A high-toughness seamless submerged arc flux-cored welding wire for 460mpa steel

A seamless submerged arc, flux cored wire technology, applied in welding equipment, welding media, welding/cutting media/materials, etc., can solve the problem of no seamless submerged arc flux cored wire, etc., to improve low temperature toughness and tensile strength strength, increased tensile strength, effect of toughening weld metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

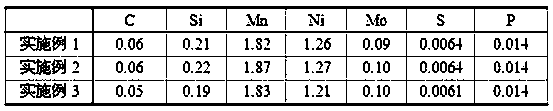

[0018] Examples 1-5 are high-toughness seamless submerged arc flux-cored welding wires suitable for 460MPa steel. The filling rate of Example 1 is 9.5%, and the diameter of the welding wire is 3.2mm. In Example 2, the filling rate is 12%, and the wire diameter is 4.0mm. In Example 3, the filling rate is 14%, and the wire diameter is 5.0mm. The composition of the drug core powder used in Examples 1 to 5 is shown in Table 1.

[0019] Table 1 Chemical composition (mass fraction, %) of the drug core powder of the embodiment of the present invention

[0020]

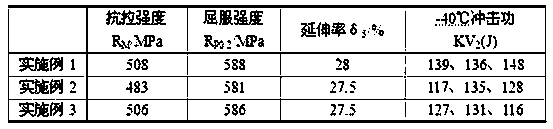

[0021] Example of implementation effect

[0022] For the three kinds of welding wire prepared above and SR-SJ613 flux, according to the national standard GB / T 5118-2012, the chemical composition analysis of the deposited metal, the mechanical performance test of the deposited metal and the determination of the hydrogen content of the deposited metal were carried out. Taking Φ4.0mm welding wire as an example, the weldin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com