Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

566results about How to "Fully melted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

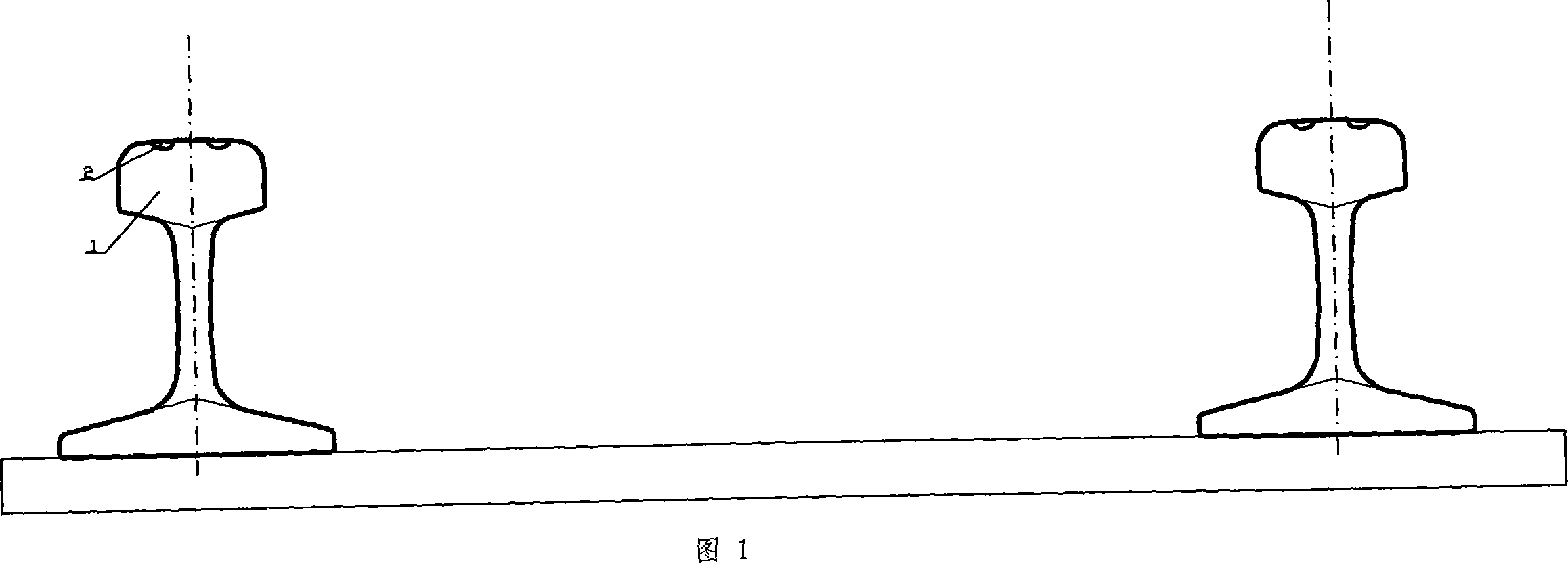

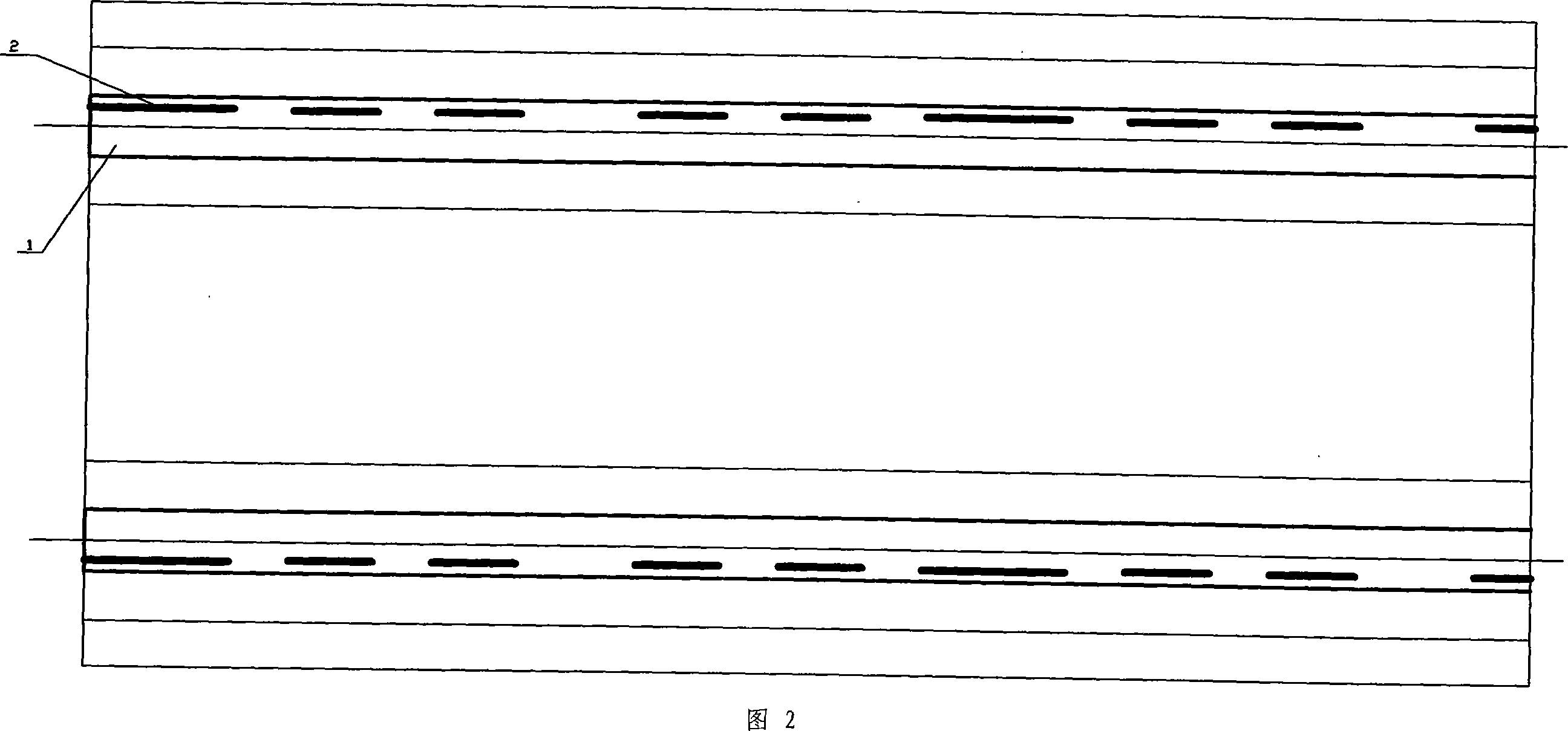

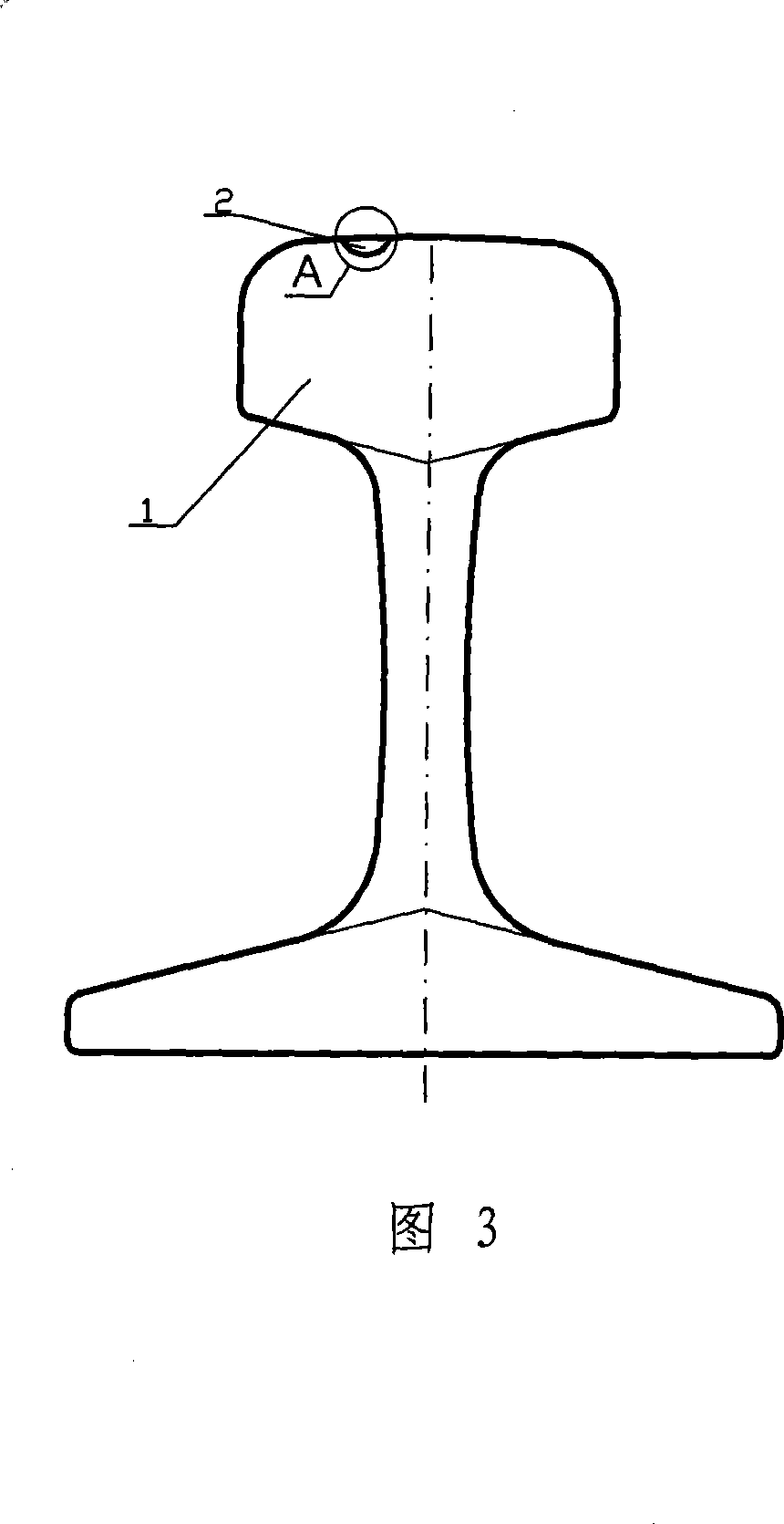

Method for melting and coating anti-rust wear-resistant alloy on steel rail surface

ActiveCN101144160AImprove efficiencyEasy to operateArc welding apparatusMetallic material coating processesBonding strengthWhite light

The present invention discloses a method for smelting rust preventing and wear resistant alloy on the surface of a steel rail. The position needing alloy smelting on the surface of the steel rail head is heated by supersonic frequency or medium frequency induction-heating equipment, the induction heater is arranged above the position needing alloy smelting on the surface of the steel rail head, and the preheating temperature is 290-450 DEG C; the alloy is smelted on the surface of the steel rail head by using plasma smelting or arc welding smelting, when the preheating temperature is 290-450 DEG C, and the welding gun of plasma build up welding or arc welding equipment is moved to the position needing alloy smelting, the alloy powder, the alloy electrode or the alloy welding wire are automatically smelted; the railroad steel rail adopting the present invention can ensure that the train wheels and the rust preventing and wear resistant alloy layer are always in a contacting and compacting state, thereby the rail circuit works normally, and the white light zone phenomenon is completely eliminated; the cracking and breaking phenomena of the steel rail do not occur, the smelted alloy has good rust preventing and wear resistant properties, high bonding strength with the steel rail, and long service life.

Owner:CHENGDU ZHONGGUI TECH CO LTD

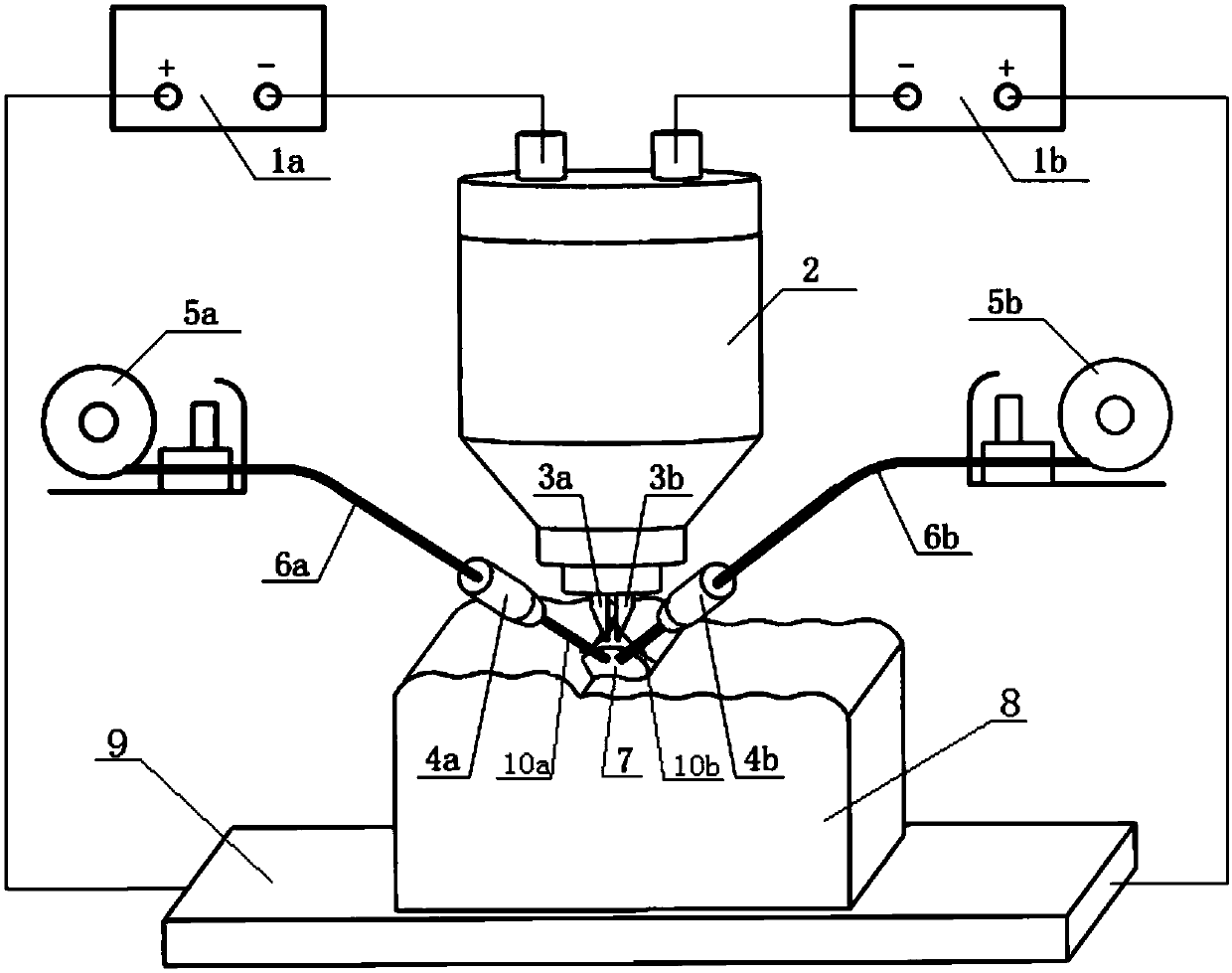

Device and method for gradient materials additive manufacturing by using two-wire twin-electrode tungsten inert gas arc

InactiveCN108788389ABroaden process specification windowImprove deposition efficiencyAdditive manufacturing apparatusArc welding apparatusMelting tankPower flow

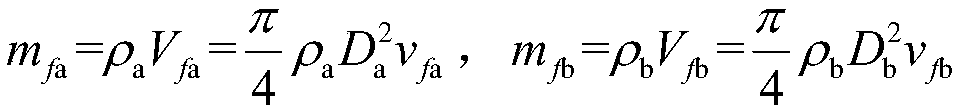

The invention provides a device and method for gradient materials additive manufacturing by using two-wire twin-electrode tungsten inert gas arc. A first partial tungsten electrode and a second partial tungsten electrode are installed below a two-tungsten-electrode argon arc additional material manufacturing gun of the device, and are vertically arranged above a base plate. A first wire guide nozzle and a second wire guide nozzle are arranged in front of the two-tungsten-electrode argon arc additional material manufacturing gun. In the deposition process, two metal wires of dissimilar compositions are conveyed to a melting bath at the same time, the composition and performance of a deposition bead are controlled by adjusting the feeding proportion of the metal wires, and thus manufacturingof the gradient material arc additional material is achieved. It is ensured that excellent forming can still be achieved in the deposition process with large current and high wire feeding speed, thecomposition of the prepared gradient material formed part can be continuously transited from the composition of one metal wire to the composition of the other metal wire without replacement of the welding wires, and the deposition efficiency is up to 330 cm<3> / h; and in addition, the deposition bead is more uniform in composition, and the relative error between the components of the deposition bead and target set compositions is smaller than 10%.

Owner:HARBIN INST OF TECH

Manufacturing method of bast fiber nonwoven fabric

InactiveCN101324012AEasy to manufactureAvoid breakingNon-woven fabricsAdhesivesNonwoven fabricMaterials science

The invention discloses a production method of a fibrilia non-woven fabric and comprises following steps: (1) opening and mixing: the fibrilia is opened once, bonding fiber and other fibers are opened for two or more times, and the opened fibrilia, bonding fiber and other fibers are mixed; (2) the mixed fibers are processed into a meshwork; (3) prickling shaping: the fiber meshwork that is obtained from step (2) is prickled by a needle machine; (4) hot rolling shaping: the fiber meshwork that is obtained after the prickling is transmitted onto a roll squeezer to be rolled, and the hot rolling shaping is implemented. The production method of the fibrilia non-woven fabric is simple, and the opening times of the fibrilia is limited, thus avoiding fibrilia break that is caused by a plurality of opening times, and consequently ensuring the length of the fibers and being convenient for the production of the non-woven fabric; simultaneously the opening of other fibers excluding the fibrilia is implemented for two or more times, thus ensuring full opening of the fibers and being convenient for the production of the non-woven fabric.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Processing method of remaking soybean cheese combinations

InactiveCN101156632AHigh nutritional valueImprove featuresCheese manufactureFood preparationSporeButterfat

The invention provides a process method for remade soybean cheese products, belongs to the food processing filed, and relates to improved remade cheese made by soybean and the producing method thereof. Firstly, lactobacillus leaven is inoculated in the bean milk, and through ferment, the clabber is made into; clabber grains are obtained through compression; mucor spore liquid is inoculated, proper metal ion is added, after cultivation, sodium chloride is added in the clabber grains, and through compression, the soybean cheese is formed; the soybean cheese is positioned with 4-8 DEG C for maturing; butterine, butterfat, stabilizing salt, or flavoring are added in the soybean cheese, through thaw, concentration, compression, and figuration, the remade soybean cheese is produced. The product has high nutrition value with low salt content, is easy to be stored, can satisfy the taste of the Chinese, and is cheap.

Owner:YANGZHOU UNIV

Vacuum brazing solder and process of Mo-Cu alloy and stainless steel

InactiveCN102554509AUniform chemical compositionReduce segregationWelding/cutting media/materialsWelding/soldering/cutting articlesHigh densityElectronic packaging

The invention relates to a vacuum brazing solder and a process of Mo-Cu alloy and stainless steel. The process comprises the steps of placing BNi2 amorphous alloy solder between preprocessed Mo-Cu alloy and surface to be brazed of austenitic stainless steel, controlling the joint gap between 40-80mum, gently placing the assembled Mo-Cu alloy and the stainless steel at a uniform temperature zone in a vacuum brazing furnace, vacuumizing and brazing, wherein the BNi2 amorphous alloy solder comprises the components in percentage by mass: 6.5-7.5% of Cr, 3.0-5.0% of Si, 2.7-3.5% of B, 2.5-3.5% of Fe, less than or equal to 0.02% of C and the balance of Ni. The Mo-Cu alloy and stainless steel joint obtained by the process disclosed by the invention have the advantages of little impurity, high density, strong high temperature resisting ability and the like and can be used for manufacturing instrument and meter elements, electronic packaging and high temperature resisting devices.

Owner:SHANDONG UNIV

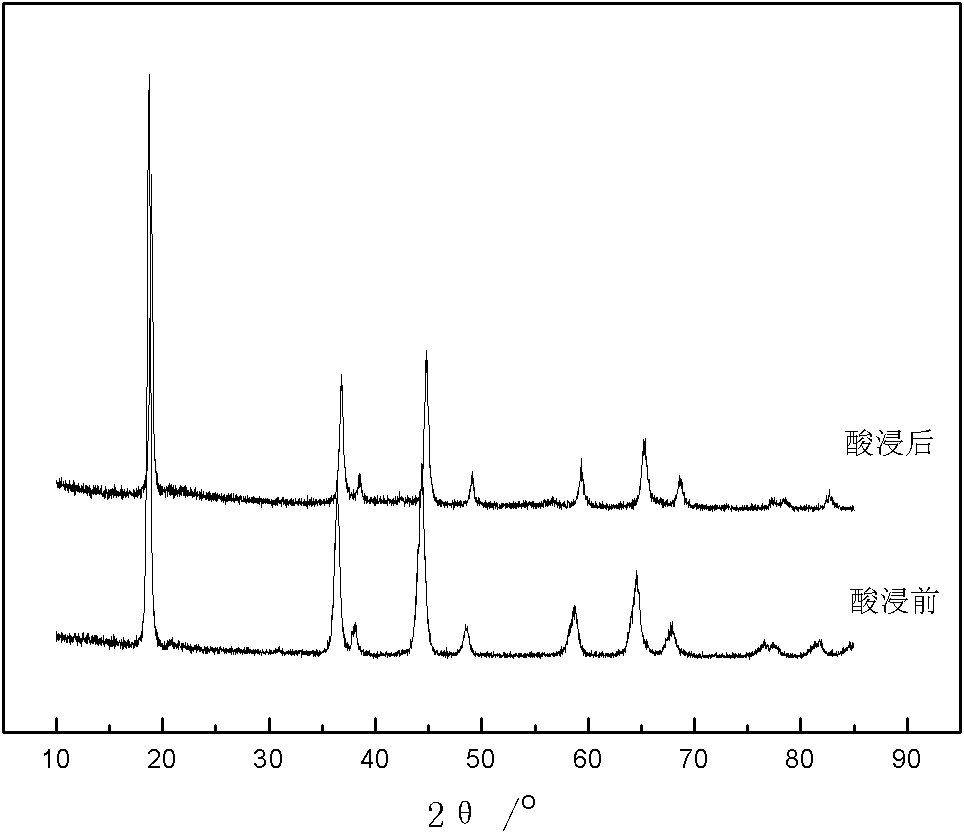

Method for preparing manganese series lithium-ion sieve adsorbent H4Mn5O12 and precursor thereof

InactiveCN101985098AThe ratio is easy to controlHas a spinel structureOther chemical processesManganese oxides/hydroxidesChemical synthesisSorbent

The invention provides a method for preparing a manganese series lithium-ion sieve adsorbent H4Mn5O12 and a precursor thereof, relating to a preparation method of an inorganic adsorbent for absorbing lithium from liquid lithium resources such as salt brine, seawater, geothermal water and the like. In the preparation method, manganese salts and lithium salts with low melting points are taken as raw materials, organic carboxylic acid is used as an ingredient, the precursor Li4Mn5O12 is obtained through soft chemical synthesis and low-temperature roasting; acid treatment is carried out on the precursor, and Li in the precursor is extracted to be converted to an H-type ion sieve represented by H4Mn5O12 or MnO2.0.31H2O; and the H-type ion sieve H4Mn5O12 is filtered, washed and dried to obtain the adsorbent capable of sieving lithium ions. The method of the invention has simple process, and the obtained ion sieve has the advantages of small dissolving loss, fast adsorption rate and high adsorption capacity.

Owner:CENT SOUTH UNIV

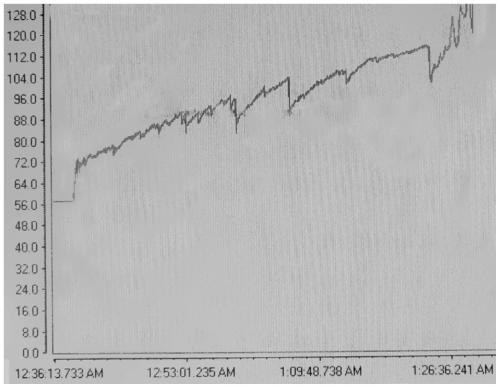

Method for controlling cleanliness of molten steel, and smelting control method capable of preventing molten steel gap from nodulation during sulphur and aluminum contained steel pouring

The invention discloses a method for controlling cleanliness of molten steel, and a smelting control method capable of preventing a molten steel gap from nodulation during sulphur and aluminum contained steel pouring, and belongs to the field of smelting. The method for controlling cleanliness of the molten steel comprises the following steps that blast furnace molten iron without desulfuration issubjected to converter smelting, and during converter tapping, deoxygenation, alloying and tapping wash heat are carried out in sequence for carrying out inclusion removal treatment. Through an LF furnace, converter tapping is subjected to refining under the condition that acid soluble aluminum is not adjusted, that is, during tapping, a slagging constituent is added for controlling refining slagcomposition, and after the slag is dissolved, deoxygenation is carried out through a deoxidizing agent. Through the process, the content of sulphur in the molten steel is monitored, ferrous sulfide is used for adjusting the content of sulphur in the molten steel to the first target value, an RH furnace is used for refining LF furnace tapping, in the process, according to the content of the acid soluble aluminum of LF furnace tapping, selective aluminum feeding is carried out to adjust the content of the aluminum to the second target value, and after RH furnace refining is finished, calcium treatment is carried out. According to the process, the cleanliness of the molten steel can be improved, the nodulation problem during molten steel pouring can be avoided, and the stopper bar curve rising can be controlled.

Owner:SGIS SONGSHAN CO LTD

Method for welding thick aluminum alloy plate

ActiveCN102922098AReduce welding distortionEasy post-weld calibrationArc welding apparatusProduct gasWelding deformation

The invention discloses a method for welding a thick aluminum alloy plate. The method comprises a cleaning process, a preheating process and a welding process, wherein the cleaning process is carried out in a chemical cleaning way and comprises steps of: dipping a part to be welded in a 8-10% NaOH solution for more than 10 minutes, and then dipping in a 40-50% HNO3 solution for 30 seconds to 1 minute, wherein sensing heating equipment is adopted in the preheating process, and the preheating is carried out at 230 to 250 DEG C; joints in the welding process are in form of angle joint, and the non-melting electrode tungsten electrode gas shielded welding is carried out in the welding method, the welding parameter can be shown as that the current is 250 to 290A, the current polarity is performed by alternating current, Ar with purity not less than 99.99% is adopted as the protective gas, and the gas flow is at 7-13 liters per minute. Through the method, little welding deformation is generated, the correcting is easily carried out after welding, the product quality can be improved, the production efficiency can be increased, and the manufacturing cost can be greatly reduced.

Owner:BEIJING CED RAILWAY ELECTRIC TECH

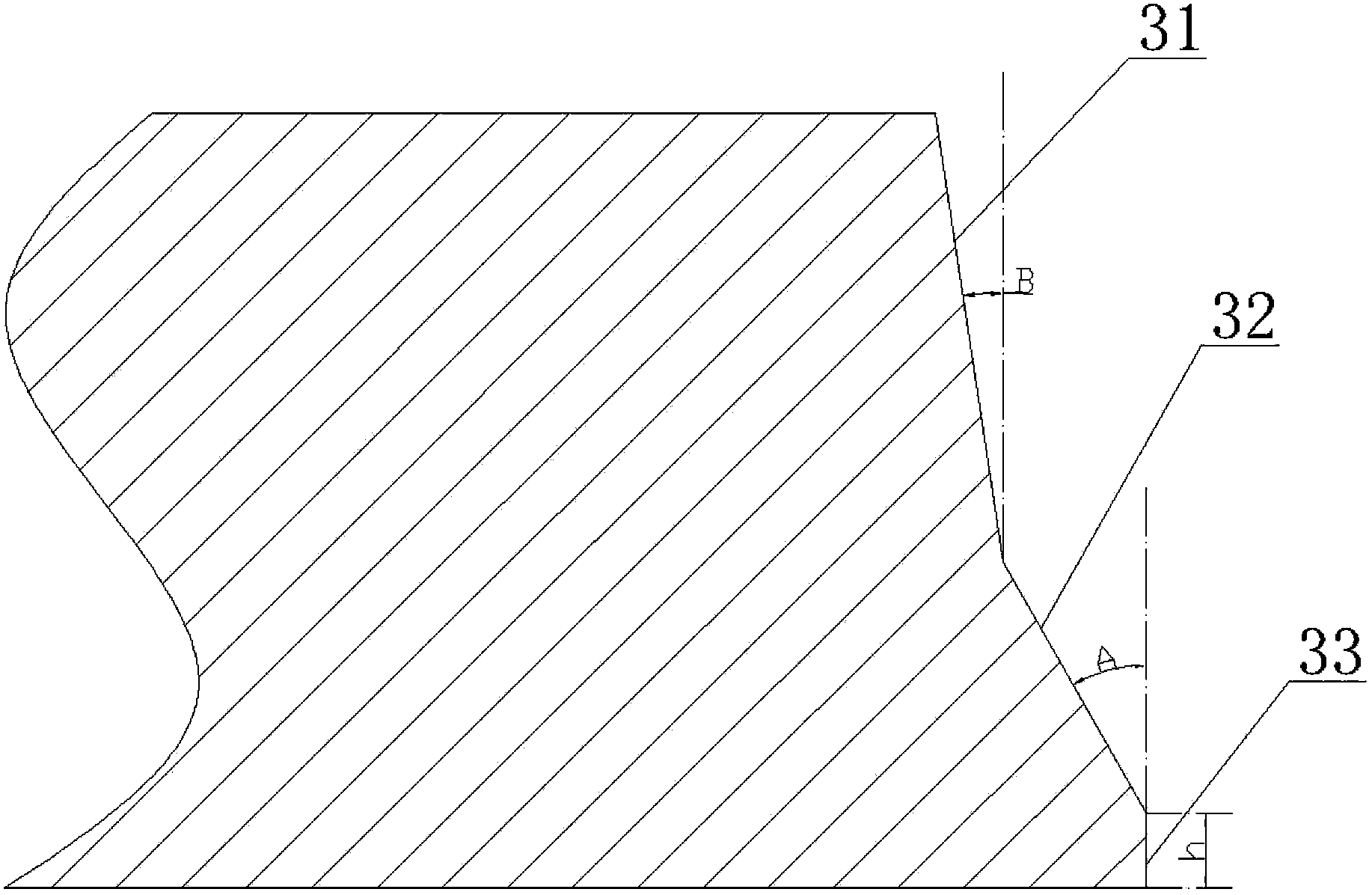

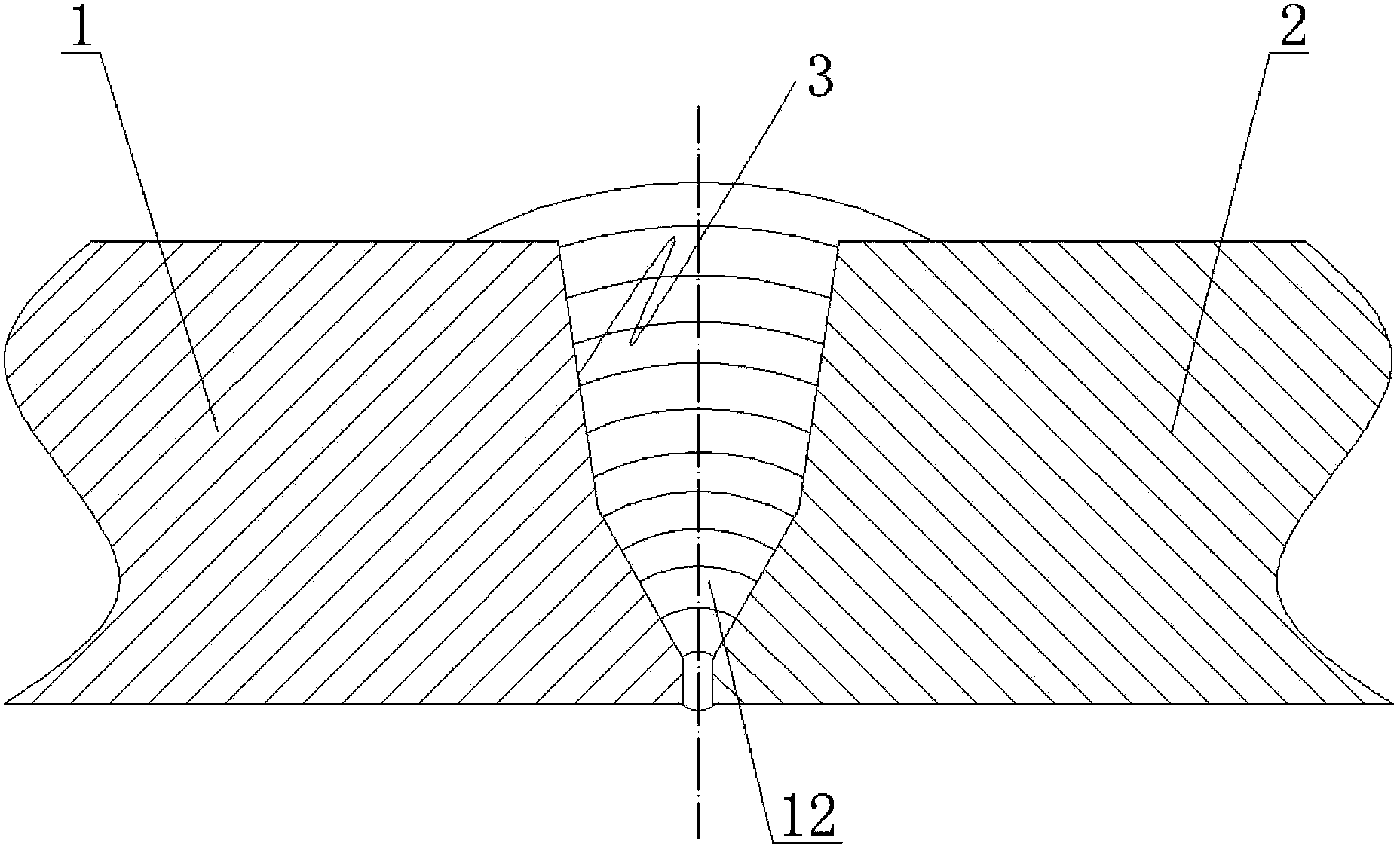

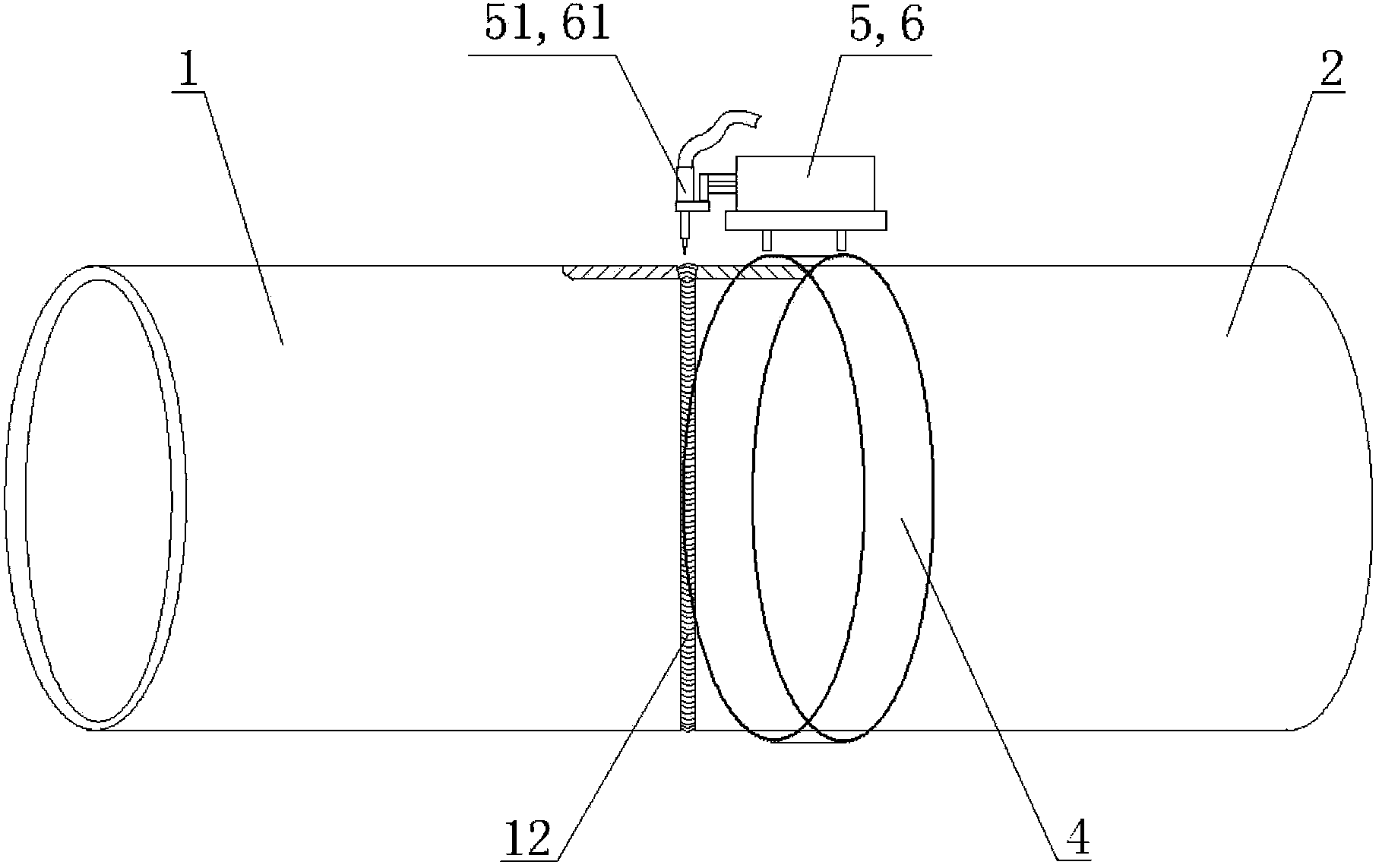

All-position automatic welding method for pipeline circumferential weld

ActiveCN103801796ALow costEasy maintenance and operationArc welding apparatusMetal working apparatusEngineeringWelding defect

The invention discloses an all-position automatic welding method for a pipeline circumferential weld and belongs to the technical field of pipeline circumferential weld welding. The method includes the following steps that firstly, steel pipes needing welding are machined to be provided with groove end faces; secondly, welding technology parameters are typed in a controller program according to the preset welding technology; thirdly, the two welded steel pipes are assembled; fourthly, one of the steel pipes is provided with a welding rail; fifthly, the welding ends of the two steel pipes are preheated before welding; sixthly, a single welding torch is used for performing root welding on grooves; seventhly, a double welding torch is used for performing hot welding, filling welding and cosmetic welding on the grooves. According to the all-position automatic welding method for the pipeline circumferential weld, due to the fact that the groove type is designed, the root welding technology, the filling welding technology and the cosmetic welding technology are adopted, the defects that in the prior art, the welding efficiency is low, a large number of welding materials are consumed, a large number of weld defects exist, the welding joint performance is poor, and the requirement for the operating skills of welders is high; or welding equipment is high in cost, and operating and maintaining are difficult are overcome.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

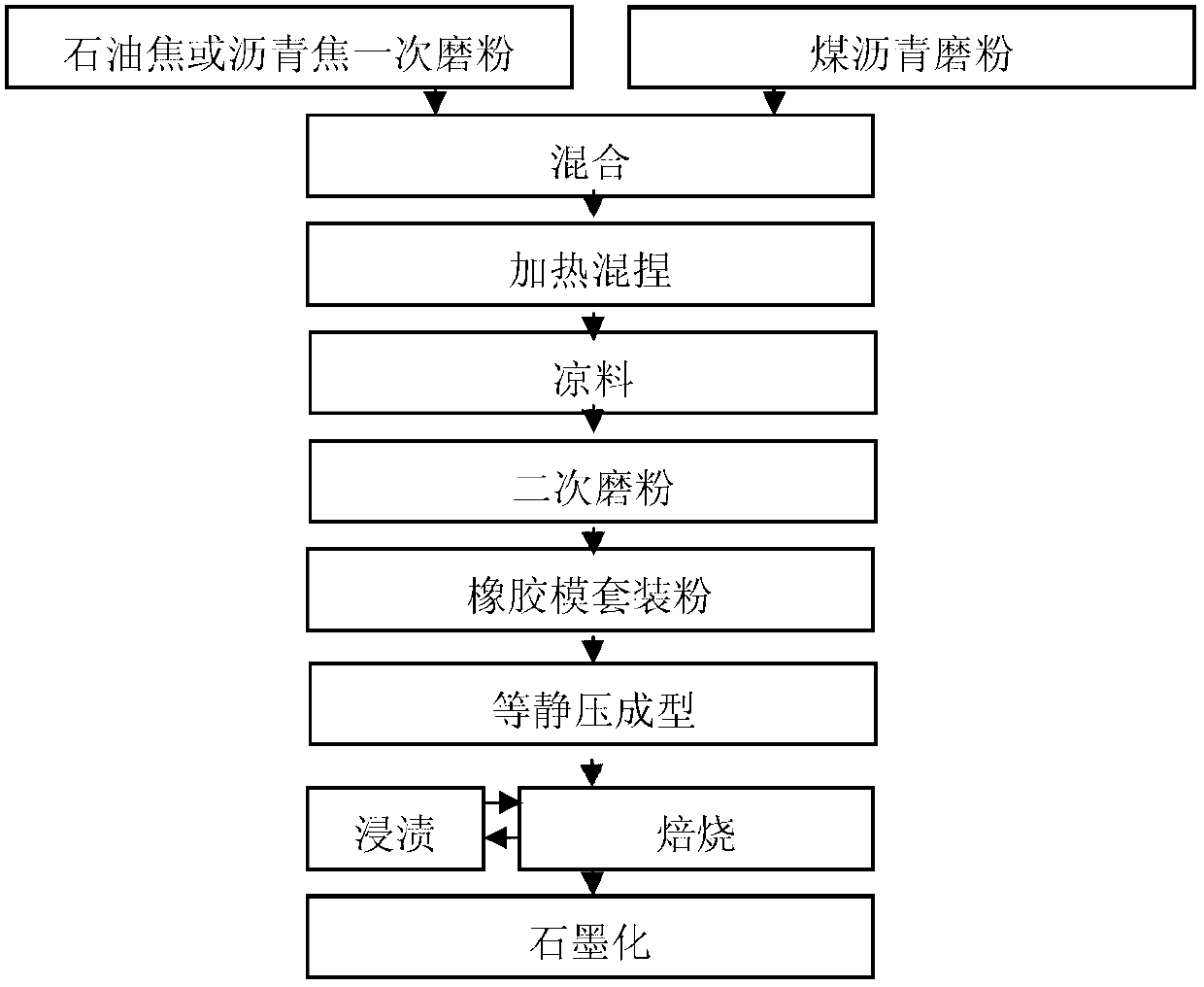

Preparation method of isostatic pressing formed graphite

InactiveCN103121671AIncrease the pre-mixing processTo achieve the purpose of structural homogeneityCarbon compoundsGraphiteCoal

The invention discloses a preparation method of isostatic pressing formed graphite. The preparation method comprises the following steps of: preliminarily grinding, grinding coal tar pitch and mixing the coal tar pitch powder with coke powder aggregate. According to the preparation method disclosed by the invention, the coke powder aggregate and the coal tar pitch powder are sufficiently mixed, so that the coal tar pitch powder is molten, sufficiently permeates into the air holes of the aggregate particle fine powder and can be uniformly coated on the surface of the particle fine powder during the next heating and kneading process, thereby achieving the purpose of homogenizing the material structure. The isostatic isotropic graphite material prepared by the preparation method disclosed by the invention is fine and compact in structure, good in uniformity, excellent in mechanics performance, wearable and isotropous.

Owner:SICHUAN GUANGHAN SHIDA CARBON

Smelting method for high-Nb-TiAl based alloy

The invention provides a smelting method for a high-Nb-TiAl based alloy. According to the smelting method, titanium sponge, a niobium-titanium alloy and aluminum shots are used as raw materials and are pressed and welded to form a consumable electrode; the consumable electrode is smelted in a vacuum consumable electric arc furnace to obtain the high-Nb-TiAl based alloy. According to the smelting method, an electrode block is prepared by a manner of combining material mixing and material distribution; the vacuum consumable electric arc furnace is used for carrying out three times of smelting; after the materials are discharged from the furnace, the materials are slowly cooled by adopting a manner of sand burying treatment or annealing treatment so that the high-Nb-TiAl based alloy with uniformly-distributed components and no cracks can be obtained. The smelting method for the high-Nb-TiAl based alloy is simple in method and strong in maneuverability; with the adoption of the method, the high-Nb-TiAl based alloy with the uniformly-distributed components and no segregation or impurities can be produced.

Owner:西安超晶科技股份有限公司

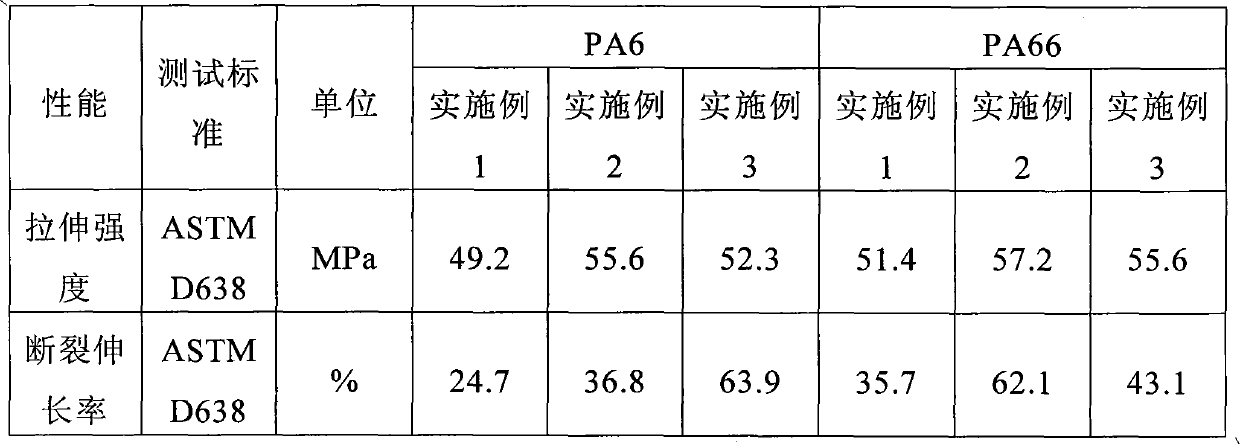

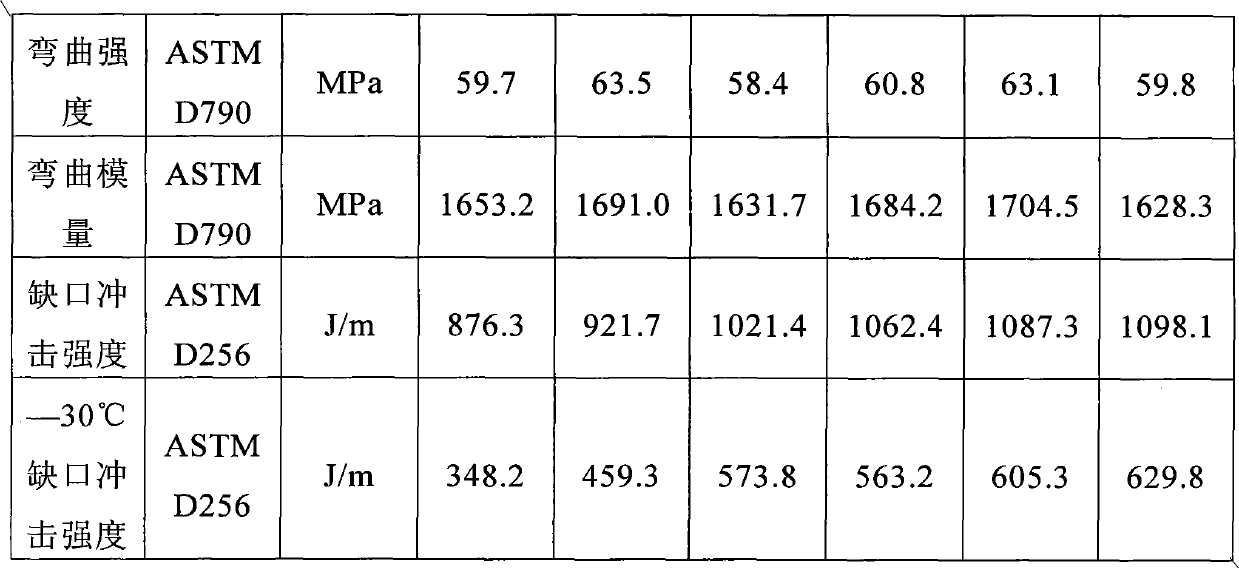

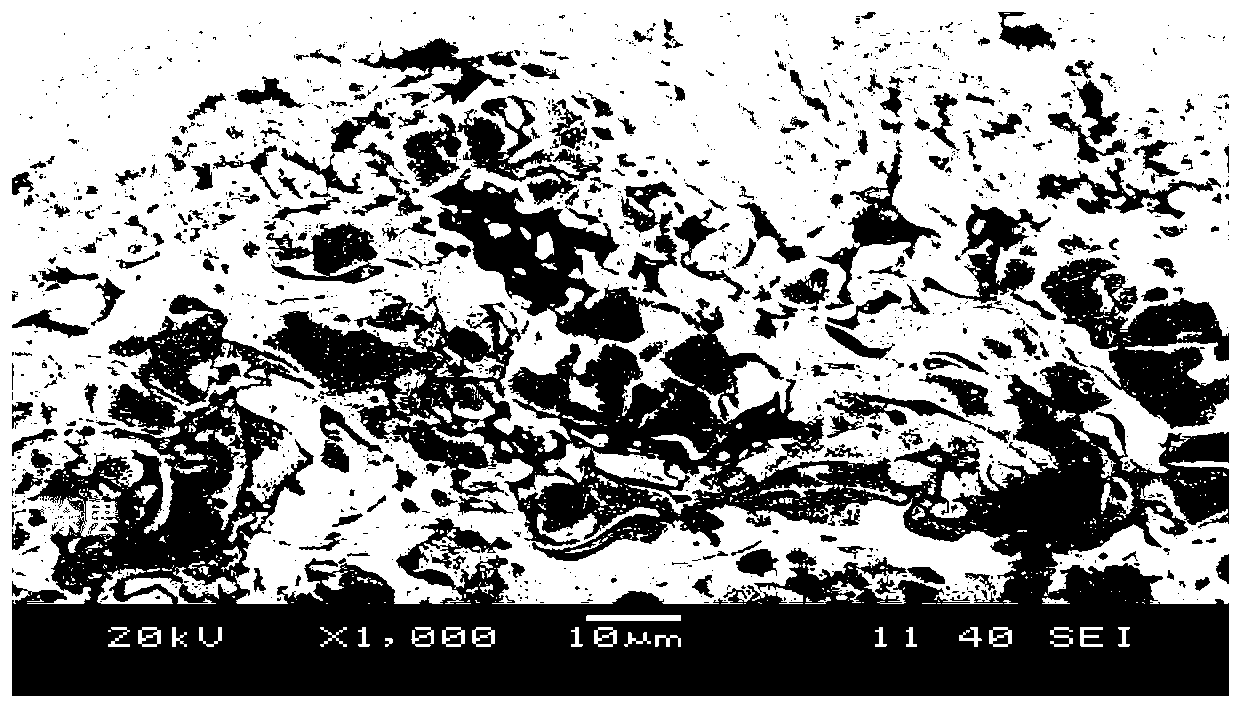

Low temperature impact resistant nylon flexibilizer and preparation method of low temperature impact resistant nylon flexibilizer

The invention relates to a low temperature impact resistant nylon flexibilizer and a preparation method of the low temperature impact resistant nylon flexibilizer. The low temperature impact resistant nylon flexibilizer comprises the following components in parts by weight: 50-95 parts of ethylene-alpha-octylene copolymer resin, 4-40 parts of polypropylene copolymer, 1-30 parts of linear low density polyethylene, 0.5-10 parts of graft monomer, 0.01-2 parts of initiator, 0.1-1 part of lubricator, 0.1-1 part of antioxidant and 0.1-2 parts of liquid additive. The preparation method of the low temperature impact resistant nylon flexibilizer comprises the steps of: mixing the above components except for the initiator, and adding into a double-screw extruder; laterally feeding and metering the initiator, and adding into the extruder; and extruding and pelletizing to obtain the low temperature impact resistant nylon flexibilizer as a product. The graft ratio of the flexibilizer is increased and the gel content of the flexibilizer is reduced by the lateral feeding technology; after the flexibilizer is applied to nylon (nylon 6, nylon 66), the flexibilizer is good in comprehensive performance and more excellent in low temperature impact performance; and the notch impact strength of the flexibilizer can reach 600J / m at a temperature of -30 DEG C, so that the flexibilizer can be applied to the fields of auto accessories and bumpers, railway equipment and the like under low temperature resistance.

Owner:SHANGHAI SUNNY

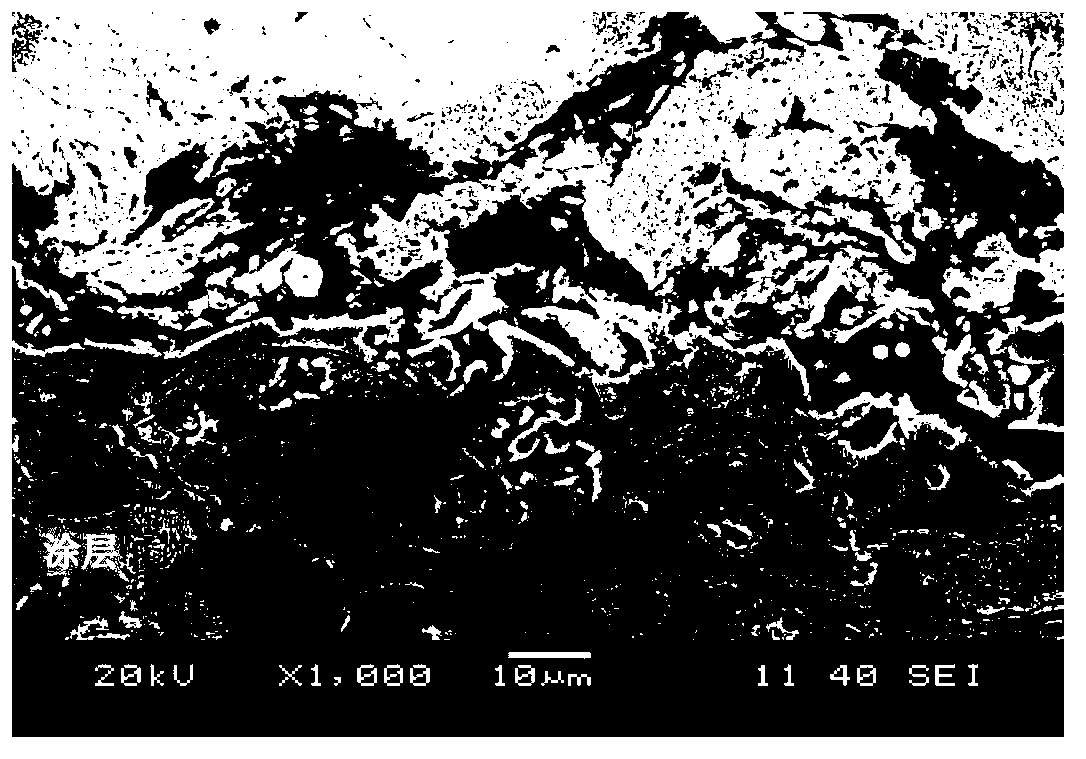

Method for preparing high-temperature wear-resistant coating on continuous casting crystallizer copper alloy plate surface

InactiveCN102851632AHigh bonding strengthImprove deposition efficiencyMolten spray coatingWear resistantThermal shock

The invention discloses a method for preparing a high-temperature wear-resistant coating on a continuous casting crystallizer copper alloy plate surface, which comprises the following step: spraying metal ceramic powder on a pretreated copper alloy plate surface by a plasma spraying process to form a metal ceramic coating of which the thickness is 0.5mm, wherein the metal ceramic powder is Cr3C2-NiCr powder of which the particle size is 325-500 meshes; the Cr3C2-NiCr powder comprises 70-80 wt% of Cr3C2 and the balance of NiCr alloy powder; and the Ni / Cr mass ratio in the NiCr alloy powder is 80:20. The coating prepared by the method disclosed by the invention has the advantages of high bonding strength, favorable thermal shock resistance and long thermal-fatigue life, can satisfy the working requirements for crystallizer copper alloy plates, and obviously prolongs the service life of the crystallizer copper alloy plate.

Owner:JIANGSU UNIV OF SCI & TECH

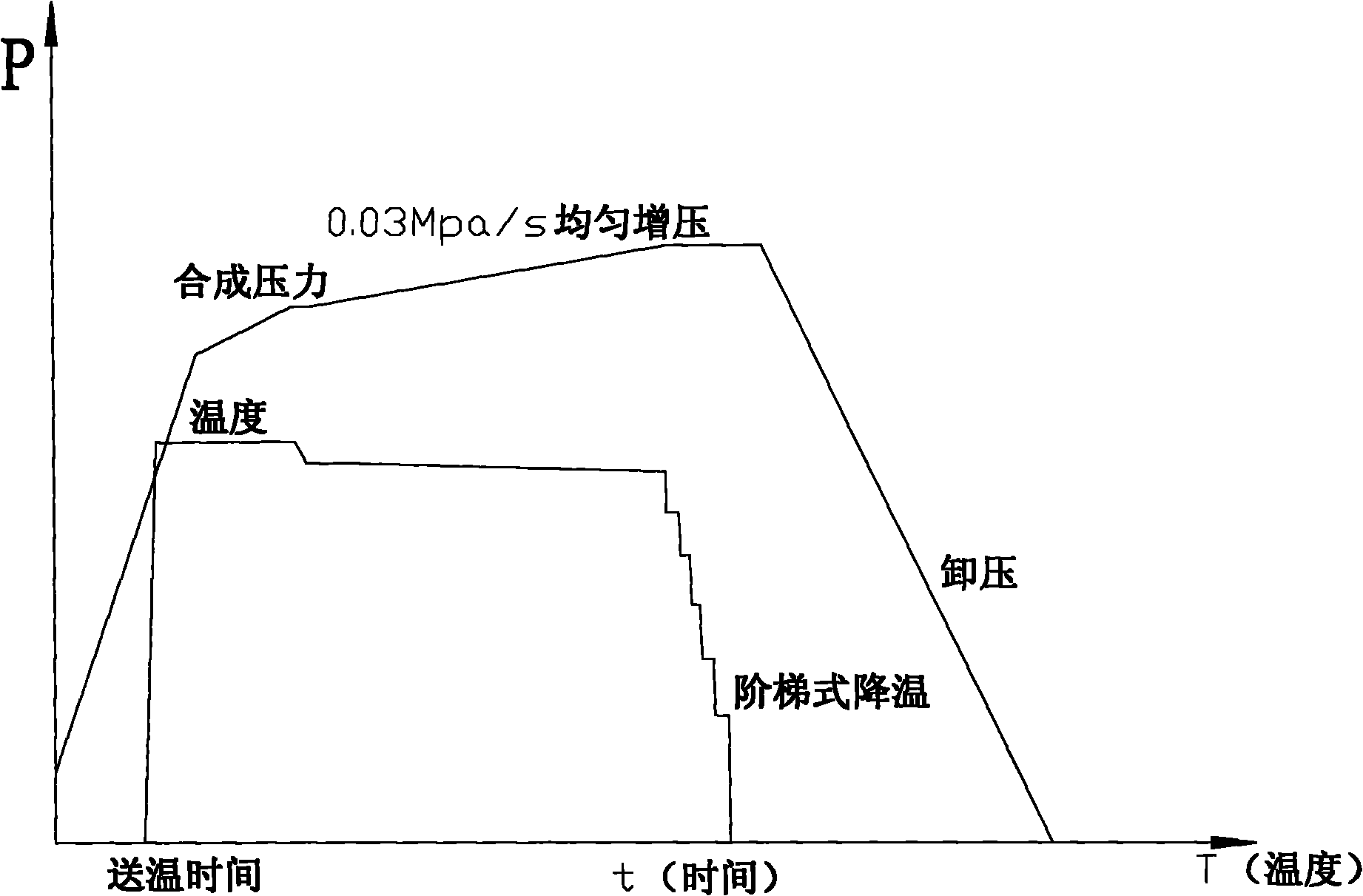

Process for synthesizing diamond

ActiveCN101862622AAvoid nucleationCrystals are complete and regularUltra-high pressure processesOverpressureHigh pressure

The invention belongs to the technical field of diamond synthesis and relates to a process for synthesizing diamond by adopting a special hexahedron press. The process has the steps as follows: (1) placing synthesized blocks in a high pressure cavity of the hexahedron press, pressurizing, connecting with overpressure to 55-65MPa after the pressure reaches 4-6MPa, preserving the pressure for 4-8min, and increasing the pressure to 70-80MPa after 15-20s; (2) preserving the pressure for 1-3min; (3) continuously increasing the pressure at the speed of 0.01-0.03MPa / s; and (4) preserving the pressure and cooling when the pressure is increased to 85-95MPa, and releasing the pressure to normal temperature when the temperature is reduced to the room temperature. The diamond product manufactured by the process for synthesizing the diamond has complete and regular crystals and golden color, and the process with short synthesis time and high extraction ratio can be used for grow the diamond products with the same particle size.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

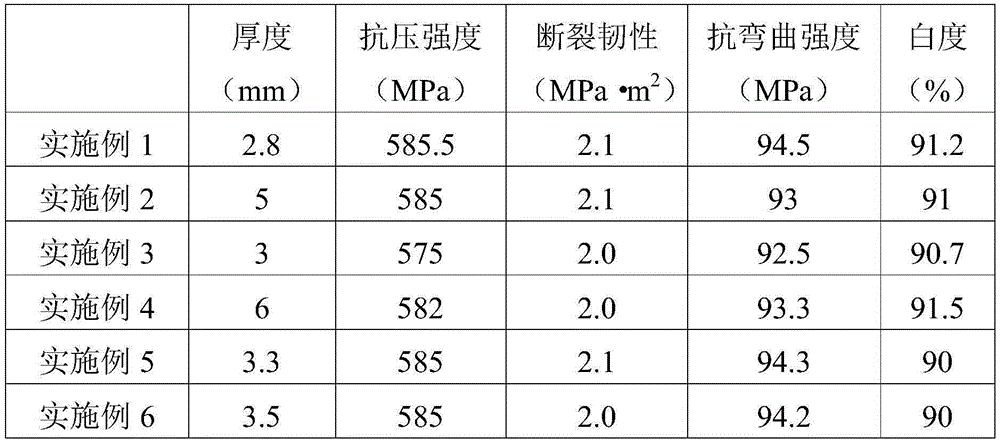

Preparation technology for glass ceramics sheet

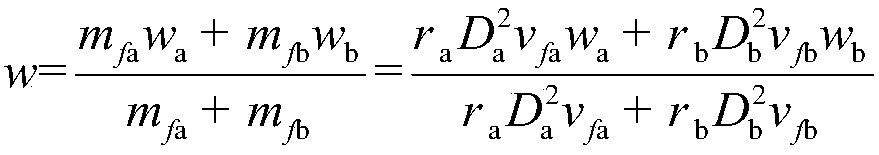

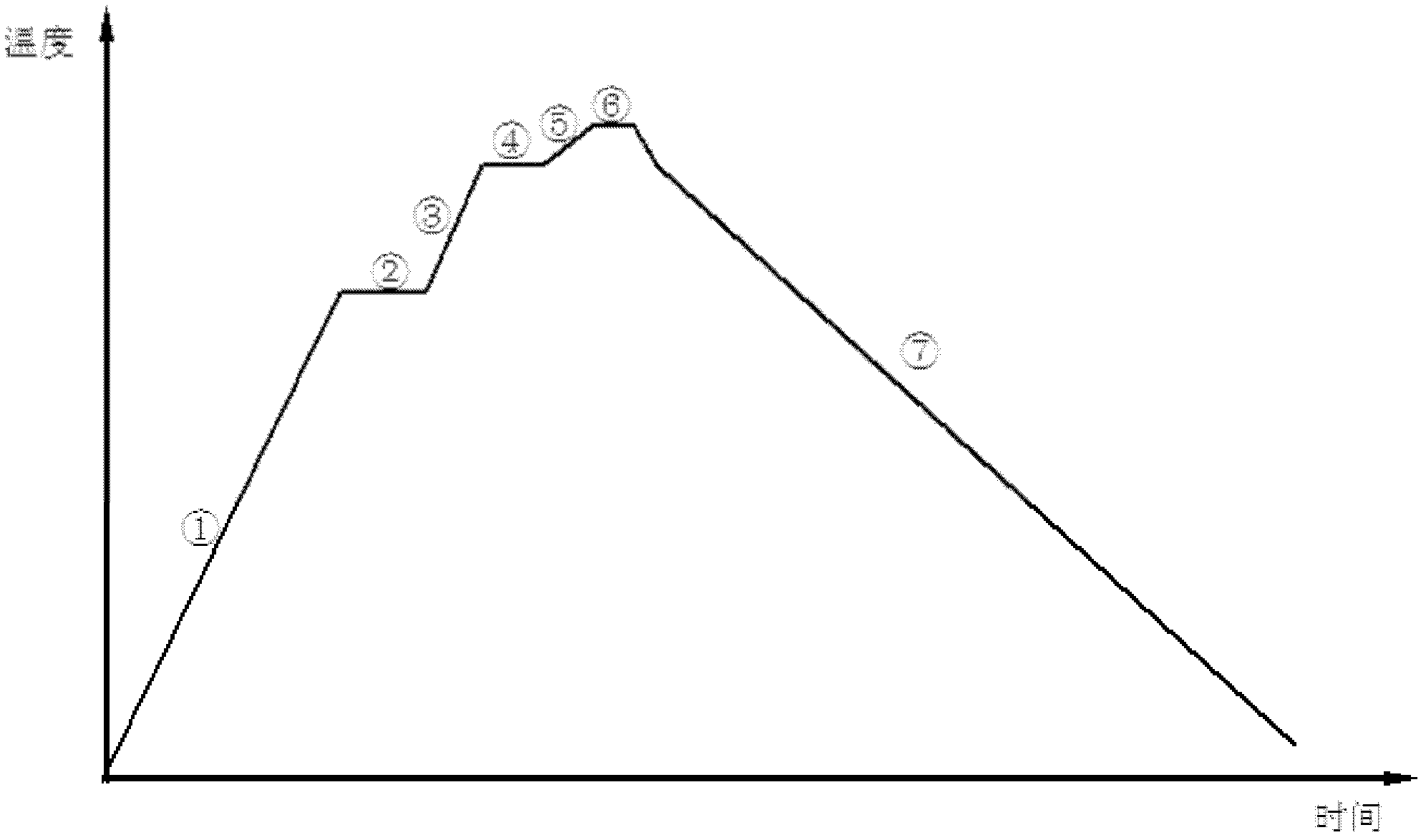

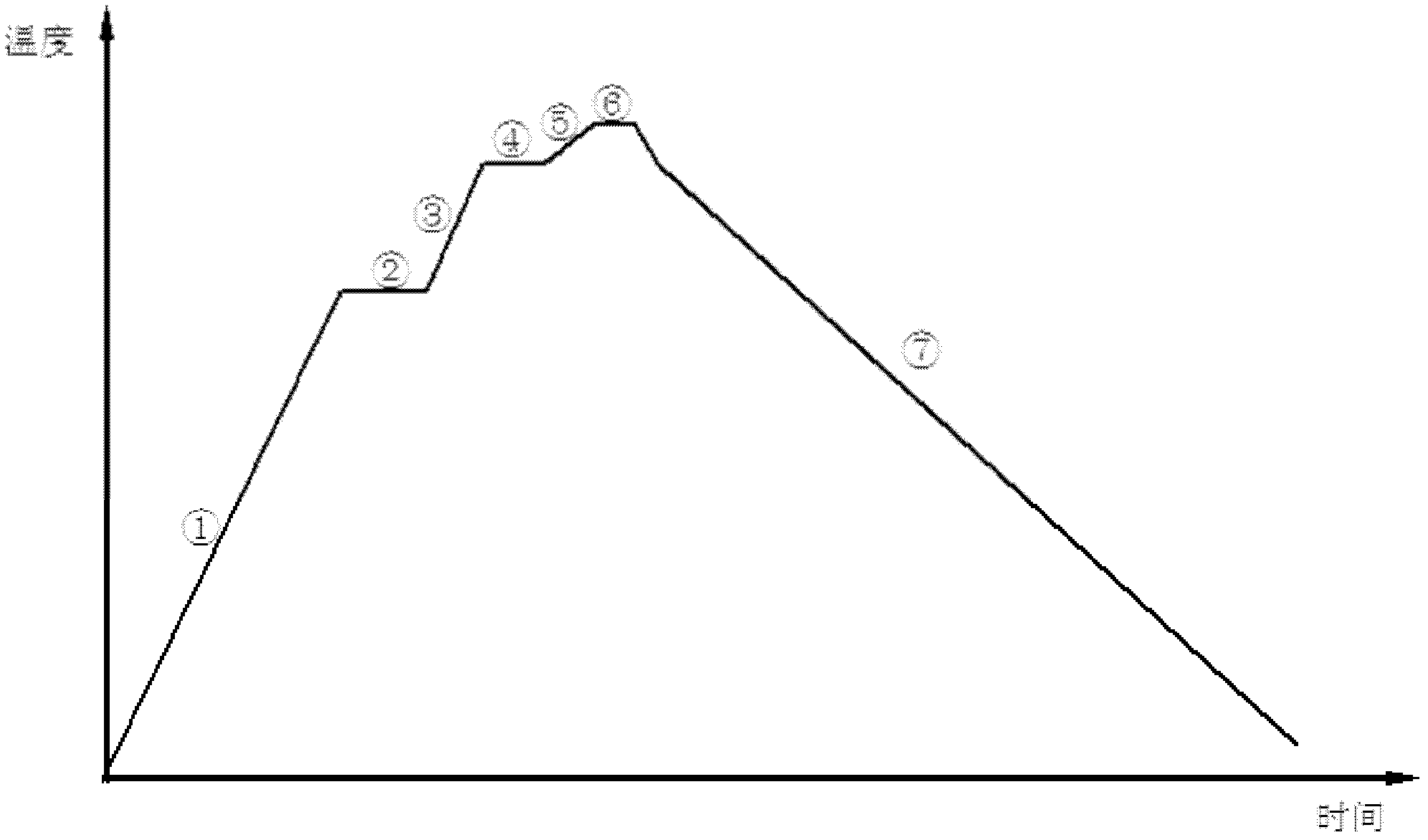

ActiveCN105271642AImprove bending abilitySolve technical problems that are easily deformedGlass rolling apparatusFlexural strengthNucleation

The invention discloses a preparation technology for a glass ceramics sheet. The preparation technology includes the steps that 1, SiO2, Al2O3, K2O, Na2O, CaO, MgO, F and a clarifying agent are weighed to obtain batch; 2, the batch is added into a melting furnace, the melting temperature is controlled to be 1510 DEG C-1520 DEG C, and the melted batch is clarified on the stirring condition to generate glass melt; 3, the glass melt enters a three-roll roller press to be rolled and calendered to form a glass plate; 4, the glass plate enters a roller kiln, and a glass ceramics sheet is obtained through primary nucleation, intensified nucleation and crystallization; 5, annealing, cooling, polishing and trimming are carried out on the obtained glass ceramics sheet to obtain the glass ceramics sheet product. The thickness of the glass ceramics sheet prepared through the preparation process according to the component content is 2-10 mm, the technical effect of bending resistance of the sheet in the production technical process is achieved, bending resistance and compressive strength are high, industrialization of the glass ceramics sheet is achieved, and market promotion is easy.

Owner:JIANGXI XINFENG MICROCRYSTALLINE JADE CO LTD

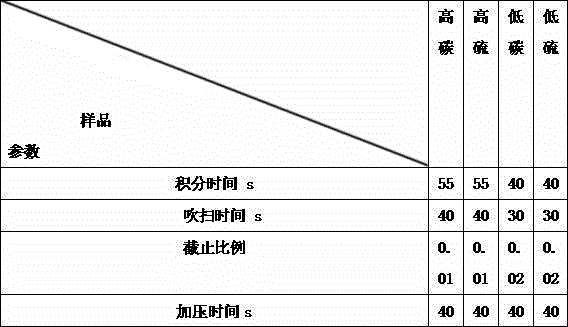

Method for determining contents of carbon and sulfur in iron-containing dust mud

InactiveCN104483286ASolve problems that cannot meet analysis requirementsAnalytical data is accurateMaterial analysis by optical meansFiltrationPhysical chemistry

Owner:INNER MONGOLIA BAOTOU STEEL UNION

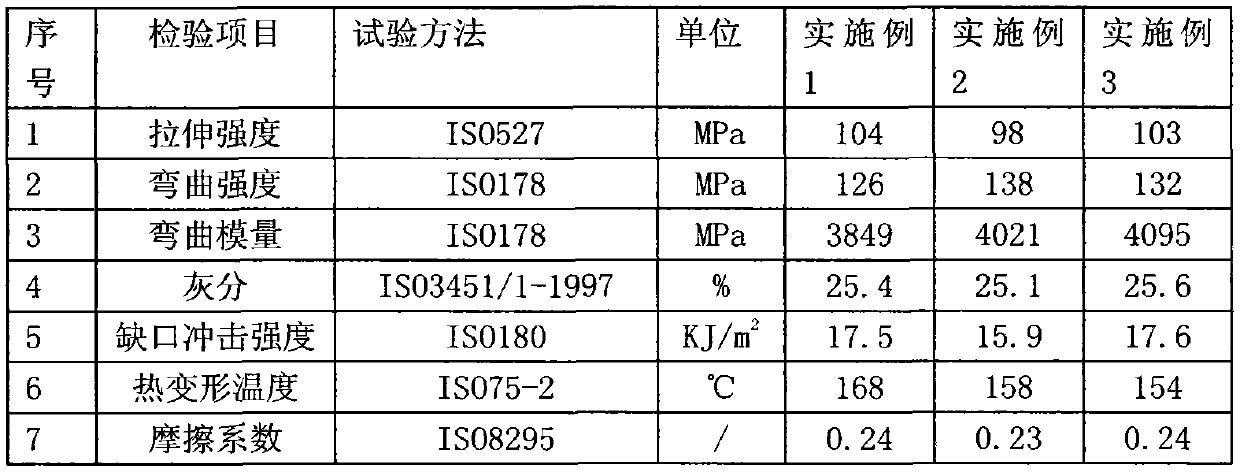

Regenerated MC nylon composite material and preparation method thereof

The invention relates to a regenerated MC nylon composite material which is prepared from the following raw materials in percentage by mass: 34.9%-67.3% of regenerated MC nylon resin, 25%-35% of glass fiber, 4%-10% of flexibilizer, 0.2%-0.6% of antioxidant, 0.5%-1.5% of lubricant, 1.0%-3.0% of black master batch, and 7%-15% of anti-wear agent. A preparation method for the regenerated MC nylon composite material comprises the following steps: a step I of drying; a step II of raw material proportioning; a step III of uniformly stirring; a step IV of extruding and pelletizing. According to the regenerated MC nylon composite material provided by the invention, mechanical performances, heat resistance and wear resistance of the regenerated MC nylon composite material are greatly improved by virtue of compounding effect of various functional auxiliaries and special screw combination; at present, the product is successfully applied to conveying pipelines in the industries such as petrol, chemical engineering, metallurgy, mine, and the like. The preparation method is simple in process, high in continuous production efficiency and stable in product quality.

Owner:NINGBO EAGLE NEW MATERIAL

Plastic and solid waste combined building material and production method thereof

The invention relates to a plastic and solid waste composite building material which comprises the following raw materials: 30-60 weight parts of plastic and 40-70 weight parts of solid waste, wherein, the plastic is one or more mixture from polyethylene, polyvinyl chloride, polypropylene, polystyrene and polyethylene terephthalate; the solid waste is one or more mixture from of furnace slag, fly ash, building material industry dust and dewatered sludge; and the building material is obtained by uniformly mixing the raw materials in proportion and delivering the raw materials to a pressing machine for press forming after the temperature is raised to 120-180 DEG C. The invention has the advantages that the sources of the raw materials are wider, washing is not required in processing, no adhesive is adopted, and the plastic raw material cannot decompose, thereby having no environmental pollution during the production process; and the product is nontoxic and odorless, and can be recycled for reuse after abrasion, no secondary pollution is caused, scraps and scrap products are all recycled and reutilized in time, and the requirements and the predominant ideas of clean production are satisfied.

Owner:BEIJING QUQUAN ENVIRONMENTAL PROTECTION TECH

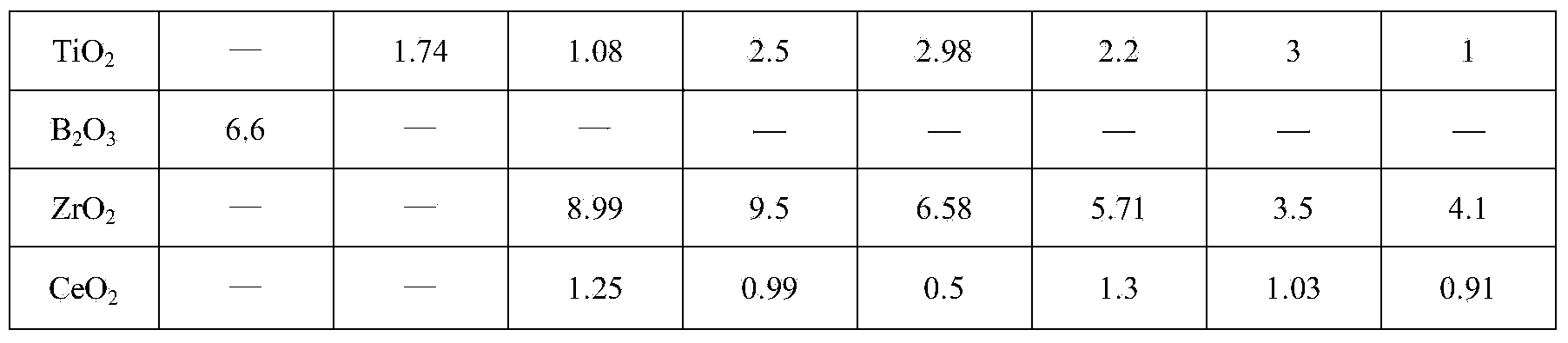

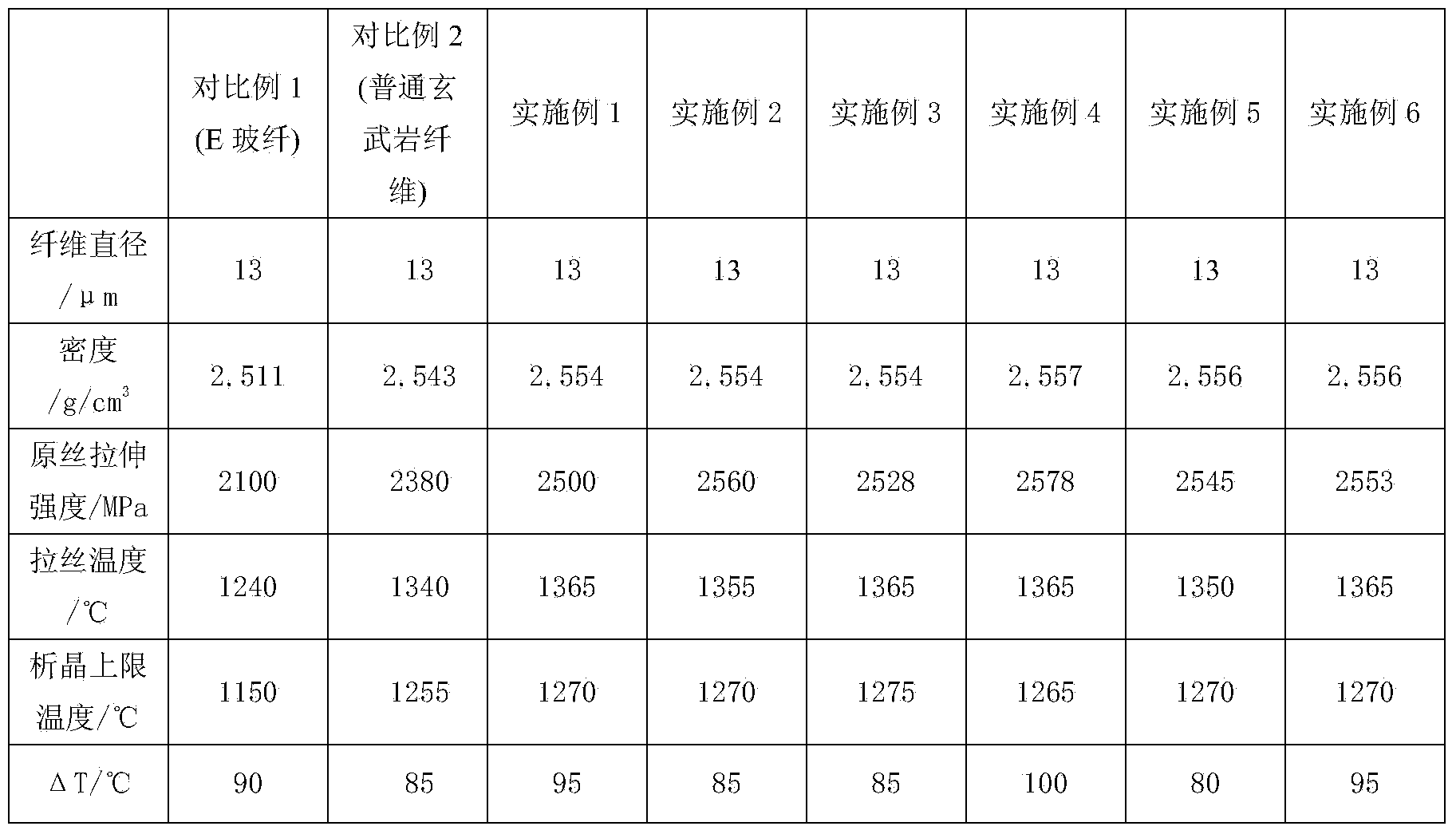

Basalt fiber composition with high alkali resistance and application method of basalt fiber composition

The invention discloses a basalt fiber composition with high alkali resistance. The basalt fiber composition comprises the following ingredients by weight: 50% to 60.5% of SiO2, 3.6% to 7.5% of Al2O3, 0.5% to 1.8% of MgO, 8.2% to 15.5% of CaO, 8% to 15% of Fe2O3 and FeO, 1% to 4.5% of K2O, 3% to 6% of Na2O, 1% to 3% of TiO2, 3.5% to 9.5% of ZrO2, and 0.5% to 1.3% of CeO2. As a proper quantity of CeO2 is used, the alkali-resisting performance and drawing operation performance of the basalt fiber are improved. The basalt fiber prepared from the raw materials has excellent mechanical property and alkali resistance, can be used for reinforcing a cement-based composite individually, and also can be used as a reinforcing material of a resin matrix-based composite with high alkali resistance.

Owner:SOUTHEAST UNIV +1

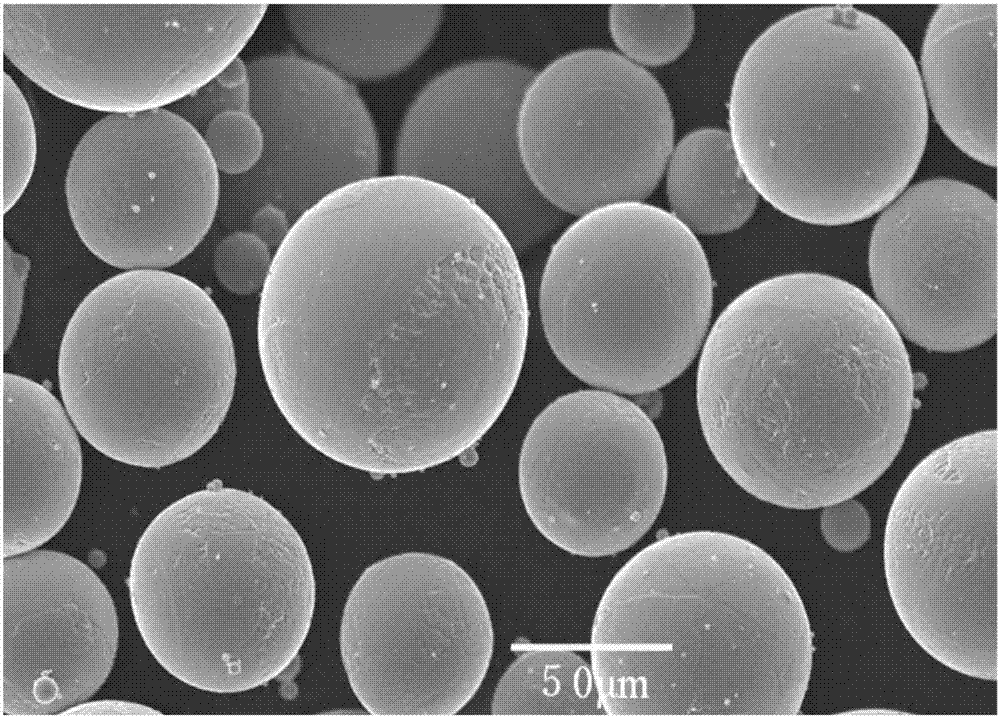

Titanium and aluminum based alloy powder material for additive manufacturing and preparation method thereof

ActiveCN107400802AImprove oxidation resistanceImproves strength and ductilityAdditive manufacturing apparatusTitaniumSystems design

The invention provides a titanium and aluminum based alloy powder material for additive manufacturing. The titanium and aluminum based alloy powder material is prepared from the following raw materials in percentage by atom: 47 to 56 percent of Al, 1.6 to 2.3 percent of Cr, 1.6 to 2.0 percent of Mo, 0.6 to 1.2 percent of TiB2 and the balance of Ti and unavoidable impurity. In addition, the invention also provides a method for preparing the alloy powder material. The method comprises the following steps of I, protecting the inner wall of a graphite flow guiding pipe by adopting a ceramic flow guiding inner core; II, preparing high-temperature-preventing carbonized coatings at the end surfaces of the graphite flow guiding pipe and then loading the graphite flow guiding pipe into a smelting chamber; III, preparing an ingot blank by adopting vacuum self-consuming arc smelting; IV, smelting to prepare an alloy melt by adopting a water-cooled copper crucible; V, carrying out atomization treatment, so that the titanium and aluminum based alloy powder material for the additive manufacturing is obtained. The alloy powder material is an alloy system designed for the additive manufacturing process and various properties of a product manufactured through the additive manufacturing technique by adopting the alloy powder material can reach expected effects.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

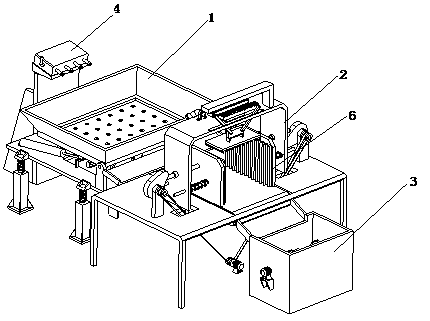

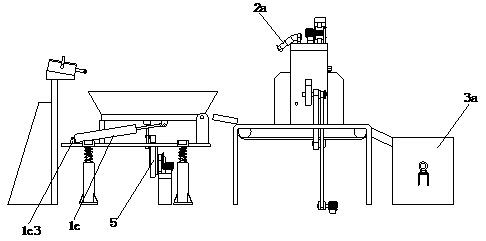

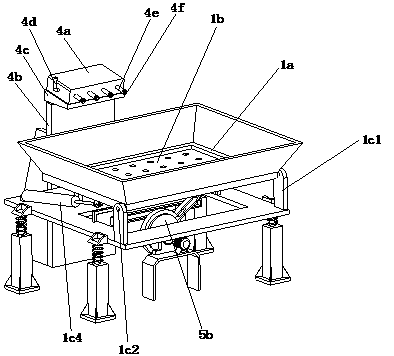

Waste automobile part recycling and processing equipment

InactiveCN110420936AReduce labor intensityAvoid affecting recycling efficiencyTransportation and packagingSolid waste disposalMotor vehicle partInjection air

The invention discloses waste automobile part recycling and processing equipment, and belongs to the field of automobile part recycling. The waste automobile part recycling and processing equipment comprises a dirt clearing mechanism, a compression crushing mechanism and an acid liquid processing mechanism, wherein the compression crushing mechanism comprises compression components on both sides,an air injection component, a workbench and a top crushing component; a conveyor belt is arranged on the workbench; the dirt clearing mechanism comprises a cleaning component, a knocking vibration component, a mounting frame and a turning component; and a filter screen is horizontally arranged in the mounting frame. The dirt clearing mechanism can be used for shaking automobile parts and clearingthe dirt on the automobile parts so as to prevent the incomplete disposal of thedirt on the automobile parts from affecting the recycling efficiency; and the compression components on the both sides can be used for compressing the automobile parts on the conveyor belt, so that the automobile parts can be fully compressed, and are prevented from occupying relatively large space of a processing box.

Owner:冯云

Silicon-based ceramic core preparation method

The invention discloses a silicon-based ceramic core preparation method. The method comprises the following steps: powder configuration and mixing, slurry preparation, compression moulding and sintering, wherein the sintering step comprises the following processes: wax melting, gasification, intensified gasification, cristobalite transitional change, cristobalite change and final sintering. The silicon-based ceramic core prepared by using the preparation method is good in creep resistance, low in high temperature deflection, low in shrinking percentage, high in strength, high in porosity, and easy for core leach.

Owner:兴化市兴东铸钢有限公司

Production technology of soft and hard layer sound insulating pad of automobile

ActiveCN102423945AImprove sound insulationFully bondedSynthetic resin layered productsLaminationSoft layerFiber

The invention relates to a production technology of a soft and hard layer sound insulating pad of an automobile, belonging to the technical field of automobile interior component manufacture. The sound insulating pad is hot-formed for one time by letting a soft layer fibrofelt, a film and a hard layer fibrofelt be subject to steam heating, wherein, the steps of the method comprise paving the raw materials, carrying out hot forming, molding through adsorption, and cutting with water. The technology reduces production procedures, greatly increases production efficiency, can well control the thicknesses of the soft layer and hard layer. According to the invention, steam has strong penetrating force and good effect of heat transfer, thus the film is completely molten, and the soft and hard layers are bonded firmly. The prepared sound insulating pad of the automobile has good sound insulation performance, and can well satisfy the using requirements of clients.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

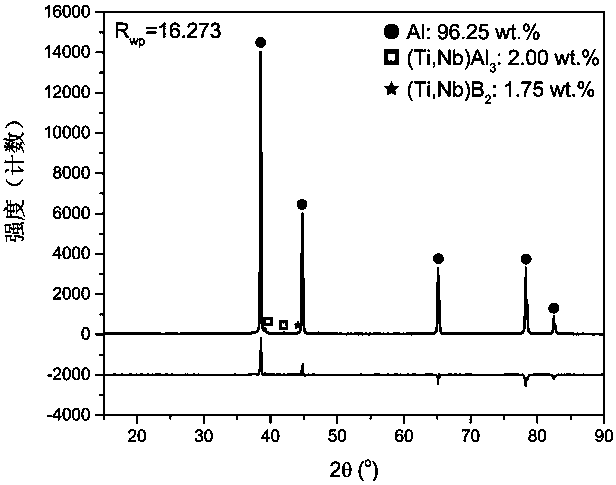

Al-Ti-Nb-B refiner for casting aluminum-silicon alloy as well as preparation method thereof and application thereof

The invention discloses an Al-Ti-Nb-B refiner for casting aluminum-silicon alloy as well as a preparation method thereof and application thereof. The Al-Ti-Nb-B refiner for casting aluminum-silicon alloy is prepared from the following components in percentage by weight: 96.20-98.90wt% of Al, 0.30-1.30wt% of Ti, 0.50-2.0wt% of Nb, and 0.30-0.50wt% of B. The Al-Ti-Nb-B refiner comprises a refining particle phase MA13 and MB2 with mass percentage of 2-4% and particle dimension smaller than 20 microns, wherein M is Ti or Nb. The preparation method for the Al-Ti-Nb-B refiner for casting aluminum-silicon alloy comprises the following steps of: a, weighing raw materials; b, smelting a Ti-Nb-B intermediate alloy; and c, smelting the Al-Ti-Nb-B refiner. A method of applying the Al-Ti-Nb-B refiner to casting aluminum-silicon alloy comprises the following steps of: a, melting the aluminum-silicon alloy; b, adding the Al-Ti-Nb-B refiner; and c, casting. The Al-Ti-Nb-B refiner prepared by the preparation method can be used for refining the crystalline grain size of alpha-Al in the aluminum-silicon alloy to be 150-450 microns, so that Nb content is greatly reduced, raw material cost is reduced,and components and structure uniformity of the prepared Al-Ti-Nb-B refiner are guaranteed.

Owner:SHANGHAI UNIV

Method for production of 110KV class XLPE cable insulation material

InactiveCN1632883AImprove product electrical performanceControl reduction contentPlastic/resin/waxes insulatorsInsulating conductors/cablesDicumyl peroxideElectricity

This invention discloses a 110 KV XLPE cable isolation material production method, which comprises the following steps: first to mix the anti-oxygen agent and high pressure polyethene for certain process; then to mix them with the filtered liquid cross linker of dicumyl peroxide under forth degrees; to product as the one in 10 KV and 35 KV to finish the process.

Owner:宋鸿文

Recovery and processing technique for waste lead acid accumulator

InactiveCN101197458ACause secondary pollutionFully meltedSolid waste disposalWaste accumulators reclaimingAtmospheric airReverberatory furnace

The invention discloses a process for recovering old and useless lead-acid storage batteries, comprising the steps of dismantling of a storage battery, processing of waste liquid, shell processing, smelting of coarse lead, deslagging of cast ingots, sedimentation of swirling flow, collecting and dust removal, dust removal of water film, etc. The invent adopts a marble acidproof and leakproof sewage pool for dealing with waste water, so the acid liquor can not permeate into and contaminate the earth; the smelting of coarse lead and deslagging of cast ingots are carried out by using a coal gas producer for gas combustion, with a plurality of coal gas nozzles providing enough fire to thoroughly smelt lead containing materials. The coal gas nozzles are arranged in the front of a reverberator the rear end of which is provided with an air exhaust opening to move the fire in the front constantly backward to thoroughly smelt lead containing materials at the back, thereby saving energy resource; a flue is formed in a S-shape, so the gas stays for a long time in the flue with a good sedimentation effect; as cloth-bag dust removal followed by the dust removal of water film is adopted, the dust is completely removed, so the discharged gas causes no pollution to the atmosphere. The invention has a perfect processing which leads to no secondary pollution to the environment.

Owner:许兴义

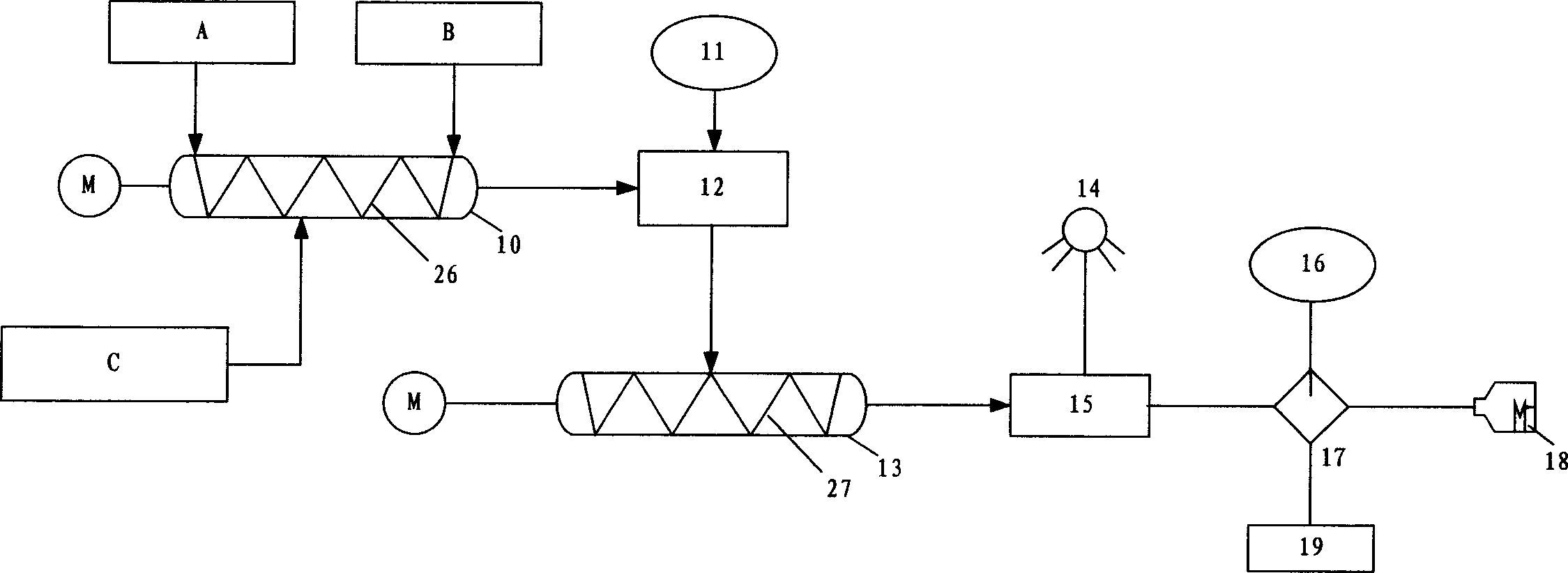

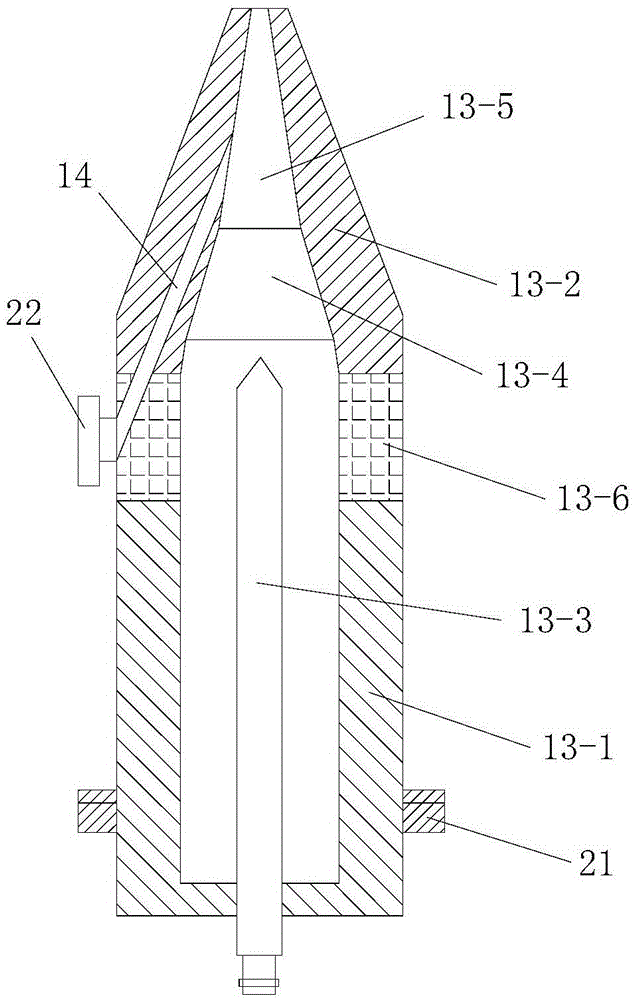

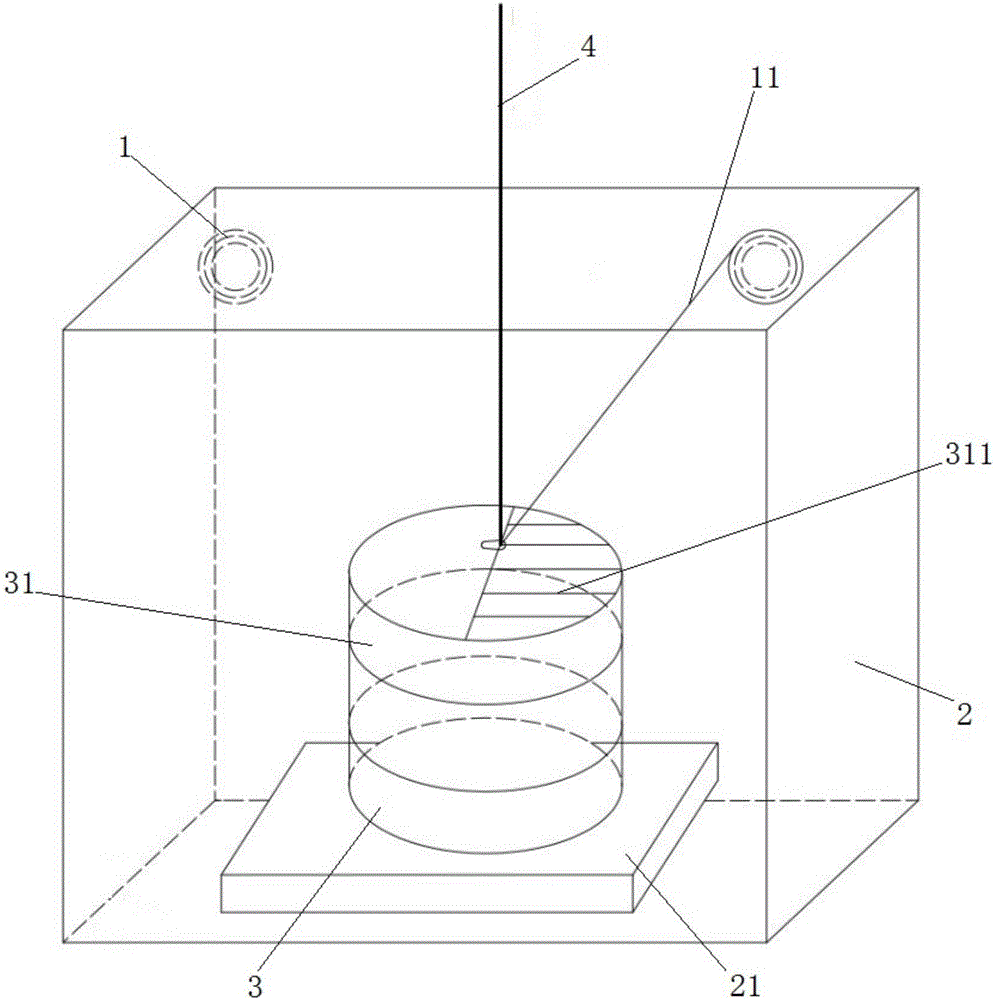

Plasma 3D printing remanufacturing equipment and method for mold

InactiveCN105642895ASimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyPlasma generatorDistance detection

The invention discloses plasma 3D printing remanufacturing equipment and method for a mold. The equipment comprises a monitoring system, a plasma beam processing system, a machining device for machining a to-be-repaired mold, a horizontal printing table for accommodating the to-be-repaired mold and a temporary fixing element for fixing the to-be-repaired mold temporarily, wherein the plasma beam processing system comprises a plasma generator, a printing position adjusting device, a gas supply device and a powder feeder; the monitoring system comprises a horizontal motion controller, a temperature detection unit, a distance detection unit, a printing distance adjusting controller and a rotation controller, and the temperature detection unit and the printing distance adjusting controller constitute a temperature regulation device. The remanufacturing method comprises steps of 1, mold defect detection and 2, mold repair. The plasma 3D printing remanufacturing equipment and method for the mold have the advantages that the design is reasonable, the operation is simple, convenient and high in efficiency, the use effect is good, a molding cavity is not needed to be closed, a repair process is performed directly in an atmospheric environment, and the quality of the repaired mold is good.

Owner:SINOADDITIVE MFG EQUIP CO LTD

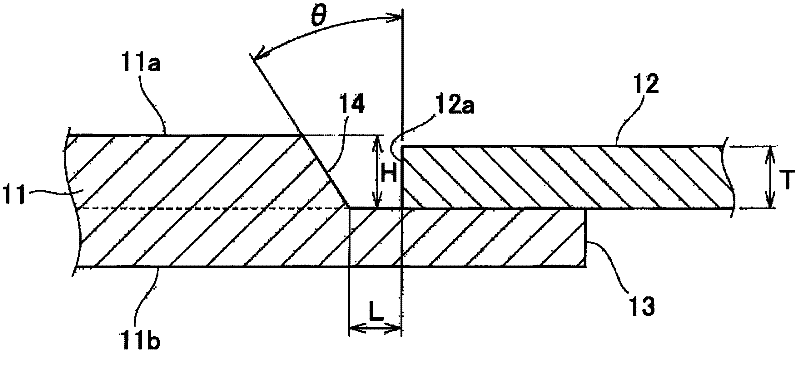

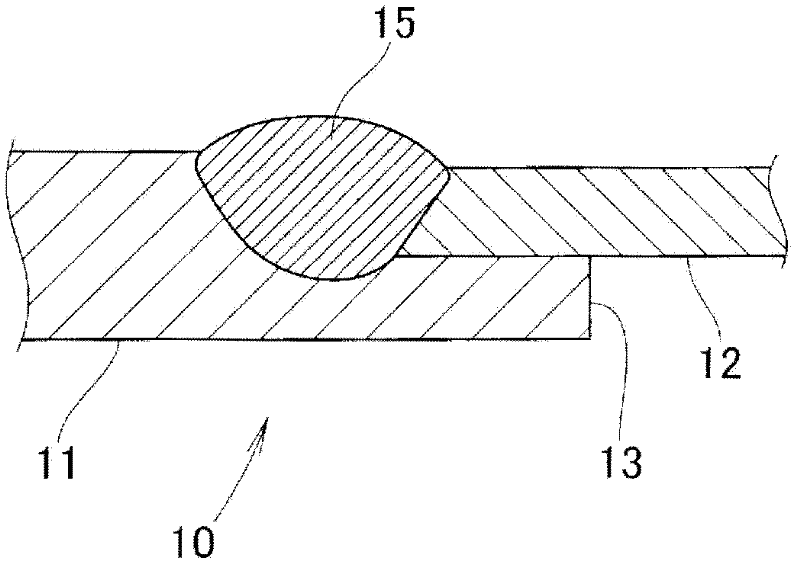

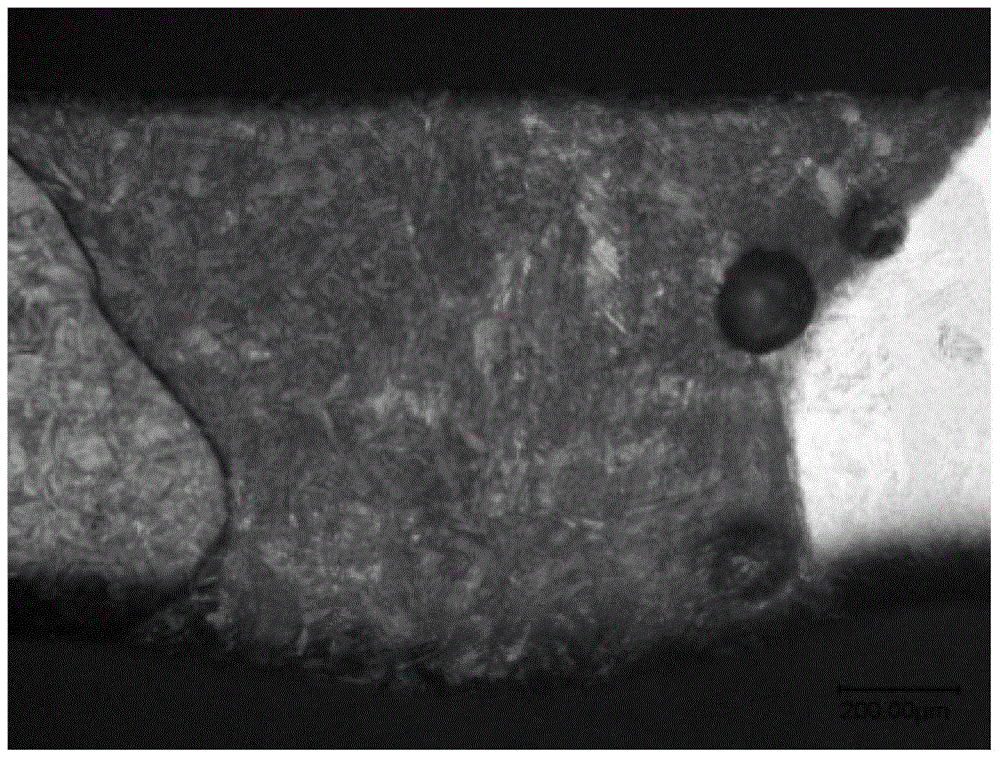

Weld joint of aluminum alloy member

InactiveCN102395443AHigh strengthQuality improvementUnderstructuresArc welding apparatusAluminium alloyWelding joint

Disclosed is a weld joint of an aluminum alloy member formed by joining one end of a wrought material (12) to one end of a cast member (11). The cast member has a chamfer (14), and an inserting portion (13) which extends from the lower end of the chamfer (14) toward the distal end of the cast member along the lower surface of the wrought material. The distance (L) from the lower end of the chamfer to the end face (12a) at one end of the wrought material is set equal to 1.0-1.7 times of the thickness (T) of the wrought material, and the chamfer is inclined so that the angle of a groove between the chamfer and the end face (12a) at one end of the wrought material is 15-45 DEG.

Owner:HONDA MOTOR CO LTD +1

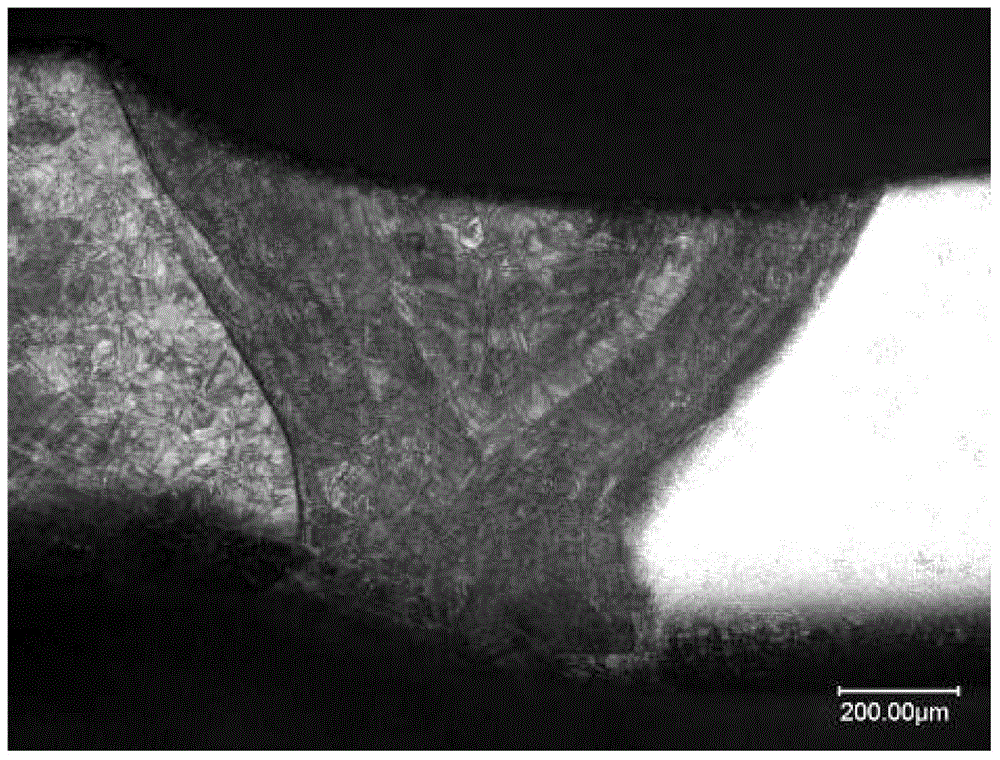

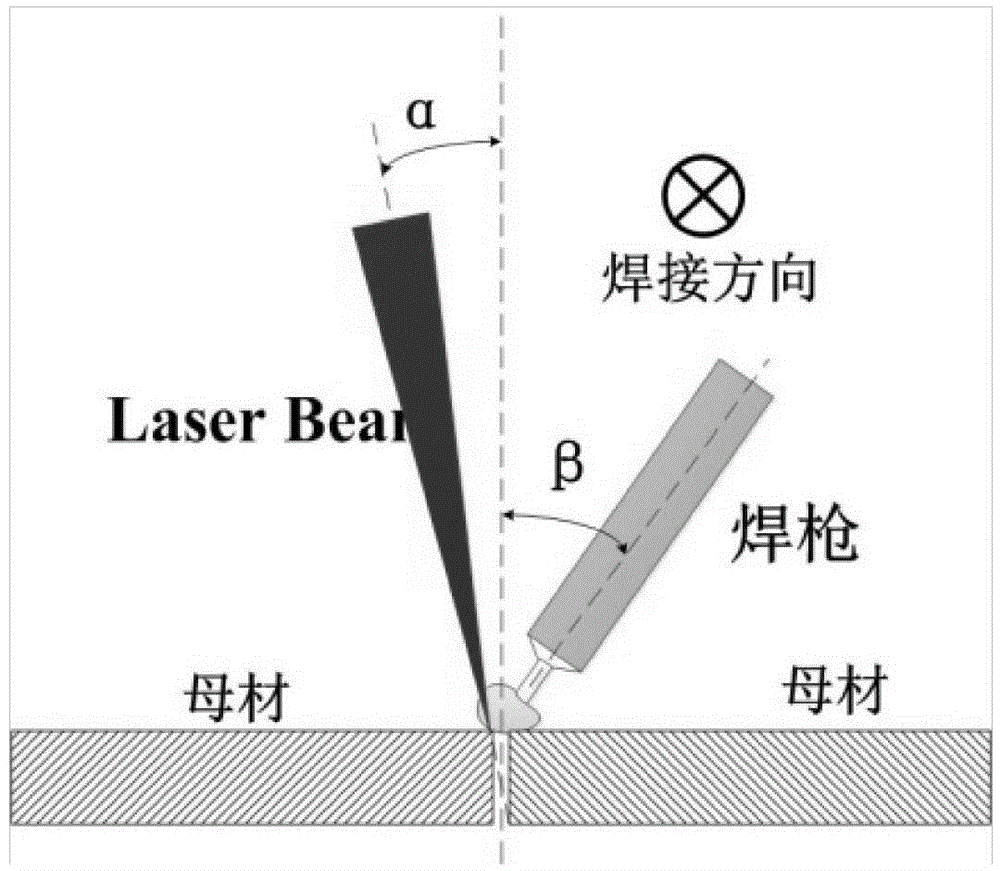

Welding method for Ti2AlNb-based intermetallic compound and dissimilar titanium alloy

InactiveCN104625411AIncrease the area of actionFully meltedArc welding apparatusLaser beam welding apparatusElectric arcIntermetallic

The invention discloses a welding method for Ti2AlNb-based intermetallic compound and dissimilar titanium alloy, and relates to a composite welding method for a bias laser and TIG electric arc in a parallel arranging mode. The method comprises the steps that: firstly, cleaning and polishing are carried out on a to-be-welded workpiece, and a fixture is fixed; secondly, a geometrical parameter is set; thirdly, a welding parameter of laser-TIG composite welding is set; fourthly, the electric arc is activated, and welding is carried out. The laser acts on one side of high-melting point base metal, and the TIG electric arc acts on one side of low-melting point base metal. Compared with laser welding, the weld heat input is lowered, the retention time on a high-temperature peak value is shortened, the welding joint of the high-temperature intermetallic compound is reduced, and therefore the high-temperature brittleness is lowered. By adding the TIG electric arc, the weld heat cycle is improved, the inter-coupling effect of two heat sources, namely the laser and the TIG electric arc, is demonstrated, the two heat sources, namely the laser and the TIG electric arc, are arranged perpendicular to the direction of the welding, the locating accuracy of the welding joint during the laser welding is greatly lowered, and the adaptability of the welding process is improved.

Owner:HARBIN INST OF TECH

Electron beam fuse wire additive manufacturing method

InactiveCN106695105AQuality assuranceImprove smoothnessElectron beam welding apparatusHearthMechanical engineering

The invention relates to an electron beam additive, and provides an electron beam fuse wire additive manufacturing method which comprises the following steps: firstly, dividing a manufactured printed part into a plurality of sediment layers by using layering processing software, performing fuse wire sedimentation along a sedimentation route of each sediment layer, and feeding fuse wires by using at least two fuse wire feeding machines corresponding to the sedimentation route of each sediment layer, thereby feeding the fuse wire corresponding to each sedimentation route from the front part of a furnace hearth. According to the electron beam fuse wire additive manufacturing method, a wire material generated from a fuse wire feeding machine corresponding to each sedimentation route is positioned in front of the sedimentation route, so that the radiation of the furnace hearth to the wire material can be relatively large, the wire material can be relatively sufficiently molten, the quality of each molded sediment layer can be effectively ensured, and the sediment layer can be relatively high in smoothness degree.

Owner:XIAN ZHIRONG METAL PRINTING SYST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com