A high-toughness titanium-alkaline seamless flux-cored wire suitable for all-position welding

A technology of seamless flux-cored welding wire and high toughness, which is applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., which can solve the problem of poor mechanical properties of welded joints in welding quality, inapplicability to all-position welding, and difficulty in obtaining welded joints. It can prevent the molten iron from falling, inhibit the nucleation of proeutectoid ferrite, and promote the formation of acicular ferrite.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

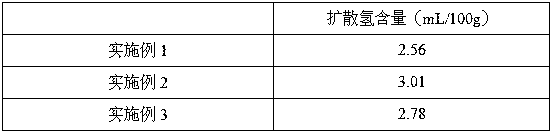

Embodiment 1

[0040] A high-toughness titanium-alkaline seamless flux-cored welding wire suitable for all-position welding. The welding wire is composed of a low-carbon steel strip on the periphery and core powder inside, wherein the core powder accounts for 15% by weight of the total weight of the wire. , The wire diameter is Ф1.2mm.

[0041] The composition of the drug core powder is: rutile: 33%, alumina: 1.5%, dehydrated feldspar: 3.5%, quartz: 2%, zircon sand: 2.5%, rare earth oxide: 1.2%, silicon powder: 14%, Iron boron: 0.2%, nickel powder: 6.5%, metal manganese: 10%, magnesium powder: 7%, the balance is iron powder and unavoidable impurities.

Embodiment 2

[0043] A high-toughness titanium-alkaline seamless flux-cored welding wire suitable for all-position welding. The welding wire is composed of a low-carbon steel strip on the periphery and core powder inside, wherein the core powder accounts for 15% by weight of the total weight of the wire. , The wire diameter is Ф1.0mm.

[0044] The composition of the drug core powder is: rutile: 39%, alumina: 1.5%, dehydrated feldspar: 3%, quartz: 1.5%, zircon sand: 2%, rare earth oxide: 1%, silicon powder: 15%, Iron boron: 0.2%, nickel powder: 6.5%, metal manganese: 8%, magnesium powder: 8%, the balance is iron powder and unavoidable impurities.

Embodiment 3

[0046] A high-toughness titanium-alkaline seamless flux-cored welding wire suitable for all-position welding. The welding wire is composed of a low-carbon steel strip on the periphery and core powder inside, wherein the core powder accounts for 15% by weight of the total weight of the wire. , The wire diameter is Ф1.0mm.

[0047] The composition of the drug core powder is: rutile: 35%, alumina: 1%, dehydrated feldspar: 2.5%, quartz: 2.5%, zircon sand: 2.5%, rare earth oxide: 1%, silicon powder: 16%, Iron boron: 0.2%, nickel powder: 6.5%, metal manganese: 12%, magnesium powder: 6%, the balance is iron powder and unavoidable impurities.

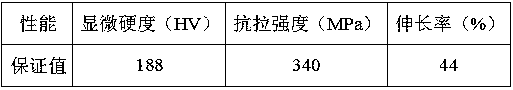

[0048] The manufacturing method of the high-toughness titanium-alkaline seamless flux-cored wire welded in all positions of the present invention is as follows: the outer skin is selected from SPHC steel strip, and the composition and properties are shown in Table 1 and Table 2; the chemical composition and mechanical properties of the welding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com