Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Moderate alkalinity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for fusing reducing iron by employing iron ore hot pressing carbon-containing agglomerate

Disclosed is a smelting reduction iron making method by iron ore hot pressing carbon bearing lump into shaft furnace, which takes iron concentrate hot pressing carbon bearing lump as raw material and shaft furnace as smelting reduction reactor. Smelting reduction iron is done by injecting pulverized coal into the shaft furnace with industrial oxygen, hot air or high oxygen hot air agitated; the iron bearing power of iron concentrate hot pressing carbon bearing lump is iron concentrate powder; the hot pressing pulverized coal is bituminous coal powder; quicklime acts as flux; the weight percent of each group is as follow: iron concentrate powder 60 to 75 percent, bituminous coal powder 20 to 35 percent and the quicklime powder 20 to 35 percent; iron concentrate pulverized coal hot pressing lump is fed through double bell mix feeding system at the top of the shaft furnace and is preheated, reduced and smelted in the shaft furnace; the pulverized coal is injected from a tuyere of the shaft furnace to supply heat for the reduction and smelting of iron concentrate hot pressing carbon bearing lump. The process is fit for iron making condition of our country with strong adaptability raw material and low energy and oxygen consumption per ton of iron, which does not depend on coke , and is environment-friendly with short flow and low cost.

Owner:NORTHEASTERN UNIV

Desulfurization gypsum basic steel slag composite gelled material and preparation method thereof

InactiveCN101538140ALow priceModerate alkalinitySolid waste managementCeramic shaping apparatusSlagMixed materials

The invention relates to a desulfurization gypsum basic steel slag composite gelled material and a preparation method thereof. The desulfurization gypsum basic steel slag composite gelled material comprises the following raw materials by weight percentage: 65-95 of desulfurization gypsum, 5-35 of steel slag and an exciting agent of 0.1-5 of the total weight of the desulfurization gypsum and the steel slag, wherein the summation of the weight percentages of the desulfurization gypsum and the steel slag is 100 percent. The preparation method of the composite gelled material comprises the following steps: sifting the steel slag and the desulfurization gypsum for filtering out large grains and pouring the steel slag and the desulfurization gypsum into a material mixing pot for mixing for 20-30 minutes; gauging a standard consistency water consumption of water and pouring the water into an agitator kettle for standby; then weighing the exciting agent, adding the exciting agent to the mixture of the desulfurization gypsum and the steel slag by a first mixing method or a simultaneous mixing method and uniformly mixing the mixture; and agitating, molding and maintaining the mixed materials to obtain the composite gelled material. The method combines two industrial wastes so as to sufficiently improve the utilization rate of the steel slag and the desulfurization gypsum, change the wastes into valuables and also form the gypsum material with good heat preservation, heat insulation and sound insulation performance.

Owner:UNIV OF JINAN

Cement-based rapid repair material with high early strength, and preparation method thereof

The invention discloses a cement-based rapid repair material with high early strength, wherein the cement-based rapid repair material is prepared from the following raw materials by mass: 500-650 parts sulphoaluminate cement, 200-400 parts of ordinary Portland cement, 800-900 parts of quartz sand, 4.5-9.0 parts of nanometer silicon dioxide, 0.25-0.6 part of a dispersing agent, 1.1-10.8 part of a water reducing agent, 0.045-0.160 part of a retarder, 0.10-0.25 part of a defoaming agent and 315-360 parts of water. The invention further provides a preparation method of the cement-based rapid repair material with improved early strength. According to the invention, the field preparation is convenient and easy, sulphoaluminate cement and Portland cement are compounded so as to ensure the early strength and the later strength, the microstructure of the composite repair system is obviously improved through the nanometer material, the early mechanical property of the cement-based material is remarkably improved, the driving quality and the driving safety of the repaired pavement are ensured, the repair cost is low, and the practicability is high.

Owner:GANSU ELECTRIC POWER DESIGN INST

Cable low heat resistance protection medium and preparing method thereof

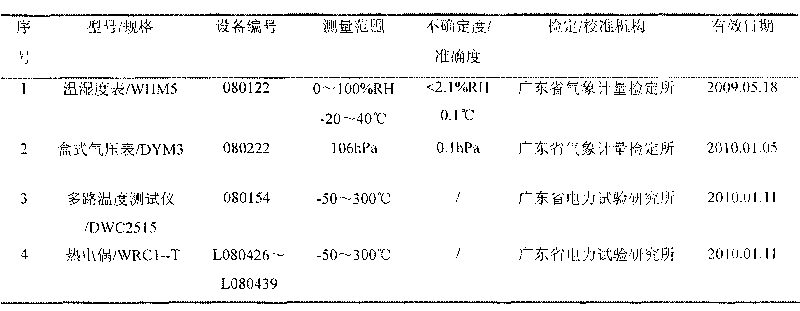

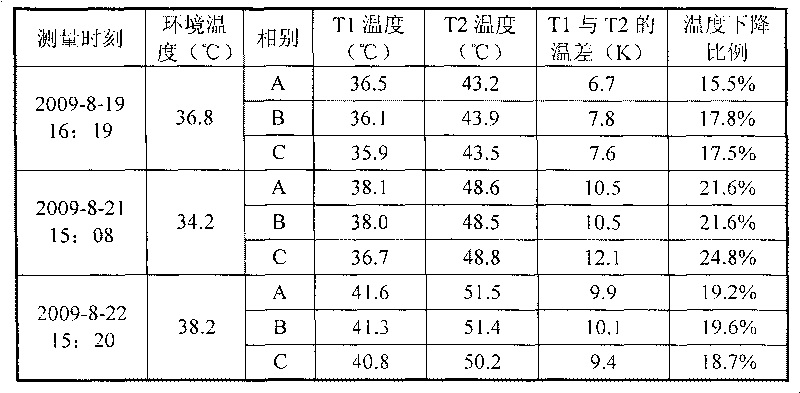

ActiveCN101764384AReduce thermal resistanceIncrease thermal resistanceCable installations on groundAlkalinityElectrical conductor

The invention discloses a cable low heat resistance protection medium with high water content, high stability, low heat resistance, environment protection and effective prevention of termite damage, and a preparation method thereof. The filling medium is prepared by mixing bentonite, fine quartz sand, water and cement, and using a small amount of tartaric acid and sodium sesquicarbonate as additives. As accounted by 100% of mass fraction, the filling medium is preferably prepared by 54%-57% of bentonite, 24%-28% of fine quartz sand, 14%-16% of water, 2.5-3.5% of cement, 0.24%-0.26% of tartaric acid and 0.24%-0.26% of sodium sesquicarbonate. Before condensation, the filling medium has the advantages of better initial liquidity, moderate alkalinity, low bleeding rate and the like. After condensation, compared with traditional material, the filling medium has the advantages of high water content and high stability, and enables the surroundings of the cable to maintain low heat resistance for long term, the heat resistance is smaller than that of soil, and the hardness is higher, therefore the current carrying amount of the cable is improved, or the running temperature of the cable conductor is reduced.

Owner:广州骏拓电力科技有限公司

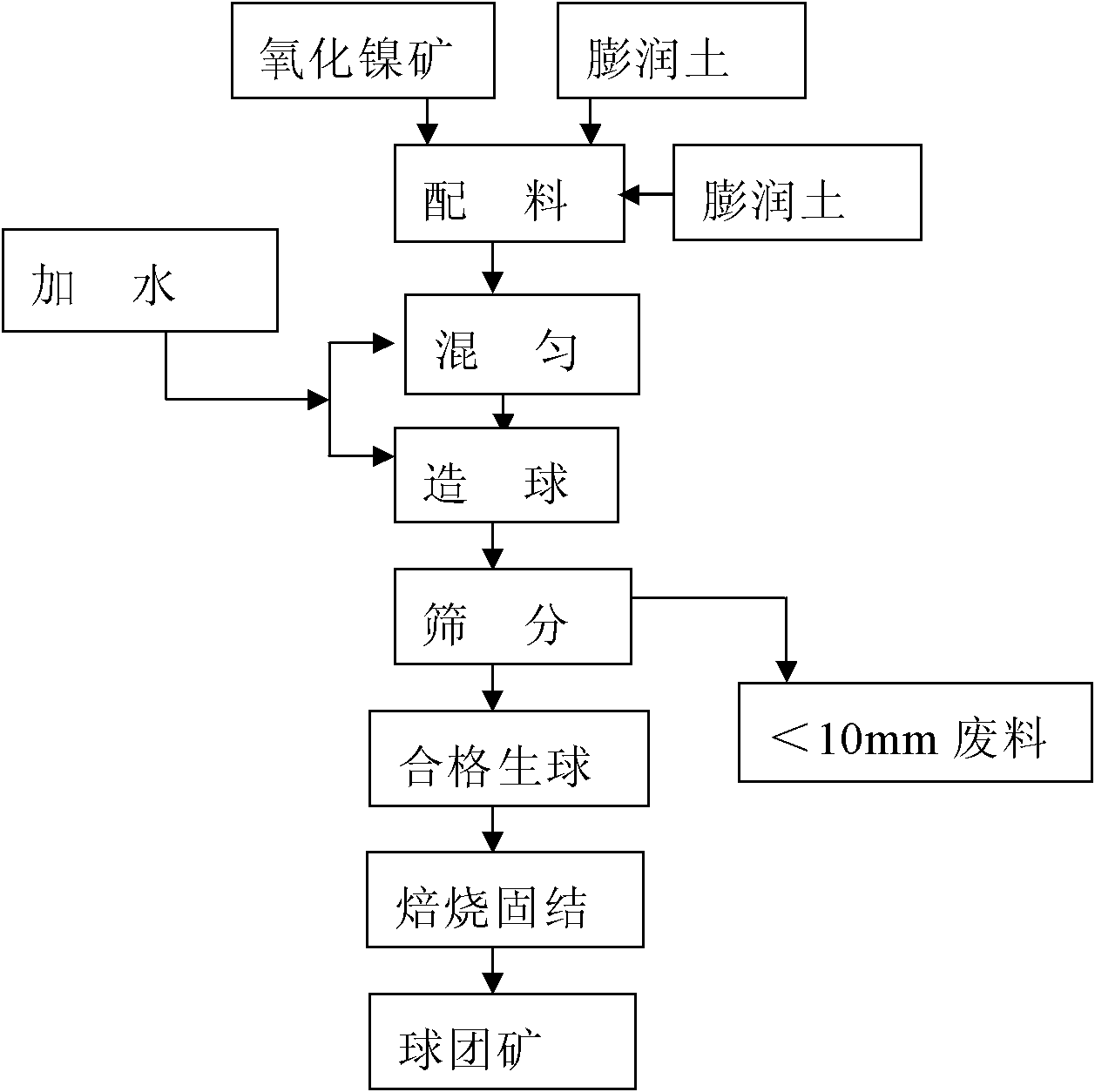

Method for producing pellets from laterite-nickel ore

The invention belongs to production techniques of ferronickel, and particularly relates to a method for producing pellets from laterite-nickel ore, which comprises the following steps: proportioning: evenly mixing 1-4 wt% of bentonite, 1-8 wt% of quicklime and the balance of nickel oxide; pelletizing: adding water to the uniform mixture until the water content reaches 10-15%, and pelletizing by using a pelletizer; screening to remove raw materials of which the particle sizes are smaller than 10mm, thereby obtaining qualified raw pellets; and roasting to solidify, and cooling to obtain the nickel pellets. In the invention, the pellets are made into alkaline ore with a certain alkalinity, and the amount of coke is reduced in the blast-furnace smelting, thereby improving the physical properties of the blast-furnace smelted ferronickel; and in the ferronickel smelting process, the coke ratio is low, the yield is high, and the content of nickel in the smelted ferronickel is high.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Apex slag of ladle in use for refinement of vacuum decarburization in vacuum tank

This invention provides ladle top-slag used for vacuum decarbonization and refinery in vacuum tank. The ladle top-slag comprises: CaO 30-45 wt.%, SiO2 12-18 wt.%, Al2O3 25-35 wt.%, FeO 5-15 wt.%, MgO 3-8 wt.%, and H2O 0-0.2 wt.%. This ladle top-slag is granular mixture with granule sizes of 3-10 mm. The ladle top-slag can transfer oxygen from to steel melt, promote vacuum decarbonization without air, effectively inhibit residue overflow during decarbonization, improve the adsorption of lards in the steel melt after decarbonization, and promote desulfurization and deoxidization of the steel melt.

Owner:BAOSHAN IRON & STEEL CO LTD

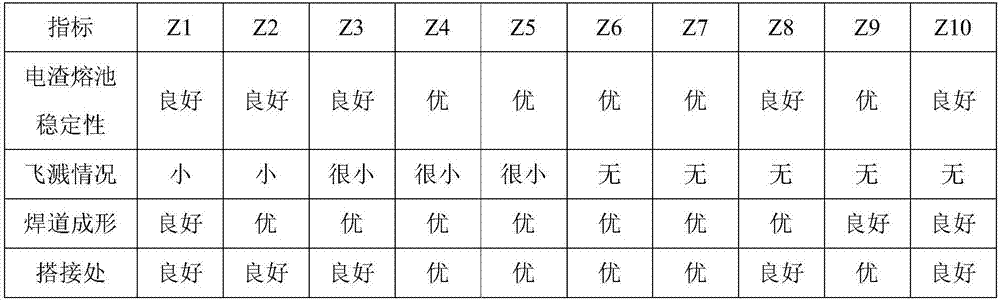

Sintered flux for nickel base strip electrode electro-slag welding

ActiveCN104708231AReduce burning lossImprove the transition coefficientWelding/cutting media/materialsSoldering mediaFerroniobiumSlag

The invention relates to sintered flux for nickel strip electrode electro-slag welding. The sintered flux for the nickel strip electrode electro-slag welding is characterized in that the intered flux is prepared from dry powder components and binder water glass; the dry powder components comprise, by mass, 45-75% of CaF2, 15-35% of Al2O3, 1-5% of SiO2, 1-5% of CaO, 1-5% of MgO, 1-10% of sodium fluoroaluminate, 1-5% of rare earth fluoride and 1-5% of ferroniobium alloy powder; the ratio of potassium to sodium of the binder water glass is 1 to 1, the molar ratio is 2.2-3.5, the baume degree at room temperature is 38-50, and the dosage is 15-25% of the weight of the dry powder. The sintered flux can be used through being matched with various nickel base welding strip such as EQNiCrMo-3 and EQNiCr-3, when strip electrode electro-slag surfacing is conducted through matching with the nickel base welding strip, stable electro-slag process and welding technological property can be maintained at the quick welding condition of 250 mm / min, the quality of formation of surfacing layers is good, defects do not exist in lap joint, and various indexes of the surfacing layers can meet usage requirements of users.

Owner:BEIJING JINWEI WELDING MATERIAL +1

Anti-bonding bleed-out continuous casting covering slag

The invention relates to a covering powder material, in particular to an anti-bonding bleed-out continuous casting covering slag. The components of the anti-bonding bleed-out continuous casting covering slag in weight percent are as follow: 2-8% of Al2O3, 2-7% of F, 4-8% of Na2O, less than 4% of Li2O, 2-15% of B2O3, 0.7-3% of C, less than 3% of impurities carried in by raw materials, and balance of CaO and SiO2 with the weight ratio of CaO / SiO2 being 0.5-0.8. The properties of the covering slag are as follows: solidification temperature is less then 980 DEG C, viscosity at 1300 DEG C is 0.2-0.5Pa.s, and no crystal is precipitated during solidification. The usabilities of the covering slag are as follows: consumption rate is larger than or equal to 0.4kg / t steel, and the thickness of melt slag layer is 10-16mm. The anti-bonding bleed-out continuous casting covering slag in the invention can prevent the phenomenon of bonding bleed-out, improve operation rate of continuous casting machine, and reduce cost and accidents.

Owner:BAOSHAN IRON & STEEL CO LTD

Low-nickel high-nitrogen austenitic stainless steel continuous casting crystallizer covering slag

The invention relates to low-nickel high-nitrogen austenitic stainless steel continuous casting crystallizer covering slag, and belongs to the technical field of metal smelting accessories. The low-nickel high-nitrogen austenitic stainless steel continuous casting crystallizer covering slag is prepared from, by weight, 33.5-38.25 parts of CaO, 25.4-29.6 parts of SiO2, 3-6 parts of Al2O3, larger than 0 and smaller than or equal to 4 parts of Fe2O3, 2-5 parts of MgO, 3.5-9.5 parts of Na2O, 4.5-8.5 parts of F and 3-7 parts of C. The covering slag has the appropriate alkalinity, smelting point, viscosity and carbon addition, suitable heat transfer ability and good filling performance, and can well adapt to characteristics of low-nickel high-nitrogen austenitic stainless steel continuous casting.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Environment protective, high effective washing cream

InactiveCN1570052AImprove decontamination abilityImprove cleaning and decontamination effectSurface-active detergent compositionsDetergent materialsAlkalinitySurface-active agents

The invention discloses an environment protective, high effective washing cream prepared by compounding two types of surface active agents and using 4A zeolite as the detergency promoter, the formulation comprises dodecylbenzene sulfonic acid sodium 0-15 wt%, dodecyl sodium sulfate 0-15 wt%, 4A zeolite 10-20wt%, sodium silicate 5-10wt%, sodium chloride 1-10 wt%, addition agent 0-10 wt%, water 20-50 wt%.

Owner:SOUTHWEST PETROLEUM UNIV

Ladle covering agent prepared through utilizing blast furnace slag

ActiveCN103173592AImprove reducibilityNo carbon increaseProcess efficiency improvementSlagSolid particle

The invention provides a ladle covering agent prepared through utilizing blast furnace slag. The ladle covering agent is composed of 30-40 parts by weight of blast furnace slag, 26.7-40 parts by weight of limestone, 15-20 parts by weight of vermiculite and 5-15 parts by weight of fluorite, wherein the total weight part of the above raw materials is 100. The main raw materials of the ladle covering agent have the advantages of low cost, suitable melting point, short fusing time and good spreadability; and limestone decomposes at 800-1200DEG C, foams and expands, vermiculite expands at a high temperature, and the friction force among solid particles is lower than the inner friction force among powders, so the spreadability and the heat insulating property are good. The ladle covering agent can prevent the secondary oxidation and too large temperature decrease of molten steel, and has a certain impurity adsorption and inclusion capability to purify the molten steel because of the appropriate alkalinity. The ladle covering agent has no carbon, does not carburize the molten steel, and is in favor of the component control of the production process.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

Low-alloy steel welding rod capable of achieving postweld heat treatment

ActiveCN107088719AImprove stabilitySolve crackingWelding/cutting media/materialsSoldering mediaManganesePotassium/sodium ratio

The invention provides a low-alloy steel welding rod capable of achieving postweld heat treatment. An H08E carbon steel welding core is used as a welding core. A flux cover comprises, by weight, 42-55 parts of marble, 18-24 parts of fluorite, 0,5-2 parts of rutile, 3-9 parts of quartz, 0.3-0.8 part of sodium carbonate, 0.3-0.8 part of CMC, 0.2-0.5 part of graphite, 3-9 parts of silicon iron, 3-9 parts of manganese, 9-18 parts of alloy, and 20-25 parts of water glass. Alloy powder comprises, by weight, 25-35 parts of nickel powder, 5-15 parts of ferromolybdenum, 5-15 parts of ferrotitanium and 90-110 parts of iron powder. Potassium-sodium water glass with the modulus M being 3.4 and the potassium-sodium ratio being 1 / 2-3 / 4 is adopted to serve as the water glass. According to the low-alloy steel welding rod capable of achieving postweld heat treatment, the manufacturability is good; and under the wide technological specification, electric arcs are stable, deslagging is easy, and weld beads are formed uniformly and are attractive.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Desulfurization gypsum basic steel slag composite gelled material and preparation method thereof

InactiveCN101538140BLow priceModerate alkalinitySolid waste managementCeramic shaping apparatusSlagMixed materials

Owner:UNIV OF JINAN

Aviation engine carbon deposit cleaning agent and preparation method thereof

InactiveCN112680289AClean up thoroughlyGuaranteed integrityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsActive agentEnvironmental geology

The invention provides an aviation engine carbon deposit cleaning agent and a preparation method thereof. The aviation engine carbon deposit cleaning agent comprises the following components in parts by weight: 10-25 parts of alcohol ether solvent, 5-10 parts of closed dodecylbenzene sulfonic acid, 2-8 parts of a sophorolipid biosurfactant, 2-5 parts of alkenyl succinic anhydride, 2-5 parts of a complexing agent, 2-5 parts of a ternary polycarboxylic acid composition, 1-3 parts of a compound corrosion inhibitor, 1-10 parts of an alkalinity improver, 0.1-1.0 part of a defoaming agent and 50-70 parts of water. The aviation engine carbon deposit cleaning agent is suitable for various assemblies made of different materials in an engine, can protect all the assemblies of the engine from being corroded, oxidized and discolored, meanwhile, removes carbon deposit and dirt on all the assemblies of the engine thoroughly, and guarantees a good cleaning effect.

Owner:苏州禾川化学技术服务有限公司

Cable high-thermal-conductivity backfilling material

ActiveCN104261785AIncrease thermal resistanceReduce thermal resistanceSolid waste managementElectrical conductorAdhesive

The invention discloses a cable high-thermal-conductivity backfilling material which comprises slag stone, calcium oxide, polyvinyl acetate adhesive, water and sodium silicate. The cable high-thermal-conductivity backfilling material is proportionally prepared from the slag stone, calcium oxide, polyvinyl acetate adhesive, water and sodium silicate by a special technique. The cable high-thermal-conductivity backfilling material has the technical characteristics of favorable initial flowability, moderate alkalinity, low bleeding rate and the like before solidifying. After solidifying, the cable high-thermal-conductivity backfilling material has the advantages of high water content, high stability, smaller thermal resistance ratio than soil, favorable heat dissipation property and higher hardness, and can keep the periphery of the cable at lower thermal resistance for a long time, thereby enhancing the current capacity of the cable or lowering the working temperature of the cable conductor. Compared with the cable with the same specification in the prior art, the current capacity is increased by 15-28%, thereby greatly lowering the project investment cost. The cable using the backfilling material has the advantages of low thermal resistance, environment friendliness, no harm or toxicity and long service life, and can protect the filling medium.

Owner:广州骏拓电力科技有限公司

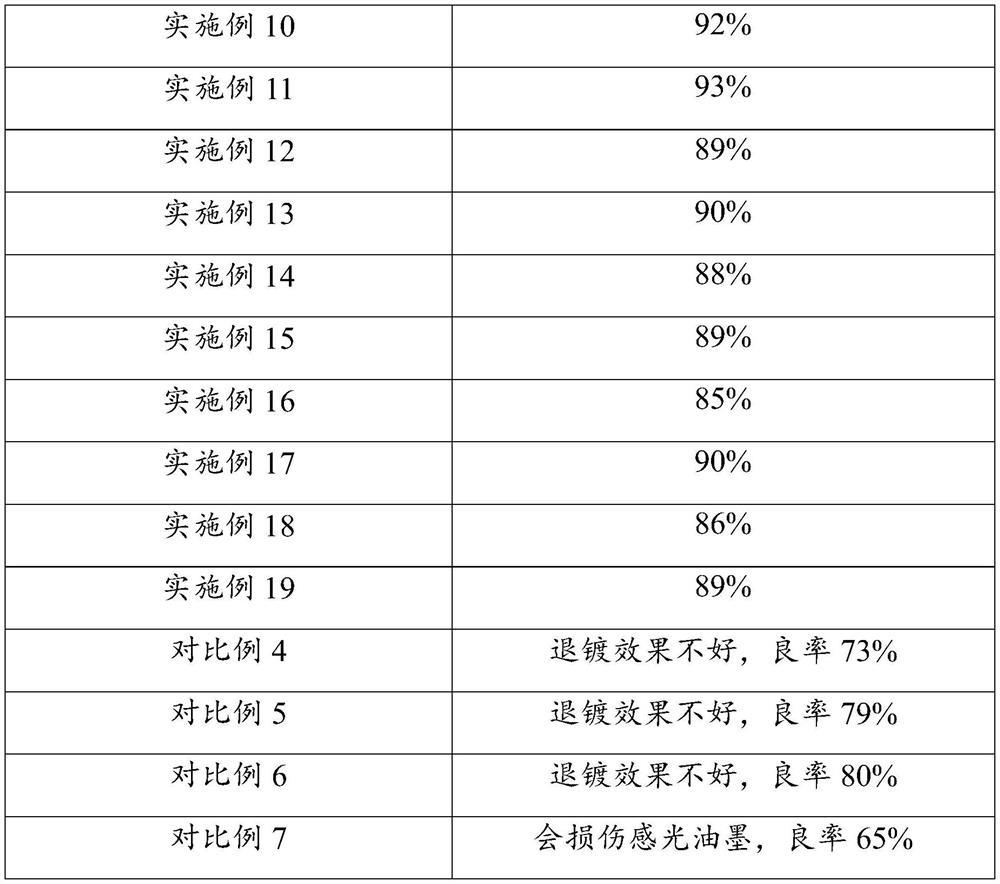

Deplating solution and deplating technology for removing glass NCVM film layer

The invention discloses a deplating solution and a deplating technology for removing a glass NCVM film layer, and relates to the technical field of glass deplating. The deplating solution comprises the following components by mass percentage: 10-30% of soluble carbonate, 5-15% of a complexing agent, 1-5% of penetrant and the balance of water. In the deplating technology, the deplating solution isused for deplating the NCVM film layer of a glass product. By adopting the deplating solution and the deplating technology provided by the invention, the technical problems that a strong alkaline deplating solution used for the removal of the NCVM film layer easily causes damage to photosensitive ink after exposure and development and the product yield is low in a traditional technology are alleviated. The deplating solution provided by the invention mainly uses the soluble carbonate as a main deplating agent, and by cooperating with the complexing agent and the penetrant, not only can the NCVM film layer be cleanly removed with a good deplating effect, but also no damage is caused to the photosensitive ink after exposure and development, and the glass product after being deplated with thedeplating solution has a good appearance and a high yield.

Owner:LENS TECH CHANGSHA

Internal recycling method for KR desulfurized slag steel mill

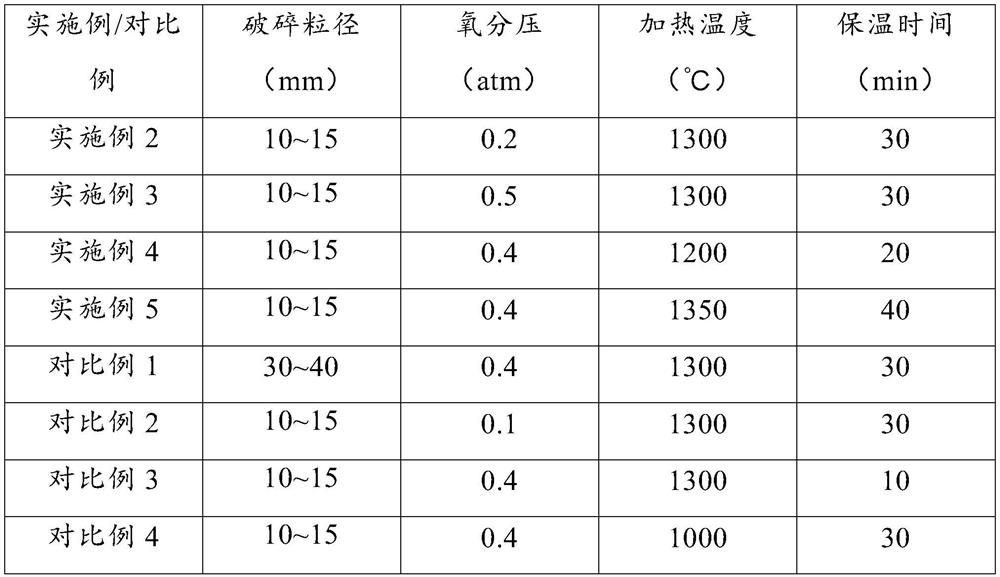

PendingCN113373275AEfficient separationReduce slagging pressureSulfur compoundsManufacturing convertersSteelmakingFlue gas

The invention provides an internal recycling method for KR desulfurized slag in a steel mill. The internal recycling method comprises the following steps that KR desulfurized slag is crushed, and then subjected to magnetic separation to obtain slag iron and tailings; then, the tailings are subjected to high-temperature oxidation treatment, and sulfur-containing flue gas and pre-melted slag are obtained; and then sulfur-containing flue gas is collected and treated, the pre-melted slag is used as a slagging material for converter early-stage slagging, and internal recycling of the KR desulfurized slag in the steel mill is achieved. Through the manner, the slag iron in the KR desulfurized slag can be effectively separated from the tailings which are difficult to recycle, and the tailings are subjected to high-temperature oxidation treatment, so that the iron in the tailings is oxidized into iron oxide while sufficient desulfurization is performed, and the sulfur-free pre-melted slag rich in CaO and iron oxide is obtained; and further, by utilizing the synergistic effect between the CaO and the iron oxide, the pre-melted slag is used as a slagging material for converter early-stage slagging, so that the iron oxide promotes quick dissolution of lime, and the slagging pressure of converter steelmaking is reduced while comprehensive utilization of the KR desulfurized slag is realized.

Owner:WUHAN UNIV OF SCI & TECH

Regeneration method for desulfurization liquid of coal-to-fuel gas wet oxidation method desulfurization

InactiveCN103275768AReduce dosageReduce suspended sulfur contentCombustible gas purificationChemical recyclingThermodynamicsPtru catalyst

The present invention provides a regeneration method for a desulfurization liquid of coal-to-fuel gas wet oxidation method desulfurization, wherein a desulfurization liquid changed into a pregnant solution is introduced into a regeneration tank under a catalysis condition, oxygen gas and air are mixed according to a volume ratio of 1:(5-6), the mixed gas is introduced into the pregnant solution in the regeneration tank, and a reaction is performed to obtain the finished product. The regeneration method has characteristics of simple process, easy condition control, and low cost. During a desulfurization liquid regeneration process, a catalyst use amount is low, a secondary salt production amount is less, sulfur foam characteristics are stable, flotation is easily performed, desulfurization efficiency is high, a desulfurization liquid regeneration effect is good, and a recycling rate is high.

Owner:SICHUAN COAL COKING GRP

Ladle covering agent prepared through utilizing blast furnace slag

ActiveCN103173592BImprove reducibilityNo carbon increaseProcess efficiency improvementSlagSolid particle

The invention provides a ladle covering agent prepared through utilizing blast furnace slag. The ladle covering agent is composed of 30-40 parts by weight of blast furnace slag, 26.7-40 parts by weight of limestone, 15-20 parts by weight of vermiculite and 5-15 parts by weight of fluorite, wherein the total weight part of the above raw materials is 100. The main raw materials of the ladle covering agent have the advantages of low cost, suitable melting point, short fusing time and good spreadability; and limestone decomposes at 800-1200DEG C, foams and expands, vermiculite expands at a high temperature, and the friction force among solid particles is lower than the inner friction force among powders, so the spreadability and the heat insulating property are good. The ladle covering agent can prevent the secondary oxidation and too large temperature decrease of molten steel, and has a certain impurity adsorption and inclusion capability to purify the molten steel because of the appropriate alkalinity. The ladle covering agent has no carbon, does not carburize the molten steel, and is in favor of the component control of the production process.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

Sintering method for improving vanadium-titanium sinter output and quality

ActiveCN112760479AHigh strengthGood low temperature reduction performancePollutant emissionsTitanium

The invention discloses a sintering method for improving the vanadium-titanium sinter output and quality. The method comprises the following steps of preparing a vanadium-titanium sinter raw material into a high-alkalinity mixture and a low-alkalinity mixture, and sequentially distributing two sintering mixtures with different kinds of alkalinity on a sintering trolley, so that sintering materials are of a double-layer mixture layer structure with two kinds of alkalinity, and finally, carrying out primary ignition sintering, crushing and cooling to obtain vanadium-titanium sinter. The method can effectively solve the problems that a vanadium-titanium sinter product is low in yield, poor in strength and particularly poor in low-temperature reduction degradation performance, meanwhile, the heat storage effect of a material layer can be fully utilized, sintering energy consumption is remarkably reduced, and pollutant emission is reduced.

Owner:CENT SOUTH UNIV

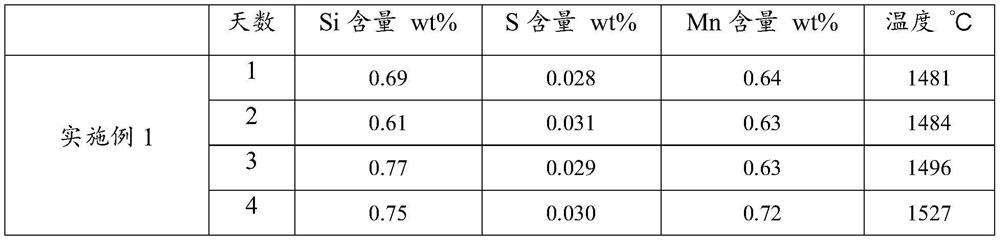

The method of cleaning the blast furnace before shutting down

The application provides a method for cleaning a blast furnace before shutting down, and belongs to the technical field of shutting down an empty material line for blast furnace ironmaking. The method of washing the blast furnace before shutting down includes distributing cloth in the throat of the blast furnace, and then performing furnace washing and smelting. The standards for the furnace washing and smelting steps include: the edge temperature is 250-300°C, and the molten iron temperature is ≥1480°C. Through the step of distributing materials, in the step of furnace washing and smelting: in the slag, R is 1.05-1.16, the content of MgO is 8.0-9.0wt%, and the content of Al 2 o 3 The content of Si is ≤15.0wt%; in molten iron, the content of Si is 0.60-0.90wt%, the content of S is 0.025-0.045wt%, and the content of Mn is 0.50-0.80wt%. It can shorten the cleaning time of the furnace wall and the furnace hearth, and effectively save the shutdown time of the blast furnace.

Owner:SGIS SONGSHAN CO LTD

Apex slag of ladle in use for refinement of vacuum decarburization in vacuum tank

ActiveCN100408702CImprove liquidityWeak storage capacityProcess efficiency improvementSlagGranularity

This invention provides ladle top-slag used for vacuum decarbonization and refinery in vacuum tank. The ladle top-slag comprises: CaO 30-45 wt.%, SiO2 12-18 wt.%, Al2O3 25-35 wt.%, FeO 5-15 wt.%, MgO 3-8 wt.%, and H2O 0-0.2 wt.%. This ladle top-slag is granular mixture with granule sizes of 3-10 mm. The ladle top-slag can transfer oxygen from to steel melt, promote vacuum decarbonization without air, effectively inhibit residue overflow during decarbonization, improve the adsorption of lards in the steel melt after decarbonization, and promote desulfurization and deoxidization of the steel melt.

Owner:BAOSHAN IRON & STEEL CO LTD

Anti-bonding bleed-out continuous casting covering slag

The invention relates to a covering powder material, in particular to an anti-bonding bleed-out continuous casting covering slag. The components of the anti-bonding bleed-out continuous casting covering slag in weight percent are as follow: 2-8% of Al2O3, 2-7% of F, 4-8% of Na2O, less than 4% of Li2O, 2-15% of B2O3, 0.7-3% of C, less than 3% of impurities carried in by raw materials, and balance of CaO and SiO2 with the weight ratio of CaO / SiO2 being 0.5-0.8. The properties of the covering slag are as follows: solidification temperature is less then 980 DEG C, viscosity at 1300 DEG C is 0.2-0.5Pa.s, and no crystal is precipitated during solidification. The usabilities of the covering slag are as follows: consumption rate is larger than or equal to 0.4kg / t steel, and the thickness of melt slag layer is 10-16mm. The anti-bonding bleed-out continuous casting covering slag in the invention can prevent the phenomenon of bonding bleed-out, improve operation rate of continuous casting machine, and reduce cost and accidents.

Owner:BAOSHAN IRON & STEEL CO LTD

Stripping solution and stripping process for stripping glass ncvm film

Owner:LENS TECH CHANGSHA

Environment protective, high effective washing cream

InactiveCN1243816CImprove decontamination abilityImprove hard water resistanceSurface-active detergent compositionsDetergent materialsAlkalinitySurface-active agents

The invention discloses an environment protective, high effective washing cream prepared by compounding two types of surface active agents and using 4A zeolite as the detergency promoter, the formulation comprises dodecylbenzene sulfonic acid sodium 0-15 wt%, dodecyl sodium sulfate 0-15 wt%, 4A zeolite 10-20wt%, sodium silicate 5-10wt%, sodium chloride 1-10 wt%, addition agent 0-10 wt%, water 20-50 wt%.

Owner:SOUTHWEST PETROLEUM UNIV

Cold heading steel, ladle furnace refining process of cold heading steel and production process of cold heading steel

InactiveCN104513931BImprove machinabilityImprove cleanlinessProcess efficiency improvementElectric furnaceRoom temperatureUltimate tensile strength

The present invention provides a cold heading steel, a cold heading steel ladle furnace refining process and a cold heading steel production process. The cold heading steel comprises the following chemical components by weight: 0.19-0.22% of C, less than or equal to 0.10% of Si, 0.75-0.90% of Mn, less than or equal to 0.025% of P, less than or equal to 0.030% of S, more than or equal to 0.02% of AlT, less than or equal to 0.20% of Cr, less than or equal to 0.20% of Ni, less than or equal to 0.20% of Cu, and the balance of Fe. According to the present invention, in the cold heading steel production process, application of aluminum to carry out deep deoxidation, silicon calcium wire feeding, immersion type nozzle application and other steps are adopted, such that the internal components of the produced cold heading steel are reasonably matched, and especially the combination of the C with the content of 0.19-0.22% and the Si with the content of less than or equal to 0.10% makes the cold heading steel meet strength, toughness and other comprehensive mechanical properties, such that the workability of the cold heading steel at a room temperature is good.

Owner:NEW FOUNDER HLDG DEV LLC +2

Regeneration method for desulfurization liquid of coal-to-fuel gas wet oxidation method desulfurization

InactiveCN103275768BReduce dosageReduce suspended sulfur contentCombustible gas purificationChemical recyclingThermodynamicsPtru catalyst

The present invention provides a regeneration method for a desulfurization liquid of coal-to-fuel gas wet oxidation method desulfurization, wherein a desulfurization liquid changed into a pregnant solution is introduced into a regeneration tank under a catalysis condition, oxygen gas and air are mixed according to a volume ratio of 1:(5-6), the mixed gas is introduced into the pregnant solution in the regeneration tank, and a reaction is performed to obtain the finished product. The regeneration method has characteristics of simple process, easy condition control, and low cost. During a desulfurization liquid regeneration process, a catalyst use amount is low, a secondary salt production amount is less, sulfur foam characteristics are stable, flotation is easily performed, desulfurization efficiency is high, a desulfurization liquid regeneration effect is good, and a recycling rate is high.

Owner:SICHUAN COAL COKING GRP

Sintered flux for nickel base strip electroslag welding

ActiveCN104708231BOptimize the amount of additionAdjust conductivityWelding/cutting media/materialsSoldering mediaFerroniobiumSlag

The invention relates to sintered flux for nickel strip electrode electro-slag welding. The sintered flux for the nickel strip electrode electro-slag welding is characterized in that the intered flux is prepared from dry powder components and binder water glass; the dry powder components comprise, by mass, 45-75% of CaF2, 15-35% of Al2O3, 1-5% of SiO2, 1-5% of CaO, 1-5% of MgO, 1-10% of sodium fluoroaluminate, 1-5% of rare earth fluoride and 1-5% of ferroniobium alloy powder; the ratio of potassium to sodium of the binder water glass is 1 to 1, the molar ratio is 2.2-3.5, the baume degree at room temperature is 38-50, and the dosage is 15-25% of the weight of the dry powder. The sintered flux can be used through being matched with various nickel base welding strip such as EQNiCrMo-3 and EQNiCr-3, when strip electrode electro-slag surfacing is conducted through matching with the nickel base welding strip, stable electro-slag process and welding technological property can be maintained at the quick welding condition of 250 mm / min, the quality of formation of surfacing layers is good, defects do not exist in lap joint, and various indexes of the surfacing layers can meet usage requirements of users.

Owner:BEIJING JINWEI WELDING MATERIAL +1

A cement-based rapid repair material with high early strength and its preparation method

A high-early-strength cement-based rapid repair material is made of raw materials including the following components by mass: 500-650 parts for sulphoaluminate cement, 200-400 parts for ordinary Portland cement, and 800 parts for quartz sand ~900 parts, 4.5~9.0 parts of nano-silica, 0.25~0.6 parts of dispersant, 1.1~10.8 parts of water reducer, 0.045~0.160 parts of retarder, 0.10~0.25 parts of defoamer, 315~360 parts of water . The invention also provides a preparation method of the cement-based quick repair material with improved early strength. It is convenient and easy to prepare on site. It is compounded with sulphoaluminate cement and Portland cement to ensure the early and late strength. Nanomaterials can significantly improve the microstructure of the composite repair system and significantly improve the early mechanical properties of cement-based materials; The driving quality and driving safety of the repaired road surface; the repairing cost is low and the practicability is strong.

Owner:GANSU ELECTRIC POWER DESIGN INST

A kind of planting concrete material prepared by wet grinding potassium feldspar and phosphorus tailings and preparation method thereof

ActiveCN112321226BElicitor activityImprove mechanical propertiesSolid waste managementOXALIC ACID DIHYDRATEMining engineering

The invention relates to a planted concrete material prepared by wet grinding potassium feldspar and phosphorus tailings and a preparation method thereof. The planted concrete material is composed of the following components in parts by weight: 22-33 parts of coarse aggregate, 5.3-7.154 parts of cement, 1.378-1.86 parts of water, 0.0159-0.0214 parts of polycarboxylate water reducing agent, 0.795-1.323 parts of wet-milled phosphorus tailings powder, 0.795-1.323 parts of wet-milled potassium feldspar powder, and 1.1528-1.3675 parts of 3 wt% oxalic acid solution. In the present invention, phosphorus tailings and potassium feldspar are mixed into the cementitious material after wet grinding, which can improve the mechanical properties of the cementitious material in the later stage; Dissolution K + , P + , in order to play the role of slow-release fertilizer, so as to continuously provide necessary mineral elements for the growth of plants; in the later stage, the pH value of the system is effectively reduced by acid spraying and alkali reduction, which provides good growth conditions for plants, which is conducive to improving the performance of planted concrete materials. comprehensive performance.

Owner:HUBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com