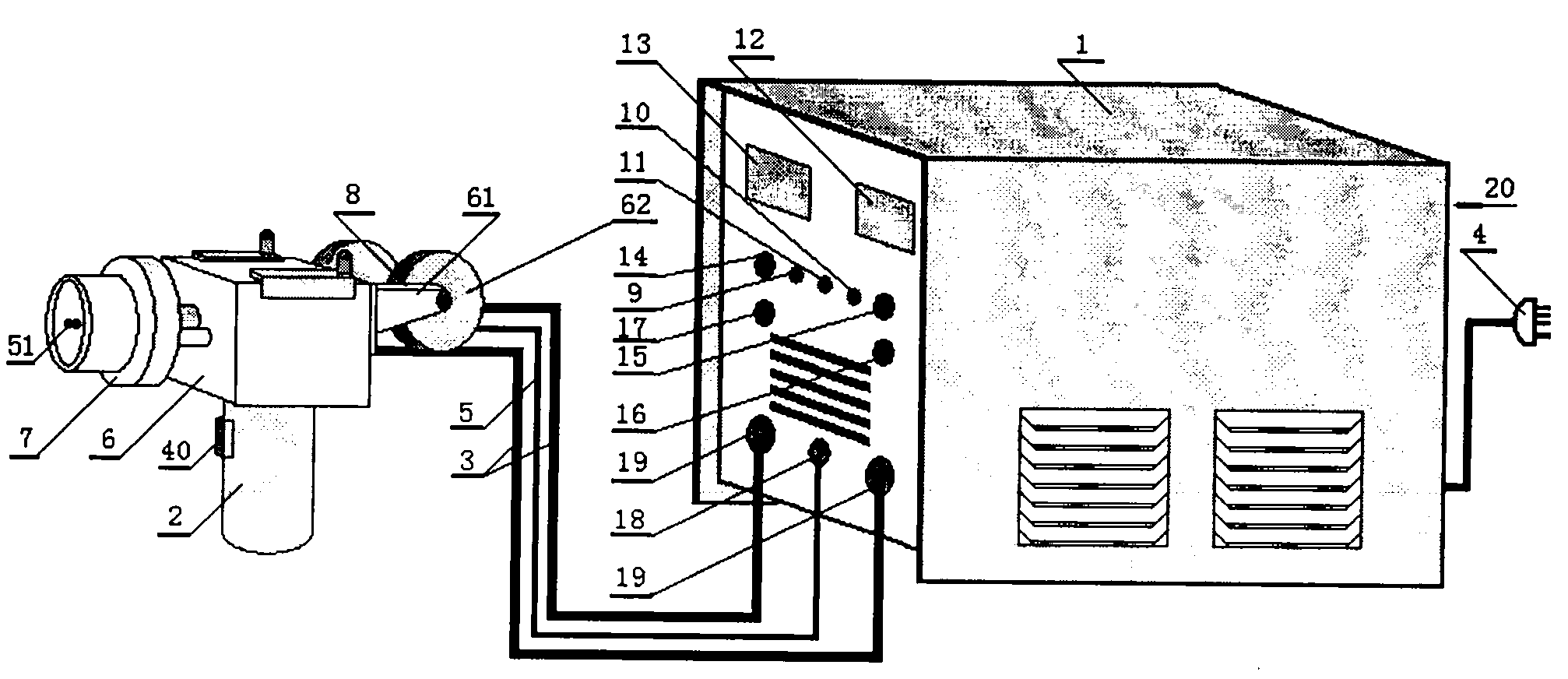

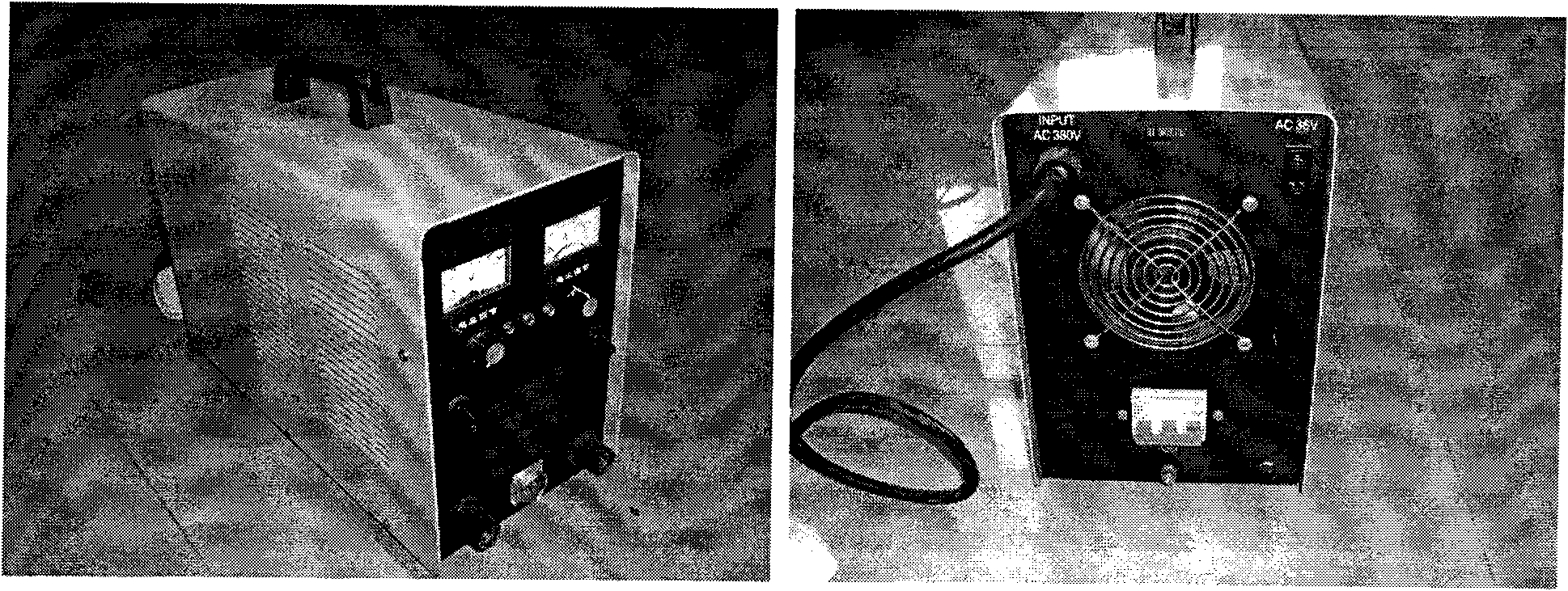

Small-sized wire drawing type electric arc spraying equipment

An arc spraying equipment and wire drawing technology, applied in arc spraying, coating, melt spraying and other directions, can solve the problems of waste of spraying materials, large volume, inconvenient handling and construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

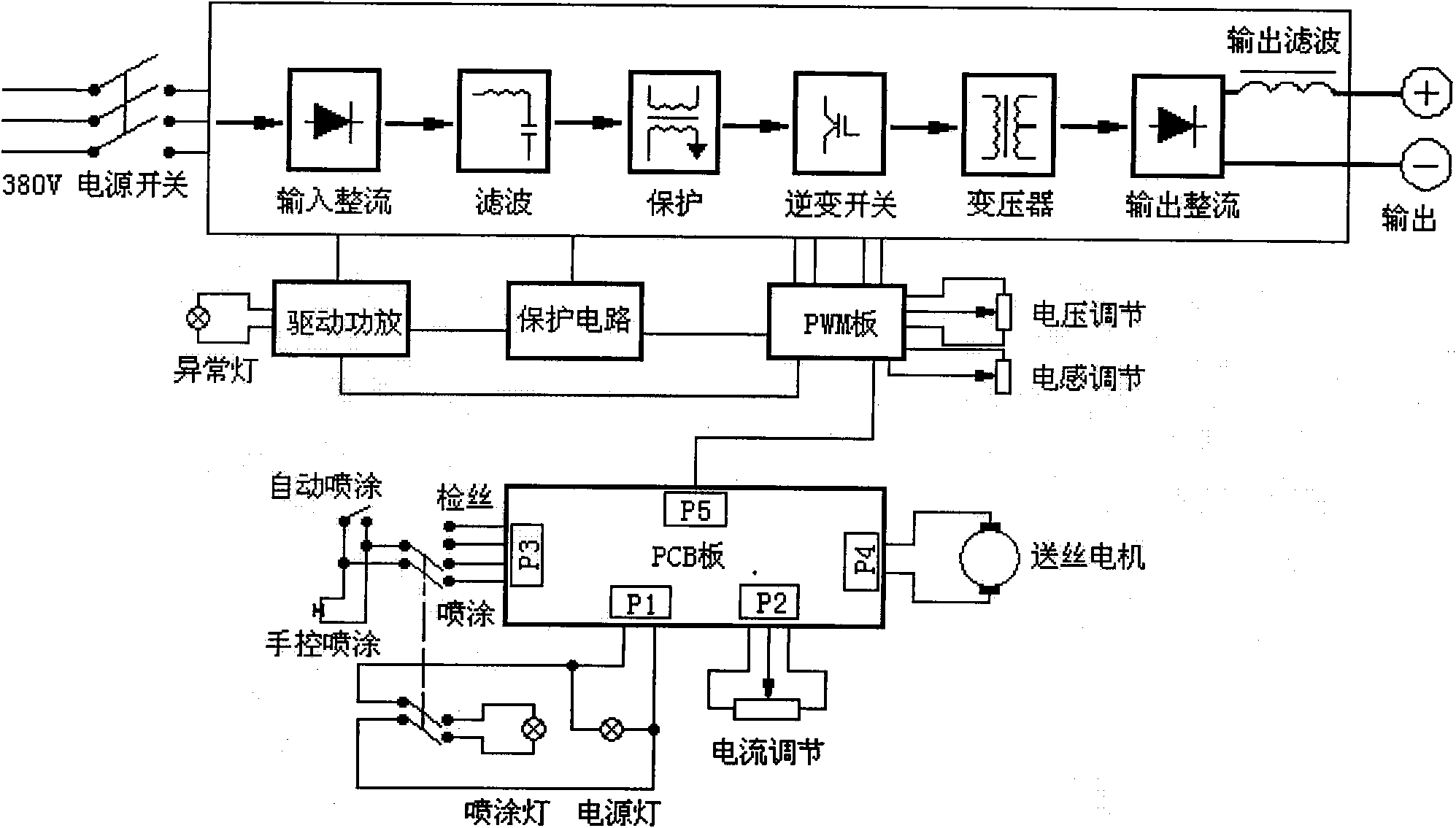

Method used

Image

Examples

Embodiment 1

[0088] Example 1: Spraying of small stone lion exterior decoration

[0089] 1. Conditions: Spray metal coating on the surface of the stone lion as decoration, which requires beautiful appearance and resistance to atmospheric corrosion. According to the characteristics of the small wire drawing type spraying equipment of the present invention, the height of the stone lion body shape is most suitable below 500mm.

[0090] 2. Coating design: According to the use conditions of the spraying object, choose brass (other metal materials, such as Al, Fe) as the spraying material, and the diameter of the wire is Φ1.2mm. The coating of this low-power spraying is relatively Uniform and dense, delicate and beautiful, according to user requirements, the coating thickness can be 0.10 ~ 0.20mm.

[0091] 3. Spraying process: adopt the small-scale spraying equipment of the present invention, according to the shape of the spraying object, adopt the manual operation spraying operation mode, beca...

Embodiment 2

[0093] Embodiment 2: Field construction spraying of anti-corrosion coating on the surface of underground gas pipeline valves

[0094] 1. Current status of use: For the laying of gas pipelines in small and medium-sized cities along the coast, many gas pipeline valves are installed in underground wells. The space is relatively small, generally 2.5M high, 1.5M wide, and 2.5M long. Water accumulated at the bottom of the well all the year round, and the pipes and valves were severely corroded, requiring frequent painting protection. The spraying method can significantly improve the protection life, but it is difficult to construct due to the small working space. The construction of this project can be realized conveniently by adopting the small spraying equipment of the present invention.

[0095] 2. Coating design: According to the protection mechanism of severe wet corrosion, Zn-Al spraying wire is selected. As we all know, the protection life of this material can reach at least...

Embodiment 3

[0098] Example 3: On-site spraying of locomotive bearing positioning hole out-of-tolerance repair

[0099] 1. Conditions of use: During the maintenance and repair of train locomotives, it is often found that the bearing positioning hole (on the locomotive shell) is worn out of tolerance due to long-term use, so that the outer ring of the bearing and the positioning hole cannot be tightly matched and slip. If the welding method is used for repairing, the welding operation is more difficult because the shell is large and the position cannot be changed. In addition, it is difficult to ensure the dimensional accuracy in post-welding processing, so the method of cementing is generally used for repairing, but the service life is short. The method can effectively solve this problem, but it is difficult to construct due to the small working space. By adopting the small spraying equipment of the present invention, the construction in a small space can be realized conveniently.

[0100] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com