104259687BLow diffusible hydrogen contentImprove deposition efficiencyArc welding apparatusWelding/cutting media/materialsRare earthFerrosilicon

The invention discloses a metal powder-cored flux-cored welding wire for X80 low-alloy high-strength pipeline steel welding, which is composed of a carbon steel strip and a metal powder core. , nickel powder, ferromolybdenum, ferroboron, magnesium powder, rare earth fluoride and the balance of iron powder. The present invention is characterized by adopting Ni-Mo-Ti-B alloy system, which is used for root welding, filling and capping welding of X80 low-alloy high-strength pipeline steel, and is especially recommended for root welding, with fast melting speed and good deposition High efficiency, all-position welding can be realized, the content of diffusible hydrogen is extremely low, and KV2 (‑45°C) is greater than 100J.

Owner:TIANJIN YONGCHANG WELDING WIRES

A manual arc welding electrode for welding low-nitrogen and non-magnetic naval steel

ActiveCN112404794BGood welding performanceImprove purityWelding/cutting media/materialsSoldering mediaIron powderManganese

The invention relates to a manual arc welding electrode used for welding low-nitrogen and nonmagnetic naval steel. The technical solution is: the manual arc welding electrode is composed of 70-80wt% high-alloy steel core and 20-30wt% coating; the preparation method is to add water glass to the chemical components of the coating, stir, press It is produced by coating on the surface of high alloy steel core. Composition and mass content of high alloy steel core: C is 0.03-0.05%, Si is 0.2-0.4%, Cr is 23-25%, Mn is 8-10%, Ni is 17-20%, N is 0.25% ~0.45%, P≤0.006%, S≤0.003%, the balance is Fe and unavoidable impurities. The composition and mass content of the coating: 45-47% for marble, 20-23% for fluorite, 3-5% for lithium fluoride, 2-4% for quartz sand, 10-12% for rutile, nitrided Manganese is 6-8%, and the rest is iron powder. The welding seam metal formed by welding the low-nitrogen non-magnetic naval steel provided by the invention has the advantages of non-magnetism, high strength, good ductility and seawater corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Spot welding workstation for automobile welding

InactiveCN108856967ASuitable for flexible production needsLow costWelding accessoriesEngineeringWorkstation

The invention discloses a spot welding workstation for automobile welding. The spot welding workstation comprises a special spot welding machine and a protective structure surrounding the special spotwelding machine, wherein the special spot welding machine comprises a transverse delivery rail, a walking platform arranged on the transverse delivery rail and a lifting guide rail arranged on the walking platform, wherein the lifting guide rail is provided with a longitudinal delivery rail, the end of the longitudinal delivery rail is provided with the spot welding machine capable of longitudinally moving, the longitudinal delivery rail is provided with a weld gun rotating mechanism for driving the spot welding machine to rotate, the outer side of the transverse delivery rail is provided with two transversely arranged clamp racks, the clamp racks are detachably provided with clamp devices, positioning mechanisms for locking the clamp devices and the clamp racks are arranged between the clamp devices and the clamp racks, and a grinding machine is arranged between the two clamp racks. The spot welding workstation for automobile welding makes clamp switching convenient, is high in welding efficiency, make weld gun operation easy and flexible, can achieve full-position welding and is suitable for the flexible production demands of various parts of automobiles.

Owner:广州德恒汽车装备科技有限公司

A special ultra-low hydrogen electrode for welding e911 steel high-pressure steam pipelines and its preparation method

ActiveCN112475665BEasy to operateWeld firmlyWelding/cutting media/materialsSoldering mediaManganeseFerrosilicon

A special ultra-low hydrogen electrode for welding E911 steel high-pressure steam pipelines and a preparation method thereof. The invention belongs to the technical field of welding materials. The purpose of the invention is to ensure the uniform distribution of alloy elements in the welding seam of the E911 steel high-pressure steam pipeline, and to ensure the stability of the mechanical properties of long-term operation. The electrode of the present invention is prepared from a welding core and a coating, the coating is formed by mixing coating powder and potassium sodium water glass, and the coating powder is composed of 20 to 40 parts of calcite, carbonic acid 2-10 parts of barium, 17-28 parts of fluorite, 1-8 parts of quartz, 1-7 parts of rutile, 0.5-2 parts of soda ash, 1-6 parts of ferrosilicon, 1-5 parts of electrolytic manganese, 0.5-5 parts of metal chromium powder 5 parts, 0.5-4 parts of medium-carbon ferrochromium, 0.5-4 parts of metal molybdenum powder, 2-15 parts of iron powder, 0.5-2 parts of aluminum-magnesium alloy, 2-5 parts of metal tungsten and 0.5-3 parts of ferro-titanium boron made. Method: uniformly mix the coating powder with potassium sodium water glass, then press-coat it on the welding core, then dry it at room temperature, dry it at low temperature and dry it at high temperature in sequence to obtain the welding rod.

Owner:HARBIN WELL WELDING CO LTD

A high-toughness titanium-alkaline seamless flux-cored wire suitable for all-position welding

ActiveCN108406159BSimple processImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaCrack resistanceManganese

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com