Pervious concrete of recycled aggregate and preparation method thereof

A technology for recycling aggregate and concrete, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc. Good development prospects, simple and easy-to-understand preparation process, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

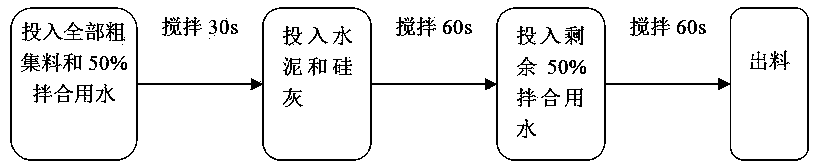

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Taking the case where the recycled aggregate content is 50% as an example, the recycled aggregate permeable concrete was prepared.

[0028] (1) Prepare raw materials: ordinary Portland cement with a strength grade of 42.5; ordinary silica powder, the dosage is 6% of the cement mass; ordinary drinking water; Recycled crushed stones, the performance indicators of which basically meet the standards for Class II stones, are manually screened, rinsed with water, stacked separately, and air-dried naturally.

[0029] (2) Determination of the basic physical properties of coarse aggregate data are shown in Table 1:

[0030] Table 1 Basic physical performance data of coarse aggregate

[0031] Gravel category Single Grain Grading (mm) Mud content (%) Crushing index (%) Moisture content (%) Water absorption (%) Porosity (%) Natural bulk density (kg / m 3 ) Tap density (kg / m 3 ) Apparent density (kg / m 3 ) natural 16~19 1.2 14.2 1.0 ...

Embodiment 2

[0039] Example 2: Taking the case where the recycled aggregate content is 0% as an example, the recycled aggregate permeable concrete was prepared.

[0040] Except for the mixing ratio, others are the same as Example 1. The design mix ratio of 1 cubic meter of concrete is as follows: mass of coarse aggregate: mass of cement: mass of water: mass of silica fume = 1641.50kg: 427.24kg: 147.74kg: 27.27kg.

[0041]

Embodiment 3

[0042] Example 3: Taking the case where the recycled aggregate content is 100% as an example, the recycled aggregate permeable concrete was prepared.

[0043] Except for the mixing ratio, others are the same as Example 1. The design mix ratio of 1 cubic meter of concrete is as follows: mass of coarse aggregate: mass of cement: mass of water: mass of silica fume = 1529.78kg: 402.54kg: 173.58kg: 25.69kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com