Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Excellent ultra-low temperature toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

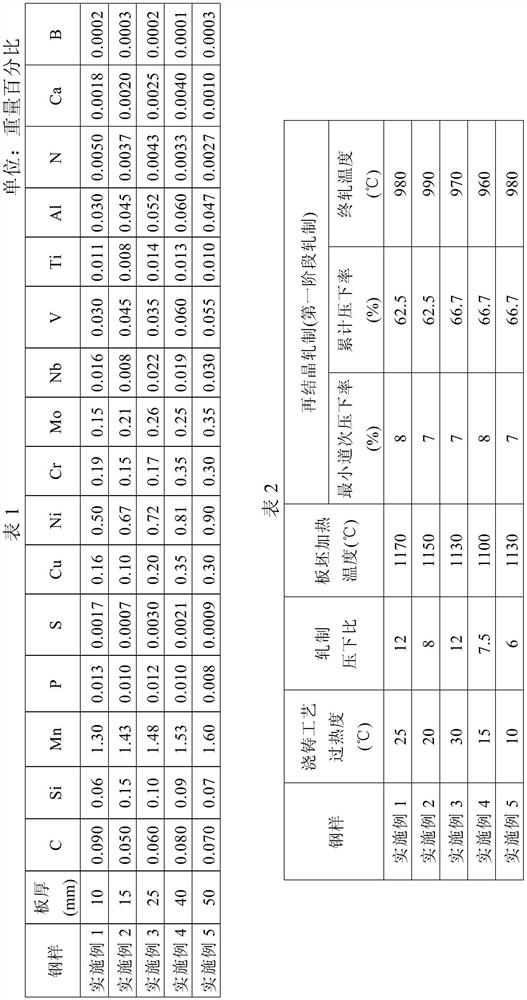

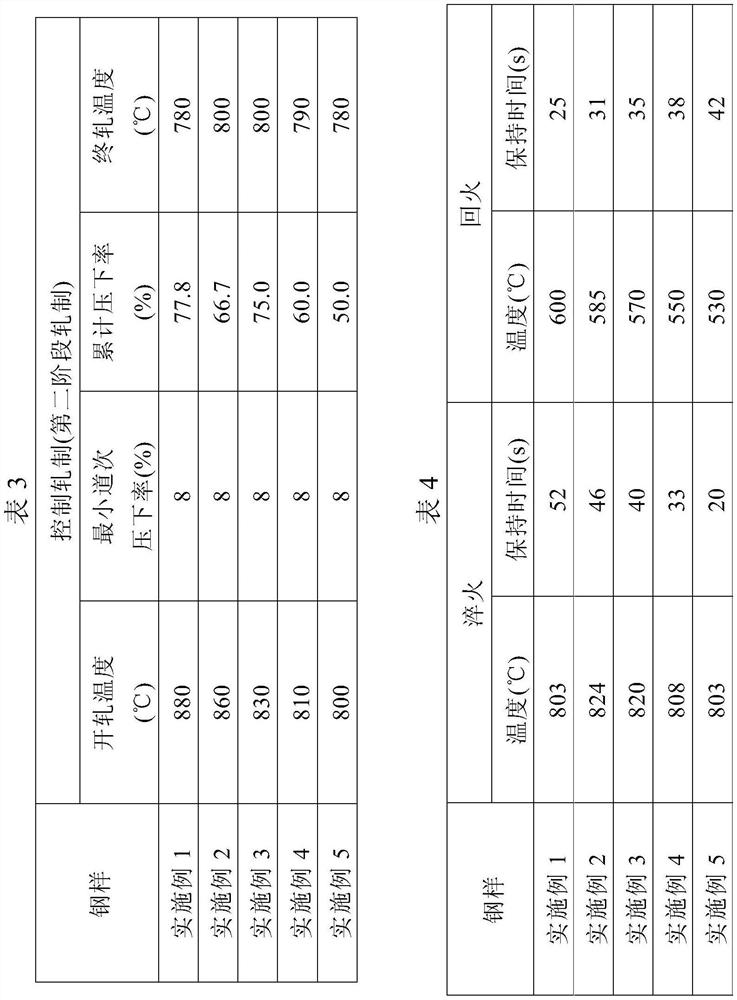

Steel used at lower temperature and method for manufacturing same

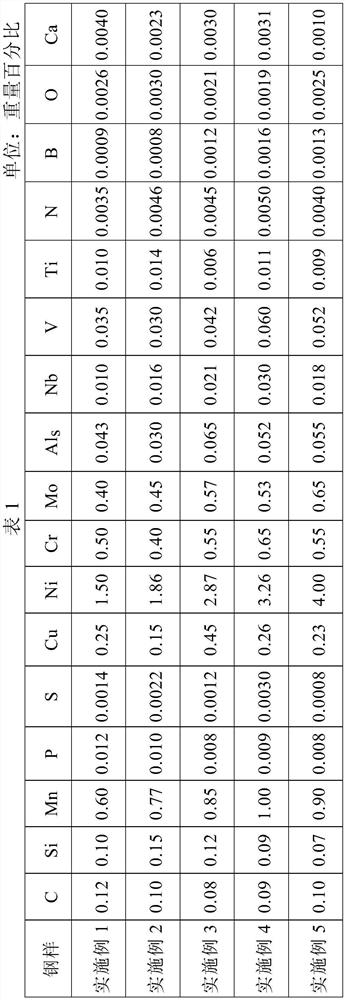

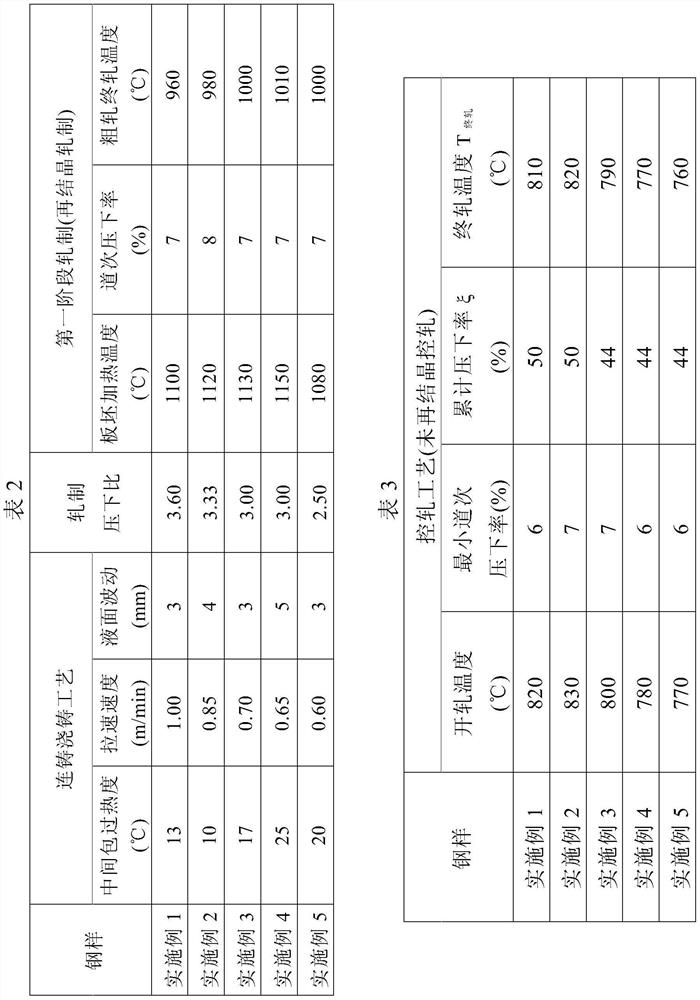

ActiveCN101545077AIncrease the content of acid-soluble AlsEliminate Recycling DifficultiesMetal rolling arrangementsSheet steelChemical composition

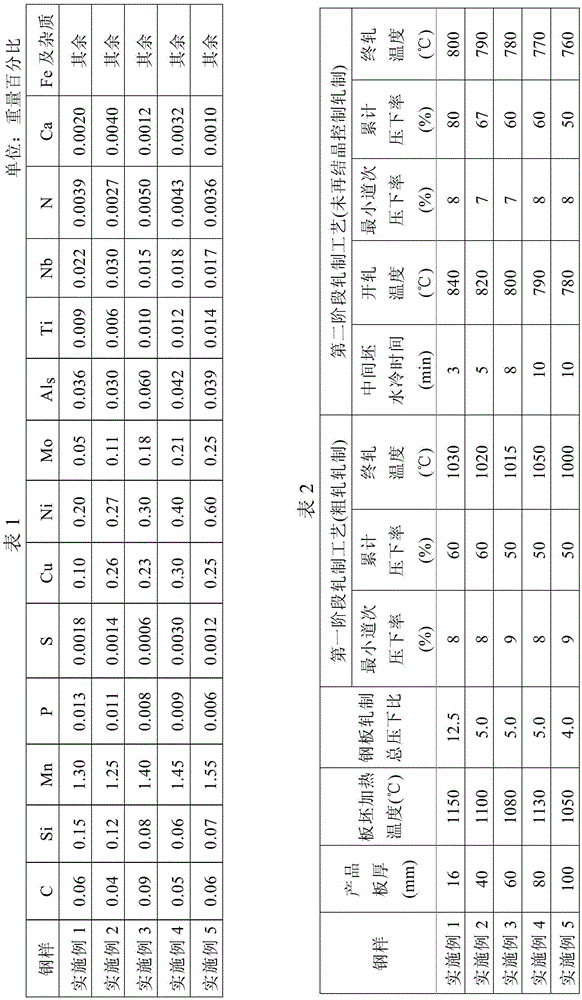

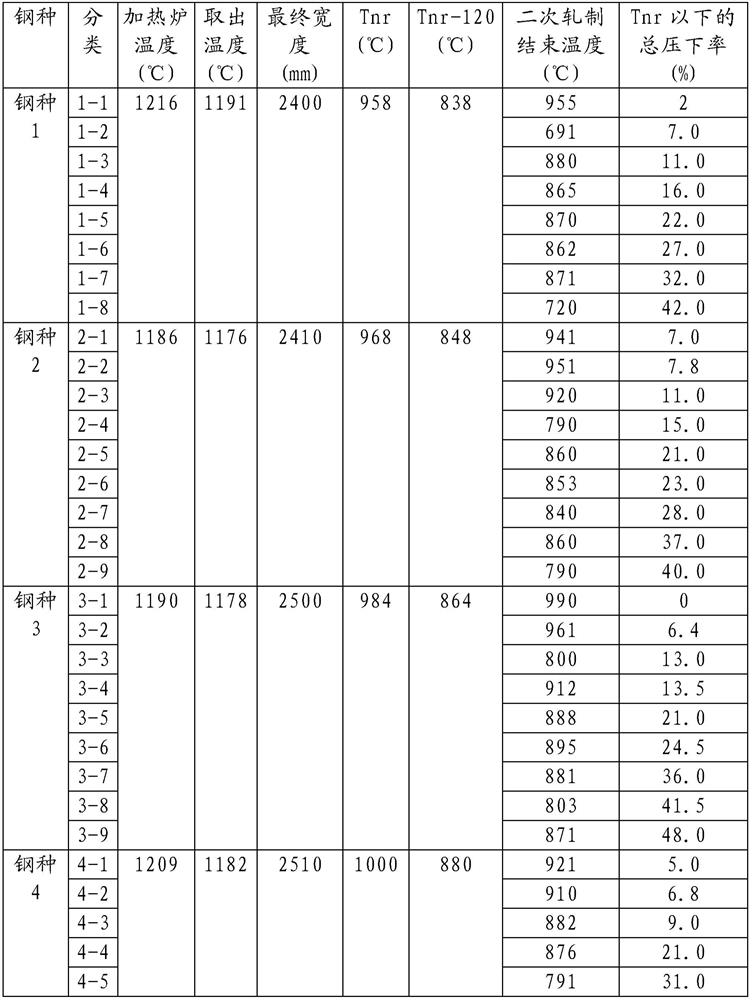

The invention discloses a steel used at a lower temperature and a method for manufacturing the same. The steel comprises the following chemical components by weight percentage: 0.060 to 0.090 percent of C, less than or equal to 0.20 percent of Si, 1.10 to 1.50 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.003 percent of S, 0.040 to 0.070 percent of Als, 0.05 to 0.45 percent of Cu, 0.05 to 0.35 percent of Ni, 0.05 to 0.30 percent of Cr, 0.007 to 0.011 percent of Ti, 0.007 to 0.020 percent of Nb, less than or equal to 0.0040 percent of N, 0.001 to 0.011 percent of Ca, and the balance of Fe and inevitable impurities. The manufacturing process comprises of the steps: making the steel plate obtain excellent low-temperature toughness and making the steel plate bear the big line energy welding. The steel and the method can be widely applied to petroleum natural gas pipelines, low-temperature gas tank bodies LPG, low temperature steel plates of LNG.

Owner:BAOSHAN IRON & STEEL CO LTD

HT550 steel plate with ultrahigh toughness and excellent weldability and manufacture method thereof

ActiveCN103320692AImprove performanceShorten the manufacturing cycleFurnace typesQuenching agentsSheet steelYield ratio

Owner:BAOSHAN IRON & STEEL CO LTD

Full-automatic submerged-arc welding solid-core welding wire for high-manganese steel for preparing LNG storage tank

ActiveCN107052618AAvoid organizationAvoid performance changesArc welding apparatusWelding/cutting media/materialsUltimate tensile strengthToughness

The invention discloses a full-automatic submerged-arc welding solid-core welding wire for high-manganese steel for preparing an LNG storage tank. According to the technical scheme, the full-automatic submerged-arc welding solid-core welding wire comprises 0.25-0.45wt% of C, 23-26wt% of Mn, 6-8wt% of Ni, 3-5wt% of W, 0.02-0.04wt% of N, less than or equal to 0.02wt% of P, less than or equal to 0.001wt% of S and the balance of Fe and inevitable impurities. The full-automatic submerged-arc welding solid-core welding wire has the advantages that the price of adopted alloy elements is low, and an alloy component system is simple; and the low-temperature toughness of weld metal formed by the prepared full-automatic submerged-arc welding solid-core welding wire is excellent, the strength of the full-automatic submerged-arc welding solid-core welding wire is matched with the strength of the ultralow-temperature high-manganese steel for preparing the LNG storage tank, and the technical requirements for the strength and the ultralow-temperature toughness of the welded LNG storage tank can be met.

Owner:WUHAN UNIV OF SCI & TECH +1

Tungsten electrode argon arc welding solid cored welding wire used for welding ultralow-temperature high manganese steel

ActiveCN107009046AAvoid performance changesReduce contentWelding/cutting media/materialsSoldering mediaUltimate tensile strengthToughness

The invention relates to a tungsten electrode argon arc welding solid cored welding wire used for welding ultralow-temperature high manganese steel. According to the technical scheme of the solid cored welding wire, the tungsten electrode argon arc welding solid cored welding wire used for welding the ultralow-temperature high manganese steel comprises the chemical components of 0.25-0.55 wt% of C, 23-26 wt% of Mn, 8-10 wt% of Ni, 3-5 wt% of W, less than or equal to 0.002 wt% of P, less than or equal to 0.001 wt% of S and the balance Fe and inevitable impurities. The solid cored welding wire is low in price of alloy element content and simple in alloy component system; and formed weld metal has good low-temperature toughness, and the strength of the weld metal is matched with the ultralow-temperature high manganese steel, and the technical requirements for the strength and ultralow-temperature toughness of LNG devices and other devices prepared through welding.

Owner:WUHAN UNIV OF SCI & TECH +1

High-efficiency submerged arc welding metal powder-cored flux-cored wire used for ultra-low-temperature high-manganese steel

ActiveCN109530964AAvoid microstructureAvoid mechanical propertiesWelding/cutting media/materialsSoldering mediaElectrolysisSilicon alloy

The invention discloses a high-efficiency submerged arc welding metal powder-cored flux-cored wire used for ultra-low-temperature high-manganese steel, the high-efficiency submerged arc welding metalpowder-cored flux-cored wire is composed of a steel strip and a metal powder core, the chemical composition of the steel strip is as follows: C is 0.20-0.23 wt%, Si is 0.03-0.05 wt%, Mn is 6-8 wt%, P<=0.002 wt%, S <=0.001 wt%, the balance is Fe and unavoidable impurities. The chemical composition of the metal powder core is as follows: 18-20wt% of electrolytic manganese, 3-4wt% of manganese-silicon alloy, 8-10wt% of nickel powder, 6-8wt% of low-carbon ferrochromium, 4-6wt% of tungsten powder, 2.0-3.0 wt% of potash feldspar, and the balance of iron powder, and the total component content is 100%. The invention can meet the technical requirements for the strength and ultra-low temperature toughness of the welded LNG storage tank.

Owner:NANJING IRON & STEEL CO LTD +1

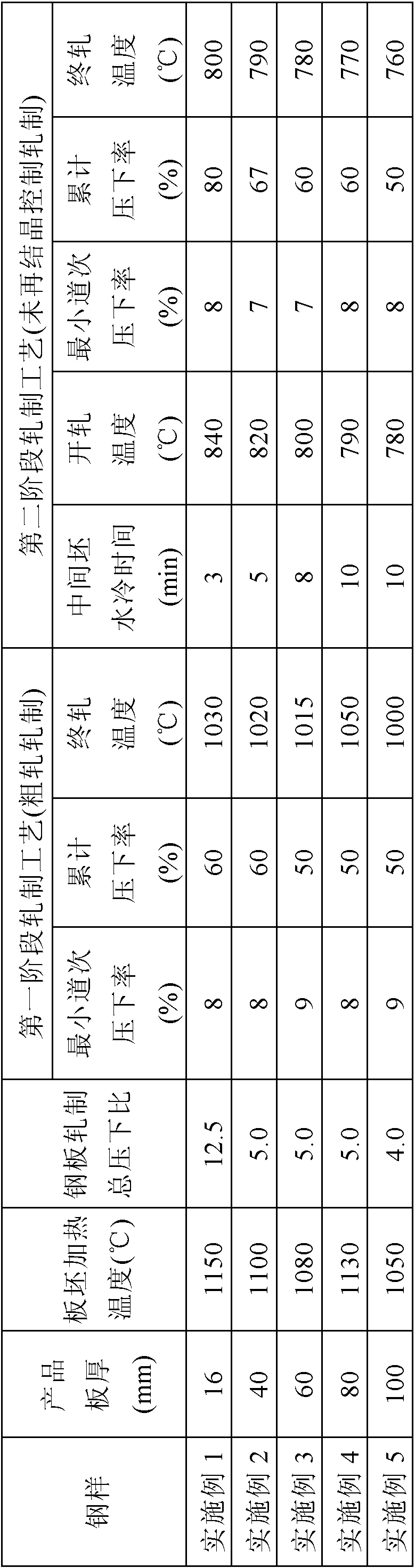

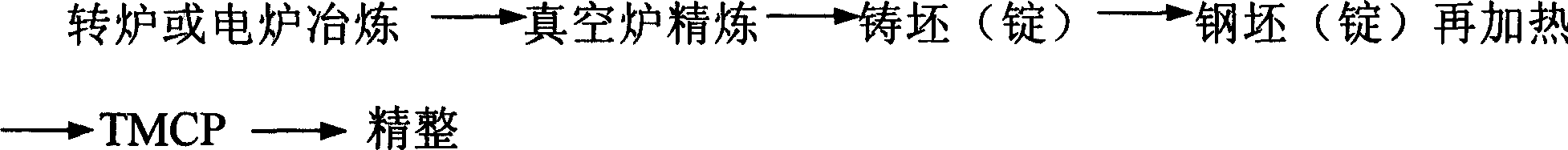

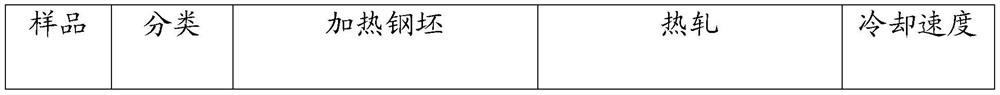

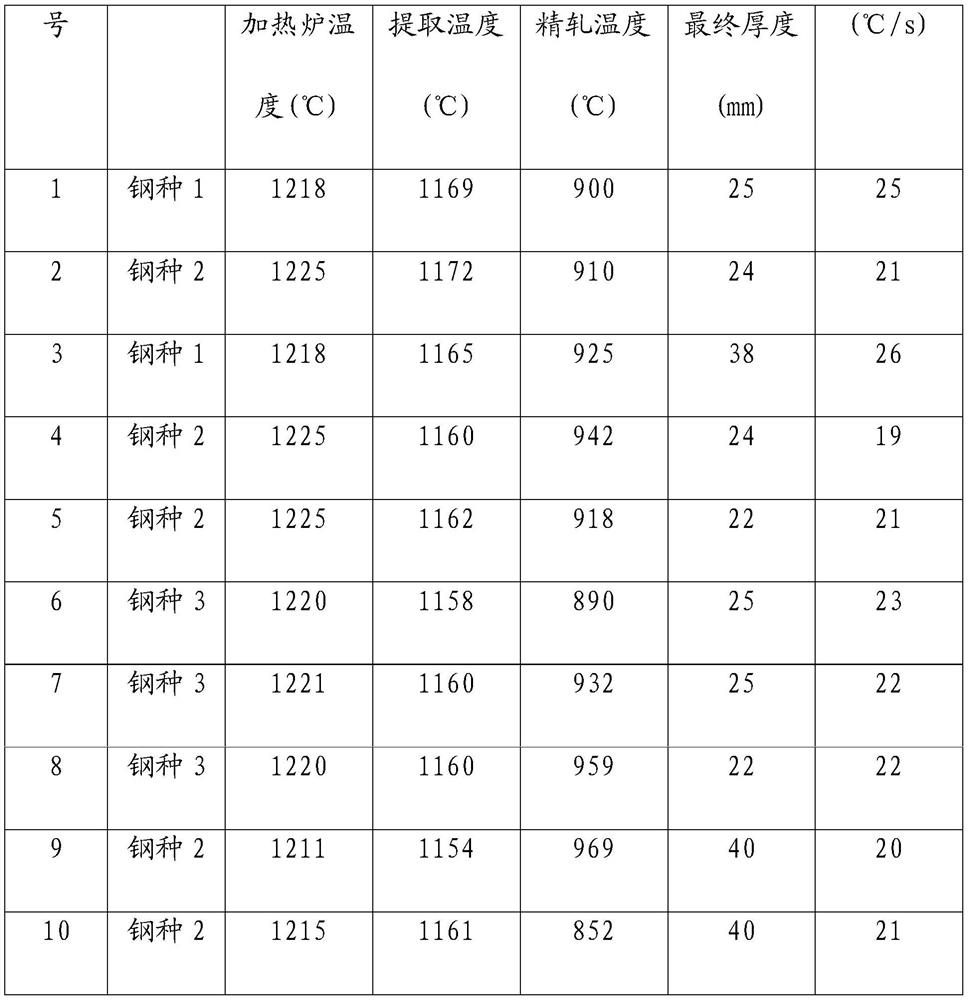

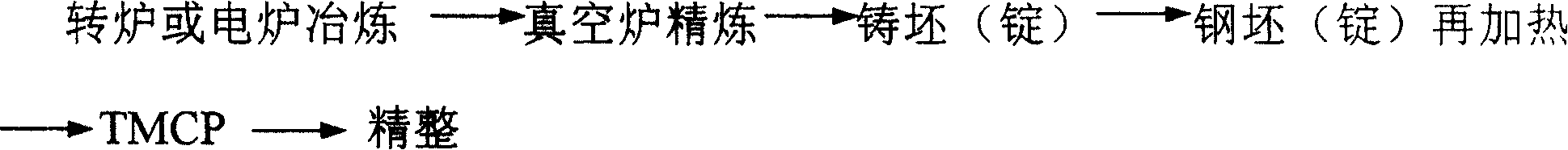

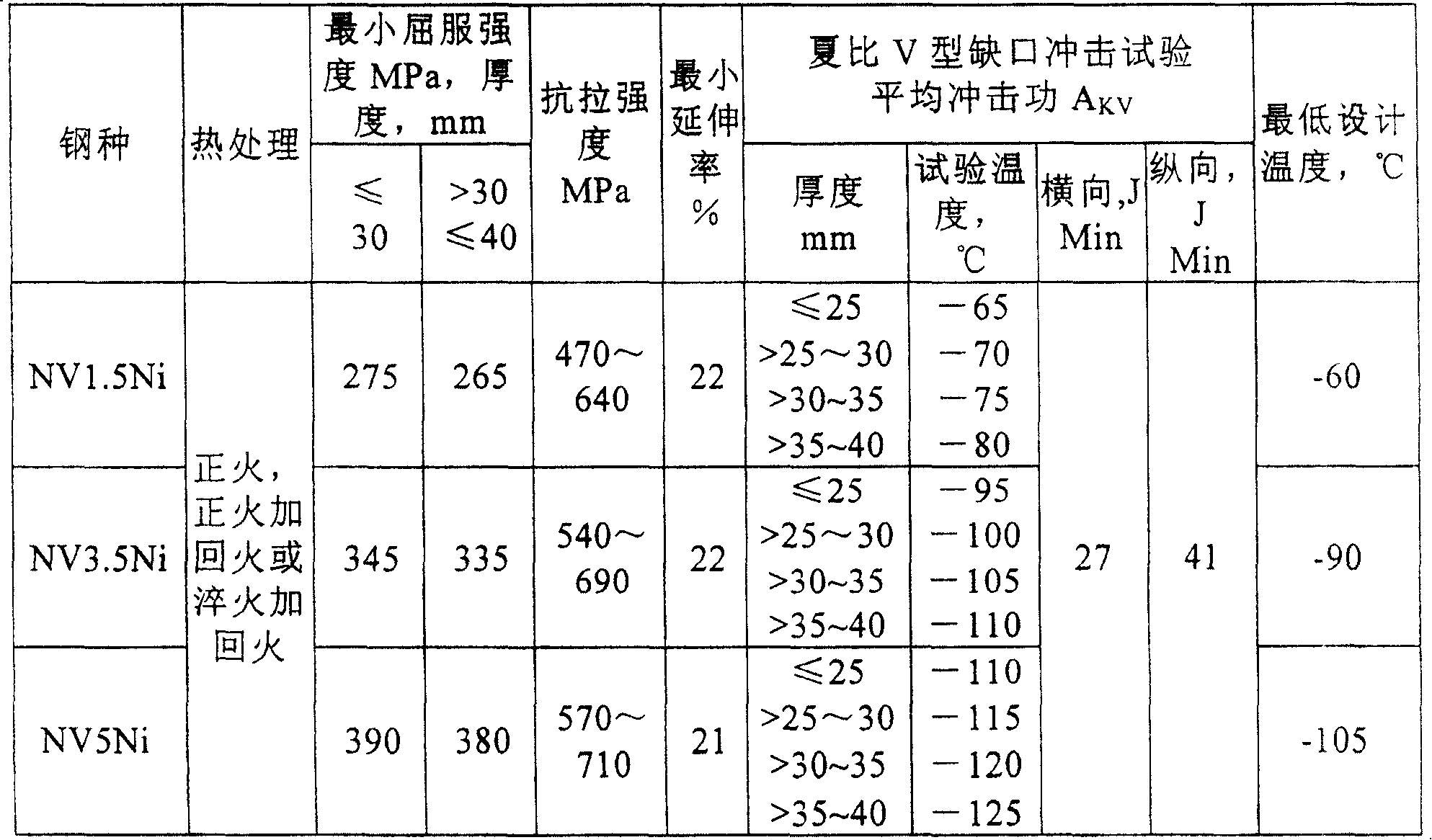

Steel for low temperature and high tenacity structure use and its production method

InactiveCN1840725AIncrease the amount of participationIncrease the precipitation densityChemical compositionForeign substance

The invention provides a low-temperature high ductility constructional steel, wherein the chemical constituents include (by weight percent): C 0.04-0.08, Si 0.60-0.80, Mn 1.65-2.15, Nb 0.055-0.075, Ti 0.010-0.020, AlT 0.025-0.045, P<=0.012, S<=0.003, O<=0.0015, N 0.008-0.012, balancing Fe and unavoidable foreign substance. The preparation method comprises the steps of smelting, refining, casting, billet reheating, rolling, fast cooling, and finishing.

Owner:BAOSHAN IRON & STEEL CO LTD

Ultra-thick, ultra-high-toughness and excellent-weldability 1000 MPa-grade steel plate and manufacturing method thereof

ActiveCN112143958AHigh strengthGood plasticityFurnace typesHeat treatment furnacesTemperingToughness

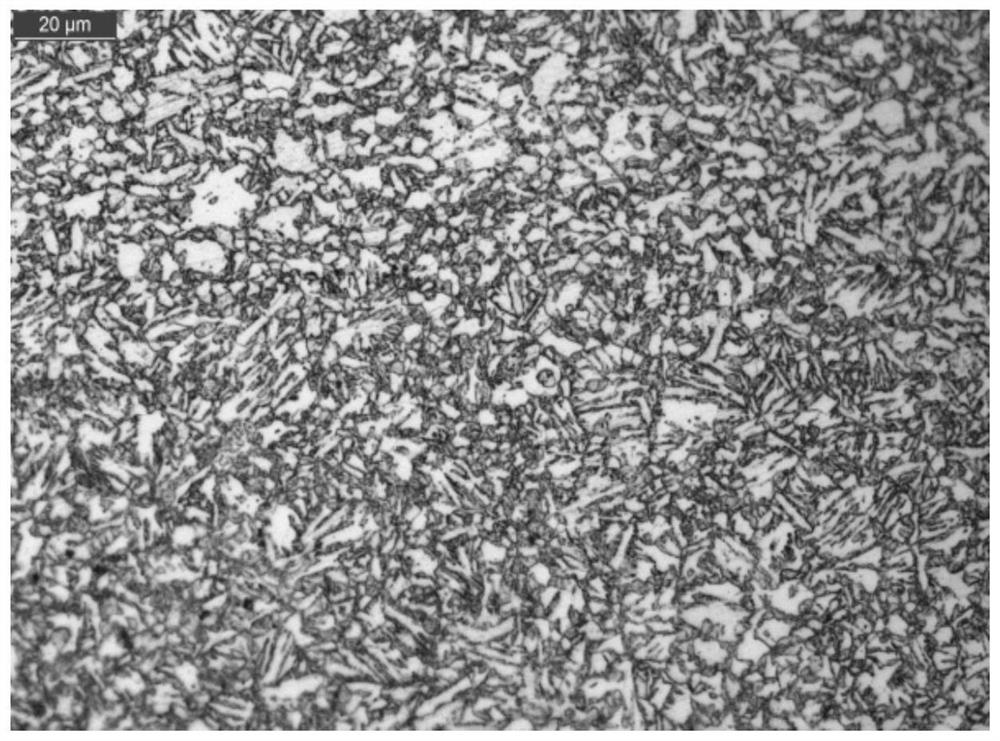

The invention discloses an ultra-thick, ultra-high-toughness and excellent-weldability 1000 MPa-grade steel plate and a manufacturing method thereof. A component system of ultra-low C-ultra-low Si-medium Mn-(Ti+Nb+V+B) microalloyed steel is adopted as the basis, the content of acid-soluble Als in the steel is properly increased, metallurgical methods that Als / [(%N)-0.292(%Ti)] is larger than or equal to 23, (%C)*(%Si) is smaller than or equal to 0.016, Ca treatment is performed, a Ca / S ratio is 1.00-3.00, and (%Ca)*(%S)0.18 is smaller than or equal to 2.5*10<-3> are adopted, TMCP plus off-linequenching and tempering process (QT) is optimized, [H*(t<relaxation>)*xi] / [(T<finish rolling>-T <cooling stopping>)*(Ceq*V<cooling rate>)] is controlled to be larger than or equal to 40 and smaller than or equal to 550, (T<quenching>)*[lg(t<quenching maintenance>)] / [(%Mo)+0.73(%Cr)+1.67(%V)+311(%B)] is controlled to be larger than or equal to 730 and smaller than or equal to 1050, and [(T<tempering>)*[lg(t<tempering maintenance>)] / DI is controlled to be larger than or equal to 320 or smaller than or equal to 120, the microstructure of the finished steel plate is fine low carbon tempered martensite plus little tempered lower bainite, the average crystal size is less than 20[mu]m, and the excellent plasticity and toughness HT950 steel plate is obtained.

Owner:BAOSHAN IRON & STEEL CO LTD

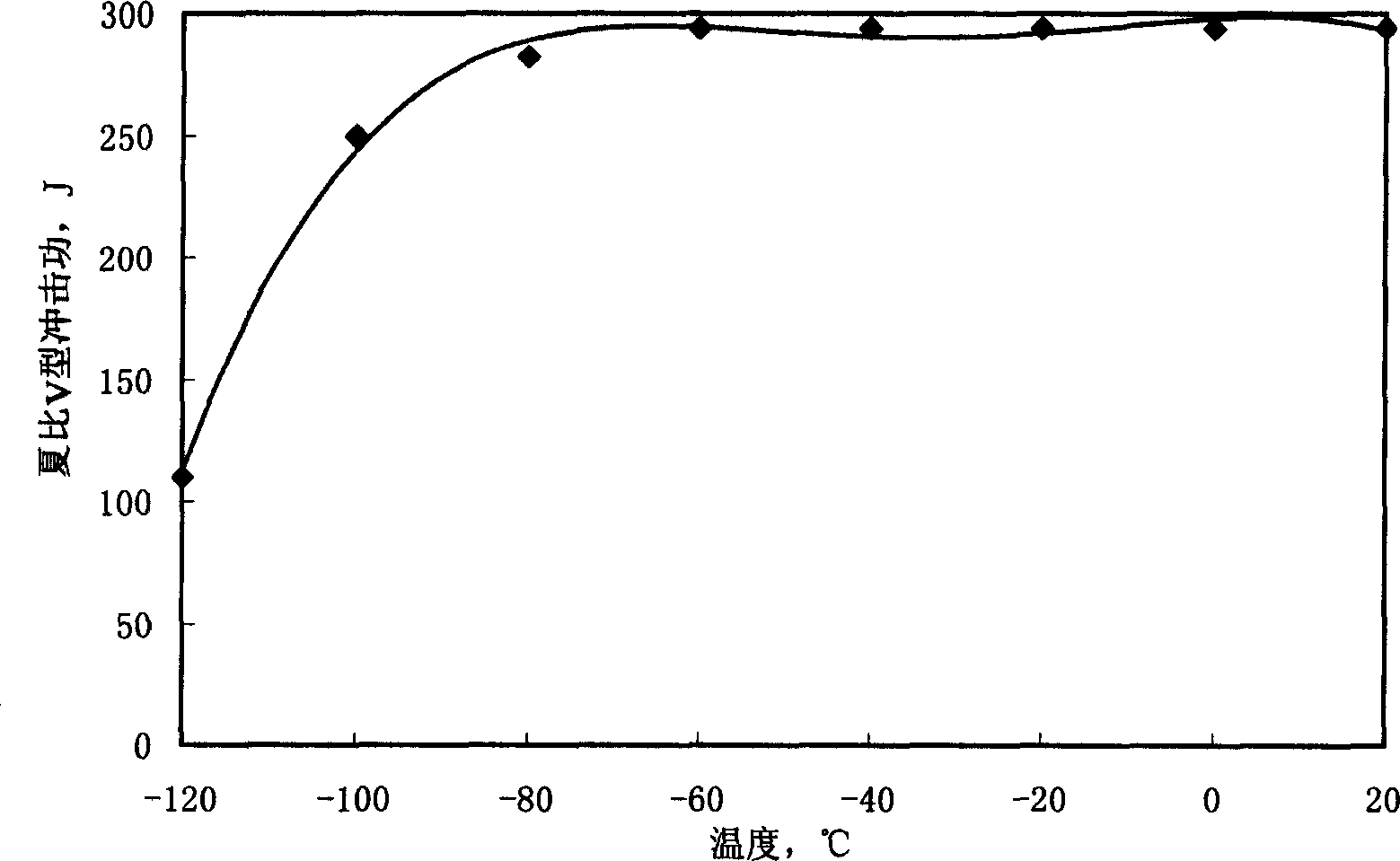

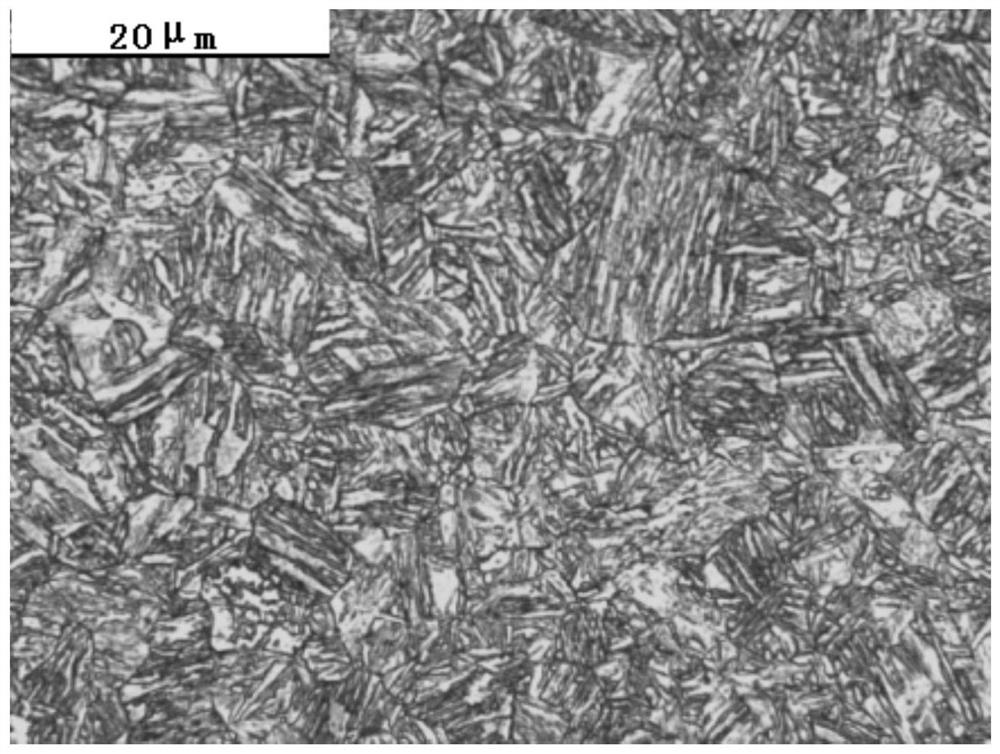

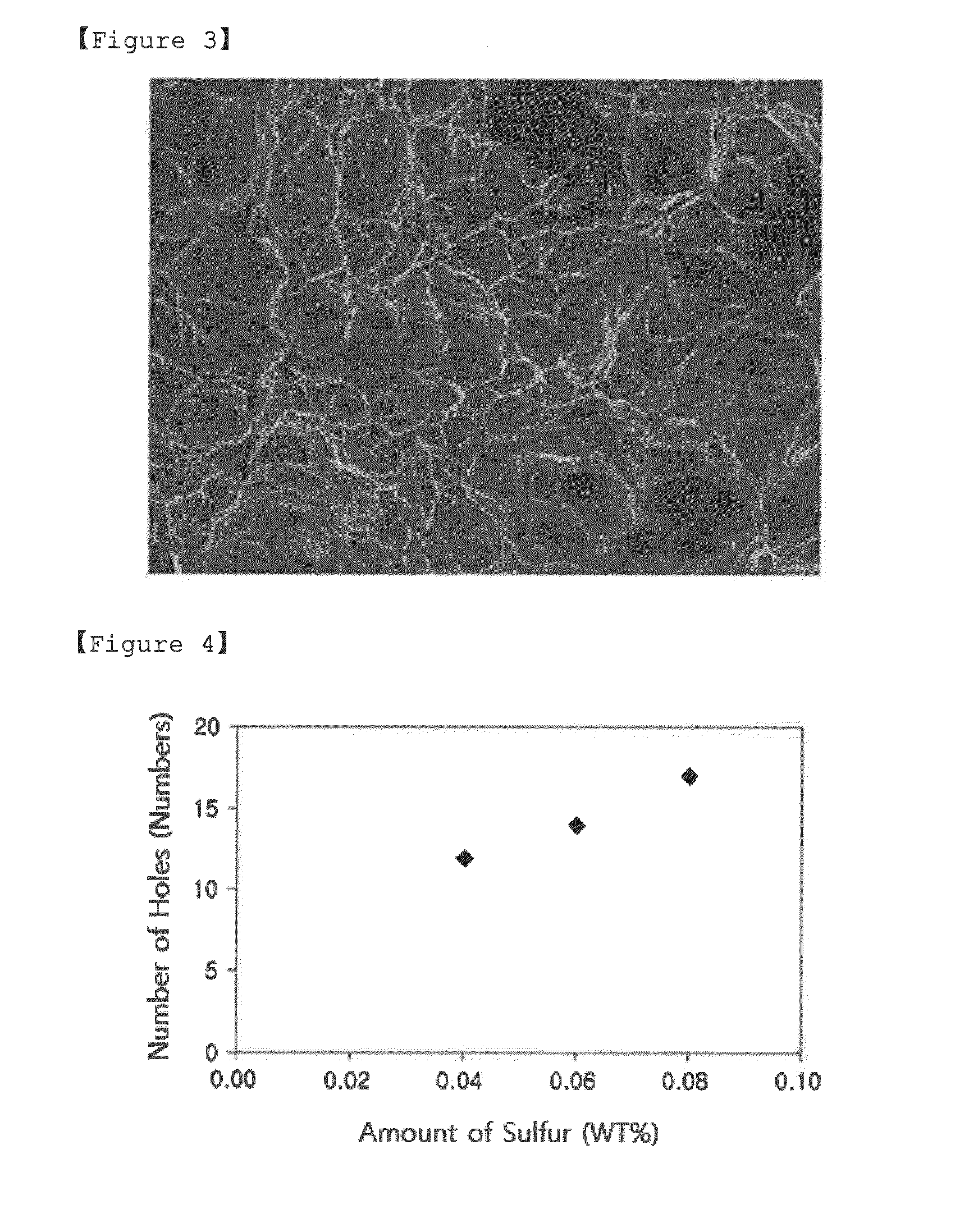

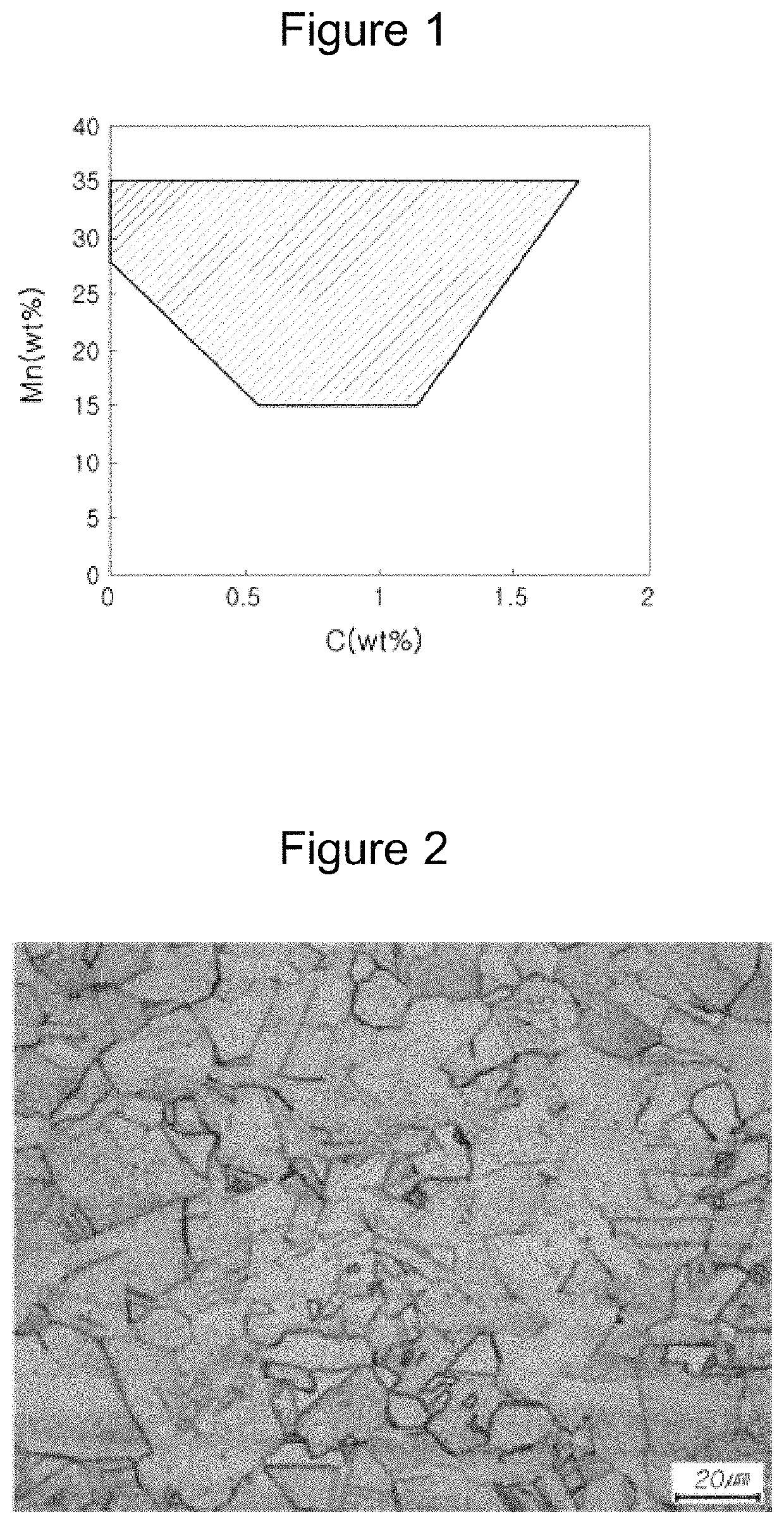

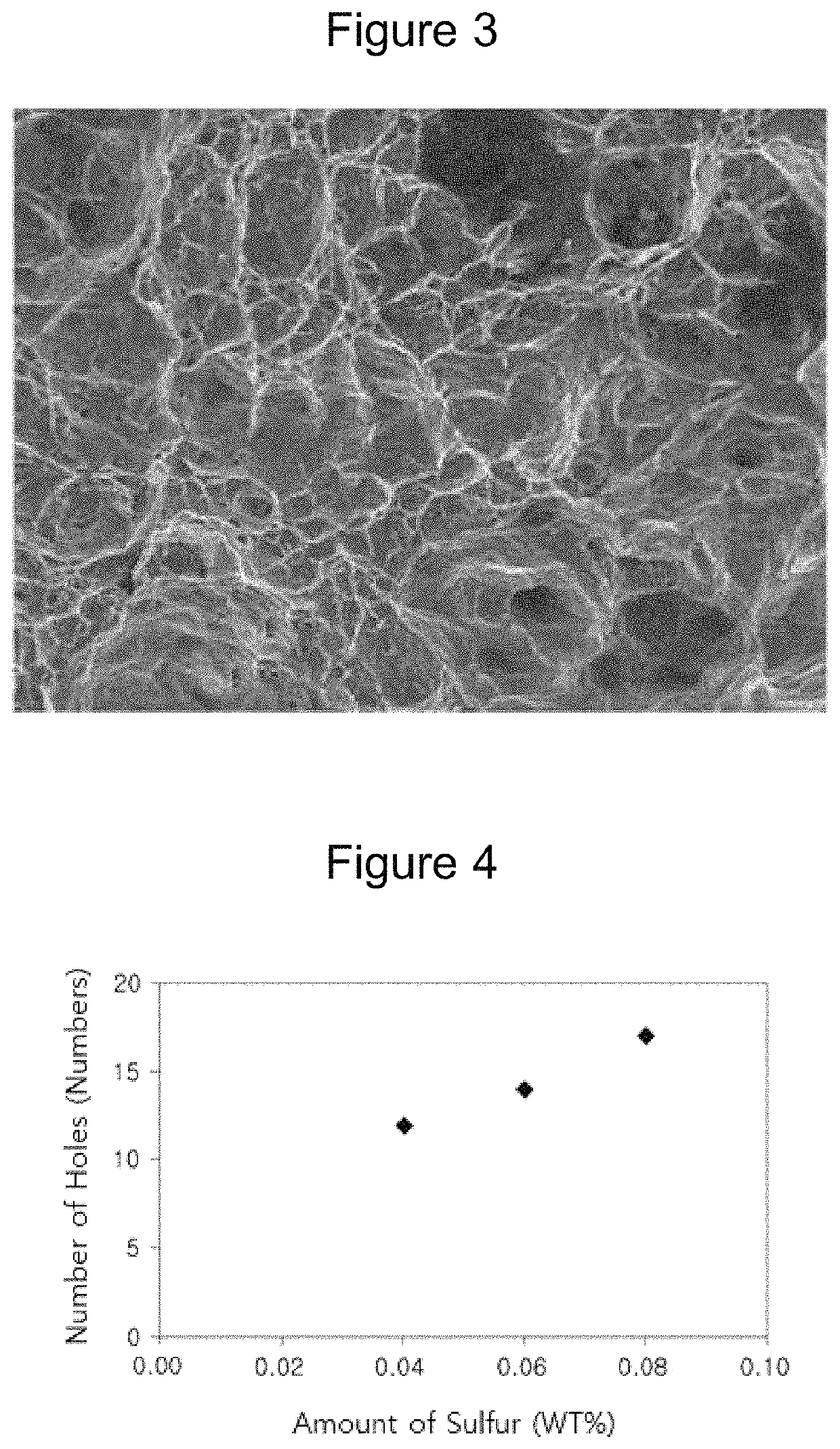

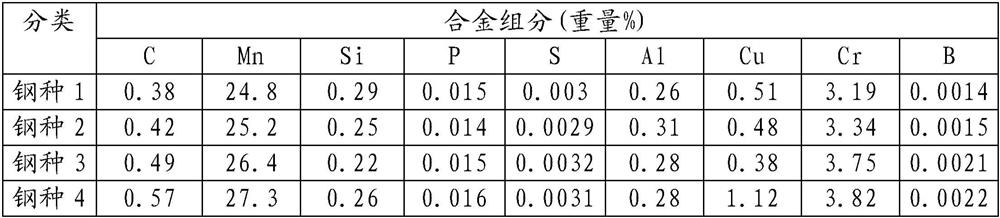

Ultralow-temperature excellent-tenacity high-manganese medium-thick plate and preparation method thereof

ActiveCN108504936AExcellent ultra-low temperature toughnessHigh strengthAlloy elementChemical composition

The invention discloses an ultralow-temperature excellent-tenacity high-manganese medium-thick plate and a preparation method of the medium-thick plate, and belongs to the technical field of steel materials. The medium-thick plate is prepared from, by weight, 0.31-0.67% of C, 0.02-0.48% of Si, 22.0-27.3% of Mn, 0.08% or less of P, 0.06% of less of S, 1.5-4.64% of Al and the balance Fe and inevitable impurities. The preparation method comprises the steps that 1, a steel blank is heated and kept warm; 2, the heated steel blank is rolled in the first stage to form a hot-rolled steel material; and3, the hot-rolled steel material is cooled, and the -196 DEG C excellent-tenacity high-manganese medium-thick plate is obtained. The high-manganese medium-thick plate can be used after being rolled and has excellent ultralow-temperature tenacity and high strength, alloy elements do not need to be added, and the cost is far lower compared with 9Ni steel.

Owner:NORTHEASTERN UNIV

Austenitic steel having excellent machinability and ultra-low temperature toughness in weld heat-affected zone, and method of manufacturing the same

ActiveUS20150020928A1Excellent ultra-low temperature toughnessImprove machinabilityFurnace typesWelding/cutting media/materialsHeat-affected zoneManganese

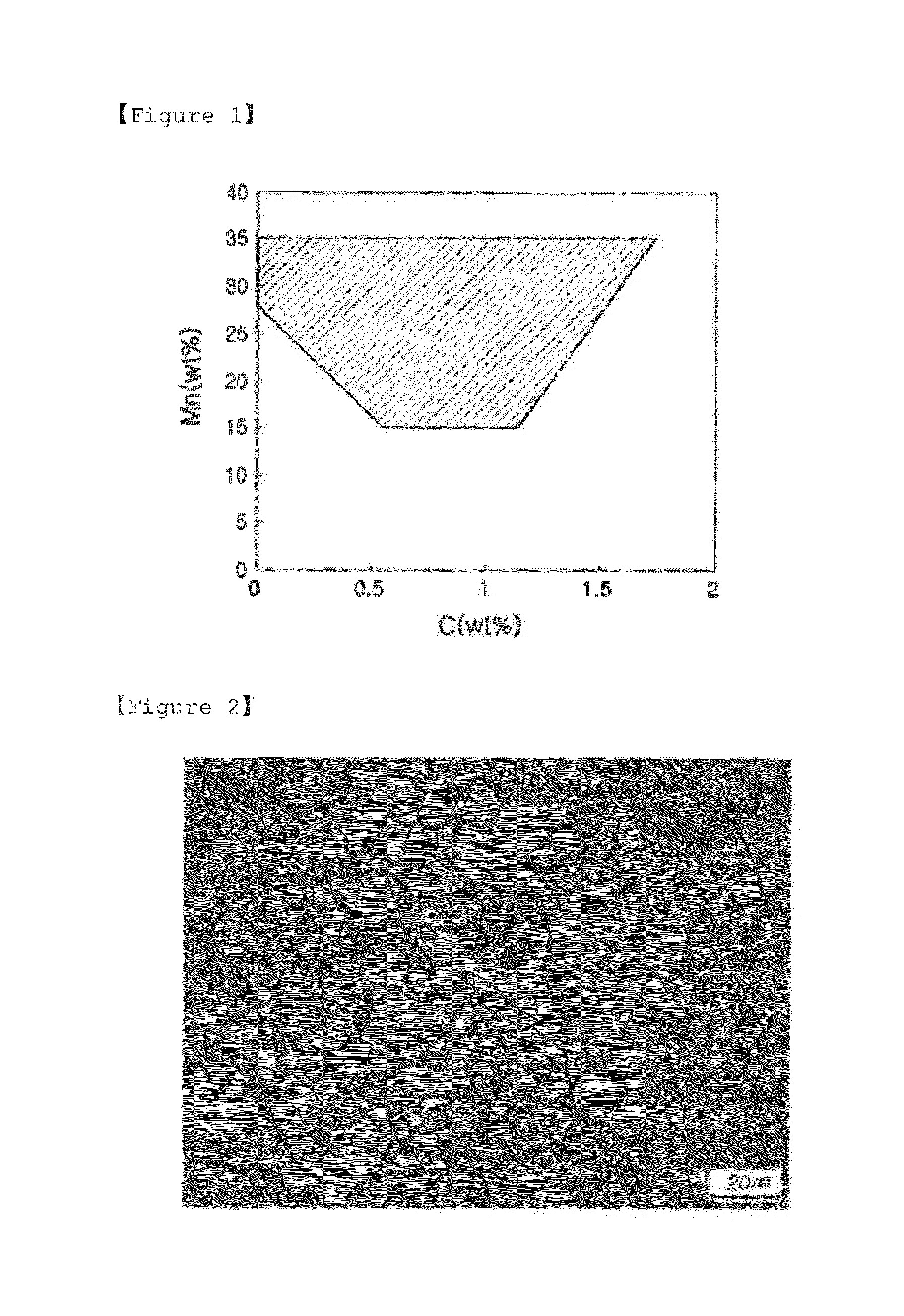

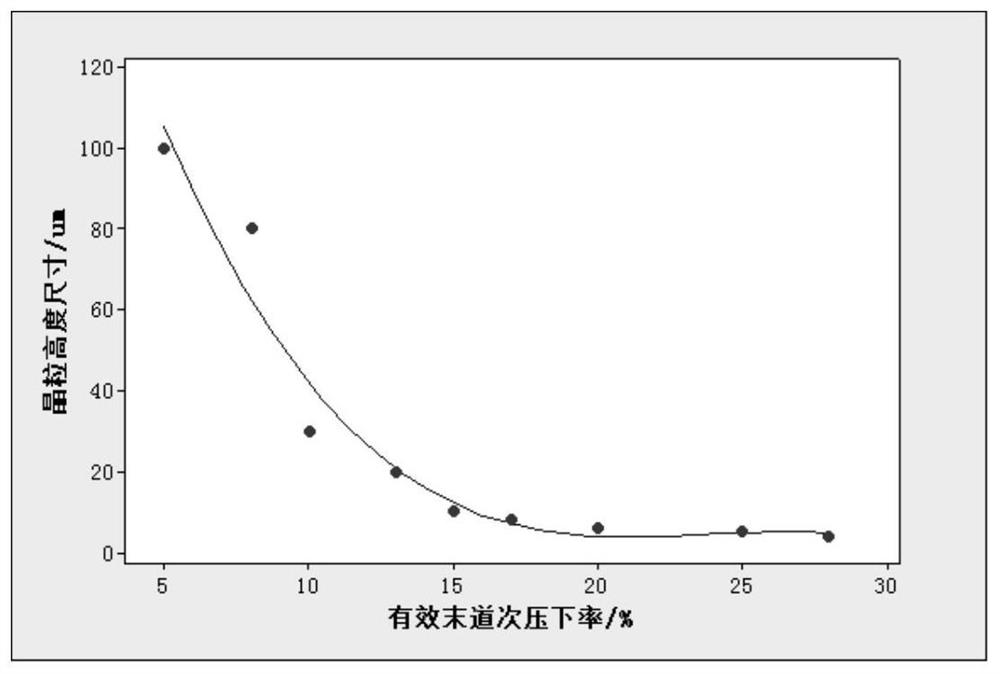

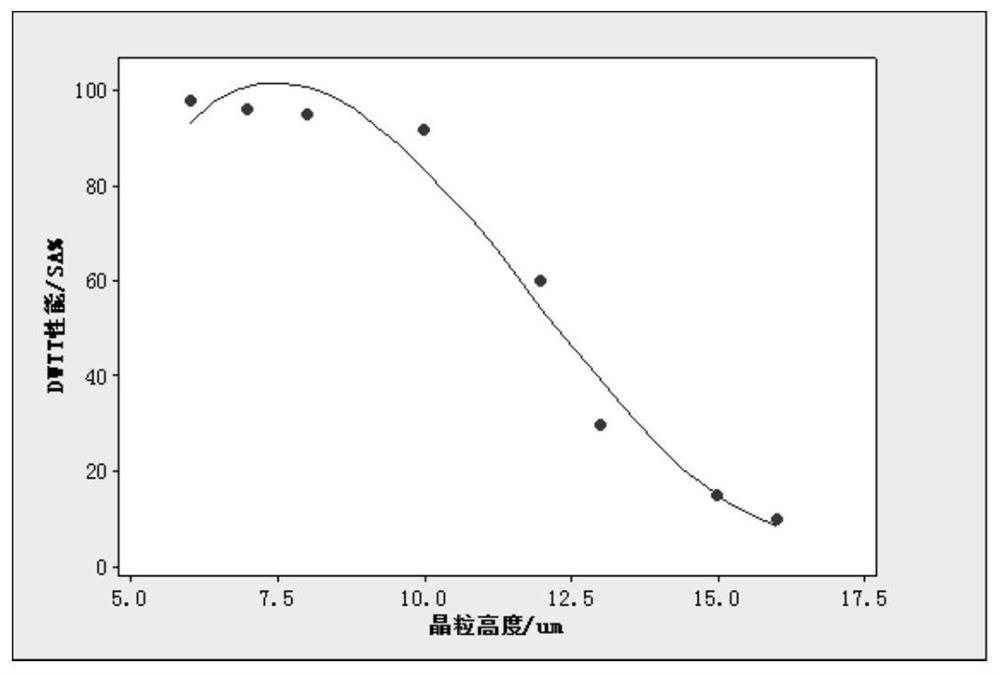

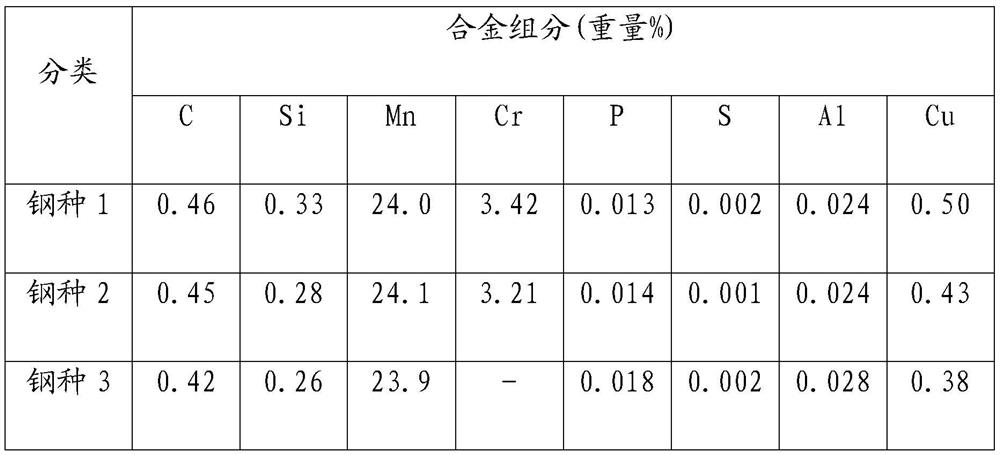

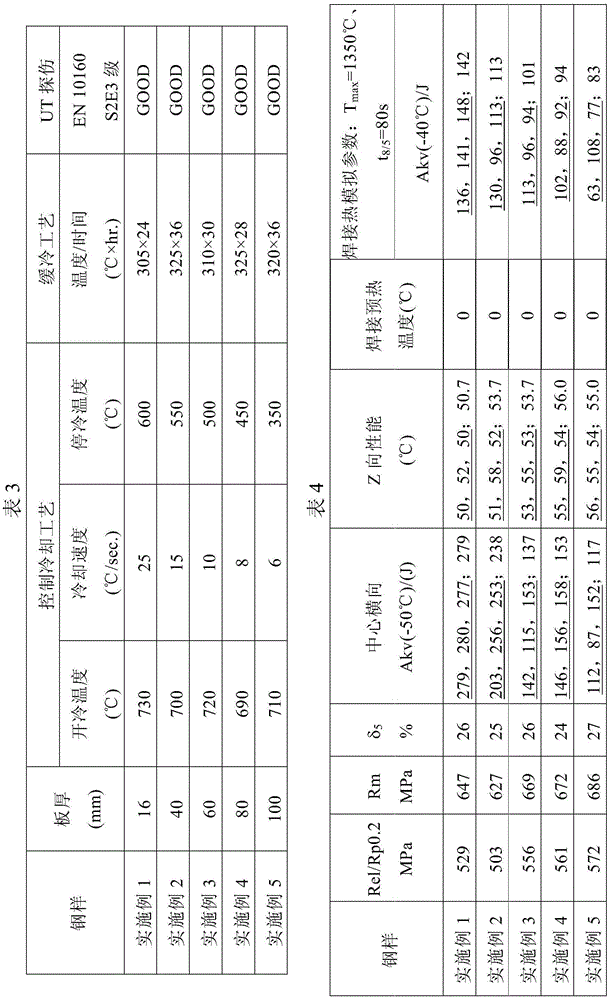

Provided are an austenitic steel having excellent machinability and ultra-low temperature toughness in a weld heat-affected zone including 15 wt % to 35 wt % of manganese (Mn), carbon (C) satisfying 23.6C+Mn≧28 and 33.5C−Mn≦23, 5 wt % or less (excluding 0 wt %) of copper (Cu), chromium (Cr) satisfying 28.5C+4.4Cr≦57 (excluding 0 wt %), and iron (Fe) as well as other unavoidable impurities as a remainder, wherein a Charpy impact value of a weld heat-affected zone at −196° C. is 41 J or more, and a method of manufacturing the steel.According to the present invention, a low-cost ultra-low temperature steel may be obtained, a stable austenite phase may be formed at low temperature, carbide formation may be effectively suppressed, and a structural steel having excellent machinability and ultra-low temperature toughness in a weld heat-affected zone may be provided.

Owner:POHANG IRON & STEEL CO LTD

Steel used at lower temperature and method for manufacturing same

ActiveCN101545077BIncrease the content of acid-soluble AlsEliminate Recycling DifficultiesMetal rolling arrangementsCompound (substance)Toughness

Owner:BAOSHAN IRON & STEEL CO LTD

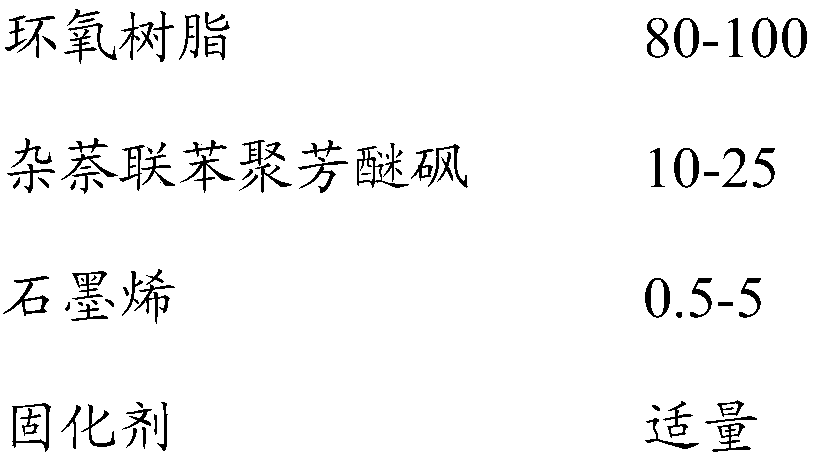

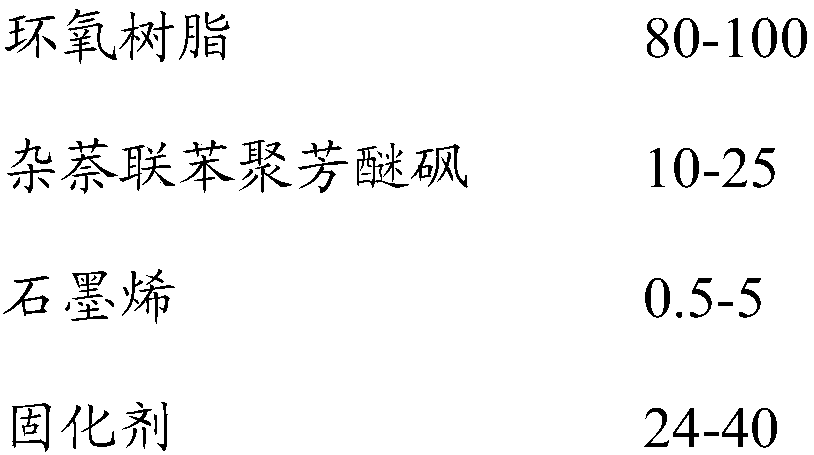

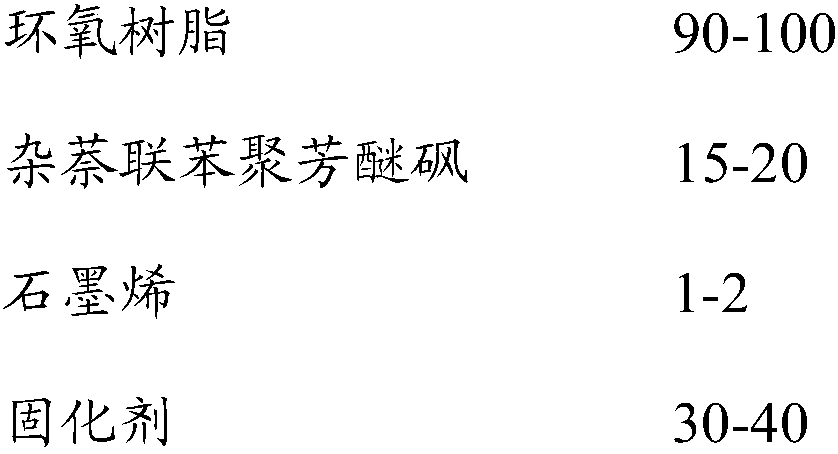

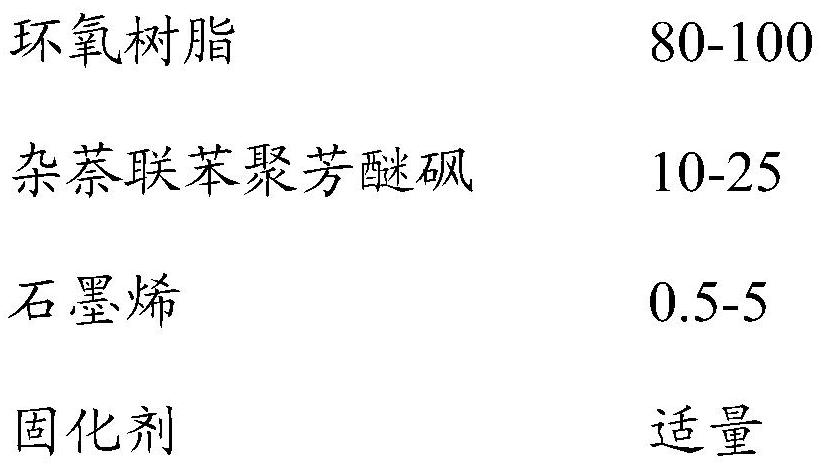

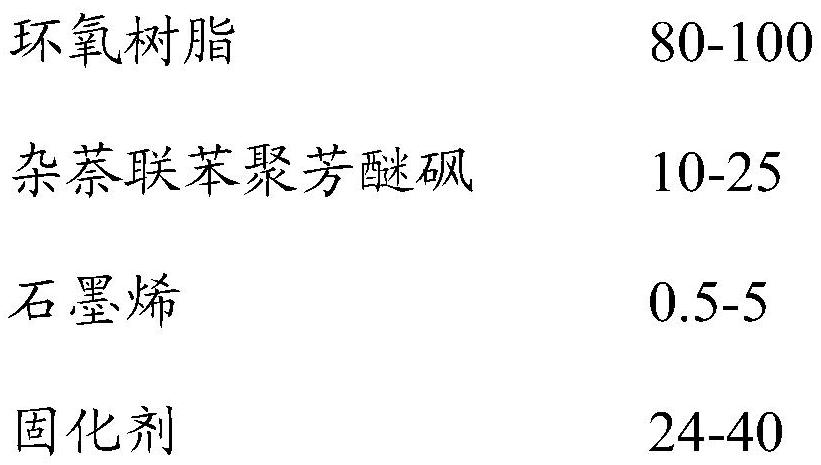

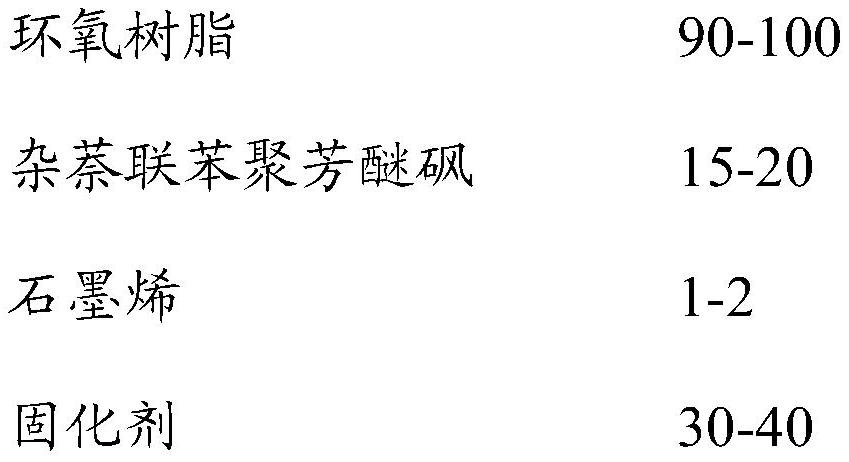

Low-temperature resistant epoxy resin material and preparation method thereof

The present invention provides a low-temperature resistant epoxy resin material and a preparation method thereof. The material is composed of epoxy resin, poly (phthalazinone ether sulfone), grapheneand a curing agent, and the graphene and the poly(phthalazinone ether sulfone) have a synergistic effect. The graphene regulates the phase separation degree of the poly (phthalazinone ether sulfone) and the epoxy resin in the solidification process, so that the phase structure of the composite material stays in a ''bicontinuous phase structure'' during the solidification process. Therefore, the epoxy resin composite material has good ultralow-temperature toughness; the graphene and the poly (phthalazinone ether sulfone) can achieve the synergistic effect by adjusting of distribution ratios andcontents of various groups, and the epoxy resin material with greatly-improved comprehensive low-temperature resistance can be obtained. The epoxy resin material has the advantages of high mechanicalproperties and excellent thermal stability at the liquid nitrogen temperature, and is easy to manufacture and process.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Manual electric arc welding welding rod used for ultralow-temperature high manganese steel

InactiveCN112894197ALow priceReduce manufacturing costWelding/cutting media/materialsSoldering mediaAlloyUltimate tensile strength

The invention relates to a manual electric arc welding welding rod used for ultralow-temperature high manganese steel. According to the technical scheme, the manual electric arc welding welding rod is composed of a welding rod core and a coating; the welding rod core comprises the following chemical components of 0.75-0.95 wt% of C; 26-30 wt% of Mn; 4.5-6.5 wt% of Ni; 1.5-3.5 wt% of Cr; 3.5-5.5 wt% of Al; P less than or equal to 0.002 wt%; S less than or equal to 0.002 wt%; and the balance Fe and inevitable impurities, the coating comprises the following chemical components of 40-45 wt% of fluorite; 15-20 wt% of marble; 4-10 wt% of rutile; 3-6 wt% of zircon sand; 1-2 wt% of sodium carbonate; and the balance Fe powder; and a preparation method of the manual electric arc welding welding rod comprises the following steps of blending according to the chemical components of the coating, mixing, adding a binder, uniformly stirring, and pressing and coating on the surface of the welding rod core to prepare the manual electric arc welding welding rod used for the ultralow-temperature high manganese steel. The manual electric arc welding welding rod used for the ultralow-temperature high manganese steel is low in cost and simple in alloy system; and formed weld metal has the characteristics of ultralow temperature and high toughness, and the strength is matched with the strength of the ultralow-temperature high manganese steel.

Owner:浙江鸿途焊接科技有限公司 +2

MIG welding solid-core welding wire for high-manganese austenite low-temperature steel and welding process of MIG welding solid-core welding wire

PendingCN114289929AReduce surface tensionRealize all position weldingArc welding apparatusWelding/cutting media/materialsManganeseUltimate tensile strength

The invention relates to an MIG welding solid-core welding wire for high-manganese austenite low-temperature steel and a welding process of the MIG welding solid-core welding wire. According to the technical scheme, the MIG welding solid-core welding wire for the high-manganese austenite low-temperature steel comprises the following chemical components: 0.20-0.60 wt% of C; si is less than or equal to 0.05 wt%; the content of Mn is 20-32 wt%; the content of Ni is 0.1 to 2 weight percent; the content of Cr is 0.1 to 1.8 wt%; the content of Cu is 0.55 to 1.00 wt%; the content of W is 0.5 to 1.9 weight percent; the content of Mo is 1.3 to 3.0 wt%; the content of Al is 0.5 to 2 weight percent; nb + V + Ti + B + RE < = 0.5 wt%; p < = 0.002 wt%; s < = 0.001 wt%; and the balance of Fe and inevitable impurities. Full-automatic and all-position welding can be achieved, the welding efficiency is high, forming is good, and the mechanical property is excellent; the strength of weld metal formed through inert gas protection is matched with that of high-manganese austenite low-temperature steel, the forming performance is good, the low-temperature toughness is excellent, and the technical requirements for the strength and ultralow-temperature toughness of the LNG storage tank at the working temperature of-196 DEG C can be met.

Owner:WUHAN UNIV OF SCI & TECH

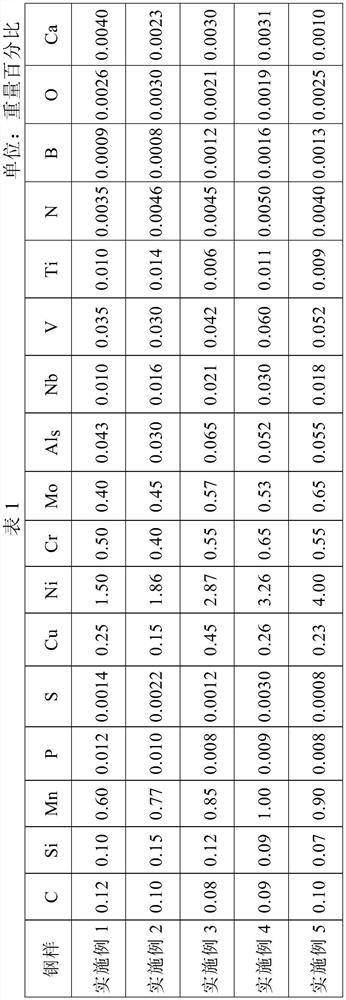

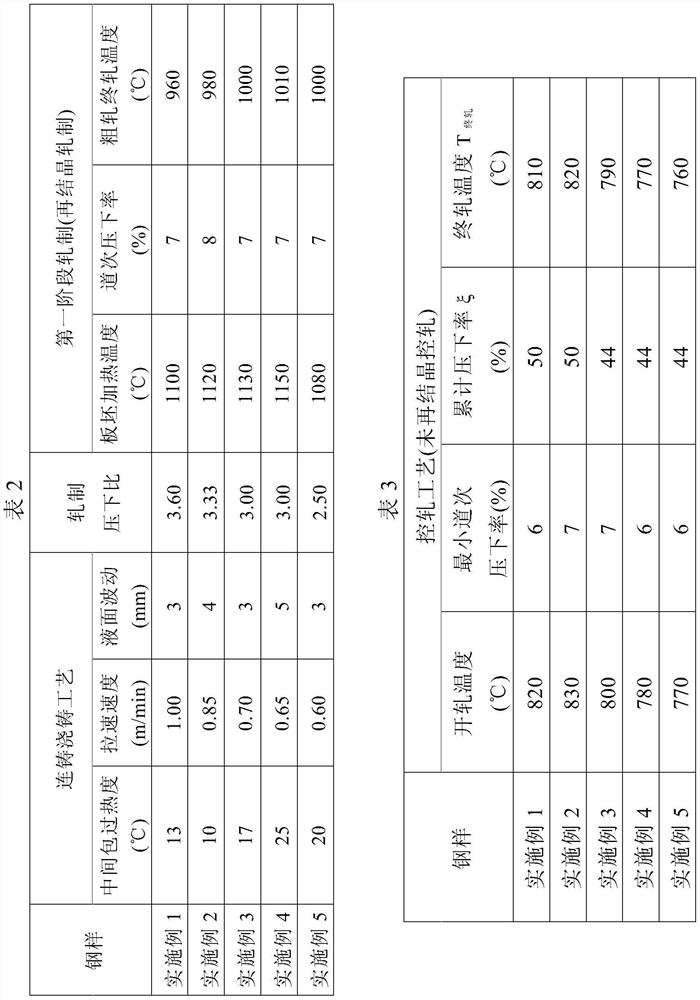

700 MPa grade low temperature quenched and tempered steel plate with excellent weldability and fatigue resistance and manufacturing method thereof

ActiveCN111621723AExcellent ultra-low temperature toughnessHigh strengthUltimate tensile strengthToughness

The invention discloses a 700 MPa grade low temperature quenched and tempered steel plate with excellent weldability and fatigue resistance and a manufacturing method thereof. The steel plate comprises the following components in percentage by weight: 0.050-0.090% of C, less than or equal to 0.15% of Si, 1.30-1.60% of Mn, less than or equal to 0.013% of P, less than or equal to 0.0030% of S, 0.10-0.35% of Cu, 0.50-0.90% of Ni, 0.15-0.35% of Cr, 0.15-0.35% of Mo, 0.008-0.030% of Nb, 0.030-0.060% of V, 0.008-0.014% of Ti, 0.030-0.060% of Al, less than or equal to 0.0003% of B, less than or equalto 0.0050 % of N, 0.0010 -0.0040% of Ca, and the balance Fe and inevitable inclusions. A component system of ultra-low C-Mn-(Ti plus Nb plus V) microalloyed steel is adopted as a substrate, so that an excellent fit of strength, ultra-low temperature toughness and strength-toughness of the 700 MPa grade low temperature quenched and tempered steel plate is obtained, and the weldability and machinability of the steel plate are also excellent.

Owner:BAOSHAN IRON & STEEL CO LTD

A kind of high-manganese medium-thick plate with excellent ultra-low temperature toughness and preparation method thereof

ActiveCN108504936BHigh strengthExcellent ultra-low temperature toughnessThick plateChemical composition

A high-manganese medium-thick plate with excellent ultra-low temperature toughness and a preparation method thereof, belonging to the technical field of iron and steel materials, the chemical composition of the medium-thick plate is: C: 0.31-0.67%, Si: 0.02-0.48%, Mn: 22.0- 27.3%, P: ≤0.08%, S: ≤0.06%, Al: 1.5~4.64%, the balance is Fe and unavoidable impurities; preparation method: 1) billet heating and heat preservation; 2) conduct a Rolling in stages to obtain hot-rolled steel; 3) cooling the hot-rolled steel to obtain a high-manganese medium-heavy plate with excellent toughness at -196°C; the high-manganese medium-heavy plate of the present invention can be used in the rolled state, and has excellent ultra-low temperature toughness and High strength, without adding alloy elements, the cost is much lower than 9Ni steel.

Owner:NORTHEASTERN UNIV LIAONING

Laser-arc hybrid welding solid welding wire for high-manganese austenite low-temperature steel and welding process

PendingCN114289930AReduce surface tensionGuaranteed comprehensive mechanical propertiesWelding/cutting media/materialsSoldering mediaElectric arcMechanical properties of carbon nanotubes

The invention relates to a laser-arc hybrid welding solid wire for high-manganese austenite low-temperature steel and a welding process. According to the technical scheme, the laser-arc hybrid welding solid-core welding wire for the high-manganese austenite low-temperature steel comprises the following chemical components: 0.20-0.60 wt% of C; si is less than or equal to 0.05 wt%; the content of Mn is 20-32 wt%; the content of Ni is 0.1 to 2 weight percent; the content of Cr is 0.1 to 1.8 wt%; the content of Cu is 0.55 to 1.00 wt%; the content of W is 0.5 to 1.9 weight percent; the content of Mo is 1.3 to 3.0 wt%; the content of Al is 0.5 to 2 weight percent; the content of Nb + V + Ti + B + RE is 0-0.5 wt%; p < = 0.002 wt%; s < = 0.001 wt%; and the balance of Fe and inevitable impurities. The welding process is laser-arc hybrid welding. Full-automatic welding can be achieved, the welding efficiency is high, welding smoke is little, welding deformation is small, forming is good, and the mechanical property is excellent; a laser and electric arc hybrid welding process is adopted, so that the characteristics of good forming, small welding smoke dust, small welding deformation, high welding efficiency and high ultralow-temperature toughness are achieved, and the strength is matched with that of high-manganese austenite low-temperature steel.

Owner:WUHAN UNIV OF SCI & TECH

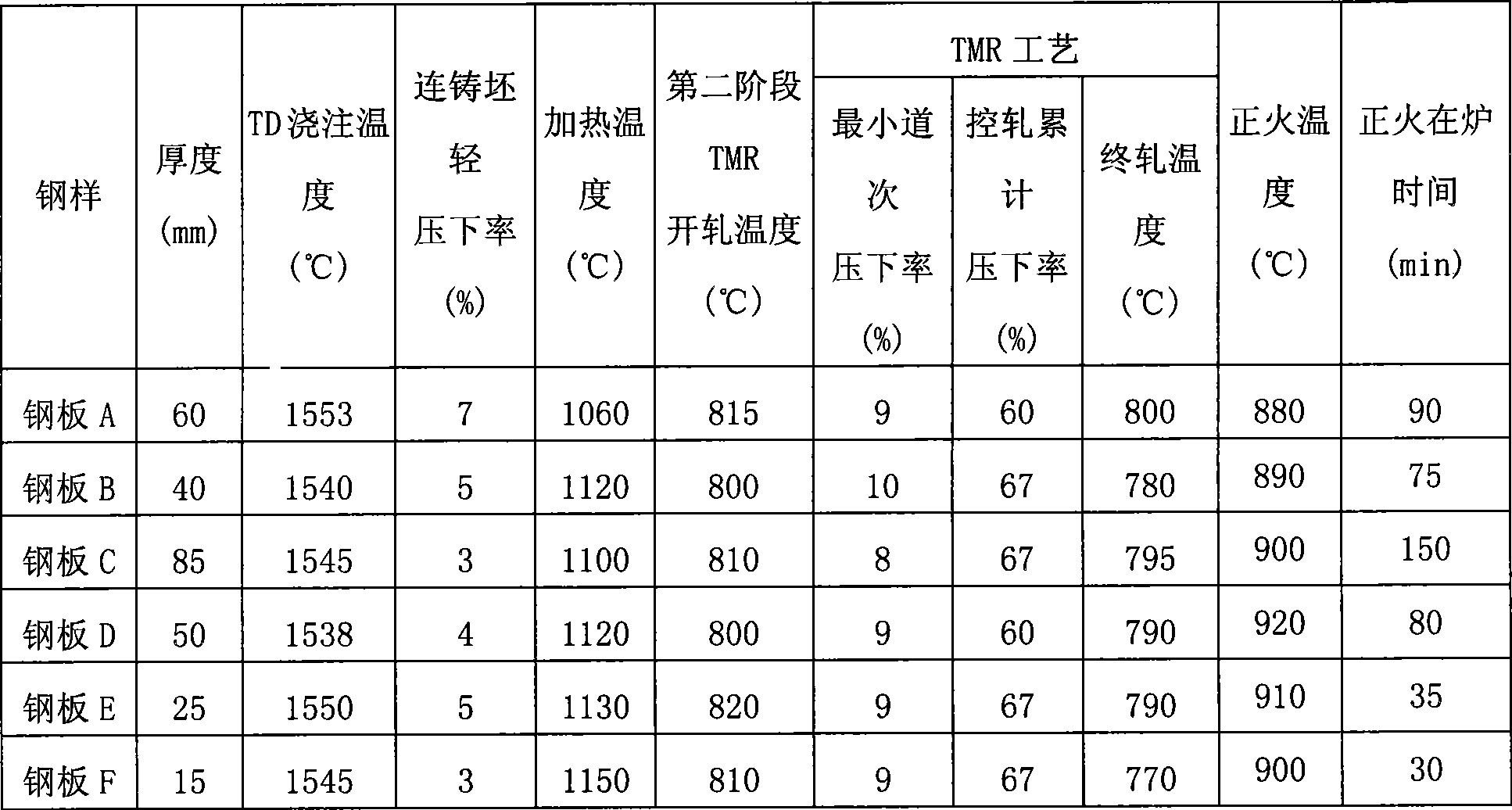

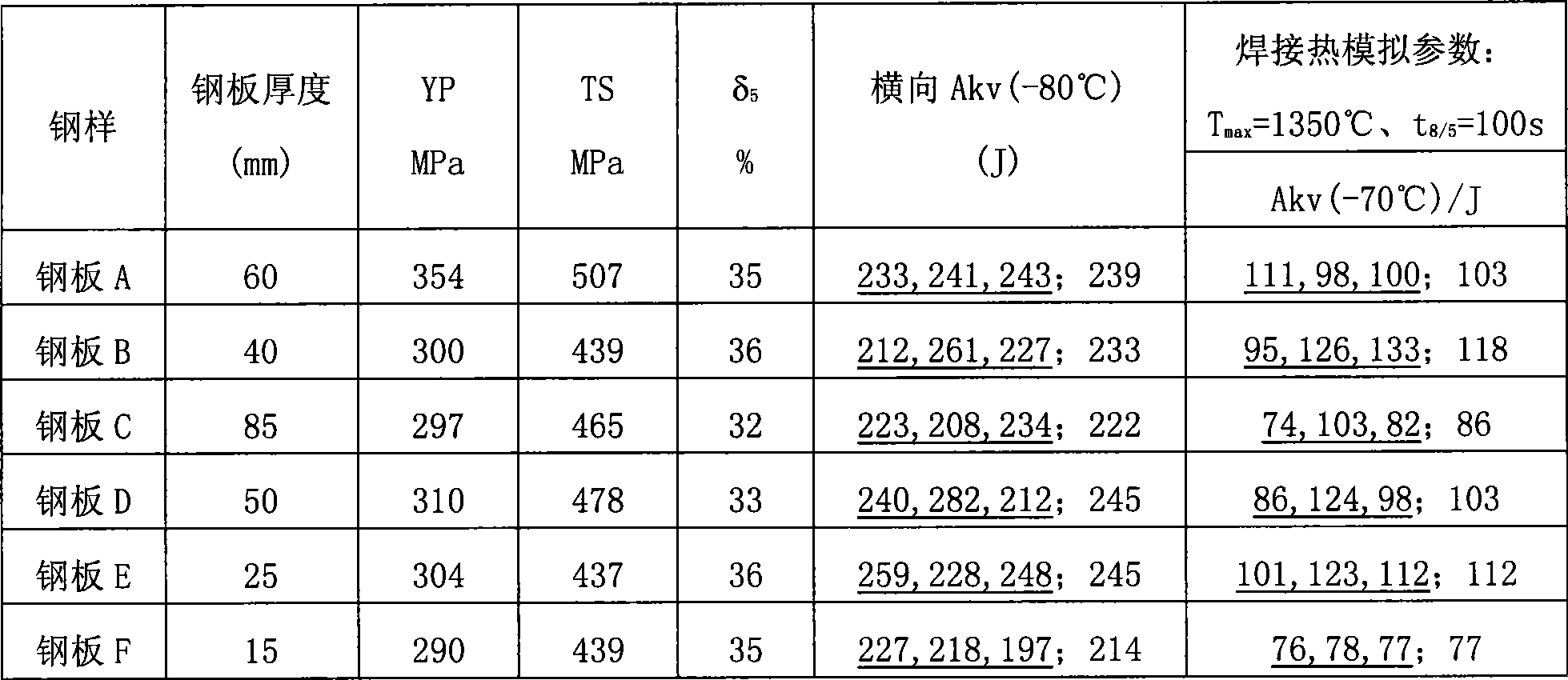

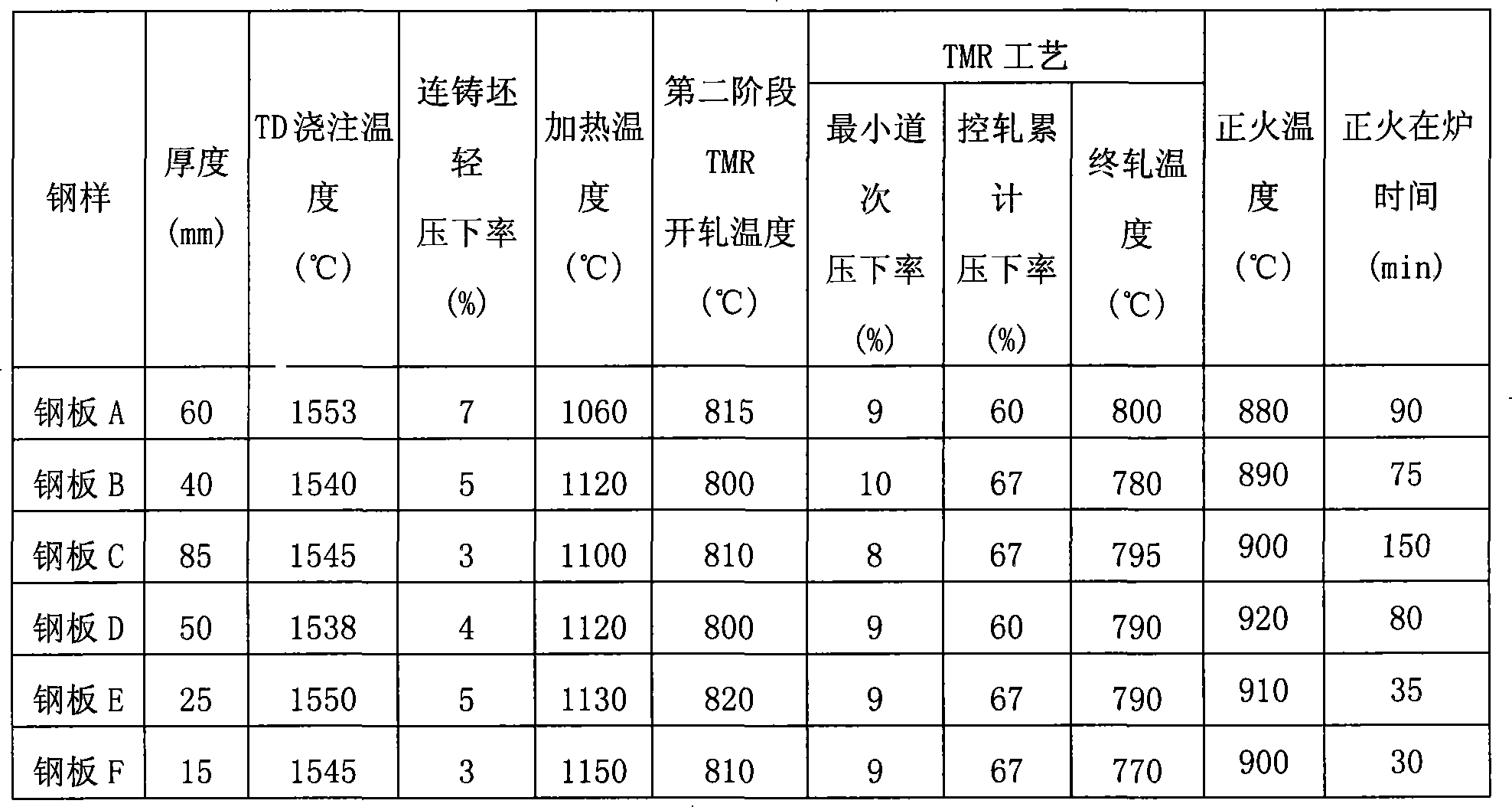

Manufacturing method of X70M pipeline steel plate used under low-cost and ultralow-temperature conditions

ActiveCN112375997AReduce manufacturing costExcellent ultra-low temperature toughnessLine tubingAlloy

The invention relates to a manufacturing method of an X70M pipeline steel plate used under low-cost and ultralow-temperature conditions. The X70M pipeline steel plate used under the low-cost and ultralow-temperature conditions is manufactured through the process steps of KR molten iron pretreatment, BOF smelting, RH vacuum degassing, LF refining, RH vacuum degassing, continuous casting of a continuous casting billet with the thickness of 150mm, checking and cleaning of the continuous casting billet, hot charging and hot conveying at the temperature of 350-680 DEG C, casting billet heating, high-pressure water descaling, rolling, ACC cooling, straightening, steel plate shearing and inspection and warehousing in sequence. The pipeline steel plate produced by adopting a hot charging and hot conveying process, an ultralow C and microalloy composite adding process and a controlled rolling and controlled cooling process can meet the use requirements under the ultralow-temperature conditionsthat the Charpy impact work at -80 DEG C is greater than or equal to 120J and the drop hammer shearing area at -20 DEG C is greater than or equal to 85%.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Cryogenic austenitic high-manganese steel having excellent corrosion resistance, and manufacturing method therefor

PendingCN112912531AExcellent ultra-low temperature toughnessImprove corrosion resistanceFurnace typesHeat treatment furnacesCorrosion resistantHigh concentration

The cryogenic austenitic high-manganese steel having excellent corrosion resistance, according to one aspect of the present invention, comprises 0.2-0.5 wt% of C, 23-28 wt% of Mn, 0.05-0.5 wt% of Si, 0.03 wt% or less of P, 0.005 wt% or less of S, 0.5 wt% or less of Al, and 3-4 wt% of Cr, with the remainder being Fe and other unavoidable impurities, also comprises at least 95 area% of austenite as a microstructure, and has Cr concentration sections continuously formed within an area of 50 um in the thickness direction from the surface, wherein the Cr concentration sections comprise a high Cr concentration section having a relatively high concentration of Cr, and a low Cr concentration section having a relatively low concentration of Cr, and the high Cr concentration section may be distributed at 30 area% or less (but not 0%) relative to the whole surface area of the Cr sections.

Owner:POSCO

Steel for low temperature and high tenacity structure use and its production method

InactiveCN100392132CIncrease the amount of participationIncrease the precipitation densityChemical compositionForeign substance

The invention provides a low-temperature high ductility constructional steel, wherein the chemical constituents include (by weight percent): C 0.04-0.08, Si 0.60-0.80, Mn 1.65-2.15, Nb 0.055-0.075, Ti 0.010-0.020, AlT 0.025-0.045, P<=0.012, S<=0.003, O<=0.0015, N 0.008-0.012, balancing Fe and unavoidable foreign substance. The preparation method comprises the steps of smelting, refining, casting, billet reheating, rolling, fast cooling, and finishing.

Owner:BAOSHAN IRON & STEEL CO LTD

Tungsten argon arc welding solid wire for ultra-low temperature high manganese steel welding

ActiveCN107009046BAvoid performance changesReduce contentWelding/cutting media/materialsSoldering mediaUltimate tensile strengthToughness

The invention relates to a tungsten electrode argon arc welding solid cored welding wire used for welding ultralow-temperature high manganese steel. According to the technical scheme of the solid cored welding wire, the tungsten electrode argon arc welding solid cored welding wire used for welding the ultralow-temperature high manganese steel comprises the chemical components of 0.25-0.55 wt% of C, 23-26 wt% of Mn, 8-10 wt% of Ni, 3-5 wt% of W, less than or equal to 0.002 wt% of P, less than or equal to 0.001 wt% of S and the balance Fe and inevitable impurities. The solid cored welding wire is low in price of alloy element content and simple in alloy component system; and formed weld metal has good low-temperature toughness, and the strength of the weld metal is matched with the ultralow-temperature high manganese steel, and the technical requirements for the strength and ultralow-temperature toughness of LNG devices and other devices prepared through welding.

Owner:WUHAN UNIV OF SCI & TECH +1

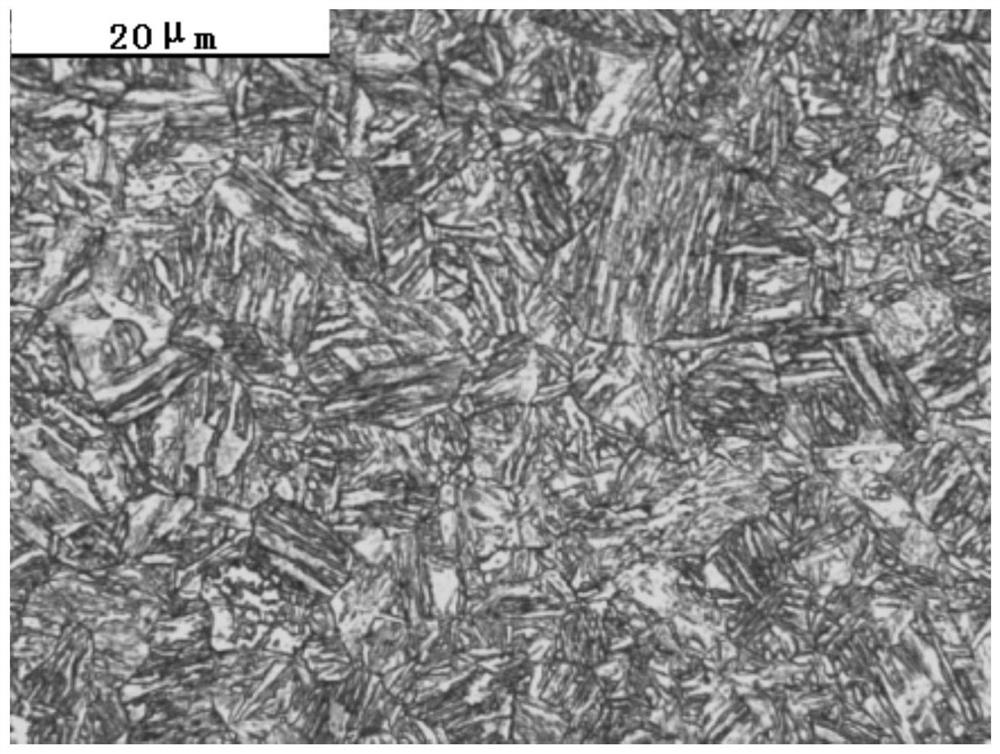

Ultra-thick, ultra-high toughness and excellent weldability 1000mpa grade steel plate and manufacturing method thereof

ActiveCN112143958BExcellent ultra-low temperature toughnessGood welding performanceFurnace typesHeat treatment furnacesTemperingToughness

The ultra-thick, ultra-high toughness and excellent weldability 1000MPa steel plate and its manufacturing method are based on the composition system of ultra-low C-ultra-low Si-medium Mn-(Ti+Nb+V+B) microalloy steel, and the appropriate Increase the content of acid-soluble Als in steel, and Als / [(%N)-0.292(%Ti)]≥23, (%C)×(%Si)≤0.016, Ca treatment, Ca / S ratio is 1.00-3.00, And (%Ca)×(%S) 0.18 ≤2.5×10 -3 and other metallurgical means, optimize TMCP + off-line quenching and tempering process (QT), control 40≤[H×(t 弛豫 )×ξ] / [(T 终轧 -T 停冷 )×(Ceq×V 冷速 )]≤550, 730≤(T 淬火 )×[lg(t 淬火保持 )] / [(%Mo)+0.73(%Cr)+1.67(%V)+311(%B)]≤1050 and 320≤[(T 回火 )×[lg(t 回火保持 )] / DI≤120, so that the microstructure of the finished steel plate is fine low-carbon tempered martensite + a small amount of tempered lower bainite, the average grain size is below 20 μm, and excellent ductility and toughness of HT950 steel plate is obtained.

Owner:BAOSHAN IRON & STEEL CO LTD

A kind of manufacturing method of x70m pipeline steel plate used under low-cost and ultra-low temperature conditions

ActiveCN112375997BReduce manufacturing costExcellent ultra-low temperature toughnessLine tubingHigh pressure water

The invention relates to a manufacturing method of X70M pipeline steel plate used under low-cost and ultra-low temperature conditions, KR molten iron pretreatment-BOF smelting-RH vacuum degassing-LF refining-RH vacuum degassing-150mm thickness continuous casting slab continuous casting-continuous Billet inspection and cleaning—350~680°C hot charging and hot delivery—casting billet heating—high pressure water descaling—rolling—ACC cooling—straightening—steel plate shearing—inspection of warehousing process steps, low-cost manufacturing and use under ultra-low temperature conditions X70M pipeline steel plate. The pipeline steel plate produced by hot charging and hot delivery process, ultra-low C, micro-alloy composite addition and controlled rolling and controlled cooling process can meet the Charpy impact energy of ‑80 °C ≥ 120J and the drop hammer shear area of ‑20 °C ≥ 85%. Requirements for use under ultra-low temperature conditions.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

MIG/MAG welding wire for -196°C working temperature

ActiveCN106938375BLow content priceReduce manufacturing costWelding/cutting media/materialsSoldering mediaWorking temperatureImpurity

The invention relates to a melting electrode gas shielded welding wire suitable for the working temperature of -196°C. The technical solution is: the chemical composition of the metal gas shielded welding wire is: C is 0.30~0.55wt%, Mn is 24~26wt%, Ni is 6.4~8.2wt%, W is 2.5~4.0wt%, P≤0.002wt%, S≤0.001wt%, the balance is Fe and unavoidable impurities. The invention has low preparation cost and simple alloy composition system; the formed weld metal has the characteristics of ultra-low temperature and high toughness, its strength matches that of ultra-low temperature high manganese steel, and the welded joint has high strength and excellent mechanical properties of ultra-low temperature toughness, which can meet the requirements of Specifications for strength and cryogenic toughness of devices to be welded at ‑196°C.

Owner:WUHAN UNIV OF SCI & TECH

Ultra-high toughness, excellent weldability ht550 steel plate and manufacturing method thereof

ActiveCN103320692BImprove performanceShorten the manufacturing cycleFurnace typesQuenching agentsTowerUltimate tensile strength

Ultra-high toughness, excellent weldability HT550 steel plate and its manufacturing method adopt the ultra-low C-high Mn-Nb micro-alloying-ultra-micro Ti treatment composition system as the basis, and control Mn / C between 15 and 30, (% Si) ×(%Ceq)≤0.050, (%C)×(%Si)≤0.010, (%Mo)×[(%C)+0.13(%Si)] in 0.003~0.020, Ti / N=2.0~4.0, (Cu+Ni+Mo) alloying, Ni / Cu≥1.0, Ca treatment, Ca / S ratio between 0.80 and 3.00. By optimizing the TMCP process, the microstructure of the steel plate is fine ferrite + autotempered bainite. , the average grain size is below 15μm, the yield strength is ≥460MPa, the tensile strength is 550MPa~700MPa, the yield ratio is ≤0.85, and the Charpy impact energy (single value) at -60℃ is ≥60J; in order to obtain uniform and excellent strength, toughness and strong plasticity While matching, the steel plate can withstand large heat input for welding, and is especially suitable for cross-sea bridge structures, ocean wind tower structures, ocean platform structures and hydropower structures.

Owner:BAOSHAN IRON & STEEL CO LTD

Austenitic steel having excellent machinability and ultra-low temperature toughness in weld heat-affected zone, and method of manufacturing the same

ActiveUS10655196B2Excellent ultra-low temperature toughnessImprove machinabilityFurnace typesWelding/cutting media/materialsHeat-affected zoneManganese

Provided are an austenitic steel having excellent machinability and ultra-low temperature toughness in a weld heat-affected zone including 15 wt % to 35 wt % of manganese (Mn), carbon (C) satisfying 23.6C+Mn≥28 and 33.5C−Mn≤23, 5 wt % or less (excluding 0 wt %) of copper (Cu), chromium (Cr) satisfying 28.5C+4.4Cr≤57 (excluding 0 wt %), and iron (Fe) as well as other unavoidable impurities as a remainder, wherein a Charpy impact value of a weld heat-affected zone at −196° C. is 41 J or more, and a method of manufacturing the steel.According to the present invention, a low-cost ultra-low temperature steel may be obtained, a stable austenite phase may be formed at low temperature, carbide formation may be effectively suppressed, and a structural steel having excellent machinability and ultra-low temperature toughness in a weld heat-affected zone may be provided.

Owner:POHANG IRON & STEEL CO LTD

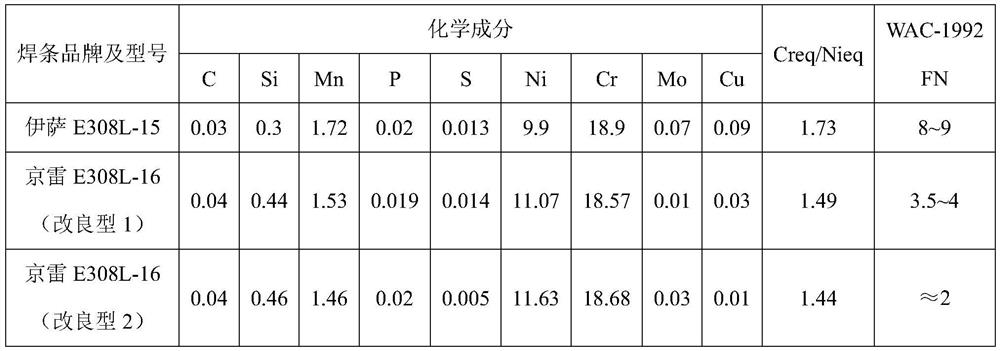

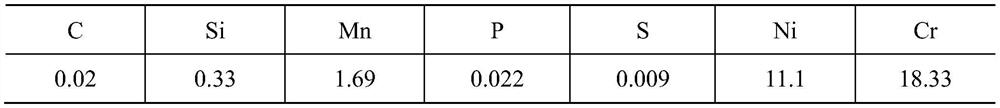

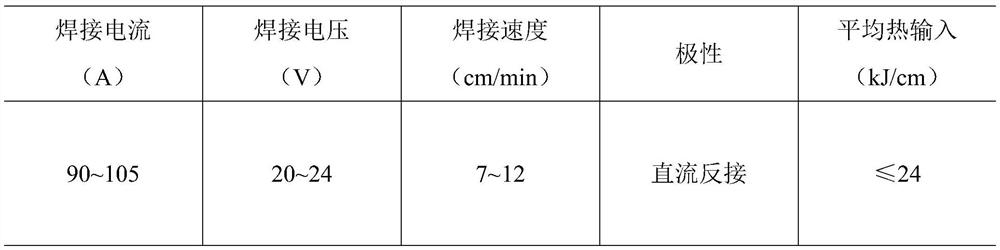

A kind of deposited metal material and preparation method for ultra-low temperature 304l austenitic stainless steel welding

ActiveCN111266713BHigh strengthExcellent ultra-low temperature toughnessWelding/soldering/cutting articlesWelding accessoriesCrack resistanceMetallic materials

Owner:WUHAN YIYE STEEL STRUCTURE

Self-protection flux-cored wire suitable for ultralow-temperature high manganese steel

ActiveCN114131243APlay the role of gas protectionGuaranteed compatibilityWelding/cutting media/materialsProcess efficiency improvementManganeseAlloy

The invention relates to a self-protection flux-cored wire suitable for ultralow-temperature high manganese steel. According to the technical scheme, the self-protection flux-cored wire is composed of a carbon steel strip, a single-strand alloy welding wire and flux-cored powder. The carbon steel strip comprises the following chemical components: 0.03-0.05 wt% of C, 0.05-0.08 wt% of Si, 0.5-0.8 wt% of Mn, less than or equal to 0.005 wt% of P, less than or equal to 0.005 wt% of S and the balance of Fe. The single-strand alloy welding wire comprises the following chemical components: 0.3-0.6 wt% of C, 0.05-0.2 wt% of Si, 24-33 wt% of Mn, less than or equal to 0.003 wt% of P, less than or equal to 0.003 wt% of S and 4-7 wt% of Ni. The flux core powder comprises the following chemical components in percentage by weight: 40 to 50 percent of barium fluoride, 10 to 17 percent of rutile, 4 to 7 percent of aluminum powder and 2 to 6 percent of sodium fluoroaluminate. Among the three chemical components, the balance is Fe and inevitable impurities. Weld metal formed by the self-protection flux-cored wire suitable for the ultralow-temperature high-manganese steel has the characteristic of high toughness under the ultralow-temperature service condition, and the strength of the weld metal is matched with that of the ultralow-temperature high-manganese steel.

Owner:WUHAN UNIV OF SCI & TECH

Fully automatic submerged arc welding solid wire for high manganese steel for lng storage tank

ActiveCN107052618BAvoid performance changesLow P and S contentArc welding apparatusWelding/cutting media/materialsFully automaticUltimate tensile strength

The invention discloses a full-automatic submerged-arc welding solid-core welding wire for high-manganese steel for preparing an LNG storage tank. According to the technical scheme, the full-automatic submerged-arc welding solid-core welding wire comprises 0.25-0.45wt% of C, 23-26wt% of Mn, 6-8wt% of Ni, 3-5wt% of W, 0.02-0.04wt% of N, less than or equal to 0.02wt% of P, less than or equal to 0.001wt% of S and the balance of Fe and inevitable impurities. The full-automatic submerged-arc welding solid-core welding wire has the advantages that the price of adopted alloy elements is low, and an alloy component system is simple; and the low-temperature toughness of weld metal formed by the prepared full-automatic submerged-arc welding solid-core welding wire is excellent, the strength of the full-automatic submerged-arc welding solid-core welding wire is matched with the strength of the ultralow-temperature high-manganese steel for preparing the LNG storage tank, and the technical requirements for the strength and the ultralow-temperature toughness of the welded LNG storage tank can be met.

Owner:WUHAN UNIV OF SCI & TECH +1

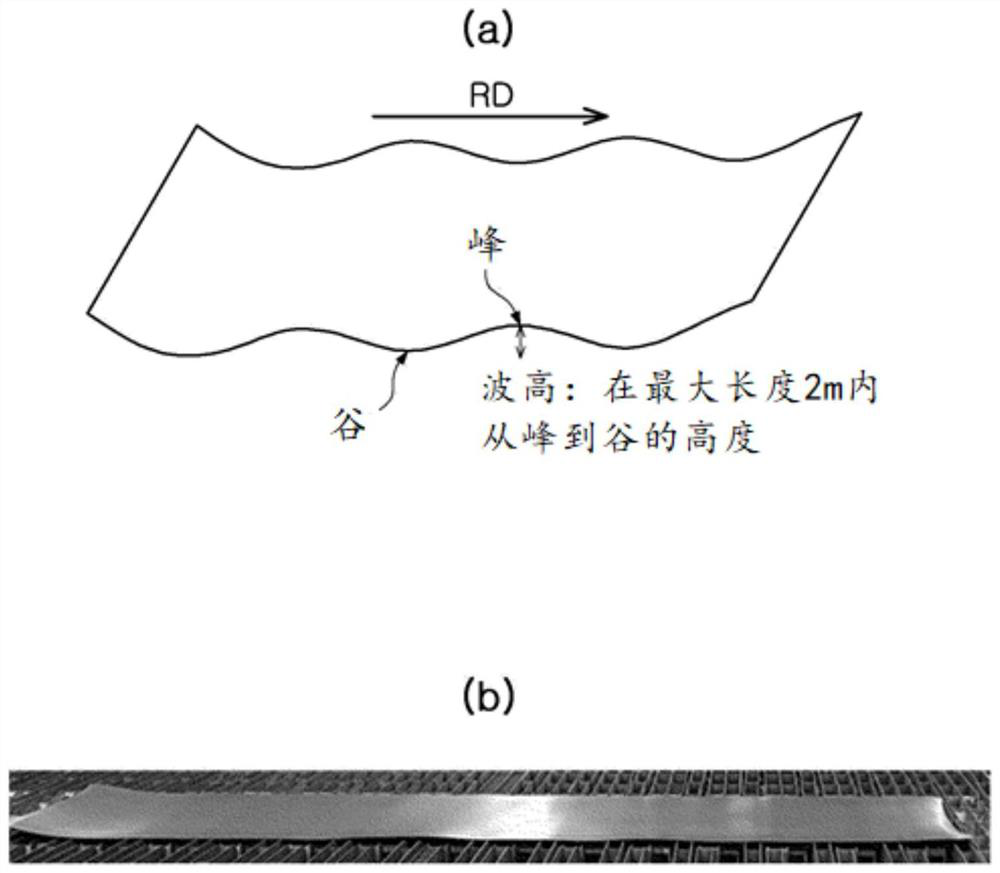

Cryogenic austenitic high-manganese steel having excellent shape, and manufacturing method therefor

PendingCN112930415AExcellent ultra-low temperature toughnessEasy to shapeFurnace typesHeat treatment furnacesManganeseAustenite

The cryogenic austenitic high-manganese steel having an excellent shape, according to one aspect of the present invention, comprises 0.2-0.5 wt% of C, 23-28 wt% of Mn, 0.05-0.5 wt% of Si, 1 wt% or less (but not 0 wt%) of Cu, 0.03 wt% or less of P, 0.005 wt% or less of S, 0.5 wt% or less of Al, 2.5-4.5 wt% of Cr, and 0.0005-0.01 wt% of B, with the remainder being Fe and other unavoidable impurities, and also comprises at least 95 area% of austenite as a microstructure, wherein the Charpy impact toughness at -196 DEG C is least 30 J (based on a thickness of 5 mm), and the maximum difference in height between a crest and a trough formed within an area of 2 m along the direction of rolling may be at most 10 mm.

Owner:浦项股份有限公司

A kind of low temperature resistant epoxy resin material and preparation method

The present invention proposes a low-temperature-resistant epoxy resin material and a preparation method thereof. The material is composed of epoxy resin, polyaryl ether sulfone, graphene and a curing agent. The graphene and polyaryl ether sulfone of the present invention are Aryl ether sulfone has a synergistic effect. Graphene regulates the phase separation degree of polyaryl ether sulfone and epoxy resin during the curing process, so that the phase structure of the composite material stays in the "double continuous phase structure" during the curing process. , so that the epoxy resin composite material has good ultra-low temperature toughness; the present invention achieves a synergistic effect between graphene and polyaryl ether sulfone by adjusting the proportion and content of various components and obtains a greatly improved comprehensive low temperature resistance performance The epoxy resin material, that is, the epoxy resin material of the present invention has the advantages of high mechanical properties and excellent thermal stability at the temperature of liquid nitrogen, and is easy to manufacture and process.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com