Method for melting and coating anti-rust wear-resistant alloy on steel rail surface

A technology of cladding alloys and wear-resistant alloys, applied in metal processing equipment, metal material coating technology, welding media, etc. Short service life and other issues to achieve the effect of guaranteed performance, strong directivity, and reduced residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

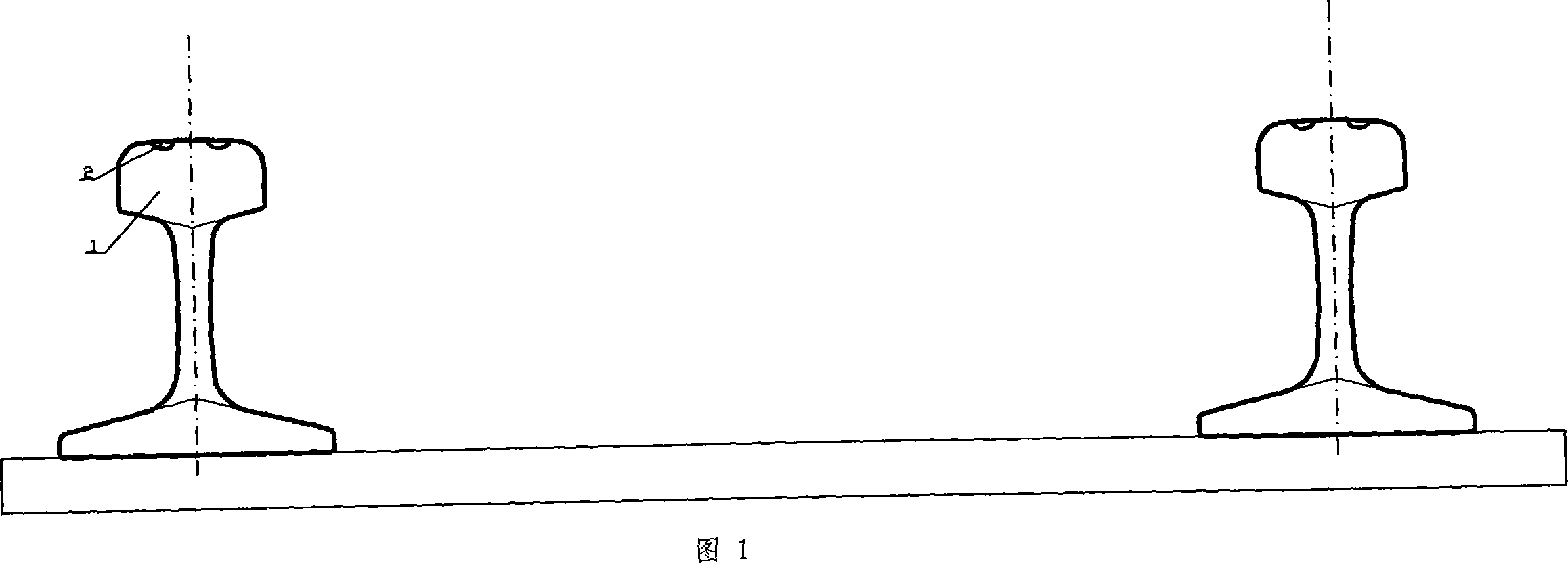

[0040] A method for cladding the surface of a steel rail with an anti-rust and wear-resistant alloy, comprising the following steps:

[0041] A. Preheating, using super-audio frequency or intermediate frequency induction heating equipment to heat the part of the surface of the rail head 1 to be clad with alloy, the induction heater is arranged above the part of the surface of the rail head 1 to be clad with alloy, and the induction heater moves at a constant speed, Evenly heat the part of the surface of the rail head to be clad with alloy. The size of the preheating part is: width 50mm, length 250mm, and the preheating temperature is 290 ° C ~ 450 ° C;

[0042]B. Cladding: Plasma cladding or arc welding is used to clad the alloy on the surface of the rail head 1, the induction heater moves at a constant speed, and the plasma cladding or arc welding equipment also moves at a constant speed; when the preheating temperature is 290 ° C ~ 450°C, when the welding torch of the plasma...

Embodiment 2

[0046] The more optimized cladding alloy method of the present invention is as follows:

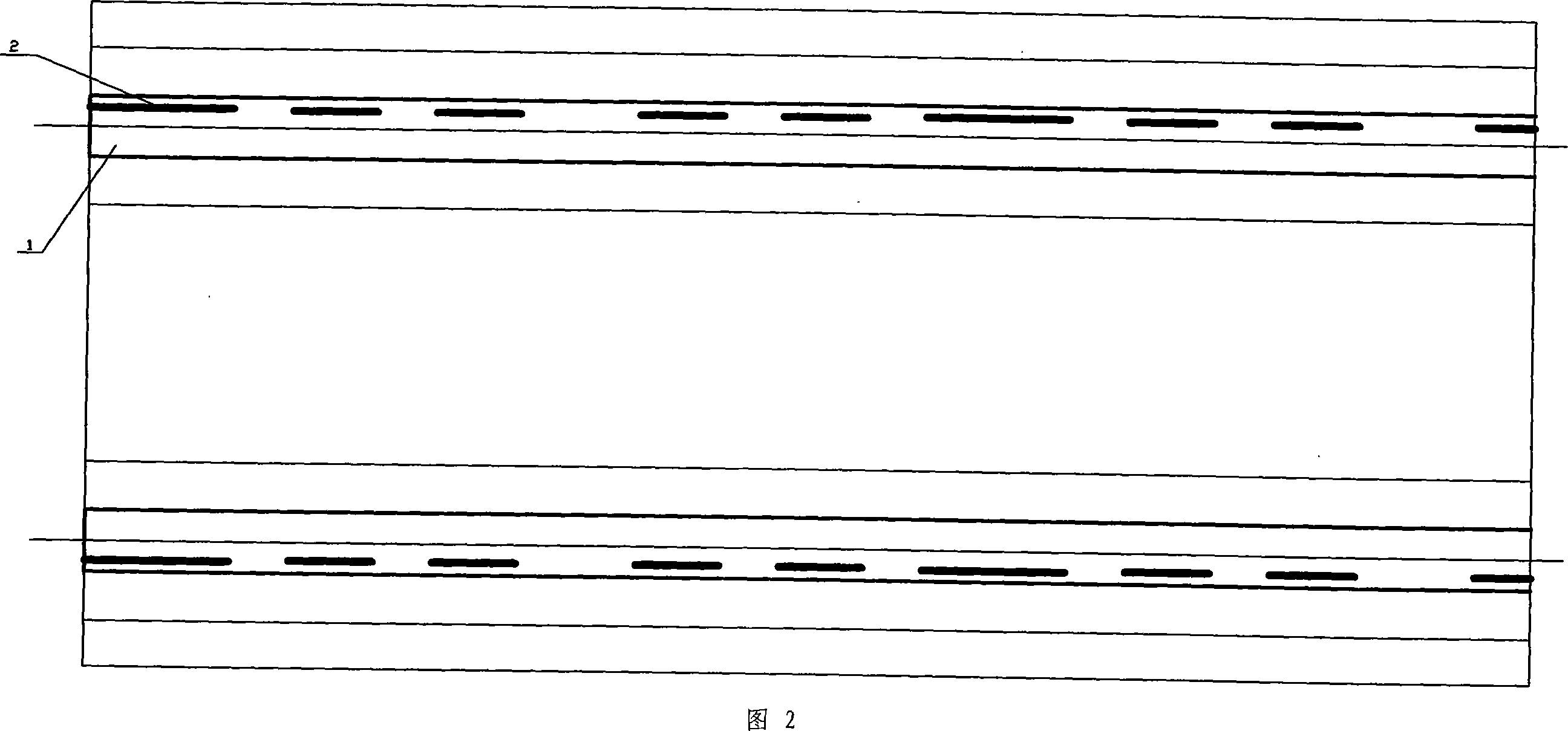

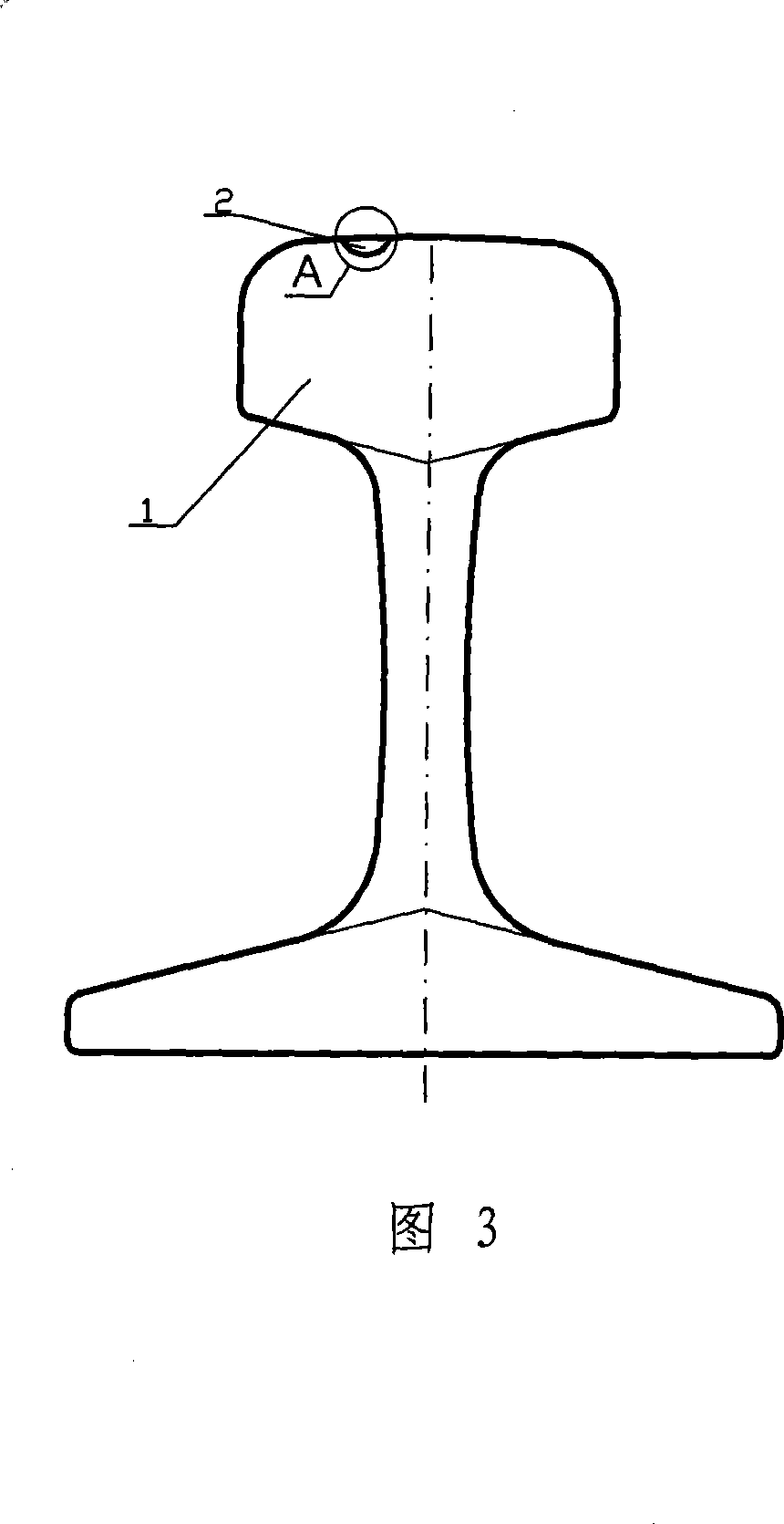

[0047] A. Grooving, machining the cladding groove 2 on the surface of the rail head 1;

[0048] B. Magnetic particle flaw detection, using magnetic particle flaw detection equipment to detect flaws in the surface of the rail head 1, the mechanically processed cladding groove 2, and check whether there are cracks, pores, inclusions and other defects in the cladding groove 2;

[0049] C. To clean the surface, first use a brush to clean the magnetic powder, and then use a cleaning agent to clean the oil on the 2 parts of the cladding tank;

[0050] D. Preheating, using super-audio frequency or intermediate frequency induction heating equipment to heat the surface cladding groove 2 of the rail head 1, the induction heater is arranged above the surface cladding groove 2 of the rail head 1, and the induction heating equipment moves at a constant speed, Evenly heat the 2 parts of the cladding t...

Embodiment 3

[0061] There are several methods for cladding alloy on the surface of the rail head 1 as follows:

[0062] (1) Oxygen-acetylene flame surfacing welding

[0063] (2) resistance welding

[0064] (3) arc welding

[0065] (4) Plasma cladding

[0066] (5) Laser cladding

[0067] The invention adopts plasma cladding and arc welding cladding alloy, and its advantages are: high energy density, high arc temperature, energy concentration, stable process, good performance, strong directivity, little interference from external factors, sufficient alloy melting, cladding alloy layer 3 Strong bonding force with the substrate; the shape and size of the cladding alloy layer 3 can be precisely controlled, especially thin-layer welding is difficult to achieve, and spraying is even more difficult to control; the cladding dilution rate is low, so that the performance of the alloy powder can be fully guaranteed, and the flame welding is very easy Difficult to achieve; small thermal impact, sma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com