A Stepless Adjustable Eccentric Rotating MIG Gas Shielded Welding Torch

A melting electrode gas, eccentric rotation technology, which is applied in the field of melting electrode gas shielded welding and eccentric rotating melting electrode gas shielded welding torches, can solve the problems of short service life, large welding torch size, complex eccentric mechanism, etc., to achieve stable welding and improve welding. Quality, simple and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

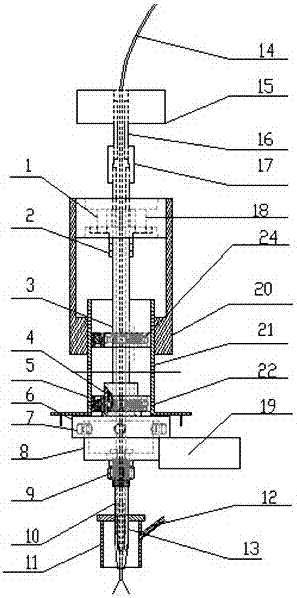

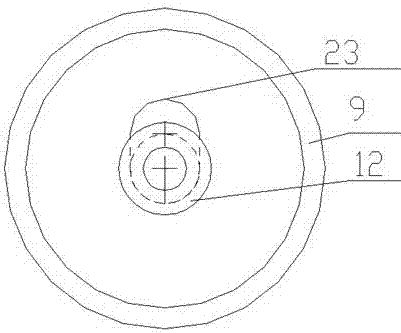

[0030] Such as figure 1 , figure 2 As shown, the present invention provides a steplessly adjustable eccentric rotating gas shielded welding torch, including a driving device, an eccentric device, a gas shielding device, a conductive rod, and a carbon brush.

[0031] The conductive rod is located in the middle of the driving device, the eccentric device, and the gas protection device, and the inside of the conductive rod is provided with a welding wire 14; the conductive rod is composed of upper and lower parts, the upper conductive rod 3 is fixed, and the lower conductive rod 10 is removable;

[0032] The driving device includes a hollow shaft torque motor 1, a connecting sleeve 2, an encoder 15, a connecting rod 16, and a shaft coupling 17; the motor 1 is fixed on the motor bracket 20, the upper end of the connecting sleeve 2 has a bolt hole, and the lower end is provided with a through hole. hole; motor 1 is provided with a through hole 18 to cooperate with the through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com