Aviation engine carbon deposit cleaning agent and preparation method thereof

A carbon deposit cleaning agent, engine technology, applied in the direction of detergent compounding agent, detergent composition, chemical instrument and method, etc., can solve the problem that carbon deposit is not easy to be completely removed, the effect of carbon deposit removal is not complete, and the piston of antifreeze is easy to be blocked And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

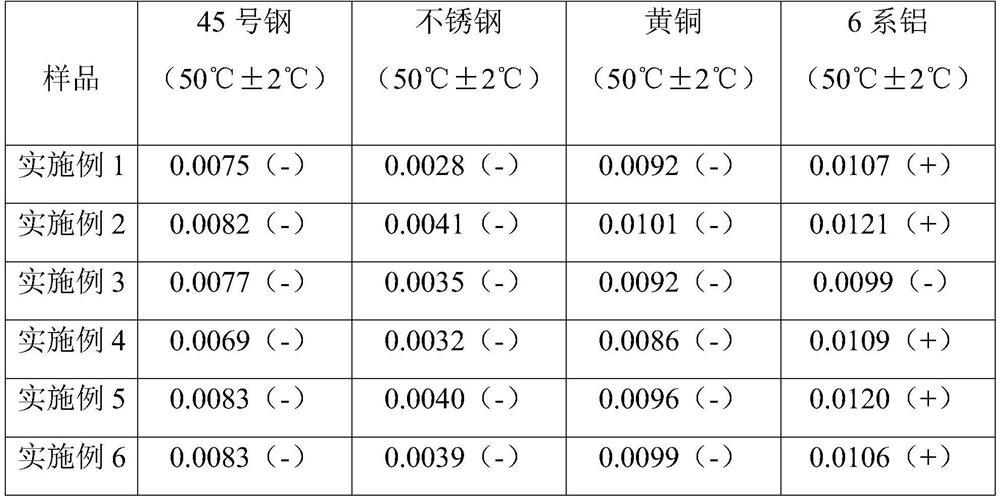

Examples

Embodiment 1

[0032] Components: 16 parts of alcohol ether solvent, 8 parts of blocked dodecylbenzenesulfonic acid, 2 parts of sophoryl ester biosurfactant, 2 parts of alkenyl succinic anhydride, 2 parts of complexing agent, ternary polycarboxylic acid combination 2 parts of compound corrosion inhibitor, 4 parts of alkalinity enhancer, 0.3 part of defoamer, 61.7 parts of water.

[0033] In this embodiment, the alcohol ether solvent is specifically composed of 10 parts of diethylene glycol monoethyl ether, 3 parts of ethylene glycol phenyl ether, and 3 parts of benzyl alcohol; the blocked dodecylbenzenesulfonic acid is specifically dodecylbenzene Diethanolamine salt of dodecylbenzenesulfonic acid formed by the reaction of sulfonic acid and diethanolamine; sophoryl ester biosurfactant is acid type sophoryl ester; alkenyl succinic anhydride is dodecenyl succinic anhydride; complexing agent is lemon Sodium acid; The terpolymeric acid composition is the ternary polycarboxylate of the neutralizat...

Embodiment 2

[0040] Components: 17 parts of alcohol ether solvent, 6 parts of blocked dodecylbenzenesulfonic acid, 3 parts of sophoryl ester biosurfactant, 3 parts of alkenyl succinic anhydride, 2 parts of complexing agent, terpolymeric acid combination 2 parts of compound corrosion inhibitor, 5 parts of alkalinity enhancer, 0.5 part of defoamer, and 59.5 parts of water.

[0041] In this embodiment, the alcohol ether solvent is specifically composed of 8 parts of diethylene glycol mono-n-propylene glycol, 4 parts of propylene glycol phenyl ether, and 5 parts of benzyl alcohol; the blocked dodecylbenzenesulfonic acid is specifically dodecylbenzene Diethanolamine salt of dodecylbenzenesulfonic acid produced by the reaction of sulfonic acid and diethanolamine; sophorose ester biosurfactant is mixed type sophorose ester; alkenyl succinic anhydride is dodecenyl succinic anhydride; complexing agent is glycine The ternary polycarboxylate composition is a ternary polycarboxylate generated by the n...

Embodiment 3

[0046] Components: 15 parts of alcohol ether solvent, 7 parts of blocked dodecylbenzenesulfonic acid, 2 parts of sophoryl ester biosurfactant, 3 parts of alkenyl succinic anhydride, 2 parts of complexing agent, terpolymeric acid combination 2 parts, compound corrosion inhibitor 2.5 parts, alkalinity enhancer 5 parts, defoamer 0.8 parts, water 60.7 parts.

[0047] In this embodiment, the alcohol ether solvent is specifically composed of 10 parts of dipropylene glycol methyl ether and 5 parts of propylene glycol phenyl ether; Triethanolamine dialkylbenzenesulfonate; Sophoryl ester biosurfactant is mixed type Sophoryl ester; Alkenyl succinic anhydride is dodecenyl succinic anhydride; Complexing agent is sodium diethylenetriaminepentaacetate; Ternary The polycarboxylic acid composition is a trivalent polycarboxylate formed by the neutralization reaction of a trivalent polycarboxylic acid and ammonia water; the compound corrosion inhibitor consists of 1 part of 5-phenyltetrazolium,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com