High-strength high-tenacity sintered flux for afterheat-free welding

A sintered flux, high toughness technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as no requirements, achieve good weld surface quality, improve forming and slag removal, welding Beautifully stitched

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

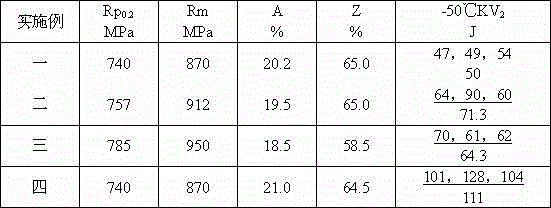

[0034] Below in conjunction with embodiment further specifically illustrate this patent. But the scope of protection of this patent is not limited to specific implementation manners.

[0035] 1) Components: See Table 1 for the components of Example 1 to Example 4. In the formula, the content of molybdenum in ferromolybdenum is 55~58%; the content of silicon in ferrosilicon is 43~46%; the specific composition of manganese ore is manganese compound, including Mn 2 o 3 , Mn 3 o 4 etc., the total content of Mn in the compound is 53~56%, and the specification is ≤80 mesh; the specific composition of magnesia is MgO≥99%, and the specification is ≤40 mesh; the specific technical index requirements for rare earth fluoride are: REO≥83%, Fluorine ≥ 26%, particle size ≤ 100 mesh.

[0036] component name Embodiment one Embodiment two Embodiment Three Embodiment Four fluorite 18 18 19 23 Magnesia 37 34 34 33 Bauxite 16 14 17 14 quartz ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com