Internal recycling method for KR desulfurized slag steel mill

An internal circulation, desulfurization slag technology, applied in chemical instruments and methods, sulfur compounds, process efficiency improvement, etc., can solve the problems of long treatment process, insufficient use of desulfurization slag value, etc., to achieve good fluidity and reduce slag. Consume, speed up the effect of the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a kind of KR desulfurization slag (42.88% CaO, 11.74% SiO 2 , 3.29% MgO, 1.58% S, 3.80% CaF 2 and 36.71% MFe) the method for internal recycling in steel mills, comprising the steps:

[0038] S1. Crush the KR desulfurization slag into particles with a particle size of 10-15mm, and then perform magnetic separation to obtain slag-iron and tailings; wherein, the mass ratio of slag-iron to tailings is 0.48:1.

[0039] The iron content in the collected iron slag is 75%, which can be used to replace part of the steelmaking raw materials for steelmaking; the CaO content in the tailing slag is 63.29%, the iron content is 6.58%, and the sulfur content is 1.77%. Next step.

[0040] S2. Under an oxidizing atmosphere (oxygen partial pressure is 0.4atm), heat the tailings obtained in step S1 to 1300° C. and keep it warm for 30 minutes to perform oxidative desulfurization to obtain sulfur-containing flue gas and pre-melted slag.

[0041]Among them, the desu...

Embodiment 2~5 and comparative example 1~4

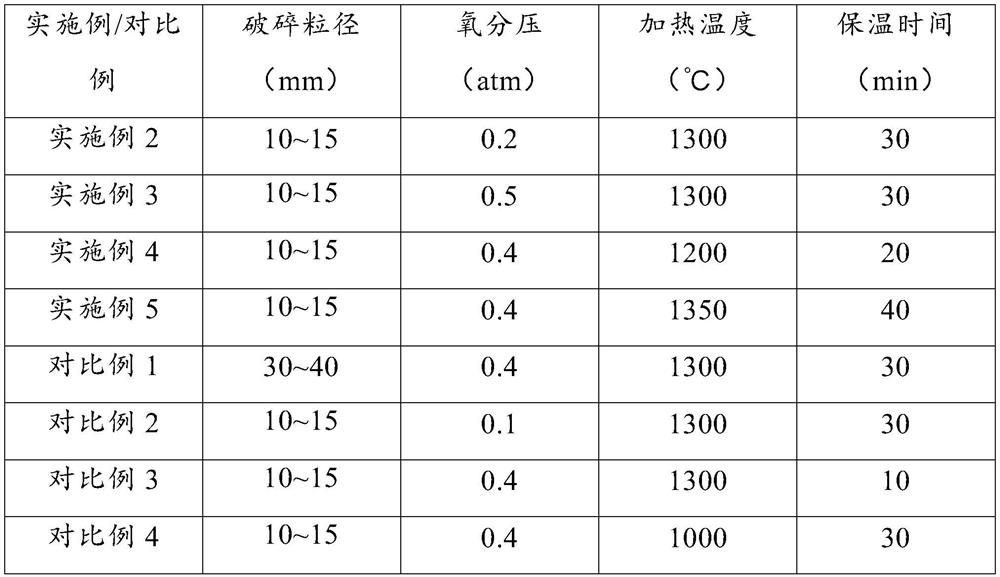

[0045] Embodiments 2 to 5 and Comparative Examples 1 to 4 respectively provide a method for internal recycling of KR desulfurization slag in a steel plant. Compared with Example 1, the difference is that the broken particle size of KR desulfurization slag or high temperature oxidation is changed. The technical parameters of the process, the corresponding technical parameters of each embodiment and comparative example are shown in Table 1, and the rest of the steps are consistent with the embodiment 1, and will not be repeated here.

[0046] The process parameter of table 1 embodiment 2~5 and comparative example 1~4

[0047]

[0048] After testing, the desulfurization rates of the methods provided in the examples and comparative examples in the oxidative desulfurization process and the semi-steel dephosphorization rates and semi-steel sulfur additions of the products used in the early slagging of converters are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com