Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Adjust conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

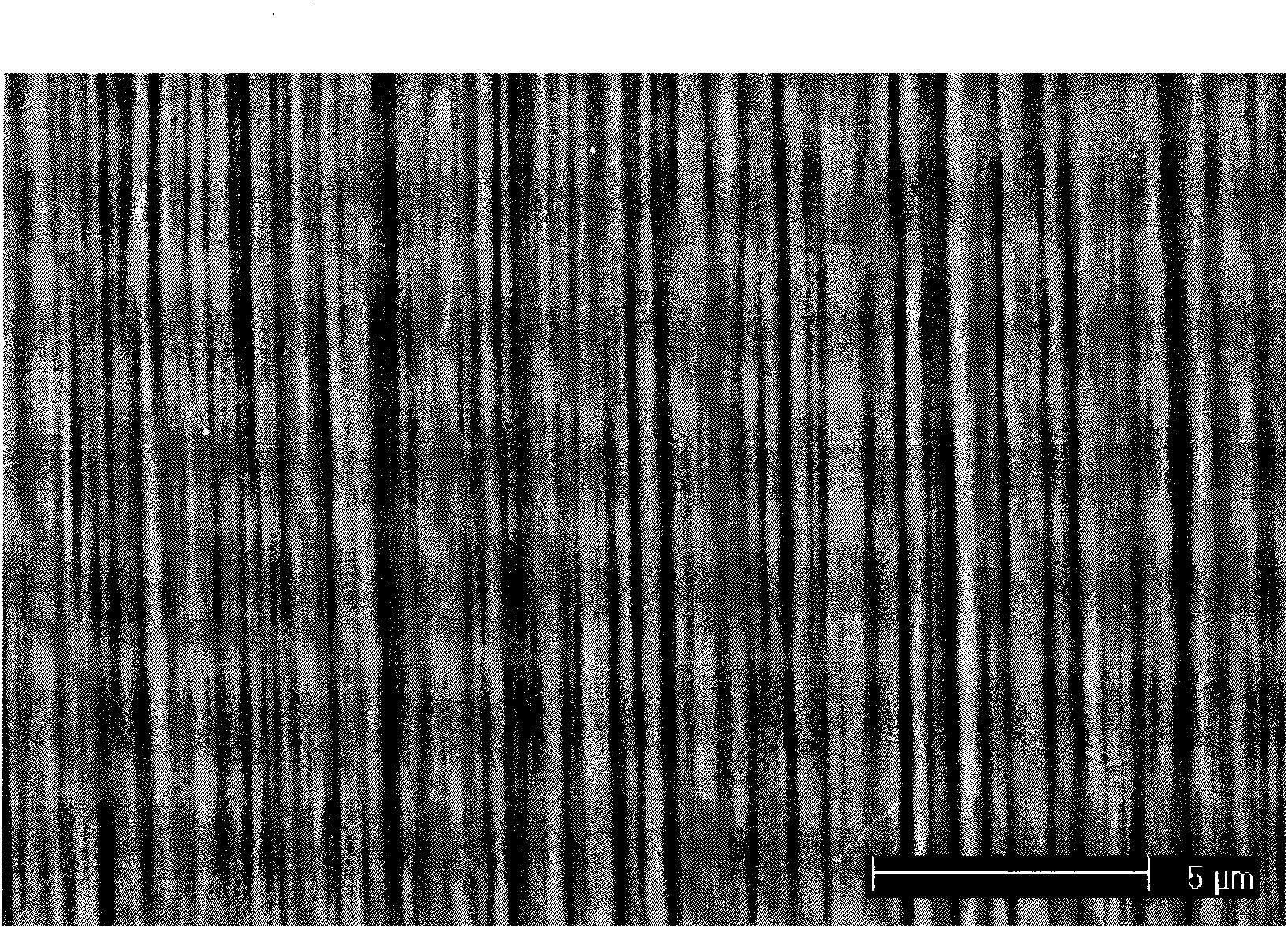

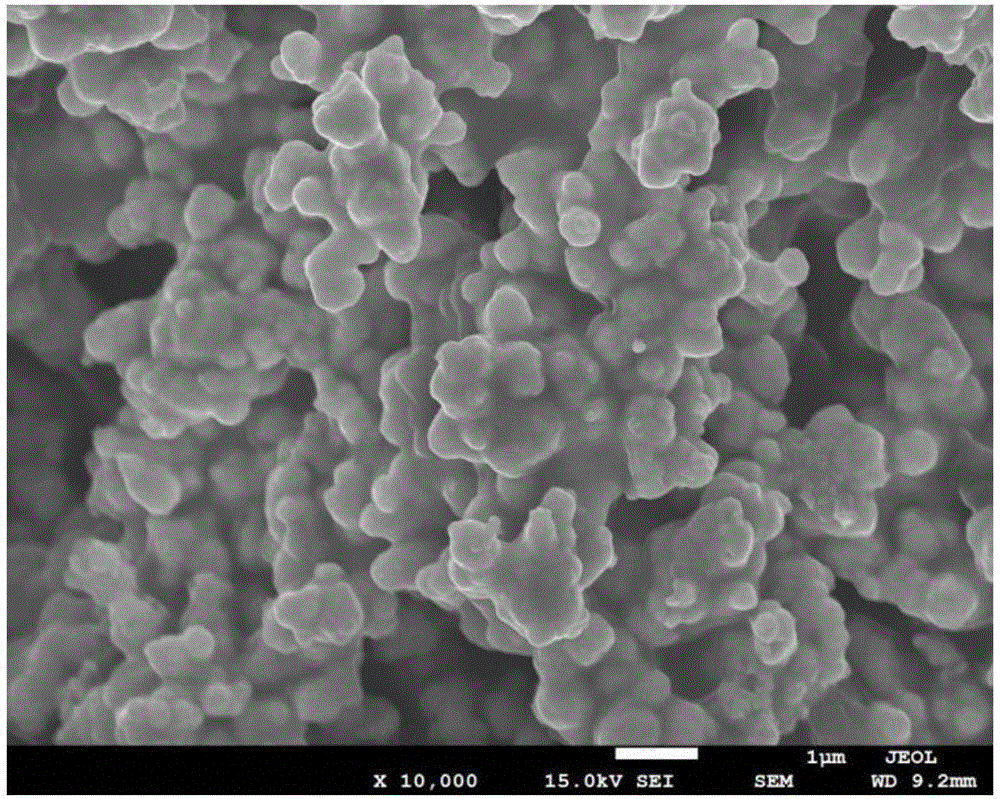

Method for uniformly and controllably coating conducting carbon layer at surface of LiFePO4 granule surface

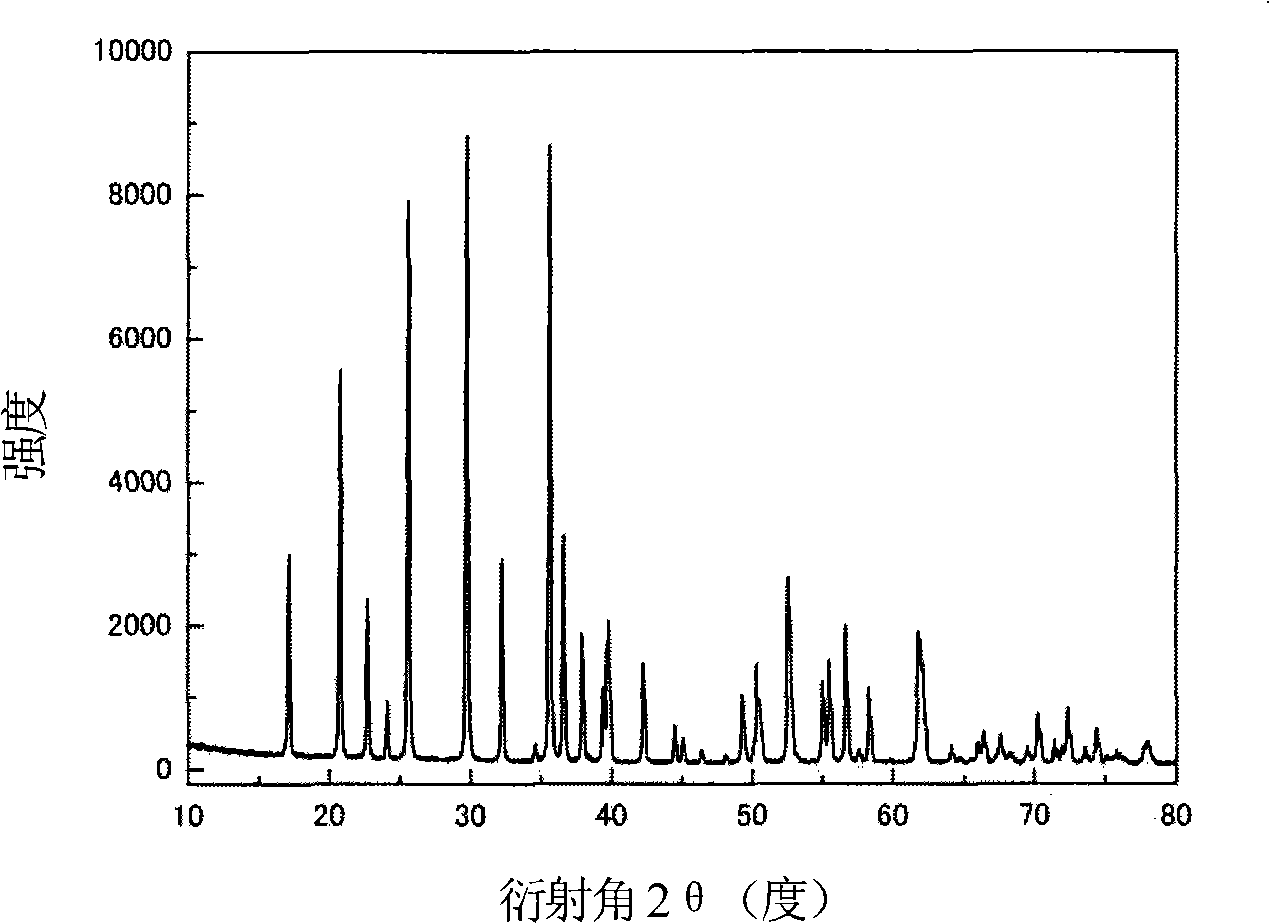

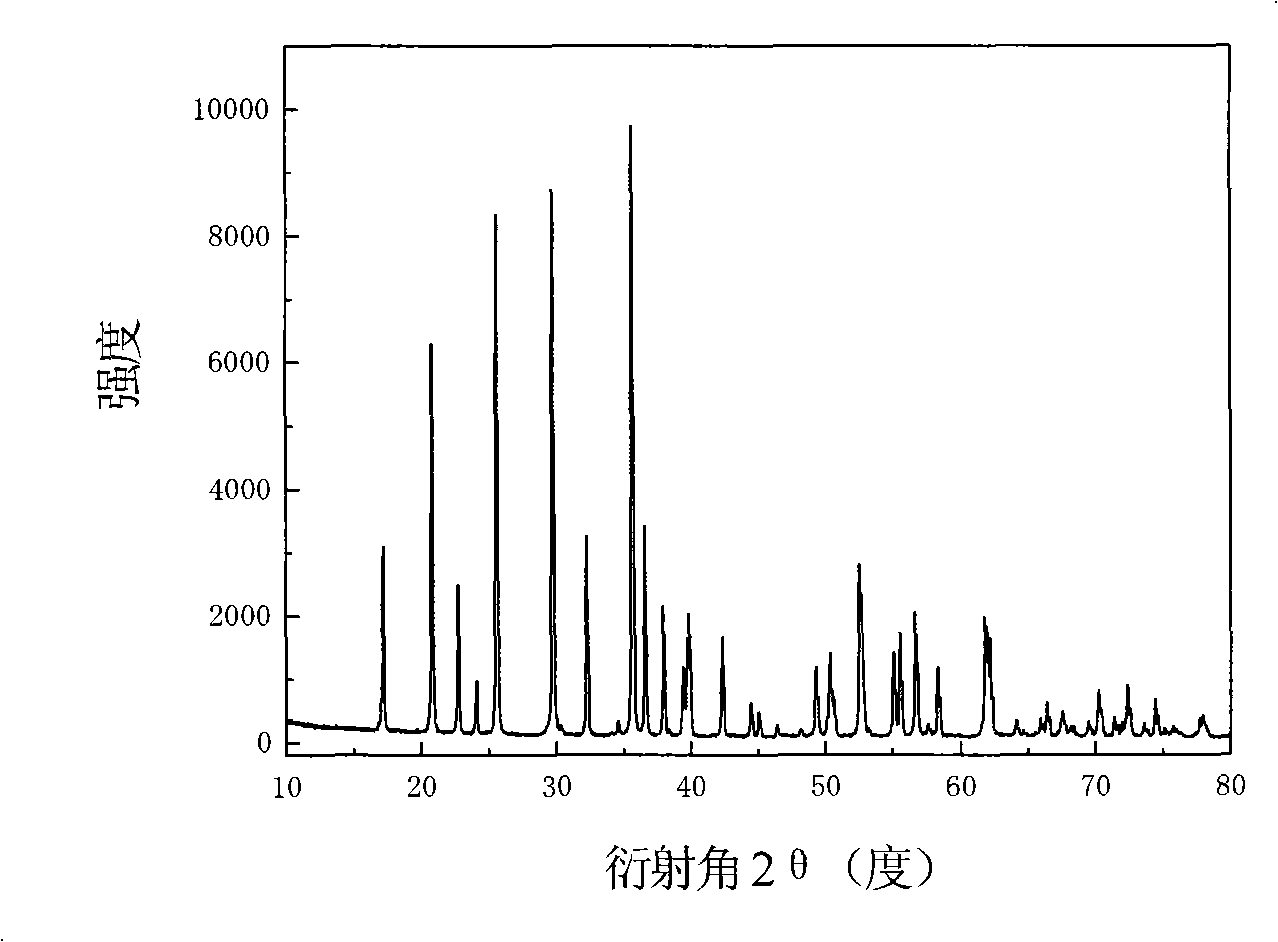

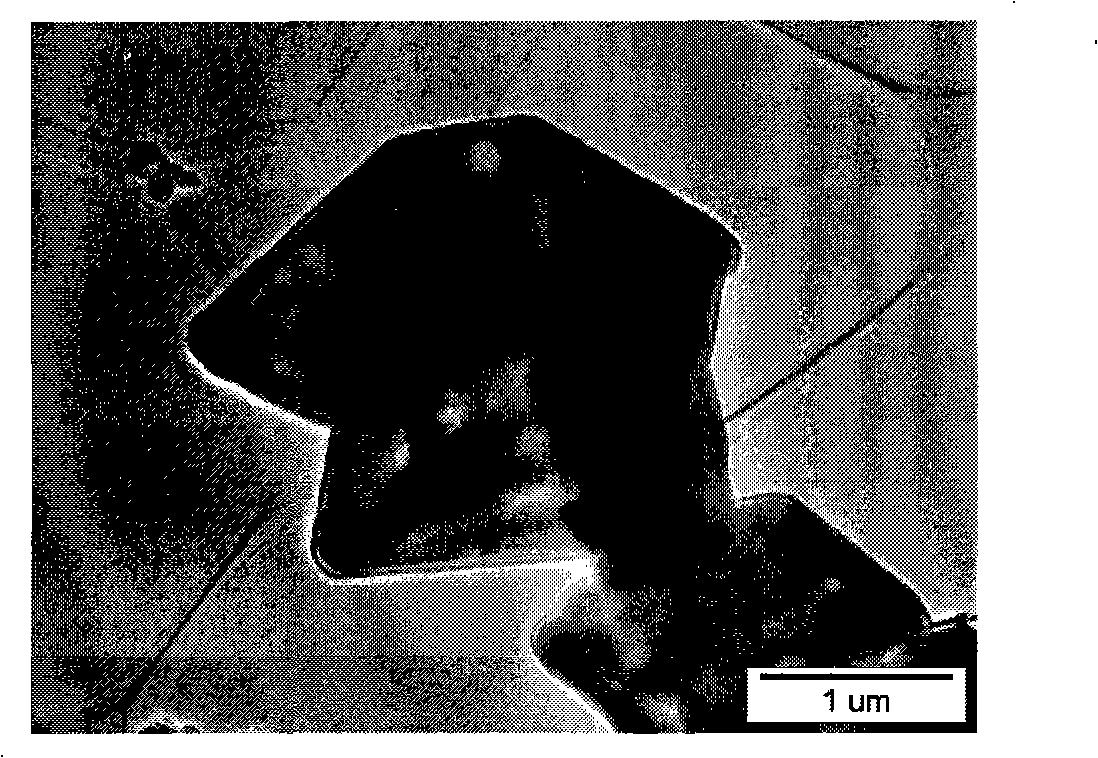

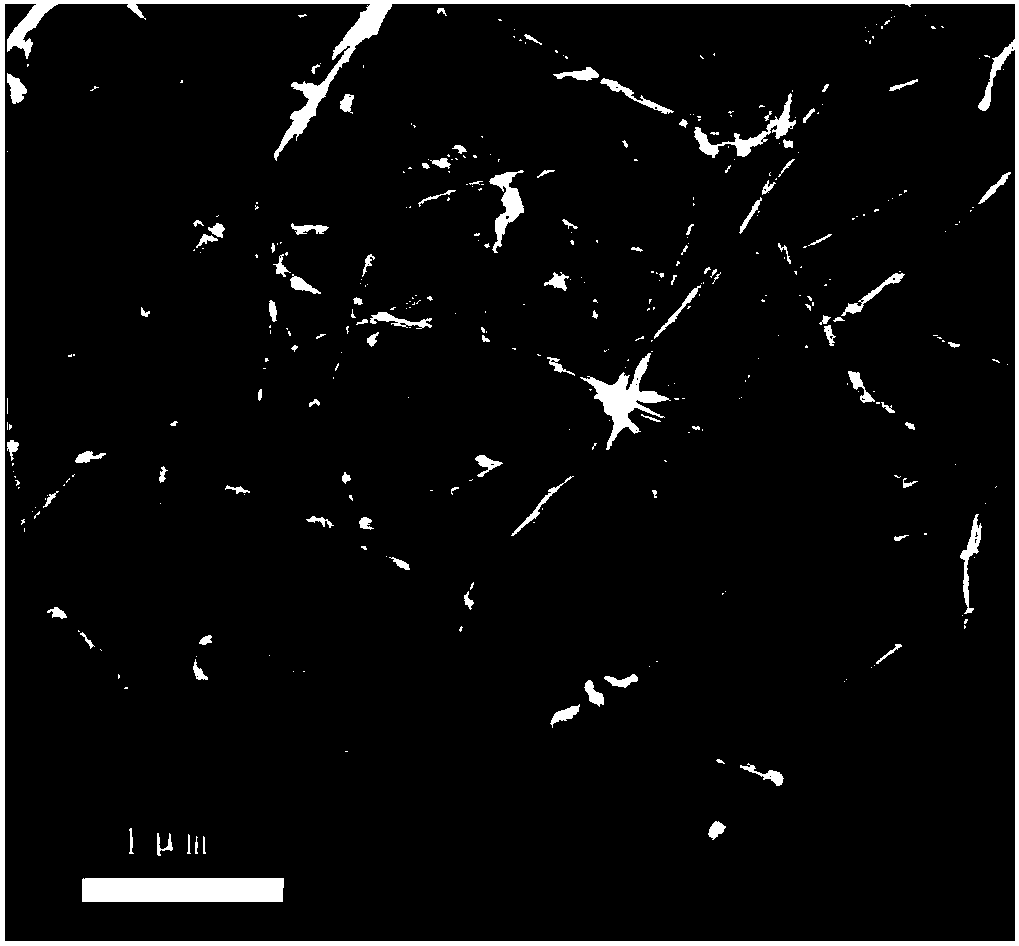

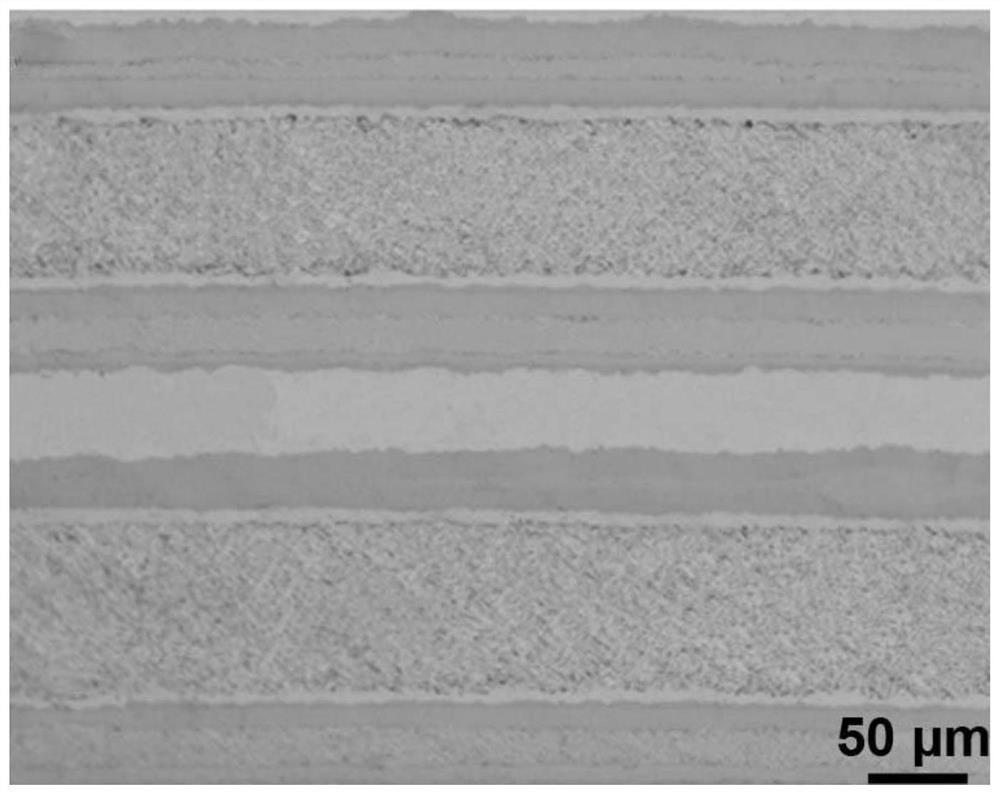

InactiveCN101333650AUniform thicknessHigh conductivityCell electrodesChemical vapor deposition coatingCarbon filmCarbon source

The invention relates to a method for coating an even and controllable deposit carbon layer on the surface of LiFePO4 particles serving as lithium ion battery cathode materials for increasing the LiFePO4 conductivity. The method adopts the concrete preparation processes that: LiFePO4 powders are placed in a constant temperature zone of a chemical vapor deposition furnace, then the air in the furnace is fully discharged for inputting inert gases, after the temperature rises to the set level, a carbon source gas is input for covering a conductivity carbon film on the surface of the LiFePO4 particles evenly, the LiFePO4 coated with the carbon film has excellent conductivity which is increased by five orders of magnitude compared with the condition before coating. The chemical vapor deposition temperature ranges from 580 to 720DEG C, the deposition time is from 1 to 10 hours, and the volume percent of the carbon source gas is between 1 and 20 percent, and a sample deposited with carbon is cooled to the room temperature with a natural furnace and is then taken out. The method can cover the conductivity carbon film on the surface of each LiFePO4 particle evenly for increasing the conductivity of LiFePO4, and the thickness of the conductivity carbon film can be accurately controlled in the range of 2 to 50 nanometers through adjusting parameters (deposition temperature, deposition time and carbon source gas volume percent) of the chemical vapor deposition process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing electrically conductive hydrogel

ActiveCN108794773AImprove mechanical propertiesImprove electrochemical performanceHydrophilic monomerHydrophilic polymers

The invention discloses a method for preparing electrically conductive hydrogel. The method includes steps of (1), uniformly dispersing hydrophilic monomers or hydrophilic polymers in hydrochloric acid aqueous solution to obtain stable dispersion liquid, adding electrically conductive monomers and metal alkoxide into the dispersion liquid and uniformly stirring the electrically conductive monomers, the metal alkoxide and the dispersion liquid; (2), adding initiators and catalysts into mixed liquid obtained at the step (1), uniformly mixing the initiators, the catalysts and the mixed liquid with one another and then carrying out reaction at the temperature ranging from -20 DEG C to 50 DEG C for 24-72 hours. The electrically conductive hydrogel can be obtained after the reaction is completely carried out. The mass of the electrically conductive monomers is 1-20% of the mass of the hydrochloric acid aqueous solution, is 20-100% of the mass of the metal alkoxide and is 0.2-85% of the massof the hydrophilic monomers or the hydrophilic polymers. The mass of the initiators is 0.5-5% of the mass of the electrically conductive monomers, and the mass of the catalysts is 0.01-5% of the massof the hydrophilic monomers. Compared with existing methods, the method has the advantages that the electrically conductive hydrogel prepared by the aid of the method is excellent in mechanical property and electrochemical performance and can be prepared at one step, and the method includes simple processes for preparing the electrically conductive hydrogel and is low in raw material usage.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

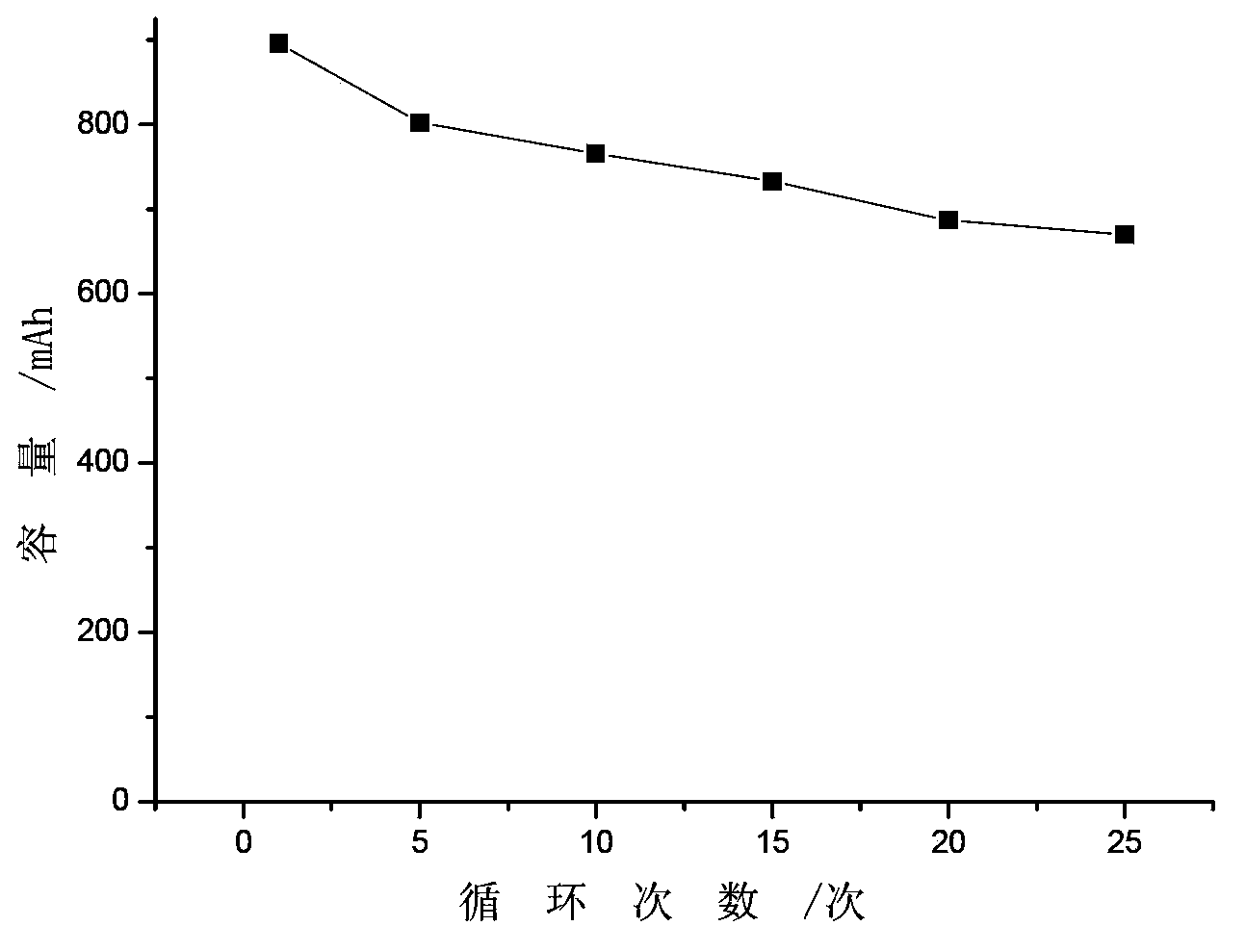

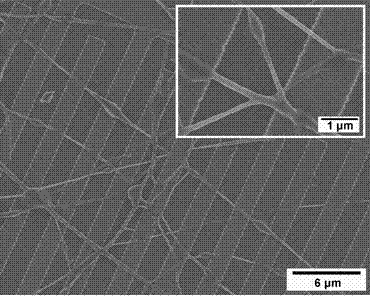

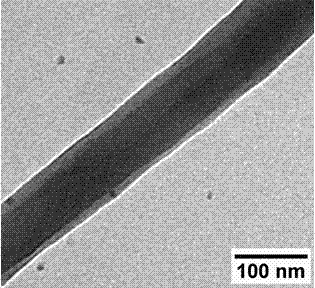

Preparation method of controllable nitrogen-doped carbon nanotubes

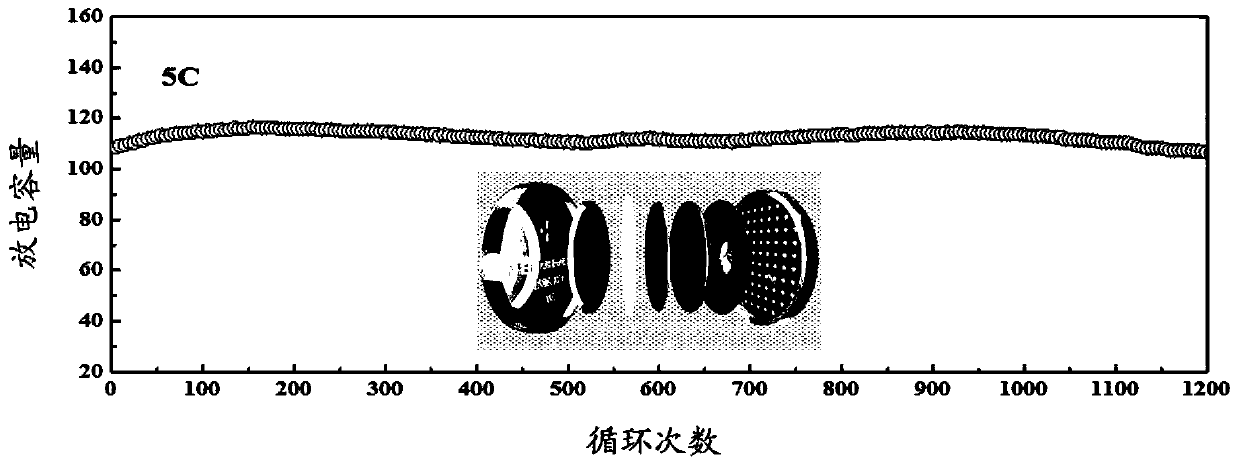

ActiveCN108689398AImprove cycle lifeSimple processCell electrodesCarbon nanotubesCarbonizationMetallic sulfide

The invention discloses a preparation method of controllable nitrogen-doped carbon nanotubes. The method comprises the following steps: dissolving a metal salt, a carbon source and a nitrogen source in an aqueous or ethanol solution, performing stirring at 60-80 DEG C until the solution volatilizes to form a sol, drying the sol at 80-120 DEG C to form a gel, carrying out high-temperature heat treatment carbonization on the above gel precursor, keeping the temperature at 350-650 DEG C for 2-4 h, keeping the temperature at 750-1000 DEG C for 5-10 h to obtain nitrogen-doped carbon nanotubes containing metal or metal sulfide, and simply corroding the nitrogen-doped carbon nanotubes containing metal or metal sulfide to obtain the nitrogen-doped carbon nanotubes. The above sol-gel technology canrealize the effective regulation of the caliber and the length of the nitrogen-doped carbon nanotubes and the adjustment of the nitrogen content, the pore structure and the conductivity of the nitrogen-doped carbon nanotubes. The nitrogen-doped carbon nanotubes can effectively prolong the cycle life of a battery when applied to the electrode material of the battery, has good electrochemical performances, and is hopeful to be applied to fields of electrochemical catalysis, energy transition and energy storage.

Owner:NANJING UNIV OF SCI & TECH

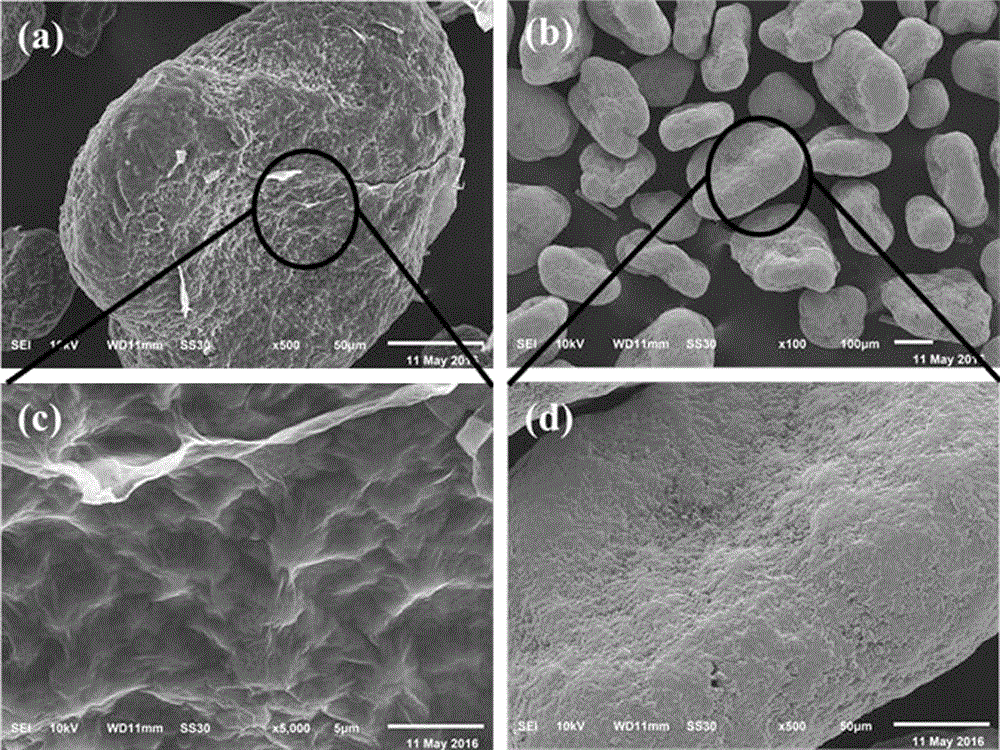

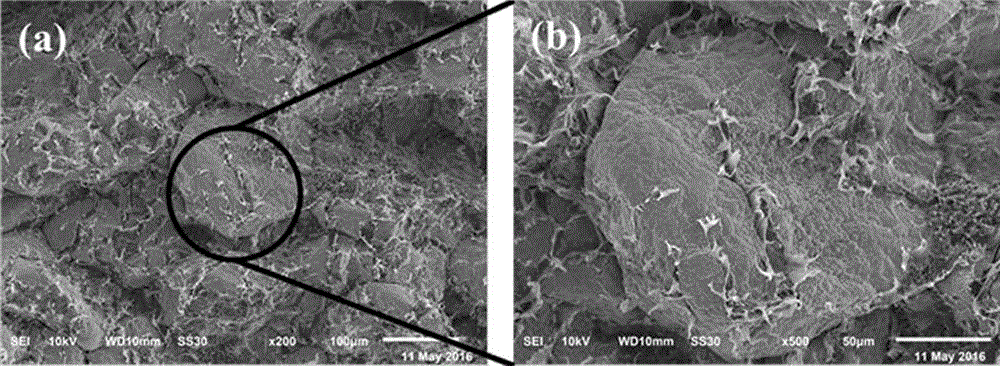

Ultra-high molecular weight polyethylene-graphene-nickel composite material and preparation method

ActiveCN106366409AImprove conductivityImprove shielding effectMagnetic/electric field screeningLiquid/solution decomposition chemical coatingElectromagnetic shieldingCvd graphene

The invention relates to the field of functional composite materials, in particular to an ultra-high molecular weight polyethylene-graphene-nickel composite material with a high electromagnetic shielding performance and a preparation method. Composite materials used for preparing the composite materials are nickel-plated graphene-coated ultra-high molecular weight polyethylene particles taking metallic nickel as a shell structure and taking graphene-coated ultra-high molecular weight polyethylene particles as a core, wherein the content of the graphene-coated ultra-high molecular weight polyethylene particles ranges from 97.42 vol% to 98.91 vol%, the content of metallic nickel ranges from 1.09 vol% to 2.58 vol%, and the content of graphene in the composite material is at least 0.028 vol%. By preparing the composite material with the isolation structure, on the condition that the content the metallic nickel and the content of the graphene are extremely low, the electric conductivity and electromagnetic shielding performance of the composite material can be significantly improved, and the purposes of the high electric conductivity and the high electromagnetic shielding performance of the composite material are achieved.

Owner:ZHONGBEI UNIV

Method for preparing low-temperature cured conductive paste

InactiveCN101697292AAdjust printabilityChange viscosityConductive materialMetal/alloy conductorsConductive pasteScreen printing

The invention discloses a method for preparing low-cost low-temperature cured conductive paste for screen printing. In the preparation method, base metal nickel (Ni) is used to replace part of used precious metal silver (Ag); nickel powder and silver powder form a conductive function phase of the conductive paste together, wherein the change of the adding proportion of the nickel powder not only can adjust the final electrical property, but also can adjust the printing performance of the paste well; the change of the adding proportion of an organic carrier can adjust the viscosity and the electric conductivity of a product; and the change of the adding proportion of a thickening agent can adjust the viscosity, the leveling property and the printing performance of the product. The quick drying and curing can be performed at a constant temperature of between 120 and 150 DEG C to form the product with good electrical property. The conductive paste of the invention adopts the base metal to replace partial precious metal silver, so the production cost is greatly reduced, and the performance reaches the level of high silver content.

Owner:IRICO

Production method for inorganic compound conductive powder body

InactiveCN101174485AWidely distributedLow priceConductive materialChemical/physical/physico-chemical processesKaoliniteAntimony

The invention relates to a preparation method for tin oxide-doped composite conductive powder using kaolinite as base material. The invention is characterized in that dispersing agent is mixed with kaolinite ore to produce homogeneous and dispersed suspended ore slurry; chemical co-precipitation method is adopted for homogeneous precipitation in the form of hydroxide or hydrous oxide, then the composite conductive powder is obtained after filtering, washing, gas-liquid separation, calcination and grinding of precipitation products. The invention has the advantages of greatly reduced preparation cost of conductive powder, greatly improved use value of kaolinite resources, easy dispersion of the composite conductive powder, stable quality, light powder color, good conductivity, conductive additives for various colors (such as white) and wide application prospect.

Owner:CENT SOUTH UNIV

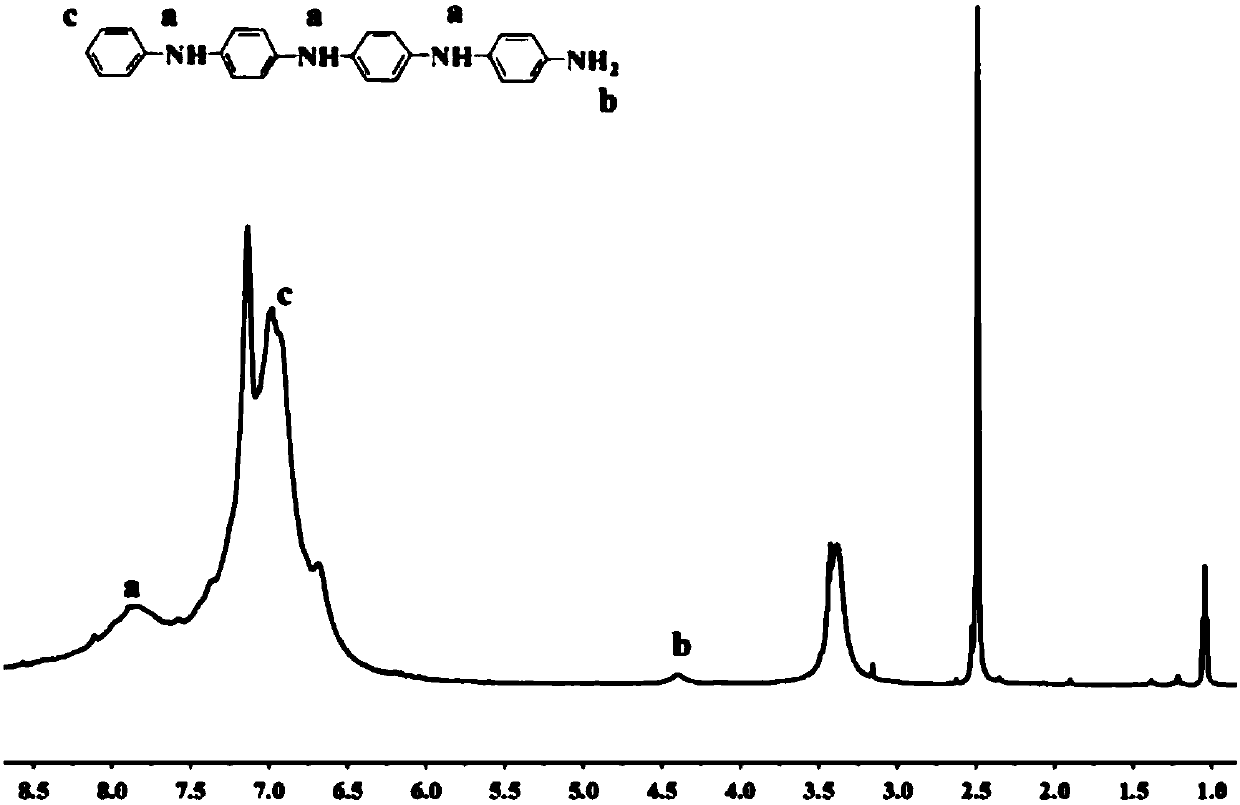

Electrically-conductive injectable hydrogel and preparation method thereof

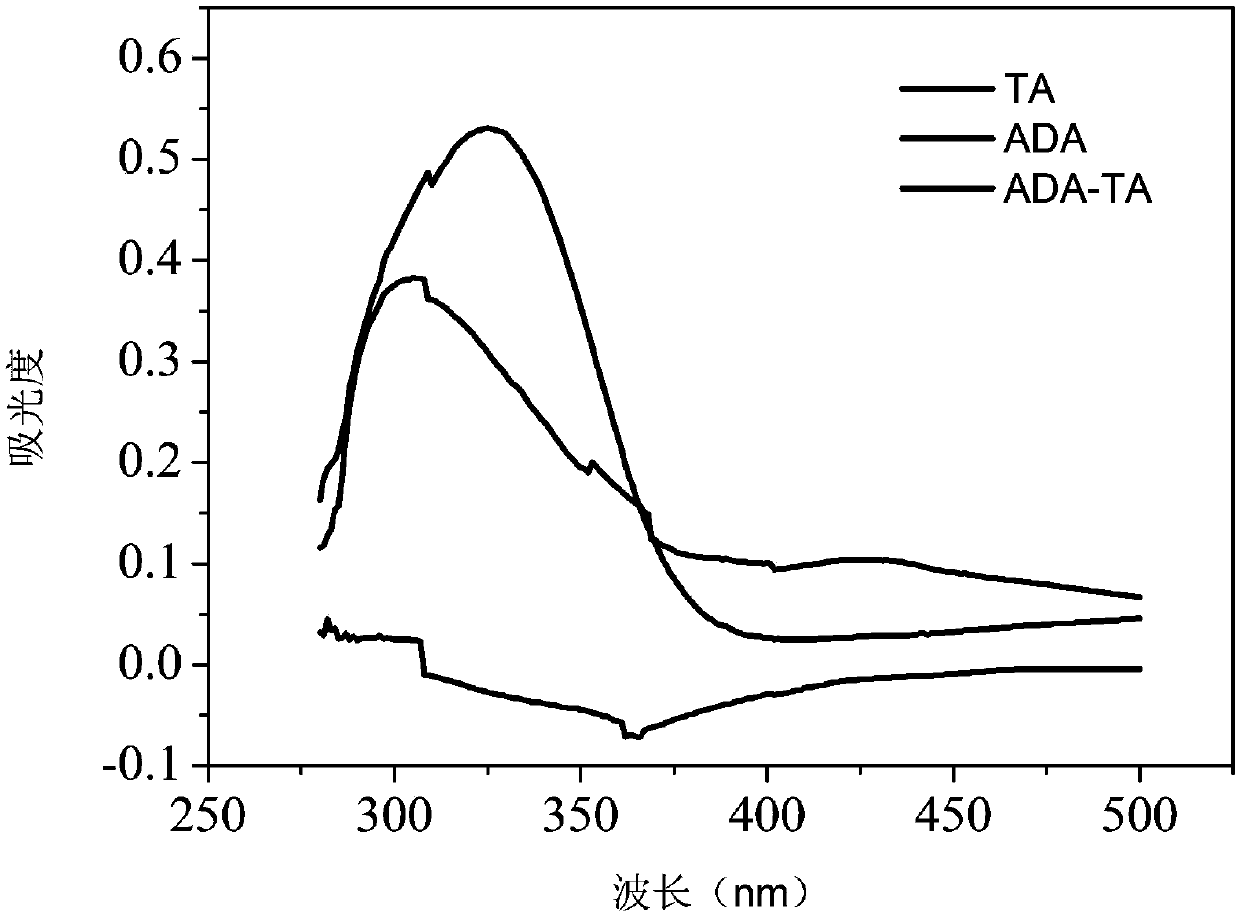

InactiveCN109666152AAdjust conductivityEasy to prepareSurgeryPharmaceutical delivery mechanismCross-linkBiocompatibility Testing

The invention provides an electrically-conductive injectable hydrogel and a preparation method thereof. The preparation method comprises: oxidizing the hydroxyl group on sodium alginate (ALG) into analdehyde group to obtain partially-oxidized sodium alginate (ADA), grafting an aniline tetramer (TA) onto the partially-oxidized sodium alginate by carrying out a reaction on the aldehyde group and the amino group on the aniline tetramer to obtain an aldehyde group-containing electrically-conductive macromolecular cross-linking agent partially-oxidized sodium alginate-aniline tetramer (ADA-TA), and blending the partially-oxidized sodium alginate-aniline tetramer (ADA-TA) and gelatin to obtain the electrically-conductive injectable hydrogel. According to the present invention, the preparation method is simple, the reaction condition is mild, the biocompatibility is good, and the electric conductivity of the gel can be adjusted by controlling the grafting ratio of the aniline tetramer.

Owner:TIANJIN UNIV

A compound conductive powder with BaSO4 and its making method

InactiveCN101123126ALow resistivitySmall particle sizeOxide conductorsSulfide conductorsTin dioxideAntimony trioxide

The invention discloses a composite conductive powder containing barium sulfate, which comprises a powder containing barium sulfate. The surface of the powder containing barium sulfate is coated with tin dioxide and antimony trioxide. The composite conductive powder containing barium sulfate in the invention is characterized by small particle size, high white degree, good dispersion, good conductivity, low production cost, simple process and fitness of industrial production.

Owner:FOSHAN ONMILLION NANO MATERIALS

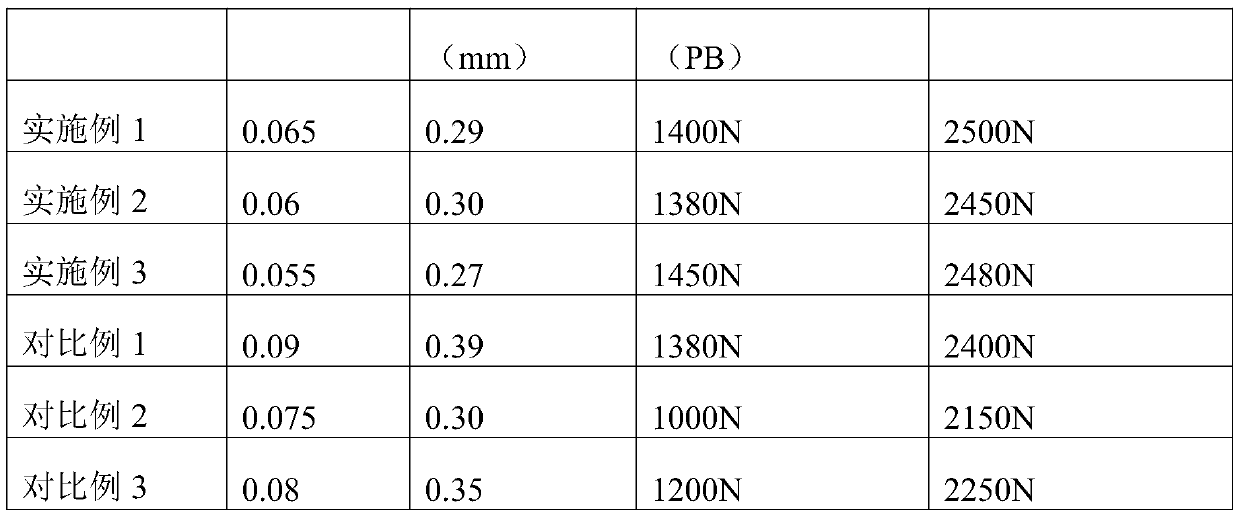

Sintered flux for nickel base strip electrode electro-slag welding

ActiveCN104708231AReduce burning lossImprove the transition coefficientWelding/cutting media/materialsSoldering mediaFerroniobiumSlag

The invention relates to sintered flux for nickel strip electrode electro-slag welding. The sintered flux for the nickel strip electrode electro-slag welding is characterized in that the intered flux is prepared from dry powder components and binder water glass; the dry powder components comprise, by mass, 45-75% of CaF2, 15-35% of Al2O3, 1-5% of SiO2, 1-5% of CaO, 1-5% of MgO, 1-10% of sodium fluoroaluminate, 1-5% of rare earth fluoride and 1-5% of ferroniobium alloy powder; the ratio of potassium to sodium of the binder water glass is 1 to 1, the molar ratio is 2.2-3.5, the baume degree at room temperature is 38-50, and the dosage is 15-25% of the weight of the dry powder. The sintered flux can be used through being matched with various nickel base welding strip such as EQNiCrMo-3 and EQNiCr-3, when strip electrode electro-slag surfacing is conducted through matching with the nickel base welding strip, stable electro-slag process and welding technological property can be maintained at the quick welding condition of 250 mm / min, the quality of formation of surfacing layers is good, defects do not exist in lap joint, and various indexes of the surfacing layers can meet usage requirements of users.

Owner:BEIJING JINWEI WELDING MATERIAL +1

Electrochemical power supply diaphragm, manufacturing method thereof, electrochemical battery or capacitor

InactiveCN103903871AHigh tensile strengthImprove the safety of useHybrid capacitor separatorsCell component detailsEmulsionHexafluoropropylene

The invention provides an electrochemical power supply diaphragm and a manufacturing method thereof. The method includes the steps that polyvinylidene fluoride-hexafluoropropylene is dissolved in acetone to prepare a polyvinylidene fluoride-hexafluoropropylene acetone solution with the mass concentration of 5-20%, then deionized water is added into the solution, and the mixture is uniformly stirred to obtain emulsion; the mass content of the deionized water in the emulsion is 1-10%; organic short fibers are added into the emulsion, and the mixture is uniformly mixed to obtain mixed emulsion; the obtained mixed emulsion is coated on a clean glass substrate, the glass substrate is removed after the mixed emulsion is dried, and accordingly the electrochemical power supply diaphragm is obtained. The organic short fibers are one or more of PET fibers, PAN fibers and aramid fibers. The electrochemical power supply diaphragm is proper in aperture and good in heat resistance and safety, and safety of an electrochemical battery or a capacitor can be effectively improved. The invention further provides the electrochemical battery or the capacitor using the diaphragm.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Ag-Cu in-situ fiber composite material and preparation method thereof

The invention discloses an Ag-Cu alloy in-situ fibre composite material with high strength, high electrical conductivity and low Cu content and a preparation technology thereof. The Cu content of thecomposite material is equal to or less than 20% by weight percent; the in-situ fiber composite material is formed by utilizing Ag-Cu alloy eutectic structure and adopting great deformation and reasonable heat treatment technology. The preparation technology comprises the following steps: pouring Ag-Cu alloy in the protective atmosphere after vacuum smelting; carrying out hot extrusion, ageing preheat treatment, cold large strain processing, intermediate heat treatment and stabilizing heat treatment to manufacture Ag-Cu composite material with strengthened Cu fiber in the dimensions of micron,submicron or nanometer. Composite material with optimal combination of tensile strength and electrical conductivity performance can be obtained by optimizing various technological parameters in the manufacturing process. The highest performance can reach that the ultimate tensile strength UTS is equal to or greater than 1GPa, and the relative electrical conductivity is equal to or greater than 60%IACS. The Ag-Cu in-situ composite material can be used as conducting material with high strength and high electrical conductivity.

Owner:KUNMING INST OF PRECIOUS METALS

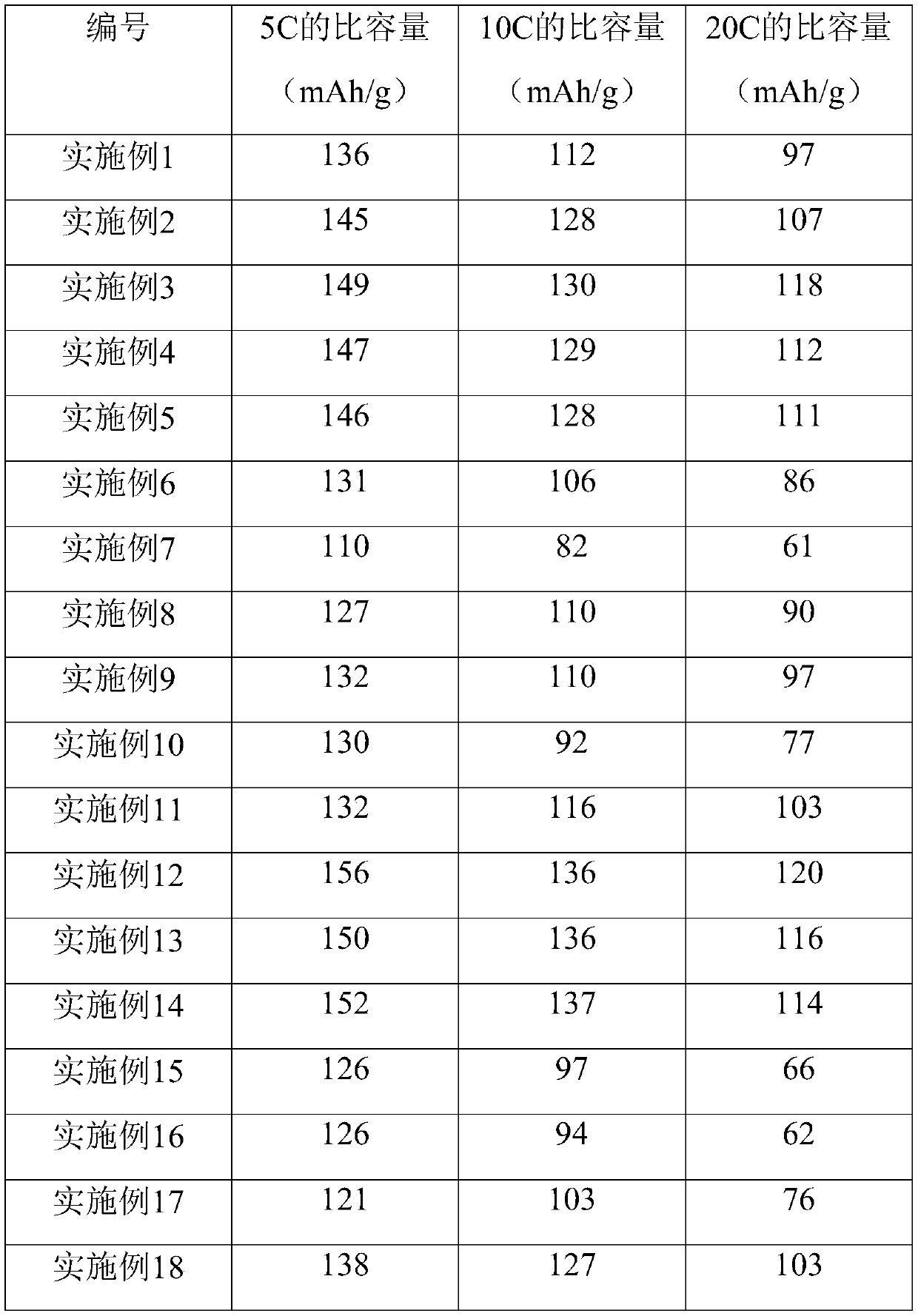

Rare earth doped lithium titanate electrode material and preparation method thereof

ActiveCN109742387AImproved magnification performanceImprove cycle stabilityElectrode manufacturing processesSecondary cellsLithium carbonateRare earth

The invention belongs to the technical field of electrode materials, and particularly relates to a rare earth doped lithium titanate electrode material and a preparation method thereof. The preparation method for the rare earth doped lithium titanate electrode material comprises the following steps that: firstly, mixing titanium dioxide, lithium carbonate, rare earth compound and carbohydrate in solvent to prepare slurry; drying the slurry; under an inert atmosphere, a reduction atmosphere or a vacuum atmosphere, carrying out first-stage calcination; and under an oxidization atmosphere, carrying out second-stage calcination to prepare the rare earth doped lithium titanate electrode material. The rare earth doped lithium titanate electrode material prepared with the preparation method has excellent characteristics, including high multiplying power performance, good cycling stability, quick charging and discharging capability and the like. In addition, the preparation method is simple and can carry out batch preparation.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

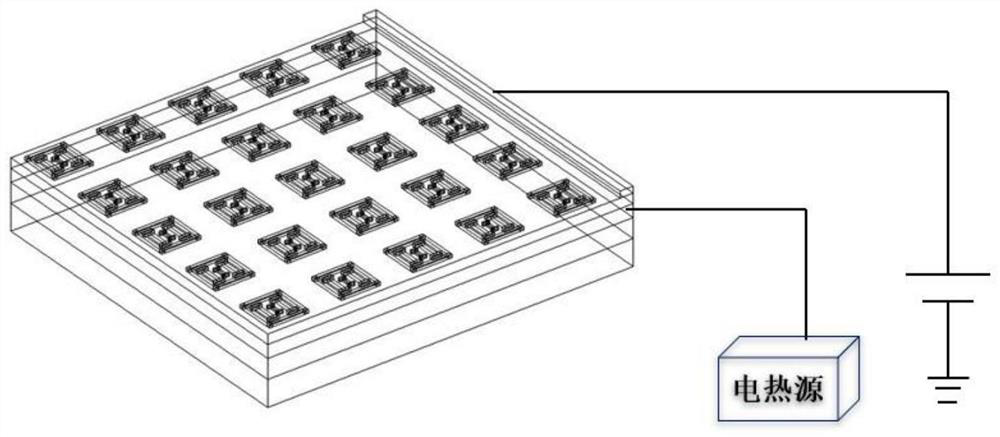

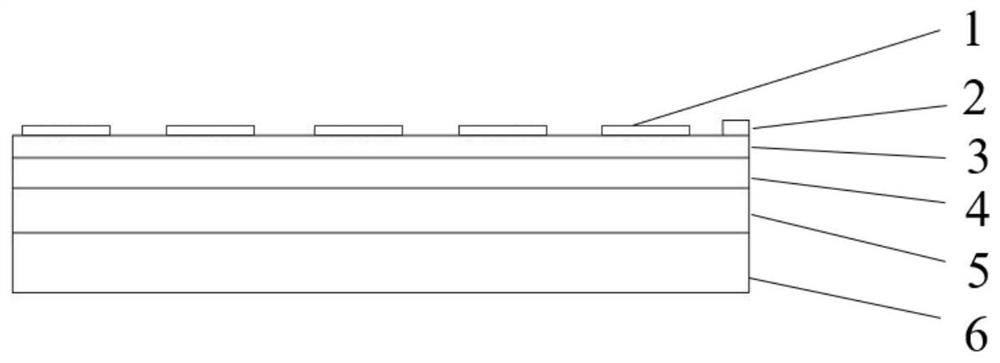

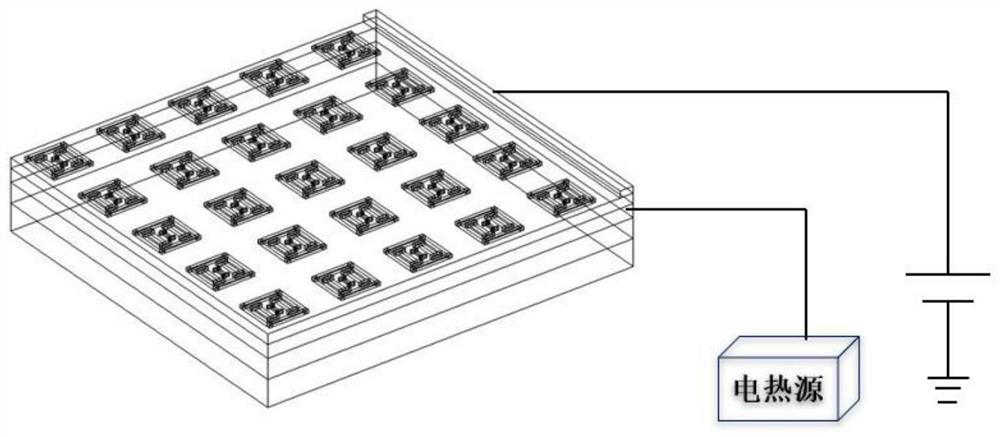

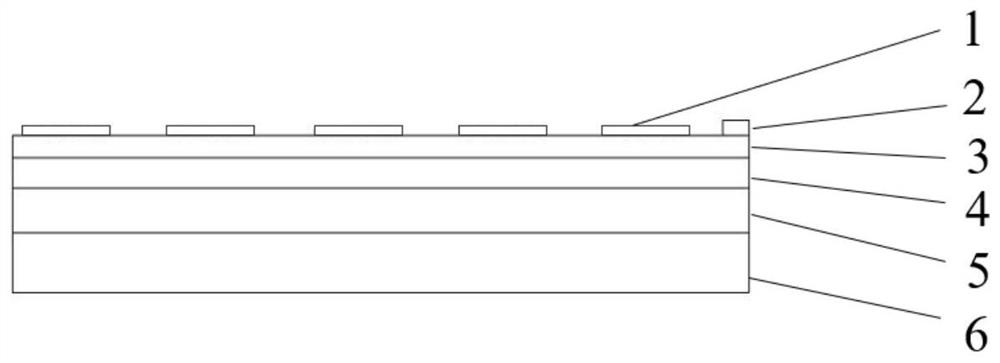

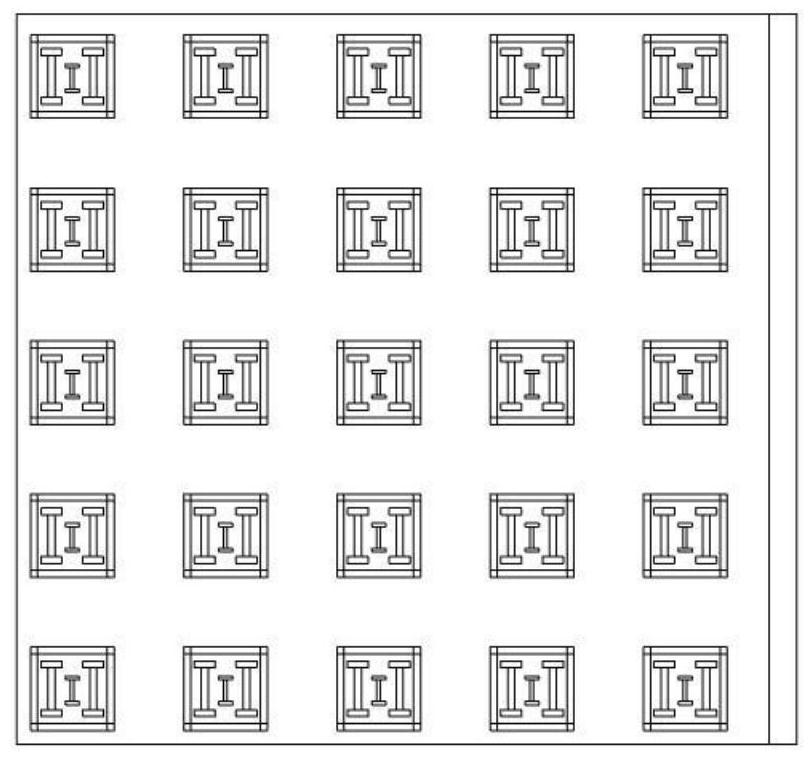

Tunable array integrated broadband terahertz wave-absorbing resonatorbased on vanadium dioxide

ActiveCN113241531AImprove absorption rateAdjust the absorbing performanceShielding materialsAntennasVanadium dioxideBroadband absorption

The invention relates to a tunable array integrated broadband terahertz wave-absorbing resonator based on vanadium dioxide. The tunable array integrated broadband terahertz wave-absorbing resonator comprises a metal reflecting layer, a middle dielectric layer, a vanadium dioxide phase change layer, a graphene adjustable conductivity layer, a top conductive electrode and metal resonant cavities which are arranged in a periodic array from bottom to top. According to the metal resonant cavity, specific geometric parameters and structures are designed, so that the whole metamaterial wave-absorbing structure generates electromagnetic resonance at a specific frequency, and the wave-absorbing structure with relatively high modulation depth is designed by utilizing the thermally induced phase change property of vanadium dioxide and the huge change of optical and electrical parameters in a semiconductor phase state and a metal phase state; and based on the adjustable conductivity property of graphene, the Fermi level of graphene is changed through external voltage, and the dielectric parameters of the wave absorbing structure are changed, so that the absorption wavelength range is changed. By combining the tuning characteristics of the two materials, the broadband absorber is actively tuned through heat / electricity, and the designed structure is compatible with the process and is easy to implement.

Owner:DALIAN UNIV OF TECH

Double-component rapid low-temperature curing conductive adhesive

InactiveCN106753027AImprove wettabilityImprove antioxidant capacityNon-macromolecular adhesive additivesEpoxy resin adhesivesSilver plateHigh density

The invention discloses a double-component rapid low-temperature curing conductive adhesive which comprises the following components in parts by mass: a conductive adhesive component A and a conductive adhesive component B, wherein the conductive adhesive component A comprises 180-200 parts of silver-plated copper powder, 100 parts of epoxy resin and 10-15 parts of a reactive diluent; the conductive adhesive component B comprises 180-200 parts of silver-plated copper powder, 10-15 parts of a reactive diluent, 20-30 parts of a curing agent, 10-20 parts of an accelerator and 5 parts of a leveling agent or a defoaming agent. As copper powder is plated with silver for three times innovatively, copper powder with a high-density silver layer can be prepared. The silver-plated copper powder can be applied to the conductive adhesive, then the double-component rapid low-temperature curing conductive adhesive can be prepared, and meanwhile a conductor prepared from the conductive adhesive applied to a substrate is high in conductivity and good in mechanical strength.

Owner:南京鑫研新材料科技有限公司

Production method for inorganic compound conductive powder body

InactiveCN100557721CGood value for moneyAbundant resourcesConductive materialChemical/physical/physico-chemical processesKaoliniteInorganic compound

A method for preparing antimony-doped tin oxide composite conductive powder with kaolinite as the matrix. In the present invention, a dispersant is added to the kaolinite mineral to make a uniformly dispersed suspension slurry; a chemical co-precipitation method is used to uniformly precipitate in the form of hydroxide or hydrated oxide, and the obtained precipitate is filtered, washed, and solidified. liquid separation, drying, roasting, and pulverization to obtain composite conductive powder. Using this method not only greatly reduces the preparation cost of conductive powder, but also greatly increases the use value of kaolin resources; the composite conductive powder prepared by this method is easy to disperse, stable in quality, light in color and good in conductivity , easily modulated into near-white and other conductive additives of various colors, and has broad application prospects.

Owner:CENT SOUTH UNIV

Acoustic surface wave type humidity sensor based on conductive polymer composite nano-fibre and preparation method thereof

InactiveCN102519504AUniversalGood processabilityDecorative surface effectsConverting sensor ouput using wave/particle radiationSurface waveHigh polymer

The invention discloses an acoustic surface wave type humidity sensor based on conductive polymer composite nano-fibre and a preparation method thereof. The acoustic surface wave type humidity sensor is prepared by depositing polyaniline and polyvinyl butyral composite nano-fibre on an acoustic surface wave device by adopting an electrostatic spinning method. The acoustic surface wave type humidity sensor has good response linearity and rapid response in a wide humidity range and also has high response sensitivity of being up to 75 kHz / %RH. For low-humidity detection, the acoustic surface wave type humidity sensor also has higher sensitivity and response linearity and is capable of detecting 0.5%RH extra-low humidity. The preparation method disclosed by the invention is simple, convenient and easy to do; the prepared acoustic surface wave type sensor can be widely applied to detecting and controlling environmental humidity in industrial and agricultural production, storage, weathers and daily lives; and signal wireless and remote transmission can be conveniently realized.

Owner:ZHEJIANG UNIV

Solid lubricant, and preparation method and use thereof

ActiveCN110257135AIncrease the number of revolutionsFlame retardantLubricant compositionConductive materialsElectromagnetic field

The invention relates to the field of material lubrication, and concretely relates to a solid lubricant, and a preparation method and a use thereof. The solid lubricant includes graphene quantum dots, fluorinated graphene quantum dots and nanometer molybdenum disulfide. The graphene quantum dots are adopted as a conductive material, and an insulator fluorinated graphene quantum dots and the nanometer molybdenum disulfide are used as auxiliary materials, so the conductivity of the solid lubricant is adjusted, the balance between the electrically conductive performance and the insulation performance is achieved, and the needs of the conductive solid lubricant under complex extreme conditions such as high vacuum, ultralow temperature, strong radiation, ultrahigh temperature, ultralow temperature, high rotating speed, high electromagnetic field, strong chemical corrosion and strong salt spray corrosion.

Owner:北京玖星智能科技有限公司

Preparation method of copper-aluminum layered composite material capable of effectively controlling interface reaction

ActiveCN111806047AImprove interface reaction bindingGood thermal conductivityLaminationLamination apparatusInterfacial reactionAluminium

The invention discloses a preparation method of a copper-aluminum layered composite material capable of effectively controlling interface reaction. The method comprises the following steps: 1, preparing GO / Al foil; 2, sequentially and alternately placing the dried GO / Al foil and the Cu foil subjected to surface pretreatment in an overlapped mode in the direction of a tiled layer, and obtaining a Cu-GO / Al prefabricated body; 3, pressurizing the Cu-GO / Al prefabricated body, then heating, and carrying out heat preservation and pressure maintaining; and 4, cooling and decompressing to obtain the copper-aluminum layered composite material. The preparation method comprises the following steps: stacking GO / Al foil with GO deposited on the surface and Cu foil, and then heating and pressurizing forpressing; the GO between the Cu foil and the Al foil is used for preventing Cu and Al from reacting at the interface to form an intermetallic compound; the Cu-Al interface reaction combination condition in the copper-aluminum layered composite material is improved, meanwhile, the heat conduction performance and the electric conduction performance of the copper-aluminum layered composite materialare guaranteed, and the structural function integrated design of the copper-aluminum layered composite material is achieved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

High-strength and temperature-sensitive polymer-graphene oxide composite hydrogel and conductive graphene composite hydrogel as well as preparation methods thereof

InactiveCN103073665BEasy to prepareMaterials are cheap and readily availablePolymer sciencePtru catalyst

The invention discloses a high-strength and temperature-sensitive polymer-graphene oxide composite hydrogel and a conductive polymer-graphene composite hydrogel as well as preparation methods thereof. The preparation methods comprise the following steps: dispersing laponite in an aqueous graphene oxide dispersion, stirring, and performing ultrasonic treatment to obtain an uniform dispersion; adding N-isopropyl acrylamide monomer, stirring uniformly and deoxidizing, adding an initiator and a catalyst, transferring the reaction liquid into a glass test tube or a reaction mold for sealing, and performing in-situ free radical polymerization at 15-25 DEG C so as to obtain the polymer-graphene oxide composite hydrogel; and then, reducing the prepared polymer-graphene oxide composite hydrogel with L-ascorbic acid so as to obtain the conductive graphene composite hydrogel. According to the invention, the prepared polymer-graphene oxide composite hydrogel has good mechanical property and thermo-sensitivity; and the prepared conductive graphene composite hydrogel also has good mechanical property, thermo-sensitivity and high conductivity simultaneously.

Owner:SOUTH CHINA UNIV OF TECH

High-toughness and low-resistivity silver-gold alloy bonding wire

ActiveCN109182826AImprove conductivityImprove toughnessSemiconductor/solid-state device detailsSolid-state devicesBond propertiesFracture load

The invention relates to a high-toughness and low-resistivity silver-gold alloy bonding wire. The high-toughness and low-resistivity silver-gold alloy bonding wire is prepared from the alloy components in percentage by weight: 80%-100.0% of Ag, 0%-20.0% of Au, and 0%-0.01% of two or more of Ce, Cu, Pd, Be, Mg and Ca which are minute in content. According to the high-toughness and low-resistivity silver-gold alloy bonding wire, the fracturing load is larger than 10 cN, meanwhile the elongation is larger than 18%, the mechanical property is adjustable and controllable, and the resistivity is smaller than 1.8 [mu]omega.cm; and the using cost of the silver-gold alloy bonding wire is lowered by 80% or above compared with the material cost of an existing bonding alloy wire, the mechanical property, the electrical property, oxidation resistance and the bonding property are excellent, and thus the high-toughness and low-resistivity silver-gold alloy bonding wire can be widely applied to the field of packaging.

Owner:CHONGQING MATERIALS RES INST

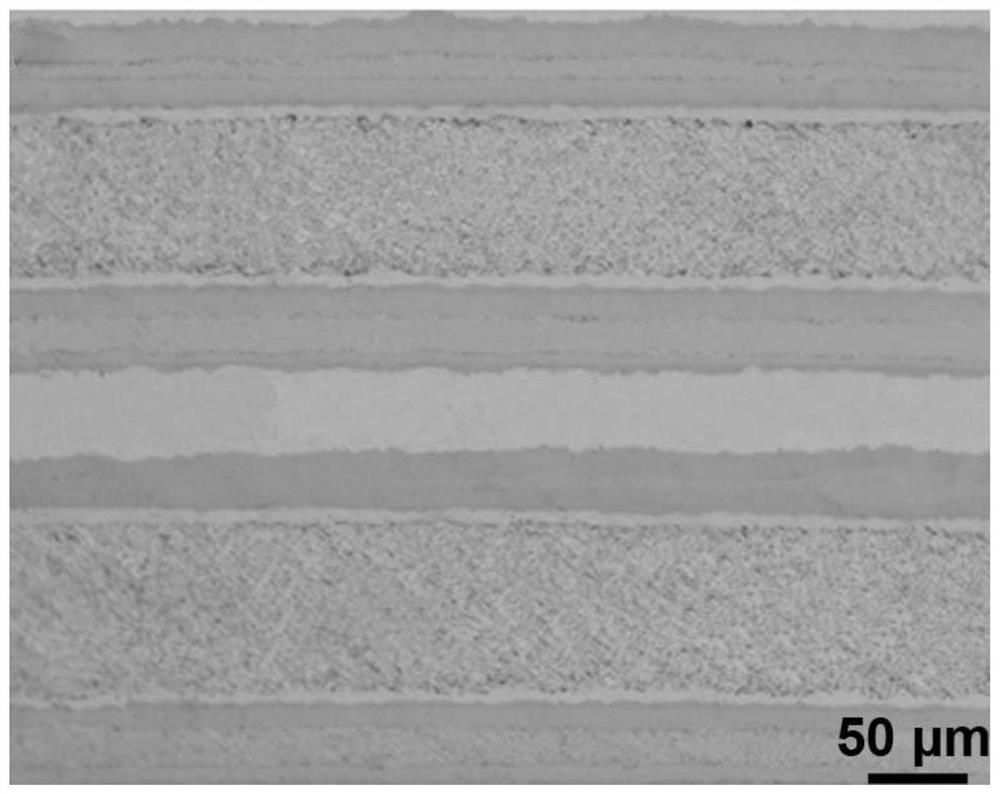

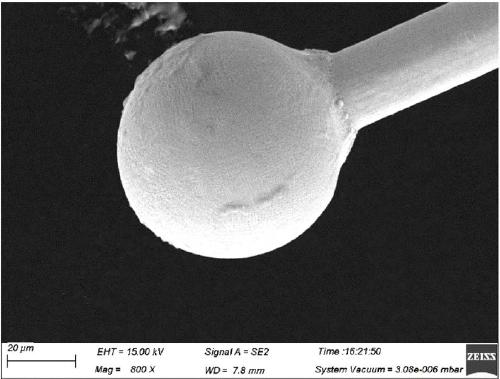

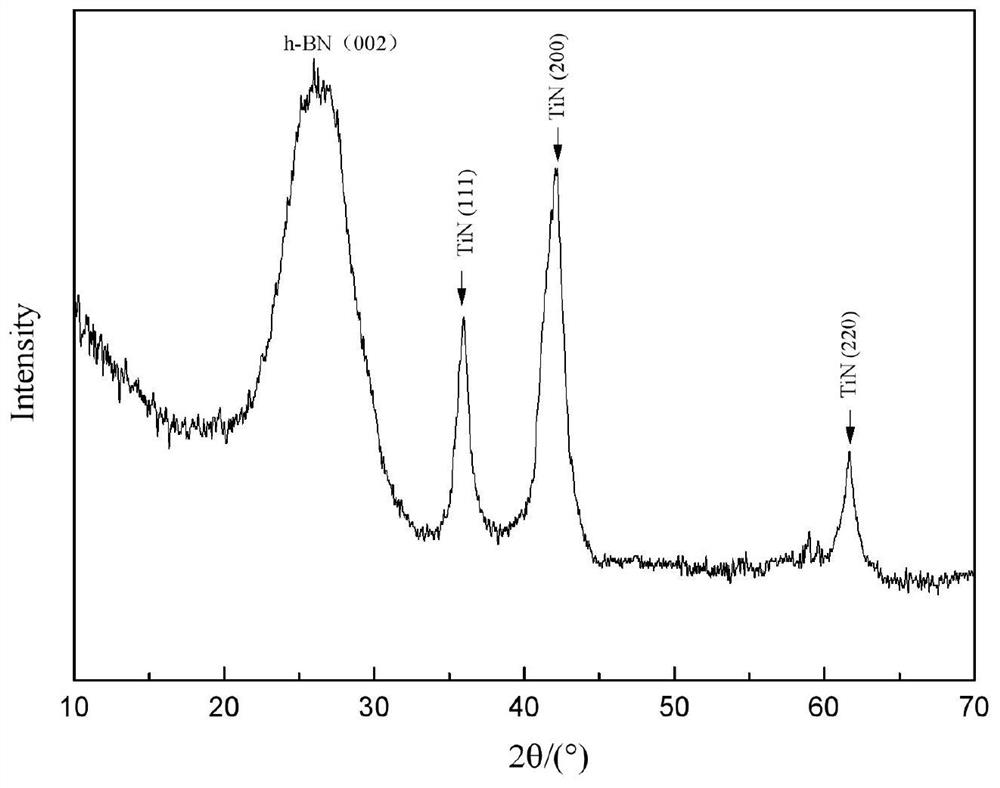

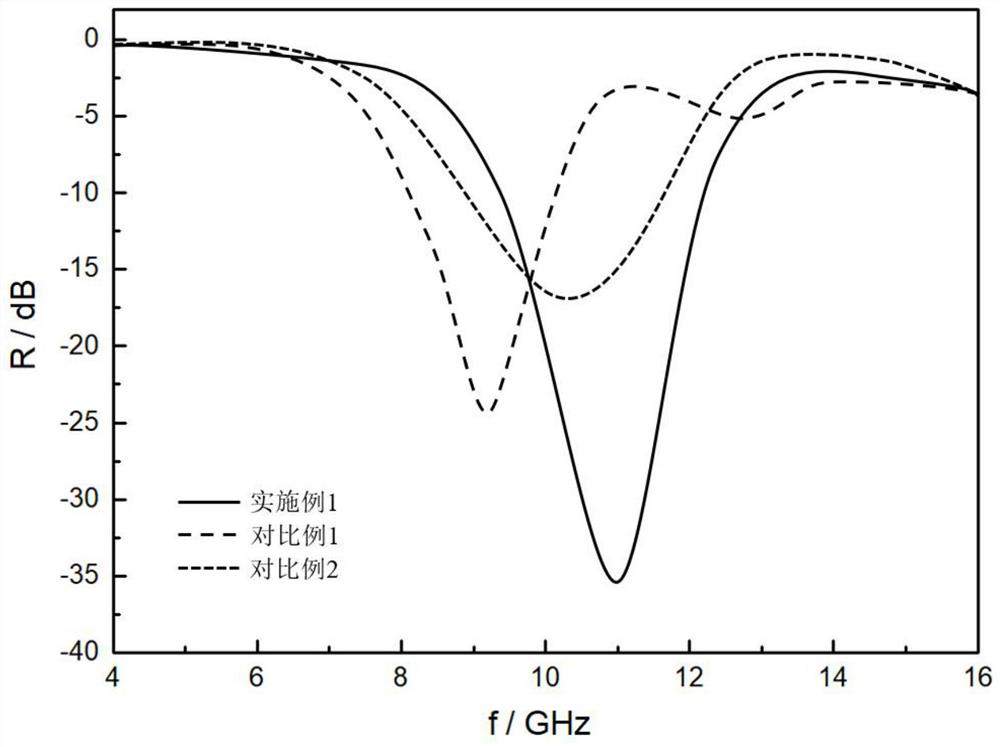

La-Al-TiN/h-BN nanosheet composite wave-absorbing material and preparation method thereof

InactiveCN112126408AAdjust conductivityIncrease structural defectsOther chemical processesMaterials preparationTitanium

The invention belongs to the technical field of composite material preparation, and particularly relates to a LaAlTiN / hBN nanosheet composite wave-absorbing material and a preparation method thereof.The preparation method comprises the steps that hBN nanosheets are prepared from boric acid and urea, then H2Ti2O4 (OH) 2 is prepared on hBN with TiO2 as a titanium source, and the composite wave-absorbing material is obtained; and finally, mixing La(NO3)3*6 H2O, Al(NO3)3*6 H2O and H2Ti2O4 (OH)2 / hBN, adding ammonia water, and calcining in an ammonia atmosphere to obtain the LaAlTiN / hBN nanosheet composite wave-absorbing material. The composite wave-absorbing material is good in wave-absorbing performance, high in wave-absorbing strength and wide in absorbing bandwidth.

Owner:陈淼荣

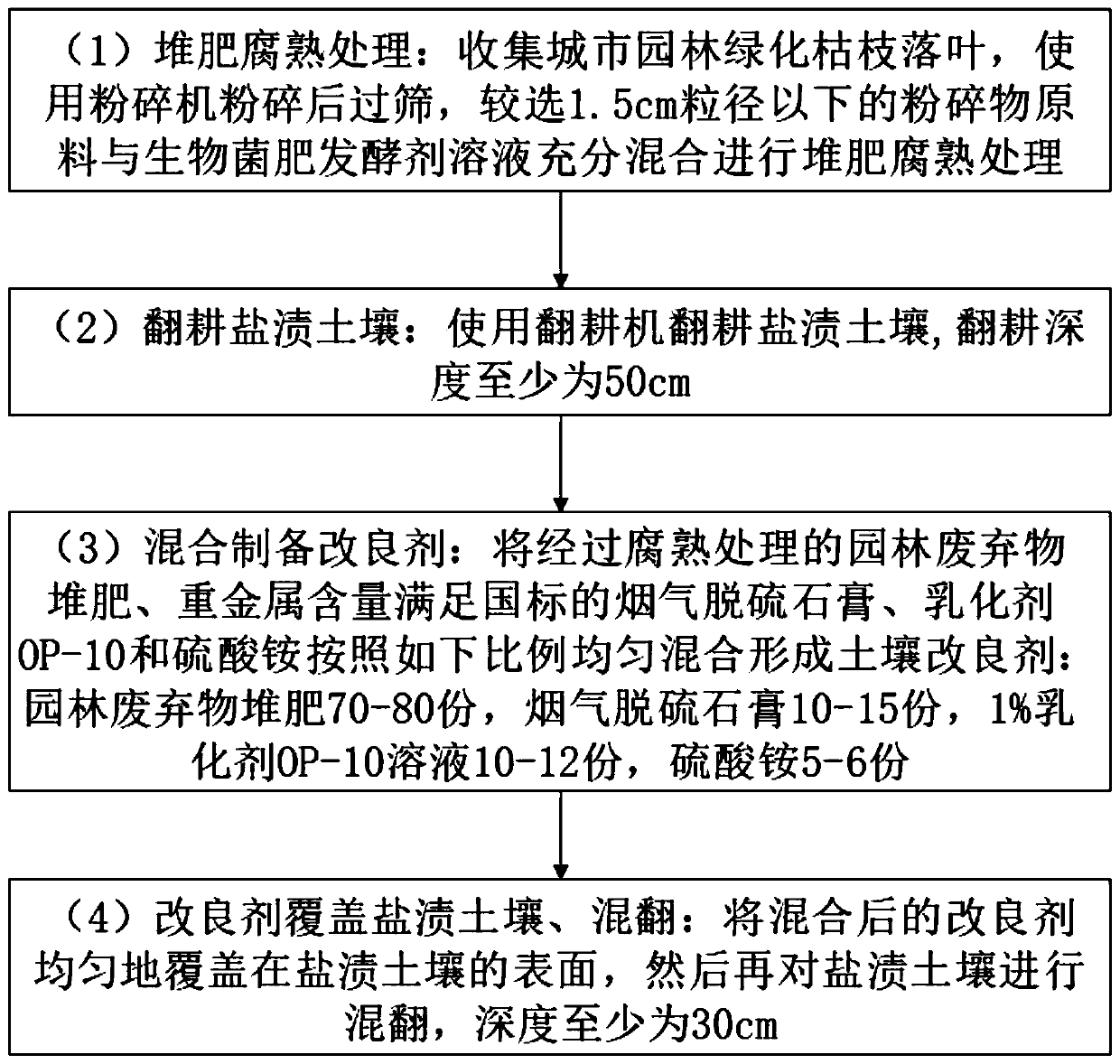

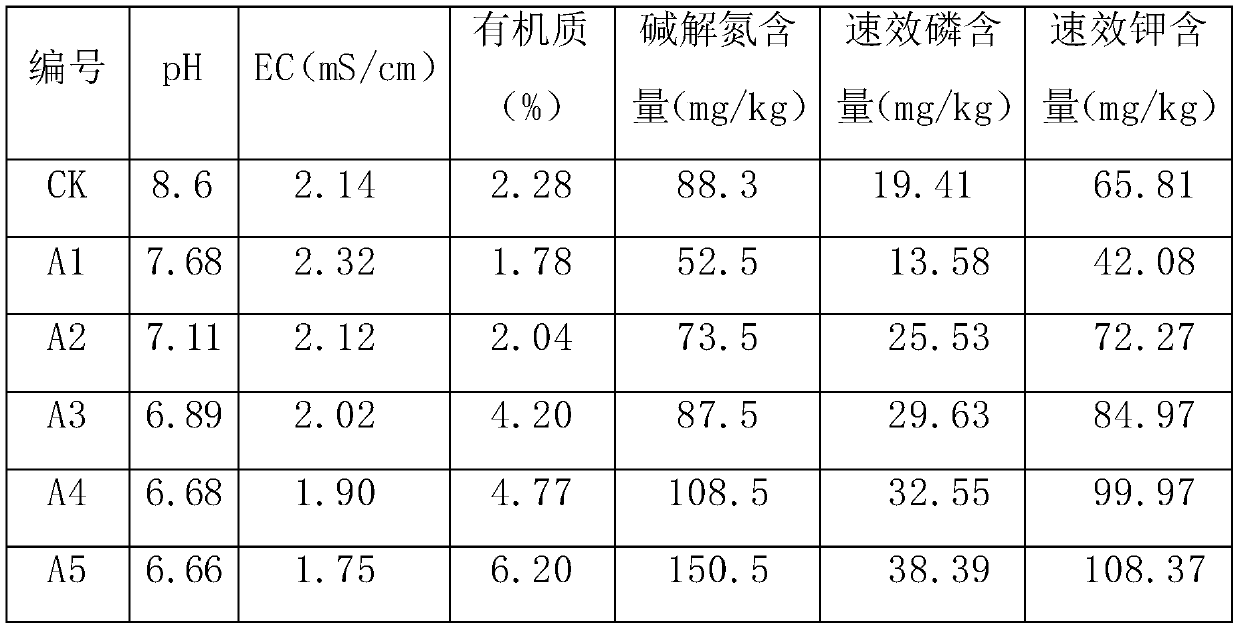

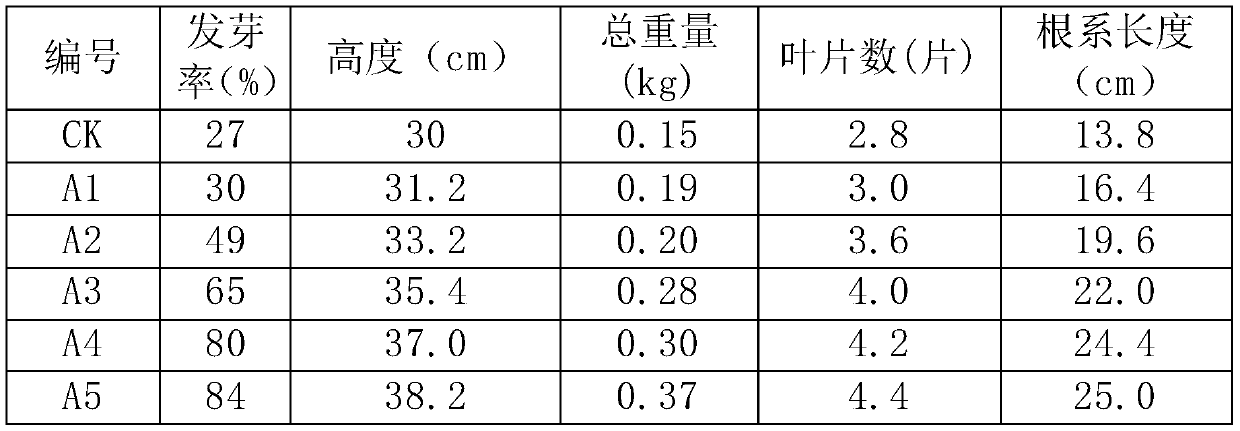

Saline soil improvement agent and saline soil improvement method

InactiveCN110105961ASimple structureLower pHOther chemical processesContaminated soil reclamationDecompositionSoil conditioner

The invention discloses a saline soil improvement agent and a saline soil improvement method. The improvement agent is prepared from, by mass, 70-80 parts of garden waste compost, 10-15 parts of fluegas desulfurization gypsum, 5-6 parts of ammonium sulfate and 10-12 parts of a 1% emulsifier OP-10 solution. The saline soil improvement method comprises the following steps of composting and decomposition treatment, saline soil ploughing, improvement agent mixing and preparation, improvement agent covering for saline soil and mixed turning. The improvement agent can reduce the pH of coastal saline soil, regulate the conductivity of the saline soil, increase soil nutrients, increase the plant biomass, and increase the nutrient content in plants.

Owner:SHANGHAI INST OF TECH +1

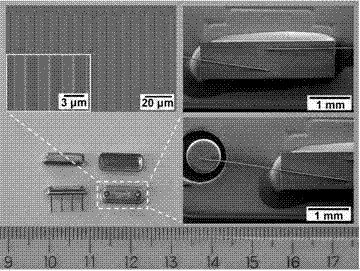

Preparation method of cellulose nano-whisker/graphene flexible transparent conductive film

InactiveCN107799229ALarge specific surface areaStrong Young's modulusCarbon-silicon compound conductorsCable/conductor manufactureCelluloseFiltration

The invention discloses a preparation method of a cellulose nano-whisker / graphene flexible transparent conductive film. Tea-oil tree shell is taken as the raw material, and tea-oil tree shell cellulose nano-whiskers are obtained by separation through the main steps of cooking through an alkali method, alkali treatment, purification, bleaching, acidolysis, centrifuging, dispersing and the like; theobtained cellulose nano-whiskers are large in specific surface area, high in Young modulus and high in reactivity; next, suction filtration is performed to obtain a substrate film which is uniform and smooth in surface, and relatively high in flexibility, light transmission, mechanical property and thermodynamic property; by taking graphene as a conductive matrix, and under the effect of CTAB, the graphene is uniformly paved on the surface of the substrate film through a suction filtration method to form a uniform and a continuous conductive layer; and by controlling the adding amount of graphene and the number of layers of graphene on the surface of the film, the prepared flexible transparent conductive film has relatively high flexibility, foldable property, elasticity, rigidity and thermal stability and bright application prospect.

Owner:林荣铨

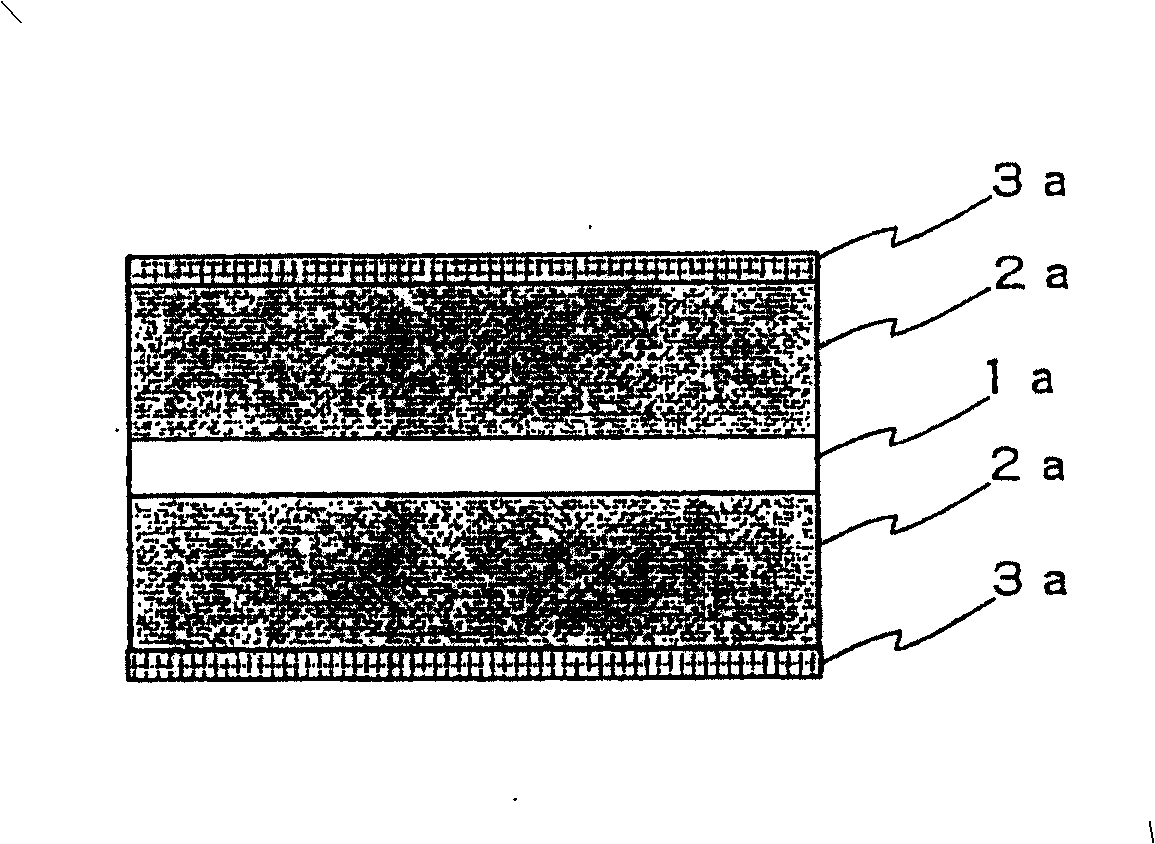

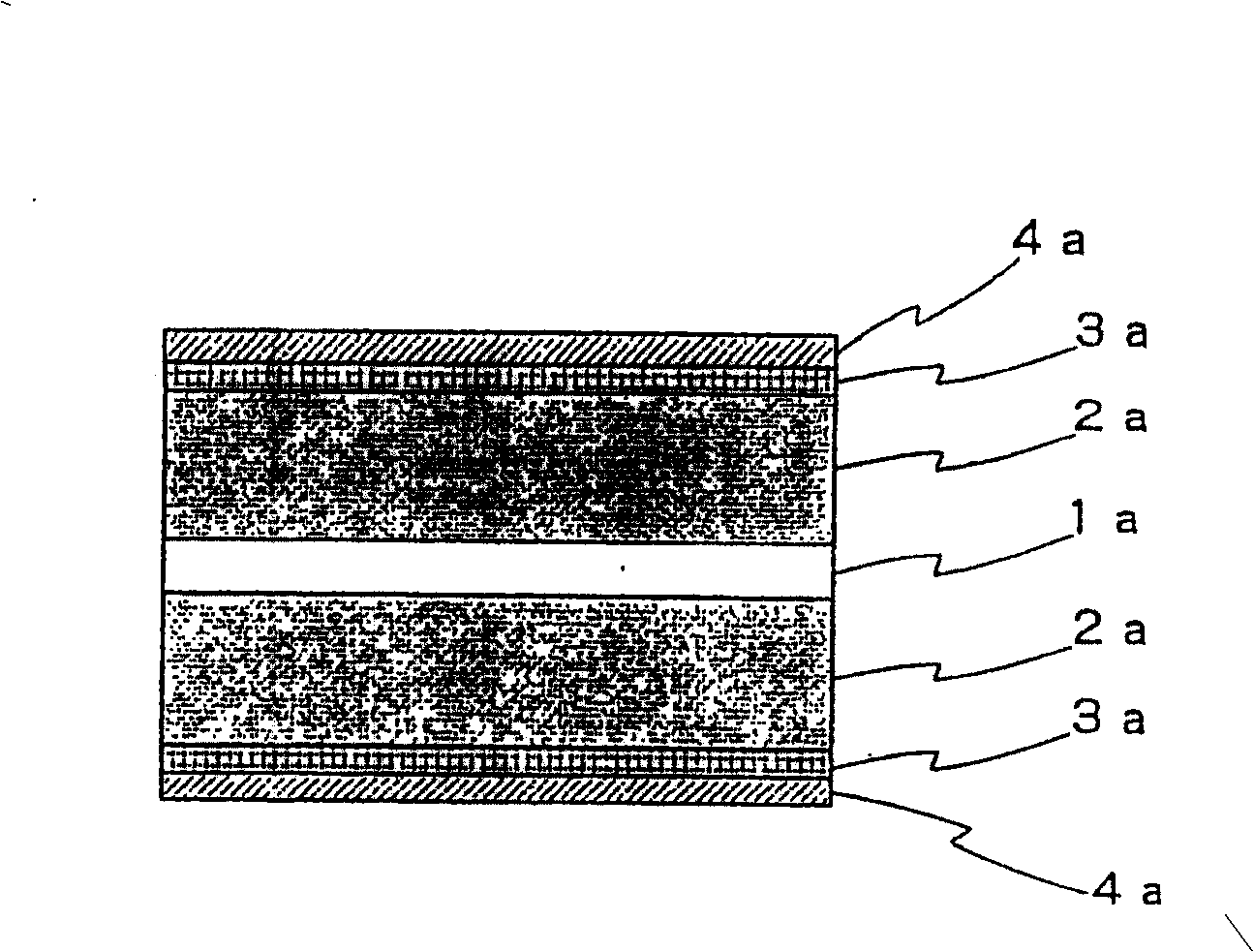

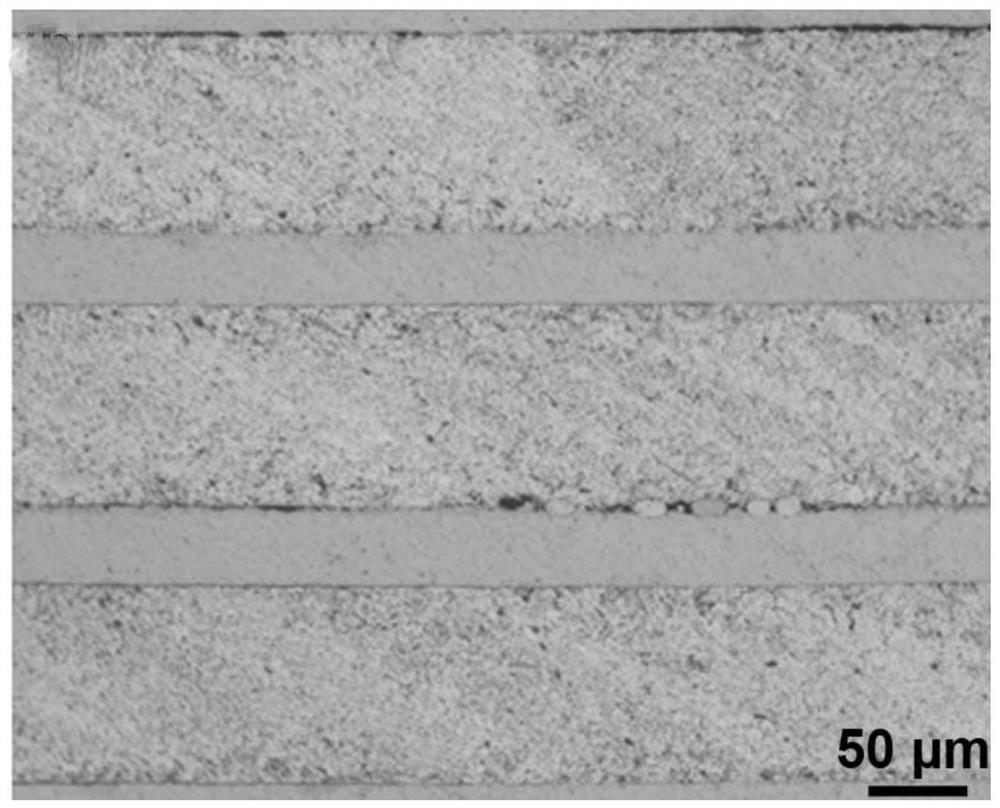

Negative electrode for secondary cell,secondary cell, and method for producing negative electrode for secondary cell

InactiveCN100431202CImprove adhesionAdjust conductivityElectrode manufacturing processesActive material electrodesCarbon layerDischarge efficiency

A multilayer negative electrode having a carbon layer as a first layer, realizing high battery capacity in the range of voltages at which a battery is actually used while maintaining high charge / discharge efficiency and good cycle characteristics by a simple method. A first layer (2a) the major component of which is carbon and a second layer (3a) the major component of which is filmy material having lithium ion conductivity are stacked on copper foil (1a). The second layer (3a) is formed by dispersing at least one kind of metal particles, alloy particles, and metal oxide particles in a solution in which a binder is dissolved and applying and drying the coating solution.

Owner:NEC CORP

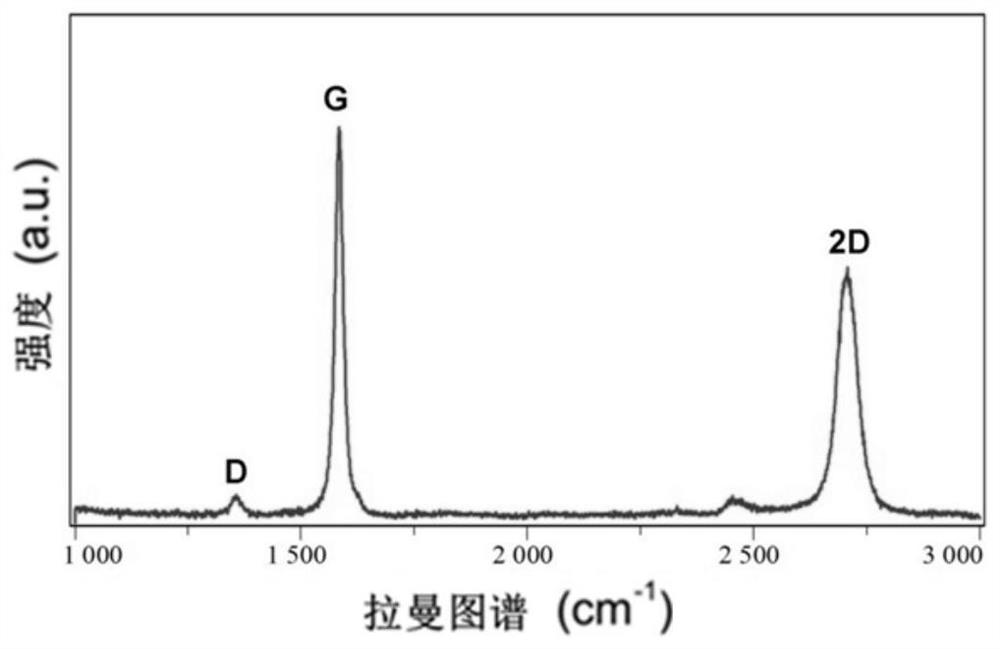

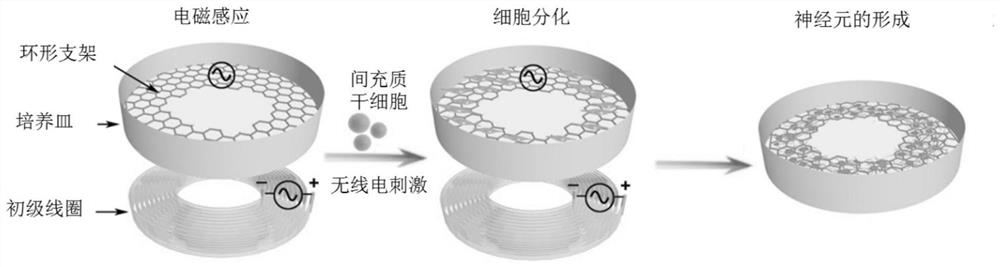

Three-dimensional annular cytoskeleton in response to radio stimulation and preparation method and application thereof

PendingCN111944750AReduce defectsQuality improvementElectroconductive/antistatic filament manufactureCulture processFiberAnuclear cell

The invention discloses a three-dimensional annular cytoskeleton in response to radio stimulation and a preparation method and application thereof. The preparation method comprises the following steps: growing graphene on a copper / nickel template by adopting a chemical vapor deposition method to prepare a three-dimensional annular cytoskeleton; or blending a conductive substance and a fiber to form a conductive fiber, and then performing treatment by adopting a template method to prepare the three-dimensional annular cytoskeleton; or printing conductive hydrogel and / or conductive aerogel by adopting a 3D printing method to prepare the three-dimensional annular cytoskeleton. The prepared three-dimensional annular cytoskeleton is accurate and controllable in size and good in conductivity; and meanwhile the three-dimensional annular cytoskeleton inoculated with the mesenchymal stem cells by using radio stimulation is simple and convenient to use, the trouble of wire connection is solved,the problems of intra-tissue flowing and low survival rate of the mesenchymal stem cells and cell transplantation injury are reduced, and cell behaviors can be controlled.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

A preparation method of copper-aluminum layered composite material with effective control of interfacial reaction

ActiveCN111806047BAvoid formingGuaranteed thermal conductivityLaminationLamination apparatusInterfacial reactionIntermetallic

The invention discloses a method for preparing a copper-aluminum layered composite material that effectively controls interfacial reactions. The method includes: 1. preparing GO / Al foil; 2. combining the dried GO / Al foil with the surface pretreated Cu-GO / Al preforms are obtained by stacking Cu foils alternately along the direction of the flat layer; 3. Pressurizing the Cu-GO / Al preforms and then heating and maintaining the pressure; 4. Cooling and depressurizing to obtain a copper-aluminum layered composite Material. In the present invention, the GO / Al foil with GO deposited on the surface and the Cu foil are stacked and then pressed by heating and pressing, and the GO between the Cu foil and the Al foil is used to avoid the reaction between Cu and Al at the interface to form an intermetallic foil. The compound improves the Cu-Al interface reaction bonding in the copper-aluminum layered composite material, and at the same time ensures the thermal conductivity and electrical conductivity of the copper-aluminum layered composite material, and realizes the integrated design of the structure and function of the copper-aluminum layered composite material.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Nanosheet silver paste capable of magnetic conduction and orientation and preparation method thereof

ActiveCN109215831BWith magnetic induction functionOrderly rowsMaterial nanotechnologyMagnetic liquidsSilver pasteAlloy

A magnetically-conductive alignable nano-sheet silver paste comprising nano-sheet silver particles, wherein the nano-sheet silver particles are nano-thick film sheets having a structure of silver-alloy-silver, wherein the single layer thickness of the silver is 5 to 20 nm; The thickness of the single layer of the alloy is 5-20nm; The total thickness of the nanosheet silver particles is 15 to 60 nm, and the particle size (d50) is 0.3 to 1. M u.m. Compared with the prior art, the nano-sheet silver paste has the following beneficial effects: the multi-element alloy in the nano-sheet silver particles has magnetic conductivity, and the nano-sheet silver is arranged in a regular manner under the guidance of a magnetic mode, so that the shape advantage of the nano-sheet silver is fully brought into play, and a nano-sheet silver paste with high electric conductivity is obtained.

Owner:SHANGHAI TRANSCOM ELECTRONICS TECH

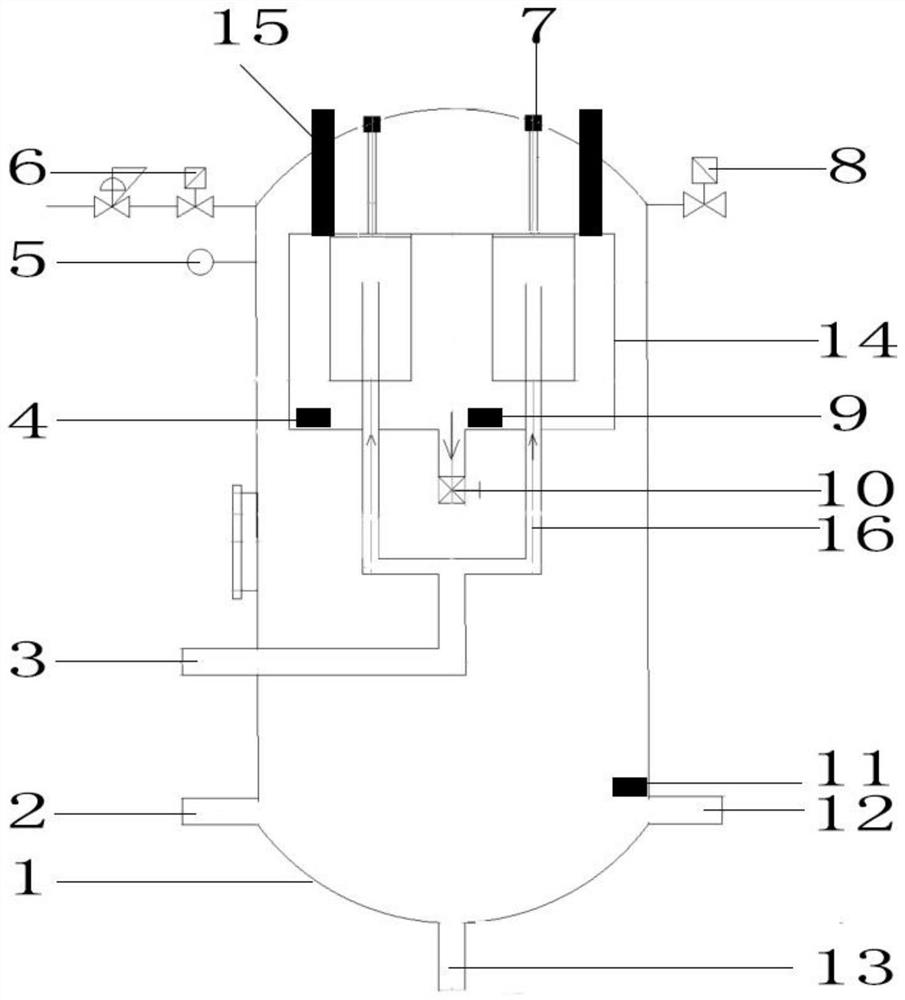

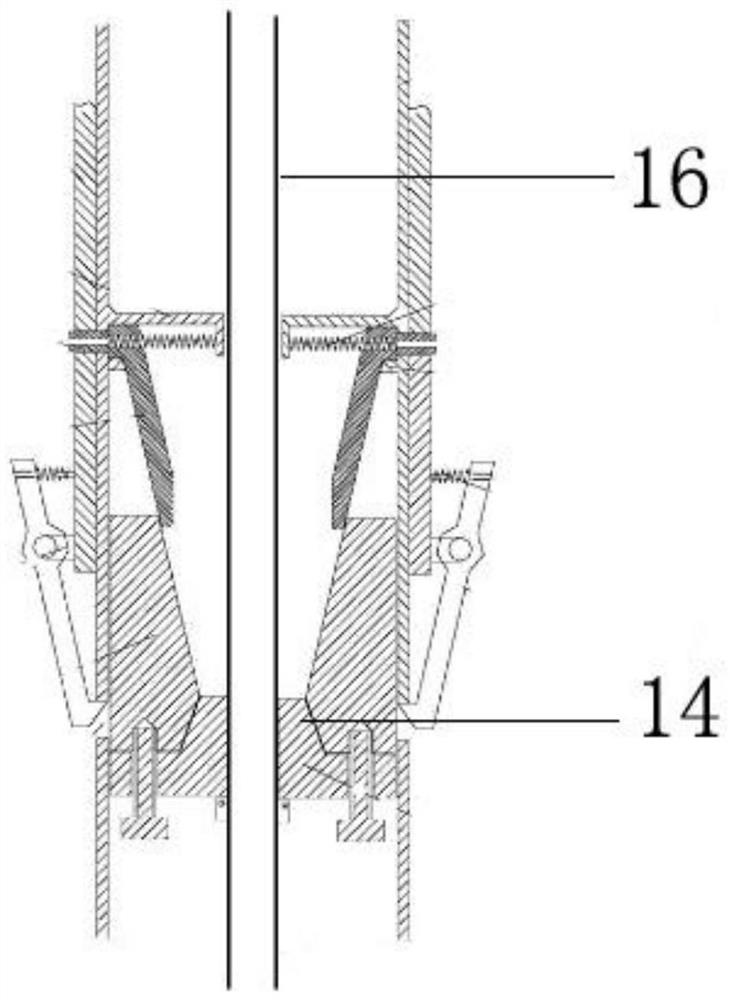

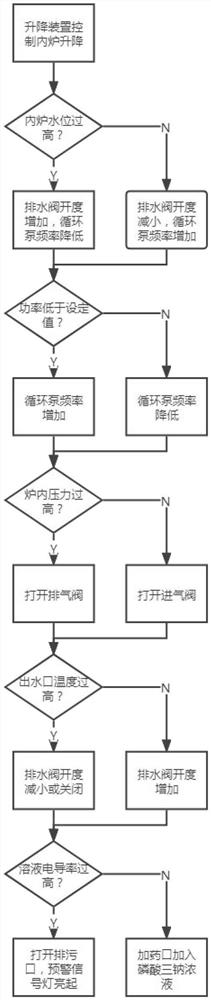

Electrode boiler device and control method thereof

PendingCN114427753AAdjust conductivityRegulating pressureControl of fluid heatersThermodynamicsExhaust valve

The invention discloses an electrode boiler device which comprises a boiler body, a drain outlet formed in the bottom end of the boiler body, a circulating water outlet and a water outlet in the side face of the bottom, a second thermometer on the inner side of the bottom, a circulating water inlet in the middle bottom, a pressure gauge on the middle top, an air inlet valve and an exhaust valve on the top and an electrode at the top end. A three-way valve and an electrode of the circulating water inlet are connected to the inner furnace, a pressure difference transmitter and a first thermometer are arranged at the bottom end of the inner furnace, and a drainage valve is arranged at the protruding position of the bottom end of the inner furnace. The pressure, temperature, water level, power and solution conductivity can be adjusted, and the electrode reaction area and the height of the inner furnace can be adjusted.

Owner:杭州杭锅电气科技有限公司

Vanadium dioxide-based tunable array-integrated broadband terahertz absorbing resonator

ActiveCN113241531BImprove absorption rateAdjust the absorbing performanceShielding materialsAntennasVanadium dioxideBroadband absorption

The invention relates to a vanadium dioxide-based tunable array integrated broadband terahertz wave-absorbing resonator, which consists of a metal reflection layer at the bottom, an intermediate dielectric layer, a vanadium dioxide phase-change layer, and graphene with adjustable conductivity from bottom to top. layer and the top layer conductive electrodes and metal resonant cavities arranged in a periodic array. By designing specific geometric parameters and structures, metal resonators make the entire metamaterial absorbing structure electromagnetically resonate at specific frequencies. Using the thermally induced phase transition properties of vanadium dioxide, optical, There is a huge change in the electrical parameters, and a wave-absorbing structure with a higher modulation depth is designed. Based on the adjustable conductivity of graphene, the Fermi level is changed by applying an applied voltage, and the dielectric parameters of the wave-absorbing structure are changed, so that the absorption The wavelength range changes. Combining the tuning properties of these two materials, the broadband absorber can be actively tuned thermally / electrically, and the designed structure is compatible with the process and easy to realize.

Owner:DALIAN UNIV OF TECH

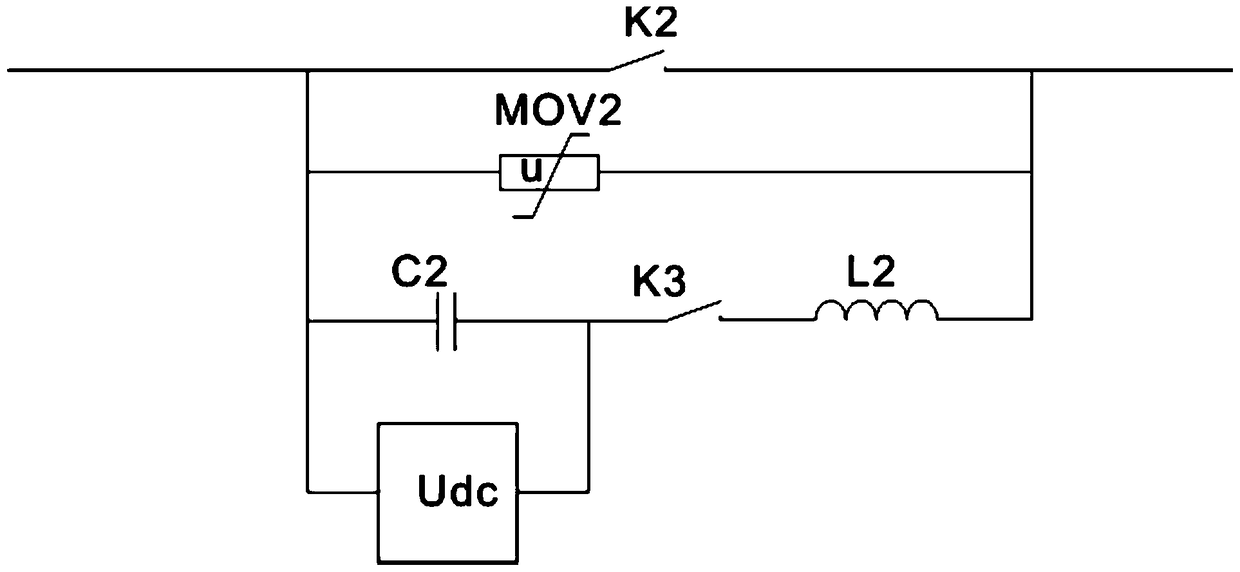

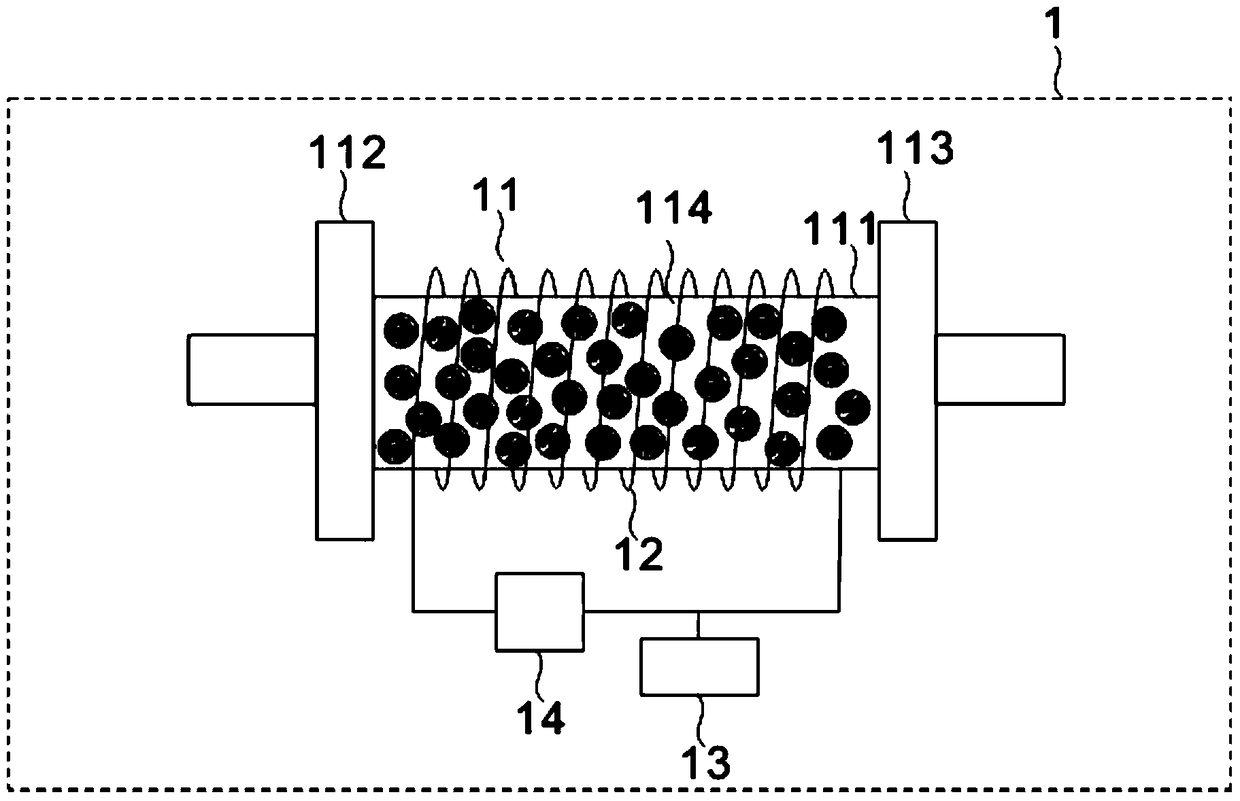

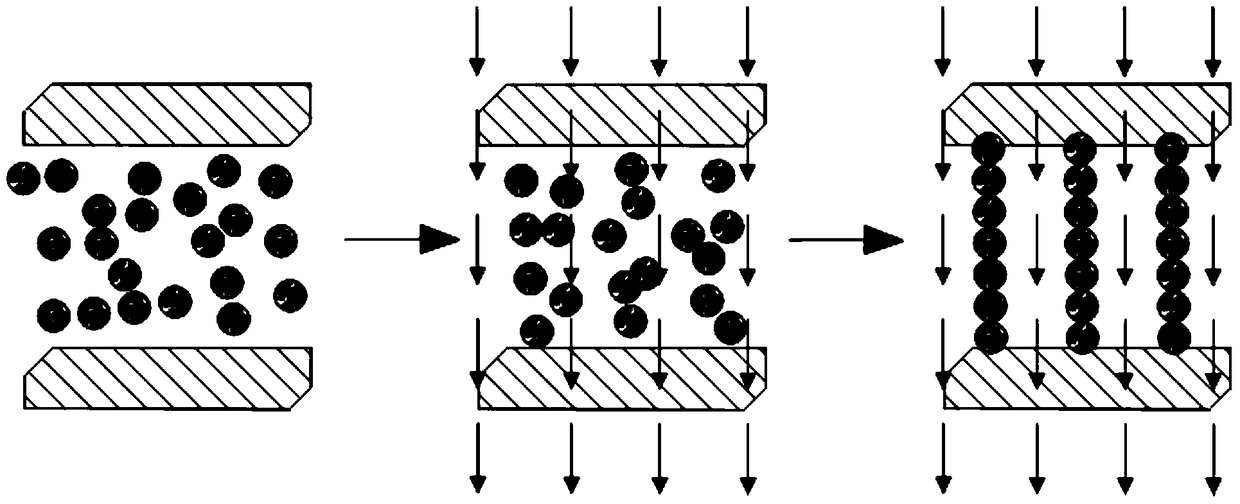

DC circuit breaker, DC circuit breaker and control method

ActiveCN105990066BImprove stabilityImprove reliabilityHigh-tension/heavy-dress switchesAir-break switchesElectricityDc circuit breaker

The present invention provides a DC circuit breaker, a DC circuit break device and a control method. The DC circuit breaker comprises a controllable unit, a coil winding wound at the periphery of the controllable unit and a control unit, wherein the two ends of the coil winding are connected with the output end of a controllable power supply electrically and separately, the control unit is connected with the controllable power supply electrically and is used to control an output current of the controllable power supply to the coil winding, and the controllable unit is used to change the conductivity along with the change of the current passing through the coil winding. By the DC circuit breaker and the DC circuit break device provided by the present invention, and by controlling the current in the coil winding, the conductivity of the controllable unit is adjusted accurately and continuously, thereby effectively reducing an arc, and improving the DC circuit break stability and reliability.

Owner:SIEMENS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com