Method for preparing manganese series lithium-ion sieve adsorbent H4Mn5O12 and precursor thereof

A lithium ion and adsorbent technology, applied in the field of preparing lithium ion sieve H4Mn5O12 and its precursor, can solve the problems of unfavorable large-scale production, complex process, harsh conditions, etc., and achieve easy control of product ratio, good cycle stability, The effect of large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

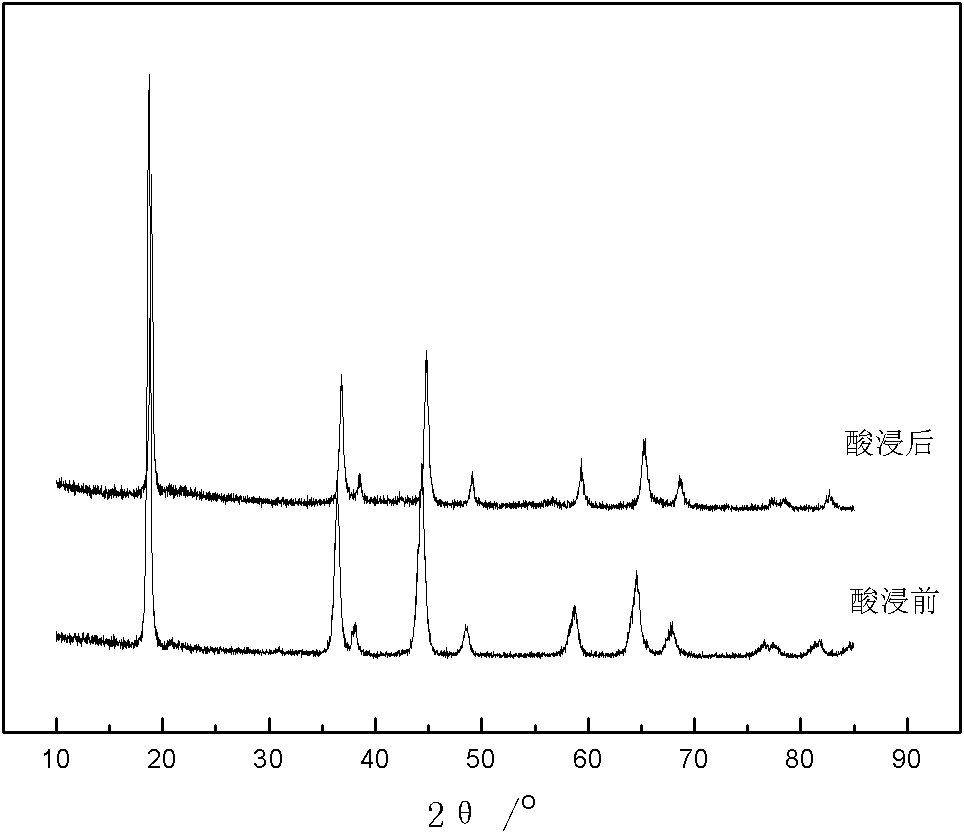

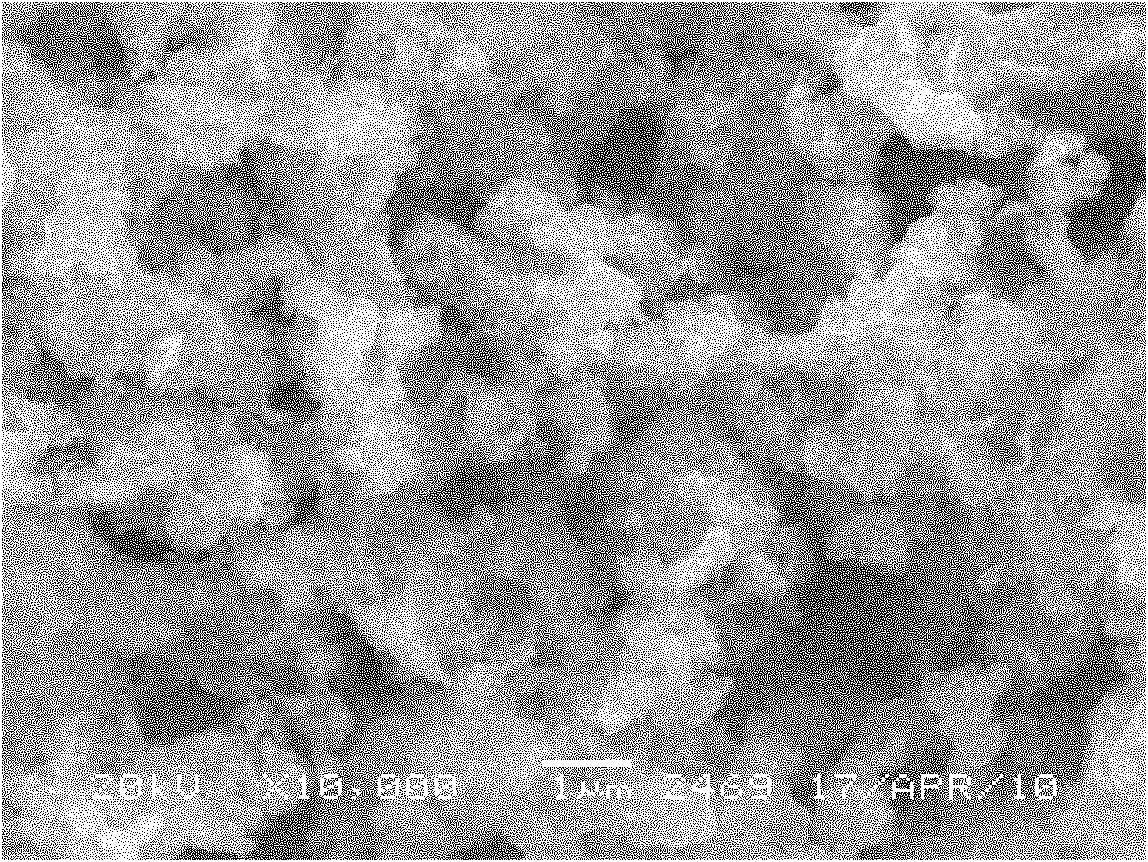

[0026] According to attached figure 1 As shown in the synthesis process, accurately weigh 4.0808 g of lithium acetate and 12.255 g of manganese acetate, add distilled water to dissolve, and obtain a mixed solution. The mixed solution was added dropwise into a citric acid solution containing 18.912 g of citric acid, and reacted in a constant temperature water bath at 80° C. for 1 h. Then the reaction product was dried in an oven at 120° C. to obtain a yellow solid. Grind the yellow solid and put it into a box furnace at a rate of 5°C / min to 400°C for 12 hours, then cool naturally to obtain the spinel lithium ion sieve precursor Li 4 mn 5 o 12 ,Such as figure 2 shown. The lithium ion sieve precursor Li 4 mn 5 o 12 Use 0.5mol / L HCl acid leaching for 24h to obtain lithium ion sieve 4 mn 5 o 12 ,Such as figure 2 shown. image 3 and Figure 4 Respectively, the obtained lithium ion sieve precursor Li 4 mn 5 o 12 SEM images before and after acid leaching. Weigh 0.3...

Embodiment 2

[0028] according to figure 1 As shown in the synthesis process, accurately weigh 4.0808 g of lithium acetate and 12.255 g of manganese acetate, add distilled water to dissolve, and obtain a mixed solution. The mixed solution was added dropwise into a citric acid solution containing 9.456 g of citric acid, and reacted in a constant temperature water bath at 80° C. for 1 h. Then the reaction product was dried in an oven at 120° C. to obtain a yellow solid. After grinding the yellow solid, put it into a box furnace at a rate of 5°C / min to 350°C for 12 hours, then cool it naturally to obtain the lithium ion sieve precursor Li 4 mn 5 o 12 . The lithium ion sieve precursor Li 4 mn 5 o 12 With 0.7mol / L HCl acid leaching for 24h, the lithium ion sieve H 4 mn 5 o 12 . Weigh 0.3g lithium ion sieve H 4 mn 5 o 12 Put in 30ml containing Li + 250mg / L in a certain salt lake brine, after 24 hours of adsorption equilibrium, the measured adsorption capacity is 10mg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com