Double-component rapid low-temperature curing conductive adhesive

A conductive adhesive, two-component technology, used in conductive adhesives, adhesives, epoxy resins, etc., can solve the problem of high price, and achieve the effect of long storage period, high conductivity and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

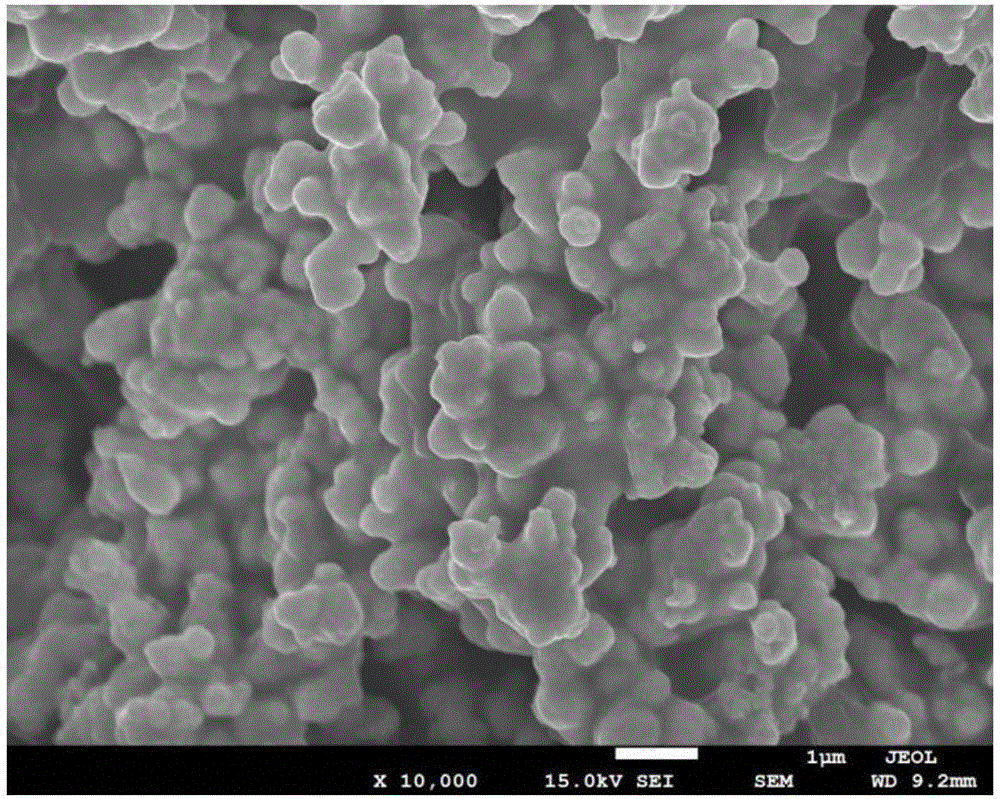

[0037] Embodiment 1 (preparation of silver-plated copper powder for three times):

[0038] The superfine copper powder prepared by direct current arc plasma method is used as raw material, the surface oxide is removed by ultrasonic treatment with 5% dilute sulfuric acid, the acid on the surface is cleaned with deionized water, and then the copper powder is vacuum-dried. Add 20g of copper powder, 10.3g of sodium hypophosphite, and 1g of PVP into 500mL of deionized water to prepare a reducing solution containing copper substrate, add ammonia water to adjust its pH value to 11; add 17g of silver nitrate, 0.5g of EDTA-2Na Prepare the oxidation solution in 500mL deionized water; slowly add the oxidation solution to the reducing solution, raise the temperature to 50°C, react for 20 minutes, and separate the primary silver-plated copper powder with a centrifuge; repeat the above plating with the primary silver-plated copper powder as the base material Two steps of silvering are used ...

Embodiment 2

[0041] Weigh 200 parts of silver-plated copper powder prepared in Example 1, 100 parts of epoxy resin, 15 parts of toluene, and high-speed mechanical stirring for 10 minutes to prepare conductive adhesive component A;

[0042] Weigh 180 parts of silver-plated copper powder prepared in Example 1, 10 parts of 1,4-butanediol diglycidyl ether, 20 parts of dimethylaniline, 20 parts of triethanolamine, 5 parts of defoamer, and high-speed mechanical stirring After 10 minutes, the conductive adhesive component B was prepared.

[0043]Mix component A and component B for 10 minutes, and then apply conductive adhesive on the overlapping surface of two stainless steel metal sheets. The length of the metal sheet is 100mm, the width is 25mm, the thickness is 2mm, and the length of the overlapping surface is 12.5mm. Put it in a blast drying oven and heat it to 150°C for 30 minutes to get a conductor, and the measured resistivity is 5.8×10 -4 Ω·cm, the shear strength is 6Mpa.

Embodiment 3

[0045] Weigh 180 parts of silver-plated copper powder prepared in Example 1, 100 parts of epoxy resin, 10 parts of acetone, and high-speed mechanical stirring for 10 minutes to prepare conductive adhesive component A;

[0046] Weigh 200 parts of silver-plated copper powder prepared in Example 1, 10 parts of 1,4-butanediol diglycidyl ether, 20 parts of methyltetrahydrophthalic anhydride, 20 parts of triethanolamine, 5 parts of defoamer part, high-speed mechanical stirring for 10 minutes, and prepared the conductive adhesive component B.

[0047] After mixing component A and component B for 10 minutes, apply conductive glue on a glass slide to form a conductive layer with a thickness of 0.2 mm and a diameter of 25 mm. Put it in a blast drying oven and heat it to 150°C to cure for 30 minutes to obtain a conductor, and the measured resistivity is 3.5×10 -3 Ω·cm, the shear strength is 13Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com