Electrically-conductive injectable hydrogel and preparation method thereof

A technology for injecting water and gel, applied in pharmaceutical formulations, medical science, surgery, etc., can solve the problems of easy inflammatory reaction, non-degradation, poor biocompatibility, etc., and achieves simple preparation method, mild reaction conditions, and biological phase. Good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

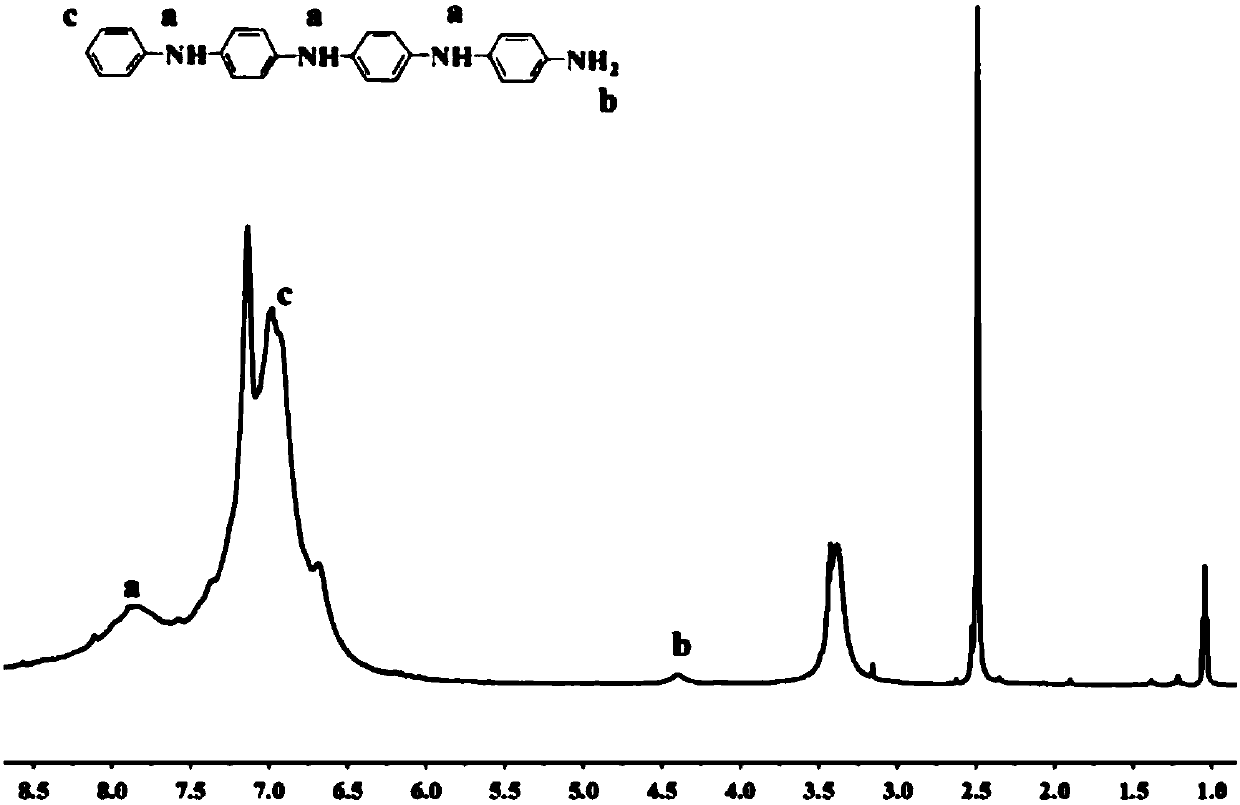

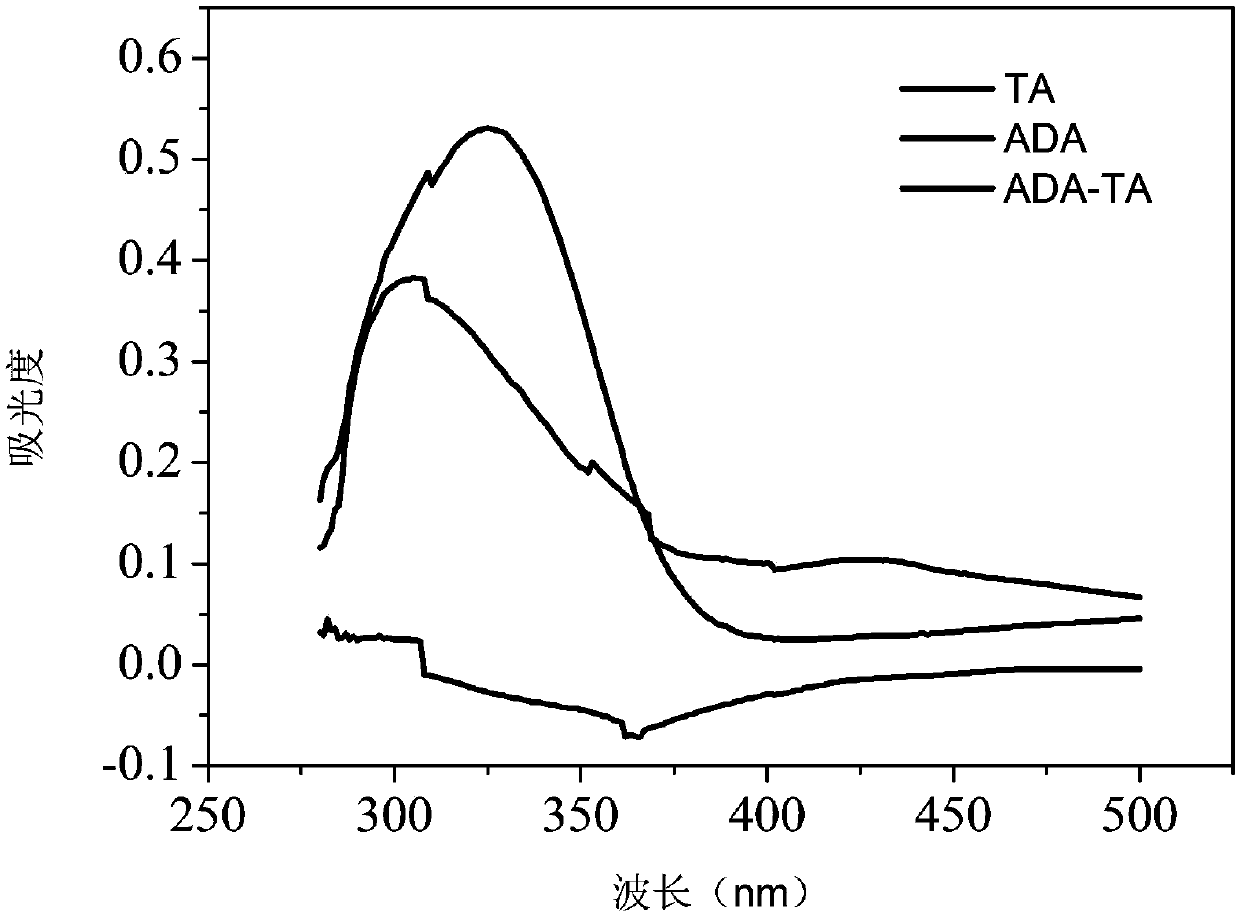

[0039] Taking the oxidation degree of 50% and the aniline tetramer feed rate of 50% as an example, the preparation of conductive alginate-based injectable hydrogel is illustrated.

[0040] Weigh 5.0 g of sodium alginate and add it to 25 ml of absolute ethanol, and stir until it is evenly dispersed. Weigh 2.67g of sodium periodate, add it to 25ml of deionized water, and stir until completely dissolved in the dark (sodium periodate is easy to decompose when exposed to light, so it needs to be stirred in the dark, and the reaction should be carried out in the dark). Pour sodium periodate into the suspension of sodium alginate and react at room temperature for 4 hours. After 4h, 5ml of ethylene glycol was added to terminate the reaction for 15min. Pour the reaction solution into a dialysis bag, and perform dialysis with deionized water for three days, and change the dialysis water every day, about 3-4 times a day. The dialysis-completed product was lyophilized to obtain a white ...

Embodiment 2

[0044] Taking the oxidation degree of 70% and the aniline tetramer feed rate of 50% as an example, the preparation of conductive alginate-based injectable hydrogel is illustrated.

[0045] Weigh 5.0 g of sodium alginate and add it to 25 ml of absolute ethanol, and stir until it is evenly dispersed. Weigh 3.74g of sodium periodate, add it to 25ml of deionized water, and stir until it is completely dissolved in the dark (sodium periodate is easy to decompose when exposed to light, so it needs to be stirred in the dark, and the reaction should be carried out in the dark). Pour sodium periodate into the suspension of sodium alginate and react at room temperature for 4 hours. After 4h, 5ml of ethylene glycol was added to terminate the reaction for 15min. Pour the reaction solution into a dialysis bag, and perform dialysis with deionized water for three days, and change the dialysis water every day, about 3-4 times a day. The dialysis-completed product was lyophilized to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation state | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| grafting efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com