Stripping solution for stripping metal cadmium-plated layer and stripping method thereof

A stripping solution and metal plating technology, applied in the field of chemical stripping, can solve the problems of skin irritation, high pollution, limited use range, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

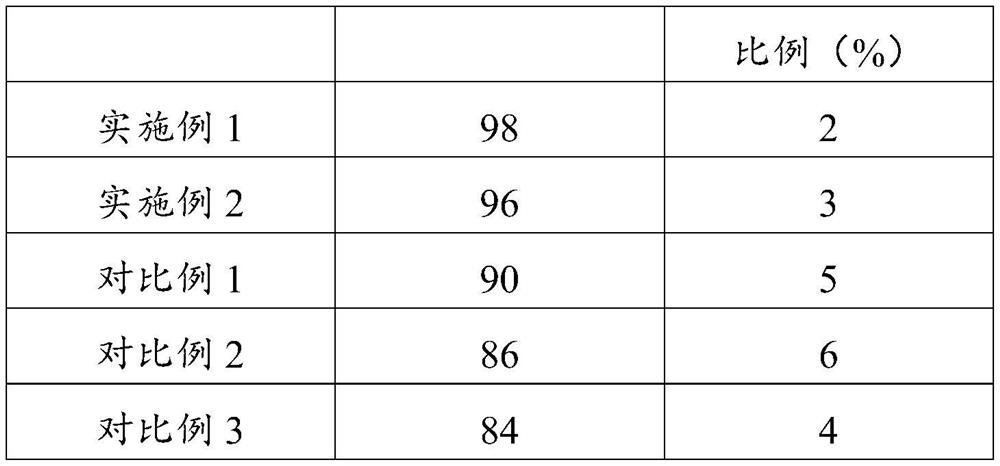

Embodiment 1

[0021] Embodiment 1 provides a raw material for the preparation of a stripping solution for removing a metal cadmium plating layer, which, in terms of weight percentages, includes: 3% of siloxane compounds, 4% of amine compounds, 8% of salt compounds, and supplemented by water. balance to 100%.

[0022] The siloxane compound is a compound of siloxane ketone and polydimethylsiloxane, the mass ratio of siloxane ketone and polydimethylsiloxane is 1.4:0.6, and the CAS number of the siloxane ketone is 1.4:0.6. It is 63148-62-9, purchased from Hangzhou Baisi Chemical Technology Co., Ltd., and the polydimethylsiloxane CAS number is 9016-00-6, purchased from Sigma-Aldrich (Shanghai) Trading Co., Ltd.;

[0023] The amine compound is a compound of ammonia water, polyacrylamide, and bis-(4-methoxybenzyl)-amine, and the quality of ammonia water, polyacrylamide, and bis-(4-methoxybenzyl)-amine The ratio is 1.0:0.2:1.4, the ammonia water CAS number is 1336-21-6, purchased from Shanghai Ala...

Embodiment 2

[0029] Embodiment 2 provides a raw material for the preparation of a stripping solution for removing a metal cadmium plating layer, which, in weight percentages, includes: 4% of siloxane compounds, 5% of amine compounds, 10% of salt compounds, and supplemented by water. balance to 100%.

[0030] The siloxane compound is a compound of siloxane ketone and polydimethylsiloxane, the mass ratio of siloxane ketone and polydimethylsiloxane is 1.4:0.6, and the CAS number of the siloxane ketone is 1.4:0.6. It is 63148-62-9, purchased from Hangzhou Baisi Chemical Technology Co., Ltd., and the polydimethylsiloxane CAS number is 9016-00-6, purchased from Sigma-Aldrich (Shanghai) Trading Co., Ltd.;

[0031] The amine compound is a compound of ammonia water, polyacrylamide, and bis-(4-methoxybenzyl)-amine, and the quality of ammonia water, polyacrylamide, and bis-(4-methoxybenzyl)-amine The ratio is 1.0:0.2:1.4, the ammonia water CAS number is 1336-21-6, purchased from Shanghai Aladdin Bio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com