Ultra-low hydrogen high-tenacity seamless flux-cored wire for 550 MPa high-strength steel

A seamless flux-cored welding wire, ultra-low hydrogen technology, applied in welding medium, welding equipment, welding/welding/cutting items, etc., can solve the problems of increased probability of hydrogen-induced cracks, and difficulty in reaching the diffusion of hydrogen in deposited metal. , to achieve the effects of low diffusible hydrogen in the deposited metal, improved electrical conductivity, and stable wire feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

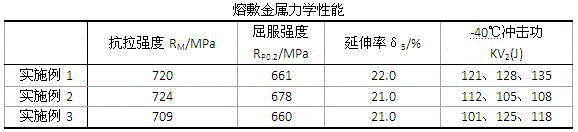

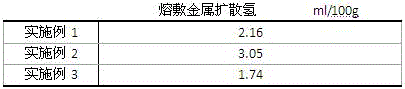

Embodiment 1

[0033] An ultra-low hydrogen high toughness seamless flux-cored welding wire for 550MPa high-strength steel, the welding wire is composed of flux core powder and a low-carbon steel strip wrapped around flux core powder, and the flux core powder is composed of 25% golden red Stone powder, 3% rare earth fluoride, 5% atomized ferrosilicon powder, 8% low-carbon ferromanganese powder, 3% aluminum-magnesium alloy powder, 3% metal titanium powder, 18% metal nickel powder, 6% % metal chromium powder, 2% metal molybdenum powder, 5% alumina powder, 5% quartz powder, and the rest are iron powder and unavoidable impurities.

Embodiment 2

[0035] A kind of ultra-low hydrogen high toughness seamless flux-cored welding wire for 550MPa high-strength steel, the welding wire is composed of flux core powder and low-carbon steel strip wrapped flux core powder, the flux core powder is composed of 35% golden red Stone powder, 1% rare earth fluoride, 4% atomized ferrosilicon powder, 6% low-carbon ferromanganese powder, 4% aluminum-magnesium alloy powder, 4% metal titanium powder, 20% metal nickel powder, 5% % metal chromium powder, 5% metal molybdenum powder, 2% alumina powder, 2% quartz powder, and the rest are iron powder and unavoidable impurities.

Embodiment 3

[0037] An ultra-low hydrogen high toughness seamless flux-cored welding wire for 550MPa high-strength steel. The welding wire is composed of flux core powder and a low-carbon steel strip wrapped around the flux core powder. The flux core powder is composed of 45% golden red Stone powder, 2% rare earth fluoride, 3% atomized ferrosilicon powder, 4% low-carbon ferromanganese powder, 2% aluminum-magnesium alloy powder, 5% metal titanium powder, 15% metal nickel powder, 3% % metal chromium powder, 3% metal molybdenum powder, 3% alumina powder, 3% quartz powder, and the rest are iron powder and unavoidable impurities.

[0038] Each composition used in the above embodiment is specifically defined as follows:

[0039] The core powder accounts for 12-16% of the total mass of the welding wire;

[0040] The particle diameter of the drug core powder is no more than 40 mesh;

[0041] The carbon content in the low-carbon ferromanganese powder is no more than 1%, and the manganese content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com