Double-well type reinforcement method of shield arrival or starting end and double-well type shield arrival method

A receiving method and dual-well technology, applied in wellbore lining, shaft equipment, earth-moving drilling, etc., can solve the problems of large-area uplift, difficult grouting pressure, and many interlayer phenomena, achieving low cost, convenient construction, The effect of simple process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0025] The shield tunnel reception or the final reception shaft at the originating end of the present invention or the advance shaft outside the station is aimed at the shield tunnel reception working condition where the buried depth of the impermeable layer under the shield tunnel is not too large.

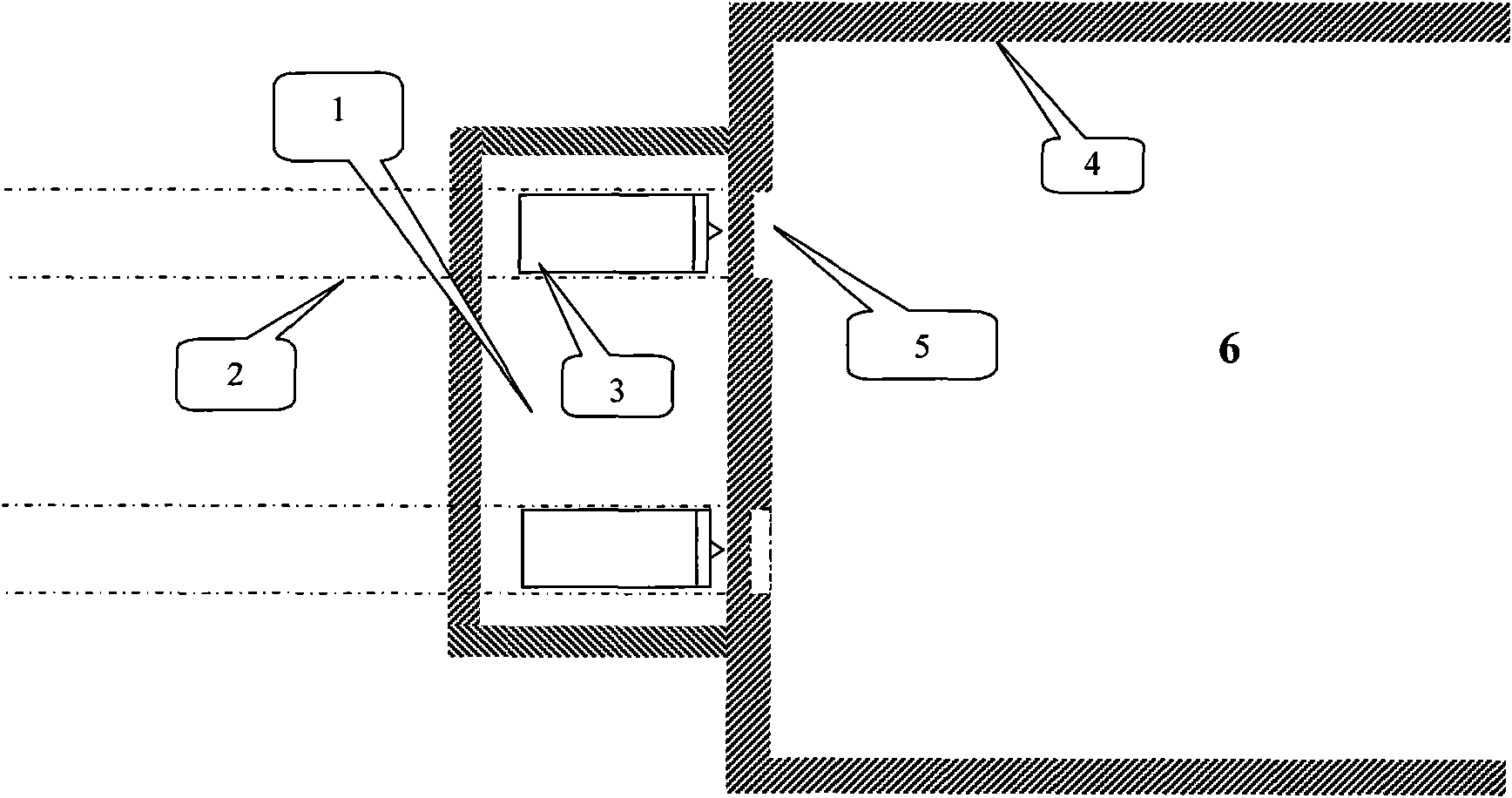

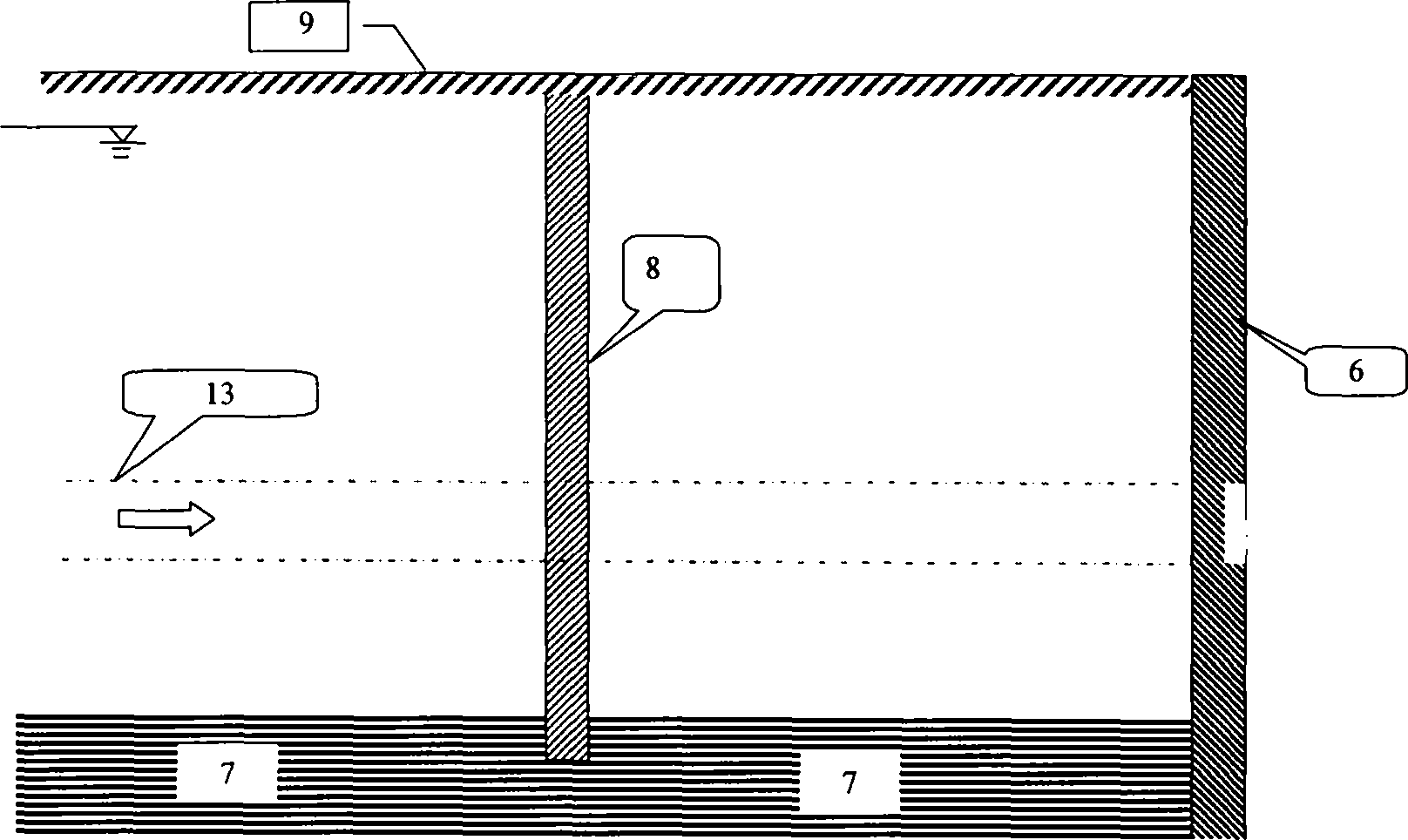

[0026] The specific implementation method is: pre-form a "["-shaped groove in a certain range outside the maintenance wall 4 of the receiving well or station, and then pour plain concrete to form an underground continuous wall, that is, the outer plain wall 8, and the outer plain wall 8 is connected to the maintenance wall 4 To form the advanced well 1, the area surrounded by the advanced well 1 should be longer than the length of the shield machine in the longitudinal direction, and should be greater than a certain distance between the outer edges of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com