Stripping solution and stripping process for stripping glass ncvm film

A technology for stripping solution and glass, applied in the field of stripping solution and stripping process, can solve problems affecting product appearance quality, unstable product yield, photosensitive ink damage, etc., to achieve good appearance, good stripping effect, guarantee gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

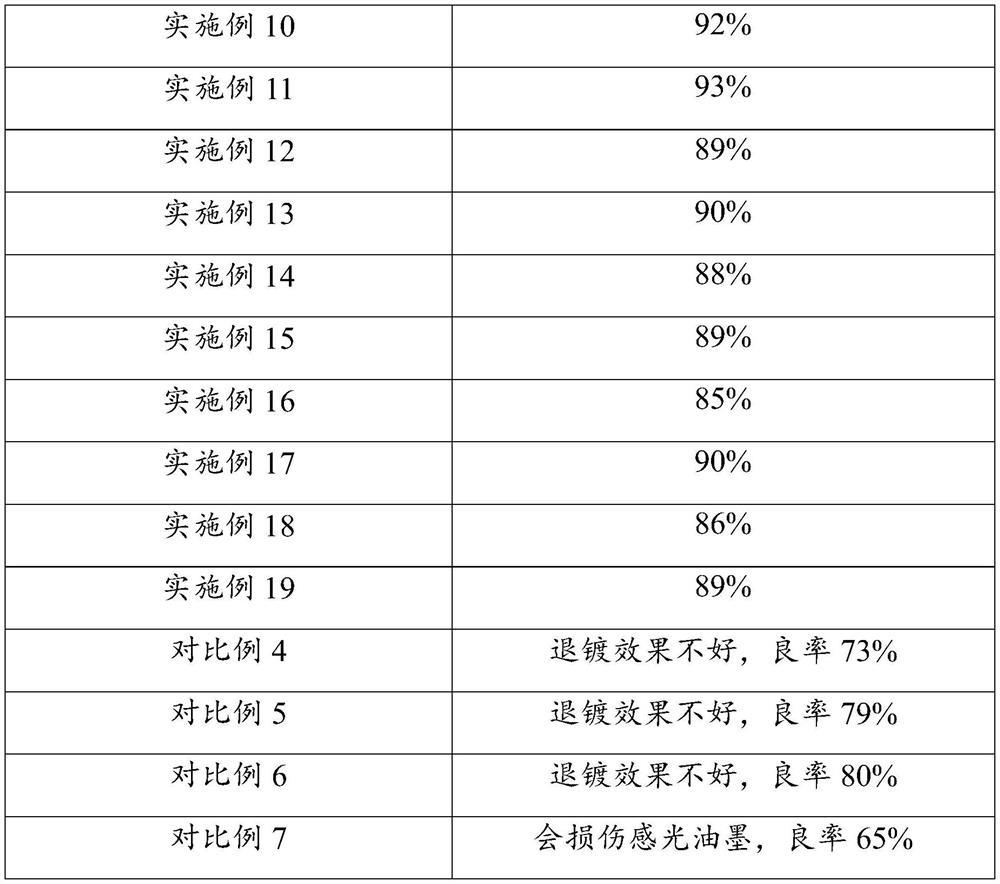

Examples

Embodiment 1

[0118] A tandem for retarding the glass NCVM membrane layer consists of the following mass percentage component: 15% sodium carbonate, 10% sodium tartrate, JFC 3%, and the rest is water.

Embodiment 2

[0120] A tandem for retarding the glass NCVM film, consists of a component of the following mass content: 25% sodium carbonate, 5% sodium trihydrate, 1% osmotic JFC, and the rest is water.

Embodiment 3

[0122] A rubber solution for retarding the glass NCVM film, consists of the following mass percentage component: 20% sodium carbonate, 8% sodium tartrate, 2% osmotic JFC, and the rest is water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com