High-toughness all-austenitic stainless steel welding wire

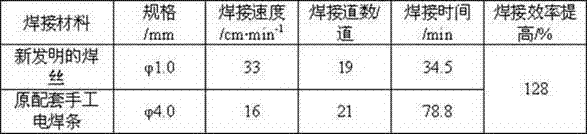

A fully austenitic, high strength and toughness technology, applied in the field of high strength and toughness full austenitic stainless steel welding wire, can solve the problems of low welding efficiency, complex welding process, slag inclusion and pores, etc., to achieve improved welding efficiency, good manufacturability and simplification The effect of the welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

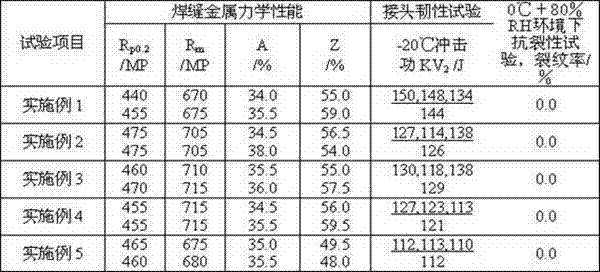

Examples

Embodiment Construction

[0027] The present invention is described in further detail below with examples, but the present invention is not limited to these examples.

[0028]The preparation process of the welding wire used in the example is: batching→induction furnace smelting→electroslag remelting→hot forging→hot rolling→heat treatment→intermediate annealing→pickling→cold drawing→cleaning→packing, wherein the initial forging temperature of the billet hot forging is 1100℃, final forging at 960℃, forging into 50mm billet; hot rolling at 1140℃, final rolling at 1000℃, rolling into 30mm billet through 6 passes, and rolling into φ5. 5mm wire rod; during cold drawing, it needs to go through 4 times of intermediate heat treatment at 900-1000 ℃, 7 times of drawing to form a φ1.0mm finished welding wire, and the surface is cleaned during the last few passes of cold drawing to ensure that the surface of the welding wire is clean.

[0029] The chemical composition of the welding wire used in the example is show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com