Seamless flux cored wire with good vertical position welding manufacturability

A seamless flux-cored welding wire, technological technology, applied in the direction of welding medium, manufacturing tools, welding equipment, etc., can solve the problems of inability to use all-position welding, stress concentration at the welding toe, poor weld bead formation, etc., and achieve mechanical properties Stable, good crack resistance, low diffusible hydrogen effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

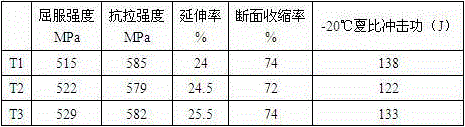

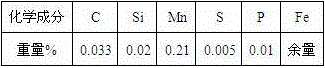

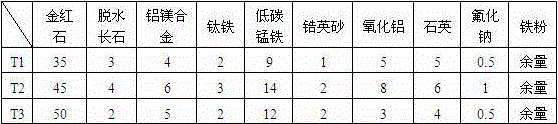

[0024] According to the component content designed in the present invention, 3 kinds of flux-cored powders were prepared, and low-carbon steel strip was used as the wire sheath, and seamless flux-cored wires were prepared according to the preparation process described in the present invention, respectively marked as T1, T2, and T3 , where T1, T3 wire diameter is 1.2mm, T2 diameter is 1.6mm. The specific mass ratio of core powder in each embodiment is shown in Table 1, and the filling rate of welding wire is shown in Table 2. The shielding gas used in welding in each embodiment is carbon dioxide. It should be noted that the present invention is not limited to these embodiments.

[0025] Table 1 Composition (wt%) of the flux core powder of the seamless flux-cored wire of the embodiment of the present invention

[0026]

[0027] In table 1, in the raw material that the present invention adopts, Al, Mg mass ratio is 1:1 in the aluminum-magnesium alloy, Ti, Fe mass ratio is 1:4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com