La-Al-TiN/h-BN nanosheet composite wave-absorbing material and preparation method thereof

A composite wave-absorbing material and nanosheet technology, which is applied in chemical instruments and methods, and other chemical processes, can solve problems such as low wave-absorbing intensity, low absorption bandwidth, and poor wave-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

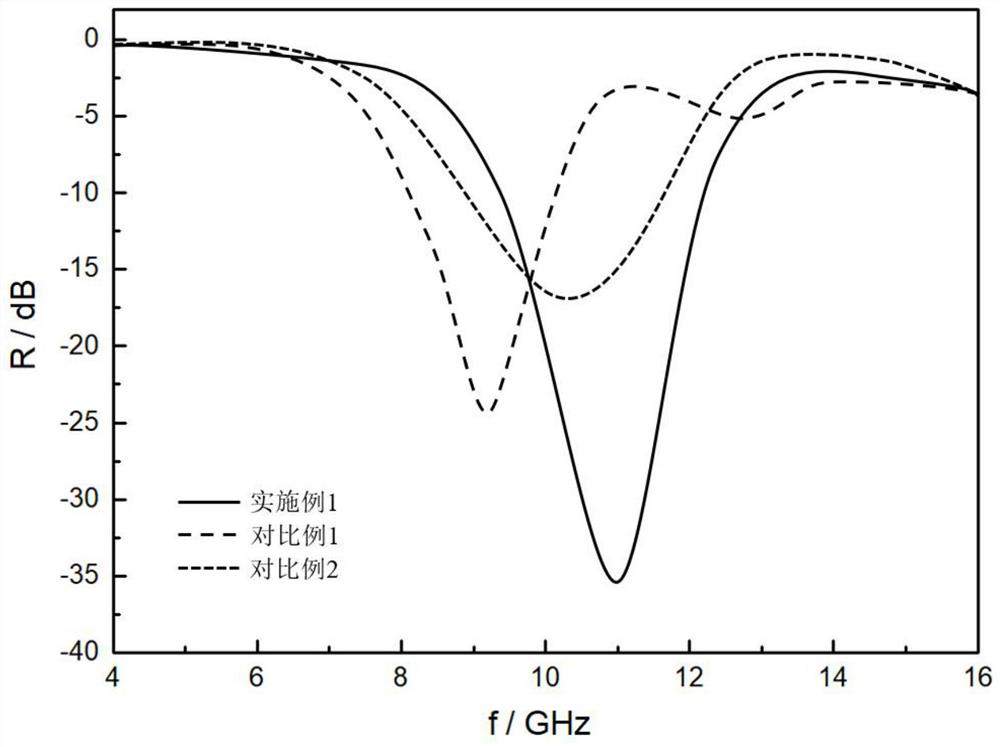

Embodiment 1

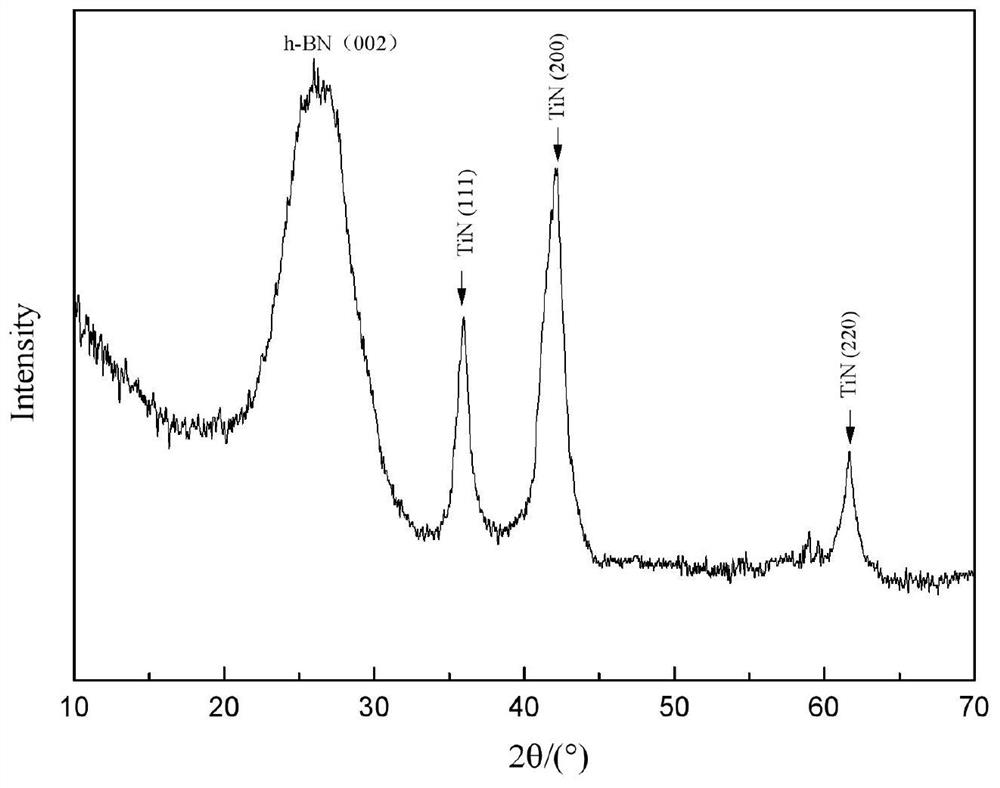

[0025] Step 1: Add 1.86g of boric acid into a mixture of 23.3ml of ethanol and 23.3ml of deionized water, add 18.1g of urea into the solution after ultrasonication for 5min, then stir in a water bath at 50°C for 3h, then put the mixed solution in a 70 The white precursor was obtained in a vacuum drying oven at ℃ for 24 hours; then the precursor was spread in a quartz boat, and the quartz boat was placed in a tube furnace, and the temperature was slowly raised to 900℃ in an ammonia atmosphere, kept for 4 hours and then cooled naturally to room temperature to prepare h-BN nanosheets.

[0026] Step 2: Add 0.62g of TiO 2 Add the h-BN nanosheets prepared in step 1 to 77.5ml of sodium hydroxide solution with a concentration of 0.4g / ml. After ultrasonication for 30min, put the mixed solution into the reaction kettle to react for 36h at a temperature of 110°C. After the reaction, use a deionized Centrifuge and wash with water until the pH value of the solution is below 9, then soak t...

Embodiment 2

[0029] Step 1: Add 2.79g of boric acid into a mixture of 46.5ml of ethanol and 23.3ml of deionized water, add 18.9g of urea into the solution after ultrasonication for 6min, then stir in a water bath at 60°C for 2h, then put the mixed solution in a 75 The white precursor was obtained in a vacuum oven at ℃ for 20 hours; then the precursor was spread on a quartz boat, and the quartz boat was placed in a tube furnace, and the temperature was slowly raised to 900℃ in an ammonia atmosphere, kept for 4 hours and then cooled naturally to room temperature to prepare h-BN nanosheets.

[0030] Step 2: Add 0.75g of TiO 2Add the h-BN nanosheets prepared in step 1 to 75.4ml of sodium hydroxide solution with a concentration of 0.4g / ml. After ultrasonication for 40min, put the mixed solution into the reaction kettle to react at 120°C for 24h. After the reaction, use deionized Centrifuge washing with water until the pH value of the solution is below 9, then soak the solid sample in hydrochlo...

Embodiment 3

[0033] Step 1: Add 2.15g of boric acid into a mixture of 32.3ml of ethanol and 21.5ml of deionized water, add 17.2g of urea into the solution after ultrasonication for 8min, then stir in a water bath at 55°C for 2h, then put the mixed solution in 72 The white precursor was obtained in a vacuum drying oven at ℃ for 23 hours; then the precursor was spread in a quartz boat, and the quartz boat was placed in a tube furnace, and the temperature was slowly raised to 900℃ in an ammonia atmosphere, kept for 5 hours and then cooled naturally to room temperature to prepare h-BN nanosheets.

[0034] Step 2: Add 0.69g of TiO 2 Add the h-BN nanosheets prepared in step 1 to 72.5ml of sodium hydroxide solution with a concentration of 0.4g / ml, and after ultrasonication for 35min, put the mixed solution into the reaction kettle to react at 123°C for 32h. After the reaction, use deionized Centrifuge washing with water until the pH value of the solution is below 9, then soak the solid sample in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com