A rutile-type flux-cored welding wire with a yield strength exceeding 890mpa

A rutile type, yield strength technology, applied in welding equipment, welding medium, metal processing equipment, etc., can solve the problems of poor welding manufacturability, poor low temperature toughness of mechanical properties, high diffusible hydrogen content, and achieve excellent welding manufacturability and welding arc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

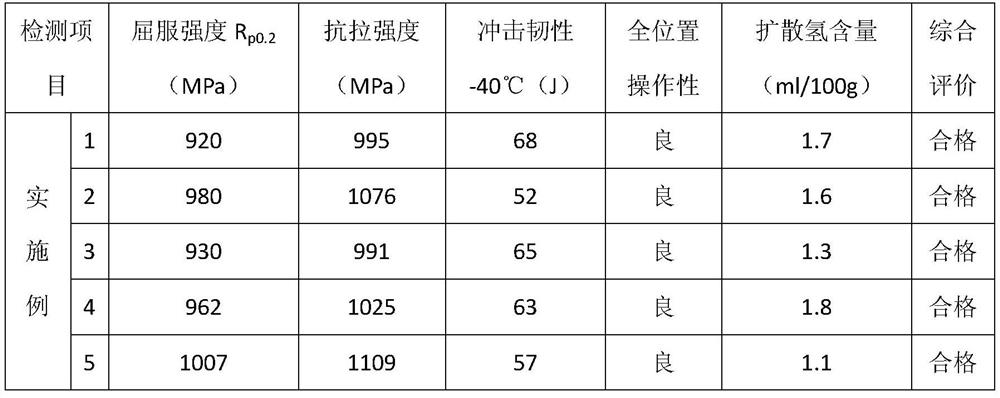

[0016] The present invention is described in further detail below in conjunction with specific embodiments:

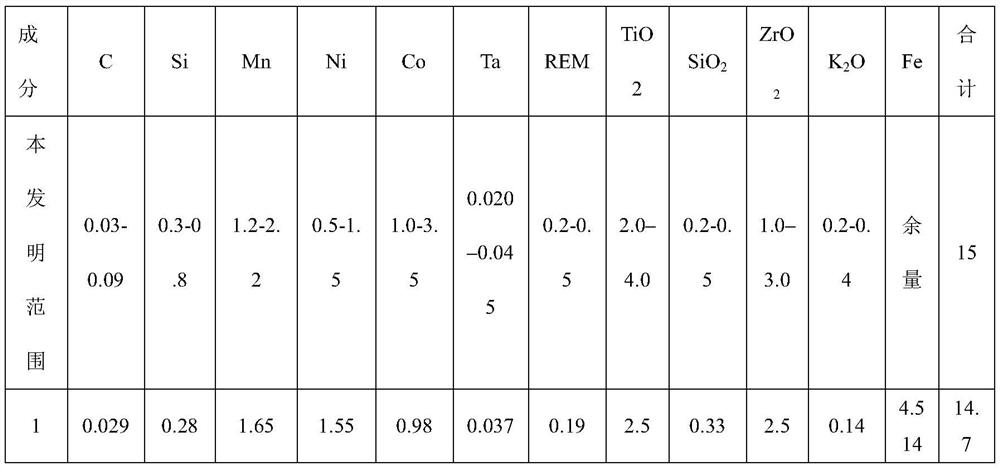

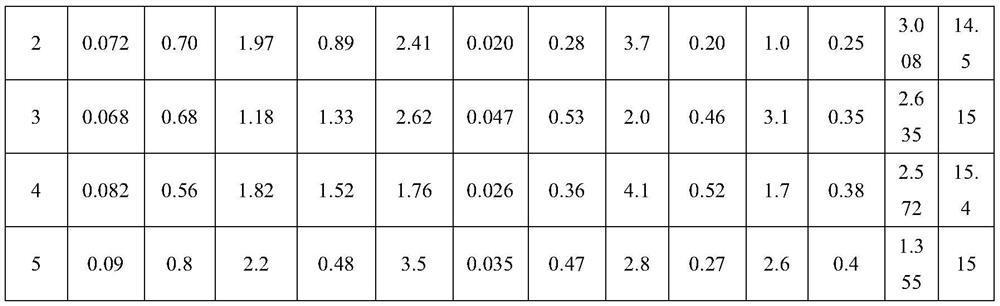

[0017] A rutile-type flux-cored wire suitable for welding low-alloy high-strength steels with a yield strength of over 890 MPa is composed of a steel strip wrapped with a flux core and a flux core filled in it. There is no gap, that is, in the form of seamless flux-cored welding wire, wherein the filling flux core contains slag-forming agent, arc stabilizer, alloying agent, etc. Has the following components:

[0018] C: 0.03-0.09%, Si: 0.3-0.8%, Mn: 1.2-2.2%, Ni: 0.5-1.5%, Co: 1.0-3.5%, Ta: 0.020-0.045%, REM (rare earth alloy): 0.2- 0.5%, TiO 2 : 2.0–4.0%, SiO 2 : 0.2-0.5%, ZrO 2 : 1.0–3.0%, K 2 O: 0.2-0.4%; the remainder is Fe and other inevitable impurities.

[0019] C can effectively improve the strength of the weld metal, but if the content is too high, the strength will increase too much and the toughness will be deteriorated. If the content is too low, it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com