Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

132results about How to "Right melting point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lead free solder alloy and its preparation method

InactiveCN1570166ARight melting pointLow costWelding/cutting media/materialsSoldering mediaMaterials scienceTin

The invention relates to a lead-free solder alloy for welding the electronic elements and its manufacturing method. The lead-free solder alloy is characterized in that the main components are Sn, Ag, Cu, and Ni, and In, Bi, Pd, P, Ge, Ga, Se, Te, La, Ce, Pr, Nd, Pm, Sm, Eu, Tm are added selectively. The preparation method is characterized by taking Sn, Ag, Cu, Ni and the additional elements in proportion and smelting them at the temperature of 1300 C. to 1500 C. to obtain the intermediate alloy by using water glass covering process; melting the residual Sn and the intermediate alloy at the temperature of 300 C. to 350 C. by using water glass covering process, and casting the molten materials into alloy pig and soldering tin rod at the temperature of between 250 C. and 350 C.. The lead-free solder alloy provided by the invention can be used for welding the Ag and Pd noble metal electronic element.

Owner:邓和升

Leadfree SnZn-base alloy solder containing rare-earth elements

InactiveCN1390672AHigh bonding strengthImprove stabilityWelding/cutting media/materialsSoldering mediaRare-earth elementMetallic materials

A lead-free alloy as solder contains Zn (5-10 wt.%), the rare-earth elements chosen from La, Ce, Pr and Nd (0.05-1), one or more of Bi (0.1-6), Cu (0.1-3), In (0.5-3), Al (0.1-1), Ni (0.01-1) and P (0.001-1), and Sn (rest). Its advantages are better wettability, fine structure, excellent mechanical performance, low cost and no poison and pollution.

Owner:DALIAN UNIV OF TECH

High-entropy brazing filler metal for brazing non-oxide ceramics and non-oxide ceramic composite material and preparation method of brazing filler metal

ActiveCN102689109AImprove performanceGood compatibilityWelding/cutting media/materialsSoldering mediaNon oxide ceramicsCeramic composite

The invention relates to a high-entropy brazing filler metal and a preparation method thereof, and particularly relates to a high-entropy brazing filler metal for brazing non-oxide ceramics and the composite material of the non-oxide ceramics and the preparation method of the brazing filler metal, aiming to solve the problem that the brazing filler metal at the joint of the non-oxide ceramics and the ceramic composite material which are soldered together is unreliable in performance at a temperature higher than 500 DEG C in the prior art. The brazing filler metal comprises the following components in parts by weight: 18 to 24 parts of Ni, 14.3 to 19 parts of Cr, 16.8 to 22.5 parts of Co, 15.9 to 21 parts of Fe, 10.1 to 13.5 parts of Cu, and 0 to 24.9 parts of Ti or TiH2. The preparation method comprises the following steps of: carrying out vacuum melting on the weighed components at the temperature of 1200 to 1800 DEG C, performing linear cutting and carrying out foiling or composite tabletting on the components, so as to obtain the brazing filler metal; or the preparation method comprises the following steps of: carrying out ball-milling on the components in a ball material mass ratio of (12-16):1, and then tabletting and cleaning the components to obtain the brazing filler metal. The strength of the alloy joint obtained by using the method reaches 35 to 71 MPa, and the strength retention of the alloy joint at a high temperature of 800 DEG C exceeds 67%.

Owner:HARBIN INST OF TECH

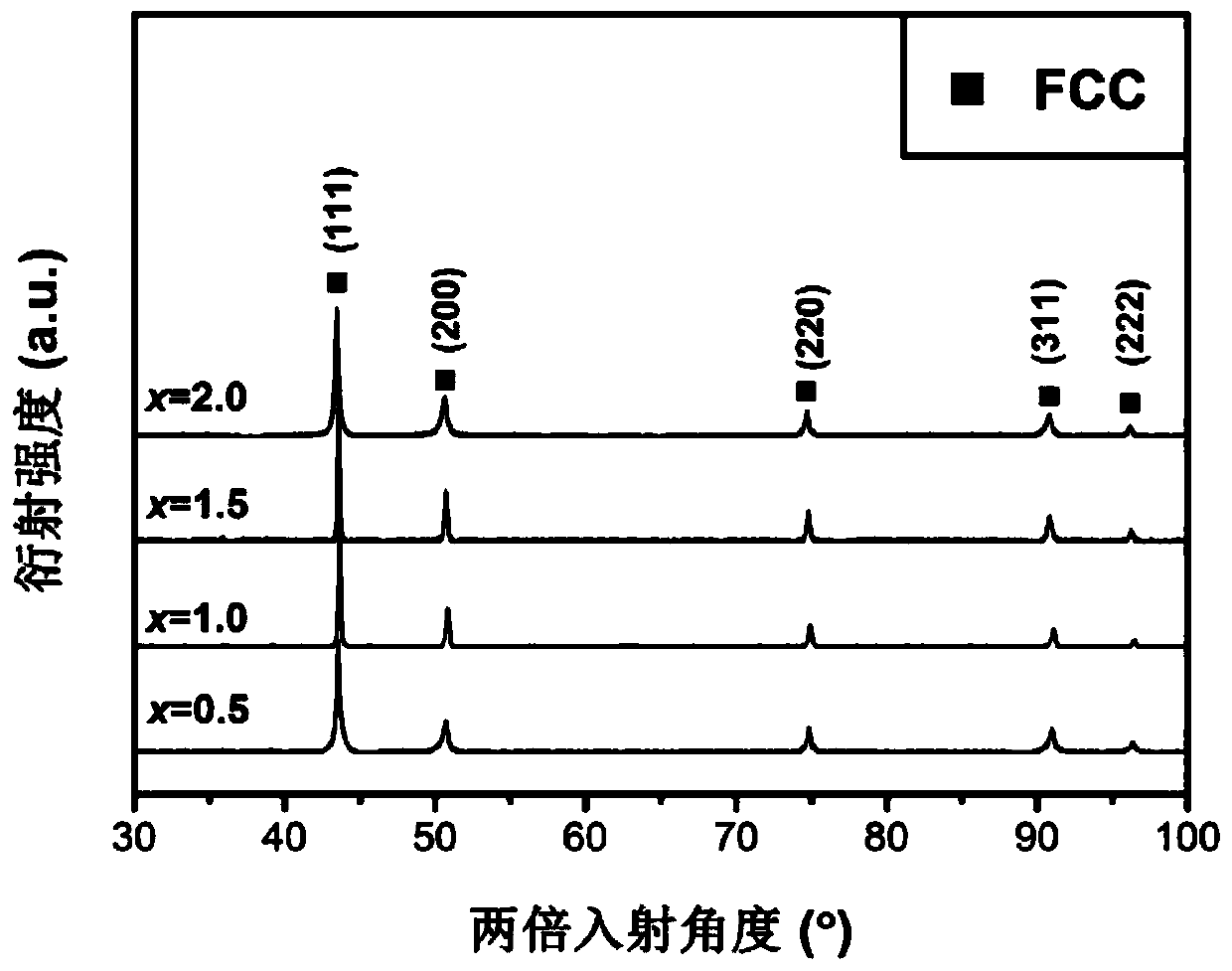

Preparation method of high-entropy alloy brazing filler metal and purpose

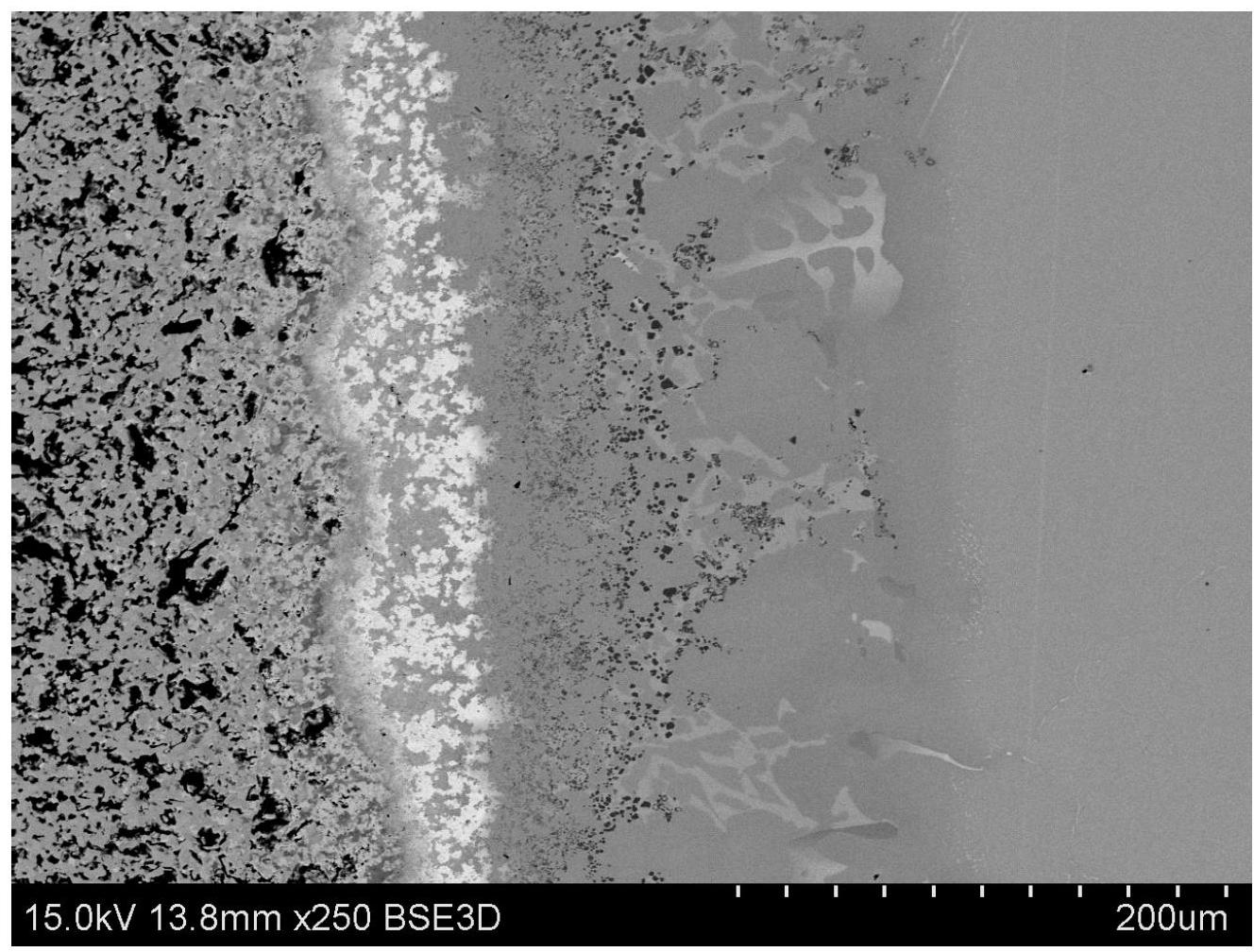

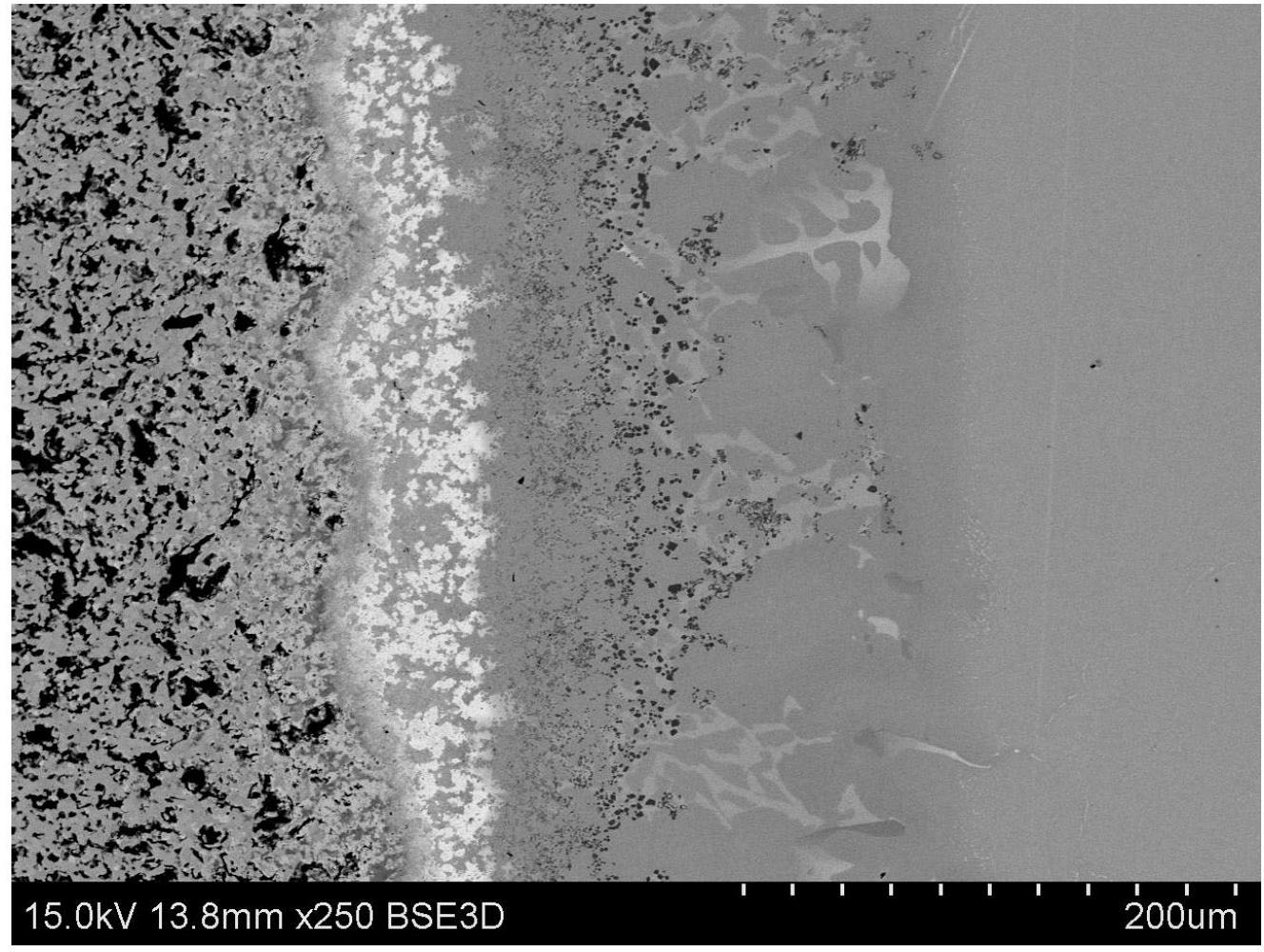

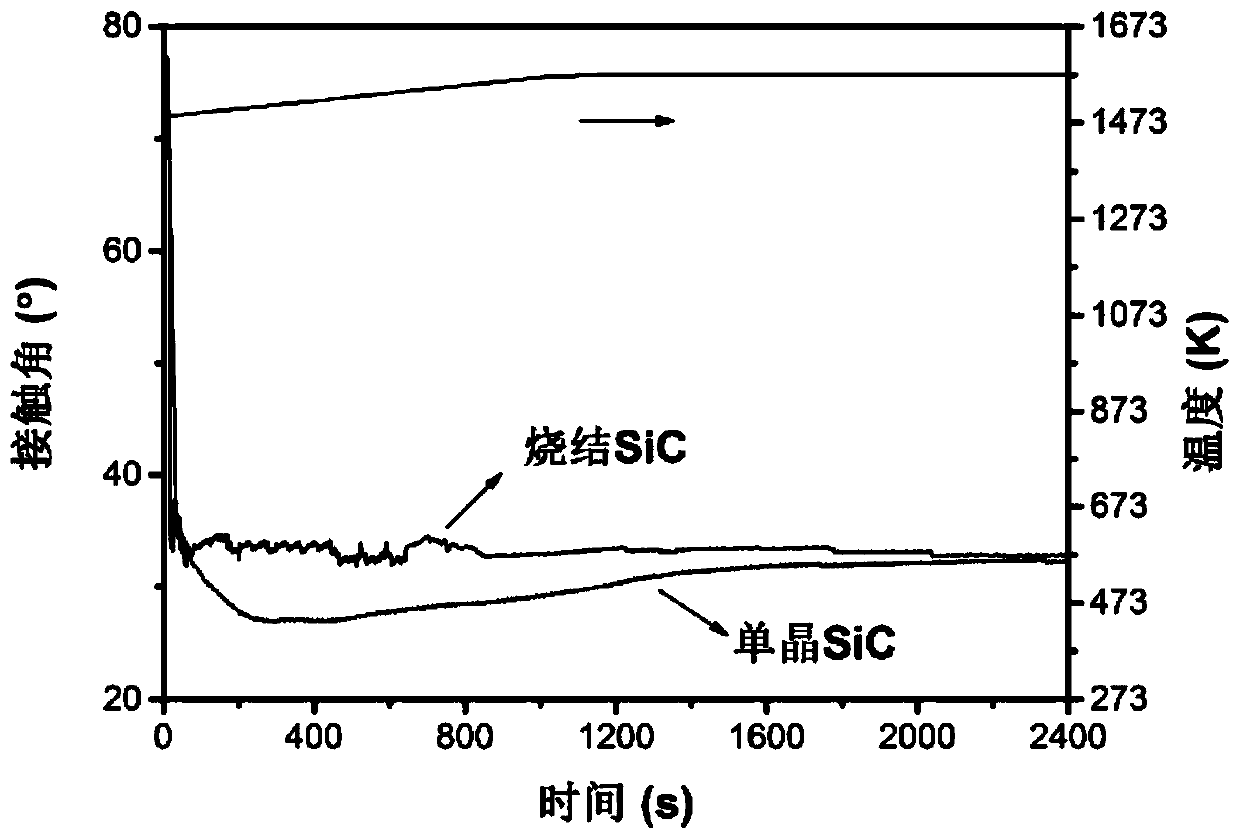

ActiveCN110438386ASintering heating rate is fastShort sintering timeWelding/cutting media/materialsSoldering mediaManufacturing technologyHigh entropy alloys

The invention relates to a manufacturing method of high-entropy alloy brazing filler metal and a purpose. The manufacturing method of the high-entropy alloy brazing filler metal comprises the steps that 1, under existence of protecting gas, 15-35% of Ni powder, 15-35% of Cr powder, 15-35% of Co powder and 15-35% of Fe powder are weighed according to the molar percentage, mixed and then subjected to high-energy ball milling; and 2, a product obtained after ball milling is subjected to discharging plasma sintering, and the high-entropy alloy brazing filler metal is obtained. According to the method, by the adoption of the high-energy ball milling and discharging plasma sintering technology, the manufacturing technology is simplified, the manufacturing efficiency is improved, the melting point of the manufactured high-entropy alloy brazing filler metal is below 1300 DEG C, the contact angle with SiC is about 40 degrees, the components are uniform, and the compactness degree is high.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Low-silver lead-free soft solder

InactiveCN102699563ALow costImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaMisch metalRare earth

The invention discloses a low-silver lead-free soft solder, which is moderate in melting point, strong in tensile strength and low in cost. Based on the total weight of the solder, the solder contains 0.1 to 0.7 weight percent of Ag, 0.1 to 1.0 weight percent of Cu, 0.01 to 5 weight percent of Bi, 0.01 to 3 weight percent of Sb, 0 to 0.5 weight percent of Ni, 0.001 to 0.1 weight percent of P, 0.001 to 0.1 weight percent of X and the balance of Sn, wherein X is any one or combination of Ga, Ge and misch metal. The low-silver lead-free soft solder is applied to wave soldering, reflow soldering and manual soldering in the field of electronic and microelectronic packaging.

Owner:ZHEJIANG ASIA GENERAL SOLDERING & BRAZING MATERIAL

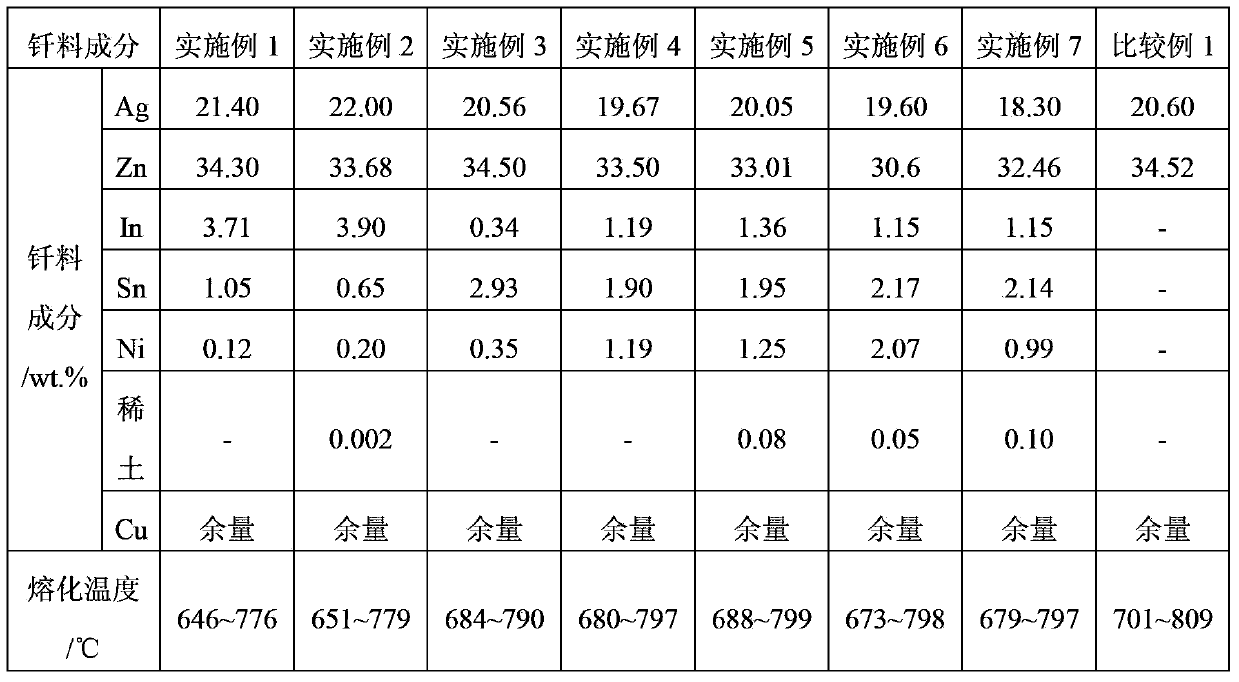

Silver solder for connecting brass and stainless steel

InactiveCN103418933ARight melting pointEasy to processWelding/cutting media/materialsSoldering mediaRare earthBrass

The invention relates to the technical field of welding materials, in particular to silver solder for connecting brass and stainless steel. The invention aims at overcoming the defects that existing solder for connecting the brass and the stainless steel is high in silver content and in welding cost, and providing the silver solder for connecting the brass and the stainless steel, wherein the silver solder is low in silver content and in welding cost, and non-cadmium silver solder containing more than 25wt.% of silver can be replaced by the silver solder for connecting the brass and the stainless steel. According to the technical scheme, the silver solder for connecting the brass and the stainless steel comprises components, by weight, 18-22 wt.% of Ag, 30-35wt.% of Zn, 0.3-4.5wt.% of In, 0.3-3.0wt.% of Sn, 0.1-2.5wt.% of Ni, 0.001-0.1wt.% of rare earth, and the balance Cu.

Owner:浙江信和科技股份有限公司

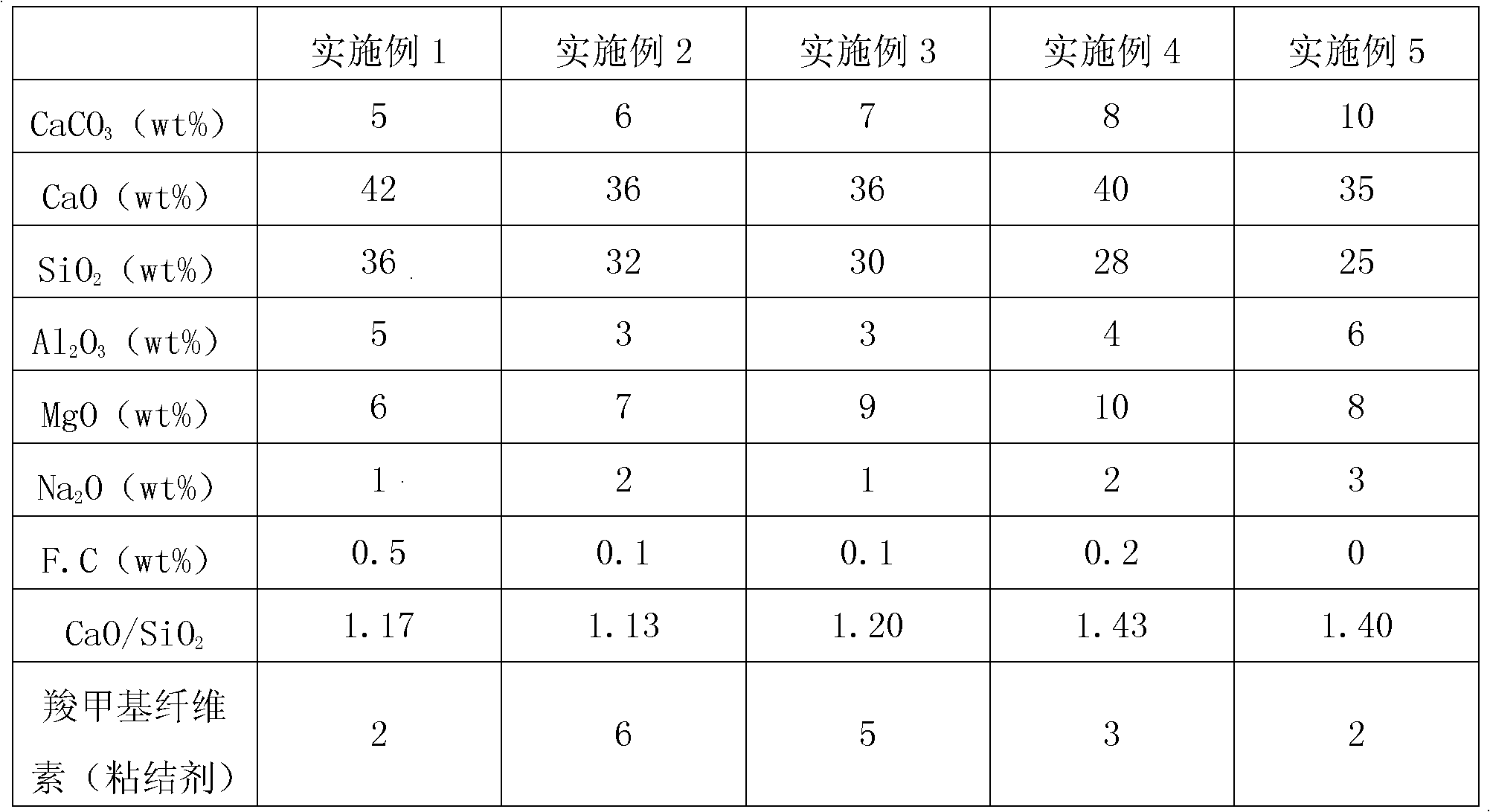

Tundish covering flux

The invention discloses a tundish covering flux, which comprises the following components by mass: 5-10% of CaCO3, 60-80% of CaO+SiO2, 3.0-6.0% of Al2O3, 6.0-10.0% of MgO, 1.0-3.0% of Na2O, 0-0.5% of fixed carbon, 0-10.0% of lightweight bulk material, 2-6.0% of binder, 0-0.5% of water and the balance of inevitable impurities, wherein the ratio of CaO to SiO2 is 1.1-1.5. The tundish covering flux is added into molten steel, and then a three-layer structure comprising a slag formation layer, a sintering layer and a melting layer is formed on the molten steel. The tundish covering flux does not incrust in a using process, and has a proper melting point, spreadability and high heat-preservation performance; and the excessive temperature drop of the molten steel in a tundish can be prevented, and a slag crust is prevented from being formed on the surface of the molten steel.

Owner:BAOSHAN IRON & STEEL CO LTD +1

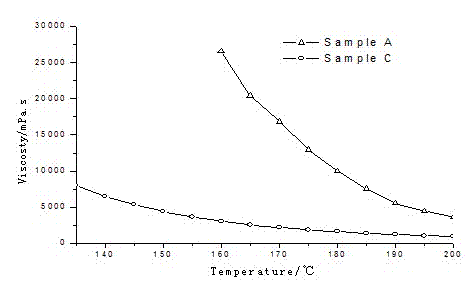

Semicrystalline polyester resin for TGIC-cured high-leveling powdery paint and synthetic method thereof

ActiveCN103483565AHigh crystallinityCrystallinity is 0~60% (XRD), high melting pointPowdery paintsPolyester coatingsPolymer sciencePolyol

The invention discloses a semicrystalline polyester resin for a TGIC-cured high-leveling powdery paint. The resin is prepared through melt phase polycondensation of the following components by weight: 29 to 45% of polyol, 45 to 65% of aromatic polyprotic acid, 5 to 15% of an acidulate agent and 0.01 to 0.15% of an esterification catalyst. The polyester resin has an appropriate degree of crystallinity, a high melting point, low viscosity and excellent storage stability; the prepared powdery paint has excellent leveling performance and mechanical properties, and a coating of the powdery paint basically has no orange peel. The invention also discloses a synthetic method for the semicrystalline polyester resin used for the TGIC-cured high-leveling powdery paint.

Owner:GUANGZHOU KINTE IND

Leadless welding alloy for welding electronic elements

InactiveCN101417375AImprove antioxidant capacityPrevent oxidationWelding/cutting media/materialsSoldering mediaRare-earth elementSoldering

The invention relates to a leadless soldering alloy used for welding of electronic elements and is characterized in that the weight percentage of all the alloying elements is as follows: 5 to 10 percent of zinc, 0.1 to 5 percent of gallium, 0.1 to 1 percent of rare earth elements and tin as the rest. The leadless soldering alloy has the advantages of low alloy cost, proximity of melting point to the traditional solder, better wettability, excellent mechanical performance, no toxicity, no pollution, excellent comprehensive performance and leading the oxidation resistance to be improved greatly, and can meet the requirements of the application fields of leadless solder of the electronic industry, in particular to household appliances and the like.

Owner:BEIJING COMPO ADVANCED TECH

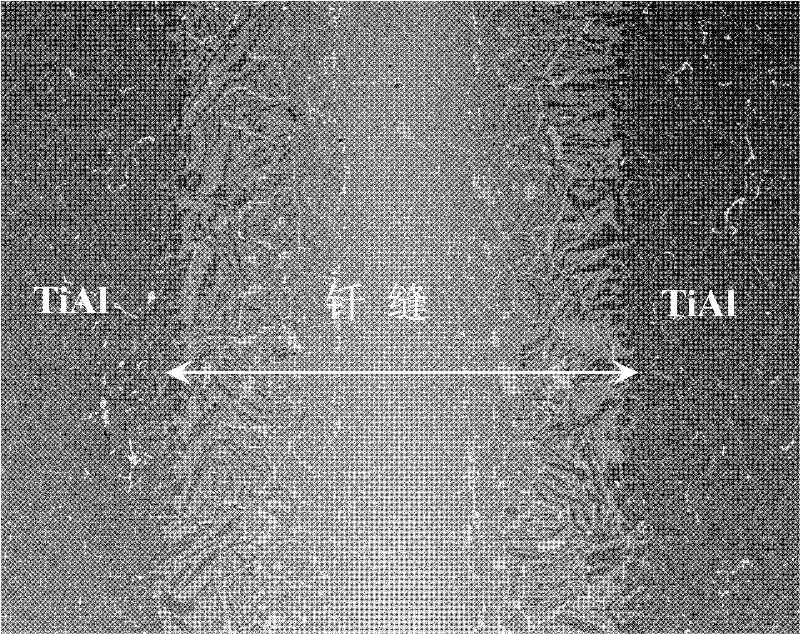

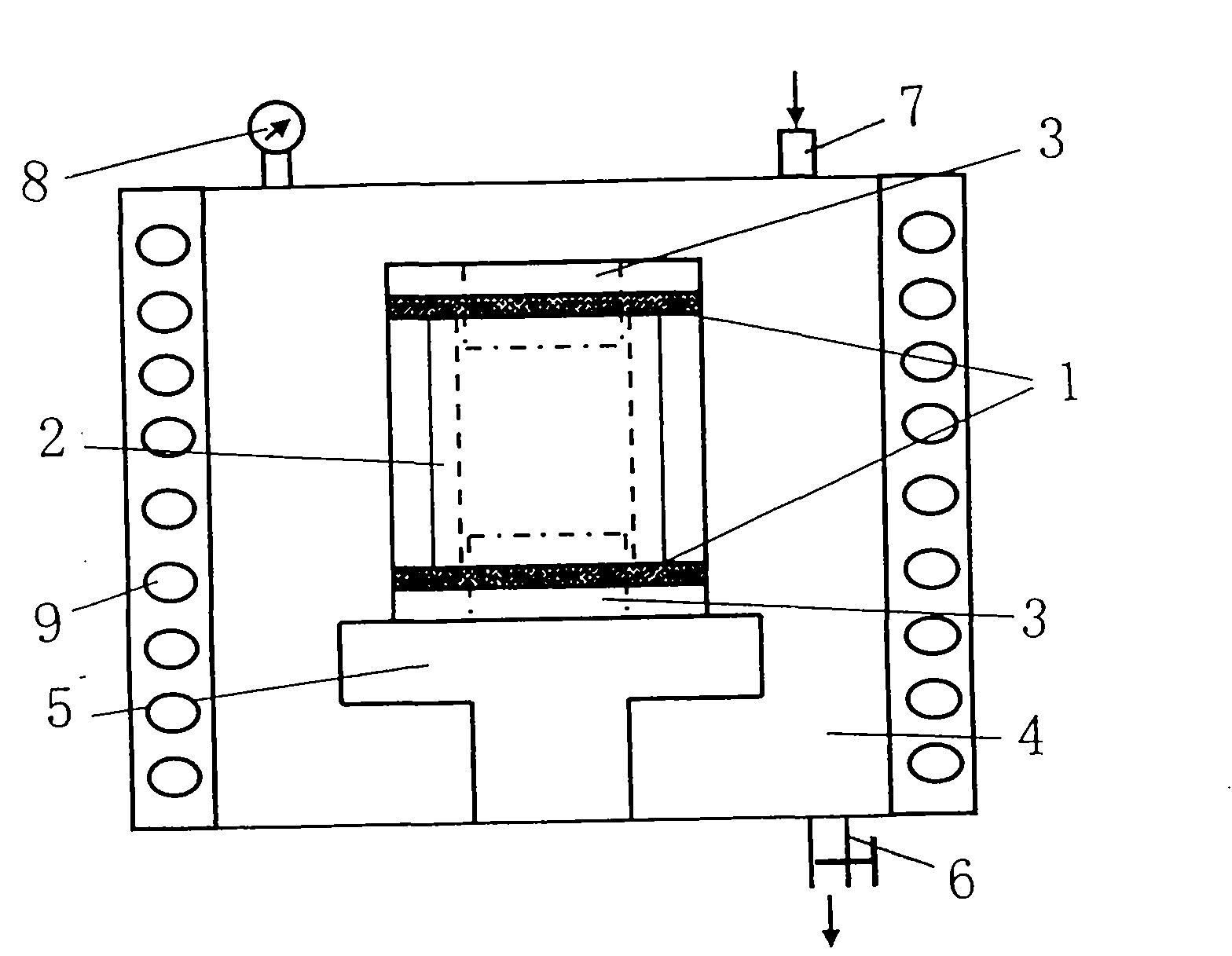

High-temperature solder for brazing TiAl-based alloy and preparation method thereof

ActiveCN102198569ARight melting pointImprove wettabilityWelding/cutting media/materialsSoldering mediaWettingNoble metal

The invention discloses a preparation method of a high-temperature solder for brazing a TiAl-based alloy, and relates to the high-temperature solder and the preparation method thereof. The invention solves the problems that a TiAl-based alloy brazing joint obtained by using the conventional solder is low in use temperature and has low performance under a high-temperature environment, the used solder is high in price, and the solder preparation technology is complicated. The solder is made of Ti, Ni and V. The preparation method comprises the following steps of: weighing raw materials; 2, filling the raw materials in arc melting equipment, vacuumizing, filling argon, melting and alloying, and repeatedly melting and cooling. Compared with the conventional solder, the solder prepared by the invention has an appropriate melting point and good wetting property; the solder components are free of noble metals, such as Ag, Zr and the like, so the cost is low; the brazing joint has high strength under the high-temperature environment of 800 DEC, and is applicable to various joints; and the preparation method is simple and convenient.

Owner:HARBIN INST OF TECH

Tin zinc copper leadless solder alloy

InactiveCN1555960AHigh bonding strengthImprove stabilityWelding/cutting media/materialsSoldering mediaMetallic materialsCopper

Owner:DALIAN UNIV OF TECH

Magnesium alloy rare earth compound flux and its production method

The present invention provides a magnesium alloy rare earth compound flux and its production method. Its composition includes (wt%) 40-55% of magnesium chloride, 15-25% of potassium chloride, 12-25% of sodium chloride, 1-6% of calcium chloride, 5-15% of calcium fluoride, 1-8% of barium chloride and 3-10% of rare earth activator. Said ivnention flux has high activity, proper melting point, density, viscosity and surface tension, and can greatly raise mechanical property of magnesium alloy and corrosion resistance.

Owner:SHANGHAI HAOHUA MOLD

Mg-Gd-Y-Zr magnesium alloy refining flux and producing method thereof

The invention provides an Mg-Gd-Y-Zr magnesium alloy refining flux and a production method thereof. The chemical components of the flux are mixed according to the following mass percentages: potassium chloride of ranging from 30 to 50 percent, barium chloride of ranging from 5 to 20 percent, sodium chloride of ranging from 2 to 10 percent, calcium chloride of ranging from 10 to 20 percent, calcium fluoride of ranging from 2 to 8 percent, cryolite of ranging from 1 to 5 percent, gadolinium compound of ranging from 3 to 8 percent, yttrium compound of ranging from 3 to 8 percent, and zirconium compound of ranging from 2 to 8 percent, wherein, the gadolinium compound is gadolinium chloride, gadolinium carbonate or gadolinium fluoride, the yttrium compound is yttrium chloride, yttrium carbonate or yttrium fluoride, the zirconium compound is zirconium tetrachloride or potassium zirconium fluoride. The flux has good melting point, viscosity, wettability and the slag removing performance which is improved greatly. Because the flux does not contain magnesium chloride or react with the lanthanon such as gadolinium and yttrium, the chemical reaction loss of the lanthanon in the refining process is not caused, thereby being particularly suitable for the refining purifying process of the Mg-Gd-Y-Zr magnesium alloy and improving the refining effect of the magnesium fused mass.

Owner:SHANGHAI JIAO TONG UNIV

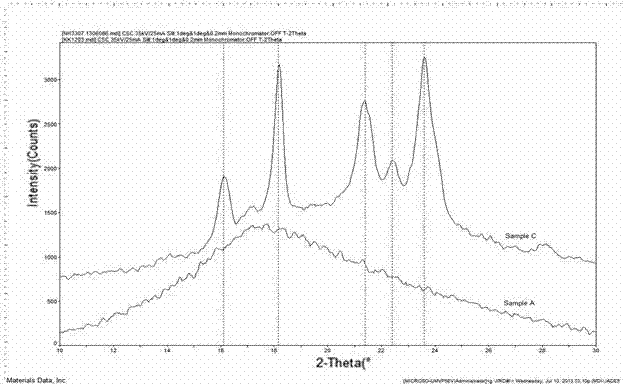

High-temperature solder for welding TiAl group alloy and preparation method thereof

InactiveCN101337307AImproved melt wettabilityRight melting pointWelding/cutting media/materialsGrain treatmentsMaterials preparationAlloy

The invention discloses a high-temperature brazing filler metal used for TiAl-based alloy braze welding, and a preparation method thereof, relates to a brazing filler metal and a preparation method thereof, and solves the problems that the strength of a TiAl-based alloy braze welding joint is low in a high-temperature environment, the price of the brazing filler metal is high, the forms of adaptable joints are restricted, and the production process of the brazing filler metal is complicated. The brazing filler metal is made from TiH2, Ni, Si and C according to certain weight percentage by two steps, namely material preparation and mechanical alloying. For TiAl-based alloy, the melting point of the brazing filler metal is appropriate, the wetting property is good, the cost is low, the braze welding quality is good, the braze welding joint has good high-temperature mechanical properties, and the requirements of various types of joints are satisfied; moreover, the production process and equipment for the brazing filler metal are simple, and the production efficiency is high.

Owner:HARBIN INST OF TECH

Ti element control method for Ti-contained corrosion resistant alloy ingot extracting electroslag remelting slab

The invention relates to a Ti element control method for a Ti-contained corrosion resistant alloy ingot extracting electroslag remelting slab. The control method comprises the following steps: a proper slag system is designed; according to each of melt electrodes with different chemical components, the TiO2 content of the slag system when the Ti element burning loss is balanced is obtained through a thermodynamic calculation method; the matched slag system is selected to control the Ti element burning loss; when the electroslag remelting begins, 3% of SiO2 is added; after the electroslag remelting is performed for 2-3 hours, 1-3% of remainder SiO2 is added in a slag pool; in the electroslag remelting process, Al particles are added for deoxidizing molten slag; and the content sum of the Al particles and Al in the electrode is controlled at 0.2% which is the upper limit of Al content in a UNSN08825 alloy. The Ti element control method solves the problem of synchronous control of surface quality, internal quality and Ti element content of the electroslag remelting slab in the ingot extracting electroslag remelting process of a Ti-contained iron nickel-based corrosion resistant alloy UNSN08825 slab in the atmospheric environment.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Alloy brazing filler metal of brazing-flux-free brazing foamed aluminum core veneer and preparation method thereof

ActiveCN102941416AImprove liquidityHigh melting pointWelding/cutting media/materialsSoldering mediaFiller metalSilicon

The invention discloses an alloy brazing filler metal of a brazing-flux-free brazing foamed aluminum core veneer and a preparation method of the alloy brazing filler metal, wherein the alloy brazing filler metal is an alloy material whose range of melting point is from 450 DEG C to 600 DEG C. Elements of Cu and Mg are added in an aluminum-silicon-based brazing flux to prepare the alloy material with better flowability and appropriate melting point as a brazing filler metal, the alloy brazing filler metal is good in flowability and low in melting point, the elements of Cu and Mg in a brazing filler metal body are dispersed towards a solid phase foamed aluminum end in the welding process and are wetted and spread out on the surface of a base metal to implement the connection of parts, no brazing flux is used in a matched way in the welding process, no vacuum or protection atmosphere condition is needed, a compact oxidation film is removed by using a mechanical / physical method in a matched way, and a compact welding line is formed during the welding to implement the high-strength welding of the foamed aluminum.

Owner:王桂长

Antistatic agent and method for preparing same

The invention relates to antistatic agent used for acrylonitrile-butadiene-styrene (ABS) resin and a method for preparing the same. Methacrylate is added to p-styrenesulfonic acid salt according to an appropriate proportion, and the methacrylate reacts with the p-styrenesulfonic acid salt under the action of initiator to generate the antistatic agent. Because the methacrylate and the p-styrenesulfonic acid salt copolymerize to generate diblock copolymer, and the diblock copolymer adjusts the high melting point of p-styrenesulfonic acid salt homopolymer, the antistatic agent can be processed in the ABS forming and processing temperature range, the antistatic performance of the ABS can be improved, and the main mechanical performance of the ABS can not be affected.

Owner:EAST CHINA UNIV OF SCI & TECH

High-entropy alloy for brazing of TiAl and nickel-based high-temperature alloy and preparation method

ActiveCN112222674AImprove wettabilityGood compatibilityWelding/cutting media/materialsSoldering mediaHigh entropy alloysIngot

The invention discloses a high-entropy alloy for brazing of TiAl and nickel-based high-temperature alloy and a preparation method. The high-entropy alloy comprises the following chemical components inatomic percent: 15-25% of Al, 10-20% of Cu, 10-20% of Co, 10-20% of Fe, 10-20% of Cr, 5-15% of Ni and 5-15% of Ti. The preparation method comprises the following steps: weighing raw materials required by smelting according to the components of brazing filler metal; smelting the raw materials to obtain a high-entropy alloy brazing filler metal ingot; and preparing a high-entropy alloy amorphous foil belt by utilizing a vacuum quenching rapid solidification technology, or preparing high-entropy alloy brazing filler metal powder by adopting a vacuum gas atomization technology. The high-entropy alloy brazing filler metal has very high mixed entropy, the structure of the high-entropy alloy brazing filler metal is mainly a solid solution structure, the high-entropy alloy brazing filler metal can be used for brazing connection between two extremely different materials, namely TiAl alloy and nickel-based high-temperature alloy, and can keep good compatibility with the two welded base materials simultaneously, and high connection strength is obtained.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Low-silver electro vacuum brazing filler metal used for sealing weld of electronic device

InactiveCN102029484AImprove wettabilityGood spreadabilityWelding/cutting media/materialsSoldering mediaElectricityIndium

The invention relates to a low-silver electro vacuum brazing filler metal used for sealing weld of an electronic device, which belongs to the technical field of brazing materials. The low-silver electro vacuum brazing filler metal comprises the following chemical compositions in percentage by mass: 41 to 43 percent of silver (Ag), 51 to 53 percent of copper (Cu), 4 to 6 percent of stannum (Sn), less than or equal to 2 percent of indium (In) and less than or equal to 0.4 percent of nickel (Ni). The low-silver electro vacuum brazing filler metal has the advantages of: contributing to reducing the silver content so as to save resources and reduce cost, and contributing to guaranteeing a proper melting point, high plasticity and high machinability so as to replace Ag72Cu brazing filler metal.

Owner:常熟市双华电子有限公司

Welding method of four-wing octagonal radio frequency quadrupole cavity

The invention relates to a welding method of a four-wing octagonal radio frequency quadrupole cavity. The welding method includes the steps that finish machining is conducted on the inner surfaces and the outer surfaces of electrodes and side wings; the electrodes and the side walls are cleaned; electrode soldering flux tanks are arranged, and soldering flux filling is conducted; the electrodes and the side wings are combined and spliced; the assembling gap of welding faces is measured and regulated; and a vacuum cavity is formed by welding the electrodes and the side wings through a vacuum brazing furnace. The cavity prepared through the method mentioned above comprises the horizontal electrodes, the vertical electrodes and the side wings; and the corresponding electrode soldering flux tanks are arranged on the two sides of each electrode, the soldering flux tanks are filled with silver-copper alloy soldering flux, and the size of the soldering flux welding tanks is regulated according to the size of the welding faces. The welding method has the beneficial effects that the welding process is simple; by selecting the soldering flux and controlling the temperature of the welding process, outflow of the soldering flux towards the interior of the cavity is reduced to a great extent, and the soldering flux is uniformly diffused; and no soldering flux exits in the cavity, the problem that high-pressure ignition is generated when the RFQ cavity operates at a high frequency can be solved, and normal operation of the RFQ cavity is ensured.

Owner:上海克林技术开发有限公司

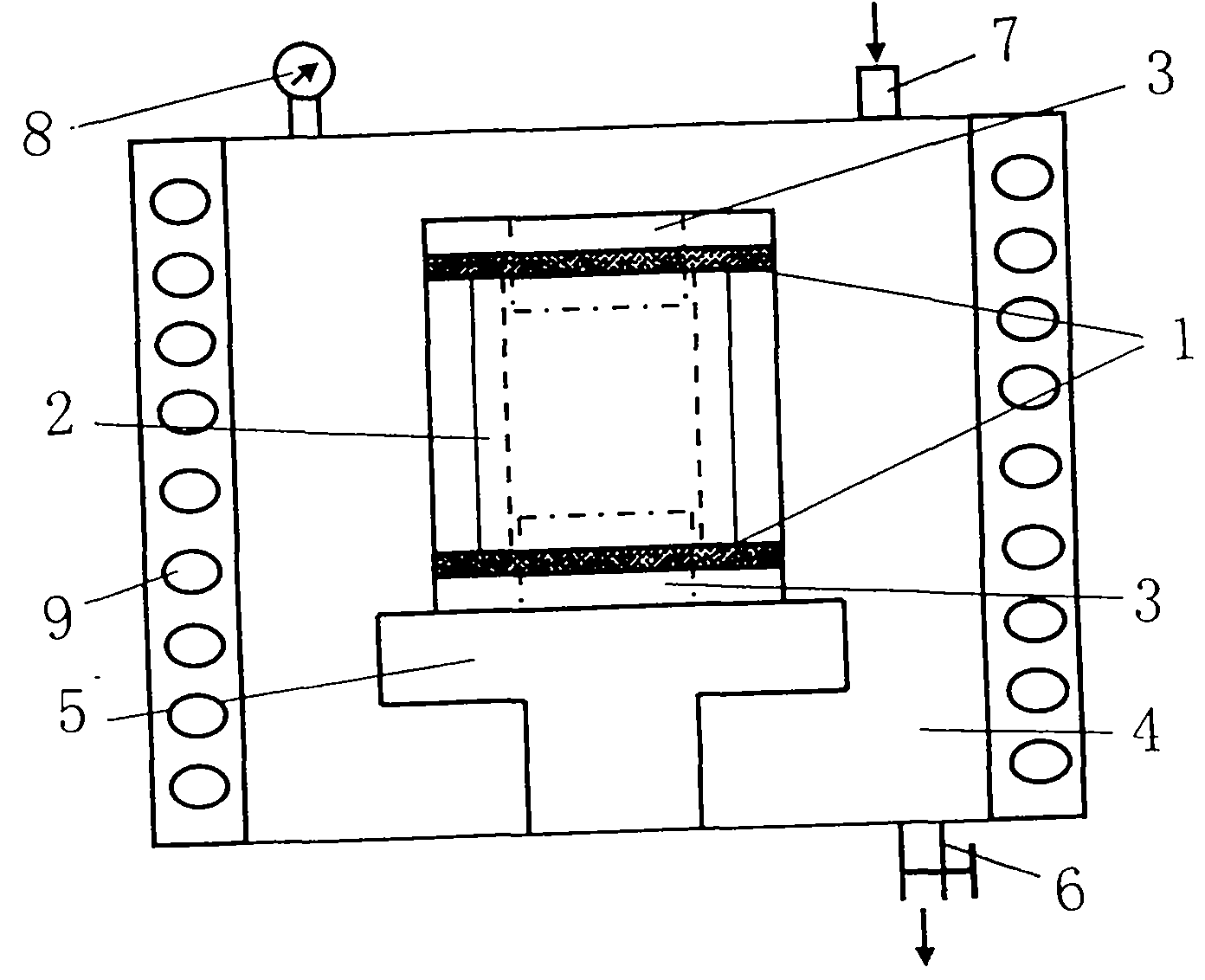

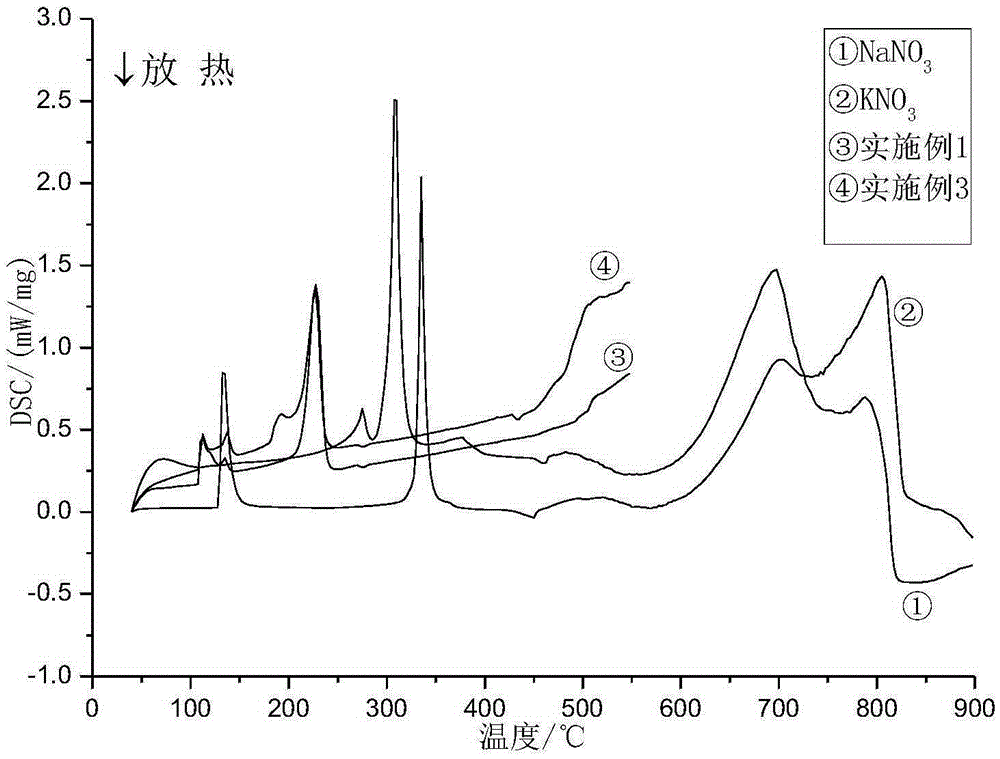

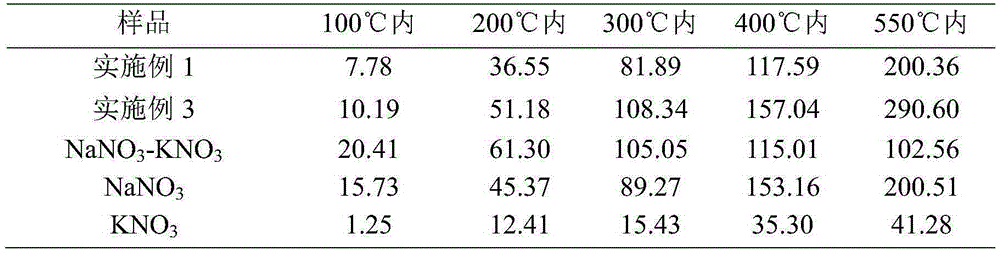

Method for preparing ternary nitric acid molten salt phase change heat storage material

ActiveCN105419732ARight melting pointImprove heat storage capacityHeat-exchange elementsMechanical crushingSodium nitrate

The invention discloses a method for preparing a ternary nitric acid molten salt phase change heat storage material. The method comprises the steps of 1, weighing sodium nitrate, potassium nitrate and neodymium nitrate, and crushing sodium nitrate, potassium nitrate and neodymium nitrate through a mechanical crushing method to obtain sodium nitrate powder, potassium nitrate powder and neodymium nitrate powder; 2, mixing the sodium nitrate powder, the potassium nitrate powder and the neodymium nitrate powder to obtain a ternary nitric acid molten salt phase change heat storage material prefabricated body; 3, first melting the ternary nitric acid molten salt phase change heat storage material prefabricated body and then sequentially performing drying and ball milling crushing treatment to obtain the ternary nitric acid molten salt phase change heat storage material. According to the method for preparing the ternary nitric acid molten salt phase change heat storage material, the problems that an existing molten salt phase change heat storage material is high in cost, long in production cycle and complex in process in the preparation process are solved, and the prepared ternary nitric acid molten salt phase change heat storage material has the advantages of being wide in use temperature range, high in heat storage capability, low in corrosiveness and good in liquidity.

Owner:辽宁卓仑科技有限公司

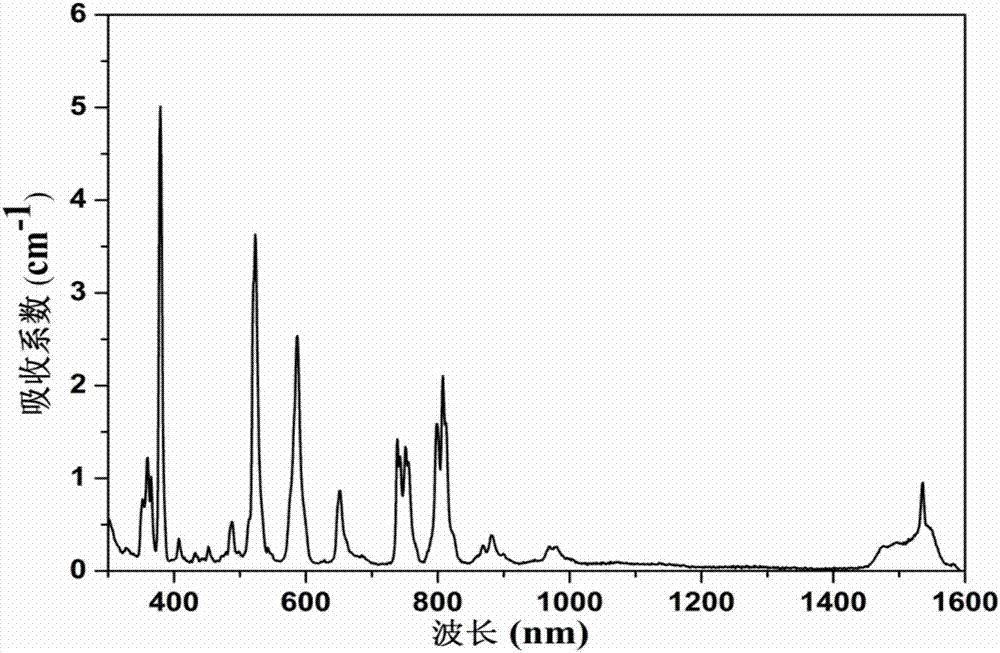

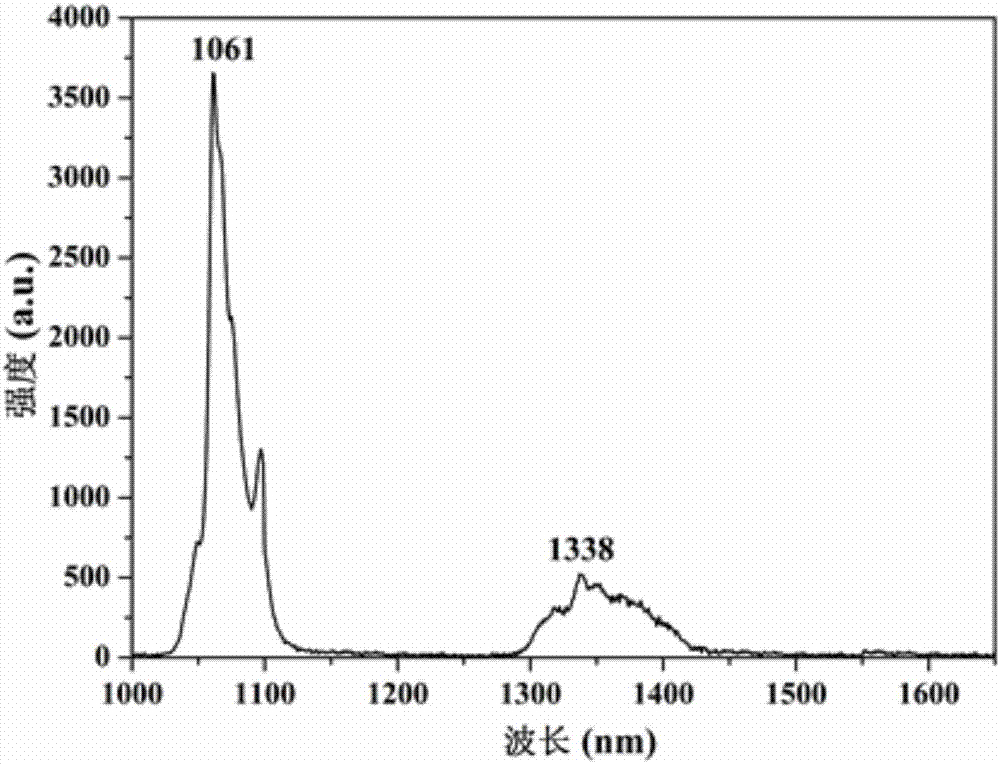

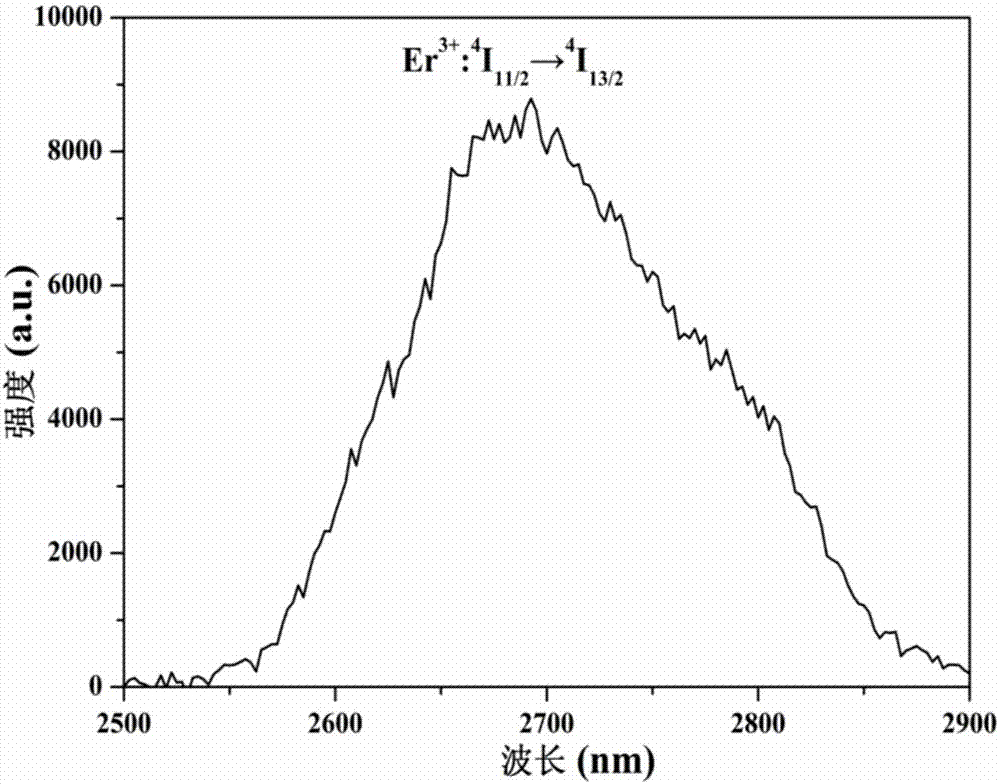

Crystal material, preparation method thereof and application as laser crystal

InactiveCN107419334AEnhanced fluorescence emissionSolution to short lifePolycrystalline material growthBy pulling from meltTetragonal crystal systemSpace group

The invention discloses a crystal material, which is characterized in that the chemical formula of the crystal material is CaNdxEryLa(1-x-y)Ga3O7, wherein x is greater than or equal to 0.01 and less than or equal to 0.05, and y is greater than or equal to 0.1 and less than or equal to 0.3; the crystal material belongs to a tetragonal system and a space group shown in the description; the crystal material is formed into a laminated electronegative skeleton structure formed by a GaO4 tetrahedron, and Nd<3+>, Er<3+>, Ca2<+> and La<3+> are distributed among layers and have an unordered crystal structure. An Nd<+> ion is doped in Er<+3> activated CaLaGa3O7 crystal to greatly enhance the adsorption efficiency of the crystal for pump light, the efficient laser output of the -2.7mu m waveband of LD pumping is realized, the fluorescence emission of the crystal in an intermediate infrared waveband is enhanced, the service life and the particle number of 4I13 / 2 are greatly decreased, a self-final state bottleneck effect is inhibited, high gain is kept by laser media in an oscillation process, and the slope efficiency of the laser output is improved.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

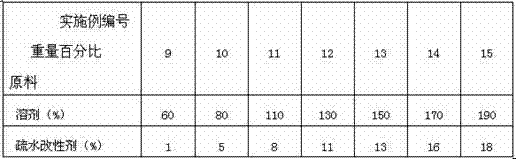

Preparation method of hydrophobic chromic oxide

InactiveCN102516823AImprove hydrophobicityEasy to absorb moistureNon-macromolecular adhesive additivesInksPolymer scienceFiltration

The invention discloses a preparation method of hydrophobic chromic oxide and the preparation method is characterized by comprising the following steps of: taking chromic oxide, taking a solvent which accounts for 50-200% of the weight of chromic oxide, taking a hydrophobic modifier which accounts for 0.5-20% of the weight of chromic oxide, mixing chromic oxide, the solvent and the hydrophobic modifier, stirring and reacting at 50-150 DEG C for 10-120 min, followed by pumping filtration, and drying the solid to prepare the hydrophobic chromic oxide. According to the invention, the raw materials are easily available; the production technology is easy to carry out; and the modified chromic oxide prepared can be used as a filling material of rubber and resin based composite materials or paints, a coloring agent for artificial leather and a special printing ink for printing bank note. The preparation method has a wide application prospect.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Low silver leadless solder and preparation

InactiveCN101239424ALow costAg content decreasedWelding/cutting media/materialsSoldering mediaCeriumOxidation resistant

The invention pertains to electronic solder technique field, and is a modified technique based on prior art, specifically relates to a low-silver leadless solder and preparing method thereof. The components and weight percent of the low-silver leadless solder are: 0.1-0.61f Ag, 0.45-0.79514612004f Cu, 1-51f Bi, 0.02-0.226154000f P, 0.02-0.09150547514f lanthanum-cerium mixed rare earth (RE), residue percent of Sn, and weight sum of each component is 100 In the precondition that the Ag content is decreased remarkably and the welding material cost is saved, the solder with a moderate fusion point, good antioxygenic property, excellent braze welding technique property and integrate mechanical property is obtaind. The invented braze welting material is provided with a stable property, a low cost and broad market application foreground.

Owner:PERFECTION SCI & TECH DONGGUAN

Low-silver copper-based solder free of spillover phenomenon during weld period

ActiveCN103008915ANo spillageRight melting pointWelding/cutting media/materialsSoldering mediaIndiumRare earth

The invention discloses a low-silver copper-based solder free of a spillover phenomenon during a weld period. Aiming at the defect that the spillover phenomenon of the solder often occurs when brazing is performed by using traditional low-silver copper-based solder, the invention aims to provide the low-silver copper-based solder which is controllable in flowability and is free of the spillover phenomenon of the traditional low-silver copper-based solder during a process of welding copper and copper alloy. The low-silver copper-based solder disclosed by the invention is realized through the following technical scheme: the low-silver copper-based solder free of the spillover phenomenon during the weld period comprises the following components in weight percent: 6.6-7.8 percent of phosphorus (P), 0.5-2.2 percent of silver (Ag), 0.01-0.4 percent of indium (In), 0.001-0.2 percent of silicon (Si), 0.001-0.1 percent of rare earth and the balance copper (Cu).

Owner:浙江信和科技股份有限公司

Coil coating resistant to wear and scratch

InactiveCN102086341AHigh hardnessIncreased abrasion and scratch resistancePolyester coatingsDiluentPolyester resin

The invention discloses a coil coating resistant to wear and scratch. The main technical formula of the coil coating is as follows: the grinding process relates to the following raw materials in parts by weight: 15-20 parts of polyester resin, 30-35 parts of titanium dioxide pigment, 2-4 parts of dispersant and 8-10 parts of diluent; and the preparation process of the coil coating relates to the following components in parts by weight: 25-30 parts of polyester resin, 4-6 parts of crosslinked resin, 0.2-1 part of catalyst, 0.2-1 part of flatting agent, 2-4 parts of additive and 6-7 parts of diluent. The coating has novel formula and simple preparation method; and the wear resistance and scratch resistance of the coated metal can be improved and the coated metal has excellent performance in a harsh service environment.

Owner:天津市新宇彩板有限公司

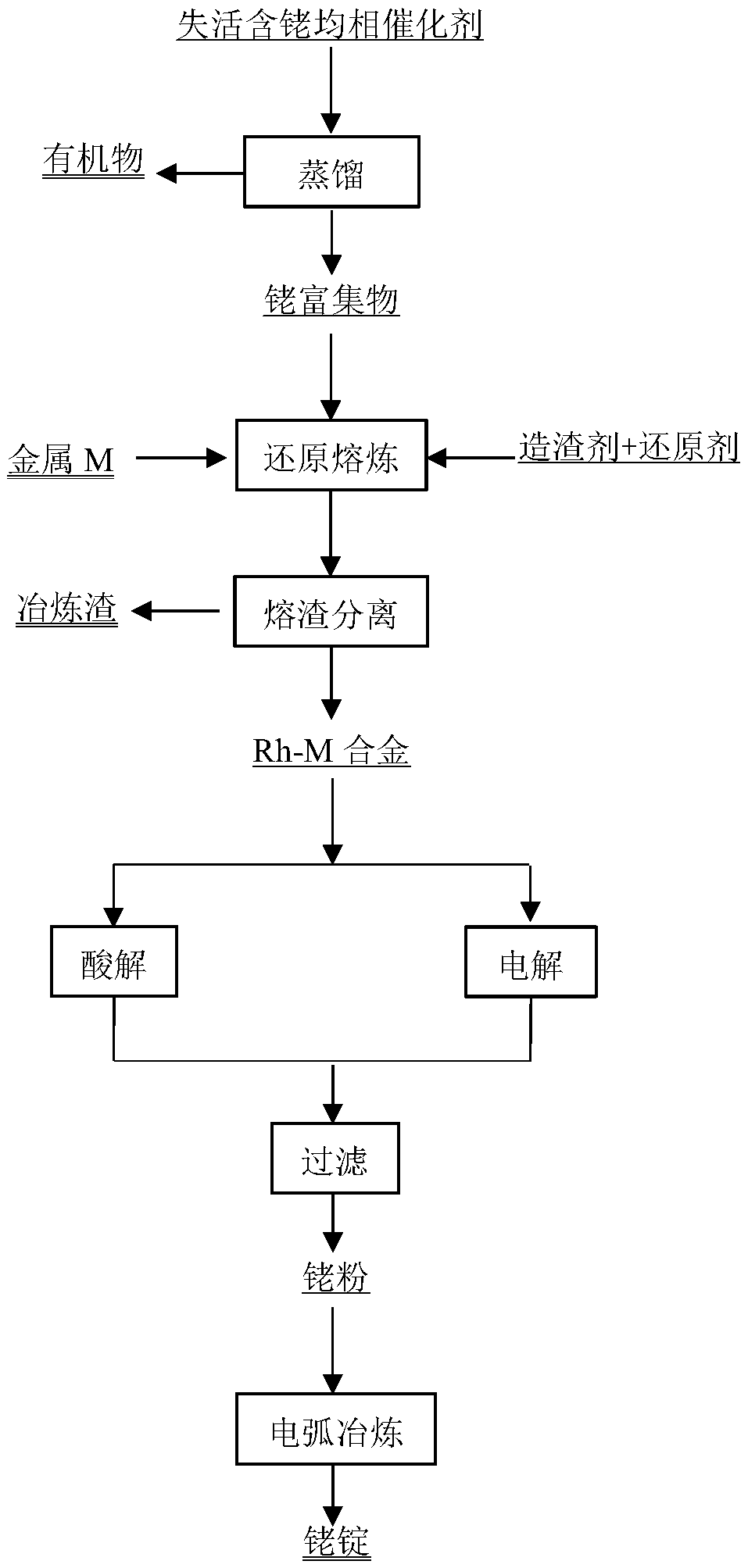

Method for recovering rhodium from inactive rhodium-containing homogeneous catalyst

ActiveCN108950233AAvoid pollutionHigh reactivityPhotography auxillary processesProcess efficiency improvementElectrolysisElectric arc furnace

The invention mainly belongs to the technical field of rhodium recovery and particularly relates to a method for recovering rhodium from an inactive rhodium-containing homogeneous catalyst. The methodcomprises the following steps that organic matter in the rhodium-containing homogeneous catalyst is recovered in a distillation mode at first, and rhodium concentrate is obtained; then the rhodium concentrate is mixed with transitional metal M, a reduction agent and a slag former, rhodium is recovered in a smelting manner and forms a low-melting-point Rh-M alloy together with the transitional metal M, then the Rh-M alloy is subjected to electrolysis or acidolysis to obtain rhodium powder, finally the rhodium powder is smelted through an electric-arc furnace, and accordingly a rhodium ingot isobtained. The method is suitable for various inactive rhodium-containing homogeneous catalysts, the situation that the organic matter is directly incinerated to cause air pollution is avoided, meanwhile, the high-melting-point rhodium can be converted into the low-melting-point high-reactivity Rh-M alloy, and subsequent rhodium smelting and purification are facilitated. The method has the advantages of being high in rhodium recovery rate and production efficiency, free of pollution and suitable for industrial application.

Owner:UNIV OF SCI & TECH BEIJING

Low-nickel high-nitrogen austenitic stainless steel continuous casting crystallizer covering slag

The invention relates to low-nickel high-nitrogen austenitic stainless steel continuous casting crystallizer covering slag, and belongs to the technical field of metal smelting accessories. The low-nickel high-nitrogen austenitic stainless steel continuous casting crystallizer covering slag is prepared from, by weight, 33.5-38.25 parts of CaO, 25.4-29.6 parts of SiO2, 3-6 parts of Al2O3, larger than 0 and smaller than or equal to 4 parts of Fe2O3, 2-5 parts of MgO, 3.5-9.5 parts of Na2O, 4.5-8.5 parts of F and 3-7 parts of C. The covering slag has the appropriate alkalinity, smelting point, viscosity and carbon addition, suitable heat transfer ability and good filling performance, and can well adapt to characteristics of low-nickel high-nitrogen austenitic stainless steel continuous casting.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

High-entropy alloy brazing filler metal and preparation method thereof

ActiveCN112222675AReduce manufacturing costLow costWelding/cutting media/materialsSoldering mediaHigh entropy alloysIngot

The invention discloses high-entropy alloy brazing filler metal and a preparation method thereof. The high-entropy alloy brazing filler metal comprises the following chemical components in atomic percent: 10-20% of Al, 10-20% of Cu, 10-20% of Co, 10-20% of Fe, 10-20% of Ni, 10-20% of Cr, 4-12% of Si and 4-12% of B. The preparation method comprises the following steps: weighing raw materials required for smelting according to the components of the brazing filler metal; smelting the raw materials to obtain a high-entropy alloy brazing filler metal ingot; and preparing a high-entropy alloy amorphous foil belt by utilizing a vacuum quenching rapid solidification technology, or preparing high-entropy alloy brazing filler metal powder by adopting a vacuum gas atomization technology. The high-entropy alloy brazing filler metal has very high mixed entropy, the structure of the high-entropy alloy brazing filler metal is mainly a solid solution structure, the high-entropy alloy brazing filler metal can be used for brazing connection between two extremely different materials, namely TiAl alloy and nickel-based high-temperature alloy, and can keep good compatibility with the two welded base materials simultaneously, and high connection strength is obtained.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Polymer sulfonate fire retardant, and preparation method as well as application thereof

The invention relates to a polymer sulfonate fire retardant, containing a copolymer obtained by polymerization reaction from an unsaturated sodium sulfonate monomer, an unsaturated potassium sulfonate monomer and a vinyl monomer; the vinyl monomer is selected from any one or more of C6-C12 aromatic vinyl compounds, a (methyl) acrylate compound, a vinyl amide compound, a vinyl ether compound or a cyanation vinyl ether compound; the mole ratio of the total of the unsaturated sodium sulfonate monomer and the unsaturated potassium sulfonate monomer to the vinyl monomer in polymer sulfonate is (0.025 to 0.5):1; the mole ratio of the unsaturated sodium sulfonate monomer to the unsaturated potassium sulfonate monomer in the polymer sulfonate is (30:70) to (90:10); a number-average molar mass of the polymer sulfonate is 1000-200000. The invention also relates to a preparation method and application of the polymer sulfonate fire retardant.

Owner:GUANGZHOU SHINE POLYMER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com