Time sequence control circuit and method for realizing constant-speed wire feeding

A timing control circuit and timing control technology, used in manufacturing tools, arc welding equipment, welding equipment, etc., can solve the problems of slow adjustment response, high cost, large size of wire feeder, etc., to achieve a wide range of applications, fast response speed , the effect of stable wire feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

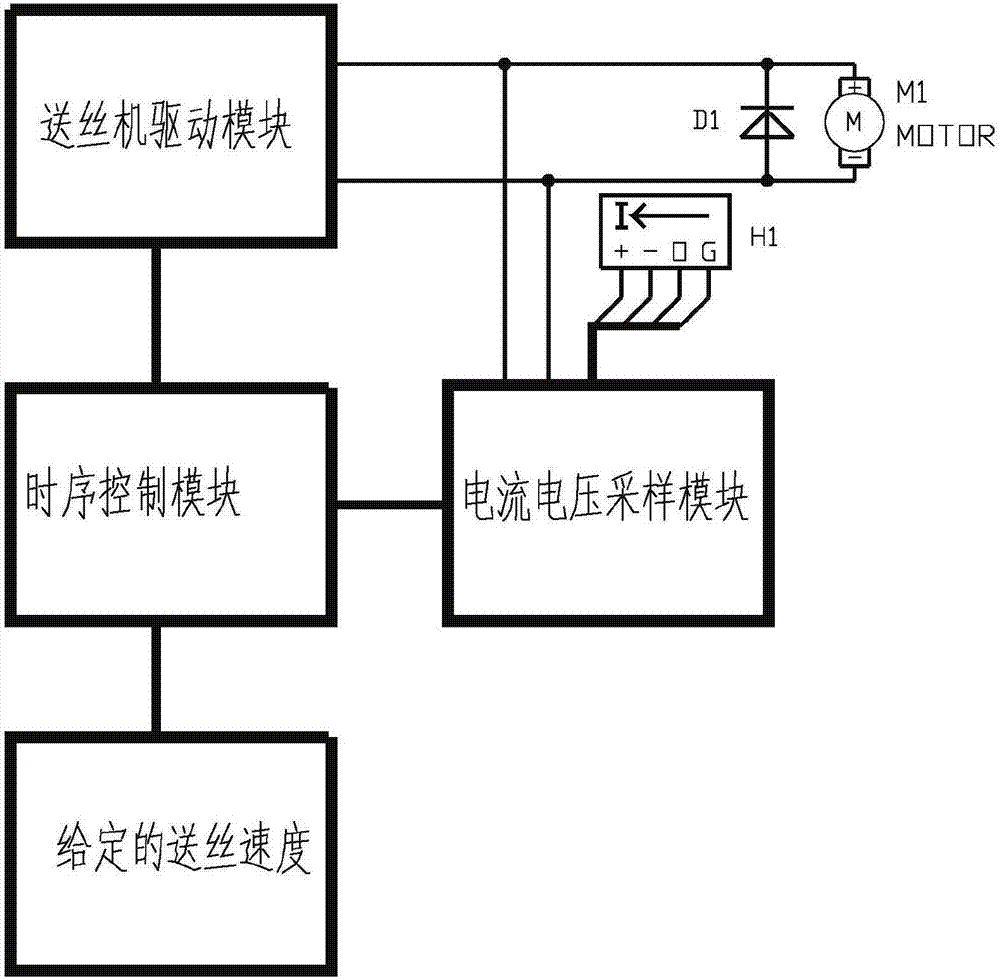

[0024] The timing control circuit for realizing constant wire feeding includes:

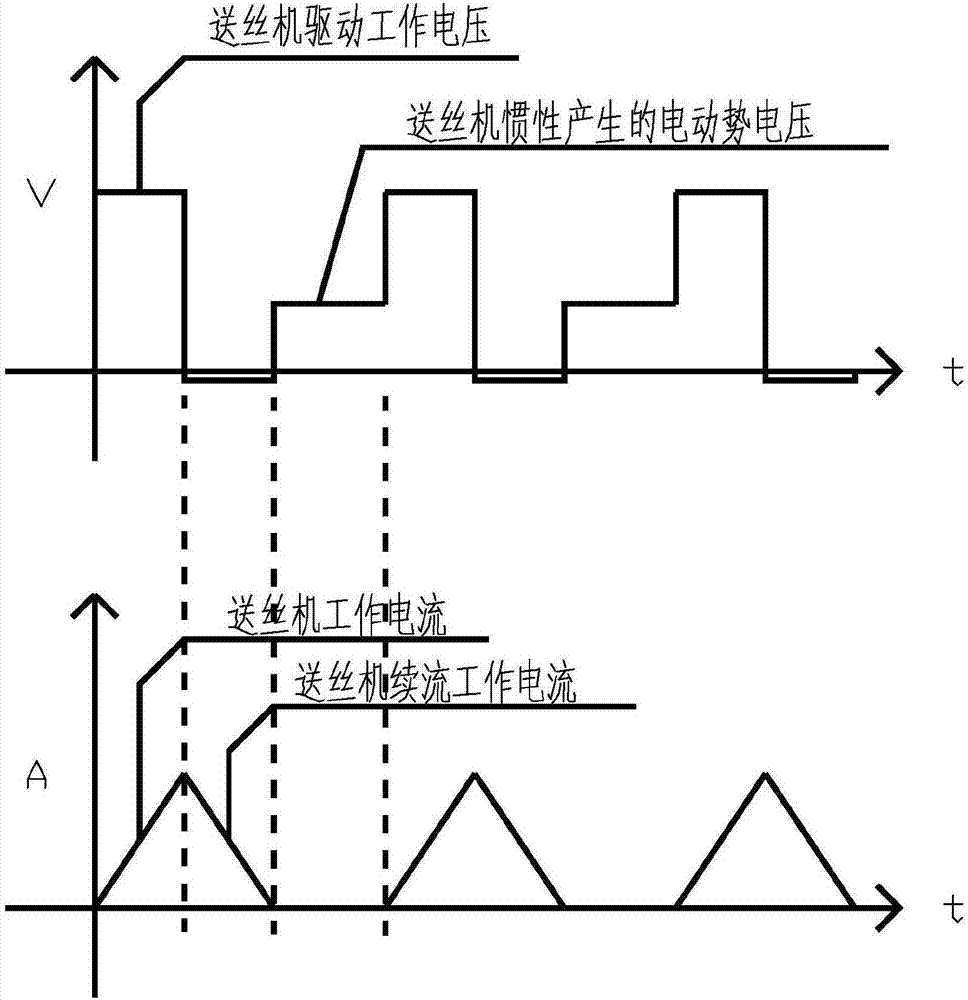

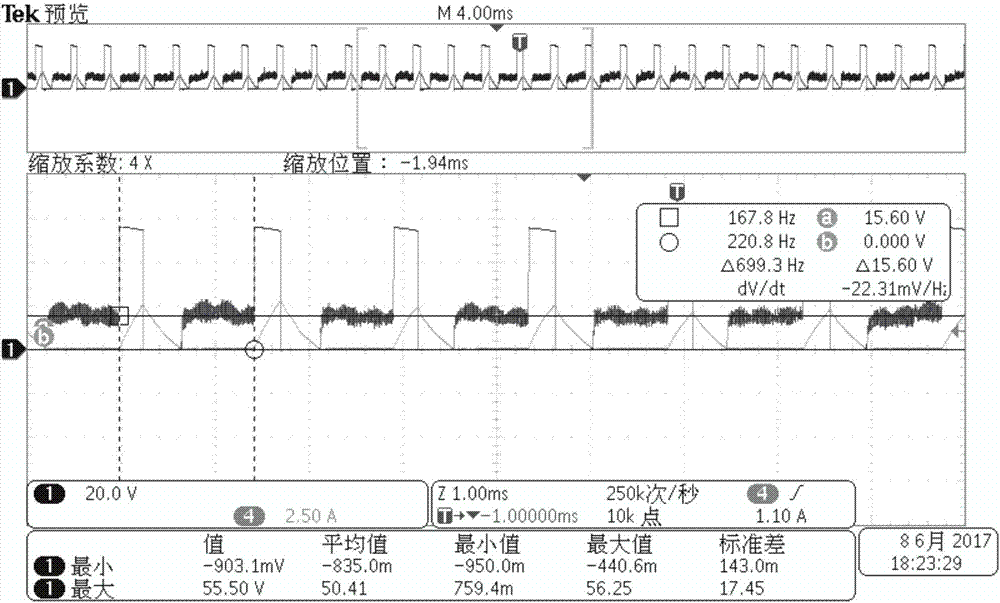

[0025] The wire feeder drive module is used to drive the wire feeder through the pulse working voltage;

[0026] A current and voltage sampling module, configured to collect the working current and electromotive voltage of the wire feeder, and send the collected data to the timing control module;

[0027] A timing control module, configured to process the data fed back by the current and voltage sampling module, and send a control signal to the wire feeder drive module; and

[0028] Wire feeding motor, freewheeling clamp diode and current sampling sensor,

[0029] Wherein, the anode of the wire feeding motor is respectively connected with the first end of the wire feeder driving module, the first end of the current and volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com