Acoustic surface wave type humidity sensor based on conductive polymer composite nano-fibre and preparation method thereof

A technology of composite nanofibers and conductive polymers, applied in the direction of transmitting sensing components using wave/particle radiation devices, processes for producing decorative surface effects, manufacturing microstructure devices, etc., can solve the problem of not being able to control sensitive films well Problems such as the uniform distribution of the film thickness sensitive film, to achieve good universality, improve contact, and speed up the response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Prepare the N,N-dimethylformamide solution of polyaniline and polyvinyl butyral doped with polystyrene sulfonic acid, in which the concentration of polyaniline is 10 mg / mL, and the concentration of polyvinyl butyral The molar ratio of styrenesulfonic acid to aniline in polystyrenesulfonic acid-doped polyaniline is 1: 1. ;

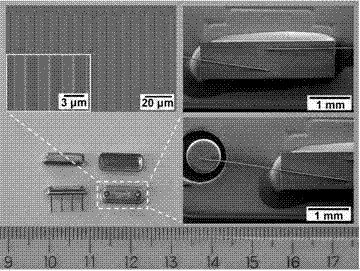

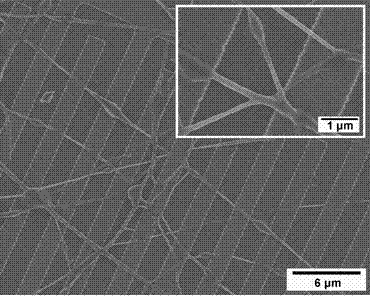

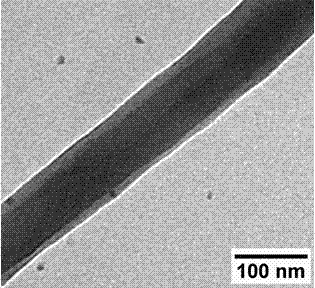

[0039] 2) Put the solution prepared in step 1) into a syringe with a needle. The injection needle is connected to the anode of the high-voltage power supply, and the cathode of the high-voltage power supply is connected to the copper plate. Surface wave device, a 5 kV power supply voltage was applied between the needle of the syringe and the copper plate, the distance between the needle and the copper plate was 5 cm, the solution in the syringe was extruded at a flow rate of 0.5 mL / h by a syringe pump, under the action of a high-voltage electric field The moisture-sensitive nanofibers were deposited on the surface of the surface acoustic wave dev...

Embodiment 2

[0042] 1) Prepare the N,N-dimethylformamide solution of polyaniline and polyvinyl butyral doped with polystyrene sulfonic acid, in which the concentration of polyaniline is 20 mg / mL, and the concentration of polyvinyl butyral The molar ratio of styrenesulfonic acid to aniline in polystyrenesulfonic acid-doped polyaniline was 5: 1. ;

[0043] 2) Put the solution prepared in step 1) into a syringe with a needle. The injection needle is connected to the anode of the high-voltage power supply, and the cathode of the high-voltage power supply is connected to the copper plate. Surface wave device, a 10 kV power supply voltage was applied between the needle of the syringe and the copper plate, the distance between the needle and the copper plate was 8 cm, the solution in the syringe was extruded at a flow rate of 0.3 mL / h by a syringe pump, under the action of a high-voltage electric field Depositing the moisture-sensitive nanofibers on the surface of the surface acoustic wave devic...

Embodiment 3

[0048] 1) Prepare the N,N-dimethylformamide solution of polyaniline and polyvinyl butyral doped with polystyrene sulfonic acid, wherein the concentration of polyaniline is 30 mg / mL, and the concentration of polyvinyl butyral The molar ratio of styrenesulfonic acid to aniline in polystyrenesulfonic acid-doped polyaniline was 6: 1. ;

[0049] 2) Put the solution prepared in step 1) into a syringe with a needle. The injection needle is connected to the anode of the high-voltage power supply, and the cathode of the high-voltage power supply is connected to the copper plate. Surface wave device, a power supply voltage of 15 kV is applied between the needle of the syringe and the copper plate, the distance between the needle and the copper plate is 15 cm, the solution in the syringe is extruded at a flow rate of 1.0 mL / h by a syringe pump, under the action of a high-voltage electric field The moisture-sensitive nanofibers were deposited on the surface of the surface acoustic wave d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com