Solid lubricant, and preparation method and use thereof

A technology for solid lubricants and uses, which is applied in the field of solid lubricants containing graphene quantum dots, and can solve the problems that solid lubricants cannot meet the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

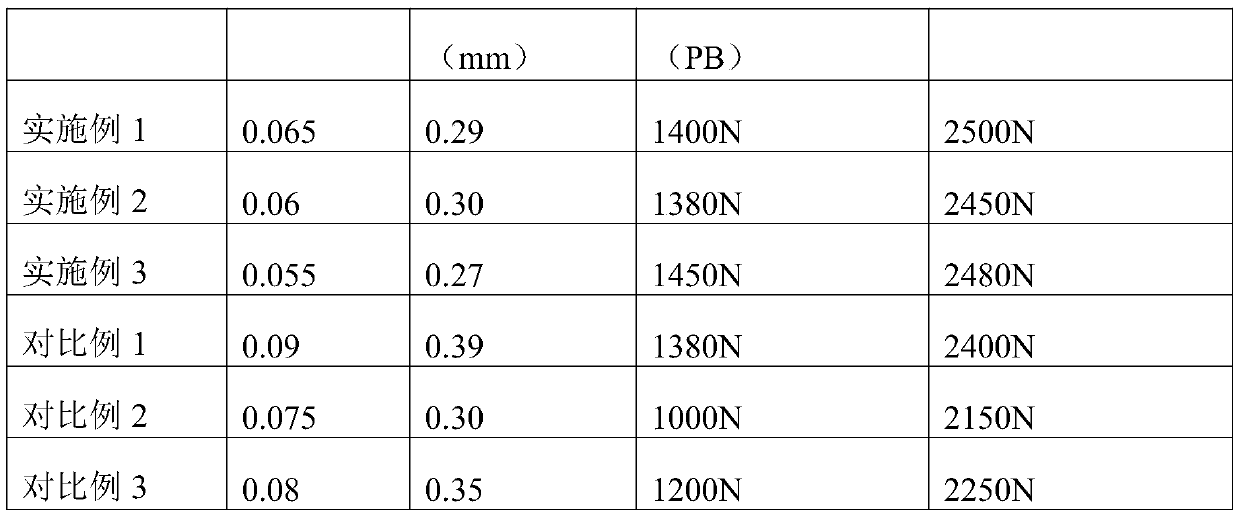

Embodiment 1

[0051] A lubricant is prepared, including: 50 parts by weight of graphene quantum dots, 40 parts by weight of fluorinated graphene quantum dots and 10 parts by weight of nanomolybdenum disulfide. Among them, the sheet diameter of graphene quantum dots is less than 80 nanometers, and more than 80% of the graphene quantum dots are less than 20 nanometers; the sheet thickness is less than 3 nanometers, and the graphene quantum dots with a sheet thickness of less than 2 nanometers account for more than 80%. , the carbon content of graphene quantum dots is above 99%. The sheet diameter of fluorinated graphene quantum dots is less than 80 nanometers, and more than 80% of the graphene quantum dots are less than 20 nanometers; the sheet thickness is less than 3 nanometers, and the graphene quantum dots with a sheet thickness of less than 2 nanometers account for 80% Above, the fluorine content of the fluorinated graphene quantum dot is about 25%, and the carbon content is about 74%. ...

Embodiment 2

[0057] A lubricant was prepared, including: 70 parts by weight of graphene quantum dots, 25 parts by weight of fluorinated graphene quantum dots and 5 parts by weight of nanomolybdenum disulfide. Among them, the sheet diameter of graphene quantum dots is less than 80 nanometers, and more than 80% of the graphene quantum dots are less than 20 nanometers; the sheet thickness is less than 3 nanometers, and the graphene quantum dots with a sheet thickness of less than 2 nanometers account for more than 80%. , the carbon content of graphene quantum dots is above 99%. The sheet diameter of fluorinated graphene quantum dots is less than 80 nanometers, and more than 80% of the graphene quantum dots are less than 20 nanometers; the sheet thickness is less than 3 nanometers, and the graphene quantum dots with a sheet thickness of less than 2 nanometers account for 80% Above, the fluorine content of the fluorinated graphene quantum dot is about 25%, and the carbon content is about 74%. ...

Embodiment 3

[0062] A lubricant is prepared, including: 80 parts by weight of graphene quantum dots, 15 parts by weight of fluorinated graphene quantum dots and 5 parts by weight of nanomolybdenum disulfide. Among them, the sheet diameter of graphene quantum dots is less than 80 nanometers, and more than 80% of the graphene quantum dots are less than 20 nanometers; the sheet thickness is less than 3 nanometers, and the graphene quantum dots with a sheet thickness of less than 2 nanometers account for more than 80%. , the carbon content of graphene quantum dots is above 99%. The sheet diameter of fluorinated graphene quantum dots is less than 80 nanometers, and more than 80% of the graphene quantum dots are less than 20 nanometers; the sheet thickness is less than 3 nanometers, and the graphene quantum dots with a sheet thickness of less than 2 nanometers account for 80% Above, the fluorine content of the fluorinated graphene quantum dot is about 25%, and the carbon content is about 74%. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com