TIP TIG welding process of duplex stainless steel

A duplex stainless steel, welding process technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of narrow application range of submerged arc welding SAW, slow welding speed, slow wire feeding speed, etc. The effect of improving welding difficulty, reducing welding heat input and reducing welding current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

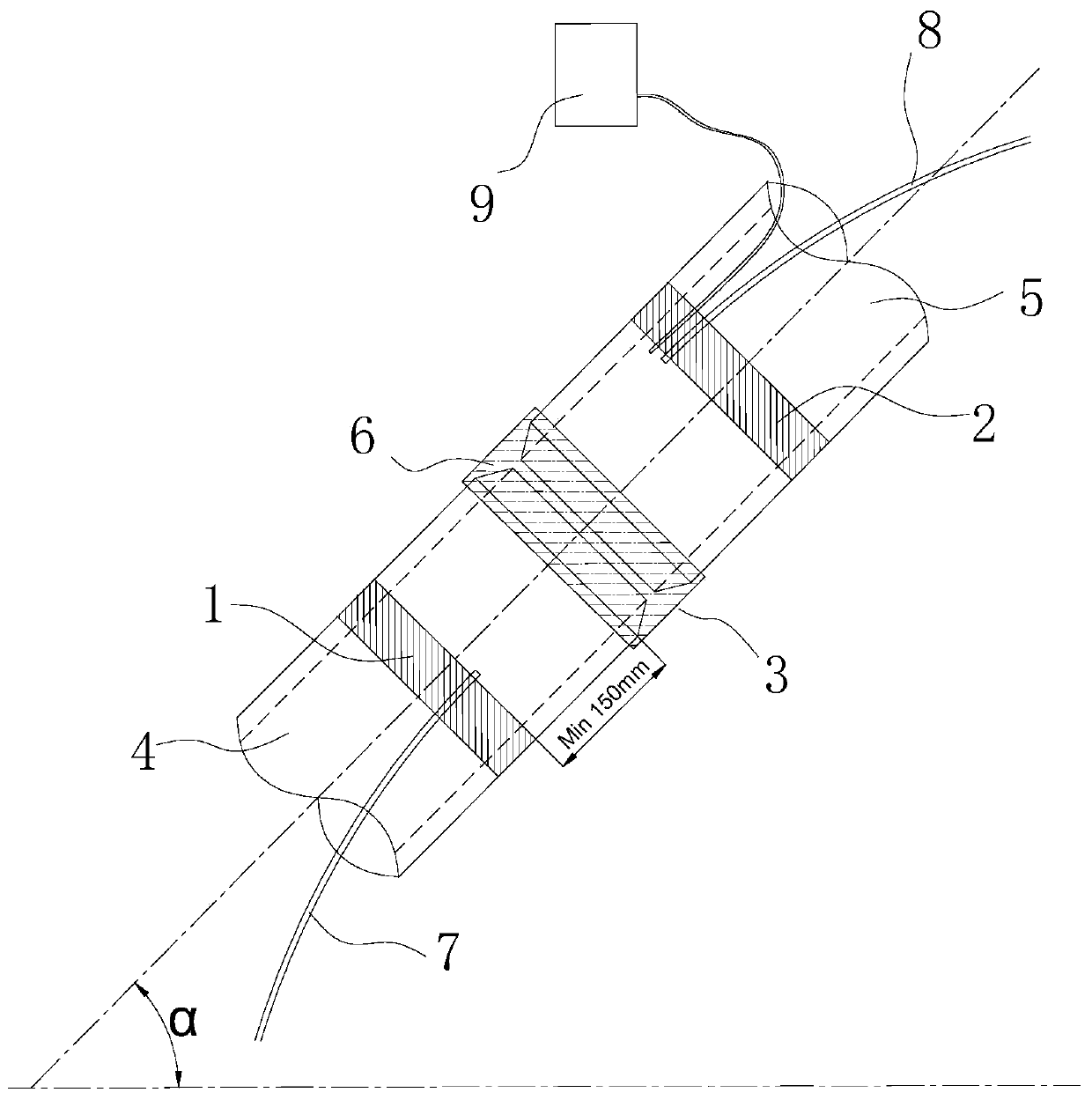

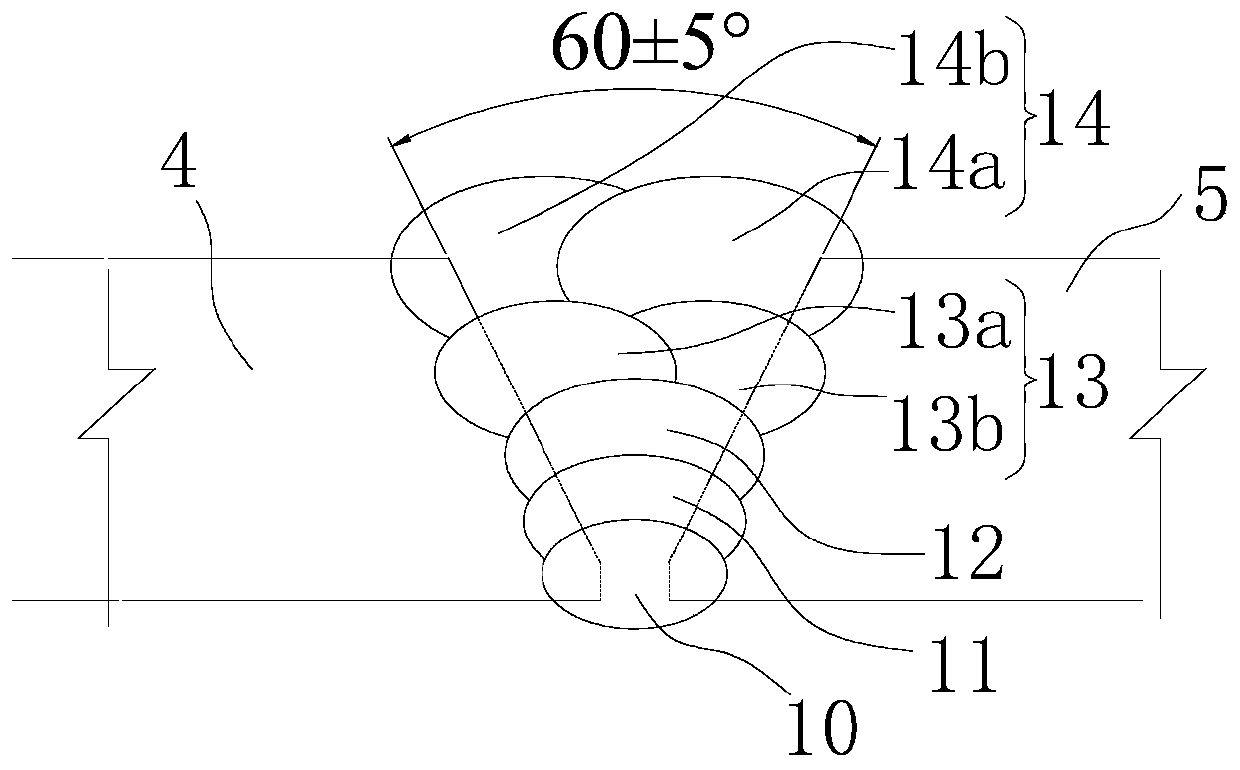

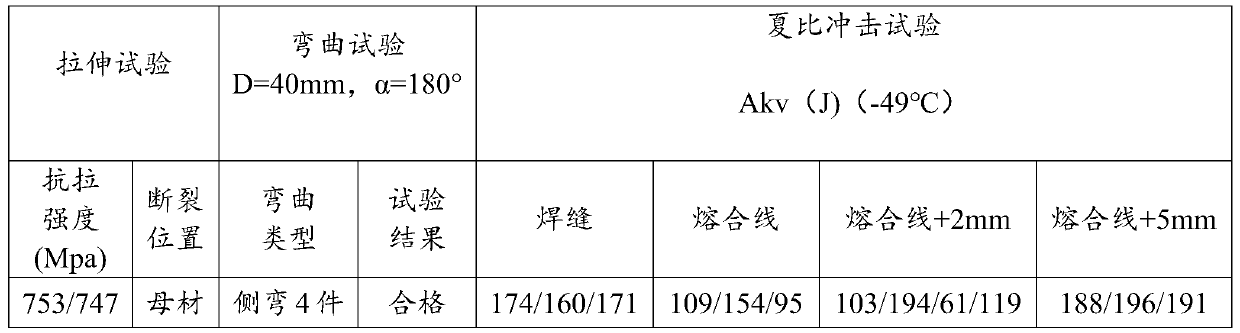

[0079] A kind of TIP TIG welding technique of duplex stainless steel, comprises the following steps:

[0080] 1. Selection of welding materials and formulation of welding process

[0081] (1) Selection of welding materials:

[0082] The duplex stainless steel parent material used in this example is 22Cr-5Ni-3Mo-N stainless steel, with a specification of Φ168mm×10.97mm, and its base material is ASTMA790 UNS S31803;

[0083]Choose AWS A5.9, AWS Classification as ER2209 welding wire, the welding wire grade is Sandvik22.8.3L, and the welding wire specification is Φ1.0mm;

[0084] (2), the choice of welding method:

[0085] The back cover welding process adopts GTAW welding or TIP TIG welding for all-position back cover welding;

[0086] The filling welding process adopts TIP TIG welding for all-position filling welding;

[0087] The cover welding process adopts TIP TIG welding for all-position cover welding;

[0088] (3), welding process parameters:

[0089] The formulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com