Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Low diffusible hydrogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

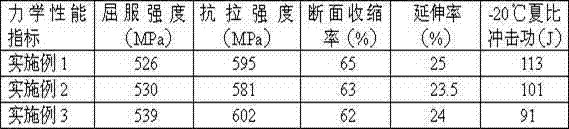

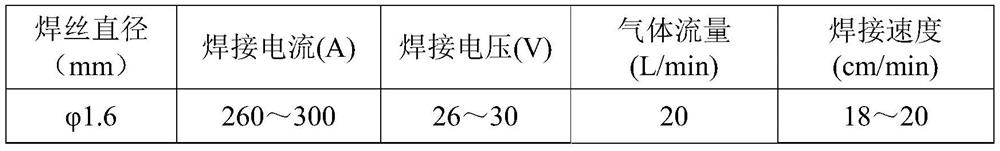

Welding method of high-strength steel for pressure steel pipe of 610MPa hydropower station

InactiveCN102101210AReduce the tendency to produceImprove toughnessArc welding apparatusAluminum silicateStress relief

The invention relates to a welding method of high-strength steel for a pressure steel pipe of a 610MPa hydropower station, belonging to the technical field of steel pipe welding. In the method, a constant-strength low-hydrogen electric welding rod is used for priming, and a constant-strength matched welding rod is adopted to continuously weld and fill a weld pass by adopting a submerged-arc welding method, wherein the welding line energy is strictly controlled to be about 30-40kJ / cm, and the interpass temperature is controlled to be 100-150 DEG C; and after welding, an aluminum silicate plate is used for covering a welding joint for slow cooling so as to realize the welding of a steel plate for a steel pipe for a 610MPa hydropower station without preheating before welding and heat treatment after welding. The method solves the problems that the traditional steel for the pressure steel pipes of the 610MPa hydropower station needs to be preheated before welding and subjected to stress relief heat treatment after welding, and the welding efficiency is low.

Owner:SHOUGANG CORPORATION

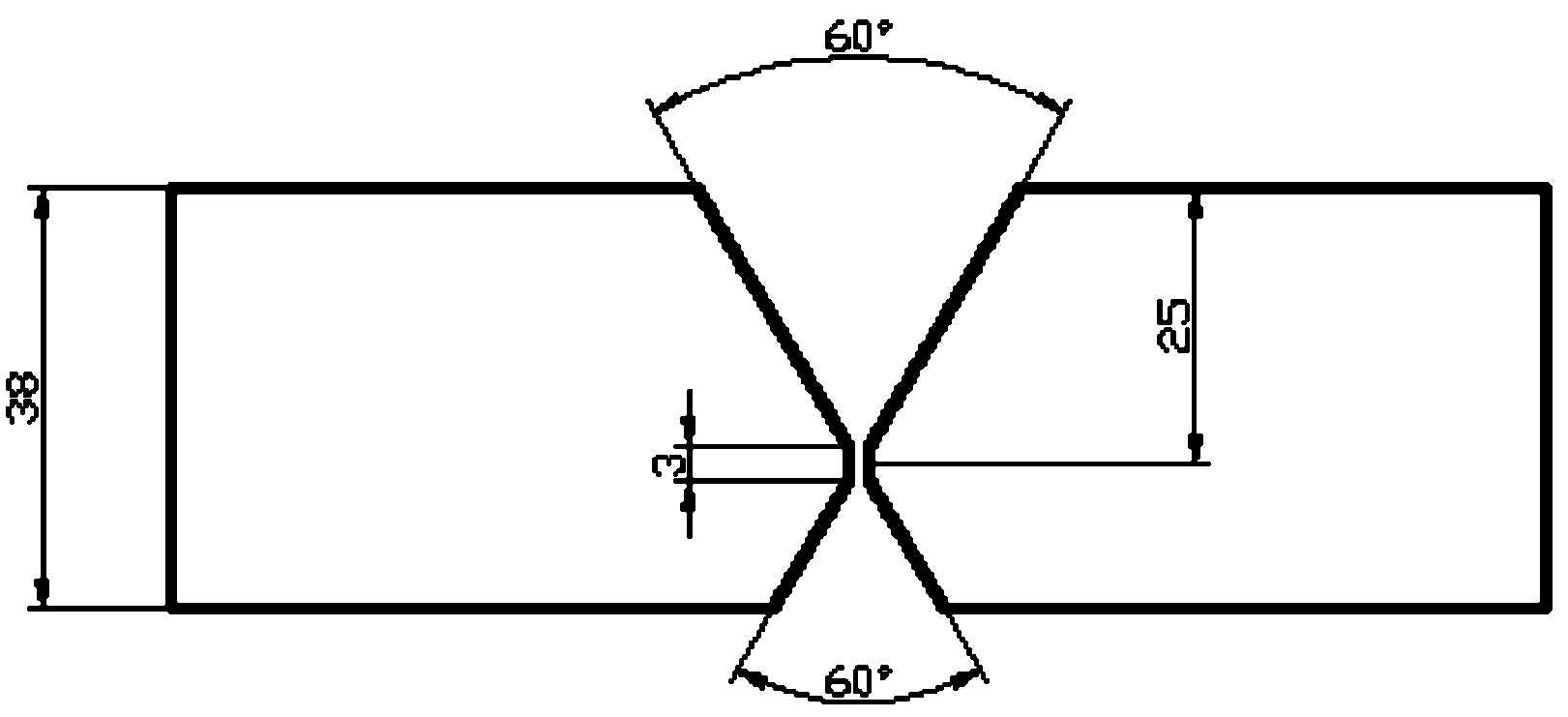

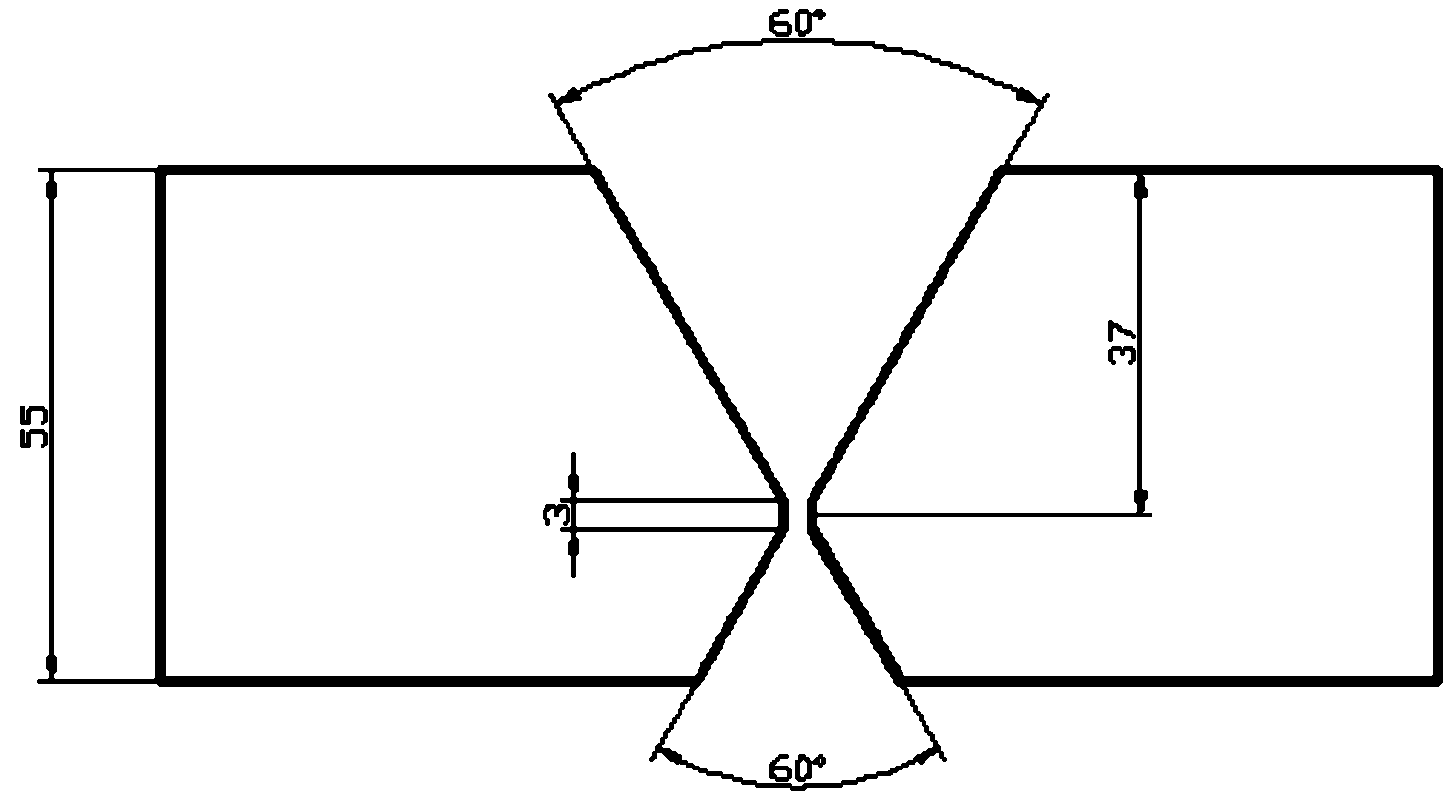

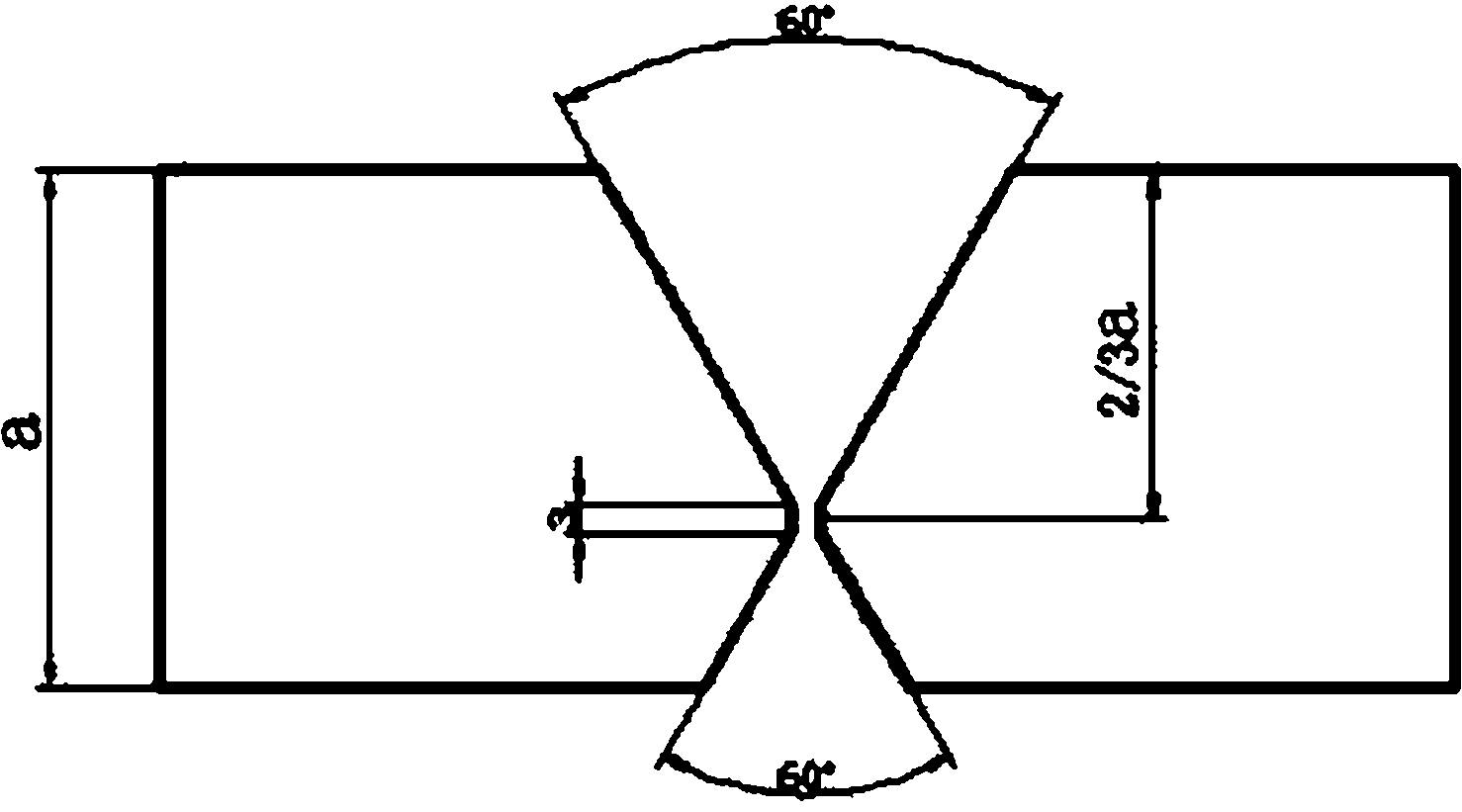

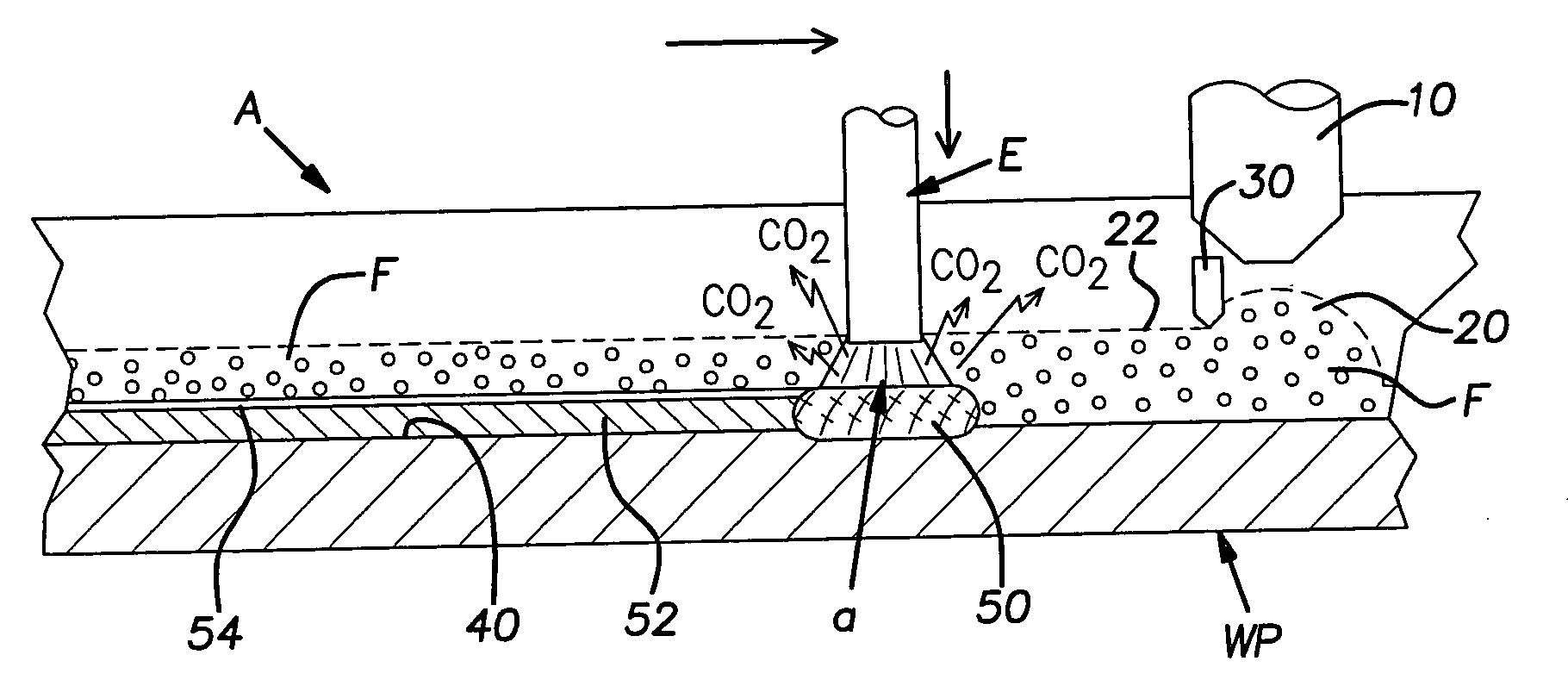

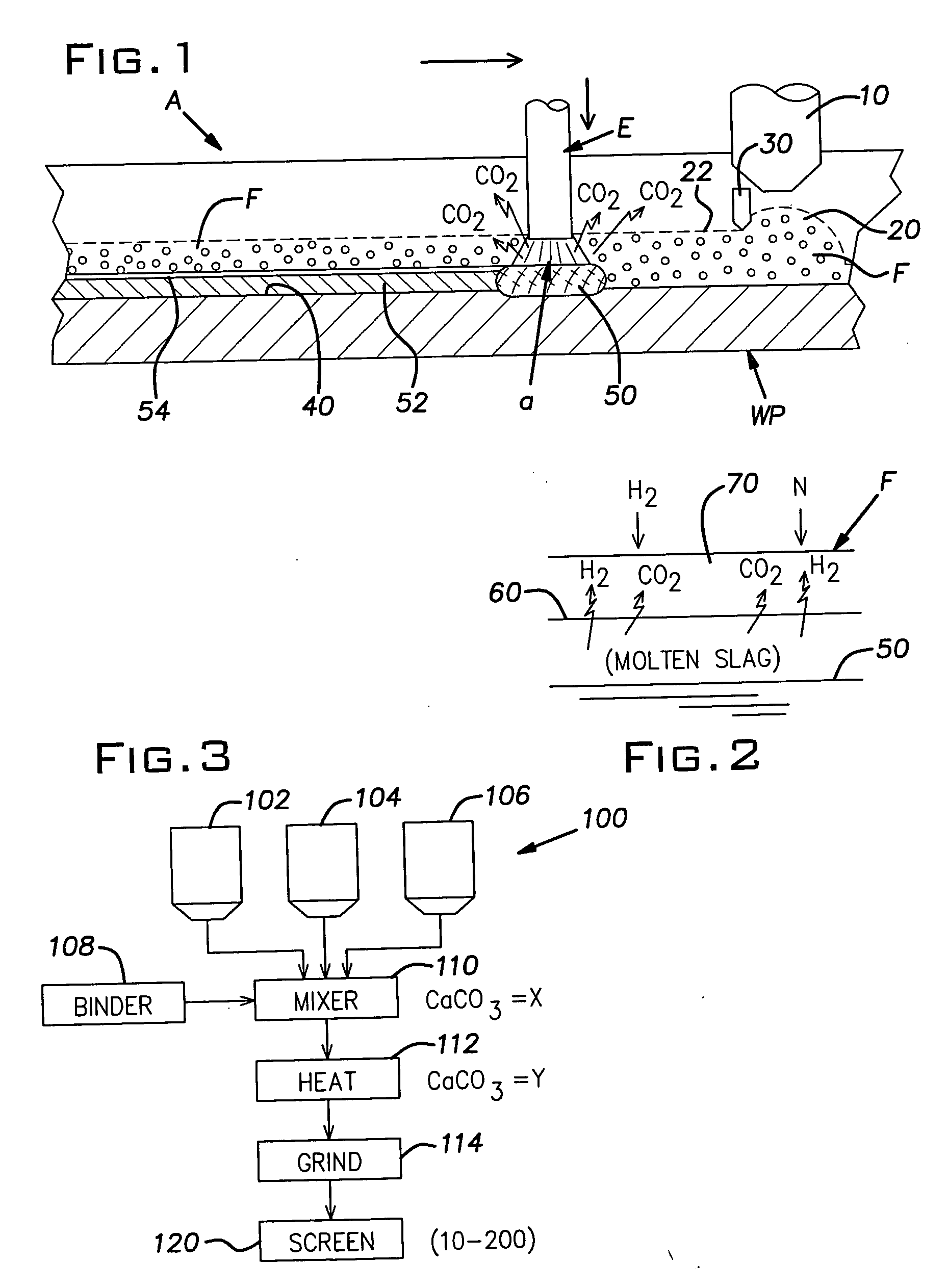

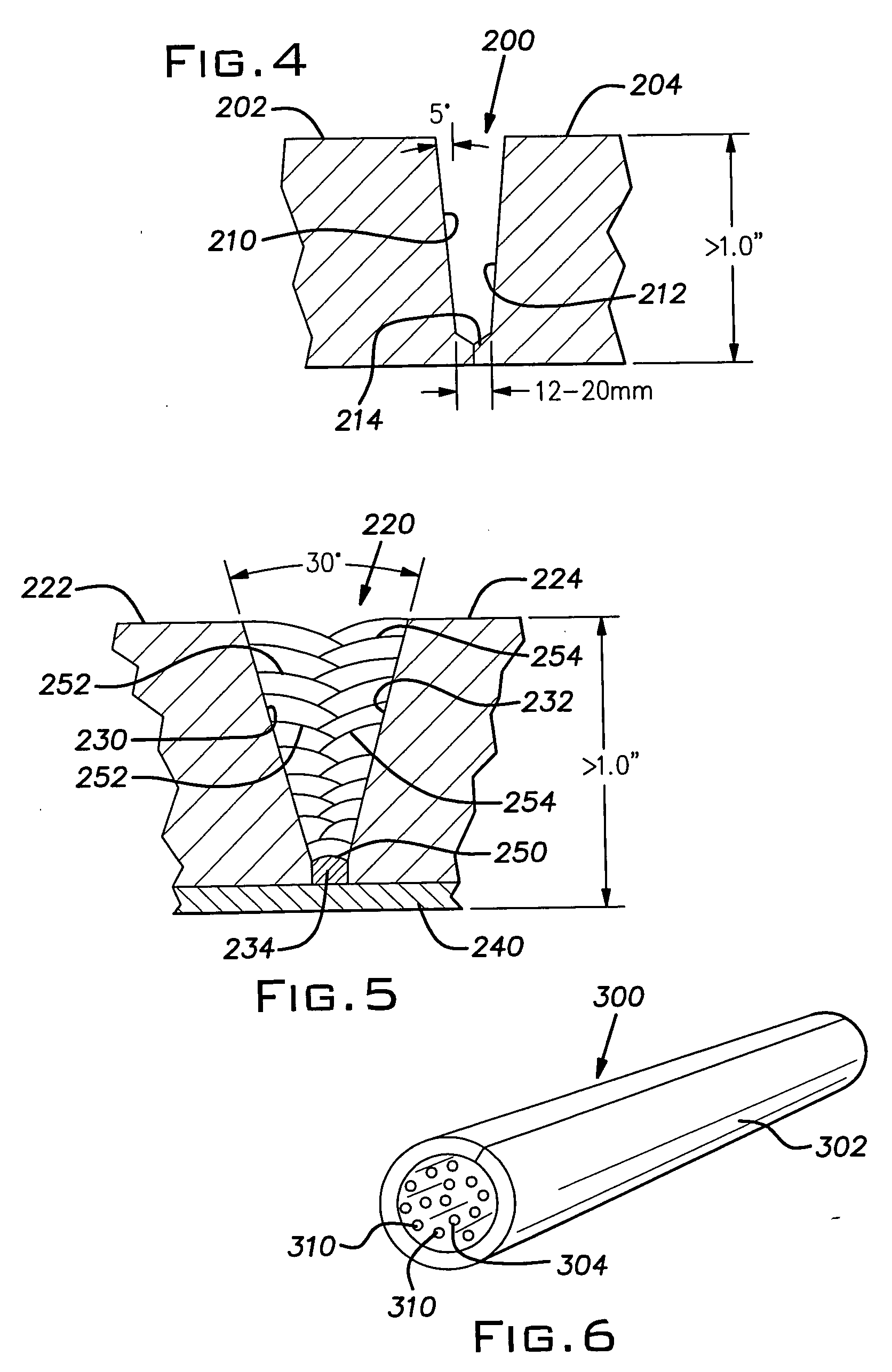

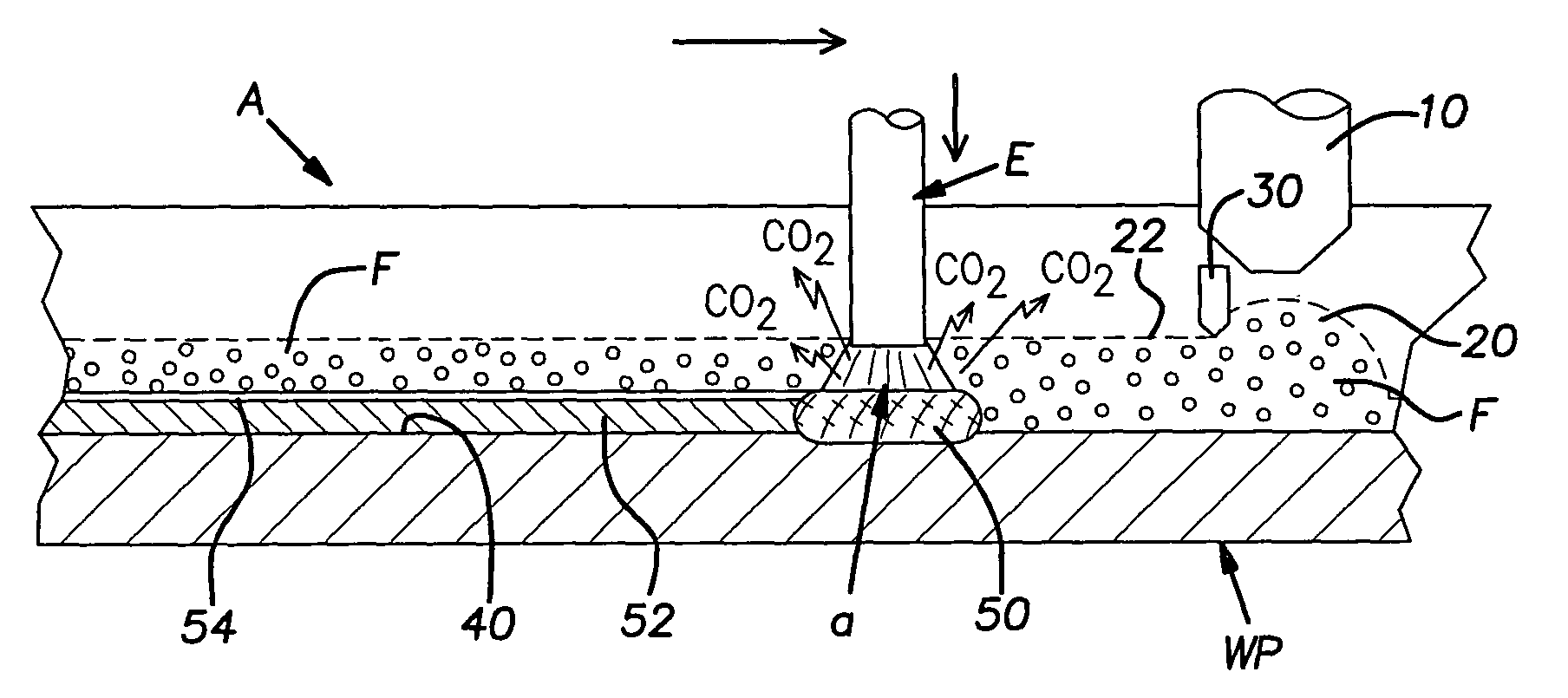

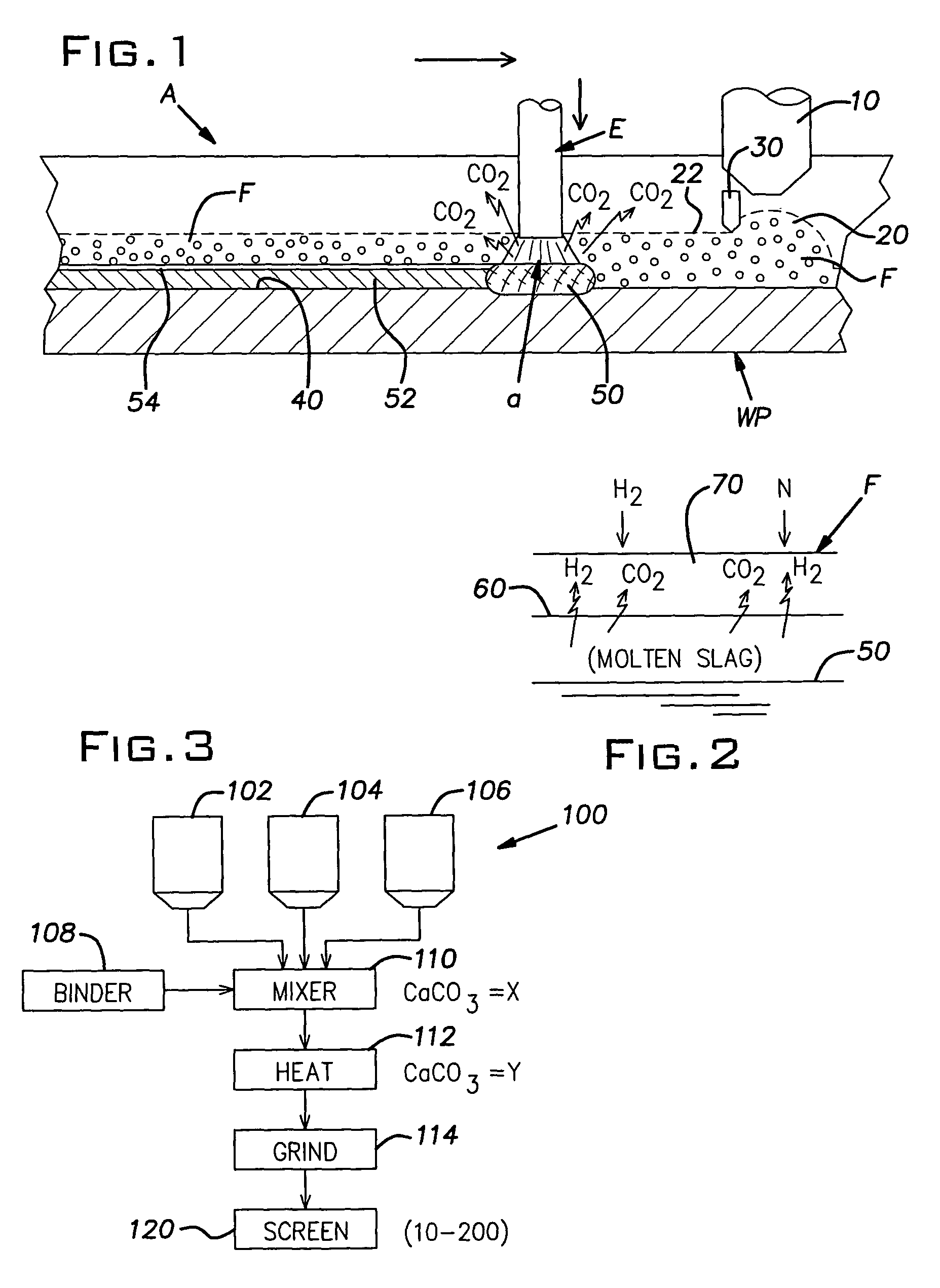

Submerged arc flux

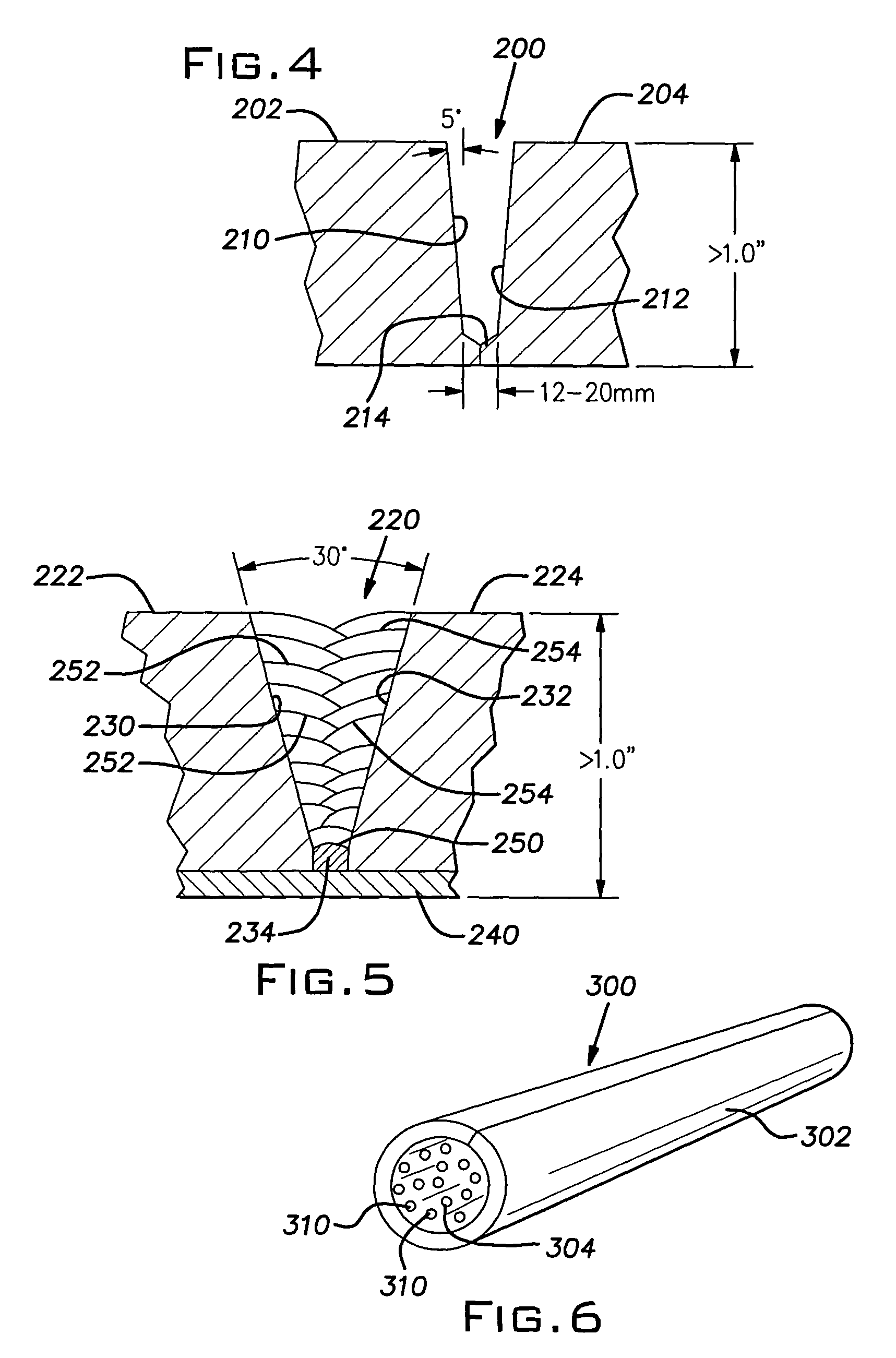

ActiveUS20060272746A1Low costImprove slag removal effectWelding/cutting media/materialsSoldering mediaHydrogenParticle flux

A highly basic particle flux for submerged arc welding that produces less than 7 ml / 100 gr of diffusible hydrogen in the weld metal, which flux comprises a carbon dioxide containing compound with an effective amount of heat releasable carbon dioxide in the range of 0.5-3.5% by weight of the flux over 10% by weight of a low melting point compound and a binder.

Owner:LINCOLN GLOBAL INC

Submerged arc flux

ActiveUS7727339B2Low costImprove slag removal effectWelding/cutting media/materialsSoldering mediaHydrogenParticle flux

Owner:LINCOLN GLOBAL INC

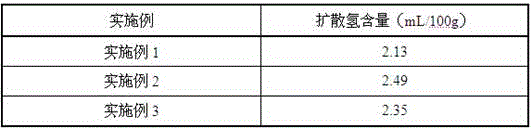

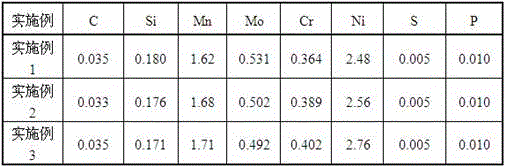

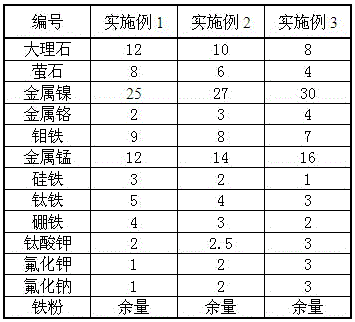

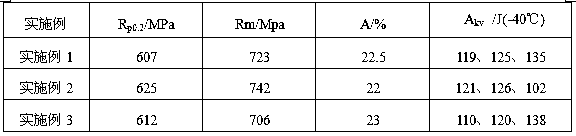

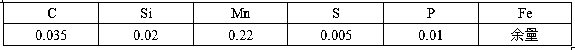

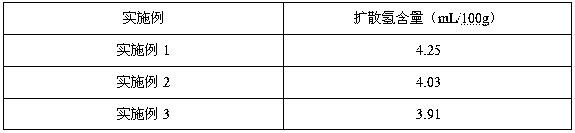

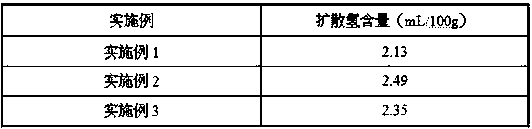

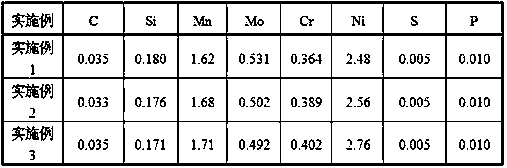

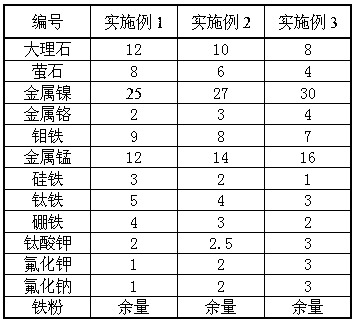

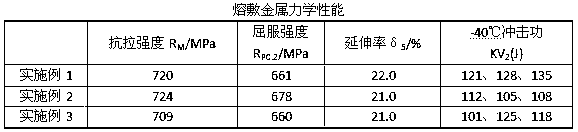

Ultralow hydrogen seamless submerged arc flux-cored wire for steel with yield strength being 690 MPa level

ActiveCN106141500AStrong resistance to moisture absorptionGood workmanshipWelding/cutting media/materialsSoldering mediaPotassium fluorideManganese

The invention discloses an ultralow hydrogen seamless submerged arc flux-cored wire for steel with yield strength being the 690 MPa level. The submerged arc flux-cored wire is composed of a sheath and flux core powder. The sheath is made of a low-carbon steel strip. The flux core powder is prepared from, by mass percent, 8%-12% of marble, 4%-8% of fluorite, 25%-30% of metal nickel, 2%-4% of metal chromium, 7%-9% of ferromolybdenum, 12%-16% of electrolytic manganese, 1%-3% of ferrosilicon, 3%-5% of ferrotitanium, 2%-4% of ferro-boron, 2%-3% of potassium titanate, 1%-3% of potassium fluoride, 1%-3% of sodium fluoride and the balance ferrous powder. The ultralow hydrogen seamless submerged arc flux-cored wire for the steel with the yield strength being the 690 MPa level is high in moisture absorption resisting property, and excellent in processing property of being matched with fluorine and alkali sintered flux SR-SJ613, diffusible hydrogen is extremely low (smaller than or equal to 4 mL / 100 g), minus 40 DEG C charpy impact energy reaches over 100 J, and the wire can be applied to welding of a steel plate with the yield strength being the 690 MPa level in the ocean engineering field.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

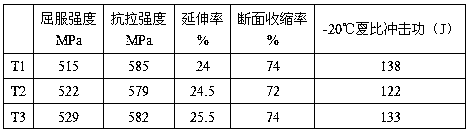

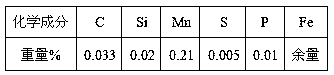

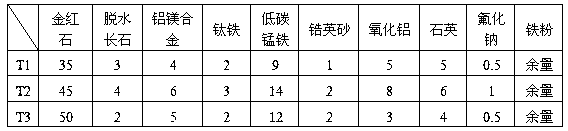

Seamless flux cored wire with good vertical position welding manufacturability

ActiveCN106736049AGood welding wire workmanshipRealize all position weldingWelding/cutting media/materialsSoldering mediaCopper platingMoisture absorption

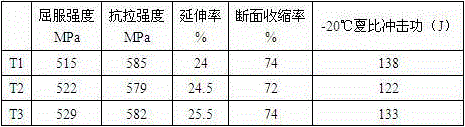

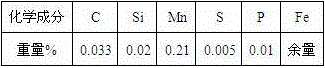

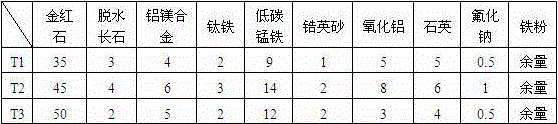

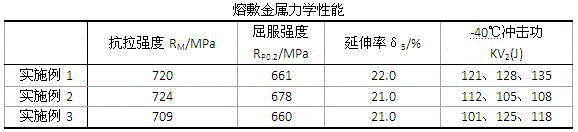

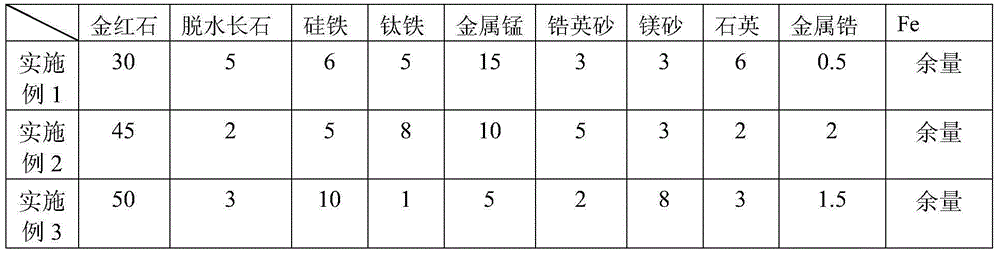

The invention discloses a seamless flux cored wire with good vertical position welding manufacturability, and relates to the field of welding materials. The seamless flux cored wire is composed of low carbon steel outer skin and flux core powder, and the flux core powder is prepared from the mixing of materials, by mass, 35%-50% of rutile, 2%-4% of dehydrated feldspar, 4%-6% of aluminum magnesium alloy, 2%-3% of ferrotitanium, 9%-14% of low carbon ferromanganese, 1%-2% of zircon sand, 3%-8% of aluminum oxide, 4%-6% of quartz, 0.5%-1% of sodium fluoride and the balance iron powder. According to the seamless flux cored wire with the good vertical position welding manufacturability, the flux core powder is added online synchronously, after the flux core powder is added into the outer skin steel belt, the outer skin steel belt is then subjected to rolling forming and welding seaming, and afterwards subjected to annealing, reducing and copper plating so that the seamless flux cored wire can be prepared. The prepared seamless flux cored wire is stable in mechanical property, low in diffusible hydrogen, high in moisture absorption performance, excellent in antirust performance, and good in welding manufacturability; meanwhile, all-position welding can be conducted, the seamless flux cored wire is particularly applicable to welding of position of vertical welding, and can be used for welding of a D36 level steel plate.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Ultra-low hydrogen high-tenacity seamless flux-cored wire for 550 MPa high-strength steel

ActiveCN106078006ALow diffusible hydrogenImprove conductivityWelding/cutting media/materialsWelding/soldering/cutting articlesRare earthFerrosilicon

Disclosed is an ultra-low hydrogen high-tenacity seamless flux-cored wire for 550 MPa high-strength steel. The flux-cored wire is composed of flux core powder and low-carbon steel band wrapping the flux core powder. The flux core powder is composed of rutile powder, rare earth fluoride, atomized ferrosilicon powder, low-carbon ferromanganese powder, aluminum-magnesium alloy powder, metal titanium powder, metal nickel powder, metal chromium powder, metal molybdenum powder, alumina powder, quartz powder, and the balance iron powder and unavoidable impurities. Re in the rare earth fluoride and a trace of calcium in the atomized ferrosilicon powder of the flux core powder form a combined effect, the size of weld metal inclusion is reduced, the combined effect of Al-Mg-Ti enables the components of the inclusion to facilitate nucleation of acicular ferrite, the content of the acicular ferrite is increased, the structure is refined, and therefore good low-temperature impact toughness is achieved, and the -40 DEG C impact energy average value can reach 80 J or above.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

High-toughness titanium alkaline type seamless flux-cored wire suitable for full-position welding

ActiveCN108406159ASimple processImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaCrack resistanceSlag

The invention discloses a high-toughness titanium alkaline type seamless flux-cored wire suitable for all-position welding. The flux-cored wire is composed of a low-carbon steel strip at the peripheryand flux core powder inside; and the flux core powder comprises the following components, by weight percentage: 30-40% of rutile, 1-2% of aluminum oxide, 2-4% of dehydrated feldspar, 1-3% of quartz,1-3% of zircon sand, 1-2% of rare earth oxide, 1-2% of silicon powder, 0.2-0.4% of ferroboron, 6-8% of nickel powder, 8-15% of metal manganese, 4-9% of magnesium powder and the balance iron powder andinevitable impurities. According to the flux-cored wire, a titanium alkaline slag system is adopted, the proportion of alloy elements is optimized, the content of mineral powder is adjusted, and under the protection of CO2 gas, horizontal, transverse and vertical position welding can be realized; the mechanical property is stable, the impact power at 40 DEG C below zero reaches 100J, the crack resistance is good, diffusible hydrogen is low, the moisture resistance is strong, the seawater corrosion resistance is good, and the anti-cracking ability is good.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Method for fabricating seamless tube welding wire containing rutile cored powders by mild-carbon steel strip

ActiveCN103753055AReduce the incidence of cracksImprove porosity resistanceWelding/cutting media/materialsSoldering mediaCopper platingManganese

Disclosed is a method for fabricating a seamless tube welding wire containing rutile cored powders by a mild-carbon steel strip. The method includes that by weight, 30%-50% of rutile, 2%-5% of dehydrated feldspar, 5%-10% of silicon iron, 1%-8% of ferrotitanium, 5%-15% of manganese metal, 2%-5% of zircon sand, 3%-8% of mineral magnesia, 2%-6% of quartz, 0.5%-2% of zirconium metal and the balance iron powders are fully and uniformly stirred to form the rutile cored powders, and the rutile cored powders are stored in a feeding device for stand-by, the mild-carbon steel strip is rolled to form a U-shaped steel strip, the cored powders are filled in the U-shaped steel strip at a rolling speed of 2-10m / s, the filling rate is controlled within 14%-18%, then a seamed tube in the diameter of D is formed by rolling, a seamless tube welding wire tube blank is formed by on-line welding of a laser-beam welding machine or a high-frequency welding machine, the seamless tube welding wire tube blank is subjected to high frequency annealing at 500-1200 DEG C, then the diameter of the seamless tube welding wire tube blank is reduced by a cold-drawn machine to form a D1 seamless tube welding wire, and then the D1 seamless tube welding wire is copperized so as to form the seamless tube welding wire containing the rutile cored powders.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

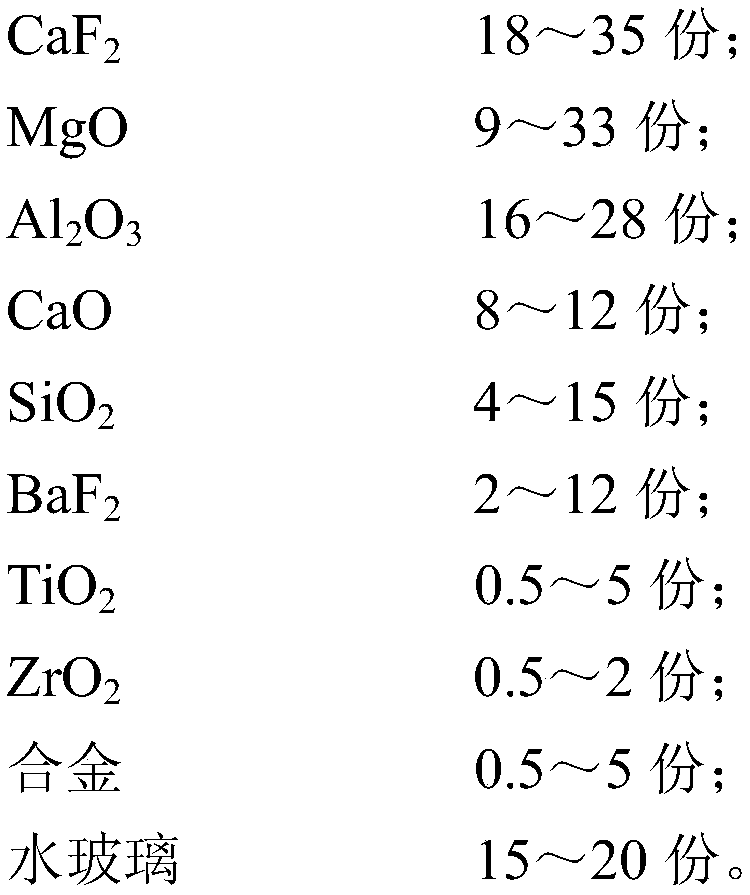

Nickel base alloy submerged arc welding sintered flux and preparation method and application thereof

InactiveCN108015453ADelay transitionImprove purityArc welding apparatusWelding/cutting media/materialsHydrogenSlag

The invention belongs to the technical field of welding materials, and particularly relates to a nickel base alloy submerged arc welding sintered flux and a preparation method and application thereof.According to the nickel base alloy submerged arc welding sintered flux, a main slag system is mainly composed of a CaF2-MgO-Al2O3-CaO-BaF2-SiO2 system, and specifically comprises the following components of, by mass, 18-35 parts of CaF2, 9-33 parts of MgO, 16-28 parts of Al2O3, 8-12 parts of CaO, 4-15 parts of SiO2, 2-12 parts of BaF2, 0.5-5 parts of TiO2, 0.5-2 parts of ZrO2, 0.5-5 parts of alloy and 15-20 parts of sodium silicate. The flux provided by the invention is good in performance and low in diffusible hydrogen, is matched with a solid welding wire ERNiCrMo-4, and is good in manufacturability, and the weld metal mechanical performance is good.

Owner:HENAN UNIV OF SCI & TECH

Acidic high-strength and high-toughness flux-cored wire

ActiveCN112122820ABeautiful weld shapeImprove welding efficiencyWelding/cutting media/materialsSoldering mediaFerrosiliconManganese

The invention provides an acidic high-strength and high-toughness flux-cored wire. The acidic high-strength and high-toughness flux-cored wire comprises a flux core and a sheath coating the outer sideof the flux core, wherein the flux core is prepared from the following components in parts by weight: 300-430 parts of rutile, 20-40 parts of feldspar, 13-25 parts of quartz, 8-20 parts of zircon sand, 4-14 parts of magnesia, 3-10 parts of sodium fluoride, 3-10 parts of sodium fluosilicate, 3-10 parts of lithium fluoride, 5-13 parts of ferrotitanium, 5-15 parts of magnesium powder, 2-9 parts of silicon-calcium alloy, 3-11 parts of aluminum-magnesium alloy, 22-40 parts of ferrosilicon, 14-25 parts of rare-earth ferrosilicon, 120-170 parts of metal manganese, 110-150 parts of nickel powder, 45-70 parts of ferromolybdenum, 3-12 parts of graphite and the balance of iron powder, wherein the sum of the parts by weight of the medicinal powder components is 1000 parts. The acidic flux-cored wireprovided by the invention still has relatively high low-temperature impact toughness and relatively good cold crack resistance at a relatively high strength.

Owner:TIANJIN YONGCHANG WELDING WIRES

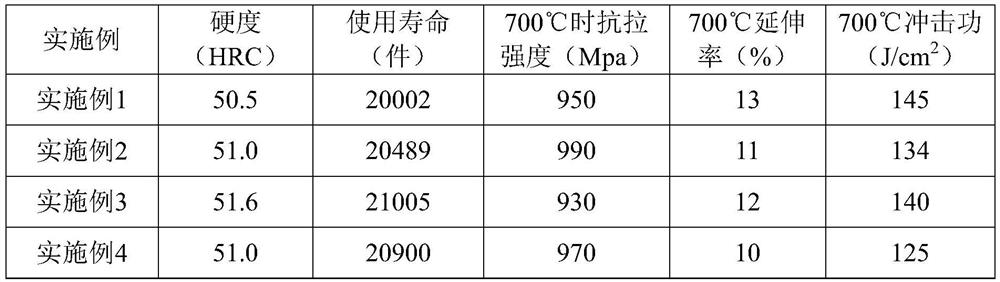

Flux-cored wire for repairing hot forging die and using method of flux-cored wire

ActiveCN113210930AGood wear hardnessGood high temperature strength and toughnessArc welding apparatusWelding/cutting media/materialsAlloy elementSodium fluoride

The invention provides a flux-cored wire for repairing a hot forging die and a using method of the flux-cored wire. The flux-cored wire comprises an alloy steel strip outer skin and flux-cored powder; the alloy steel strip outer skin is prepared from the components including, by mass, 0.20%-0.29% of C, 0.60%-0.70% of Si, 0.5%-0.8% of Mn, less than or equal to 0.01% of S, less than or equal to 0.015% of P, 12%-13% of Cr, 2%-3% of Ni, 4.0%-4.9% of Mo, 0.3%-0.5% of V and the balance Fe; the flux core powder is prepared from the components including, by mass, 55%-60% of rutile, 3%-5% of sodium fluoride, 1%-2% of magnetite, 3%-5% of potassium cryolite, 5%-8% of zircon sand, 4%-7% of potassium titanate, 2%-3% of cerium oxide and the balance Fe. According to the flux-cored wire, main alloy elements are transited through the alloy steel strip outer skin, the transition rate of the alloy elements is increased, so that surfacing metal has good abrasion resistance and impact toughness, and the service life of the hot forging die is prolonged.

Owner:泰安市瑞朗科技有限公司 +1

Preheat-free welding rod and manufacturing method and application thereof

ActiveCN102794583BHigh strengthImprove low temperature impact toughnessWelding/cutting media/materialsSoldering mediaFerrosiliconBarium carbonate

The invention discloses a preheat-free welding rod and application thereof. The preheat-free welding rod comprises a welding core and a coating and is characterized in that the coating comprises the following component in percentage by weight: 35-40% of marble, 2-5% of barium carbonate, 17-22% of fluorite, 0.5-2.0% of lithium fluoride, 2-5% of silica micro-powder, 4-6% of rutile, 3-5% of ferrosilicon, 2-4% of ferromanganese, 2-4% of ferromolybdenum, 1-2% of rare-earth ferrosilicon, 0.5-1% of sodium carbonate, 1-2% of magnesium powder, 2-4% of ferrotitanium, 8-10% of nickel powder, and the balance being iron powder. The preheat-free welding rod disclosed by the invention is specially used for welding a low-alloy high-strength steel in matched application, saves a preheat treatment in use, can remarkably reduce the content of diffusible hydrogen and the hardening capability of a welding material, reduces the number of welding cold cracks, and is of very important significance to simplification of a welding process, improvement of performances of a weld joint, reduction of production cost and improvement of working environment.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

A seamless submerged arc flux-cored welding wire for steel with a yield strength of 550mpa

ActiveCN106181122BStrong resistance to moisture absorptionGood workmanshipWelding/cutting media/materialsSoldering mediaRare earthManganese

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

An ultra-low-hydrogen high-toughness metal powder-cored seamless flux-cored wire for all-position welding

ActiveCN106891104BLow solderabilityReduced crack resistanceWelding/cutting media/materialsSoldering mediaCrack resistanceFerrosilicon

The invention provides an ultralow-hydrogen and high-tenacity metal powder core type seamless flux-cored welding wire for all-position welding. The seamless flux-cored welding wire comprises outer skin and flux core powder, wherein the inner part of the outer skin is filled with the flux core powder, and the outer skin is a low-carbon steel band. The seamless flux-cored welding wire is characterized in that the flux core powder comprises the following components in a percent by weight: 10-15% of low-carbon ferromanganese, 15-20% of atomized ferrosilicon, 2-5% of rutile, 1-5% of cryolite, 1-3% of atomized nickel powder, 1-2% of quartz, 0.5-2% of feldspar and the balance of iron powder. The seamless flux-cored welding wire is suitable for the all-position welding of carbon steel and low-alloy steel which are welded under the protection of mixed gas containing 75-85% of Ar and 15-25% of CO2. The seamless flux-cored welding wire is great in welding machinability, stable in mechanical properties, great in crack resistance, low in hydrogen dispersion and high in moisture absorbability and can be used for all-position welding.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

An ultra-low hydrogen seamless submerged arc flux-cored welding wire for steel with a yield strength of 690mpa

ActiveCN106141500BStrong resistance to moisture absorptionGood workmanshipWelding/cutting media/materialsSoldering mediaPotassium fluorideManganese

The invention discloses an ultralow hydrogen seamless submerged arc flux-cored wire for steel with yield strength being the 690 MPa level. The submerged arc flux-cored wire is composed of a sheath and flux core powder. The sheath is made of a low-carbon steel strip. The flux core powder is prepared from, by mass percent, 8%-12% of marble, 4%-8% of fluorite, 25%-30% of metal nickel, 2%-4% of metal chromium, 7%-9% of ferromolybdenum, 12%-16% of electrolytic manganese, 1%-3% of ferrosilicon, 3%-5% of ferrotitanium, 2%-4% of ferro-boron, 2%-3% of potassium titanate, 1%-3% of potassium fluoride, 1%-3% of sodium fluoride and the balance ferrous powder. The ultralow hydrogen seamless submerged arc flux-cored wire for the steel with the yield strength being the 690 MPa level is high in moisture absorption resisting property, and excellent in processing property of being matched with fluorine and alkali sintered flux SR-SJ613, diffusible hydrogen is extremely low (smaller than or equal to 4 mL / 100 g), minus 40 DEG C charpy impact energy reaches over 100 J, and the wire can be applied to welding of a steel plate with the yield strength being the 690 MPa level in the ocean engineering field.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

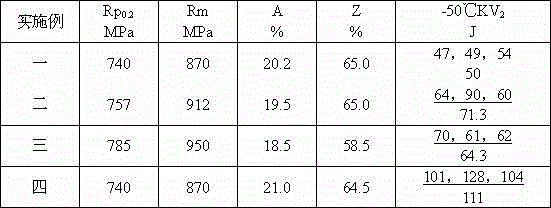

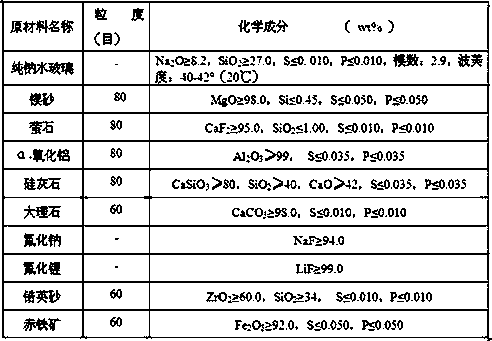

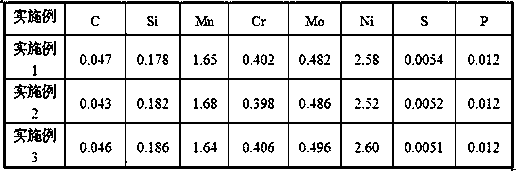

High-strength high-tenacity sintered flux for afterheat-free welding

InactiveCN103273222BRight melting pointModerate viscosityWelding/cutting media/materialsSoldering mediaSlagRare earth

The invention discloses a high-strength high-tenacity sintered flux for afterheat-free welding. The sintered flux is mixed sinter composed of dry powder and pure sodium water glass with the modulus of 2.8-3.2, and the addition amount of the water glass is 18-20% of the weight of the dry powder. The dry powder is composed of, by weight percent, 18-23% of fluorite, 33-37% of magnesia, 14-17% of bauxite, 3-5% of quartz, 7-12% of marble, 9-13% of wollastonite, 0-1.5% of ferromolybdenum, 1-3% of rare earth fluoride, 1-2% of silicon iron, 1-3% of manganese ore, and 0-3% of borax. Compared with the prior art, the sintered flux can form welding slag with an appropriate melting point and good viscosity and surface tension. In the welding process, arc combustion is stable, welding line transition is smooth, spreading is good, and appearance of welding lines is attractive. The oxygen content in the welding lines is lowered. The sintered flux can be matched with the WS80S welding wire for welding 10CrNi5MoV steel, yield strength of metal of the welding lines can reach more than 735MPa, the metal of the welding lines is -50 DEG C, impact energy can reach more than 50J, and the metal of the welding lines of afterheat-free welding can be crack-free.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

An acidic high-strength and high-toughness flux-cored welding wire

ActiveCN112122820BBeautiful weld shapeImprove welding efficiencyWelding/cutting media/materialsSoldering mediaCrack resistanceFerrosilicon

The invention provides an acidic high-strength and high-toughness flux-cored welding wire, which includes a flux core and a sheath coated on the outside of the flux core; the flux core includes the following components in parts by weight: 300-430 parts of rutile; 20-430 parts of feldspar 40 parts; 13-25 parts of quartz; 8-20 parts of zircon sand; 4-14 parts of magnesia; 3-10 parts of sodium fluoride; 5-13 parts of iron; 5-15 parts of magnesium powder; 2-9 parts of silicon-calcium alloy; 3-11 parts of aluminum-magnesium alloy; 22-40 parts of ferrosilicon; 14-25 parts of rare earth ferrosilicon; 110-150 parts of nickel powder; 45-70 parts of ferromolybdenum; 3-12 parts of graphite, iron powder balance; the sum of the parts by weight of each powder component is 1000 parts. The acidic flux-cored welding wire of the present invention still has relatively high low-temperature impact toughness and good cold cracking resistance at relatively high strength.

Owner:TIANJIN YONGCHANG WELDING WIRES

A kind of ultra-low hydrogen high toughness seamless flux-cored welding wire for 550mpa high-strength steel

ActiveCN106078006BGood workmanshipSmall sizeWelding/cutting media/materialsWelding/soldering/cutting articlesRare earthFerrosilicon

Disclosed is an ultra-low hydrogen high-tenacity seamless flux-cored wire for 550 MPa high-strength steel. The flux-cored wire is composed of flux core powder and low-carbon steel band wrapping the flux core powder. The flux core powder is composed of rutile powder, rare earth fluoride, atomized ferrosilicon powder, low-carbon ferromanganese powder, aluminum-magnesium alloy powder, metal titanium powder, metal nickel powder, metal chromium powder, metal molybdenum powder, alumina powder, quartz powder, and the balance iron powder and unavoidable impurities. Re in the rare earth fluoride and a trace of calcium in the atomized ferrosilicon powder of the flux core powder form a combined effect, the size of weld metal inclusion is reduced, the combined effect of Al-Mg-Ti enables the components of the inclusion to facilitate nucleation of acicular ferrite, the content of the acicular ferrite is increased, the structure is refined, and therefore good low-temperature impact toughness is achieved, and the -40 DEG C impact energy average value can reach 80 J or above.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

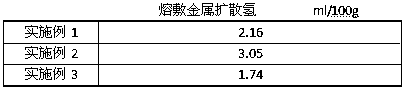

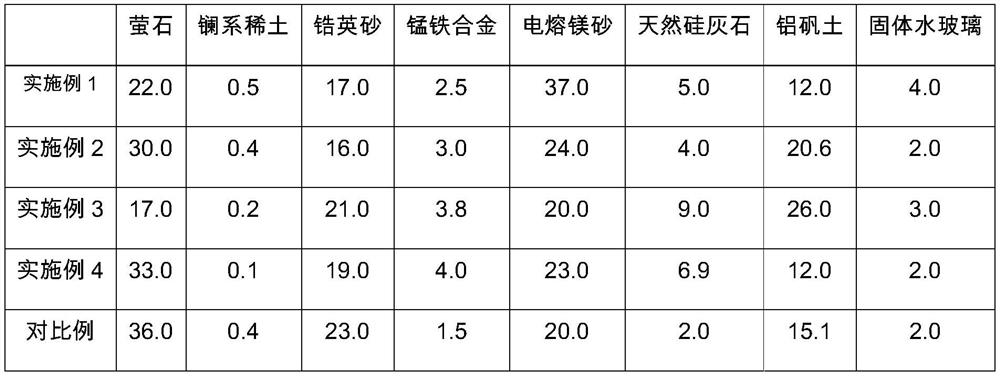

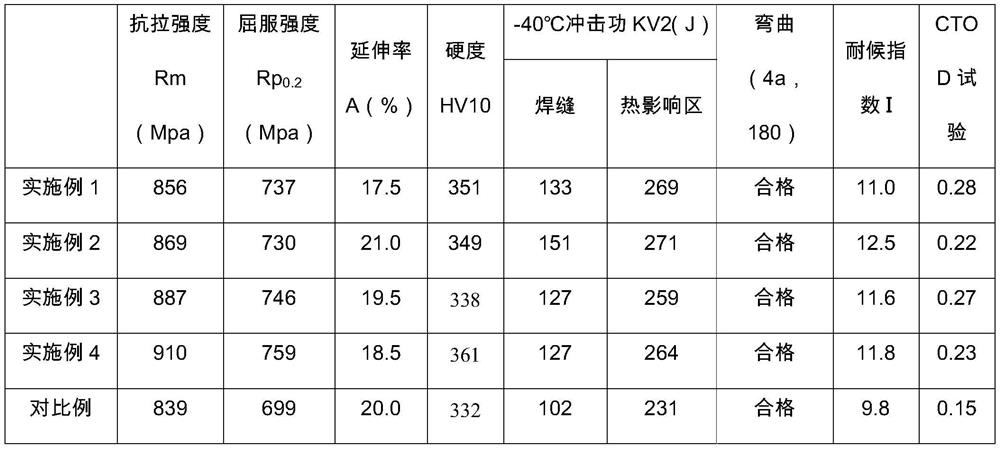

A kind of 850mpa level weather-resistant high-strength steel supporting submerged arc welding flux

ActiveCN111037155BGood workmanshipGood plasticityWelding/cutting media/materialsSoldering mediaLanthanideZircon

The invention belongs to the technical field of welding materials and discloses a submerged-arc welding flux matched with 850MPa-grade weather-proof high-strength steel and a production and use methodthereof. The welding flux is formed by mixing various ore raw materials and a small amount of alloy powder. The welding flux comprises the following main components: 17-33% of fluorite; 0.1-0.5% of lanthanide series rare earth; 16-21% of zircon sand; 2.5-4% of manganese-iron alloy; 20-37% of fused magnesia; 2-9% of natural wollastonite; 12 to 26% of bauxite; and 2-4% of solid water glass. The welding flux comprises a binder. The main components are uniformly mixed according to the proportions; 20-21.5% of the binder is added into the uniformly mixed main components; an obtained mixture is granulated; an obtained substance is subjected to low-temperature baking at 200-230 DEG C, high-temperature sintering at 680-730 DEG C, and screening sequentially, so that a flux product of which the alkalinity ranges from 2.8 to 3.0 and of which the mesh number ranges from 20 to 50 is obtained. When the welding flux and a special welding wire are matched with each other to weld the 850MPa-grade weather-proof high-strength steel, a deposited metal is obtained. The chemical component C of the deposited metal is smaller than or equal to 0.10%; the chemical component Mn of the deposited metal rangesfrom 1.0 to 2.2%; the chemical component Si of the deposited metal is smaller than or equal to 0.60%; the chemical component P of the deposited metal is smaller than or equal to 0.020%; the chemicalcomponent Cr of the deposited metal is smaller than or equal to 0.60%; the chemical component Mo of the deposited metal ranges from 0.20 to 0.60%; the chemical component Ni of the deposited metal ranges from 2.00 to 3.30%; the chemical component Cu of the deposited metal is smaller than or equal to 0.25%; and the balance of the deposited metal is Fe.

Owner:SICHUAN XIYE NEW MATERIAL

A high-toughness titanium-alkaline seamless flux-cored wire suitable for all-position welding

ActiveCN108406159BSimple processImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaCrack resistanceManganese

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

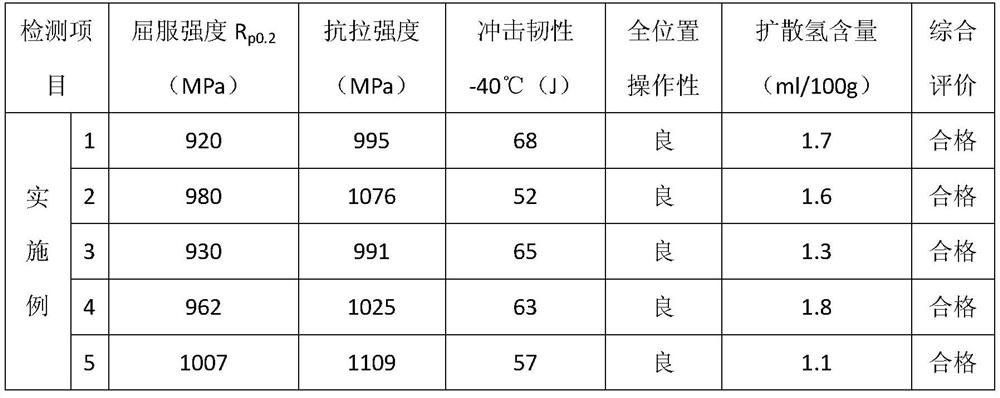

A rutile-type flux-cored welding wire with a yield strength exceeding 890mpa

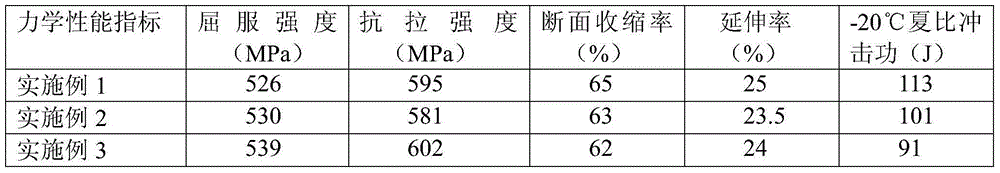

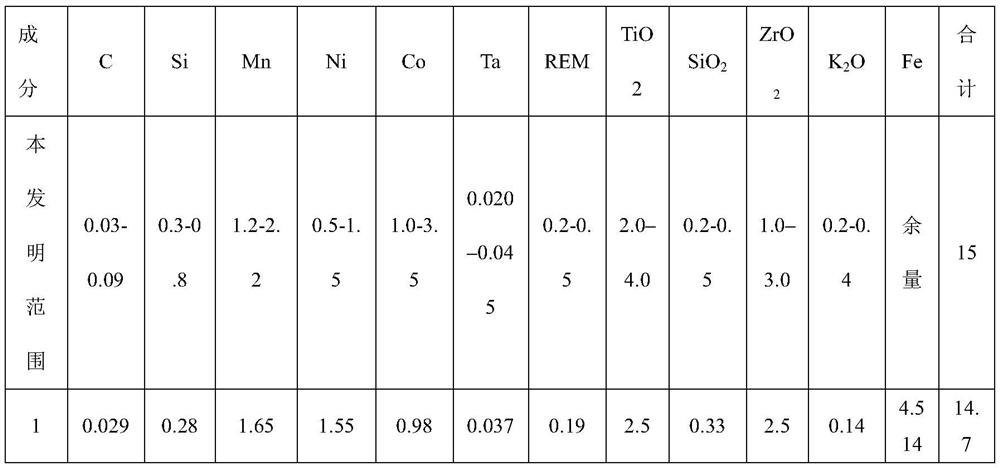

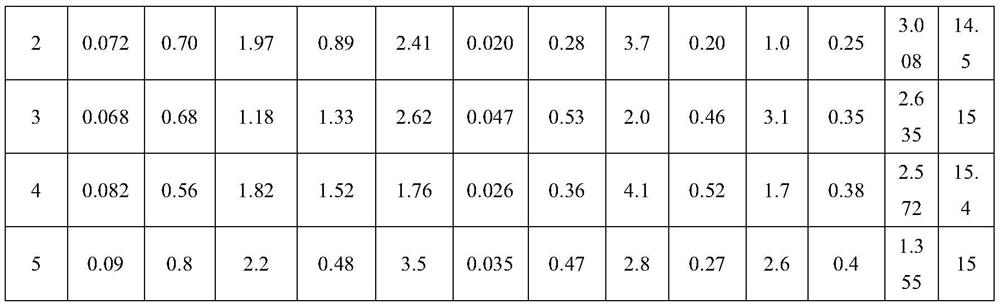

ActiveCN113798721BLow diffusible hydrogenStable welding arcWelding/cutting media/materialsSoldering mediaAlloySteel belt

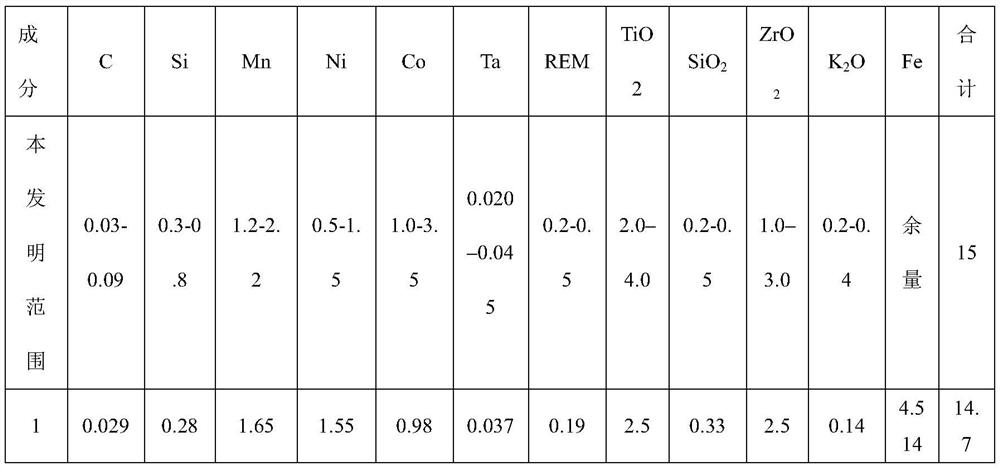

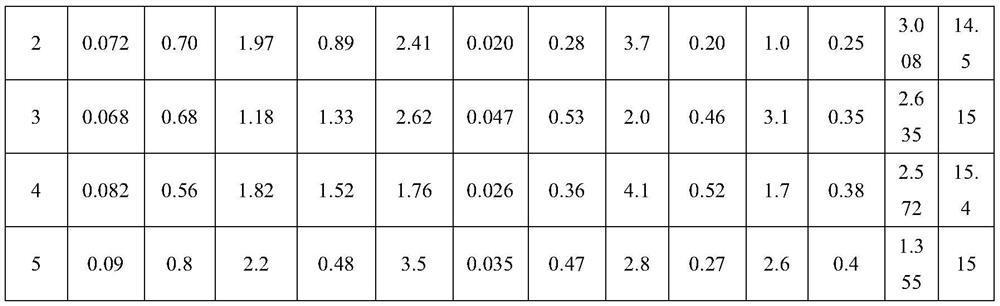

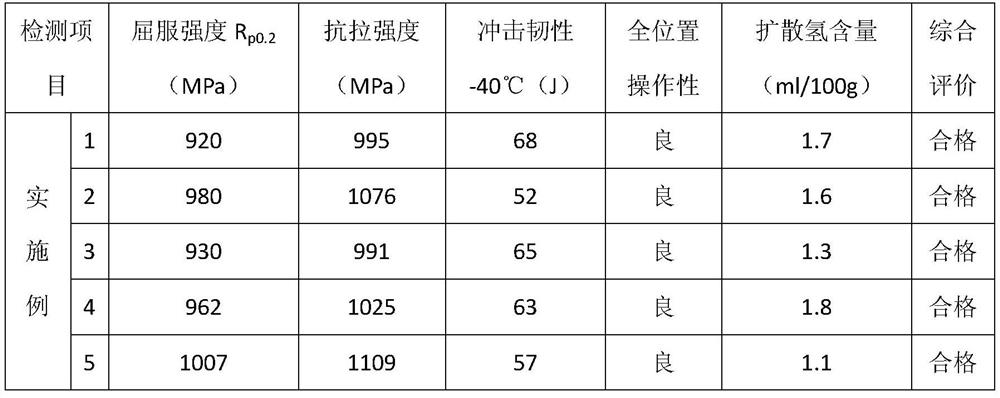

A rutile-type flux-cored welding wire with a yield strength exceeding 890 MPa is composed of a steel strip wrapping the flux-core and a flux-core filled therein, and the flux-core includes C: 0.03-0.09%, Si: 0.3-0.8% by weight percentage , Mn: 1.2‑2.2%, Ni: 0.5‑1.5%, Co: 1.0‑3.5%, Ta: 0.020–0.045%, Rare Earth Alloy: 0.2‑0.5%, TiO 2 : 2.0–4.0%, SiO 2 : 0.2‑0.5%, ZrO 2 : 1.0–3.0%, K 2 O: 0.2-0.4%; the remainder is Fe and other inevitable impurities. Welding wire adopts 80%Ar+20%CO 2 Mixed gas shielded welding has the characteristics of weld metal yield strength exceeding 890MPa, low temperature impact toughness-40℃ impact greater than 47J, diffusible hydrogen less than 2ml / 100g, stable welding arc, and excellent all-position welding processability.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

A high-toughness seamless submerged arc flux-cored welding wire for 460mpa steel

ActiveCN107378311BLow diffusible hydrogen contentImprove low temperature toughnessWelding/cutting media/materialsSoldering mediaManganeseRare earth

The invention relates to a high toughness seamless submerged-arc flux-cored wire for 460MPa steel. The high toughness seamless submerged-arc flux-cored wire for 460MPa steel is composed of a peripheral mild-carbon steel strip and flux-cored wire powder inside. The flux-cored wire powder comprises the following components in percentages by mass: 8-13% of nickel powder, 0.5-1.5% of ferromolybdenum, 12-20% of manganese metal, 3-7% of rare earth silicon iron, 2-5% of ferrotitanium, 1-3% of ferroboron, 0.5-1% of sodium fluoroaluminate, 1-2% of fluorite and the balance of iron powder and inevitable impurities. The seamless submerged-arc flux-cored wire provided by the invention is matched with fluoride-basic type sintered flux SR-SJ613, the Charpy impact energy reaches 110J or above at 40 DEG C below zero, diffusible hydrogen is smaller than or equal to 5ml / 100g, and the high toughness seamless submerged-arc flux-cored wire can be used for welding 460MPa steel.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

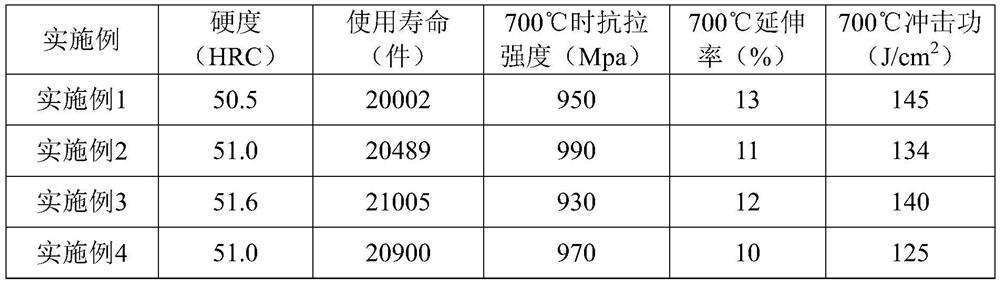

Flux-cored welding wire for repairing hot forging die and using method thereof

ActiveCN113210930BImprove transition rateExtended service lifeArc welding apparatusWelding/cutting media/materialsMaterials scienceCerium oxide

The invention provides a flux-cored welding wire for repairing a hot forging die and a method for using the same. The flux-cored welding wire includes an alloy steel strip sheath and a flux-cored powder, wherein the components in the alloy steel strip sheath and their proportion in the total mass of the steel strip sheath are provided. The percentages are: C0.20~0.29%, Si0.60~0.70%, Mn0.5~0.8%, S≤0.01%, P≤0.015%, Cr12~13%, Ni2~3%, Mo4.0~4.9 %, V0.3~0.5%, the balance is Fe; the components in the core powder and their percentages in the total mass of the core powder are: rutile 55-60%, sodium fluoride 3-5%, magnetite 1-2%, potassium cryolite 3-5%, zircon sand 5-8%, potassium titanate 4-7%, cerium oxide 2-3%, the balance is Fe; the flux-cored welding wire of the present invention passes through the alloy The main alloying elements are transferred to the outer skin of the steel strip, which improves the transition rate of the alloying elements, so that the surfacing metal has better wear resistance hardness and impact toughness, and improves the service life of the hot forging die.

Owner:泰安市瑞朗科技有限公司 +1

A kind of processing method of seamless pipe welding wire containing rutile flux core powder prepared by low carbon steel strip

ActiveCN103753055BReduce the incidence of cracksImprove porosity resistanceWelding/cutting media/materialsSoldering mediaCopper platingManganese

Disclosed is a method for fabricating a seamless tube welding wire containing rutile cored powders by a mild-carbon steel strip. The method includes that by weight, 30%-50% of rutile, 2%-5% of dehydrated feldspar, 5%-10% of silicon iron, 1%-8% of ferrotitanium, 5%-15% of manganese metal, 2%-5% of zircon sand, 3%-8% of mineral magnesia, 2%-6% of quartz, 0.5%-2% of zirconium metal and the balance iron powders are fully and uniformly stirred to form the rutile cored powders, and the rutile cored powders are stored in a feeding device for stand-by, the mild-carbon steel strip is rolled to form a U-shaped steel strip, the cored powders are filled in the U-shaped steel strip at a rolling speed of 2-10m / s, the filling rate is controlled within 14%-18%, then a seamed tube in the diameter of D is formed by rolling, a seamless tube welding wire tube blank is formed by on-line welding of a laser-beam welding machine or a high-frequency welding machine, the seamless tube welding wire tube blank is subjected to high frequency annealing at 500-1200 DEG C, then the diameter of the seamless tube welding wire tube blank is reduced by a cold-drawn machine to form a D1 seamless tube welding wire, and then the D1 seamless tube welding wire is copperized so as to form the seamless tube welding wire containing the rutile cored powders.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Rutile type flux-cored wire with yield strength exceeding 890 MPa

ActiveCN113798721ALow diffusible hydrogenStable welding arcWelding/cutting media/materialsSoldering mediaAlloySteel belt

A rutile type flux-cored wire with the yield strength exceeding 890 MPa is composed of a steel belt wrapping a flux core and the flux core filling the steel belt. The flux core comprises, by weight, 0.03%-0.09% of C, 0.3%-0.8% of Si, 1.2%-2.2% of Mn, 0.5%-1.5% of Ni, 1.0%-3.5% of Co, 0.020%-0.045% of Ta, 0.2%-0.5% of rare earth alloy, 2.0%-4.0% of TiO2, 0.2%-0.5% of SiO2, 1.0%-3.0% of ZrO2, 0.2%-0.4% of K2O, and the balance Fe and other inevitable impurities. The welding wire adopts 80% Ar + 20% CO2 mixed gas for shielded welding, and has the characteristics that the yield strength of weld metal exceeds 890 MPa, the low-temperature impact toughness is larger than 47 J at the temperature of -40 DEG C, diffusible hydrogen is smaller than 2 ml / 100 g, the welding arc is stable, and the all-position welding manufacturability is excellent.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Flux cored, gas shielded welding rod

InactiveCN100591460CLow diffusible hydrogenHigh tensile strengthArc welding apparatusWelding/cutting media/materialsHydrogenSilicon alloy

A flux cored, gas shielded arc welding electrode for depositing a weld metal with low diffusible hydrogen and having tensile strength greater than 620 N / mm 2 (90 Kpsi) and a yield strength greater than 550 N / mm 2 (80 Kpsi). The electrode includes a nickel free steel sheath with a carbon content of less than 0.05% of the sheath and a core in the range of 13-17% of the electrode wherein the core includes primary alloy particles of iron, manganese, magnesium and nickel with a minor amount of secondary alloy particles of a silicon alloy and a boron alloy in a rutile based slag system. The nickel has a controlled amount in the general range of 1.0-2.0% by weight of the electrode and the rutile is 40-60% by weight of the core.

Owner:LINCOLN GLOBAL INC

Flux cored, gas shielded welding electrode

InactiveCN1864907ALow diffusible hydrogenHigh tensile strengthArc welding apparatusWelding/cutting media/materialsHydrogenSlag

A flux cored, gas shielded arc welding electrode for depositing a weld metal with low diffusible hydrogen and having tensile strength greater than 620 N / mm 2 (90 Kpsi) and a yield strength greater than 550 N / mm 2 (80 Kpsi). The electrode includes a nickel free steel sheath with a carbon content of less than 0.05% of the sheath and a core in the range of 13-17% of the electrode wherein the core includes primary alloy particles of iron, manganese, magnesium and nickel with a minor amount of secondary alloy particles of a silicon alloy and a boron alloy in a rutile based slag system. The nickel has a controlled amount in the general range of 1.0-2.0% by weight of the electrode and the rutile is 40-60% by weight of the core.

Owner:LINCOLN GLOBAL INC

A seamless flux-cored welding wire with good vertical welding manufacturability

ActiveCN106736049BGood welding wire workmanshipRealize all position weldingWelding/cutting media/materialsSoldering mediaCopper platingMoisture absorption

The invention discloses a seamless flux cored wire with good vertical position welding manufacturability, and relates to the field of welding materials. The seamless flux cored wire is composed of low carbon steel outer skin and flux core powder, and the flux core powder is prepared from the mixing of materials, by mass, 35%-50% of rutile, 2%-4% of dehydrated feldspar, 4%-6% of aluminum magnesium alloy, 2%-3% of ferrotitanium, 9%-14% of low carbon ferromanganese, 1%-2% of zircon sand, 3%-8% of aluminum oxide, 4%-6% of quartz, 0.5%-1% of sodium fluoride and the balance iron powder. According to the seamless flux cored wire with the good vertical position welding manufacturability, the flux core powder is added online synchronously, after the flux core powder is added into the outer skin steel belt, the outer skin steel belt is then subjected to rolling forming and welding seaming, and afterwards subjected to annealing, reducing and copper plating so that the seamless flux cored wire can be prepared. The prepared seamless flux cored wire is stable in mechanical property, low in diffusible hydrogen, high in moisture absorption performance, excellent in antirust performance, and good in welding manufacturability; meanwhile, all-position welding can be conducted, the seamless flux cored wire is particularly applicable to welding of position of vertical welding, and can be used for welding of a D36 level steel plate.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Flux-cored wire for gas shielded arc welding

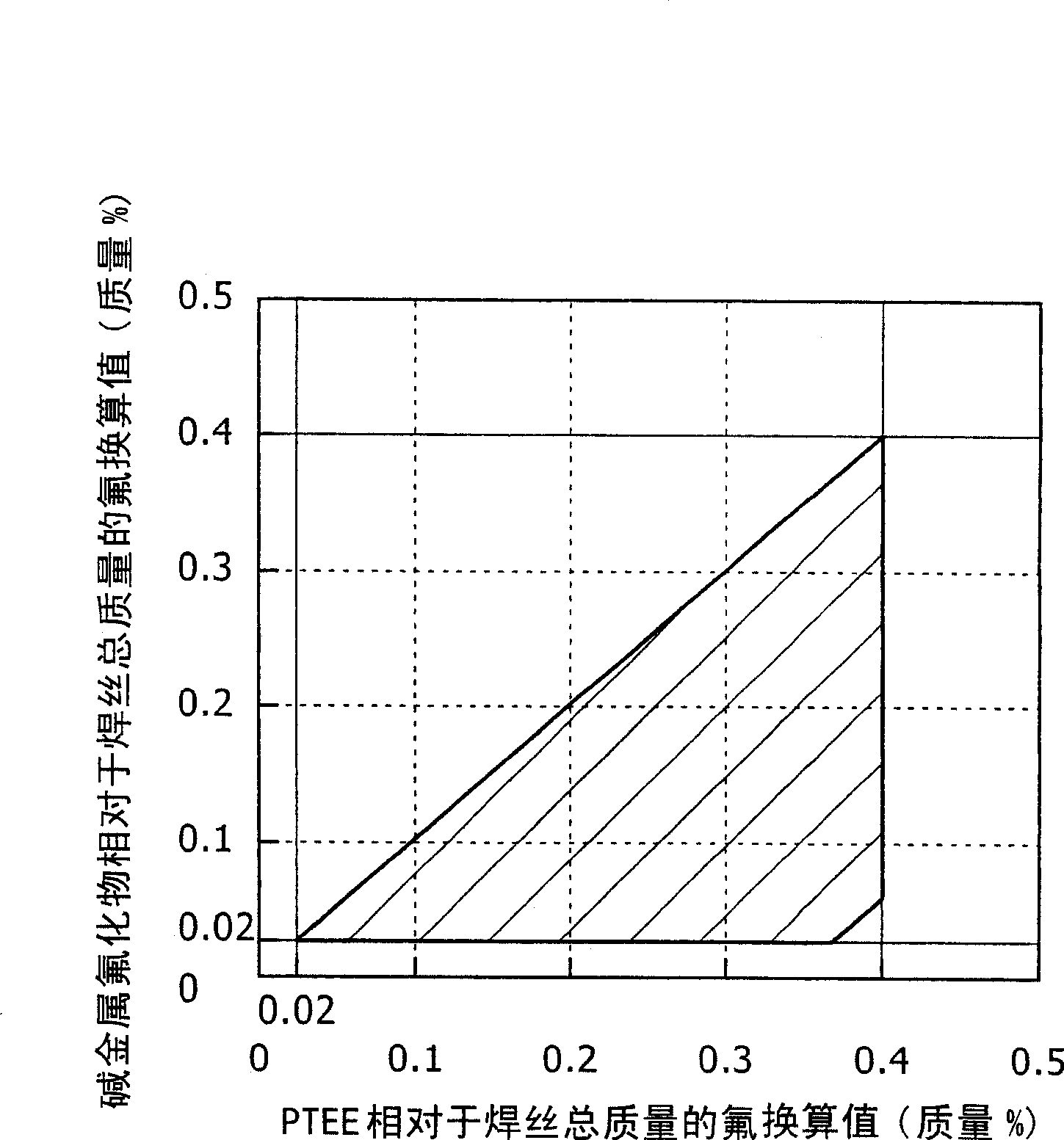

ActiveCN100462186CPrevent hydrogen embrittlementExcellent resistance to moisture absorptionArc welding apparatusWelding/cutting media/materialsAlkaline earth metalHydrogen

A flux-cored wire for gas shielded arc welding according to the present invention is formed by filling a steel casing with flux, wherein: the flux contains, by mass percentage to the total mass of the wire, titanium dioxide: 4.0 to 8.0%, alkali metal fluoride (fluorine equivalence): 0.02 to 0.40%, and PTFE (fluorine equivalence): 0.02 to 0.40%; the fluorine equivalence of alkali-earth metal fluoride is regulated to 0.01% or less by mass; and the fluorine equivalence of alkali metal fluoride and the fluorine equivalence of PTFE satisfy the following expressions; (fluorine equivalence of alkali metal fluoride) / (fluorine equivalence of polytetrafluoroethylene) 1, and (fluorine equivalence of alkali metal fluoride + 0.35) / (fluorine equivalence of polytetrafluoroethylene) >=1. By the configuration, diffusible hydrogen is prevented from intruding into a weld during arc welding and the wire is excellent in resistance to hygroscopicity and further shows good welding operability.

Owner:KOBE STEEL LTD

A kind of sintering flux for welding high-strength steel in marine engineering and preparation method thereof

ActiveCN106271218BGood workmanshipArc stabilizationWelding/cutting media/materialsSoldering mediaProcess specificationArc stability

The invention discloses sintered flux for welding of high-strength steel for ocean engineering and a preparation method of the sintered flux. The sintered flux belongs to fluoride-basic type sintered flux and is prepared from components in parts by weight as follows: 19-24 parts of MgO, 20-25 parts of CaF2, 12-16 parts of Al2O3, 4-8 parts of SiO2, 8-10 parts of CaO, 2-4 parts of BaO, 1-3 parts of NaF, 1-3 parts of LiF, 1-2 parts of ZrO2, 2-3 parts of Fe2O3, 0.5-1.5 parts of an alloy and 14-16 parts of water glass. The sintered flux has good manufacturability, has arc stability under broader process specification, can meet requirements for welding of E550 steel plates with yield strength higher than 550 MPa and E690 steel plates with yield strength higher than 690 MPa and has lower diffusible hydrogen, slag removal is easy, and welding bead forming is attractive.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com