GTAW welding system and method suitable for ultra-narrow gap

A welding system and gap technology, used in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of difficult to guarantee the stability of the welding process, sensitive arc characteristics, and arc welding wire burnback, etc. Small heat input, the effect of reducing the processing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

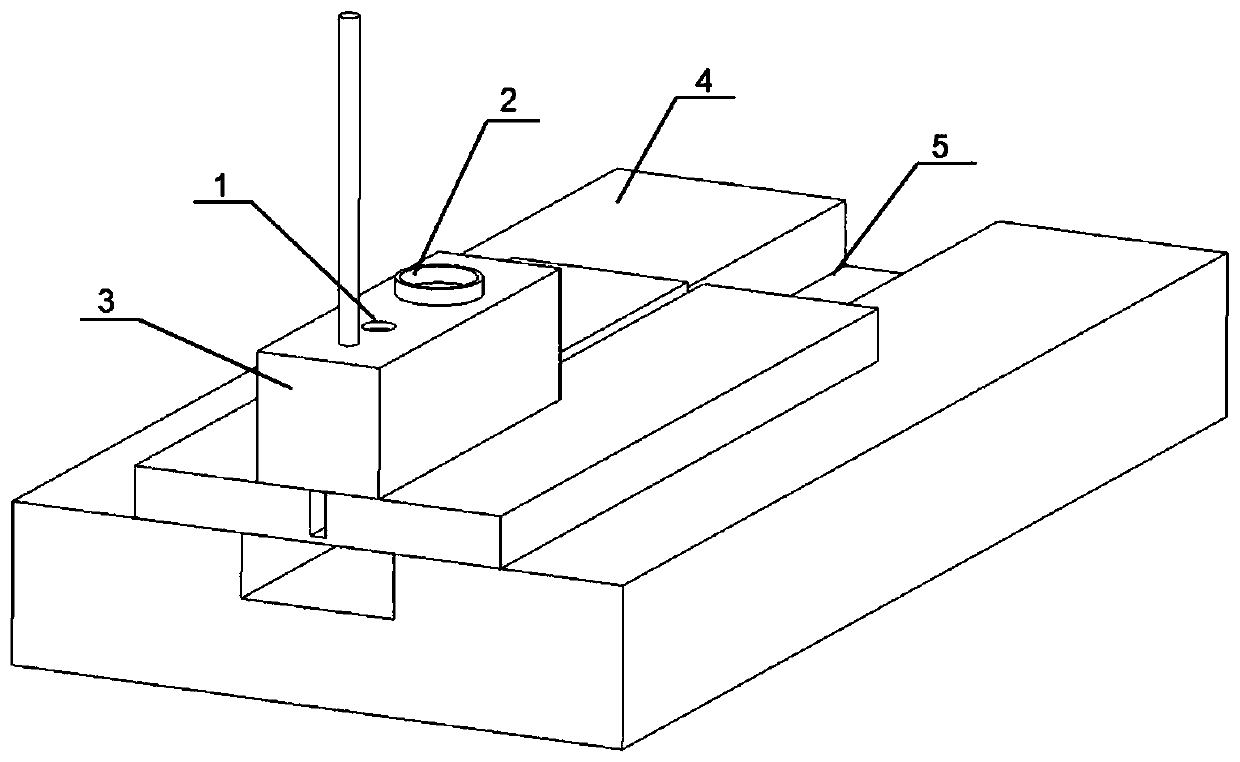

[0057] A GTAW welding system suitable for ultra-narrow gaps, including argon arc welding power supply, TIG welding torch, welding trolley, wire feeding device, and gas protection device.

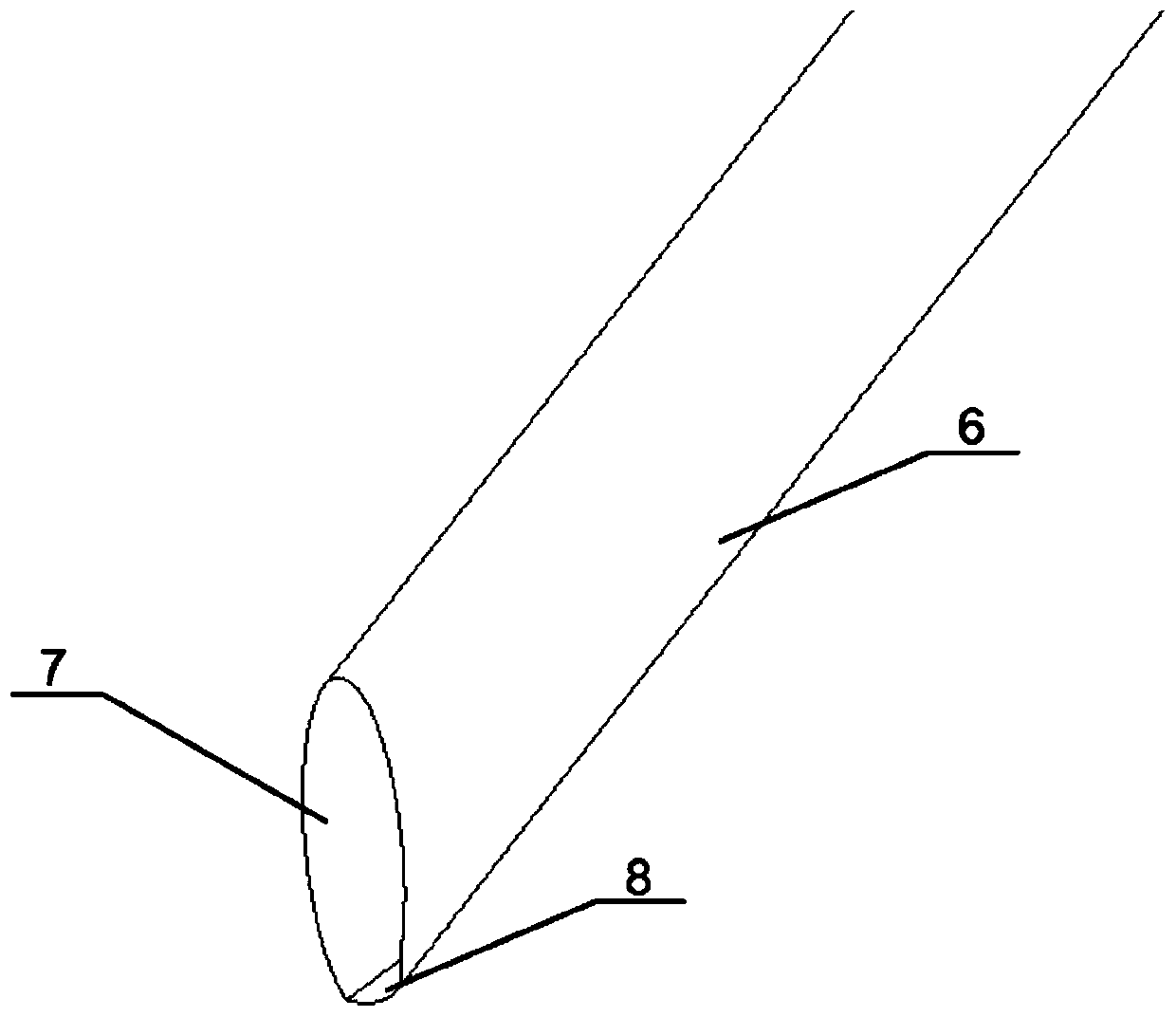

[0058] TIG welding torch includes torch shell, rotating motor, central rotating shaft, rotating tungsten pole, conductive system, and air supply system. The rotating motor is connected to the rotating tungsten pole through the central rotating shaft, and the rotating tungsten pole is non-axisymmetric. The argon arc welding power supply is connected and provides power, and the gas supply system is used to provide shielding gas to the welding torch; the rotating tungsten pole is driven to rotate periodically by a rotating motor.

[0059] The TIG welding torch is fixed on the welding trolley, and the TIG welding torch is driven by the welding trolley to move.

[0060] The wire feeding device is mechanically connected with the TIG welding torch and moves synchronously with the welding torch; the...

Embodiment 2

[0066] A GTAW welding system suitable for ultra-narrow gaps, its structure is as described in Embodiment 1, the difference is that the TIG welding torch is fixedly connected to the welding trolley through threaded bolts. The distance between the welding torch and the workpiece in the horizontal direction and the vertical height direction can be adjusted by adjusting the screw thread.

Embodiment 3

[0068] A GTAW welding system suitable for ultra-narrow gaps, its structure is as described in Embodiment 1, the difference is that the end of the central rotating shaft is tightly threaded with the rotating tungsten pole through anti-wire. On the one hand, it ensures good air tightness, and on the other hand, it ensures that the thread becomes tighter and tighter during the rotation process. During welding, the shielding gas circulates in the body of the torch to accelerate the heat dissipation of the central rotating shaft, the rotating tungsten pole and the conductive copper block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com