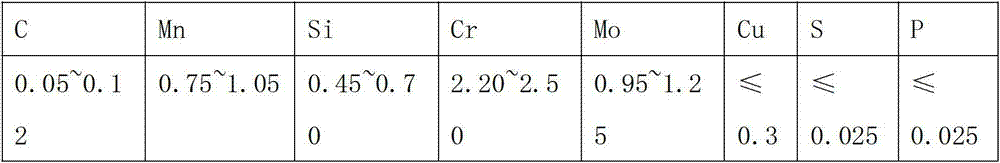

T/P91 steel electrode and manufacturing method thereof

An electrode and electrode welding technology, applied in welding media, manufacturing tools, welding equipment, etc., can solve the problems of uneven transition of alloy elements, increased thickness of electrode coating, poor welding processability, etc., and achieves stable arc and benefits all positions. Welding and spatter-less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Mix the following components by weight to make a powder mixture:

[0038] Marble (31~35), fluorite (26~29), titanium dioxide (4~7), quartz (1~2), mica (1~2), metal chromium (13~15), atomized nickel powder ( 1~2), titanium iron (7~9), molybdenum iron (1~2), niobium iron (0.5~1), vanadium iron (1~2), vanadium nitrogen alloy (1~2).

[0039] Example formula one:

[0040] Marble: 34kg Fluorite: 28kg

[0041] Titanium dioxide: 7 kg Ferroniobium: 0.5 kg

[0042] Ferro-vanadium: 1 kg Ferro-titanium: 8 kg

[0043] Vanadium nitrogen alloy: 1 kg Quartz: 2 kg

[0044] Mica: 2 kg Metal chromium: 14 kg

[0045] Ferromolybdenum: 1 kg Atomized nickel powder: 1.5 kg.

[0046] Example formula two:

[0047] Marble: 31kg Fluorite: 26kg

[0048] Titanium dioxide: 4 kg Ferroniobium: 0.5 kg

[0049] Ferro-vanadium: 1 kg Ferro-titanium: 7 kg

[0050] Vanadium nitrogen alloy: 1 kg Quartz: 1 kg

[0051] Mica: 1 kg Metal chromium: 13 kg

[0052] Ferromolybdenum: 1 kg Atomized nickel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com