Arc additive manufacturing and forging-milling composite machining forming device and method

A composite machining and arc technology, applied in the direction of additive machining, electrode support device, forging/pressing/hammer device, etc., can solve the problem that the machining accuracy cannot meet the needs of use, there are cracks, pores, residues, and the mechanical properties of the formed parts are not high. problems, to achieve the effect of improving the overall mechanical properties, dense organization, and reducing swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

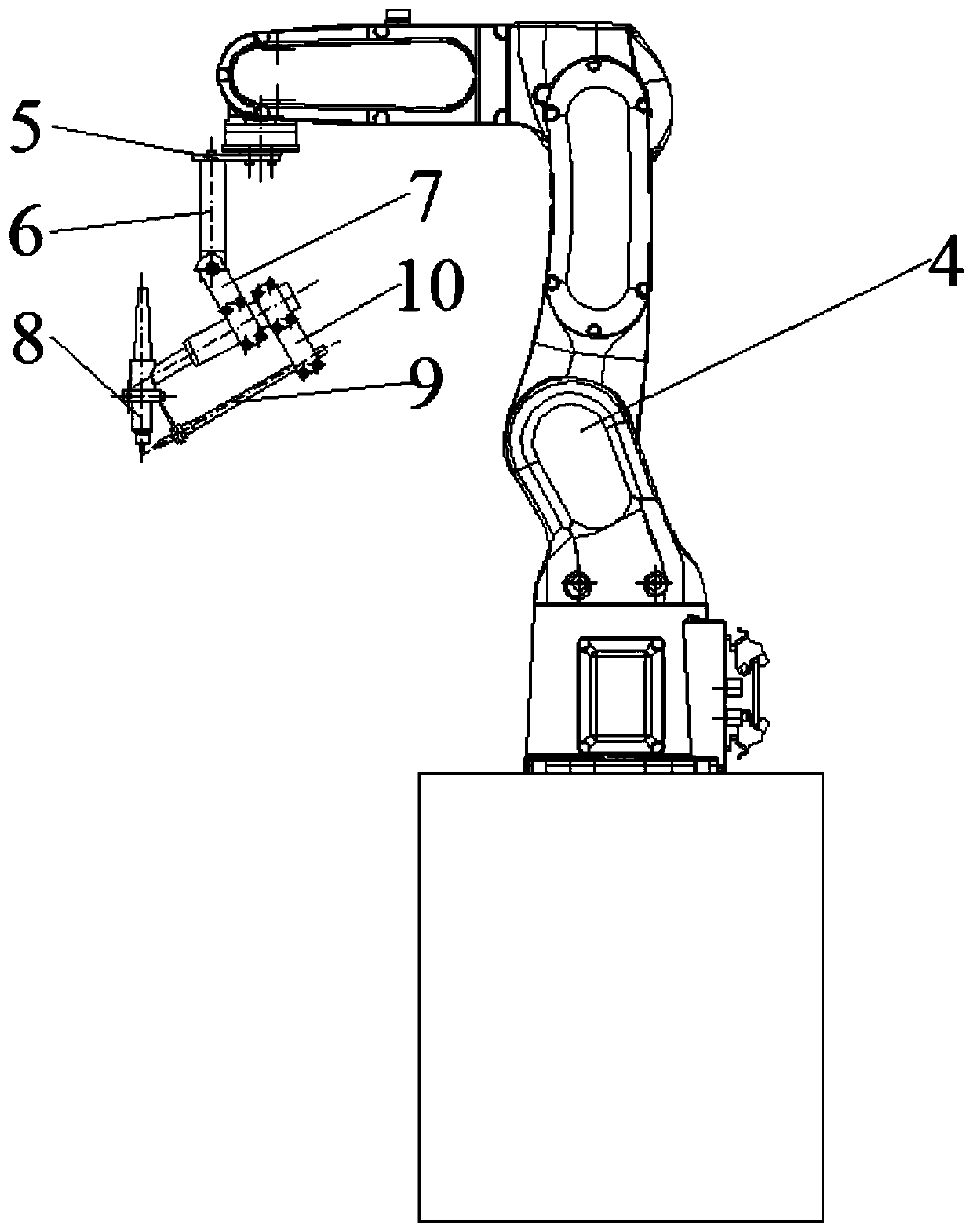

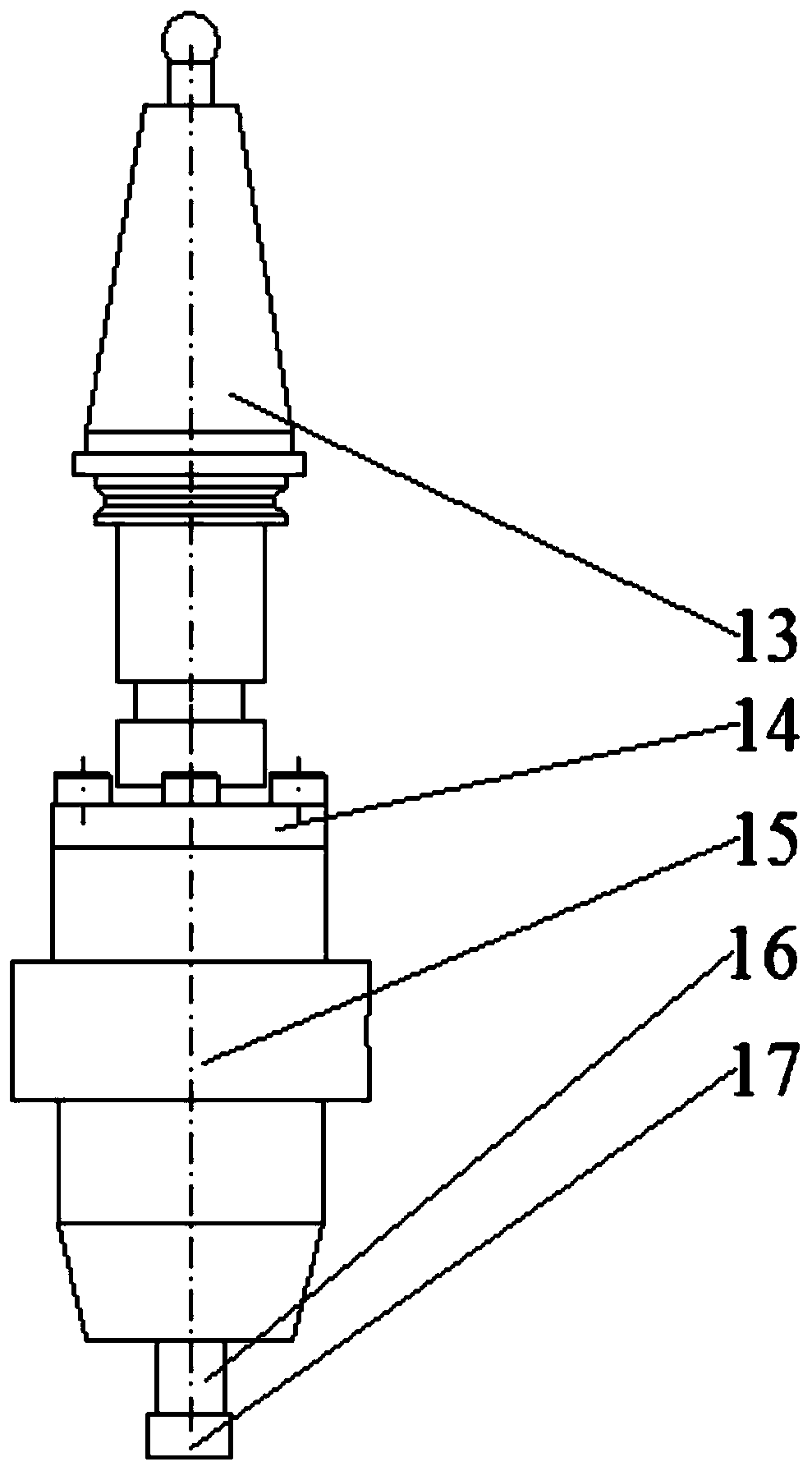

[0039] Such as figure 1 Shown is an electric arc additive and forging-milling compound processing forming device, including a manipulator arc additive manufacturing unit 1, a stroke-limited high-frequency forging modification unit 2, and a CNC milling finishing unit 3, wherein the manipulator additive manufacturing unit 1 Located directly in front of the machining center, including manipulator 4, connecting plate 5, cylindrical clamp 6, insulating block 7, welding gun 8, wire feeding tube 9, wire feeding tube clamp 10, wire feeding tube 9 is fixed to the welding gun by two stepped clamps 10 8 At the handle, the welding gun 8 is clamped by two insulating blocks 7, and the two insulating blocks 7 are fixed to one end of the cylindrical fixture 6 by screws, and the other end of the cylindrical fixture 6 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com