Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Stable wire feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

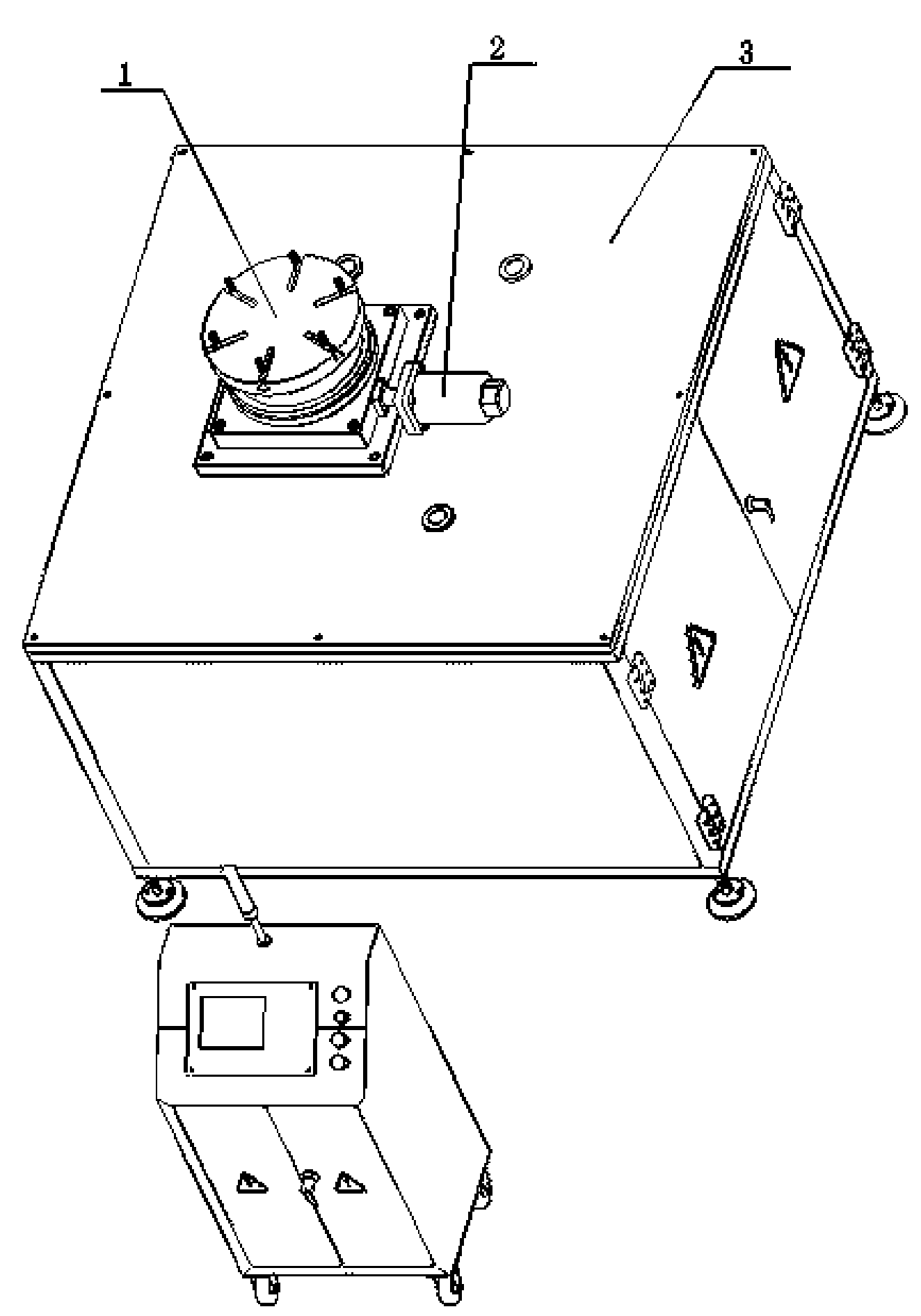

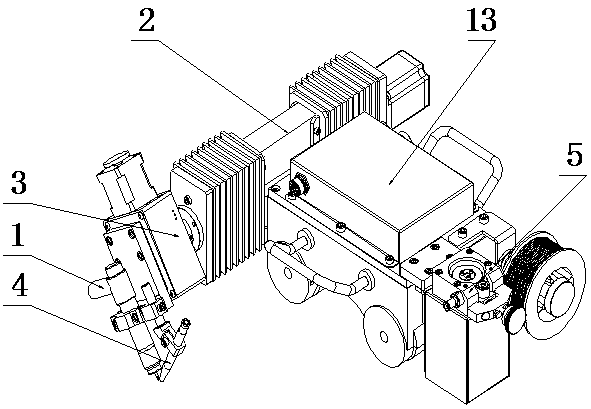

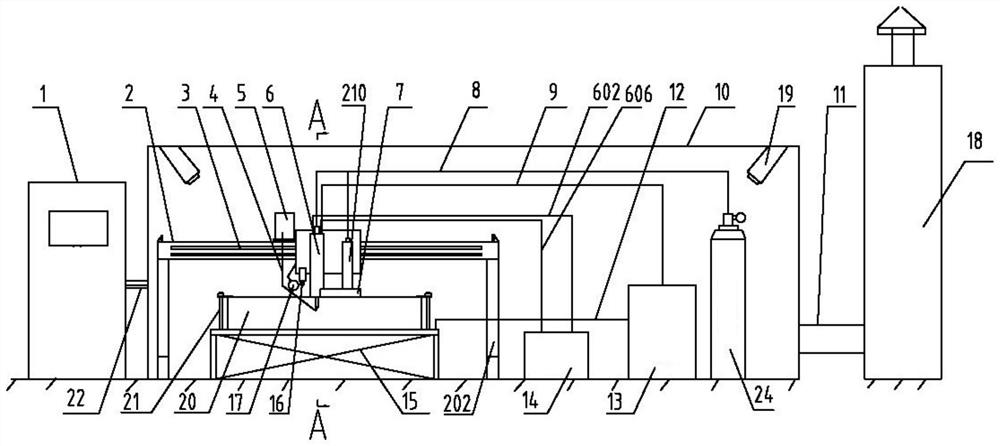

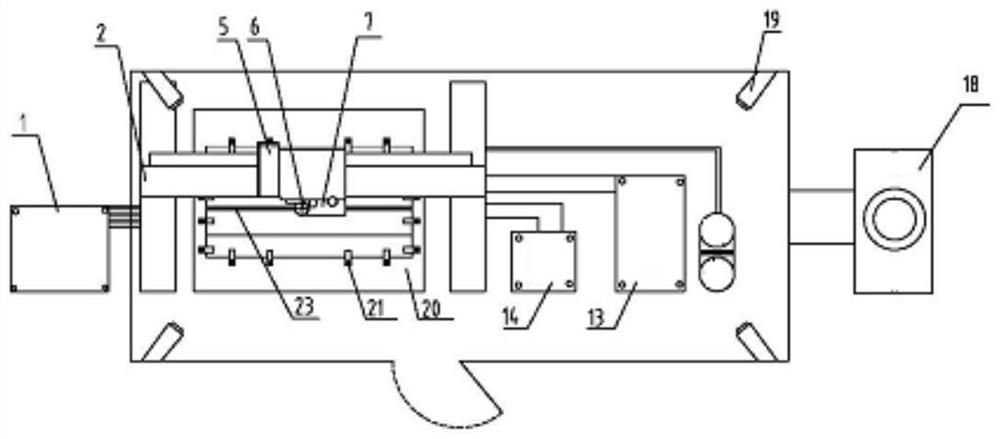

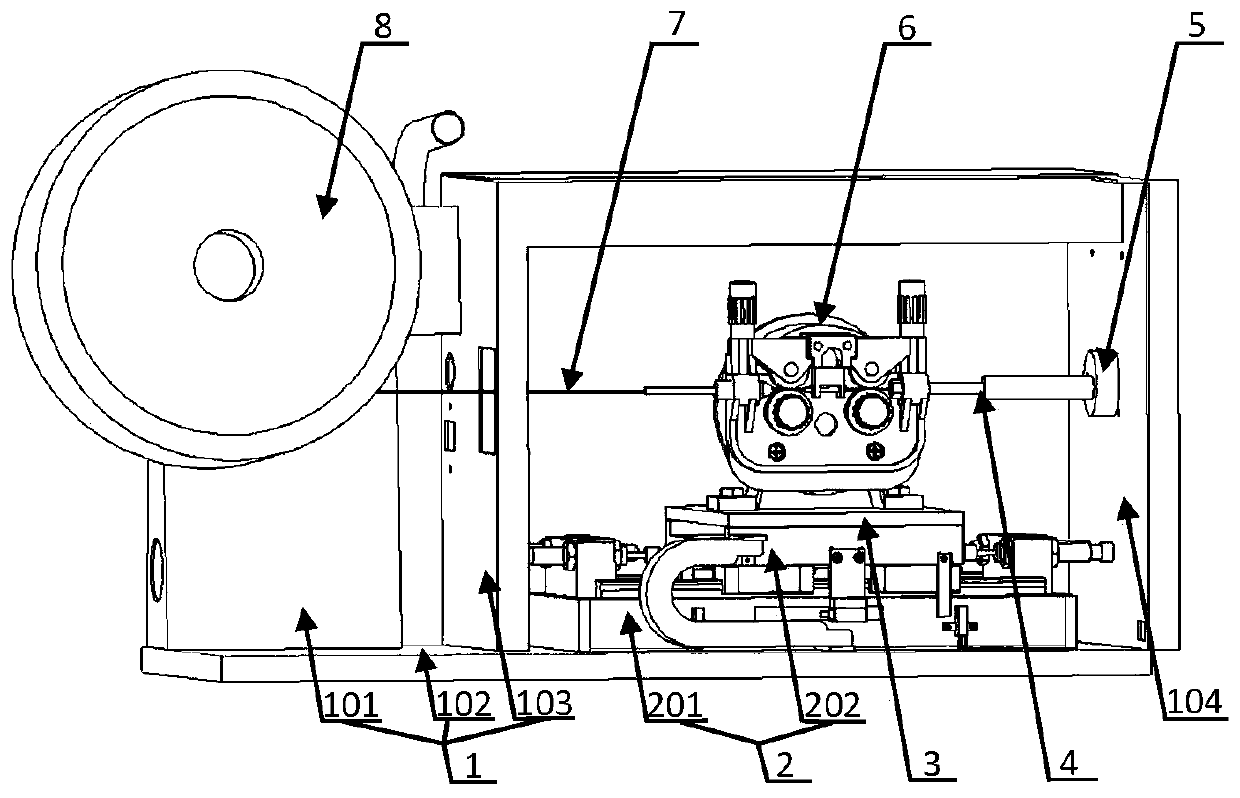

Full-automatic high speed four-shaft two-operating positions rotary welding device

InactiveCN101585109AGuaranteed correctnessIncrease productivityArc welding apparatusNumerical controlOperating point

A full-automatic high speed four-shaft two-operating positions rotary welding device, in which a rack is provided with x, y and z coordinate systems, wherein a bottom plate of a Y shaft coordinate system is connected with a rotary working platform on the rack. A rack of a Z shaft coordinate system is vertically connected to a bottom plate of the Y shaft coordinate system. The X coordinate system is vertically connected to a bottom plate of the Z shaft coordinate system. In the X coordinate system, a ball screw moving mechanism is formed by the bottom plate of the X shaft coordinate system and a ball screw assembly. The bottom plate of the X shaft coordinate system is connected with an externally extending welding gun via a welding gun adjusting system. An R shaft coordinate system is mounted at two side surfaces of the rack, respectively. The advantage is that four-shaft leakage is used for welding. The welding of different workpieces can be realized via numerical control programming, and the application range is wide. Because of using the rotary welding mode of double-gun and two-operating positions, the production efficiency is high, at the same time, the automatic tracking and welding can be performed because of mounting a welding tracking device and an automatic adjusting mechanism of welding gun position, thereby guaranteeing the stability of wielding, and the reliability and beauty of the welding quality.

Owner:柳州市利林汽车配件厂

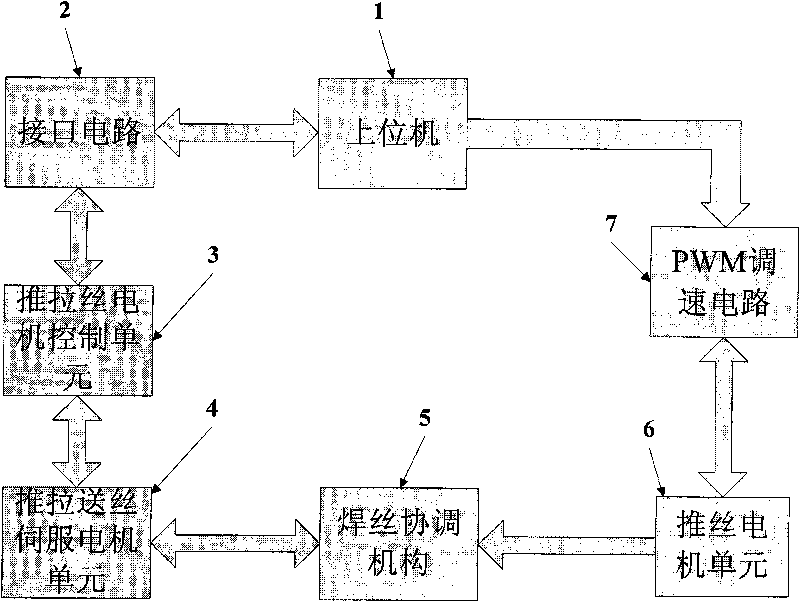

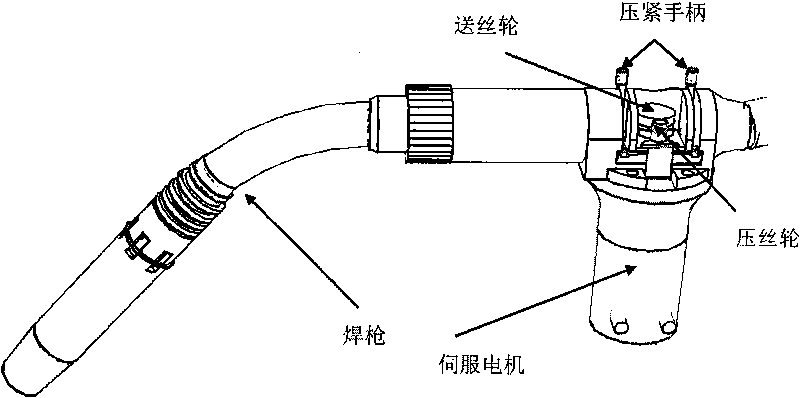

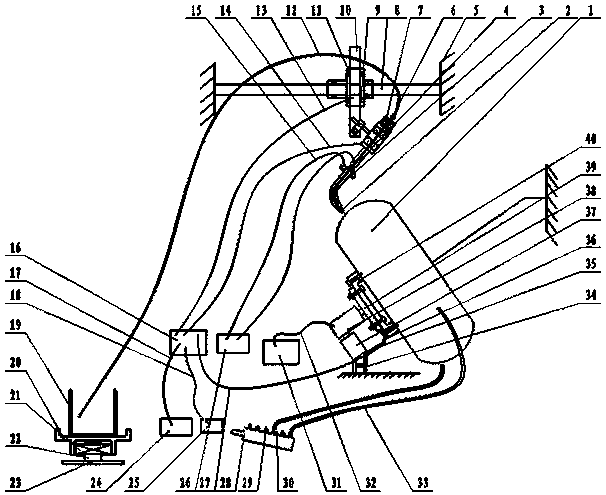

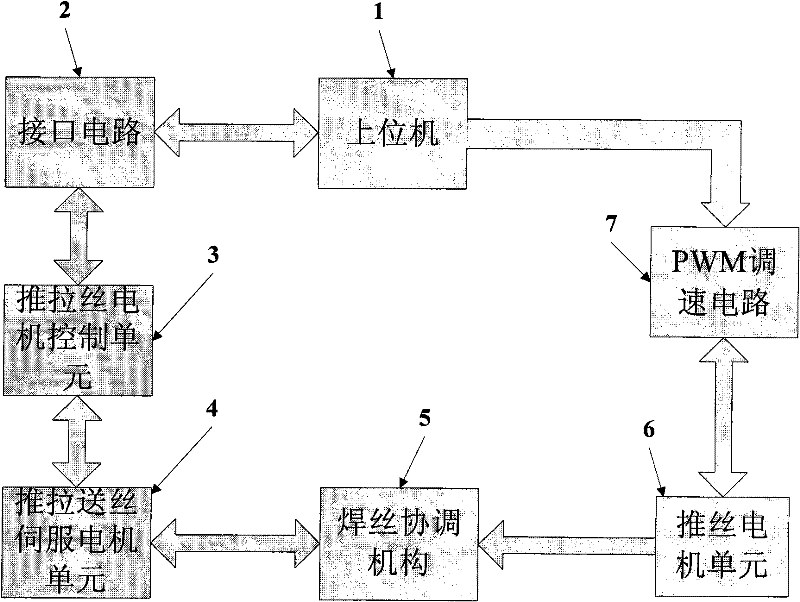

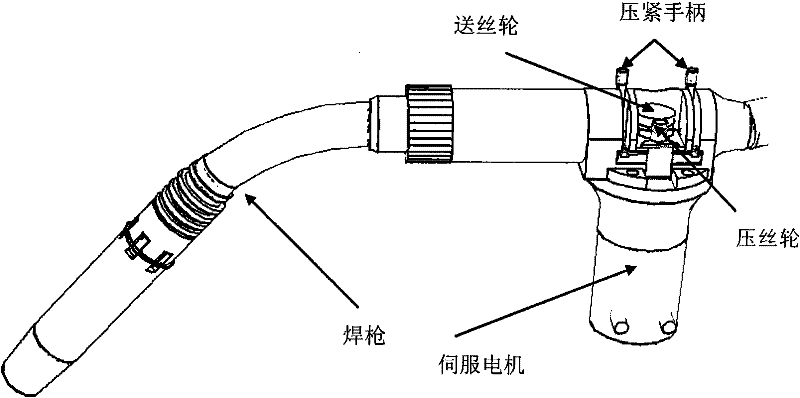

Wire feeding system of double-motor combined welding wire coordinating mechanism

The invention belongs to the field of welding devices, particularly relates to a wire feeding system of a double-motor combined welding wire coordinating mechanism. The wire feeding system specifically comprises an upper computer (1), an interface circuit (2), a push-pull wire motor control unit (3), a push-pull wire feeding servo motor unit (4), a welding wire coordinating mechanism (5), a push wire motor unit (6) and a PWM speed adjusting circuit (7), wherein the upper computer is connected with the push-pull wire motor control unit via the interface circuit and connected with the PWM speed adjusting circuit, and used for totally controlling the whole push-pull wire feeding system; the push-pull wire motor control unit is used for closed loop control of the push-pull wire feeding servo motor unit; the PWM speed adjusting circuit is used for driving and controlling the push wire motor unit; the welding wire coordinating mechanism is an intermediate link for connecting the push wire motor unit with the push-pull wire feeding servo motor unit. The wire feeding system is mainly combined with a digital welding power source and capable of realizing various welding technological methods based on high-frequency feed-draw welding wires.

Owner:BEIJING UNIV OF TECH

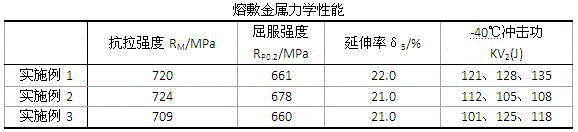

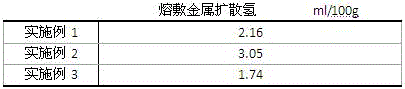

Welding wire for submerged-arc welding of high-efficiency X100 pipeline steel and application of welding wire

ActiveCN103846571ABeautiful shapeMeet welding requirementsArc welding apparatusPipeline systemsCrack resistanceWeld seam

The invention belongs to the field of a welding wire material, and particularly relates to a welding wire for submerged-arc welding of high-efficiency X100 pipeline steel and the application of the welding wire. The welding wire material comprises the chemical components in percentage by weight: 0.01-0.05 wt% of C, 1.4-2.1 wt% of Mn, 0.1-0.3 wt% of Si, 0.2-0.4 wt% of Mo, 0.05-0.1 wt% of Ti, 0.003-0.005 wt% of B, 0.1-0.4 wt% of Cr, 0.2-0.3 wt% of Cu, 0.3-0.6 wt% of Ni, 0.03-0.08 wt% of Nb, less than or equal to 0.005 wt% of S, less than or equal to 0.005 wt% of P, and the balance of Fe. The welding wire for the submerged-arc welding, disclosed by the invention is matched with an SJ101-100 welding flux deposited metal and has an excellent comprehensive mechanical property, the yield strength is greater than 690 MPa, the tensile strength is greater than 780MPa, and the impact work is greater than 108J in -20 DEG C; after welding, the forming of a welding seam is attractive, the defects of cracking, undercutting and the like do not exist, the strength is high, the toughness is good, the crack resistance is good, the welding seam has a good matching effect with the X100 pipeline steel, and the welding wire has a decisive function on performance of a weld metal as the welding wire is used as a main filling metal; according to the welding wire disclosed by the invention, the welding requirements of an oil and gas transmission pipeline under a situation of higher pressure are met.

Owner:JINZHOU SWAN WELDING CONSUMABLES

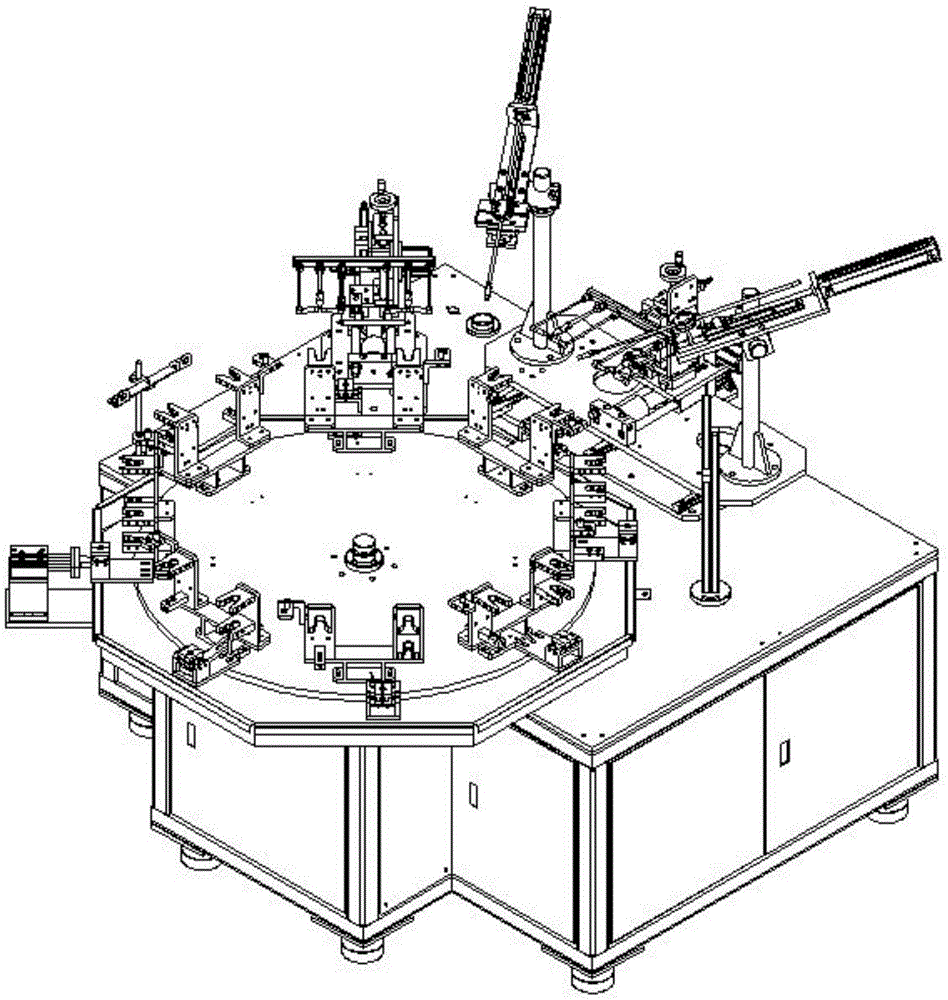

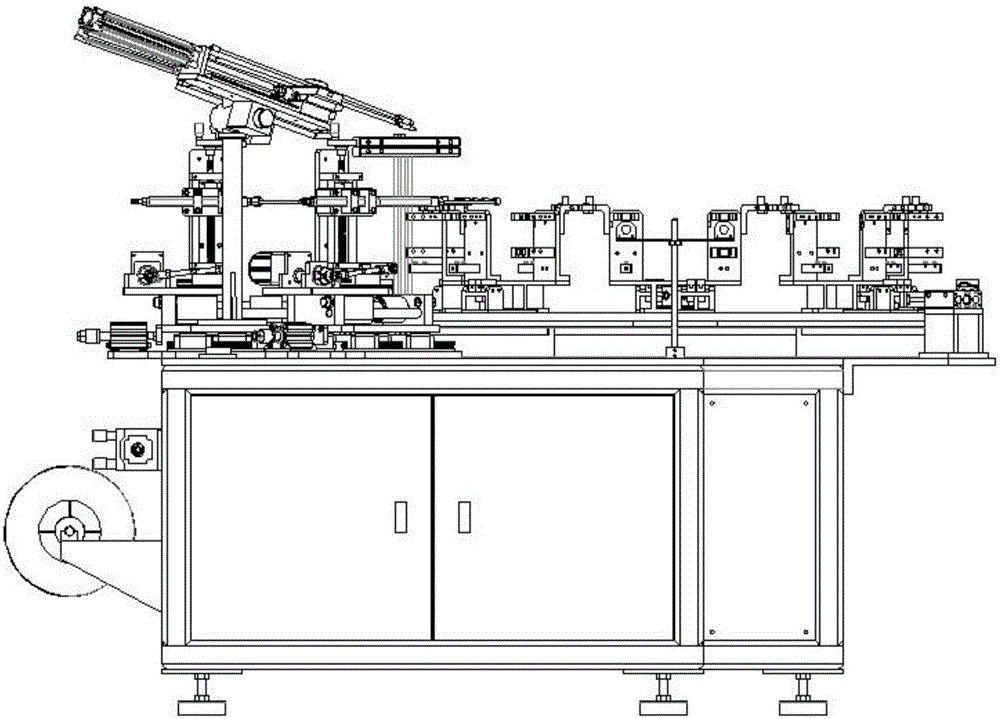

Rotary plate type multi-station automatic flame brazing machine for household air conditioner silencer assembly

InactiveCN106735683ASimple structureReasonable designMetal working apparatusSolder feeding devicesWire speedEngineering

The invention discloses a rotary plate type multi-station automatic flame brazing machine for a household air conditioner silencer assembly. The rotary plate type multi-station automatic flame brazing machine comprises a machine frame and an index rotary plate arranged at the top of the machine frame. Two welding devices and two wire feeding devices are arranged on one side of the index rotary plate. A plurality of wielding tools are arranged at the top of the index rotary plate. The whole machine adopts the rotary plate type multi-station design, servo wire feeding is adopted by the wire feeding devices, the wire speed and wire amount can be regulated and controlled, through a self-made reinforcement wire pressing device, wire feeding is stable, and slipping and wire stuck are avoided; through the self-designed welding tools, as for the same station, the left side is used for a former procedure, and the right side is used for a later procedure, so that finished products can be produced through one machine, the yield reaches 99.5% or above during usage, and the production takt is shorter than 8 second / set; the former and later procedure product can be met through the machine, finished products are obtained directly, and carrying and equipment input are reduced; two sets of products are perfectly compatible, gapless model change is achieved, machine debugging is avoided, and the equipment utilization rate is high; and the rotary plate type multi-station automatic flame brazing machine is suitable for being operated with robots and special machines online, and full-automatic manless production is achieved.

Owner:佛山市奥拓玛智能设备有限公司

Pipeline all-position automatic tungsten inert gas welding (TIG welding) machine and welding process thereof

PendingCN111054999AWarm up guaranteedReduce labor intensityElectrode supporting devicesWelding accessoriesPipe fittingEngineering

The invention discloses a pipeline all-position automatic tungsten inert gas welding (TIG welding) machine, belongs to the technical field of automatic welding equipment, and has wide applications inpipelines and pipe butt joint all-position automatic welding. The pipeline full-position automatic TIG welding machine comprises a walking welding trolley, wherein the welding trolley performs circular motion along a pipeline; a wire feeding mechanism and a welding gun are arranged on the body of the welding trolley; a hot wire nozzle is arranged at the tail end of the wire feeding mechanism; thehot wire nozzle is a copper pipe; one end of the hot wire nozzle is connected with a heating power supply through a lead wire; an anode connecting wire is also arranged; one end of the anode connecting wire is connected with the heating power supply; and the other end of the anode connecting wire is a free end. The invention solves the problem of preheating welding wires in the prior TIG welding,ensures that the welding wires are preheated before welding, and solves the problem that distance between a welding gun and a welding pipe fitting cannot be conveniently adjusted, so that wire feedingis stable, and welding quality and welding efficiency of the pipeline full-position automatic TIG welding are effectively improved.

Owner:JINAN JINLUDING WELDING TECH CO LTD

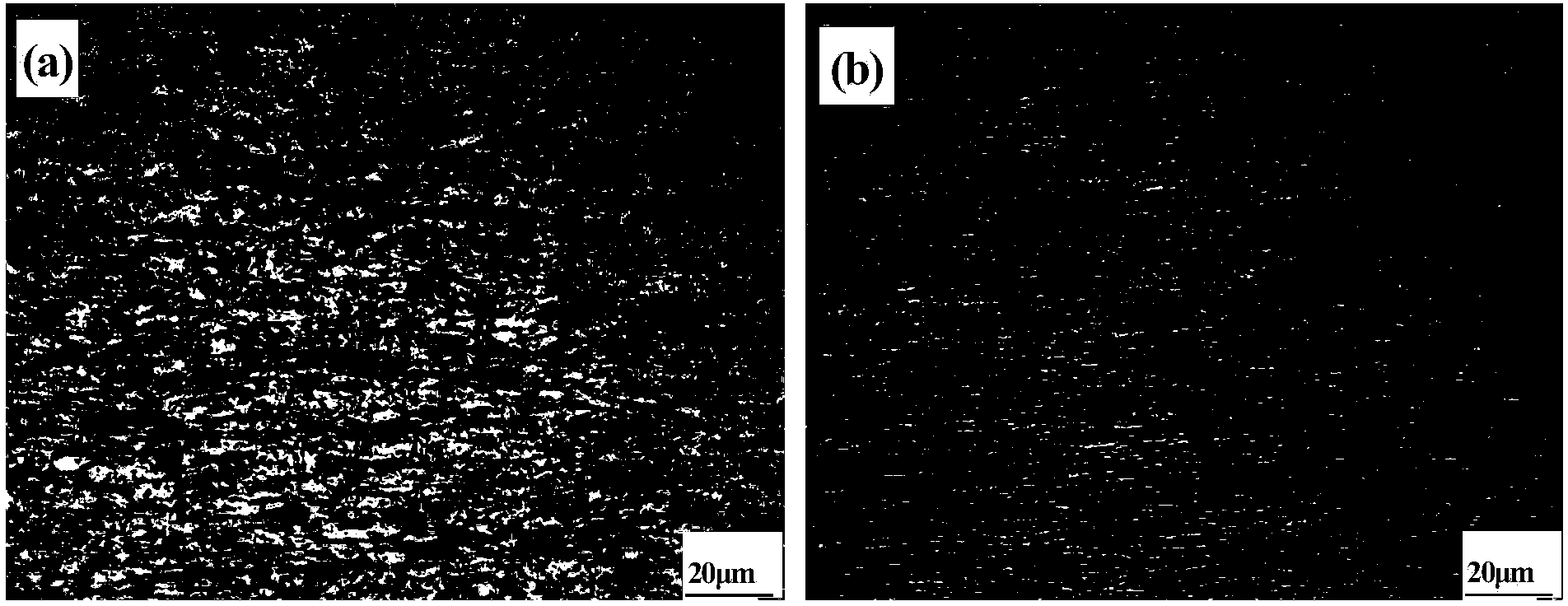

Ultra-low hydrogen high-tenacity seamless flux-cored wire for 550 MPa high-strength steel

ActiveCN106078006ALow diffusible hydrogenImprove conductivityWelding/cutting media/materialsWelding/soldering/cutting articlesRare earthFerrosilicon

Disclosed is an ultra-low hydrogen high-tenacity seamless flux-cored wire for 550 MPa high-strength steel. The flux-cored wire is composed of flux core powder and low-carbon steel band wrapping the flux core powder. The flux core powder is composed of rutile powder, rare earth fluoride, atomized ferrosilicon powder, low-carbon ferromanganese powder, aluminum-magnesium alloy powder, metal titanium powder, metal nickel powder, metal chromium powder, metal molybdenum powder, alumina powder, quartz powder, and the balance iron powder and unavoidable impurities. Re in the rare earth fluoride and a trace of calcium in the atomized ferrosilicon powder of the flux core powder form a combined effect, the size of weld metal inclusion is reduced, the combined effect of Al-Mg-Ti enables the components of the inclusion to facilitate nucleation of acicular ferrite, the content of the acicular ferrite is increased, the structure is refined, and therefore good low-temperature impact toughness is achieved, and the -40 DEG C impact energy average value can reach 80 J or above.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

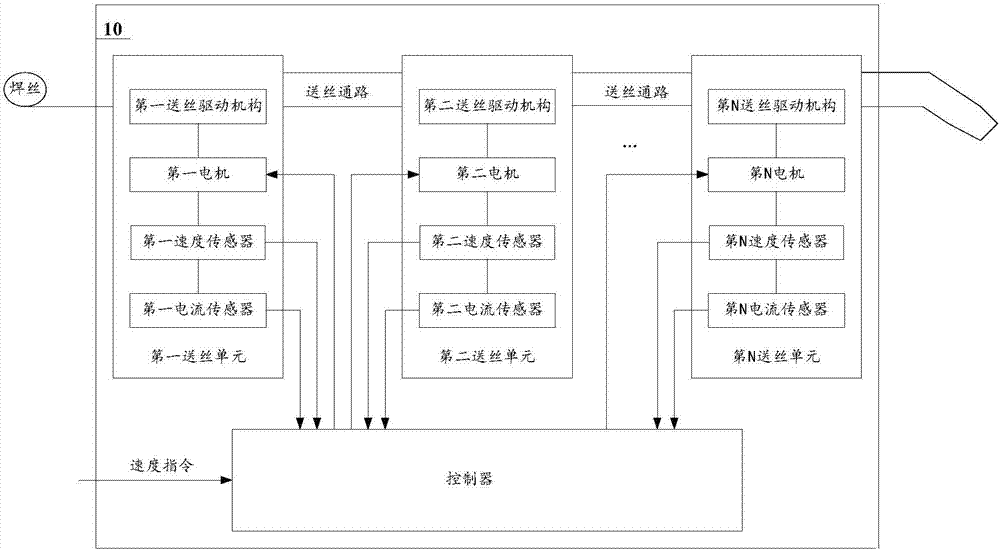

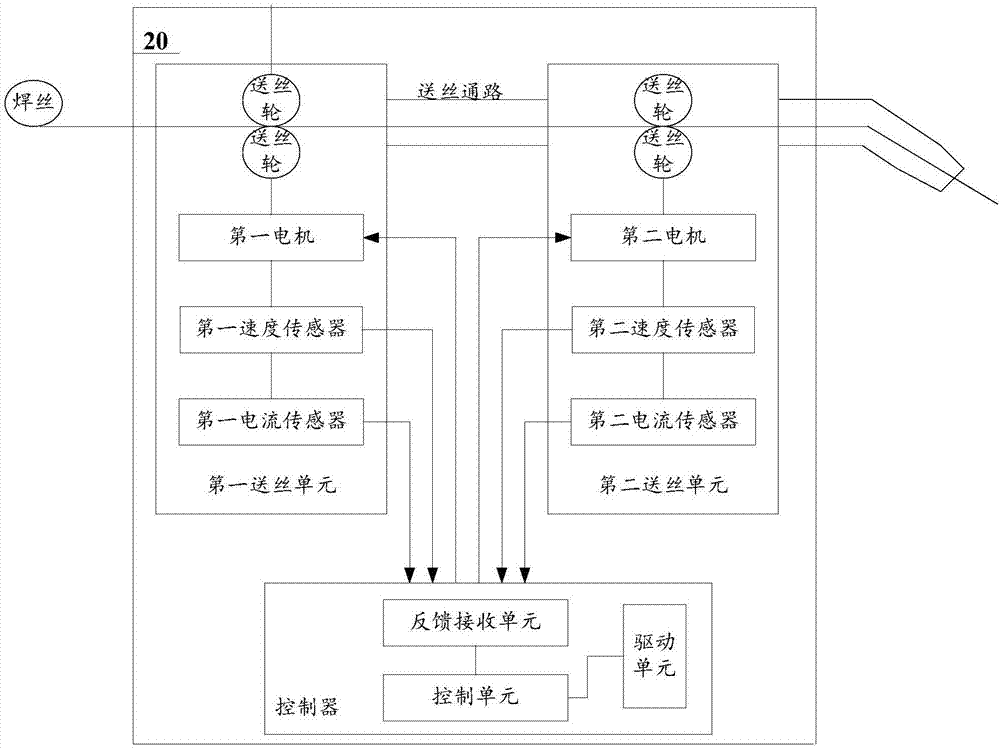

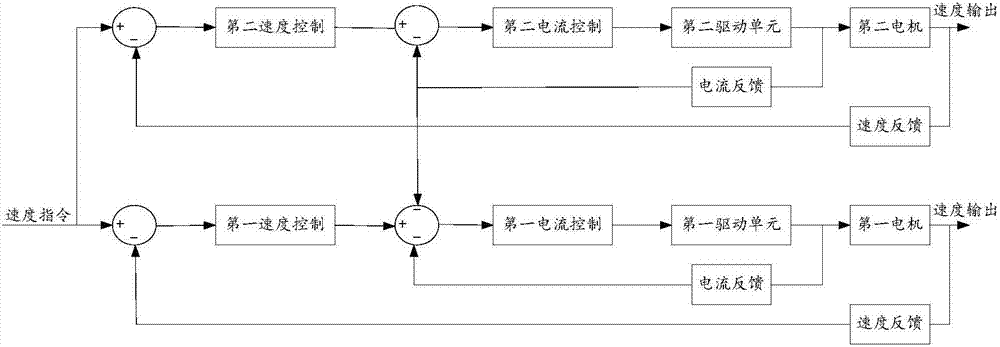

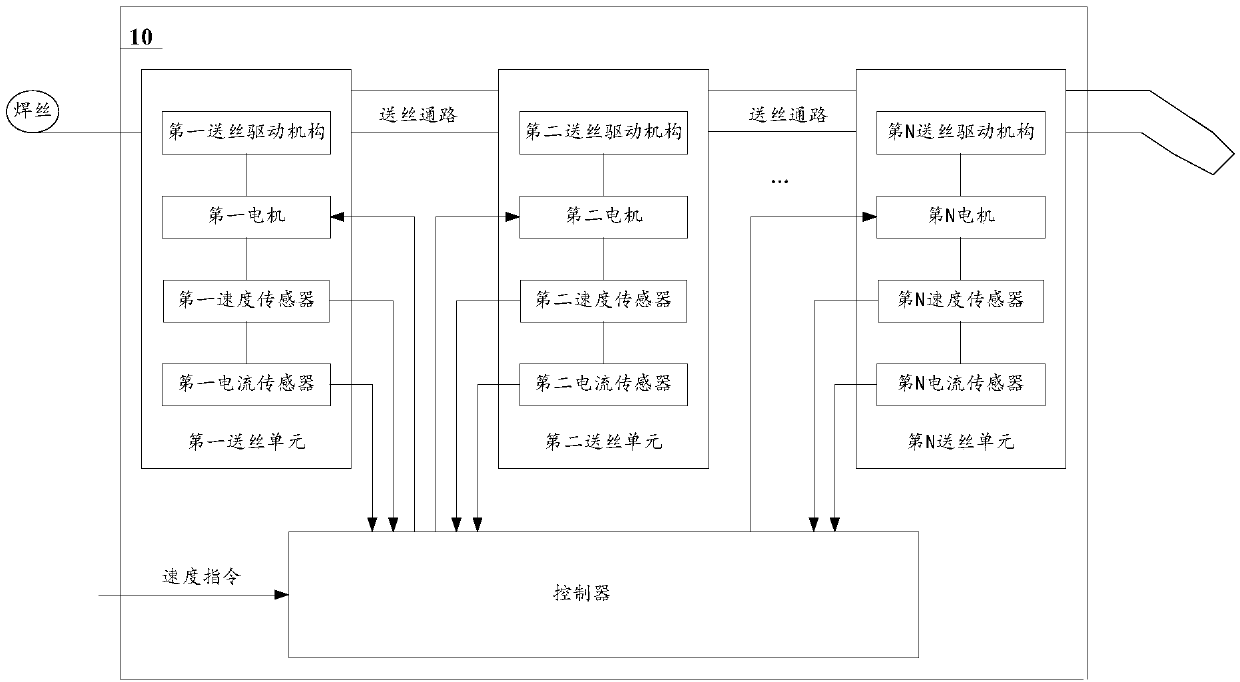

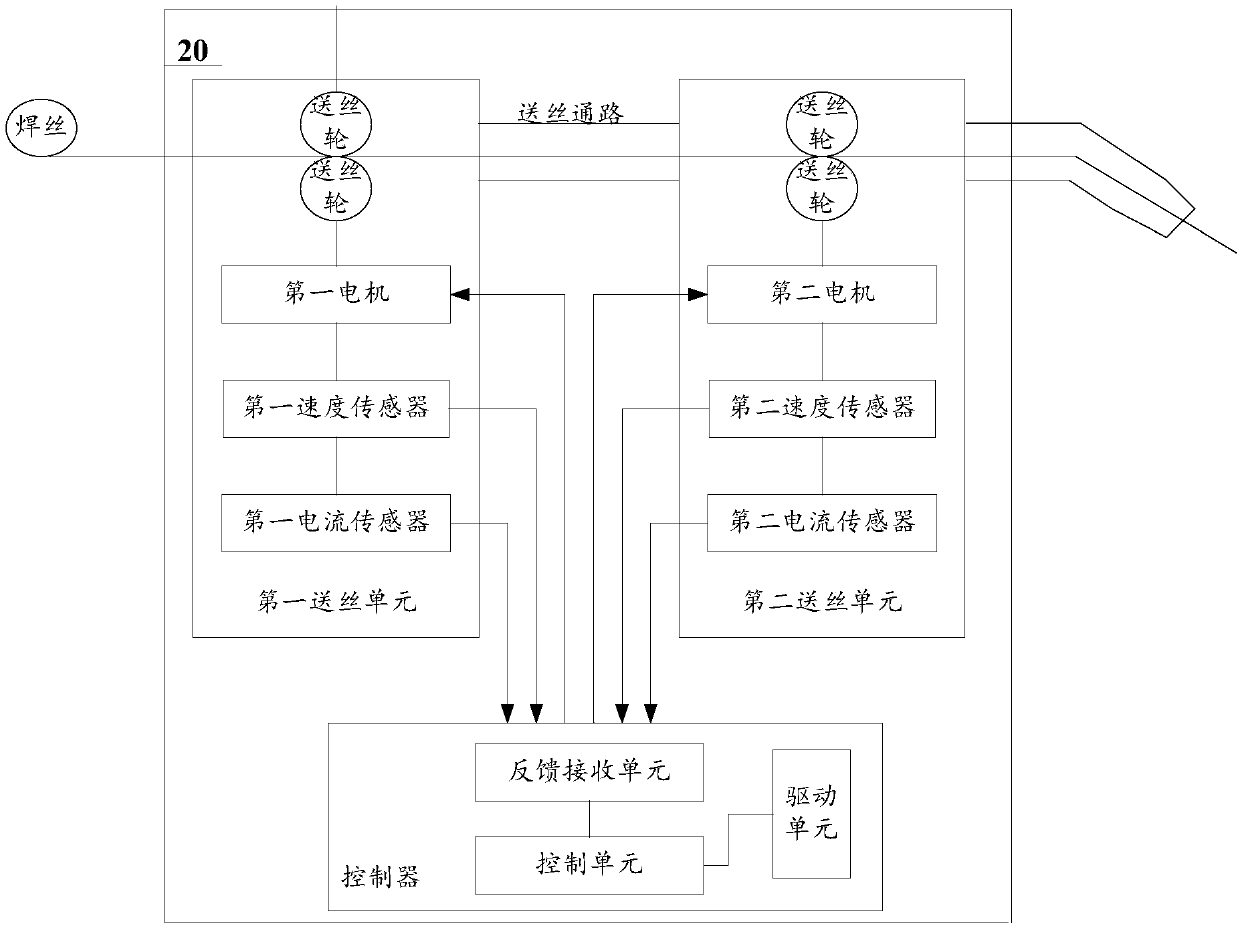

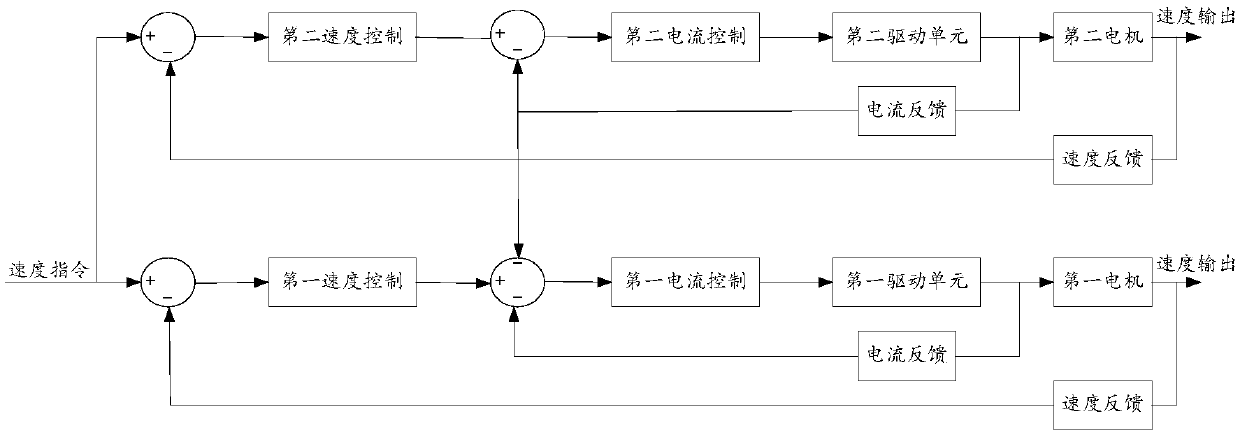

Multi-motor wire feeding control system and method

ActiveCN106891080AConstant speed and smooth operationStable wire feedingArc welding apparatusElectric machineControl system

The invention provides a multi-motor wire feeding control system and method. The multi-motor wire feeding control system comprises a plurality of wire feeding units and a controller; each wire feeding unit comprises a motor, a speed sensor, an electric current sensor and a wire feeding drive mechanism; the speed sensors are used for detecting speed signals of the motors, the electric current sensors are used for detecting electric current signals of the motors, each motor of the corresponding wire feeding unit is provided with a speed ring of the corresponding motor, and the speed rings of all the wire feeding units operate according to the same speed instruction; at least part of the motors in the multiple wire feeding units are provided with electric current rings, and at least part of the electric current rings in the electric current rings are associated with the motor electric currents of the corresponding wire feeding units and the motor electric currents of other at least one wire feeding unit; and the controller controls the motors of all the wire feeding units to perform constant-speed operation according to the speed instruction, the speed signals fed back by all the speed sensors and the electric current signals fed back by all the electric current sensors. By means of the multi-motor wire feeding control system and method, stable wire feeding can be achieved.

Owner:PANASONIC WELDING SYST TANGSHAN

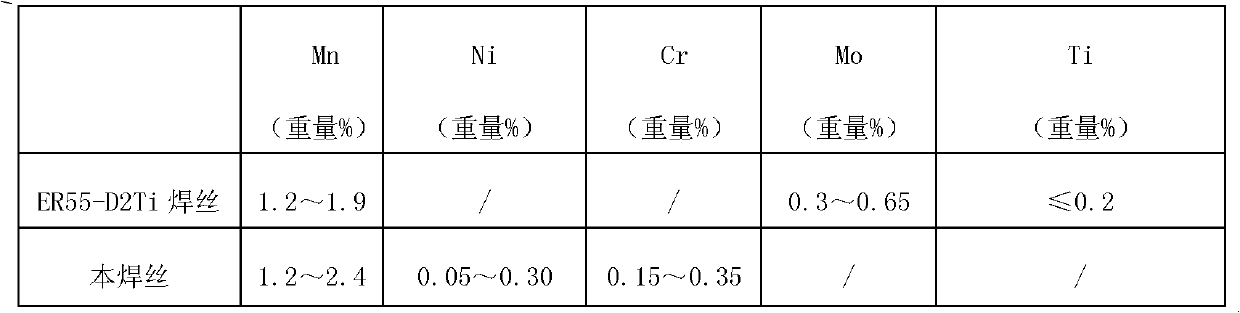

Solid welding wire for high-toughness structural steel

ActiveCN101905393AIncrease contentMeet welding requirementsArc welding apparatusWelding/cutting media/materialsChemical compositionSheet steel

The invention provides a solid welding wire for high-toughness structural steel, which comprises the following chemical components by weight percent: C: 0.06-0.12, Si: 0.4-0.8, Mn: 1.2-2.4, Ni: 0.05-0.30, Cr: 0.15-0.30, S: not more than 0.015, P: not more than 0.020 and the balance of Fe and other unavoidable impurities. As for the solid welding wire for the high-toughness structural steel provided by the invention, yield strength for deposited metal is more than 500MPa and tensile strength is more than 600MPa; after welding, welding seams have beautiful shaping, little splash and low crack sensitivity, thus meeting the welding requirement for a low-alloy high strength steel plate; and relative to an ER55-D2Ti welding wire or a 60kg of welding wire containing Ni-Mo system, the solid welding wire of the invention lowers production cost and use cost on the premise of guaranteeing intensity and impact toughness, thus being suitable for large-scale popularization and application.

Owner:YICHANG MONKEY KING WELDING WIRE

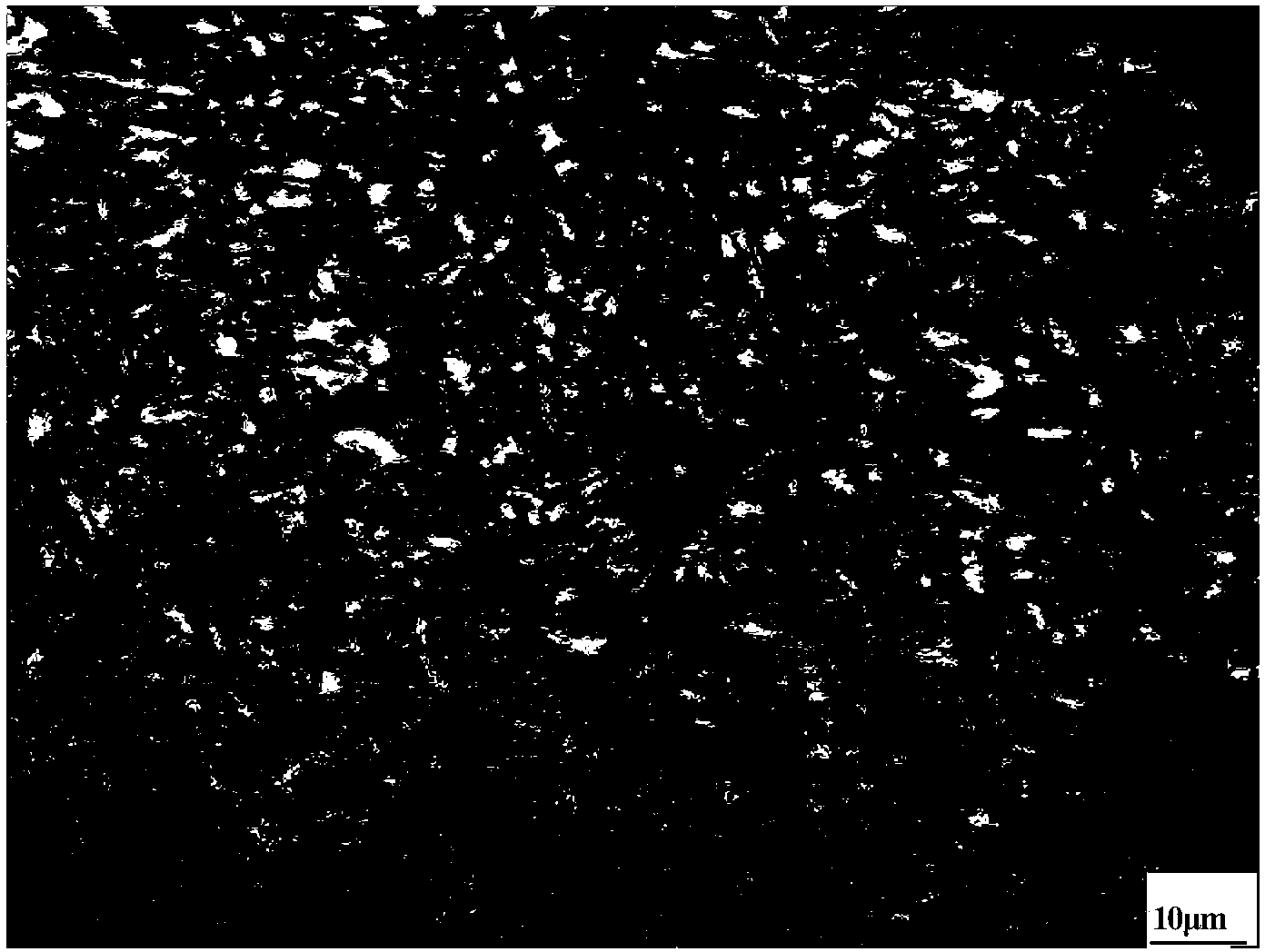

NiCrNb-Re high-temperature-resistance and corrosion-resistance welding wire for ethylene cracking furnace cast pipes and preparation method thereof

InactiveCN109894770AAvoid oxidation burnAvoid welding requirements for high temperature and corrosion resistanceWelding/cutting media/materialsSoldering mediaAcid washingAlloy

The invention discloses a NiCrNb-Re high-temperature-resistance and corrosion-resistance welding wire for ethylene cracking furnace cast pipes and a preparation method thereof, and belongs to the field of welding materials. The welding wire comprises the following components in percentage by weight: 45-50% of Ni, 35-40% of Cr, 1.00-1.50% of Nb, 0.01-0.10% of Re, 0.30-0.55% of C, 0.50-2.00% of Si,1.00-2.00% of Mn, 0.01-0.10% of Al, 0.05-0.20% of Ti, 0.01-0.10% of Zr, and the balance of Fe and inevitable impurities. The preparation method comprises the steps of alloy smelting-electroslag remelting-blooming by hot forging-hot-rolled annealing-mechanical stripping-diameter reduction by drawing-straightening and cutting or precise layer winding. The preparation method is environmentally friendly, free of acid washing pollution, stable in welding arc, free of splashing, beautiful in welding line molding, excellent in welding process and mechanical performance and dense in welding line structure, and can totally meet high-temperature-resistance and corrosion-resistance welding requirements of the ethylene cracking furnace cast pipes.

Owner:DANYANG XINHANG SPECIAL ALLOY

Narrow gap tungsten electrode argon arc welding technology method for thick plate

ActiveCN111618402APlay a binding rolePlay a buffer roleWelding accessoriesLaser rangingAC - Alternating current

The invention relates to a narrow gap tungsten electrode argon arc welding technology method for a thick plate, belongs to the technical field of narrow gap welding, utilizes narrow gap tungsten electrode argon arc welding equipment, and adopts a non-axisymmetric tungsten electrode rotation way to carry out the automatic welding of an ultra-thick plate (0-300 mm) and a narrow gap (4-10 mm). The narrow gap tungsten electrode argon arc welding technology method comprises the following steps of: (1) arranging a groove, and carrying out groove processing; (2) clamping the narrow gap tungsten electrode argon arc welding equipment; (3) installing the tungsten electrode, and carrying out equipment programing; (4) positioning: moving the tip of the welding gun tungsten electrode to the bottom of the center of a welding line, enabling a gas hood to be covered above the welding line, and then, through laser distance measurement, carrying out second positioning; (5) carrying out welding line backing weld: in a welding process, carrying out arc pressure and laser tracking to guarantee that the tungsten electrode is centered, utilizing an alternating current pulse hot filament TIG (Tungsten Inert Gas Welding) technology, and regulating welding current and pulse frequency to accurately control the heat input of the welding line; (6) carrying out layered filling weld; and (7) carrying out cosmetic weld. Compared with common tungsten electrode argon arc welding, the narrow gap tungsten electrode argon arc welding technology method disclosed by the invention greatly increases weldable platethickness and improves production efficiency and production quality.

Owner:SHANDONG UNIV +1

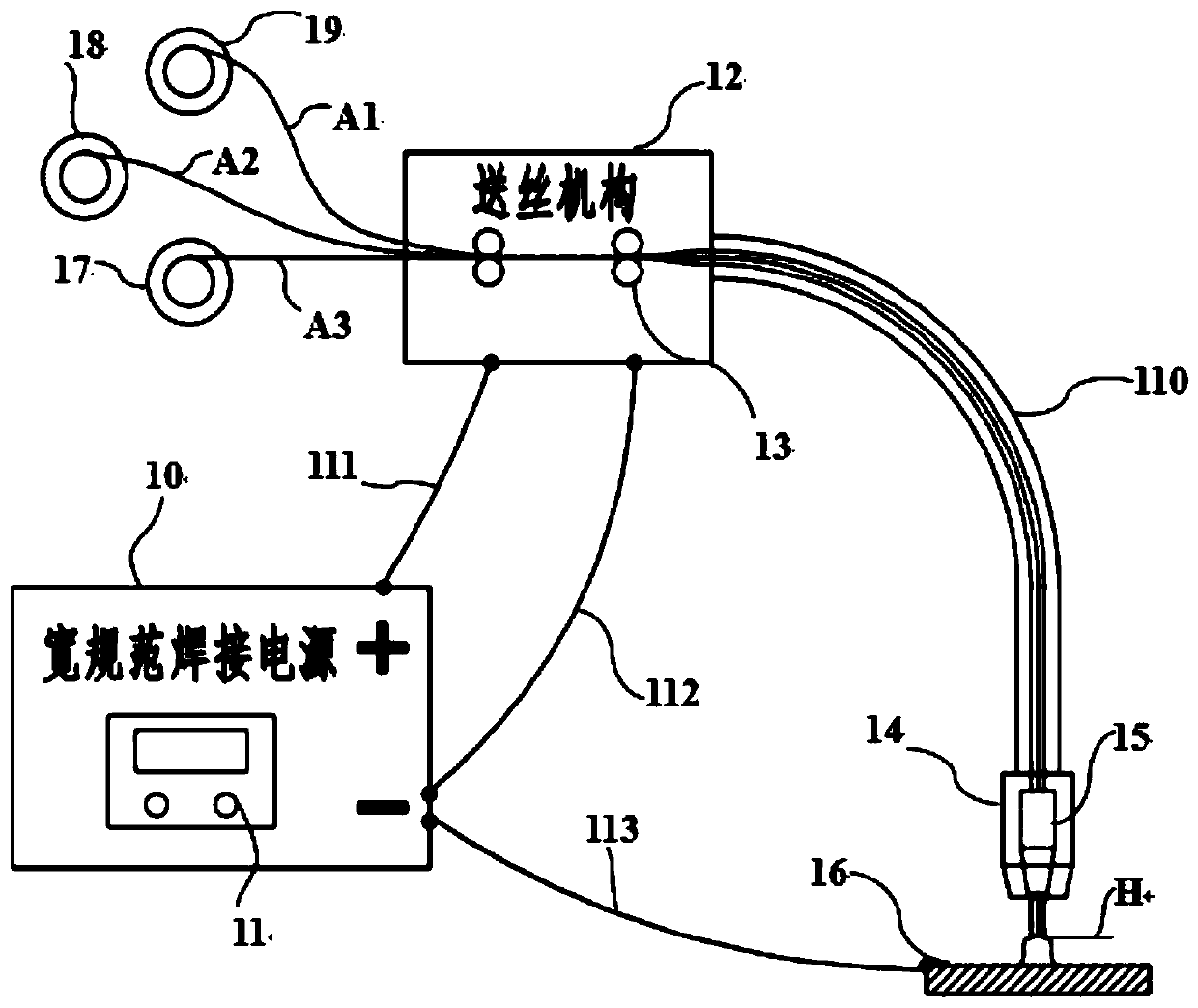

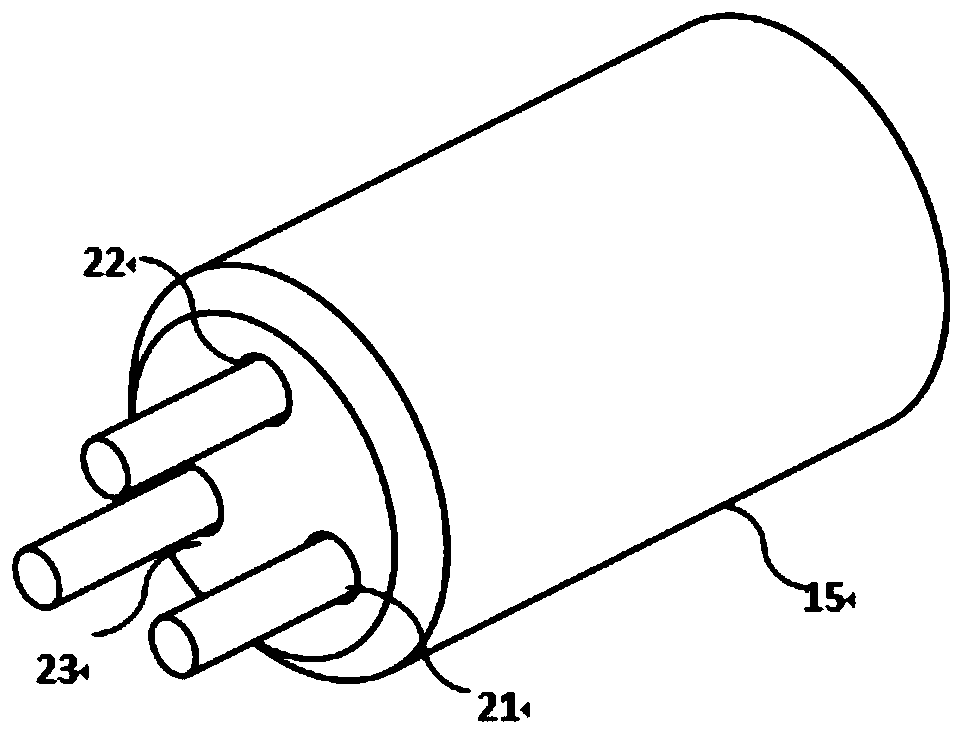

Parallel tri-wire welding system and method

PendingCN110125518ASame sizeNo arcing problemsArc welding apparatusWelding power supplySemi automatic

The invention discloses a parallel tri-wire welding system and method. The welding system comprises a wide-range welding power supply, a wire conveying mechanism with a tri-slot wire conveying wheel and a welding gun with a tri-hole conductive nozzle, wherein three welding wires are simultaneously conveyed to the welding gun through the wire conveying mechanism and separately penetrate through three independent holes which are distributed in the conductive nozzle at certain intervals; and welding waveforms output by the welding power supply are supplied to the welding wires through the conductive nozzle, and welding is carried out by simultaneously using the three wires. After the bottom ends of the three wires are molten, molten drops attract each other under electromagnetic action, and the molten drops stably and smoothly flow into a molten bath. The single-power-supply and parallel-tri-wire system has the advantages that the welding efficieny is increased, electric arc shapes and weld penetration size and contours are improved, welding flaws are reduced, and mechanical strength is improved; and at the same time, the three welding wires are stably conveyed by one wire conveying mechanism and go through one conventional welding gun, the operation is convenient, the reaching range of the welding gun is great, and manual, semi-automatic and robot welding demands can be simultaneously met.

Owner:AOTAI ELECTRIC

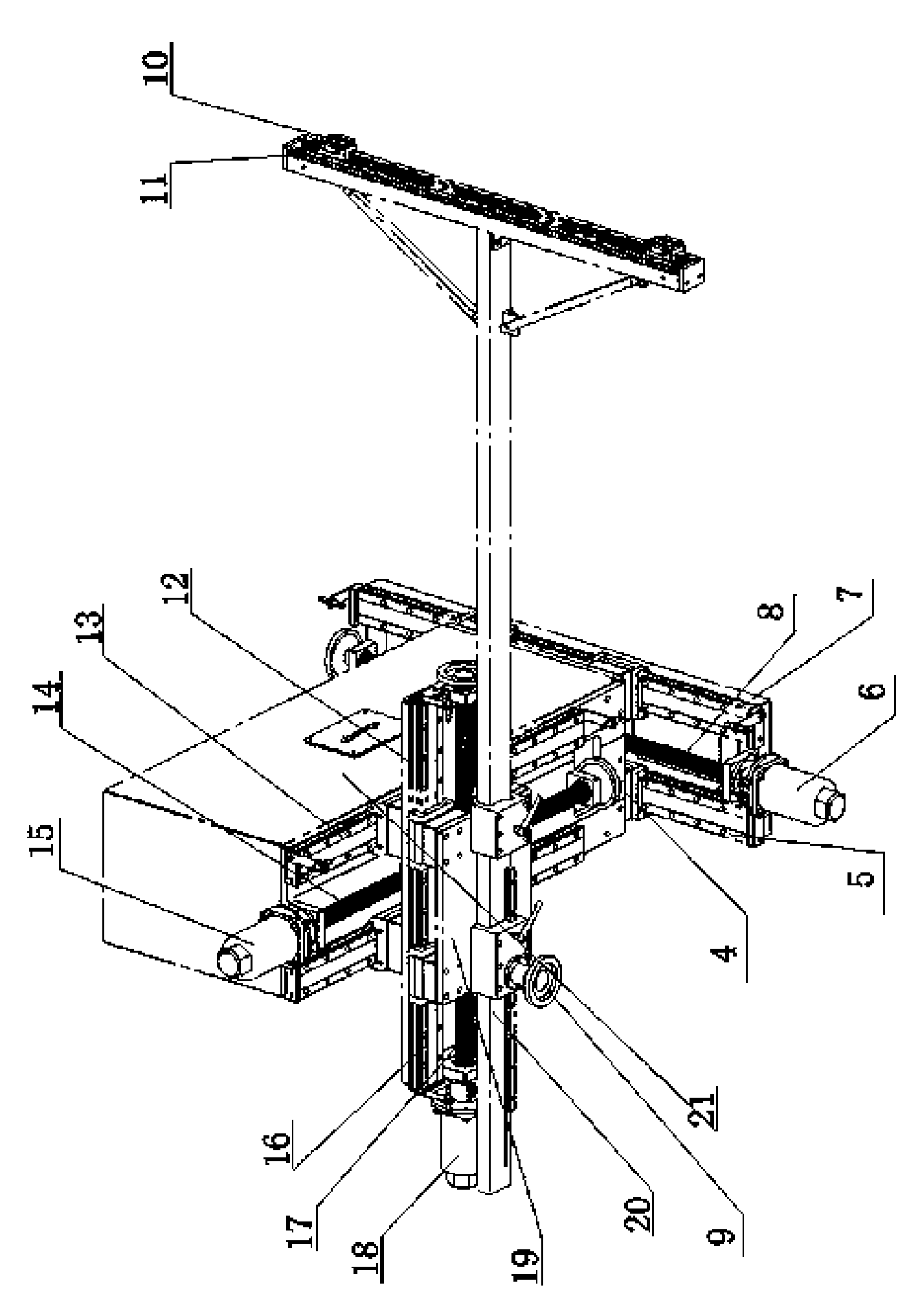

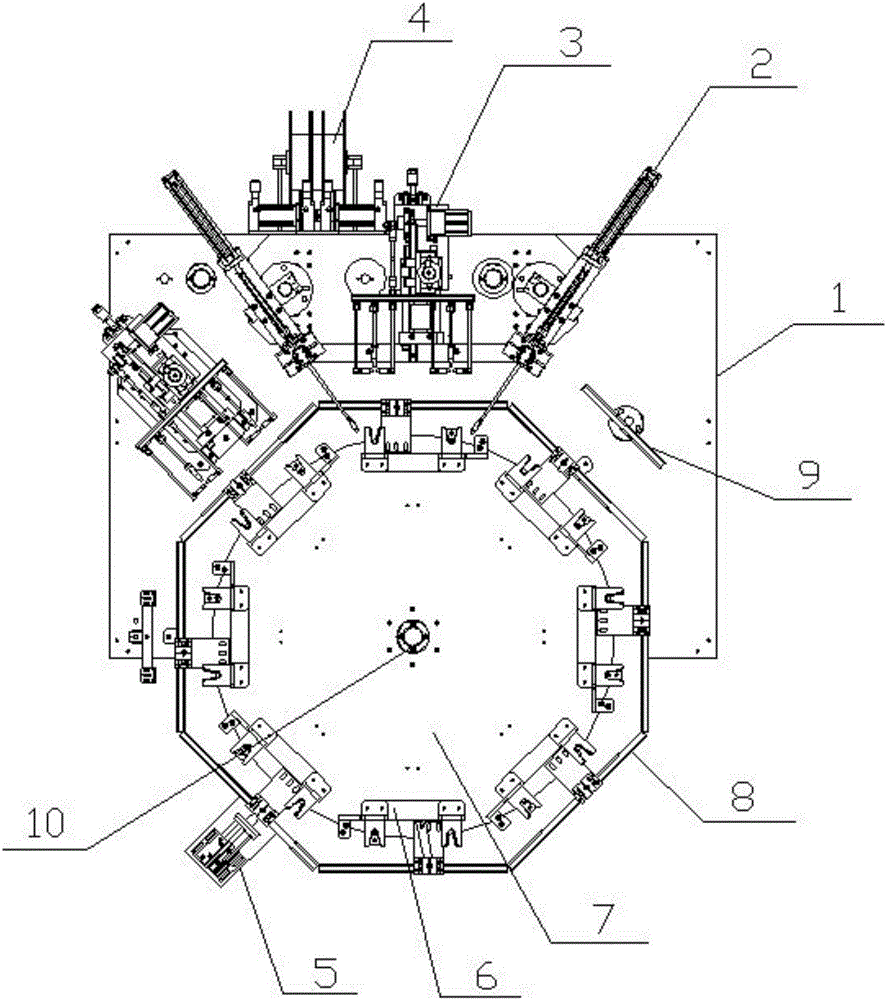

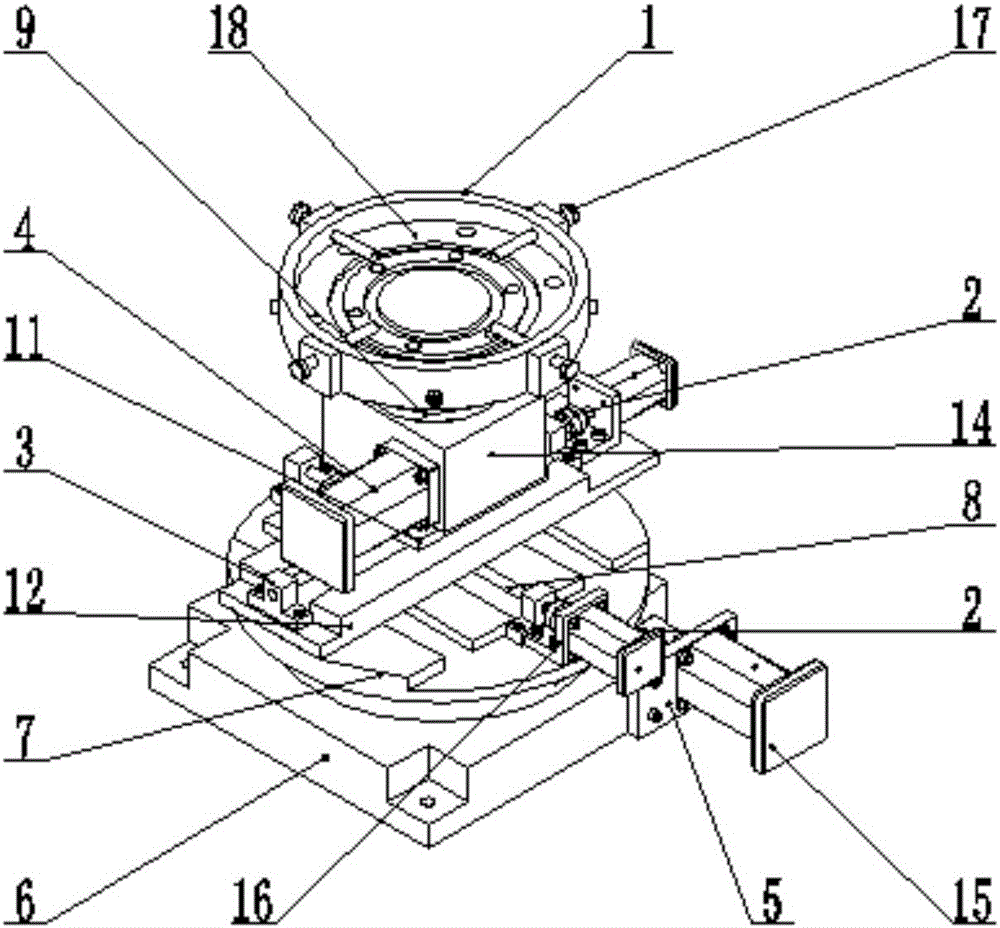

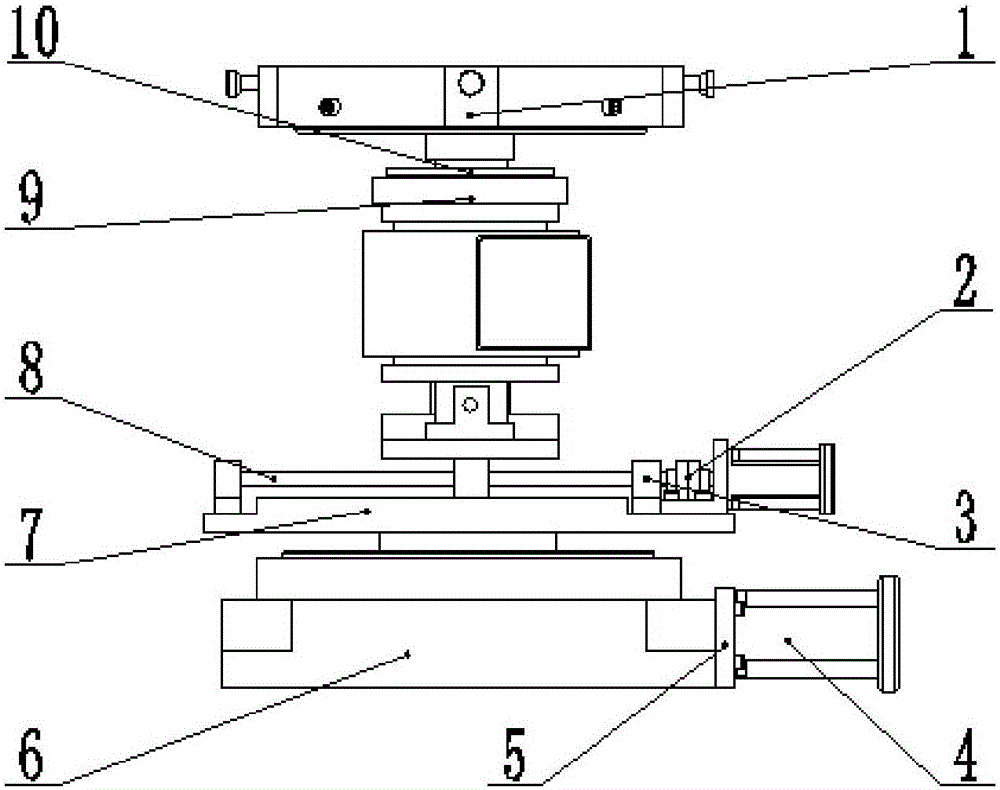

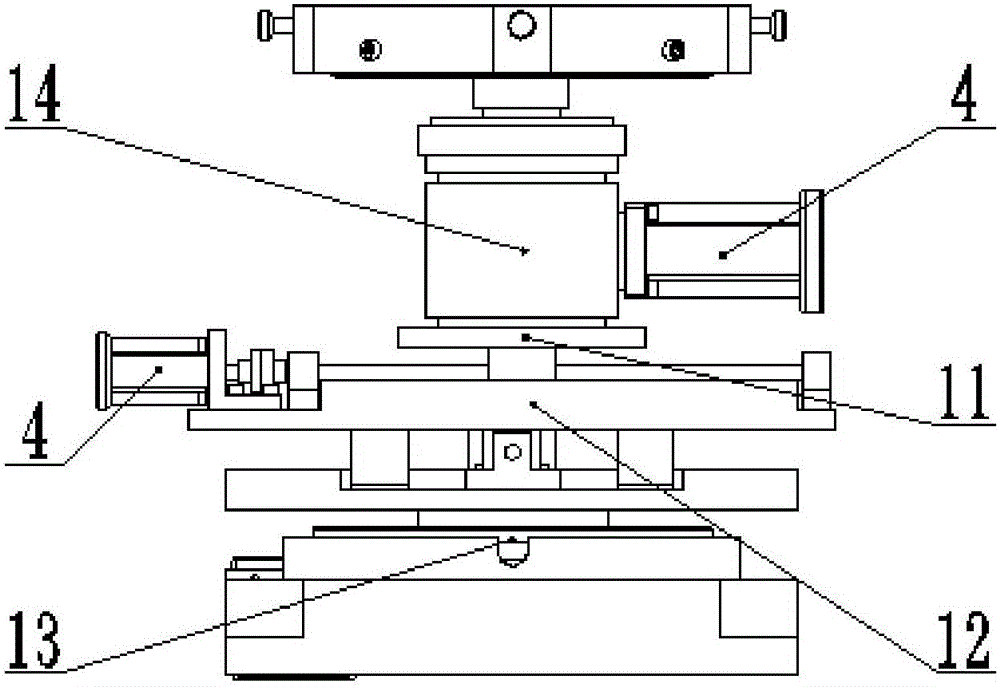

Wireless-control-based four-degree-of-freedom TIG automatic surfacing rotary workbench

ActiveCN105855667AGuaranteed stabilityStable wire feedingArc welding apparatusWireless controlCoupling

The invention discloses a wireless-control-based four-degree-of-freedom TIG automatic surfacing rotary workbench which comprises a Y-axis moving platform and an X-axis moving platform. The Y-axis moving platform is stacked on the upper surface of the X-axis moving platform, a worm-gear speed reducer is fixed on the top face of the Y-axis moving platform, a screw shaft is arranged at the bottom of the Y-axis moving platform, two ends of the screw shaft are fixed on a screw shaft fixing seat, a servo motor is fixed on the side face of the worm-gear speed reducer, the servo motor and a worm shaft inside the worm-gear speed reducer are fixedly connected through a coupler, a turnplate disc is fixed on the top face of the worm-gear speed reducer, the bottom of the X-axis moving platform is fixed on a base turnplate disc, a screw shaft is arranged at the bottom of the X-axis moving platform, two ends of the screw shaft are fixed on a screw shaft fixing seat, and the servo motor on the Y-axis moving platform and a servo motor at the bottom of the X-axis moving platform are in cross distribution. Motion of the servo motors of the degrees of freedom is controlled wirelessly to be in synthesis motion, and shape tracks of needed surfacing complex parts can be synthesized.

Owner:航天科工哈尔滨风华有限公司

Multi-pass continuous drawing method for medical stainless steel ultrafine wire

ActiveCN111346941ASmall size uniform deviationStable wire feedingDrawing diesSolution treatmentSurface finish

The invention discloses a multi-pass continuous drawing method for a medical stainless steel ultrafine wire. The method comprises the following steps that (1) a stainless steel fine wire blank of phi0.8mm is subjected to coating treatment; (2) the stainless steel fine wire blank subjected to coating treatment in the step (1) is subjected to primary cold drawing, and a stainless steel ultrafine wire is obtained; (3) the stainless steel ultrafine wire in the step (2) is subjected to online coating removal treatment and online solid solution treatment; and (4) the stainless steel ultrafine wiresubjected to online coating removal treatment and online solid solution treatment in the step (3) is subjected to secondary cold drawing and online oil removal treatment, and the medical stainless steel ultrafine wire with a bright surface is obtained. The obtained medical stainless steel ultrafine wire has the advantages of being high in strength, good in toughness and good in corrosion resistance, sizes are uniform, deviation is small, the surface brightness is high, the bright surface with metal luster is shown, the requirements of the medical stainless steel ultrafine wire are completely met, production efficiency is high, and the medical stainless steel ultrafine wire is suitable for large-scale production.

Owner:宝鸡华沃新材料有限公司

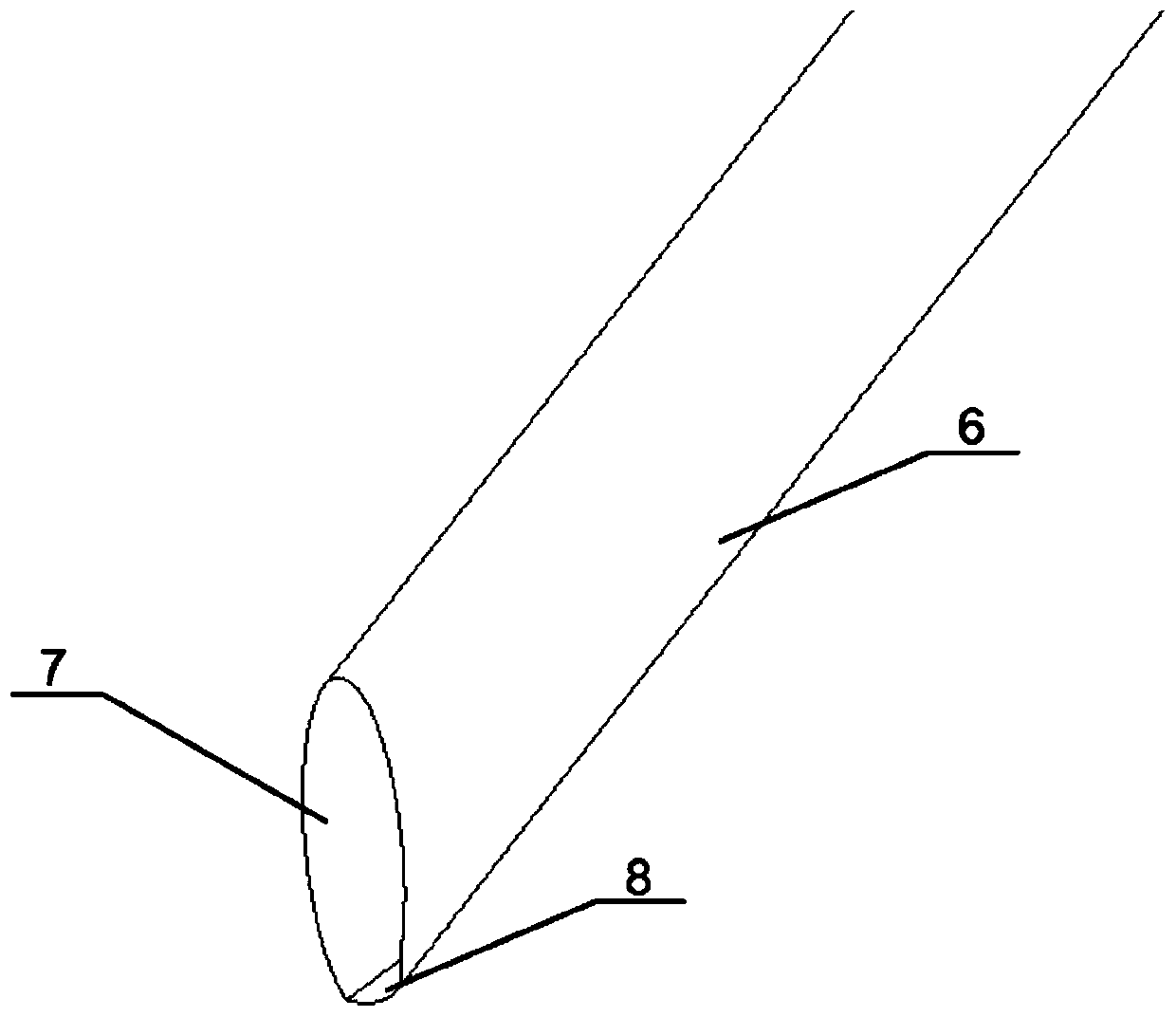

GTAW welding system and method suitable for ultra-narrow gap

ActiveCN110977109ALow heat inputReliable fusionShielding gas supply/evacuation devicesRotational axisWelding power supply

The invention relates to a GTAW welding system and method suitable for an ultra-narrow gap, and belongs to the technical field of narrow gap welding. The system comprises an argon arc welding power supply, a TIG welding gun, a welding trolley, a wire feeding device and a gas protection device; the TIG welding gun comprises a rotating motor, a rotating tungsten electrode, a conductive system and anair supply system; the rotating motor drives the rotating tungsten electrode to rotate through a central rotating shaft, the rotating tungsten electrode is a non-axisymmetric tungsten electrode, theconductive system is used for being connected with an argon arc welding power source and providing electric power, and the air supply system is used for providing shielding gas for the interior of thewelding gun; the TIG welding gun is fixedly arranged on the welding trolley and is driven by the welding trolley to move; the wire feeding device and the welding gun synchronously move; the gas protection device is a shell and covers a workpiece to be welded. The system can be suitable for ultra-narrow gaps with the gaps being less than 6 mm, electric arcs are stably combusted in the welding process, the side wall is effectively fused, heat input can be reduced, and the system is suitable for all-position welding and high in practicability.

Owner:SHANDONG UNIV

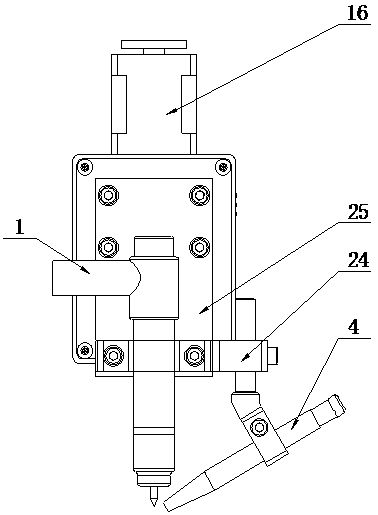

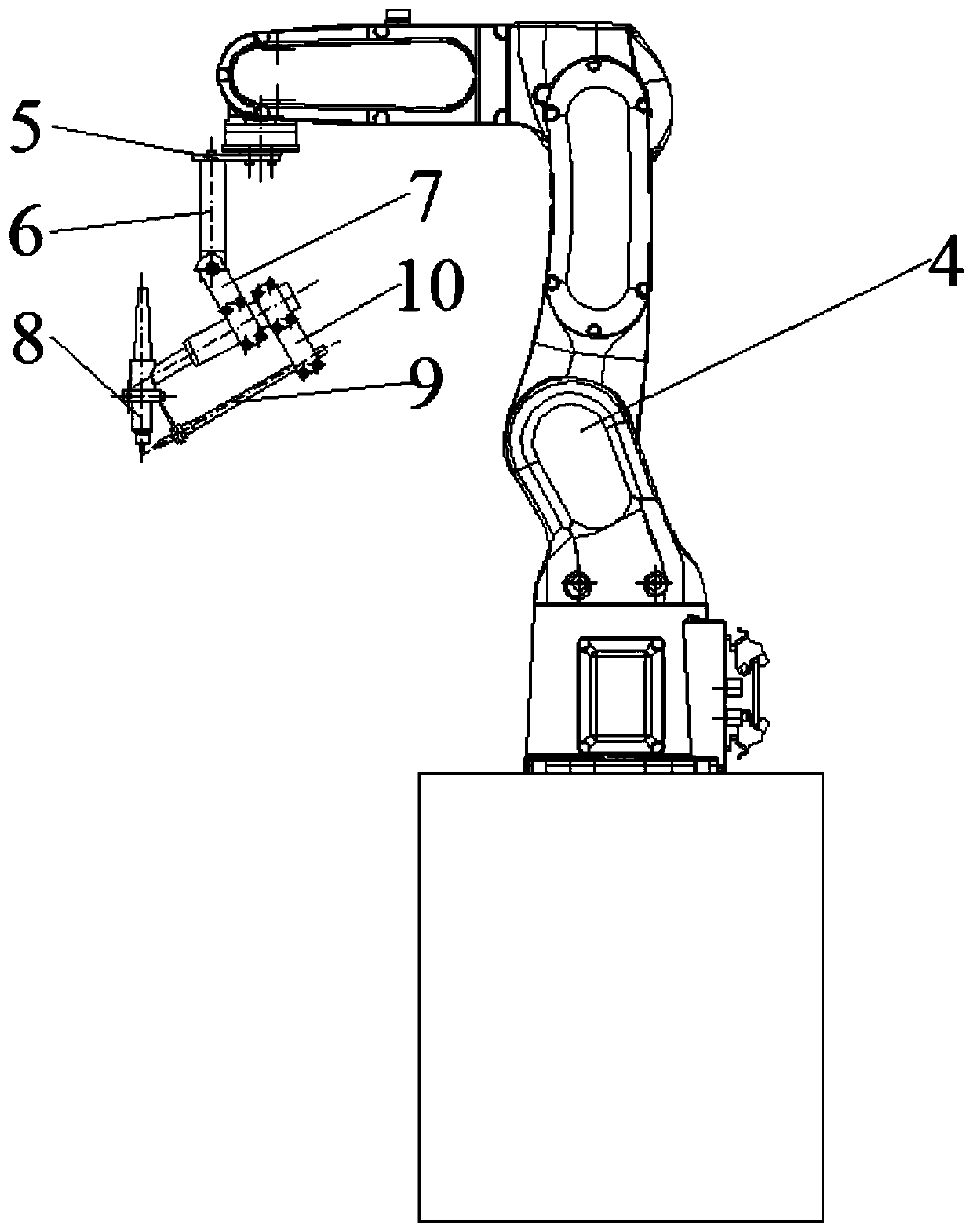

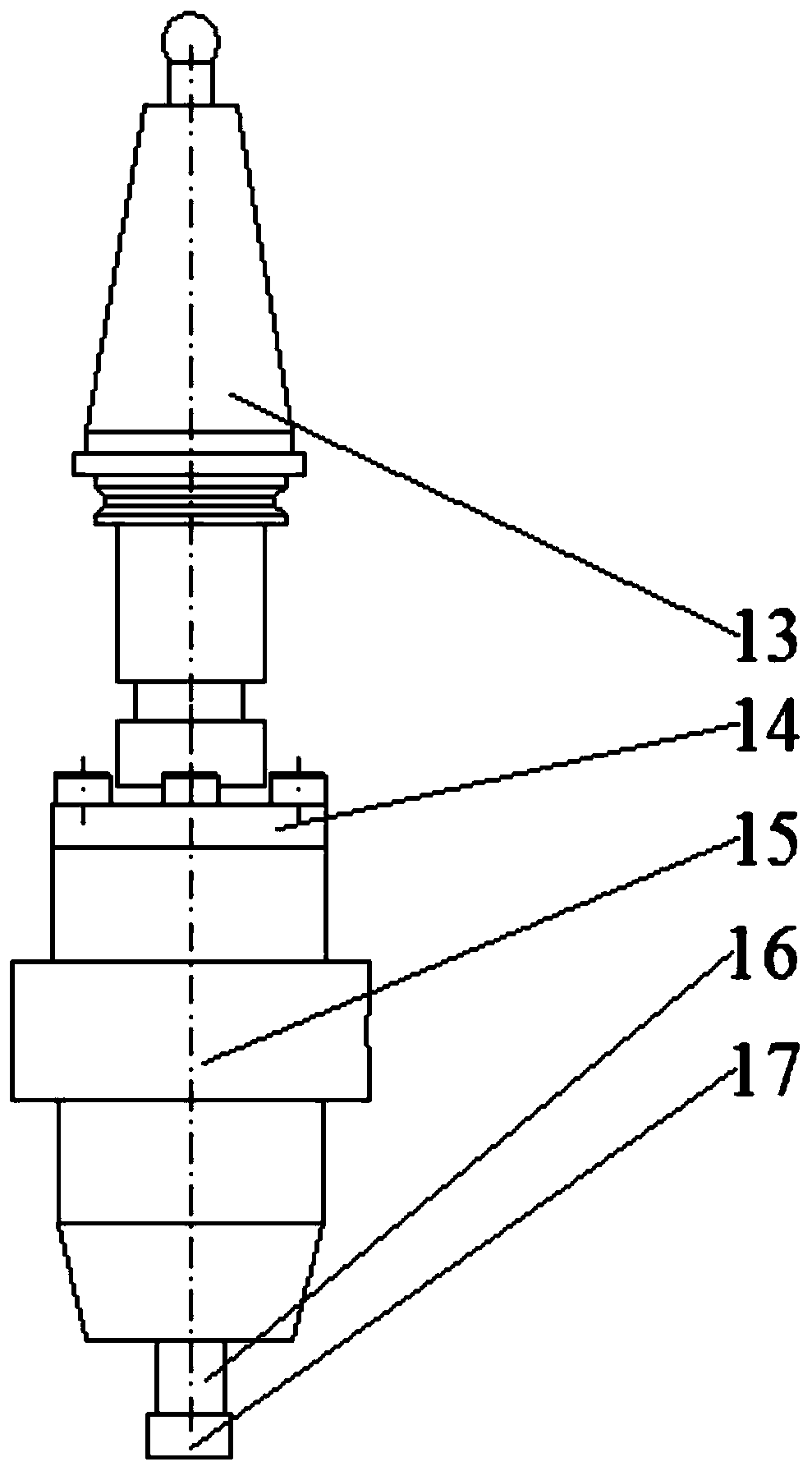

Arc additive manufacturing and forging-milling composite machining forming device and method

ActiveCN110744303AConvenient side weldingConvenience needsAdditive manufacturing apparatusWelding/cutting auxillary devicesNumerical controlRobotic arm

The invention belongs to the field of metal additive manufacturing, and relates to an arc additive manufacturing and forging-milling composite machining forming device and a method. The composite machining forming device comprises a manipulator arc additive manufacturing unit, a stroke-limiting high-frequency forging modification unit and a numerical control milling finish machining unit, the manipulator arc additive manufacturing unit comprises a manipulator, a connecting plate, a cylindrical clamp, insulating blocks, a welding gun, a wire feeding pipe and wire feeding pipe clamps, the wire feeding pipe is fixed to a welding gun handle through the two ladder type wire feeding pipe clamps, and the wire feeding pipe is parallel to the welding gun handle so that the fact that wire feeding iscarried out smoothly can be ensured. The welding gun is clamped through the two insulating blocks, so that not only the isolating insulation between the manipulator and the welding gun, but also thewelding gun rotates around the handle. The arc additive manufacturing and forging-milling composite machining forming device and the method is a integrated manufacturing equipment and integrates additive manufacturing, equal material modification and material reducing finish machining, a machining center is taken as a base, a forging device is added and cooperates with the manipulator, so that therapid integration of each module is realized, the manufacturing efficiency is improved and the automation degree is high.

Owner:JIANGNAN UNIV

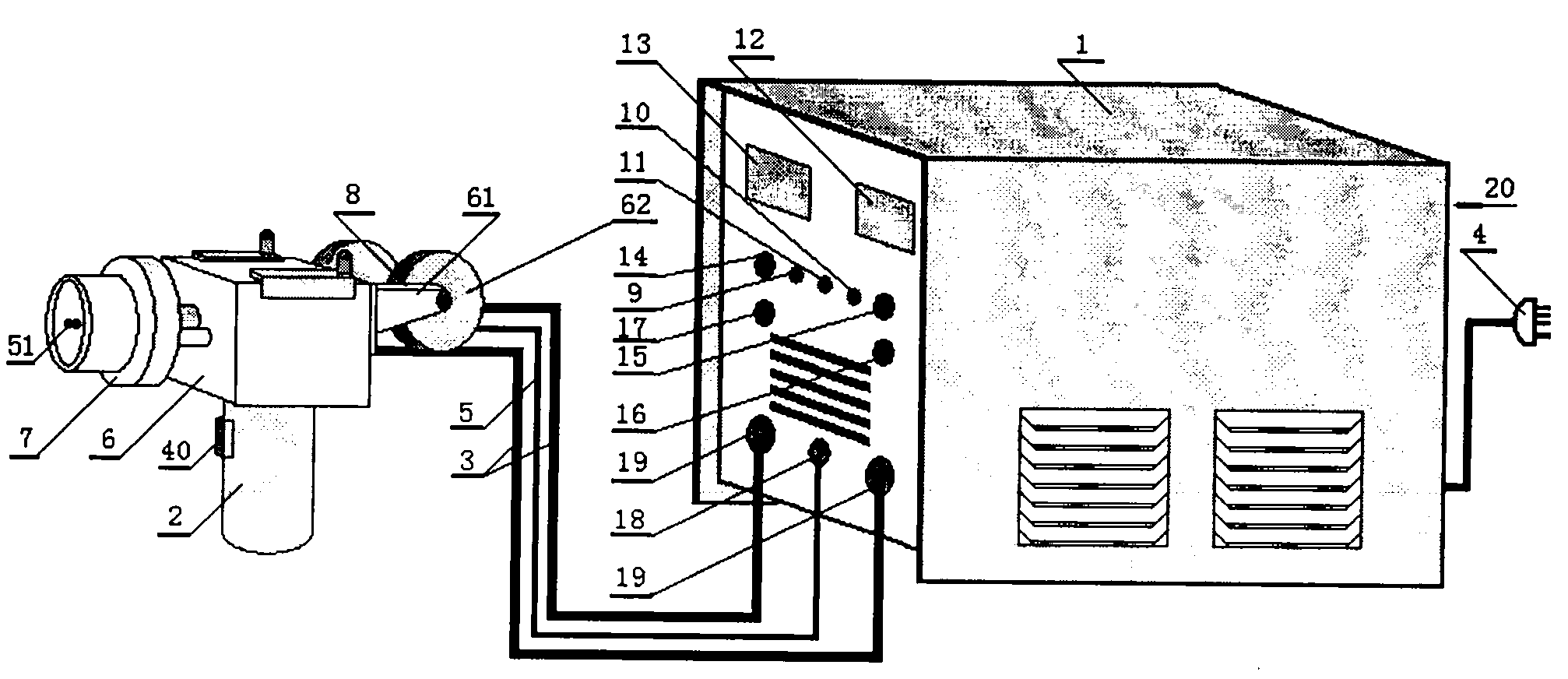

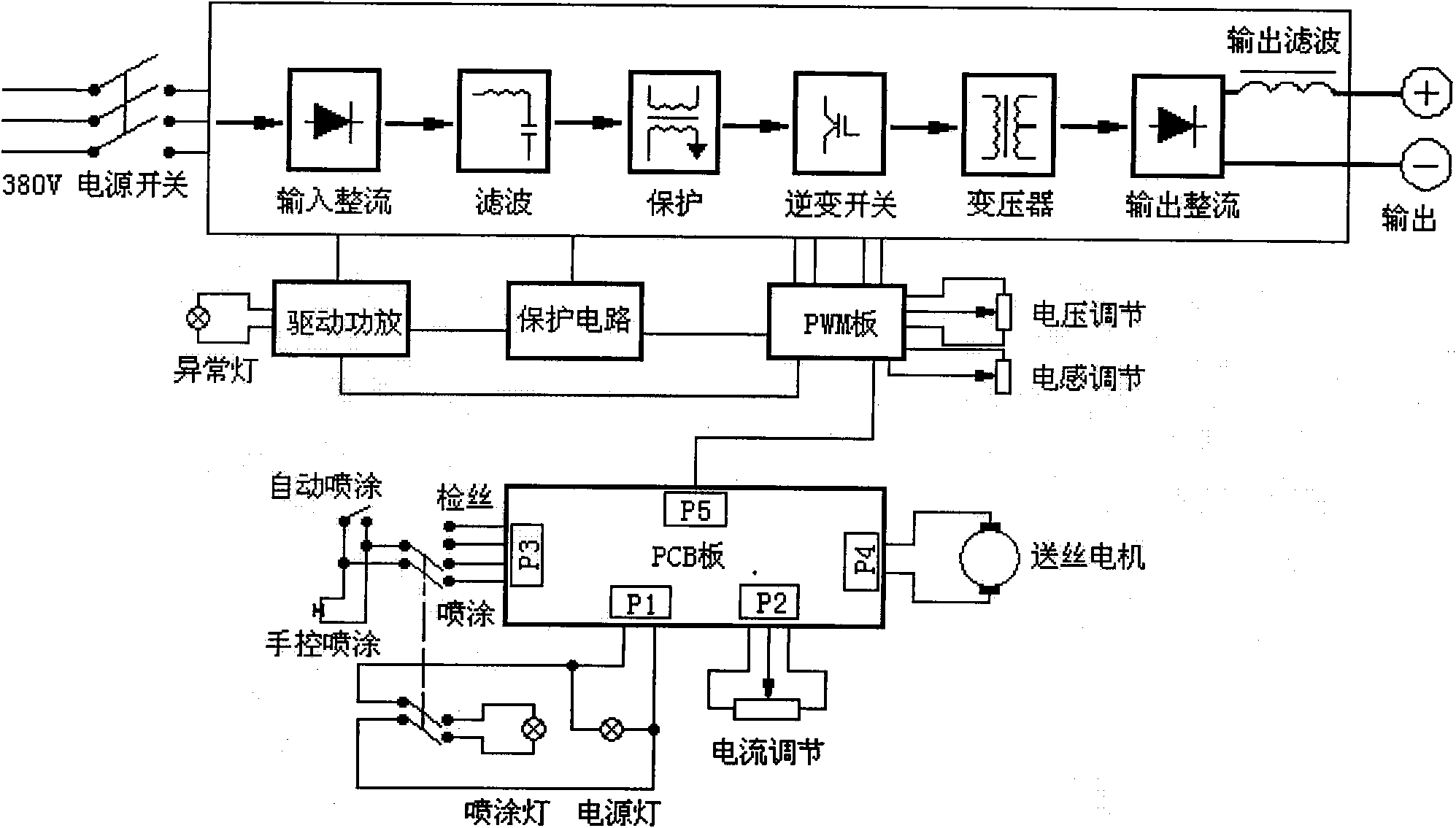

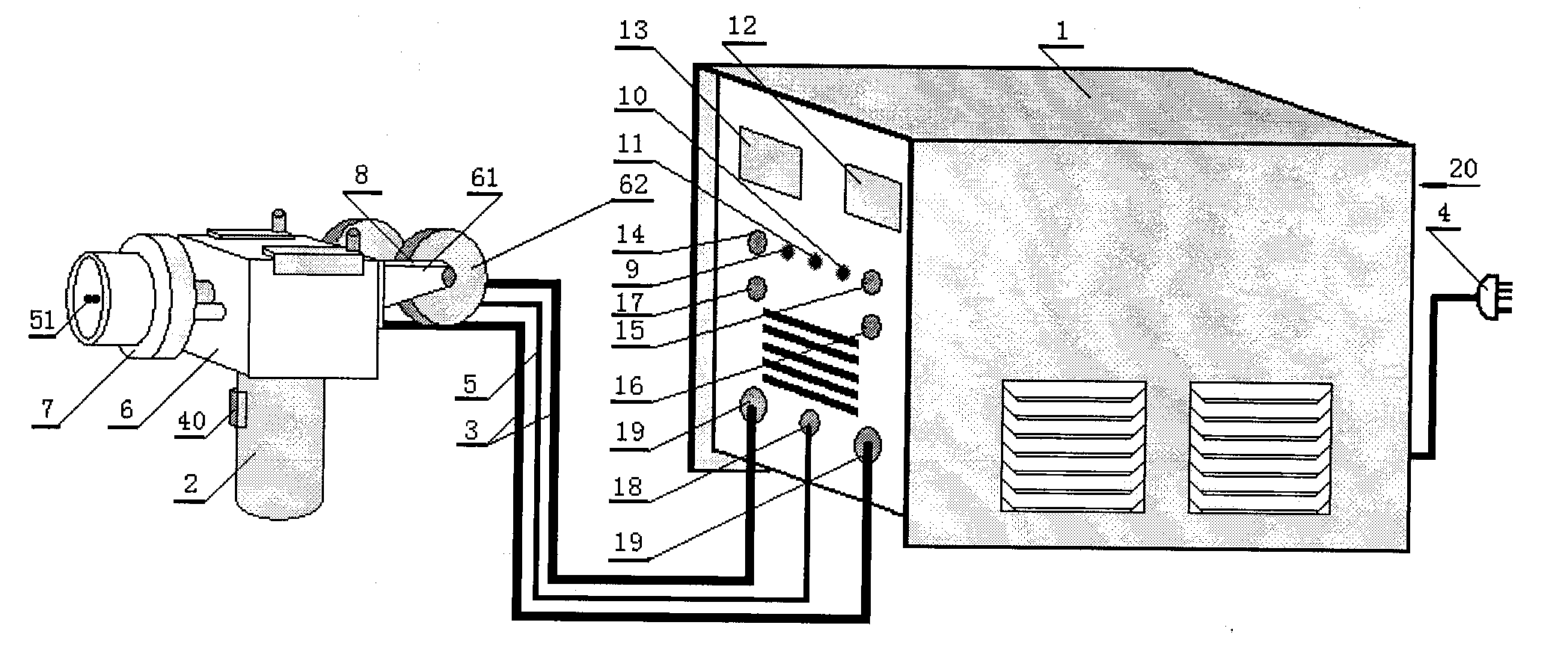

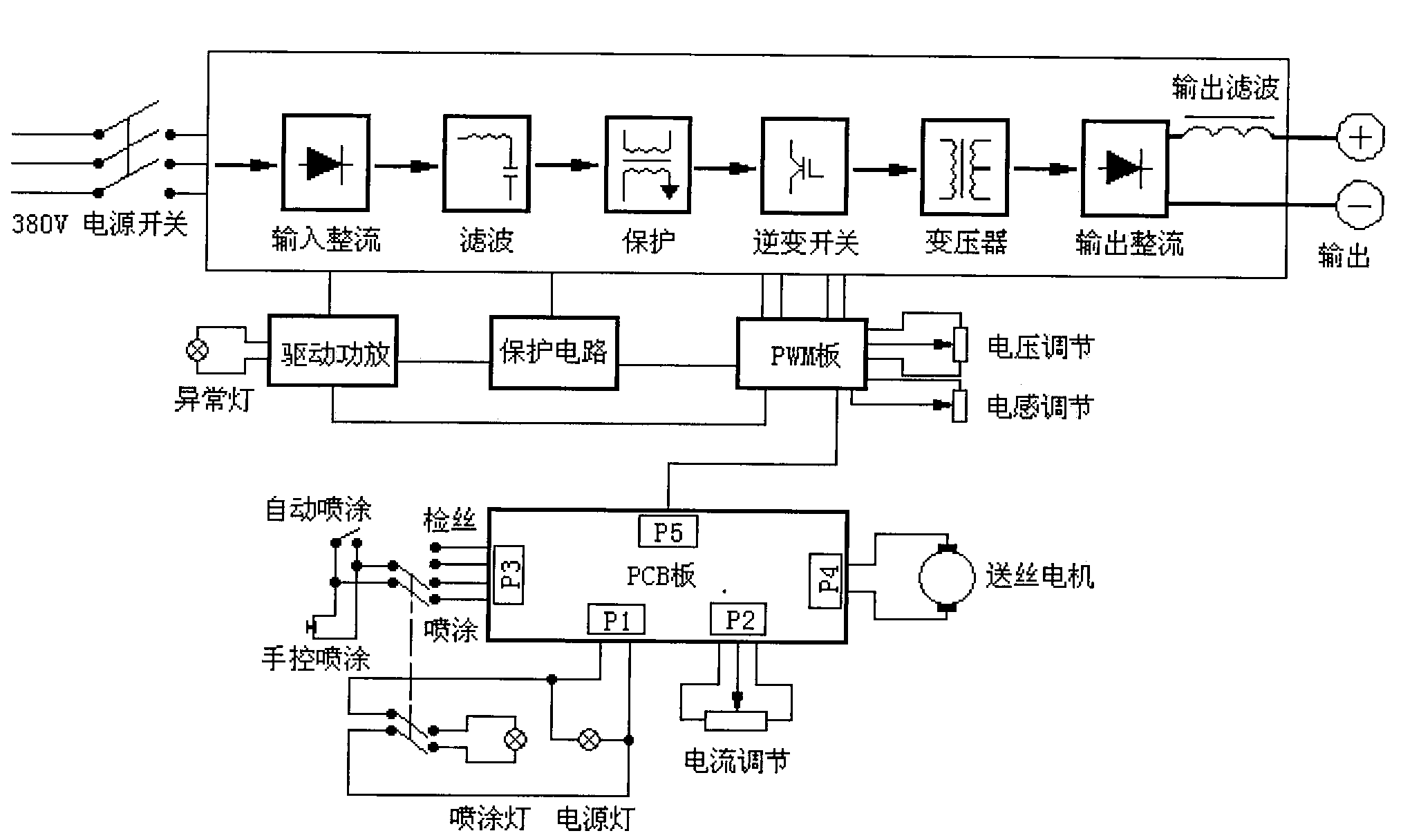

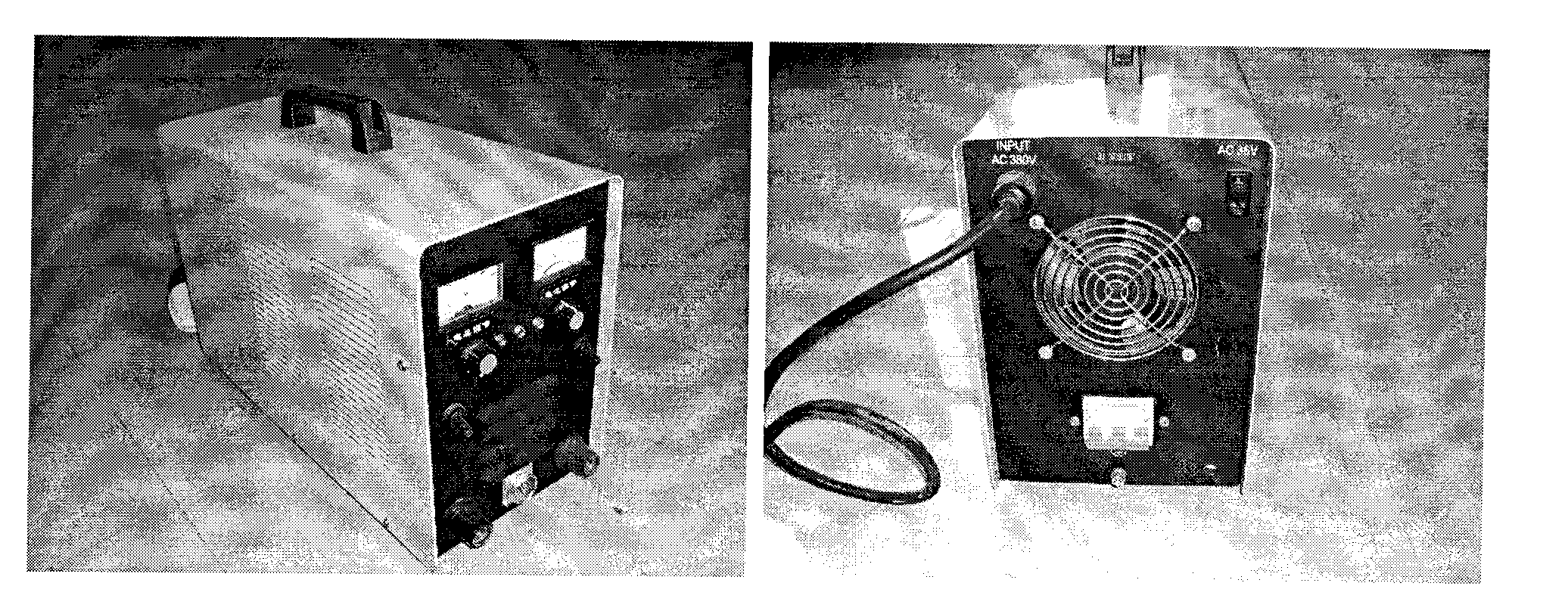

Small-sized wire drawing type electric arc spraying equipment

ActiveCN101864549AReduce volumeReduce weightMolten spray coatingElectric arc sprayingThermal sprayingPower flow

The invention relates to small-sized wire drawing type electric arc spraying equipment used for hot spraying, which is shown in the attached drawing of the abstract. The equipment adopts the technical scheme of an inversion type spraying power supply and a wire drawing type spraying gun, the output voltage of 10 to 40V is regulated in a stepless way, and the voltage can be regulated in the spraying process without stop; a manual / automatic spraying and wire inspection / spraying switch is arranged, which is convenient to select an operation mode and avoid the occurrence of the condition that electric arcs injure people and damage equipment because of the short circuit of a wire material when the spraying wire material is installed, regulated and inspected; the spraying wire material is limited to be phi 1.0 to phi 1.6mm, the maximum spraying current is 250A, the load duration rate is 100 percent, and continuous spraying is permitted; the weight of the spraying power supply is 15kg, and the weight of the spraying gun is 1.5kg; and the equipment has the characteristics of small volume, light weight, convenient carrying, safe and reliable equipment performance, convenient use, simple operation, stable spraying quality and the like, is suitable for the field operation and the use in an occasion with small spraying space and is suitable for spraying a component with a fine and small structure and a product with a fine coating.

Owner:慈溪光华金属复合材料有限公司

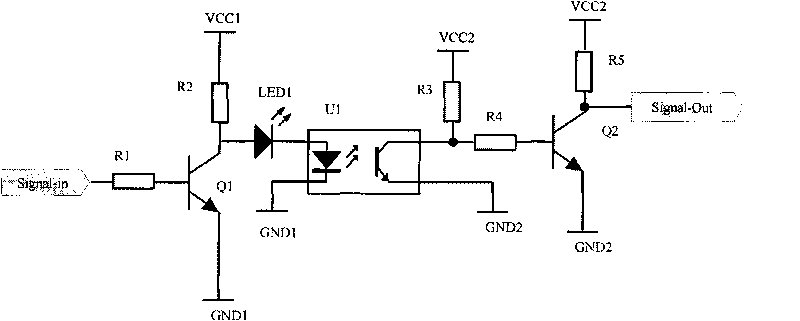

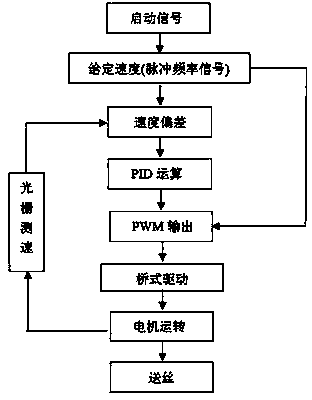

Wire-feeding speed regulating system

ActiveCN104209634AGuaranteed appearance moldingMatch wire feed speedArc welding apparatusGratingControl signal

The invention belongs to the technical field of welding, and particular relates to a wire-feeding speed regulating system. According to the wire-feeding speed regulating system, a control system is adopted, a DSP (Digital Signal Processor) chip serves as a core of the control system, a pulse frequency signal in accordance with a wire-feeding speed is obtained through the speed measure feedback of a grating and is compared with an input speed giving signal to obtain an operation result, the operation result is output through a PWM (Pulse-Width Modulation) circuit, a PWM pulse-width control signal of which the frequency is 20KHz is output to a bridge-type driving circuit, the rotating speed of a motor is timely adjusted to adjust the wire-feeding speed, the operations are cyclically performed in sequence, and therefore the stability of the wire-feeding speed is guaranteed. The wire-feeding speed regulating system has the advantages that matching of the wire-feeding speed and welding parameters is realized; when the wire-feeding speed is abnormal, the wire-feeding speed is timely adjusted, the effect of feeding wires stably is achieved, and the appearance forming of a welding seam is guaranteed.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

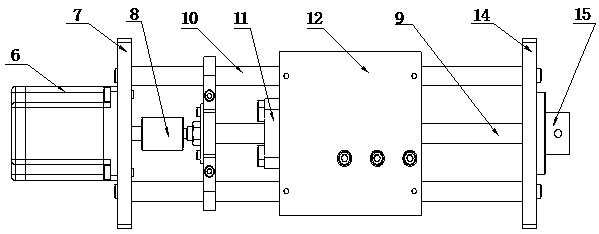

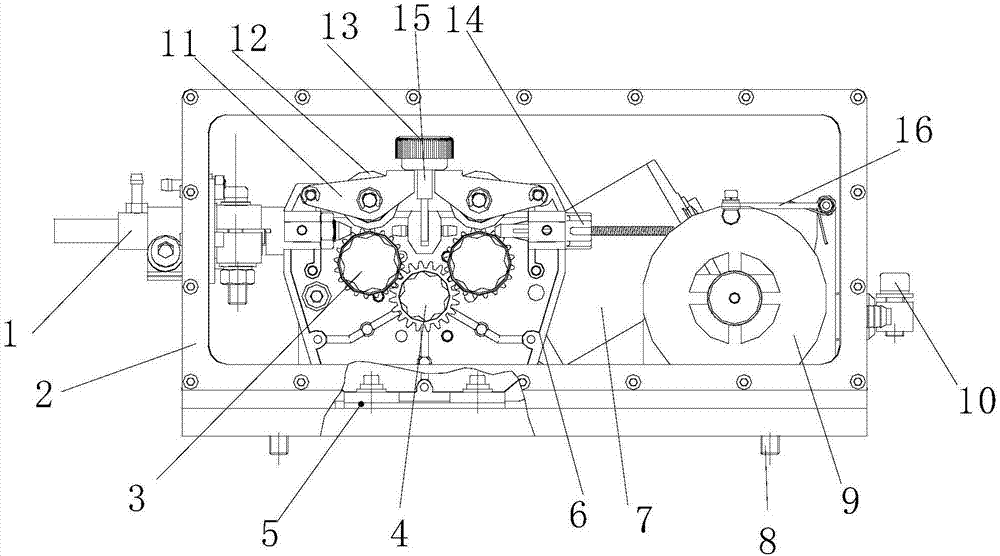

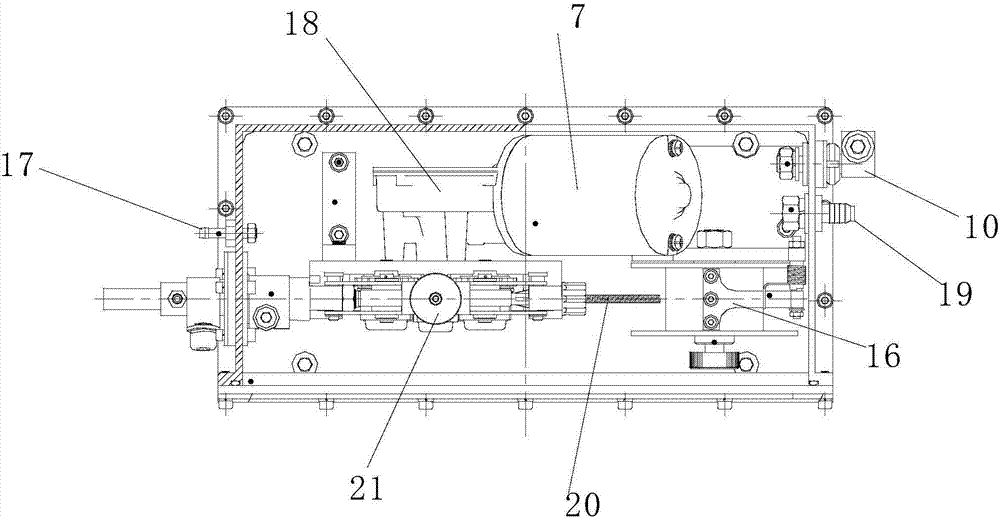

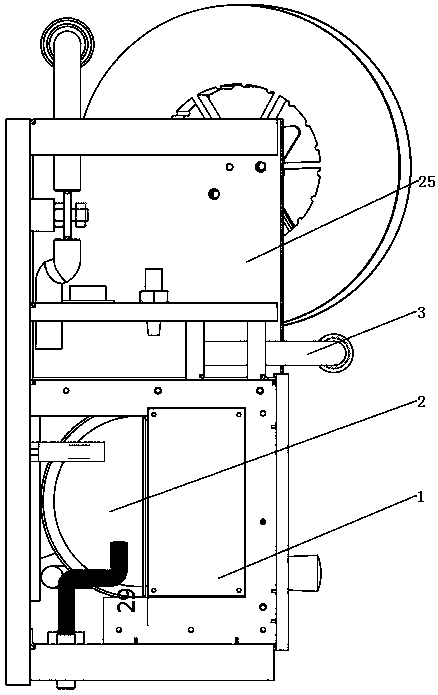

Light full-sealed underwater automatic welding wire feeder

ActiveCN107127427AImprove sealing and waterproof performanceWill not affect normal operationWelding accessoriesPower cableGear wheel

A light full-sealed underwater automatic welding wire feeder comprises a wire feeder box, a wire reel mechanism, a speed reduction transmission mechanism, a gear transmission mechanism, a wire pressing mechanism and a sealing motor with a sealed waterproof function, wherein the wire feeder box is provided with multiple interfaces, and the wire reel mechanism, the speed reduction transmission mechanism, the gear transmission mechanism, the wire pressing mechanism and the sealing motor are sealed and insulated in the wire feeder box. The interfaces on the wire feeder box include the gas way interface, the power cable interface and the welding gun interface. The inside-box gas pressure balanced with the outside-box water pressure is formed in the wire feeder box through protection gas injected into the wire feeder box through the gas way interface. The sealing motor, the speed reduction transmission mechanism and the gear transmission mechanism are sequentially connected. A pressure passageway is formed between the installed wire pressing mechanism and the installed gear transmission mechanism. A welding wire wound on the wire reel mechanism is pressed when passing through the pressure passageway and is conveyed to the welding gun interface of the wire feeder box. The light full-sealed underwater automatic welding wire feeder has the beneficial effects that the weight is small, the sealing performance is good, and the possibility that the device fails when working under water can be greatly reduced. The invention belongs to the technical field of underwater welding.

Owner:SOUTH CHINA UNIV OF TECH

A Stepless Adjustable Eccentric Rotating MIG Gas Shielded Welding Torch

ActiveCN106180990BReduce power consumptionEasy to controlElectrode supporting devicesElectrode accessoriesTorque motorWeld line

Owner:TAIYUAN UNIV OF TECH

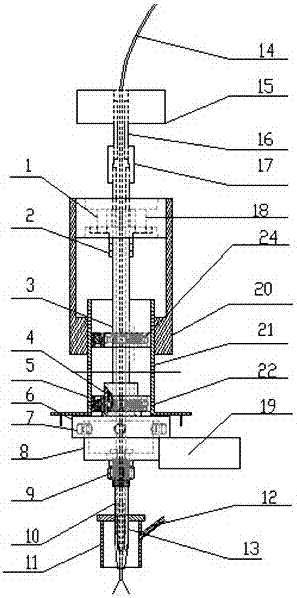

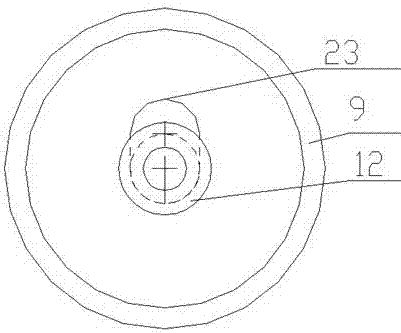

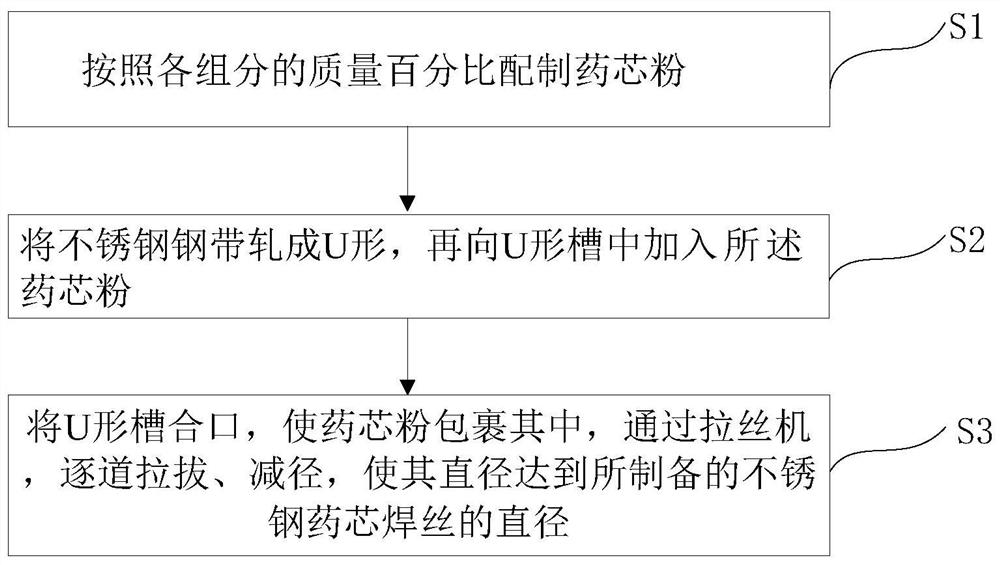

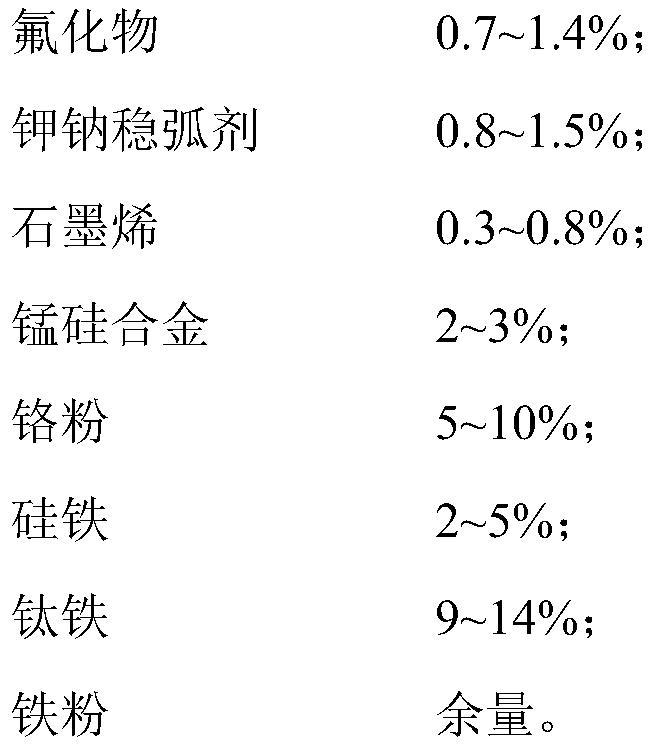

Stainless steel flux-cored wire

ActiveCN112643243ASimple welding processImprove wear resistanceWelding/cutting media/materialsSoldering mediaSilicon alloyFerrosilicon

The invention provides a stainless steel flux-cored wire. The stainless steel flux-cored wire comprises a stainless steel strip and a flux core, and the stainless steel strip is filled with the flux core. The flux core comprises, by mass, 0.7-1.4% of fluoride, 0.8-1.5% of a potassium-sodium arc stabilizer, 0.3-0.8% of graphene, 2-3% of manganese-silicon alloy, 5-10% of chromium powder, 2-5% of silicon iron, 9-14% of ferrotitanium and the balance iron powder. When the stainless steel flux-cored wire is used for welding, electric arcs are soft and stable, weld joints are attractive in appearance and small in splashing after welding, small air holes do not exist in the weld joints, and meanwhile weld joint metal has excellent abrasion resistance, corrosion resistance and high-temperature resistance.

Owner:山东聚力焊接材料有限公司

Small-sized wire drawing type electric arc spraying equipment

ActiveCN101864549BReduce volumeReduce weightMolten spray coatingElectric arc sprayingThermal sprayingOperation mode

The invention relates to small-sized wire drawing type electric arc spraying equipment used for hot spraying, which is shown in the attached drawing of the abstract. The equipment adopts the technical scheme of an inversion type spraying power supply and a wire drawing type spraying gun, the output voltage of 10 to 40V is regulated in a stepless way, and the voltage can be regulated in the spraying process without stop; a manual / automatic spraying and wire inspection / spraying switch is arranged, which is convenient to select an operation mode and avoid the occurrence of the condition that electric arcs injure people and damage equipment because of the short circuit of a wire material when the spraying wire material is installed, regulated and inspected; the spraying wire material is limited to be phi 1.0 to phi 1.6mm, the maximum spraying current is 250A, the load duration rate is 100 percent, and continuous spraying is permitted; the weight of the spraying power supply is 15kg, and the weight of the spraying gun is 1.5kg; and the equipment has the characteristics of small volume, light weight, convenient carrying, safe and reliable equipment performance, convenient use, simple operation, stable spraying quality and the like, is suitable for the field operation and the use in an occasion with small spraying space and is suitable for spraying a component with a fine and small structure and a product with a fine coating.

Owner:慈溪光华金属复合材料有限公司

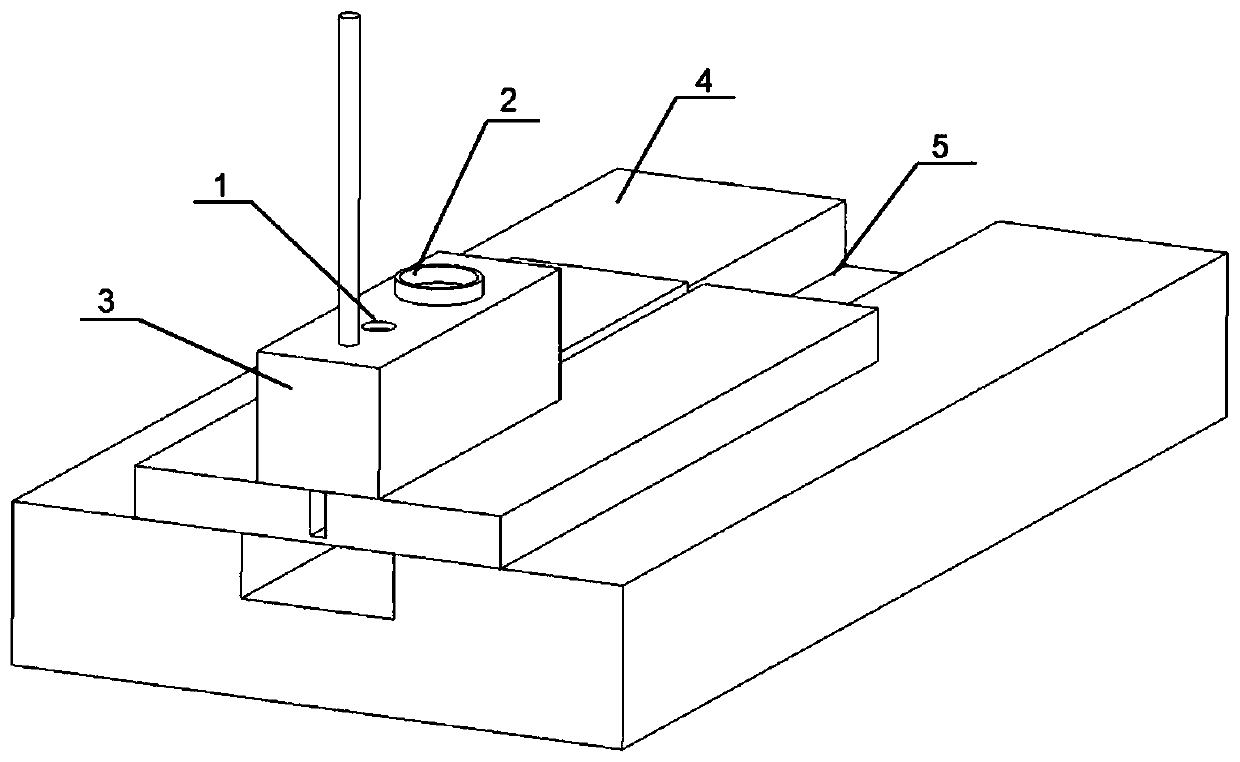

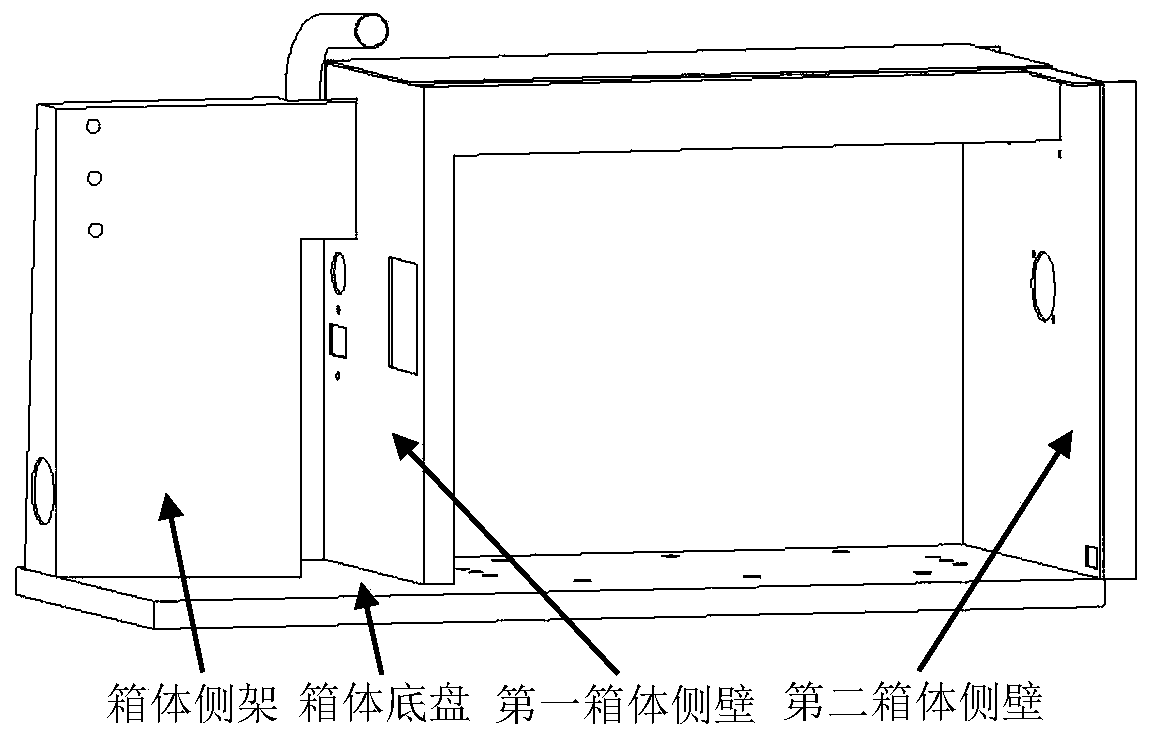

Vibrating wire feeding welding device based on linear motor

ActiveCN110560822AImprove forming qualityRealize vibrating wire feedingSolder feeding devicesVibrating wireEngineering

The invention provides a vibrating wire feeding welding device based on a linear motor, and belongs to the technical field of welding equipment. The device specifically comprises wire feeding box body, a linear motor unit, an insulation plate, a wire feeding running pipe assembly, a connector, a wire feeder unit, a welding wire and a welding wire plate, wherein the wire feeding box comprises a side frame, a box chassis and a box side wall; the linear motor unit consists of a stator and a rotor; the stator is fixed to the box chassis; the wire feeder unit is fixed to the rotor through an the insulation plate; one end of the wire feeding running pipe assembly is connected with the connector and fixed on the side wall of the box body, and the other end of the wire feeding running pipe assembly is mounted on the wire feeder unit; and the wire welding plate is hung on a side frame of the box body and supports wire feeding. The wire feeder unit receives a constant speed command to enable thewelding wire to be fed forwards at a constant speed, and after the linear motor unit receives a vibration command, the mover drives the wire feeder unit to enable the welding wire to be pushed forwards and drawn back backwards, so that the effect of vibration wire feeding is achieved. The device achieves the purposes of reducing heat input and welding defects.

Owner:BEIJING UNIV OF TECH

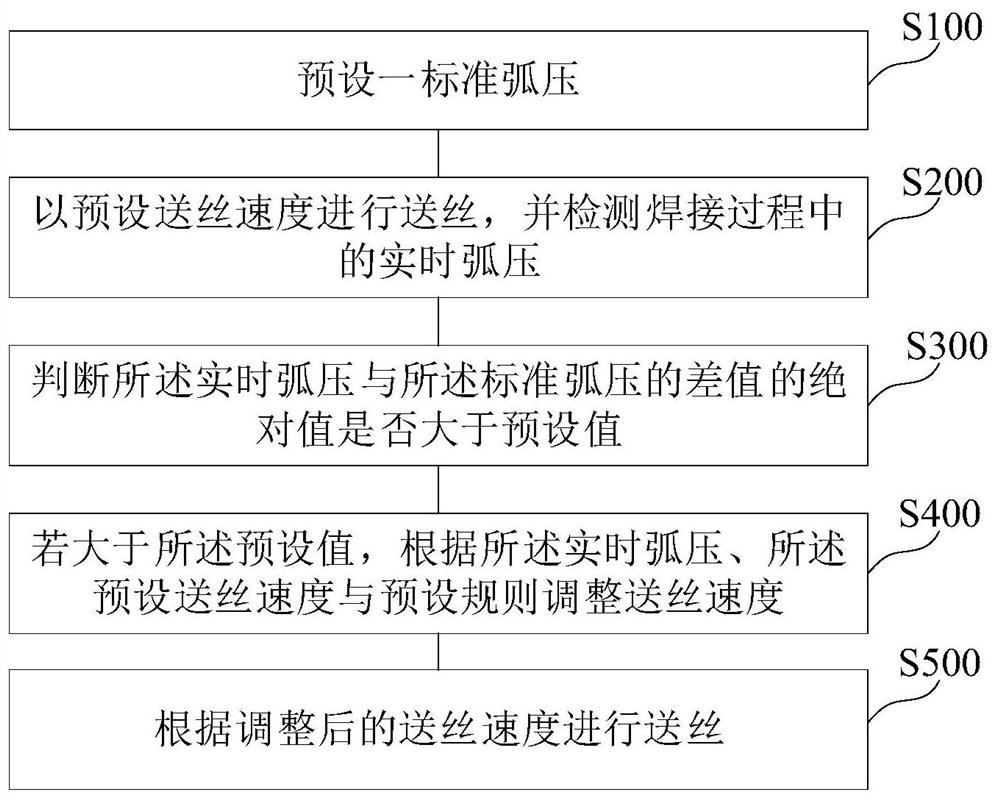

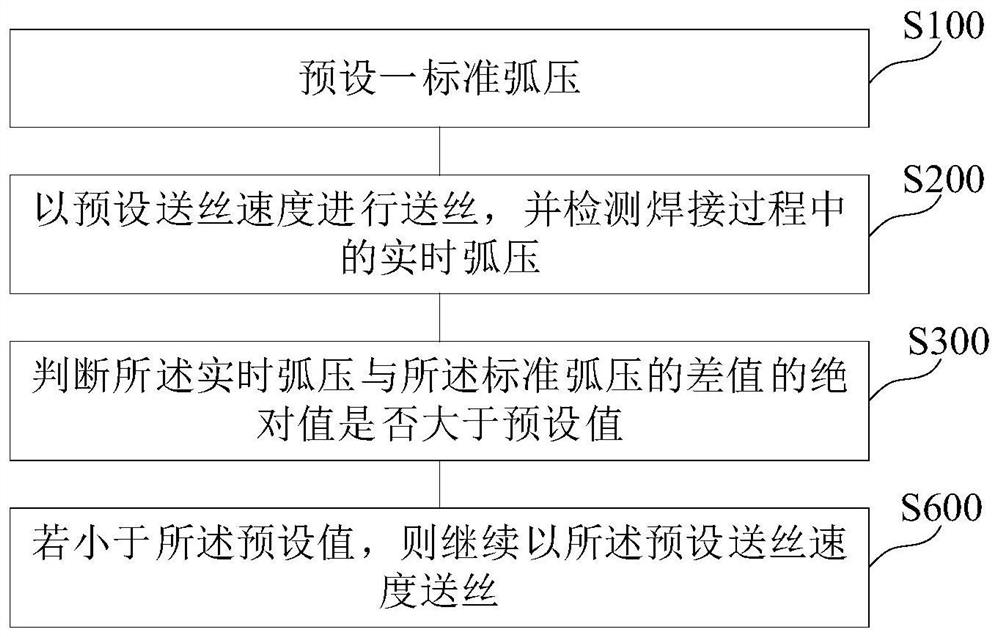

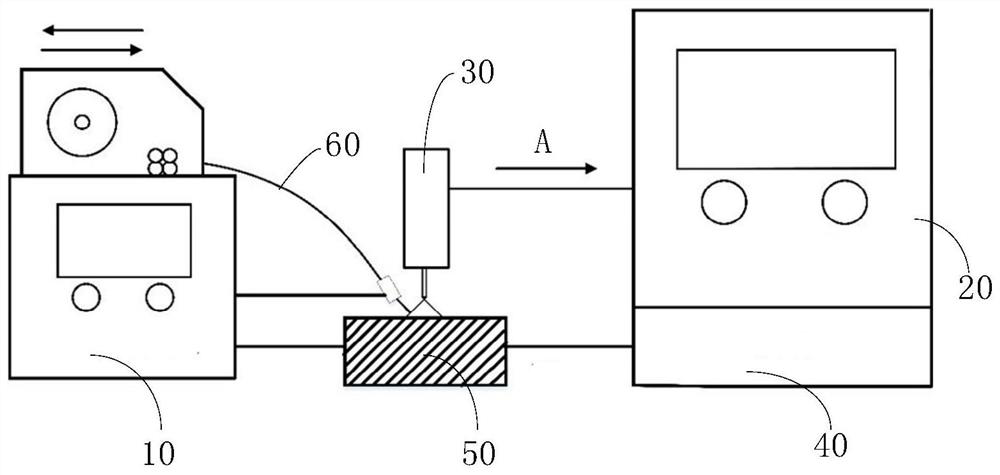

Efficient TIG wire feeding method and welding device

ActiveCN112775522AStable wire feedingWell formed weldWelding accessoriesWeld seamMechanical engineering

The invention provides an efficient TIG wire feeding method and a welding device. The wire feeding method comprises the steps that a standard arc pressure is preset; wire feeding is conducted at the preset wire feeding speed, and the real-time arc pressure in the welding process is detected; whether the absolute value of the difference value between the real-time arc pressure and the standard arc pressure is larger than a preset value or not is judged; if the real-time arc pressure is larger than the preset value, the wire feeding speed is adjusted according to the real-time arc pressure, the preset wire feeding speed and a preset rule; and wire feeding is conducted according to the adjusted wire feeding speed. According to the efficient TIG wire feeding method, the wire feeding speed can be automatically adjusted according to the feedback arc pressure in the welding process, wire feeding can be stable, and welding seam forming can be excellent.

Owner:PANASONIC WELDING SYST TANGSHAN

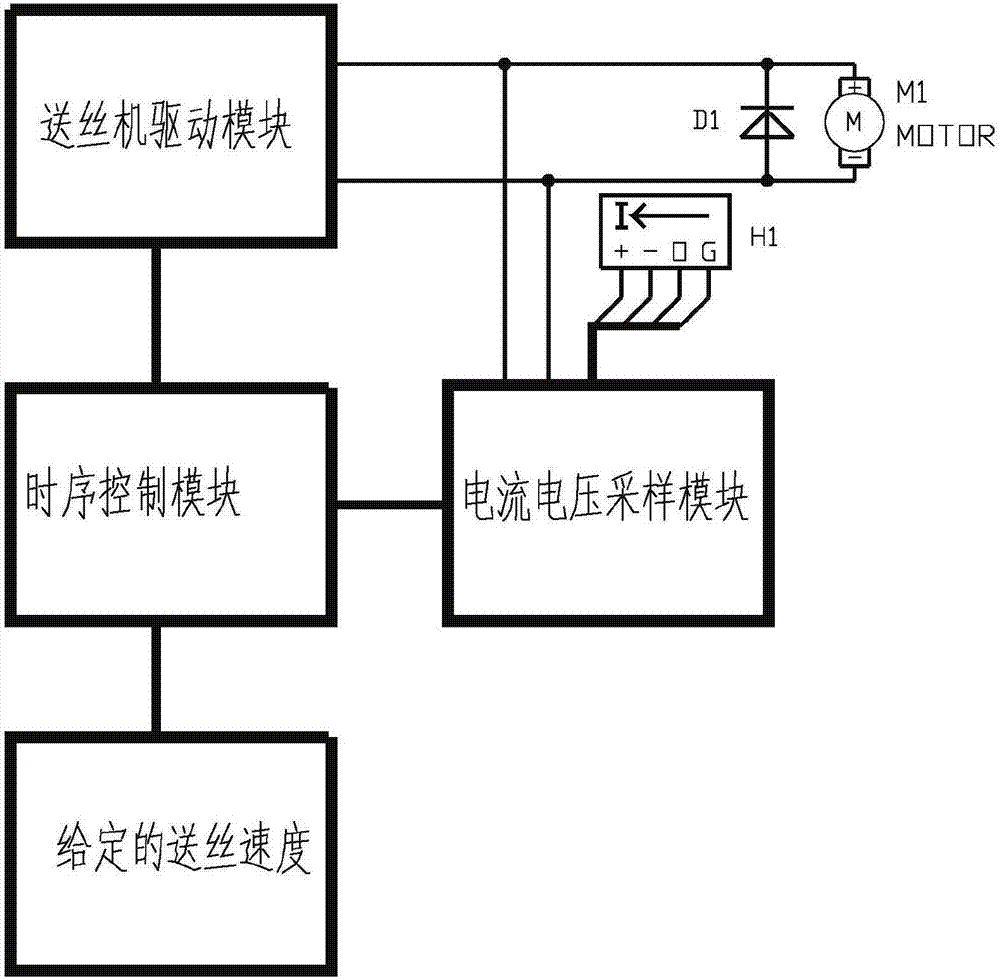

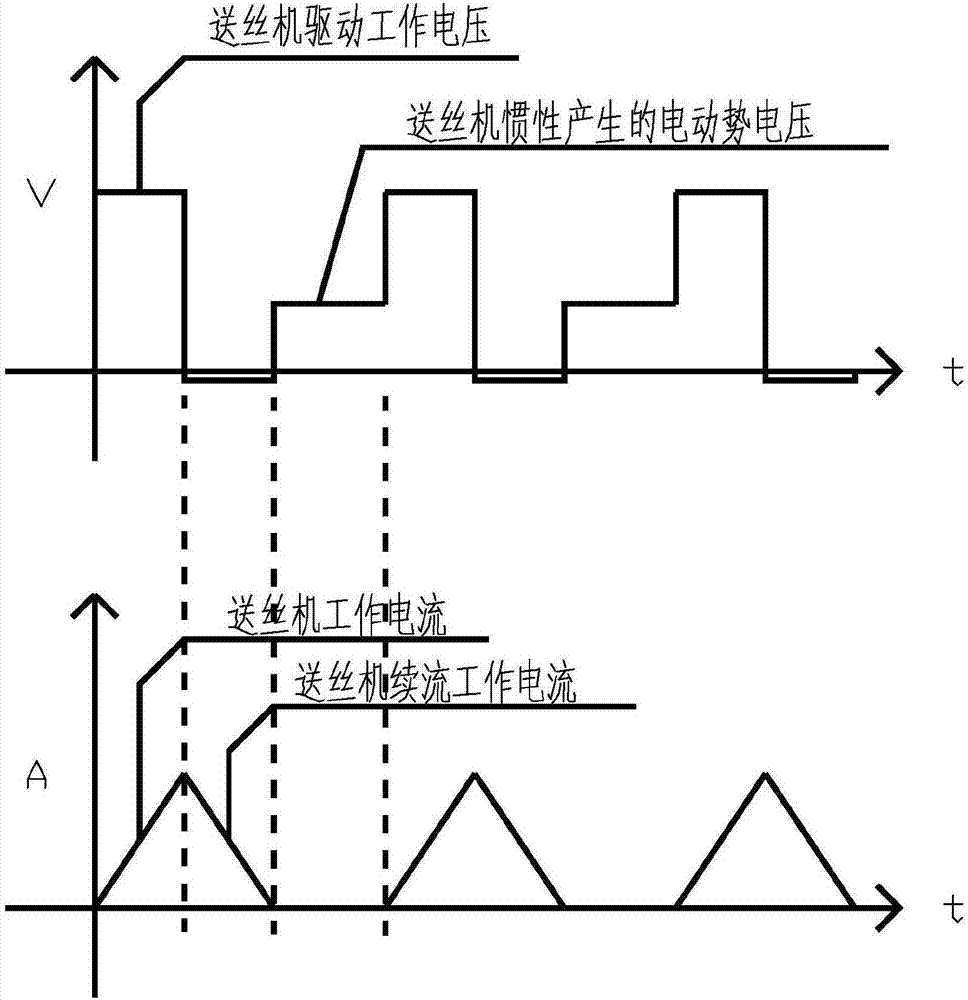

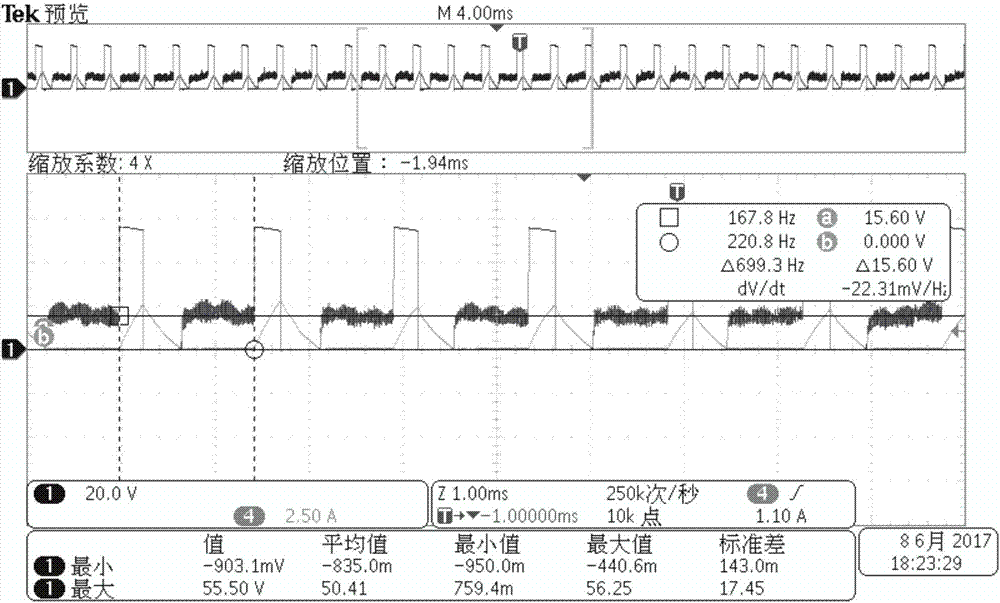

Time sequence control circuit and method for realizing constant-speed wire feeding

PendingCN107127423APrecise speed controlQuick responseArc welding apparatusDriving currentControl signal

The invention relates to a time sequence control circuit and method for realizing constant-speed wire feeding. The circuit comprises a wire feeder driving module, a current / voltage sampling module, a time sequence control module, a wire feeding motor, a follow-current catching diode and a current sampling sensor, wherein the wire feeder driving module is used for driving a wire feeder through pulse working voltage; the current / voltage sampling module is used for collecting working current and electromotive voltage of the wire feeder and sending collected data to the time sequence control module; and the time sequence control module is used for processing fed back by the current / voltage sampling module and sending a control signal to the wire feeder driving module. By adoption of the time sequence control circuit and method for realizing constant-speed wire feeding, the wire feeder can keep constant-speed wire feeding under different loads and different resistances, has the advantages of being accurate in speed control, high in response speed, stable in wire feeding and low in cost, and has wide application range.

Owner:SHANGHAI HUGONG ELECTRIC WELDING MACHINE MFG

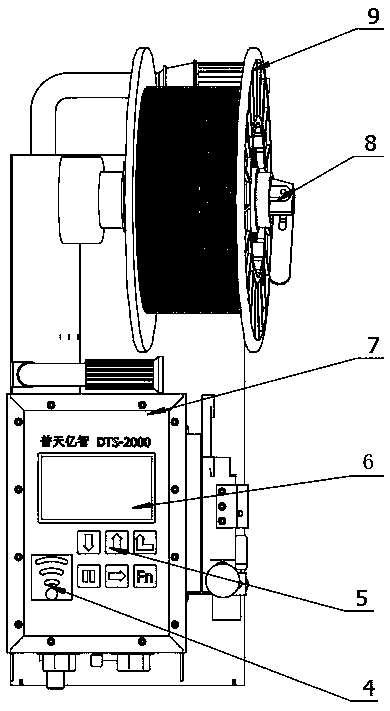

Novel digitized wire feeder

InactiveCN111299908AImprove working environmentGood estimateWelding/cutting auxillary devicesArc welding apparatusDigitizationElectromagnet

The invention relates to a novel digitized wire feeder. The novel digitized wire feeder comprises a control box, a direct current motor, a handle, a card swiping induction module, a display screen button, a display screen, a PC panel, a wire reel fixing part, a wire feeding plate, a speed measuring mechanism, a wire pressing wheel, a wire feeding wheel, a wire pressing rod, a current and voltage adjusting rotary knob, an automatic wire feeding button, a two-core pore, a gas pipeline current transformer, an electromagnet, a data transmission line, a Hall sensor, a circuit mainboard, a temperature sensor, a humidity sensor and a rack. The novel digitized wire feeder has the beneficial effects that the novel digitized wire feeder integrates various sensing units, can collect, record and upload all sensitive parameters in a welding process in real time, and can achieve digitalized control of an overall process of data collection and analysis, welding task management, staff, equipment, welding materials and the like.

Owner:福建普天亿智科技有限公司

Open arc on-line surfacing repair device and method for grinding roller of medium-speed mill

PendingCN110539124ASave human effortSave moneyCooled electrode holdersWelding accessoriesSurface layerMaterial resources

The invention relates to an open arc on-line surfacing repair device and method for a grinding roller of a medium-speed mill. The open arc on-line surfacing repair device comprises a PLC welding control box, and an electric welding machine, a welding trolley, a double-drive wire feeder and a limit switch which are connected with the PLC welding control box. A grinding roller driving device is arranged at the bottom of the grinding roller; a welding gun is arranged on the surface of the grinding roller; the rear end of the welding gun sequentially communicates with the double-drive wire feederand a welding wire straightening mechanism through a connecting rod; a welding wire placed on a wire feeding device penetrates into a wire inlet of the welding wire straightening mechanism; and the double-drive wire feeder is mounted on the welding trolley through a welding gun angle adjusting mechanism. On-line surfacing repair is carried out on the grinding roller without disassembling the grinding roller, so that a large amount of manpower and material resources are capable of being saved and the repair period is capable of being shortened. The open arc on-line surfacing repair method mainly ensures that each performance of a surfacing layer meets repair requirements by selecting welding parameters and welding modes.

Owner:甘肃酒钢集团西部重工股份有限公司

Multi-motor wire feeding control system and method

ActiveCN106891080BConstant speed and smooth operationStable wire feedingArc welding apparatusElectric machineControl system

The present disclosure provides a multi-motor wire feeding control system and method. The multi-motor wire feeding control system includes: a plurality of wire feeding units, each wire feeding unit includes a motor, a speed sensor, a current sensor and a wire feeding driving mechanism, and the speed sensor is used to detect the speed signal of the motor, so The current sensor is used to detect the current signal of the motor, wherein, the motors of each wire feeding unit have their own speed loops, and the speed loops of each wire feeding unit operate according to the same speed command, and among the multiple wire feeding units At least part of the motors have their own current loops, and at least part of the current loops in the current loops are associated with the motor current of their own wire feeding unit and the motor current of at least one other wire feeding unit; the controller, the controller according to the speed instruction 1. The speed signal fed back by each speed sensor and the current signal fed back by each current sensor control the motors of each wire feeding unit to run at a constant speed.

Owner:PANASONIC WELDING SYST TANGSHAN

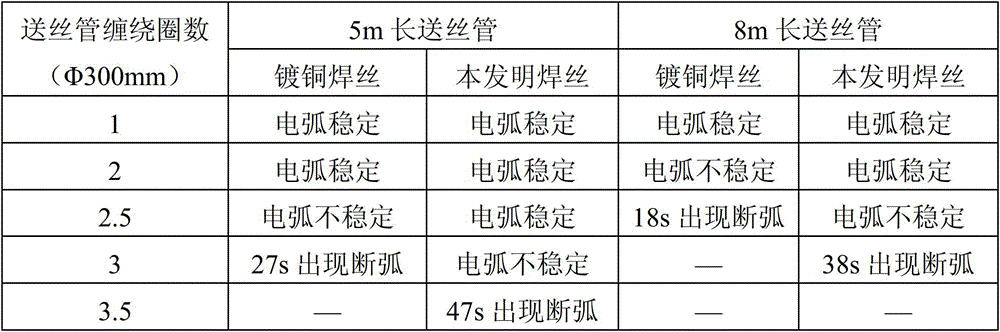

A kind of non-copper-plated solid wire for gas shielded welding and preparation method thereof

InactiveCN103537819BUniform treatmentStable wire feedingArc welding apparatusWelding/cutting media/materialsLiquid wasteCopper plating

The invention discloses a non-copper-plated solid welding wire for gas shielded welding. The non-copper-plated solid welding wire for gas shielded welding comprises a welding wire base body and a surface treatment layer, wherein the welding wire base body is formed by drawing of a wire rod, the surface treatment layer comprises a potassium base solid wire drawing lubricant agent left during drawing of the welding wire and high-voltage static coating oil, the amount of the remaining potassium base solid wire drawing lubricant agent is 5-10mg / m<2>, and the amount of the high-voltage static coating oil is 5-15mg / m<2>. The manufacturing method of the non-copper-plated solid welding wire for gas shielded welding comprises the steps that (1) husking, derusting, cleaning, lime coating and drying are carried out on the wire rod in sequence, (2) wire drawing reducing is carried out on the wire rod by means of a rough drawing reducing method and a finish drawing reducing method so that size requirements of a finished welding wire are met, (3) the lubricant agent on the surface of the welding wire is removed, (4) high-voltage static oil coating is carried out on the welding wire, (5) the welding wire is wound precisely and is packaged. The non-copper-plated solid welding wire has the advantages that surface treatment is even, wire feeding is stable, the electrical conductivity and rust resistance are high, and the success rate of arcing and the success rate of reignition of arc are high. The manufacturing method of the non-copper-plated solid welding wire for gas shielded welding has the advantages that discharging of waste acid, waste alkali, copper plating liquid waste and boron waste is avoided, water consumption is small, and environmental pollution is greatly reduced.

Owner:CHINA JINGYE ENG TECH CO LTD +1

Wire feeding system of double-motor combined welding wire coordinating mechanism

The invention belongs to the field of welding devices, particularly relates to a wire feeding system of a double-motor combined welding wire coordinating mechanism. The wire feeding system specifically comprises an upper computer (1), an interface circuit (2), a push-pull wire motor control unit (3), a push-pull wire feeding servo motor unit (4), a welding wire coordinating mechanism (5), a push wire motor unit (6) and a PWM speed adjusting circuit (7), wherein the upper computer is connected with the push-pull wire motor control unit via the interface circuit and connected with the PWM speedadjusting circuit, and used for totally controlling the whole push-pull wire feeding system; the push-pull wire motor control unit is used for closed loop control of the push-pull wire feeding servo motor unit; the PWM speed adjusting circuit is used for driving and controlling the push wire motor unit; the welding wire coordinating mechanism is an intermediate link for connecting the push wire motor unit with the push-pull wire feeding servo motor unit. The wire feeding system is mainly combined with a digital welding power source and capable of realizing various welding technological methods based on high-frequency feed-draw welding wires.

Owner:BEIJING UNIV OF TECH

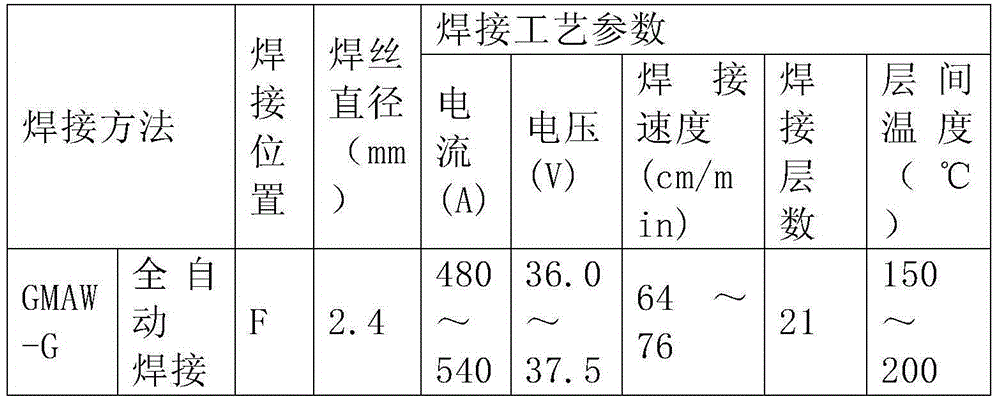

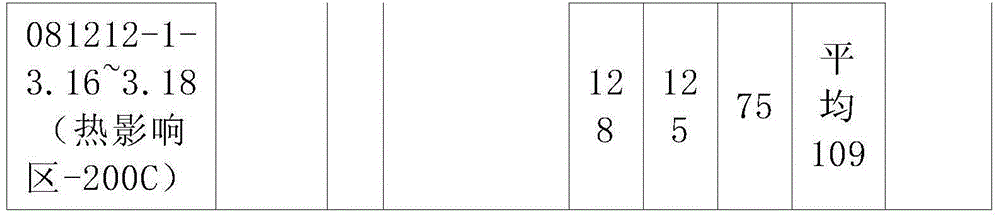

Novel copper-plating-free thick wire automatic welding technology for building steel structure

InactiveCN105149728AAttached tightlyImprove conductivityWelding/cutting media/materialsWelding/soldering/cutting articlesCopper platingThick plate

The invention discloses a novel copper-plating-free thick wire automatic welding technology for a building steel structure. In manufacturing and welding work of the building steel structure, quality and cost of a steel structural solid are affected by key processes, namely welding quality and welding efficiency of a thick plate and a long welding seam; and a butt-joint full-penetration welding seam and an angle-joint full-penetration welding seam of the thick plate are welding seams with greatest welding workload and highest technical requirements; a full automatic butt-joint process with without back chipping is adopted; and full-automatic angle joint without back chipping is realized. The novel copper-plating-free thick wire automatic welding technology is low in welding cost, good in quality and is an environment-friendly and energy-saving effective measure.

Owner:CHANGJIANG & JINGGONG STEEL STRUCTURE GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com